Preparation method of porous nanocrystalline Cu2S counter electrode of quantum-dot-sensitized solar cell

A solar cell and quantum dot sensitization technology, which is applied in the field of solar cells, can solve problems such as limiting the improvement of battery performance, insufficient bonding, and large charge loss, and achieve the effects of promoting reduction regeneration, increasing contact surface, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

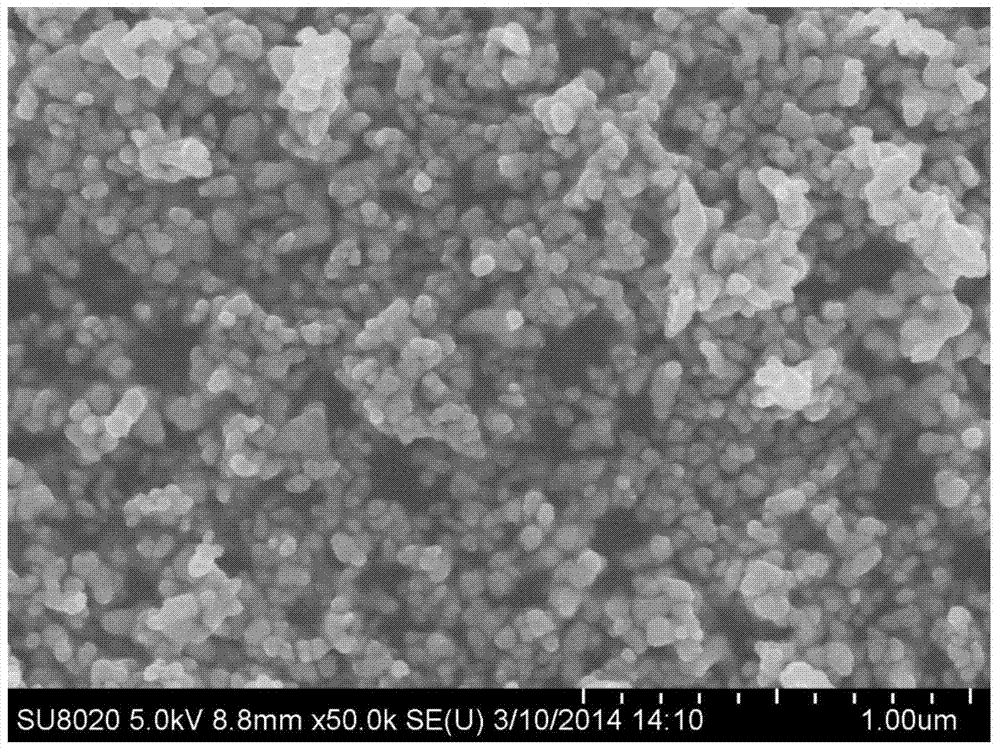

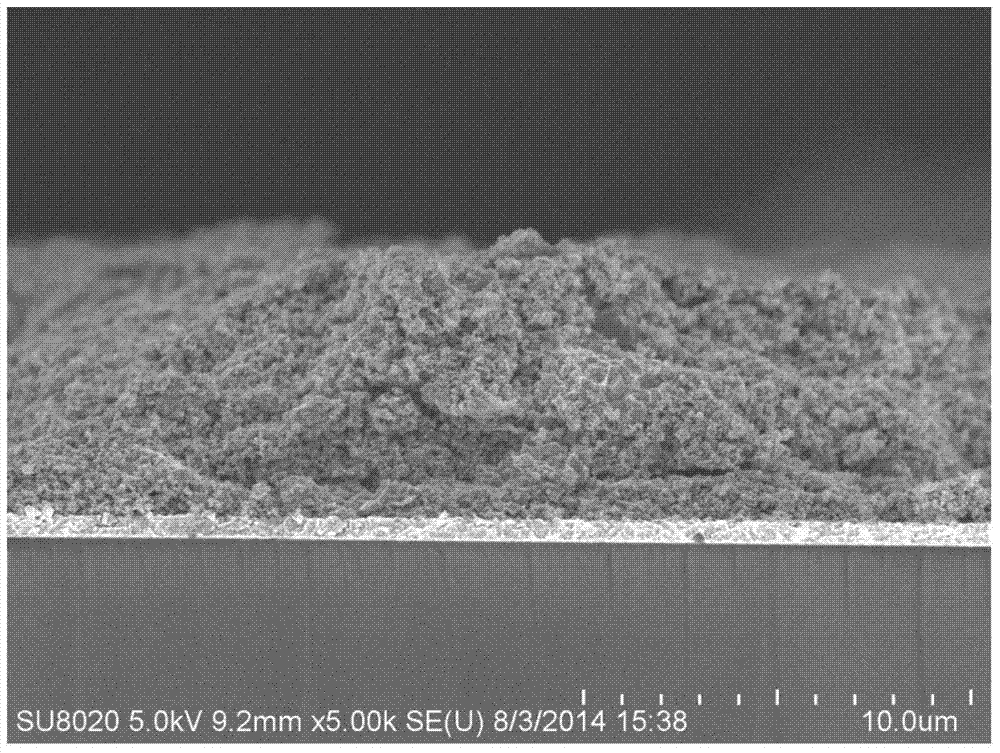

[0022] The conductive substrate was ultrasonically cleaned with deionized water and absolute ethanol for 15 minutes, and then dried; 0.03 molar concentration of copper acetate and 0.04 molar concentration of thioacetamide were ultrasonically dissolved in diethylene glycol, and then heated at 170 The two solutions were mixed and reacted for 2.5 hours under the condition of an oil bath to prepare Cu 2 S nanoparticles, and then prepare a slurry with ethanol at a mass ratio of 1:1; apply the above slurry evenly on the FTO conductive glass by the scraper coating method, and then sinter at 400°C for 40min in an argon atmosphere to obtain Cu 2 S porous nanocrystalline counter electrode.

[0023] The prepared Cu 2 The S porous nanocrystal counter electrode is assembled into a quantum dot sensitized battery for battery performance testing. The photoanode is made of nano-titanium oxide porous film prepared by the scraping method, and the quantum dot sensitizer is made of continuous io...

Embodiment 2

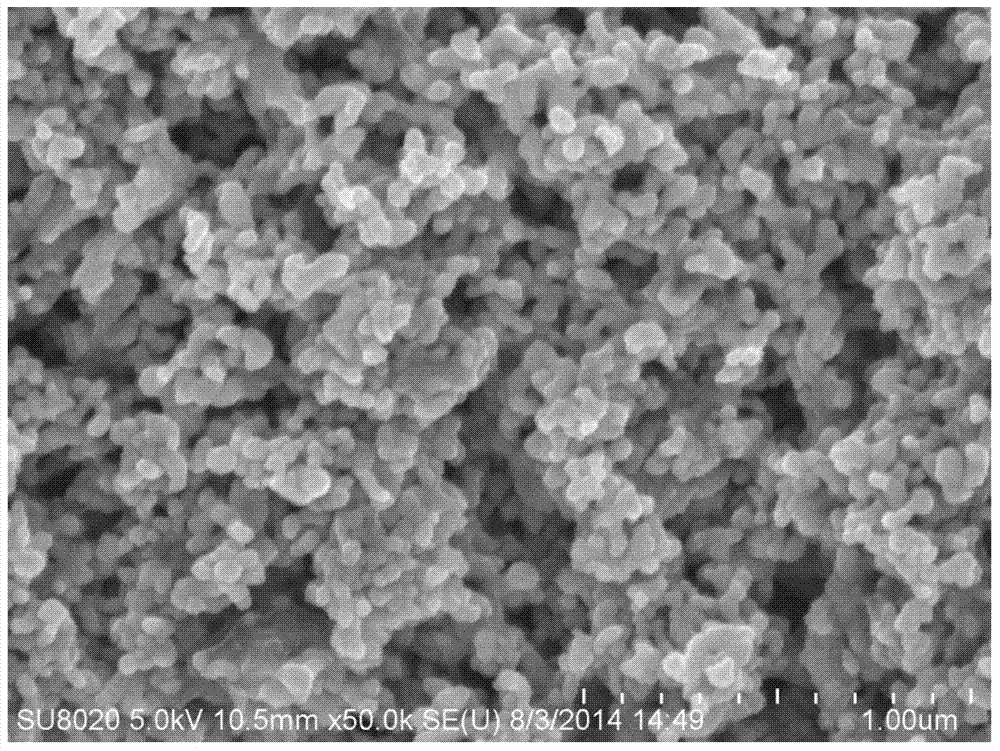

