Patents

Literature

37results about How to "Short pressing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

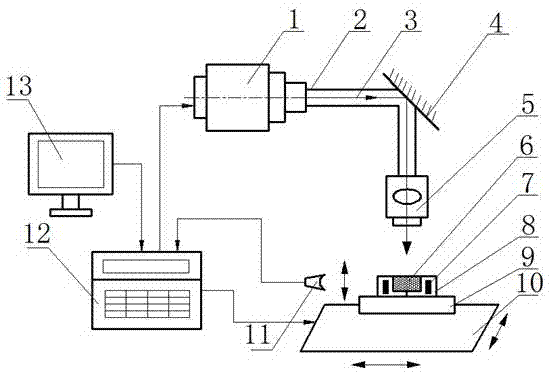

Forming method and device of anisotropic neodymium iron boron bonded permanent magnet

ActiveCN103170630AEasy to adjustImprove flexibilityInductances/transformers/magnets manufactureEpoxyMetallurgy

The invention discloses a forming method and device of an anisotropic neodymium iron boron bonded permanent magnet, belongs to the technical field of forming of bonded permanent magnets. According to the forming method and device, mixed powder of anisotropic neodymium iron boron magnetic powder, an epoxy resin binder and a curing agent is contained by adopting a split type mould, and is placed in a certain magnetic field for orientation, the mould and the mixed powder are heated to be up to a certain temperature through a resistor, and a laser impact irradiating the anisotropic neodymium iron boron powder directly is generated by using lasers to directly press the powder. According to the forming method and device, because a small amount of the binder is used and the pressure pressing of a higher laser impact wave is adopted, the magnetic property of a binding neodymium iron boron magnet is improved; and the powder is pressed when being heated, the forming procedure and the curing procedure are combined into one, and thus the circulation time of a product in the production process is reduced, the production period of the product is shortened, and the production efficiency is further improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

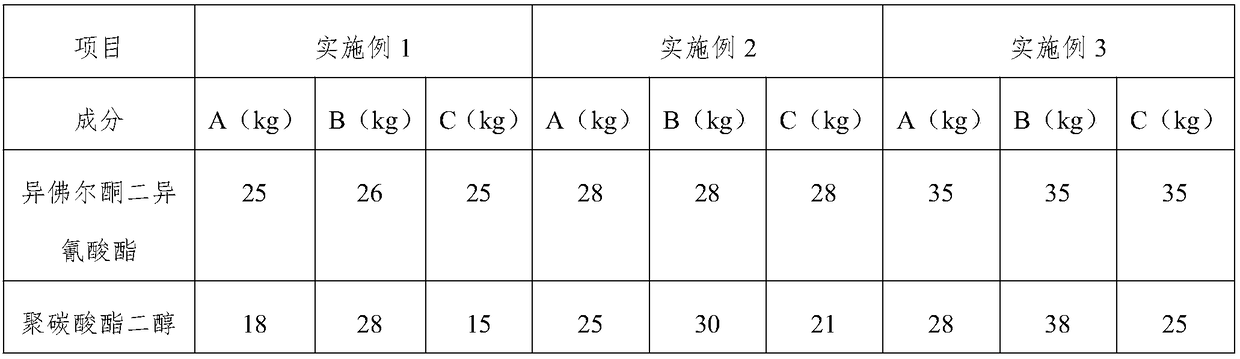

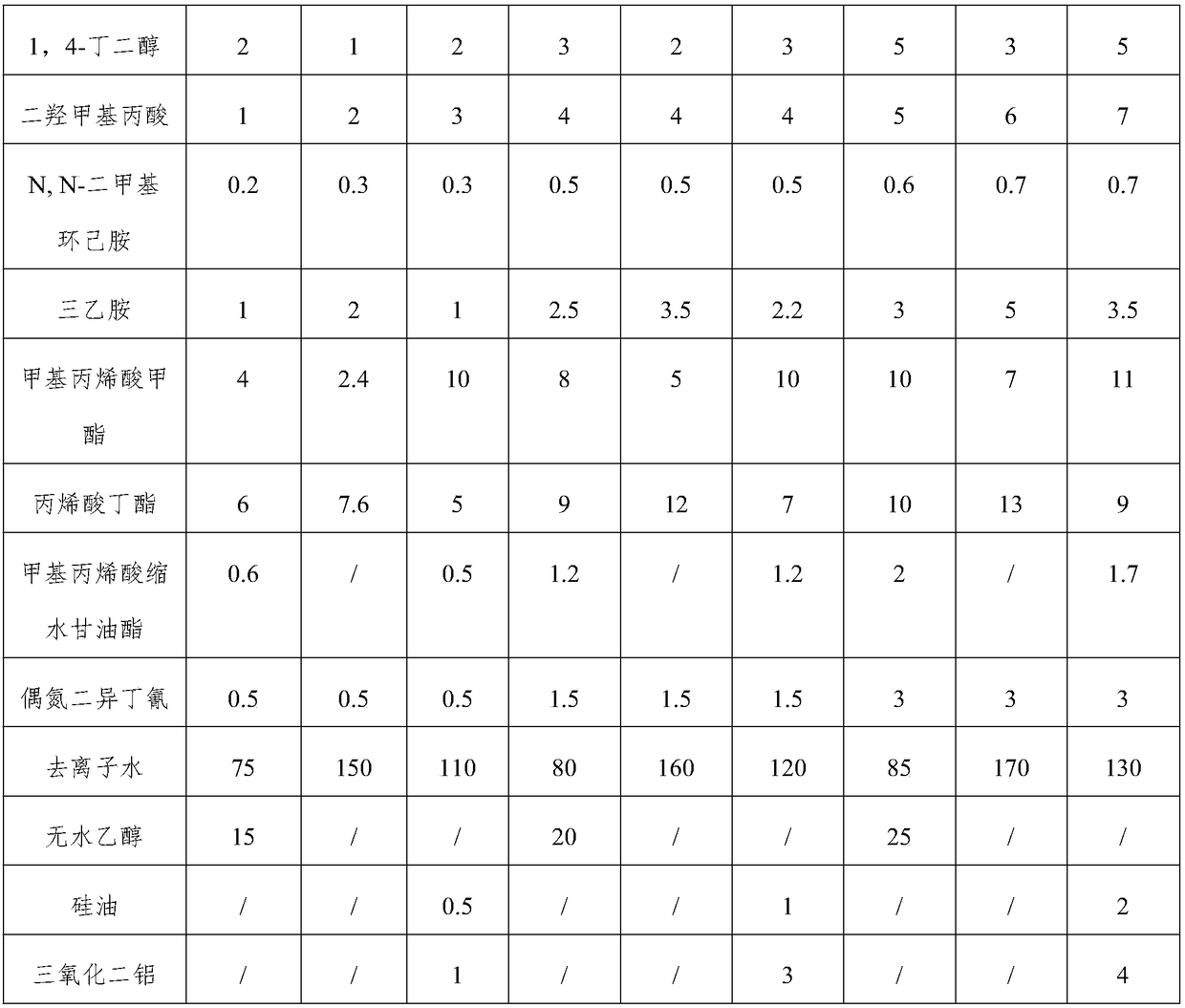

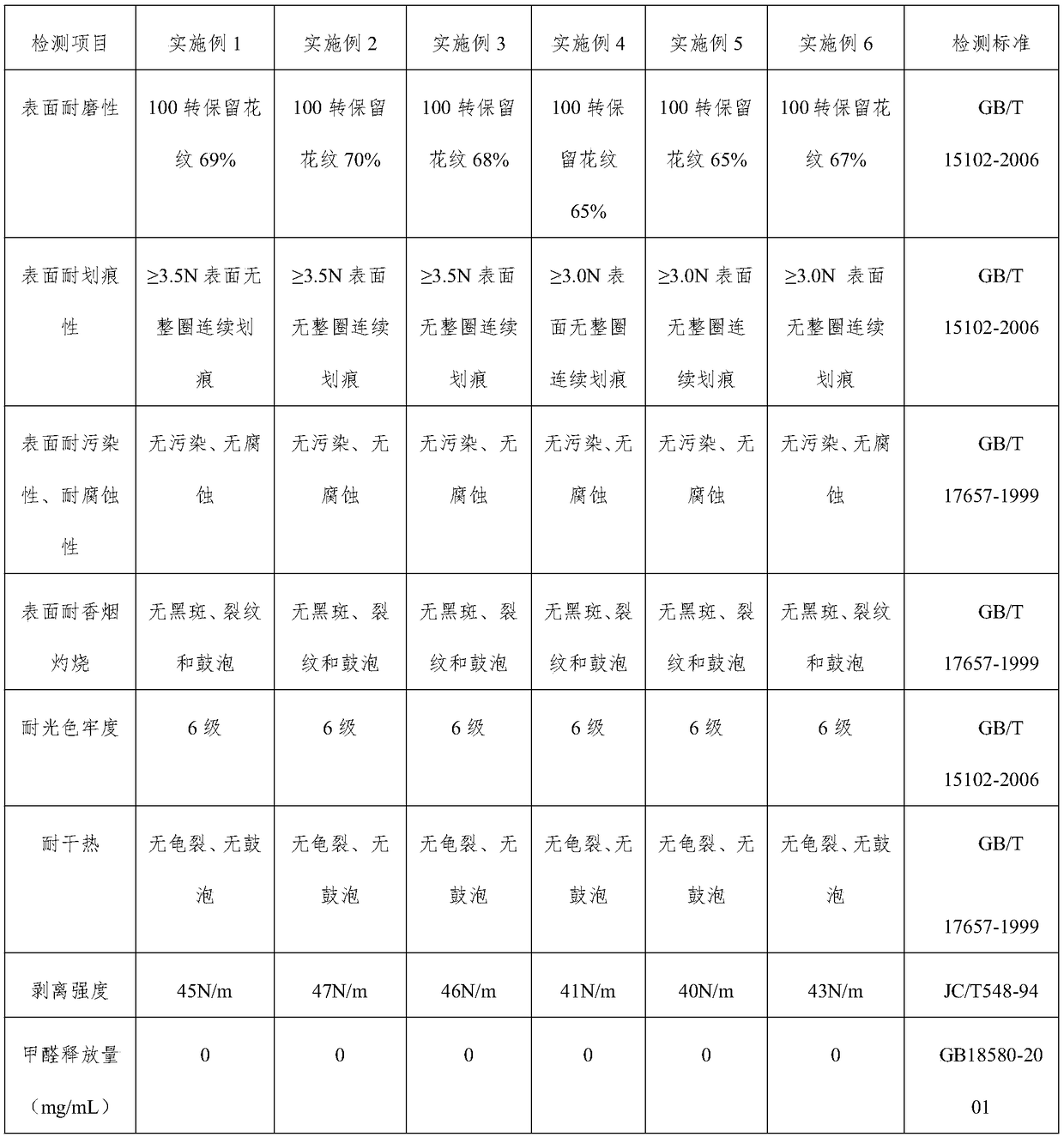

Formaldehyde-free decorative adhesive film paper and preparation method thereof

ActiveCN109457536AInhibition releaseIn line with consumer trendsPaper coatingCoatingsPolymer scienceHardness

The invention belongs to the technical field of decorative paper, and particularly relates to formaldehyde-free decorative adhesive film paper and a preparation method thereof. The formaldehyde-free decorative adhesive film paper sequentially comprises a back-coated resin layer, a first resin-impregnated layer, base material paper, a second resin-impregnated layer and a surface-coated resin layerfrom inside to outside. According to the formaldehyde-free decorative adhesive film paper, formaldehyde-free waterborne polyurethane resin serves as a preparation raw material and replaces traditionalurea resin and melamine resin, the prepared decorative adhesive film paper is green, environmentally friendly, free from formaldehyde, high in drying speed, excellent in performance and simple and convenient to construct, has hardness and toughness and can be popularized and applied.

