Formaldehyde-free decorative adhesive film paper and preparation method thereof

A technology of adhesive film and formaldehyde, which is applied in papermaking, paper coating, textile and papermaking, etc., can solve the problem of poor scratch resistance, corrosion resistance and wear resistance, easy adhesion, wear resistance and scratch resistance. problems such as poor performance, to achieve the effect of being conducive to storage and transportation, improving production efficiency, and simple and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0044] Embodiment 1~3, formaldehyde-free decorative adhesive film paper of the present invention

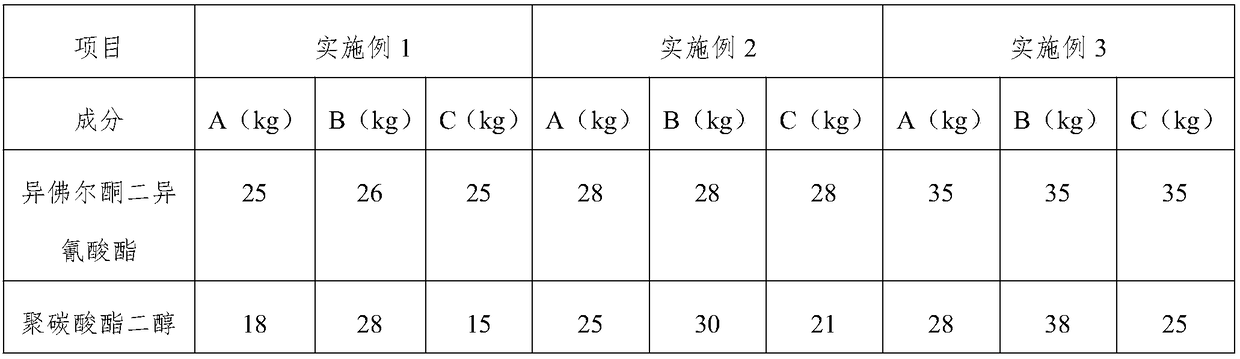

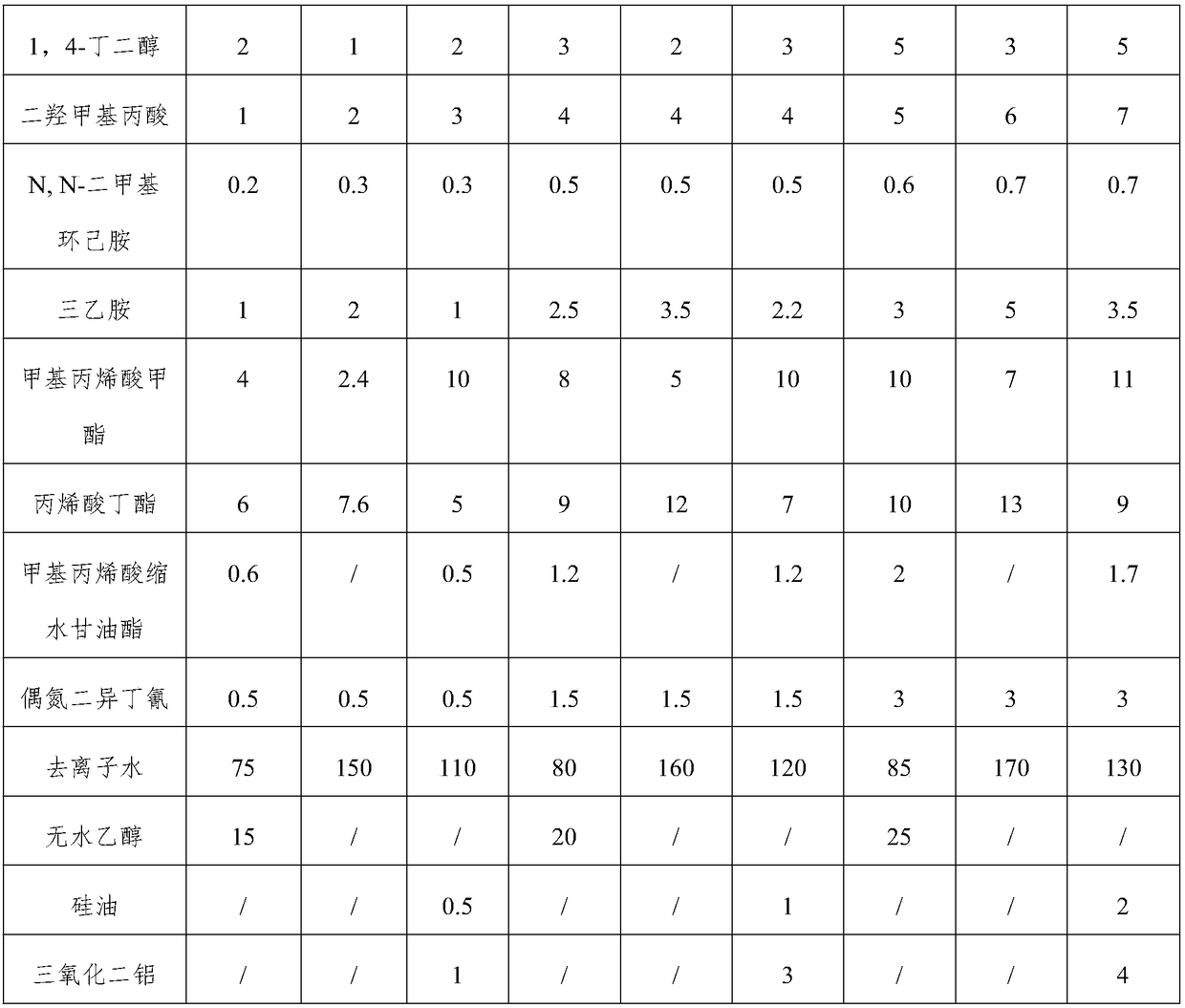

[0045] Embodiments 1 to 3 of the present invention formaldehyde-free decorative adhesive film paper, from the inside to the outside, are followed by a back-coated resin layer, a resin-impregnated layer, a substrate paper, a resin-impregnated layer and a top-coated resin layer, including the preparation of the following weights Raw materials, specifically as shown in Table 1:

[0046] Table 1 Embodiment 1~3 The preparation raw material composition of formaldehyde-free decorative adhesive film paper

[0047]

[0048]

[0049] Remarks: A: back coating resin layer; B: first impregnation resin layer; C: surface coating resin layer

[0050] The preparation method of the formaldehyde-free decorative adhesive film paper of the embodiment of the present invention 1~3 comprises the following steps:

[0051] S1. Preparation of back coating resin: According to the formula quantity, a...

Embodiment 4

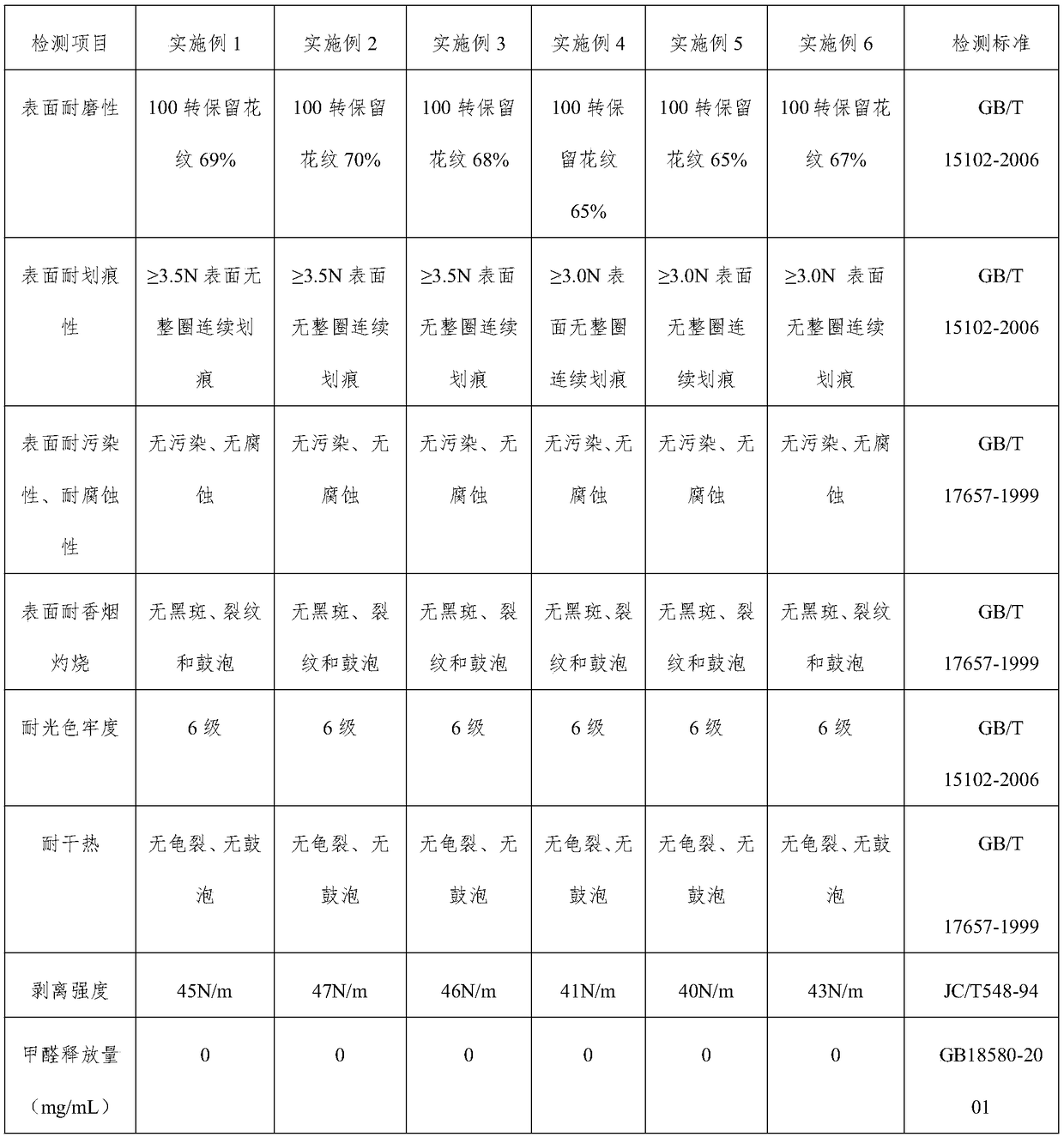

[0055] Embodiment 4, formaldehyde-free decorative adhesive film paper of the present invention

[0056] Compared with Example 2, the difference of this example is only that dicyclohexylmethane diisocyanate is used instead of isophorone diisocyanate.

Embodiment 5

[0057] Embodiment 5, formaldehyde-free decorative film paper of the present invention

[0058] Compared with Example 2, the difference of this example is only that polycaprolactone diol is used instead of polycarbonate diol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com