[0025] The conductive substrate was ultrasonically cleaned with deionized water and absolute ethanol for 5 minutes, and then dried; 0.04 molar concentration of copper acetate and 0.05 molar concentration of thioacetamide were ultrasonically dissolved in diethylene glycol, and then heated at 180 The two solutions were mixed and reacted for 3 hours under the condition of oil bath to prepare Cu 2 S nanoparticles, and then prepare a slurry with ethanol at a mass ratio of 1:2; the above slurry is uniformly coated on the FTO conductive glass by a scraper coating method, and then sintered at 450 ° C for 60 minutes in an argon atmosphere, namely Get Cu 2 S porous nanocrystalline counter electrode.

[0026] The process of assembling the battery is the same as in Example 1, and the test results are shown in Table 1.

Embodiment 3

[0028]The conductive substrate was ultrasonically cleaned with deionized water and absolute ethanol for 10 minutes, and then dried; 0.02 molar concentration of copper acetate and 0.03 molar concentration of thioacetamide were ultrasonically dissolved in diethylene glycol, and then heated at 160 Under the condition of ℃ oil bath, the two solutions were mixed and reacted for 2 hours to prepare Cu 2 S nanoparticles, and then prepare a slurry with ethanol at a mass ratio of 2:1; the above slurry is uniformly coated on the FTO conductive glass by a scraper coating method, and then sintered at 350 ° C for 30 minutes in an argon atmosphere, that is, Get Cu 2 S porous nanocrystalline counter electrode.

[0029] The process of assembling the battery is the same as in Example 1, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com