Owner:GUANGDONG T&H NEW MATERIALS CO LTD +1

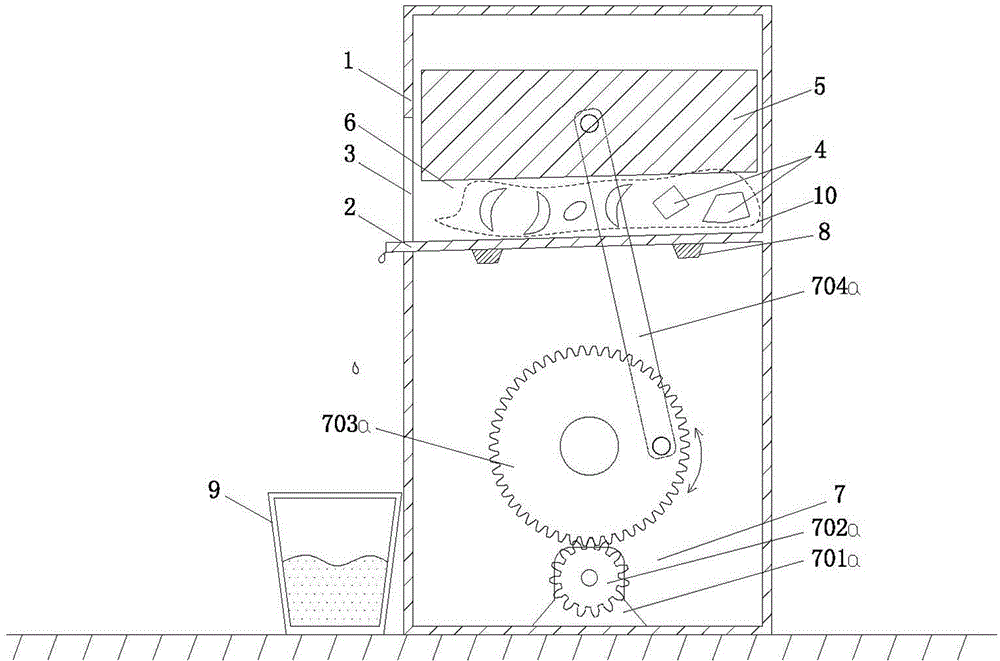

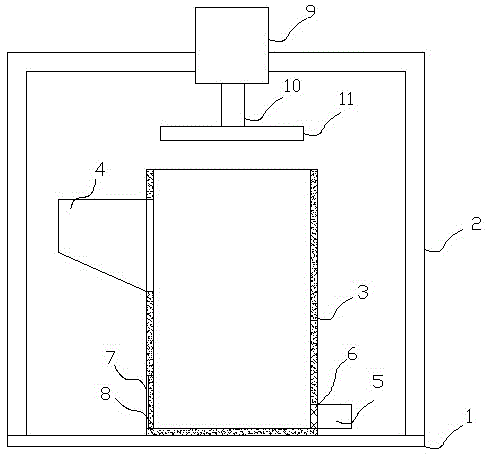

Squeezing type juicer

InactiveCN104127115ARetain nutrientsShort pressing timeJuice extractionStrainersComing outEngineering

The invention relates to a squeezing type juicer which comprises a machine body, wherein an oblique plate is fixed in the machine body, a juice discharging nozzle is formed at the lower oblique end of the oblique plate relative to the lateral surface of the machine body, a squeezing block sliding up and down is arranged above the oblique plate, a squeezing space accommodating an object to be squeezed is formed between the squeezing block and the oblique plate, a squeezing driving device is installed below the oblique plate and is in driving connection with the squeezing block to enable the squeezing block to slide towards the oblique plate in a squeezing mode, and then juice comes out through squeezing of the object to be squeezed in the squeezing space and flows out through the juice discharging nozzle. According to the squeezing type juicer, the structure is simple and reasonable, direct mechanical purely-physical squeezing is adopted, squeezing force is large, squeezing time is short, foam and heat are not generated, and the nutrient content of food is reserved to the maximum.

Owner:ZHONGSHAN MESTER IND

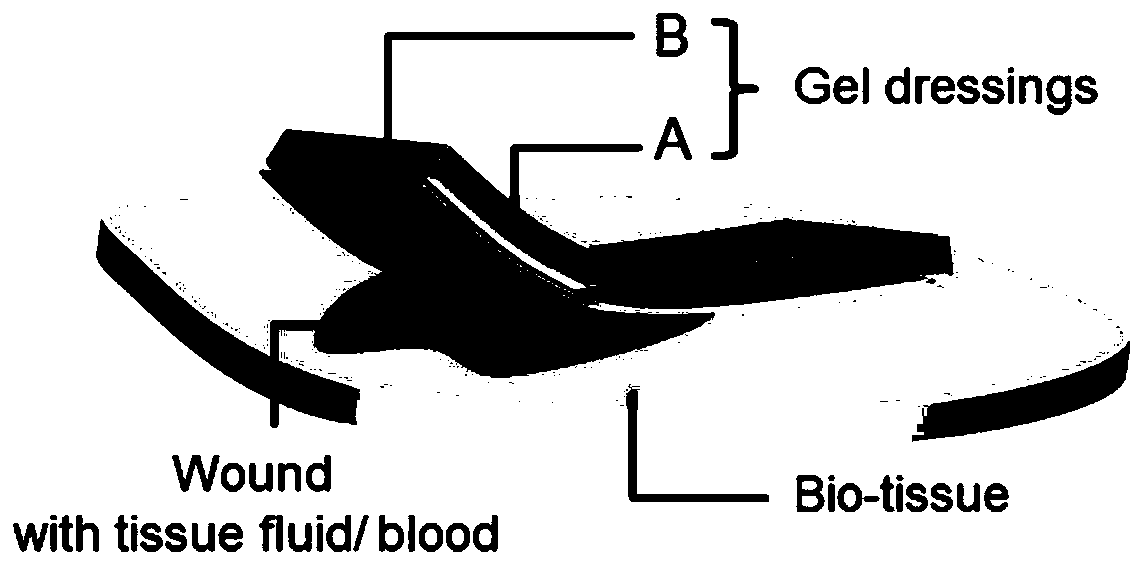

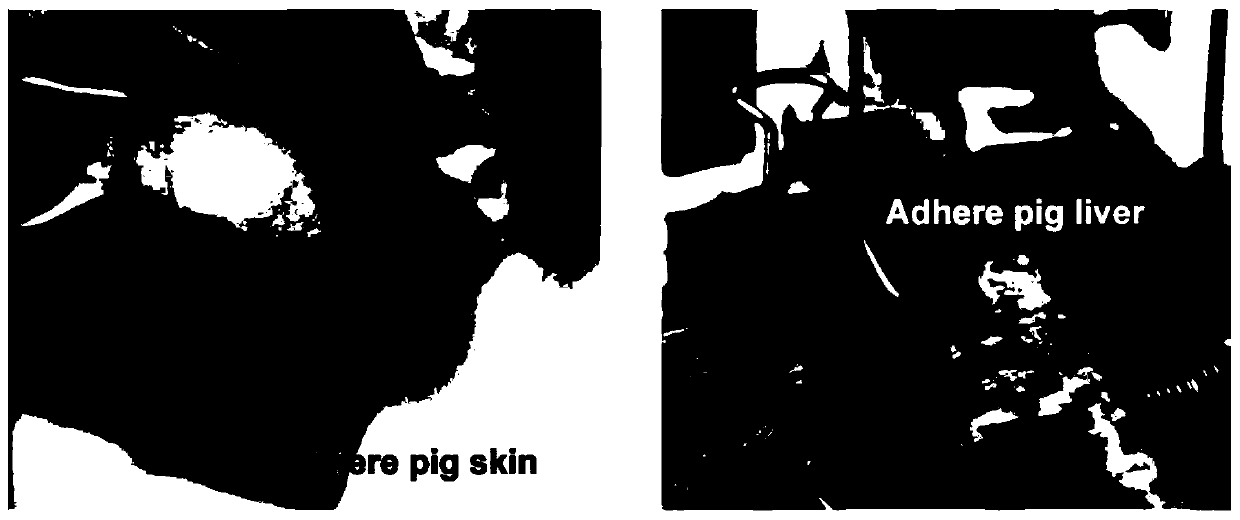

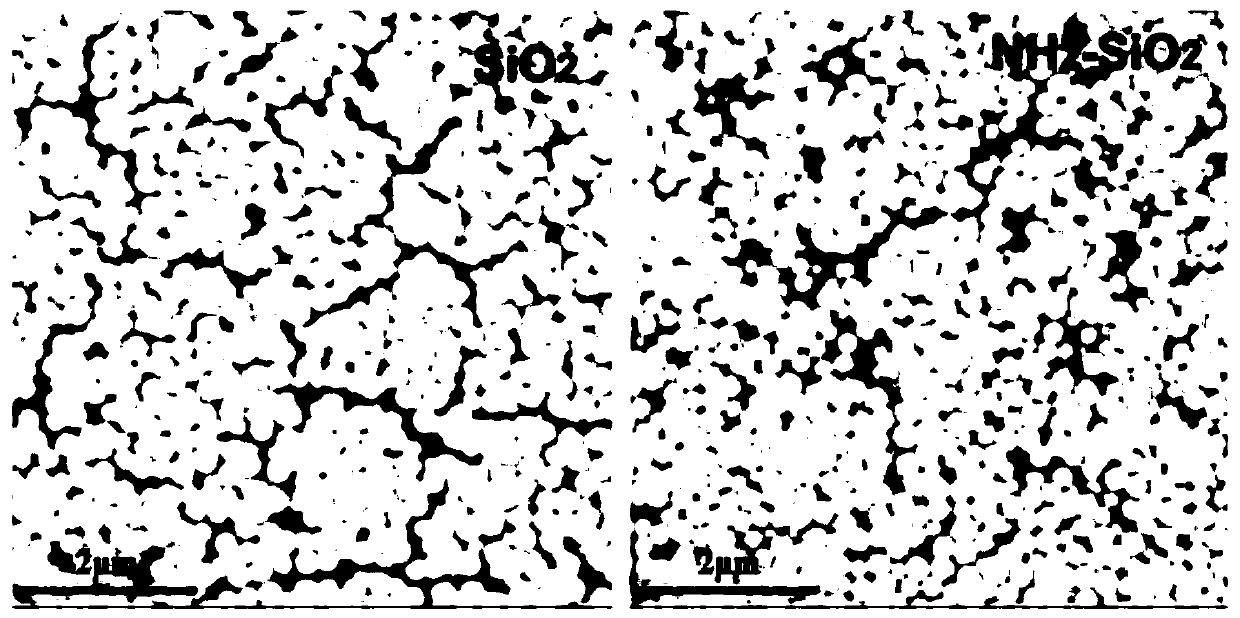

Tough and adherent wet tissue hydrogel dressing box and preparation method and application thereof

The invention provides a tough and adherent wet tissue hydrogel dressing box. The tough and adherent wet tissue hydrogel dressing box comprises two components stored separately, wherein the componentA is hydrogel formed by crosslinking sodium alginate and acrylamide, and the component B is a coupling solution prepared from the raw materials of a coupling agent, a linking agent and a buffer solution. The hydrogel dressing box is convenient to use. By adding the component B, the adhesive performance of a hydrogel dressing is significantly improved, and the hydrogel dressing has high adhesion strength to the skin surface and the surface of wet tissue in the body, is not prone to falling off and meets clinical demand. Meanwhile, the hydrogel dressing has excellent mechanical properties and biocompatibility and can be degraded. In addition, the dressing has the water content of up to 86%, can be loaded with a large number of drugs, can provide a good environment for tissue recovery and promote tissue healing. The tough and adherent wet tissue hydrogel dressing box not only solves the problems that traditional dressings have poor treatment effects of wounds and cannot be degraded and the like, but also solves the problem of poor adhesion performance of novel dressings, can further be applied to tissue in vivo, and has broad application prospects.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

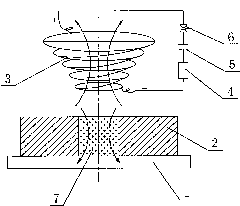

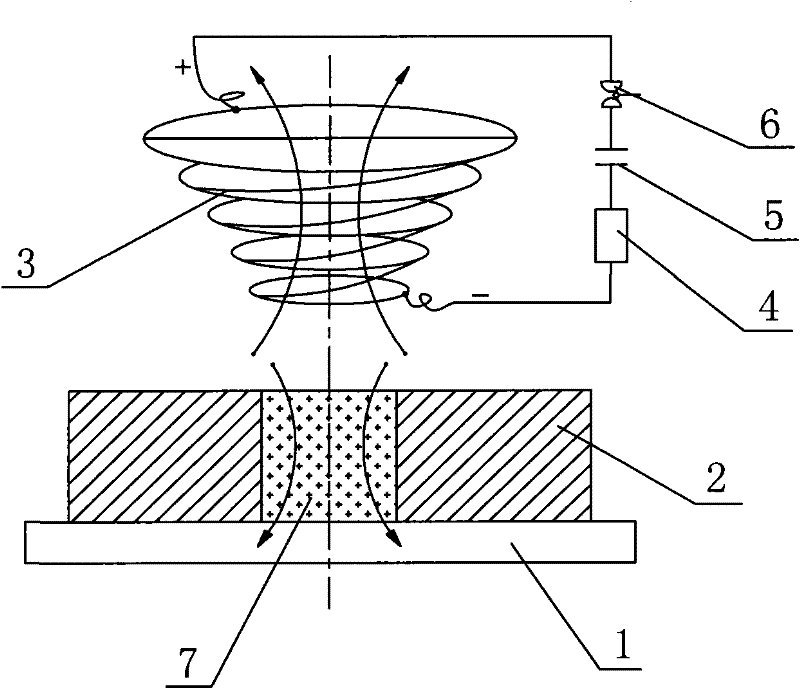

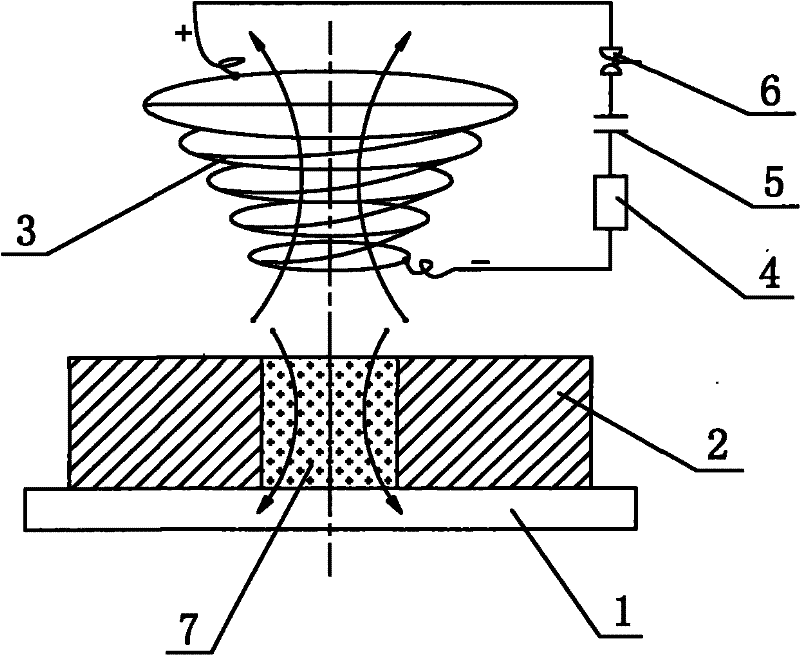

High-speed impact pressing method for metal powder

The invention discloses a high-speed impact pressing method for metal powder, which is characterized in that a die is arranged on a substrate first, a cavity is arranged on the die, a tower-shaped coil is fixed above the die, the tower-shaped coil is electrically connected with a discharge circuit, metal powder is filled in the cavity of the die, discharge processing is conducted to the tower-shaped coil, a pulsed magnetic field produced by the tower-shaped coil directly acts on the metal powder and the metal powder is pressed and formed. The invention has the advantages that the loading of impact stress waves to the metal powder is realized by using the action of electromagnetic force, the instant repetitive bidirectional compaction of the metal powder is realized by using the oscillation characteristics of the stress waves, the density of the pressed metal powder is high, the pressing time is short, the friction of the metal powder during pressing is reduced, the density distribution of the metal powder is even, the sintering shrinkage rate is reduced and the precision and the performance of parts are improved.

Owner:NINGBO UNIV

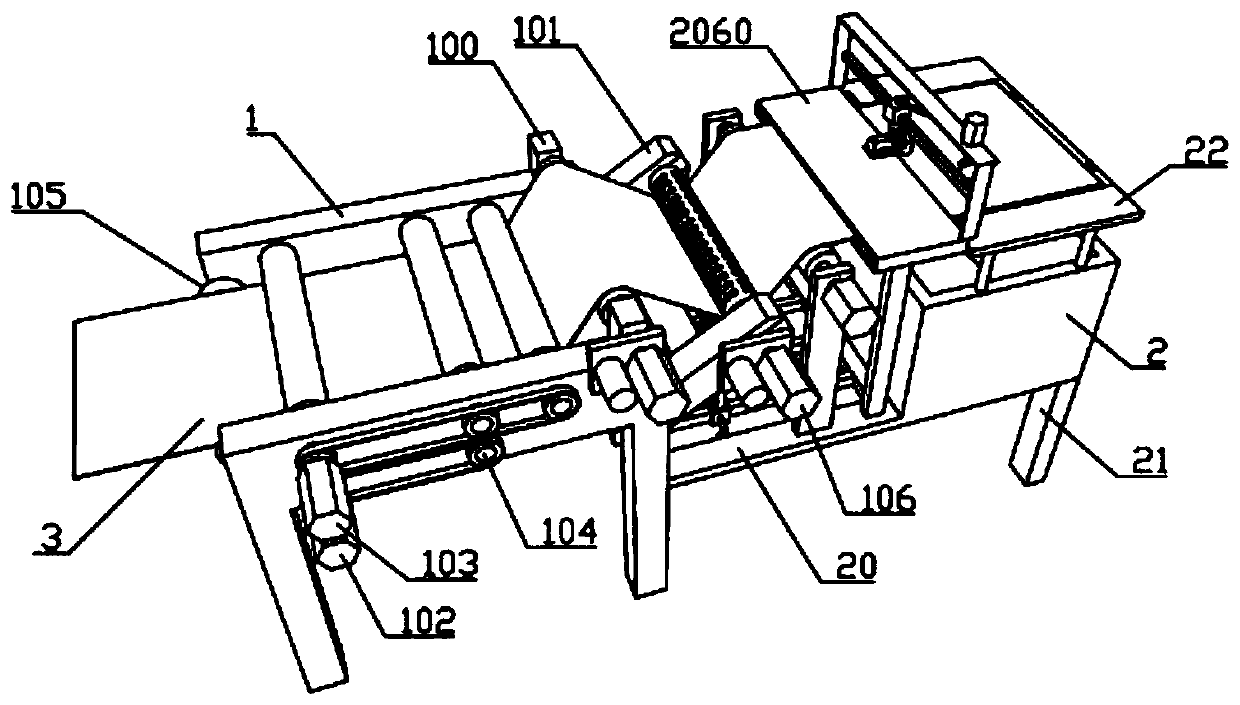

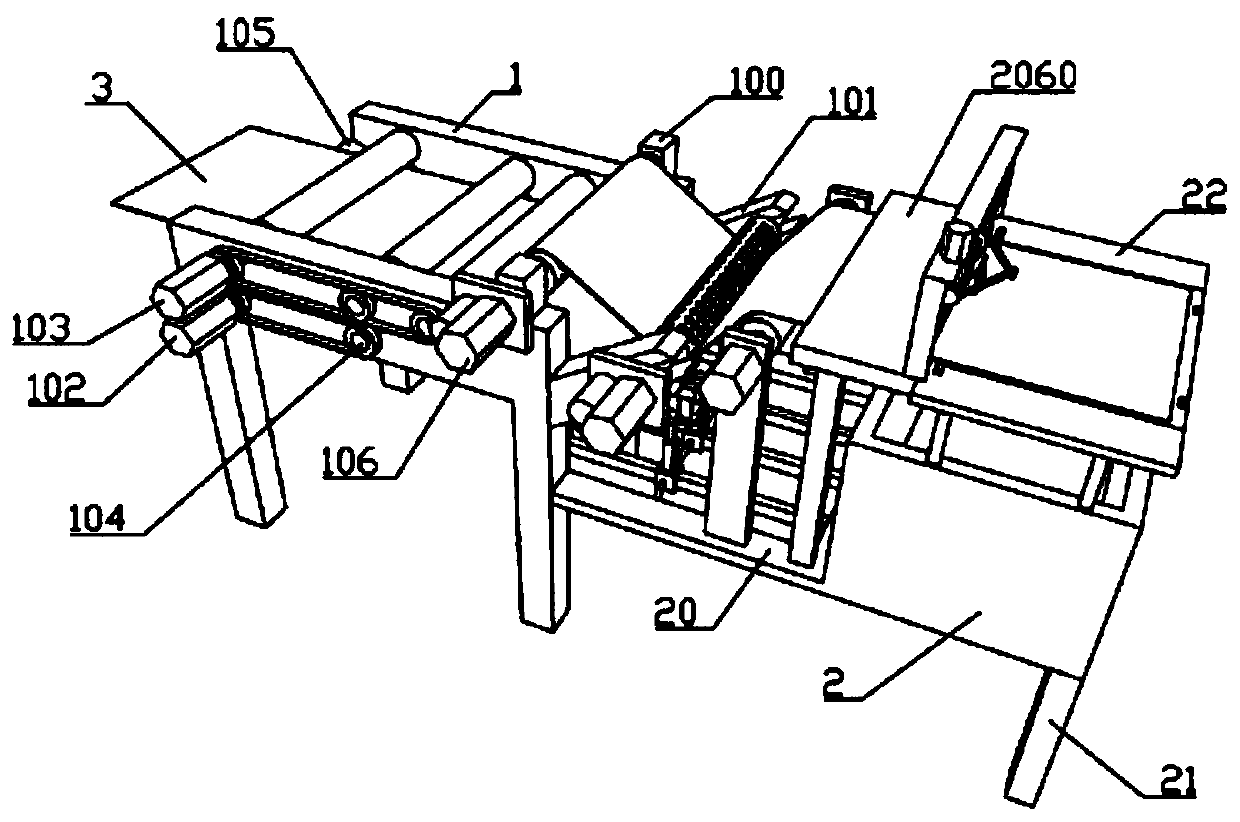

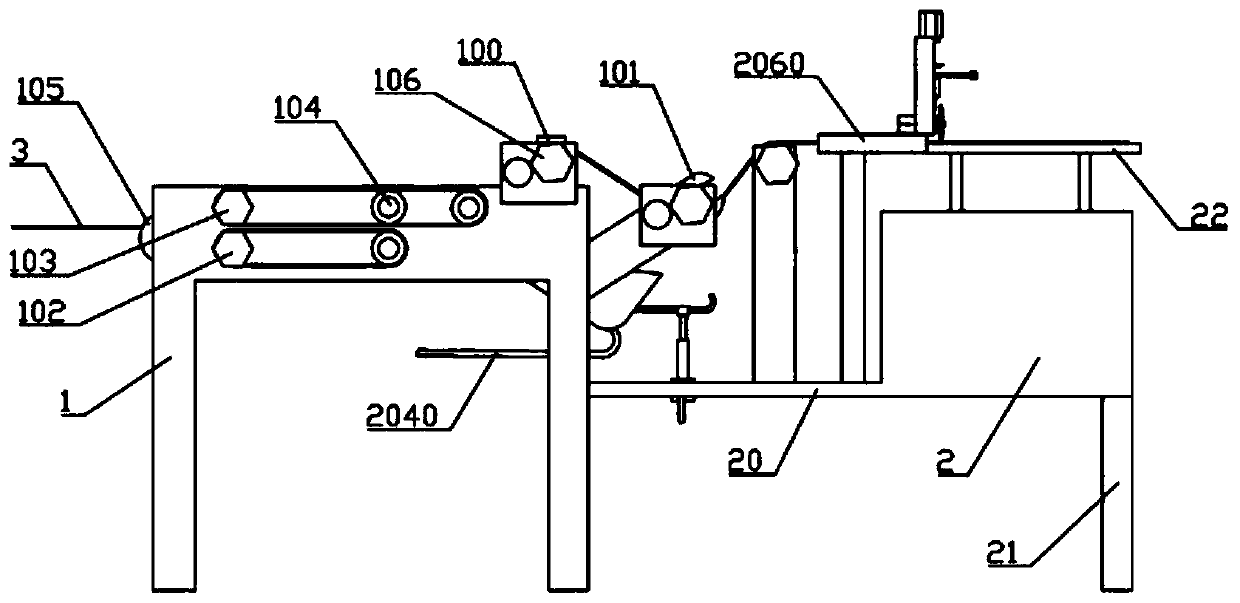

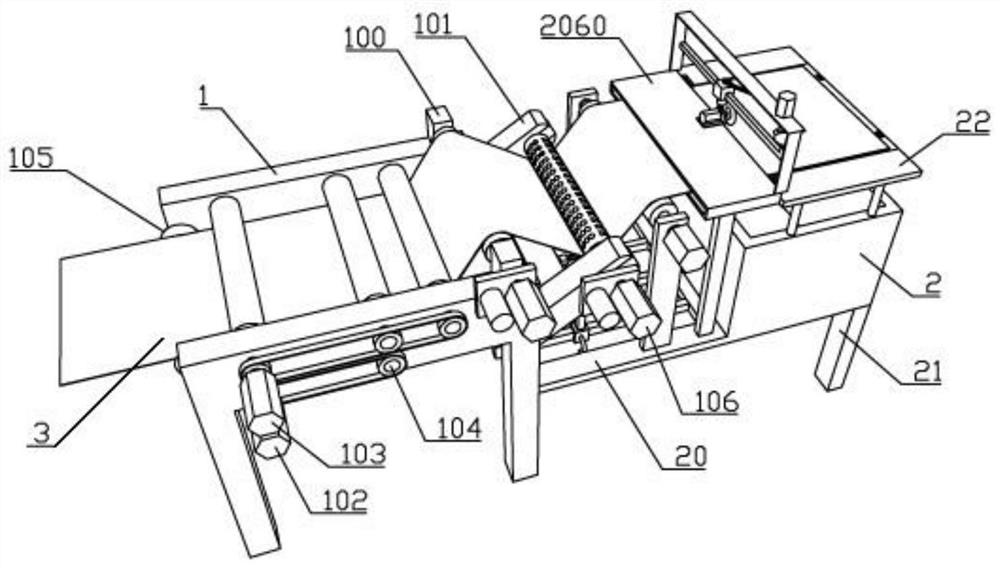

Method for gluing and drying copper-clad plate and device used by method

ActiveCN110370781AFast productionPrecision requirements are not highLamination ancillary operationsLayered product treatmentEngineeringCopper

The invention belongs to the technical field of copper-clad plate preparation, and particularly relates to a method for gluing and drying a copper-clad plate. The method comprises the steps of adhesive solution preparation, fiberglass cloth gluing, surface dry treatment, tailoring, and stacking and drying. The invention further relates to a device used by the method. The device comprises two traction supports and a drying box. The two traction supports face each other oppositely front and back, the traction supports are in reversed-U shapes, convex blocks are integrally formed at the right ends of the top surfaces of the traction supports, inclined support blocks low on the left and high on the right are integrally formed at the top ends of the right surfaces of the traction supports, gluing assemblies are mounted between the two front-back oppositely-faced convex blocks, gluing assemblies are also mounted between the two front-back oppositely-faced inclined support blocks, each gluingassembly comprises a gluing motor, a gluing rolling barrel, a fixing plate and a glue storing box, the fixing plates are fixedly mounted on power output shafts of the gluing motors, the glue storingboxes are mounted on the fixing plates, sleeve shafts are mounted at the rear end tips of the power output shafts of the gluing motors, the gluing rolling barrels sleeve the sleeve shafts and are fixed to the sleeve shafts, and first bearings are fixedly mounted at the two ends of each sleeve shaft.

Owner:黄瑞有

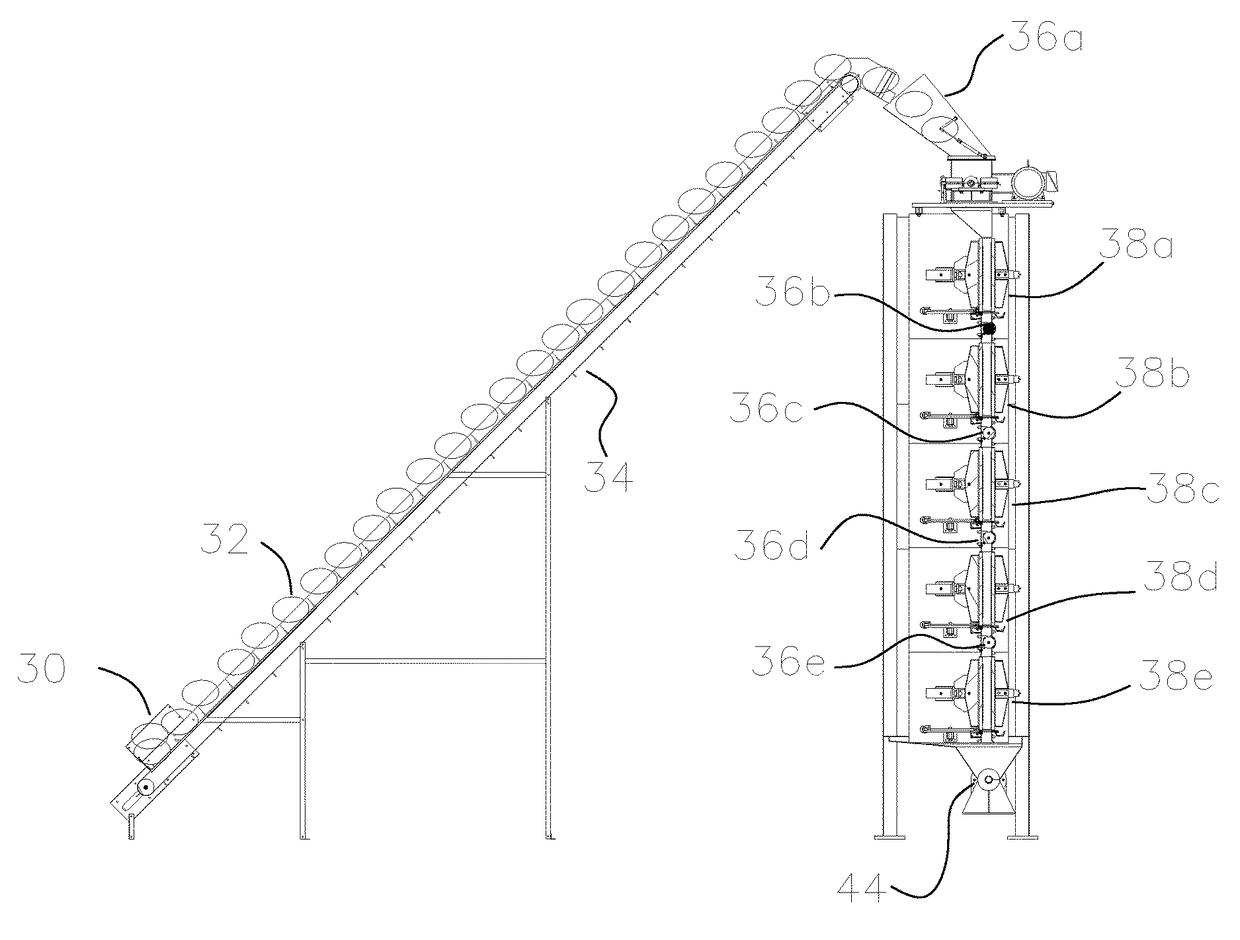

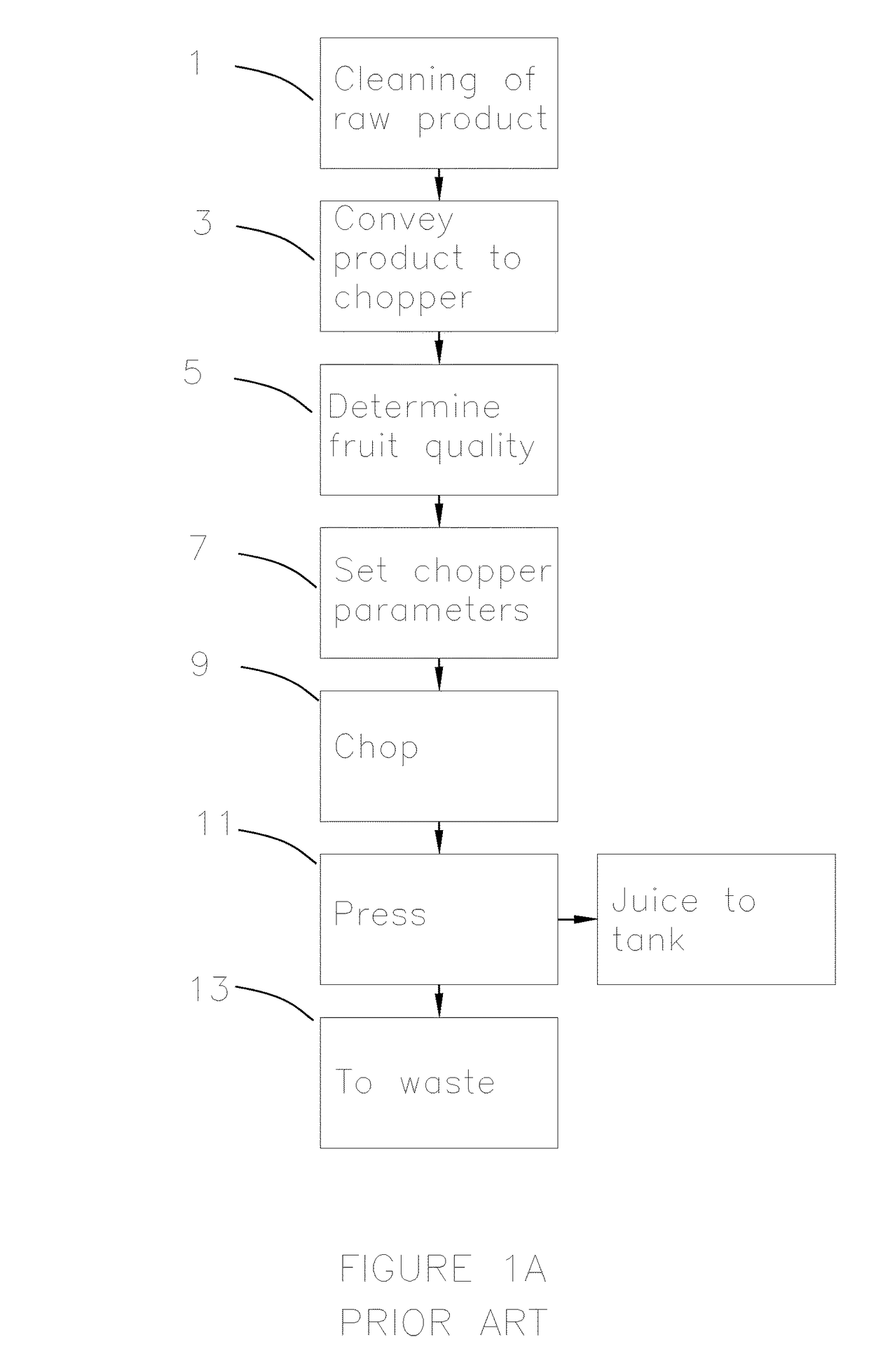

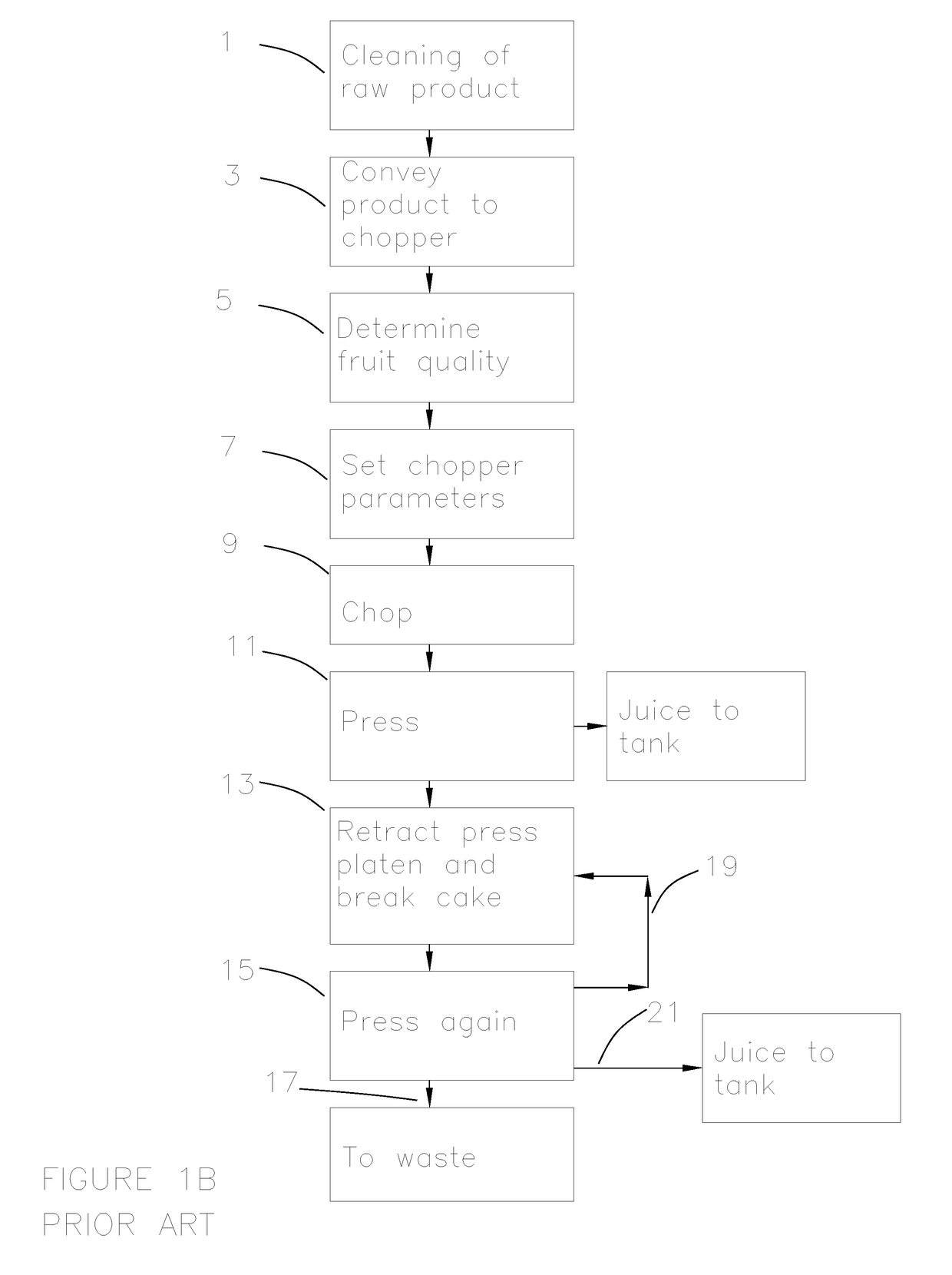

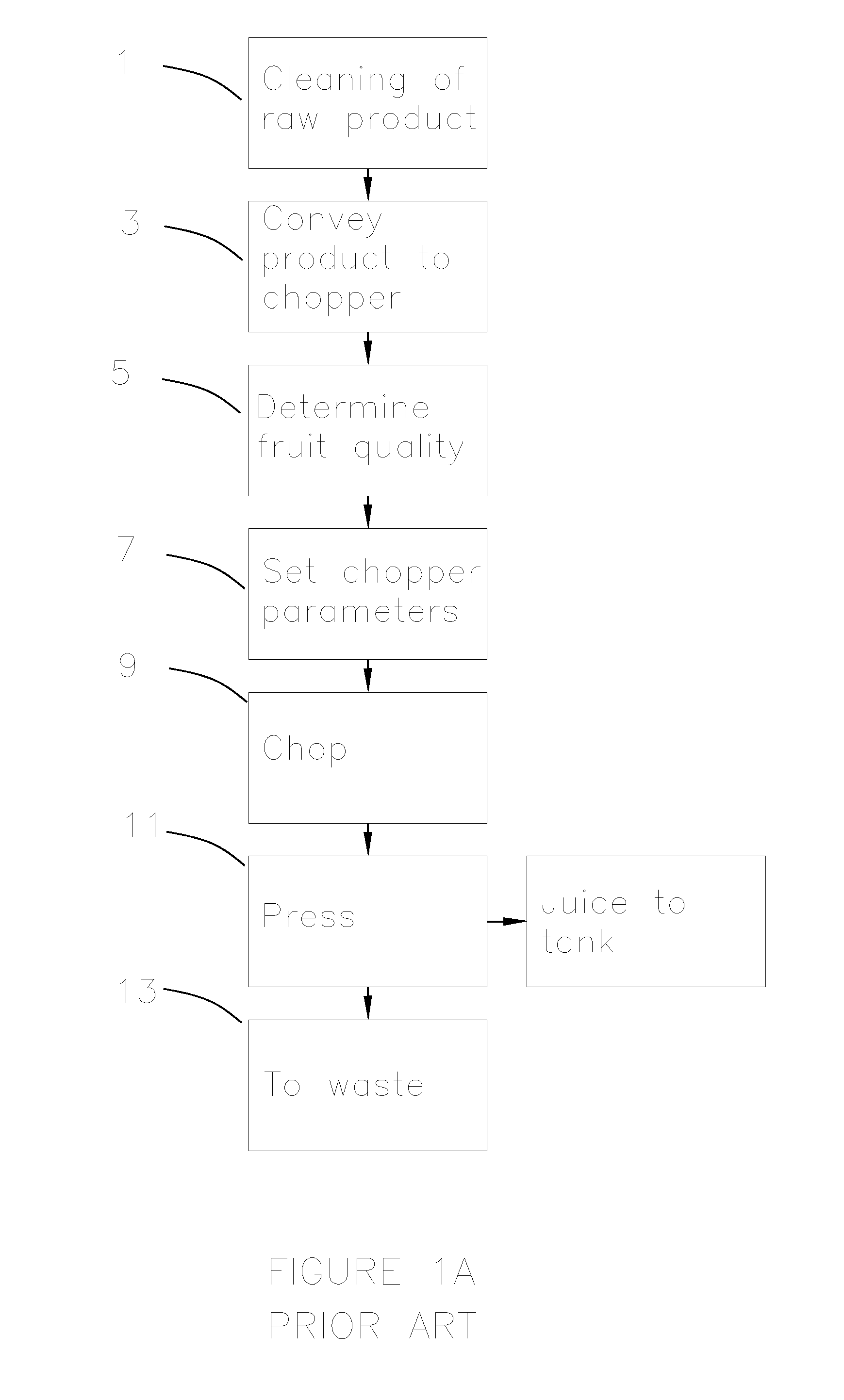

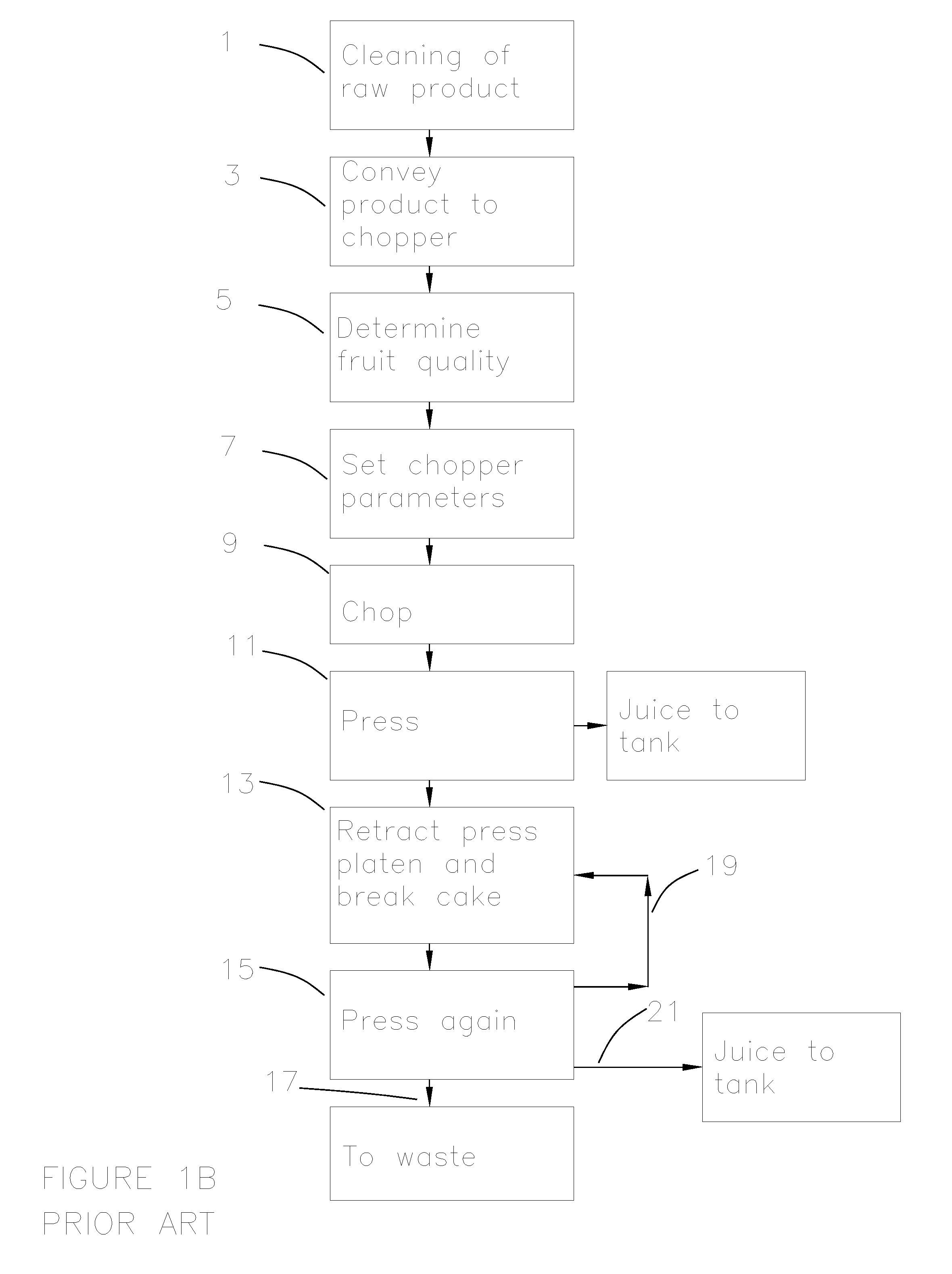

Method for multi-stage cutting and juice pressing

Juice extraction using multiple pairs of juice extractors and comminutors which reduce the food pieces into successively smaller pieces with juice extraction occurring after each comminuting step. Coarse food pieces are pressed with extracted juice directed to a juice holding tank. The pressed coarse chop food pieces fall into the hopper of a second comminutor which performs a medium chop on the now pressed but still coarse chopped food pieces. The medium chopped food pieces are then fed from the second comminutor into the juice extraction chamber of a second juice extractor whereupon the medium chopped food pieces are pressed with extracted juice directed to a juice holding tank. Any number of comminutor and juice extraction pairs may be used in serial fashion to optimize the percentage of juice extracted in a minimum amount of time.

Owner:GOODNATURE PROD INC

High-speed impact pressing method for metal powder

The invention discloses a high-speed impact pressing method for metal powder, which is characterized in that a die is arranged on a substrate first, a cavity is arranged on the die, a tower-shaped coil is fixed above the die, the tower-shaped coil is electrically connected with a discharge circuit, metal powder is filled in the cavity of the die, discharge processing is conducted to the tower-shaped coil, a pulsed magnetic field produced by the tower-shaped coil directly acts on the metal powder and the metal powder is pressed and formed. The invention has the advantages that the loading of impact stress waves to the metal powder is realized by using the action of electromagnetic force, the instant repetitive bidirectional compaction of the metal powder is realized by using the oscillation characteristics of the stress waves, the density of the pressed metal powder is high, the pressing time is short, the friction of the metal powder during pressing is reduced, the density distribution of the metal powder is even, the sintering shrinkage rate is reduced and the precision and the performance of parts are improved.

Owner:NINGBO UNIV

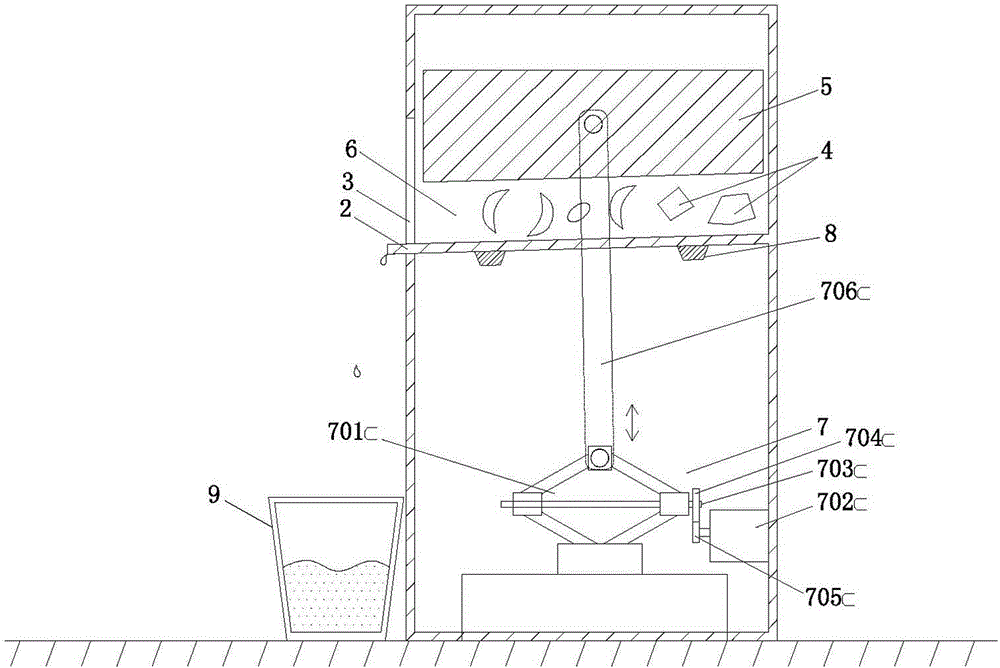

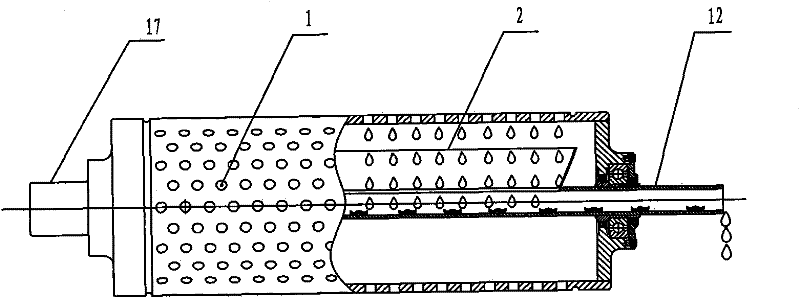

High-efficiency extraction type juice extractor

The invention provides a high-efficiency extraction type juice extractor which comprises a base, a hydraulic cylinder support and a juicing barrel. The juicing barrel is fixedly connected to the top of the base. A hydraulic cylinder is arranged in the middle of the hydraulic cylinder support. A telescopic rod is arranged at one end of the hydraulic cylinder. A pressing disc is arranged at one end of the telescopic rod. A juice outlet pipe is arranged on one side of the juicing barrel. The end, connected with the juice outlet pipe, of the juicing barrel is provided with a filter net. The high-efficiency extraction type juice extractor is high in efficiency, juice ingredients are not damaged, the hydraulic cylinder is adopted for driving the pressing disc to move to extract the juice, fruits do not need to be cut into pieces and subjected to stone removal in advance, and working efficiency is greatly improved. Juice and residues are discharged from different outlets, and therefore the quality of juice is ensured; meanwhile, an operator can use the juice extractor more conveniently and faster; in addition, the extraction process time is short, so that not too much heat is produced, and the original taste and flavor of juice are kept.

Owner:无锡太湖阳山水蜜桃科技有限公司

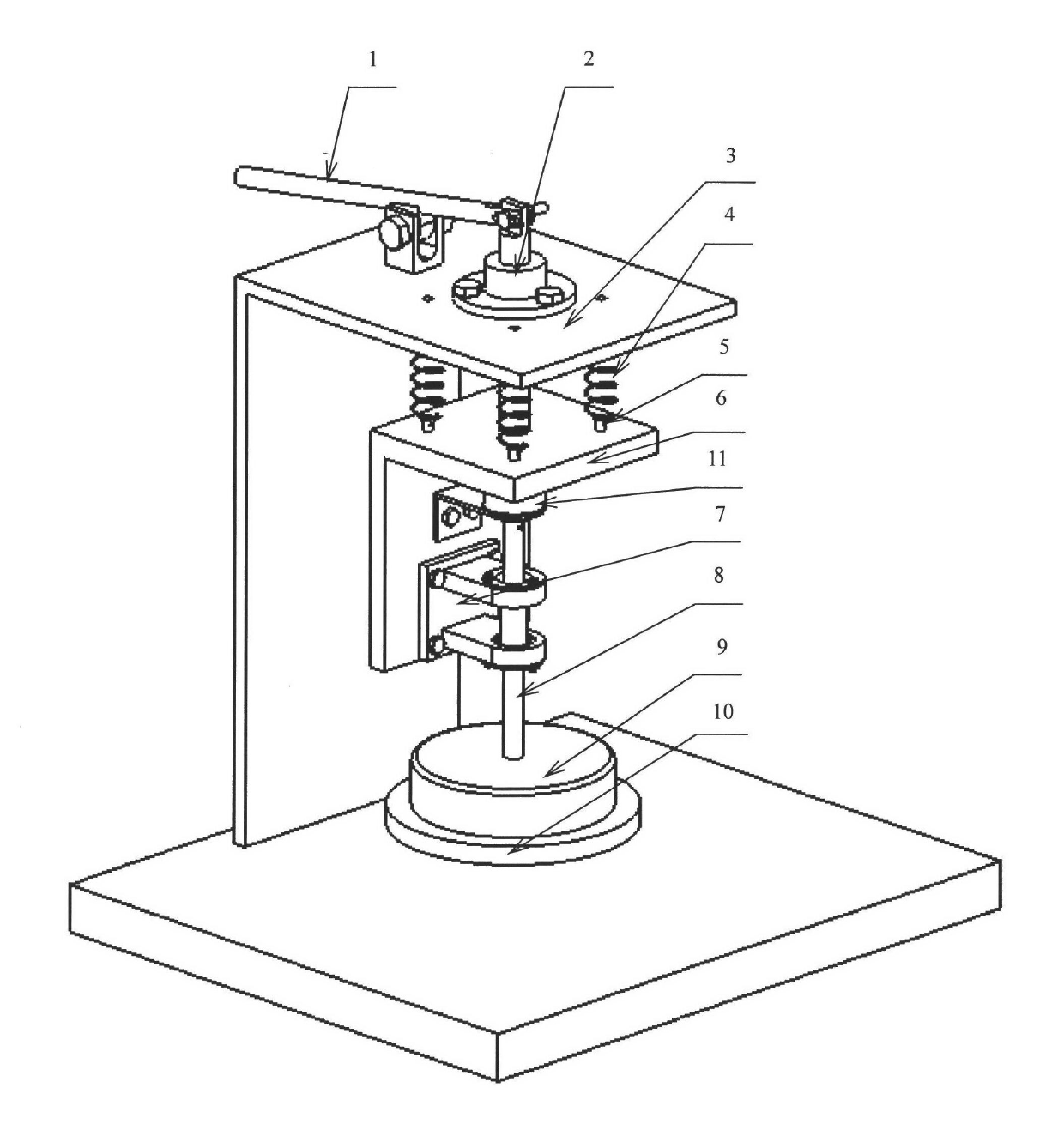

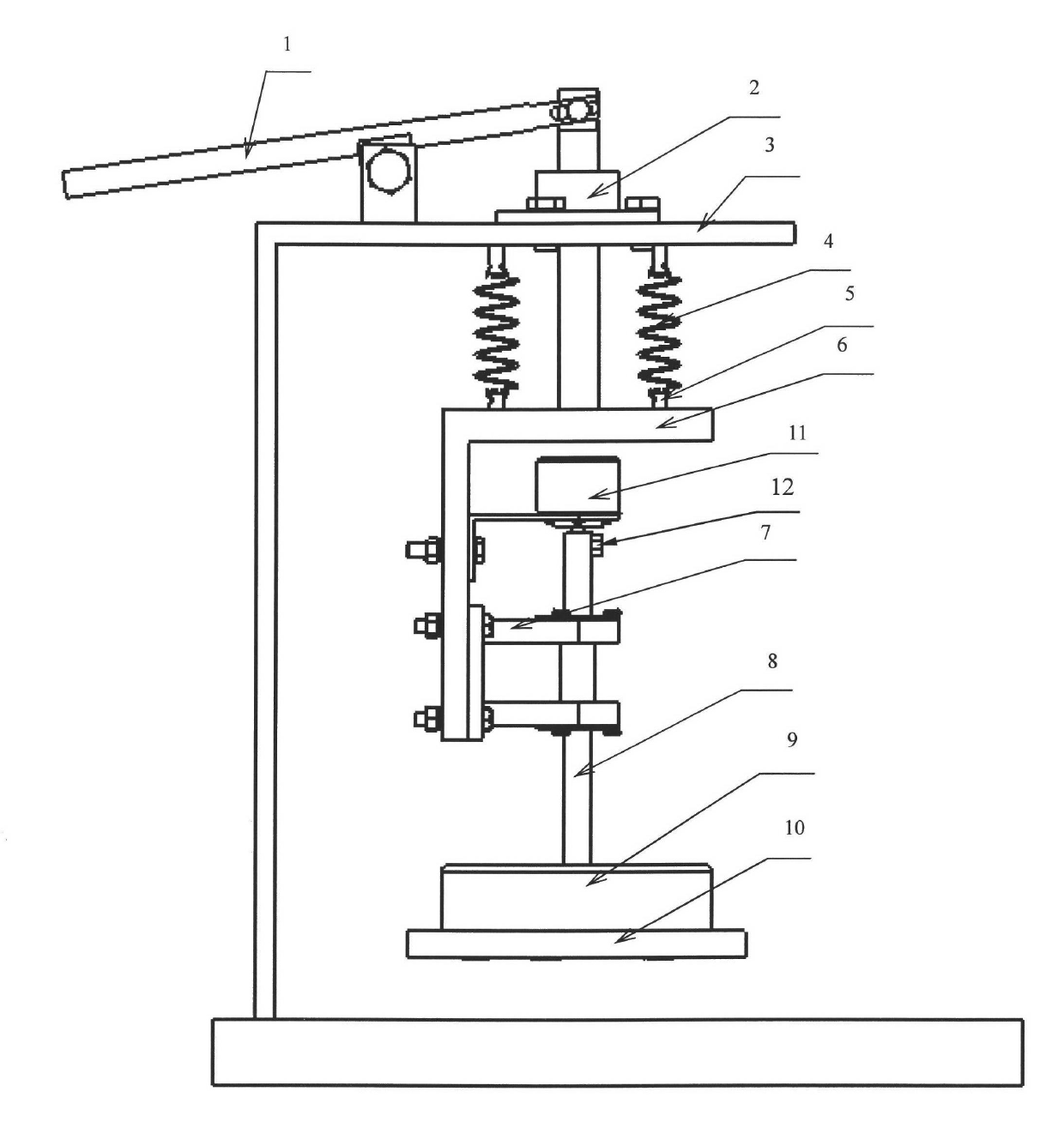

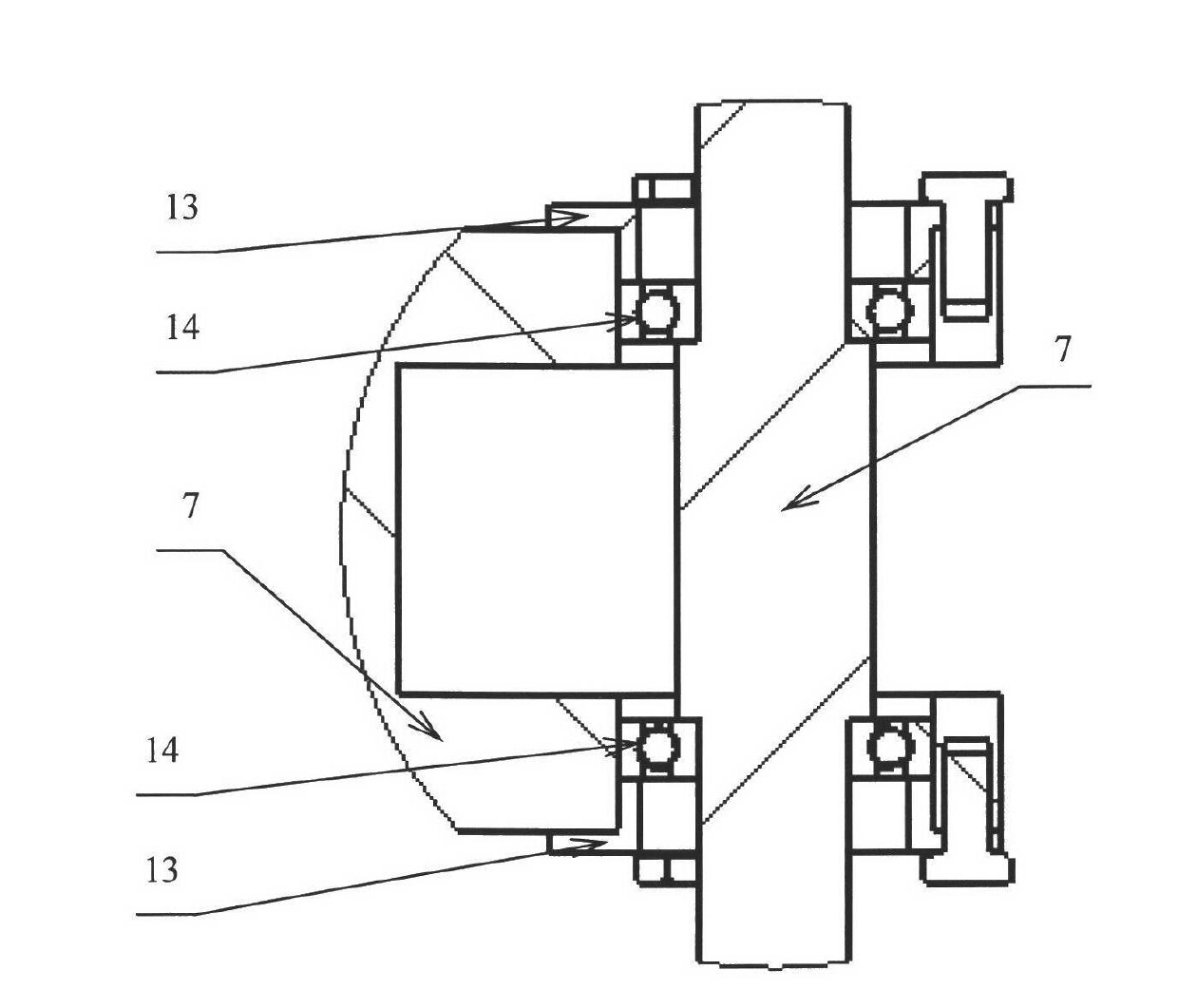

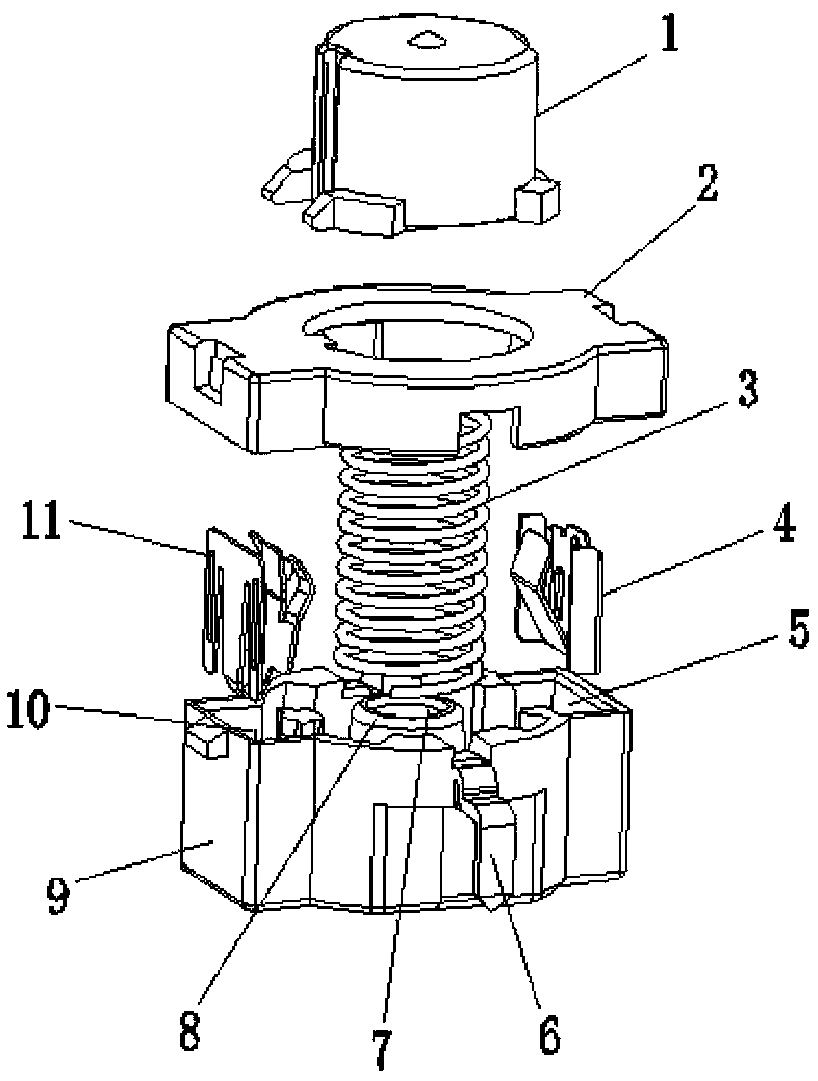

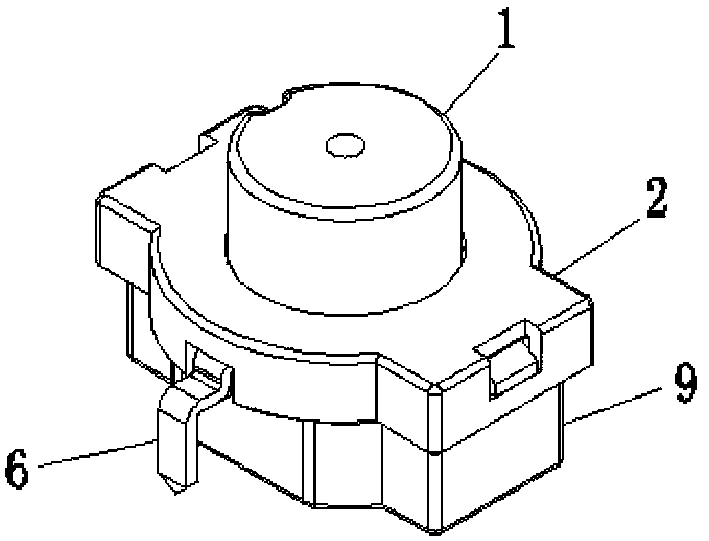

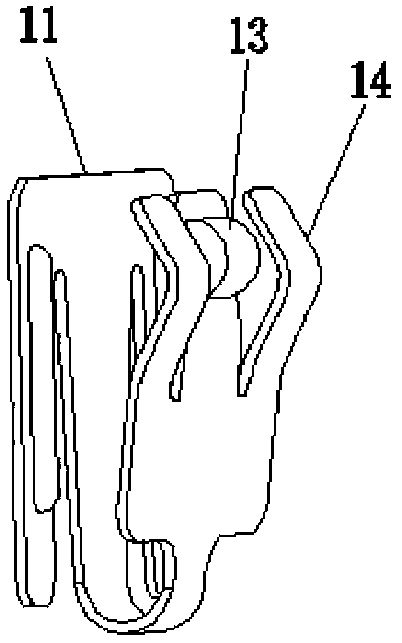

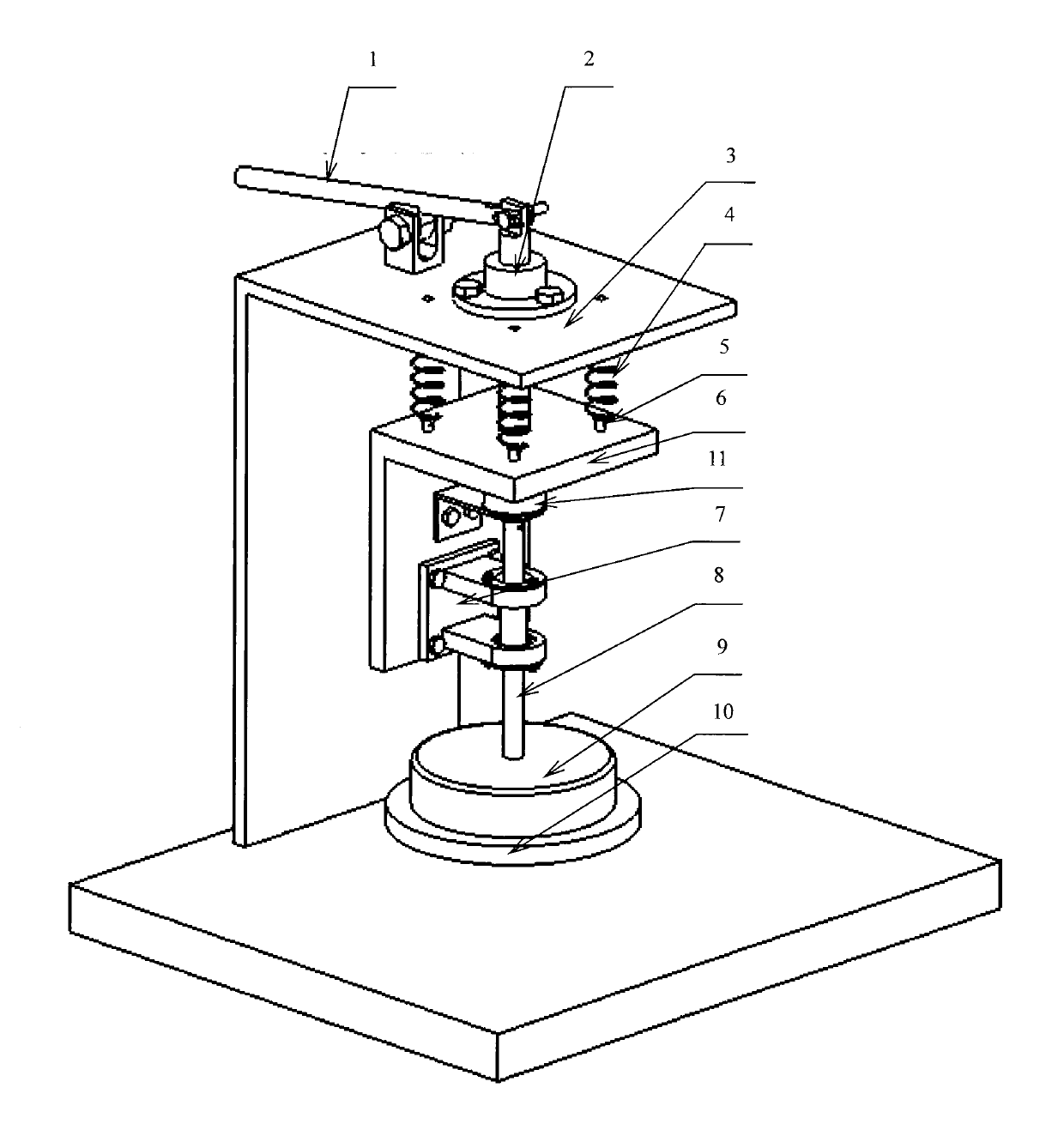

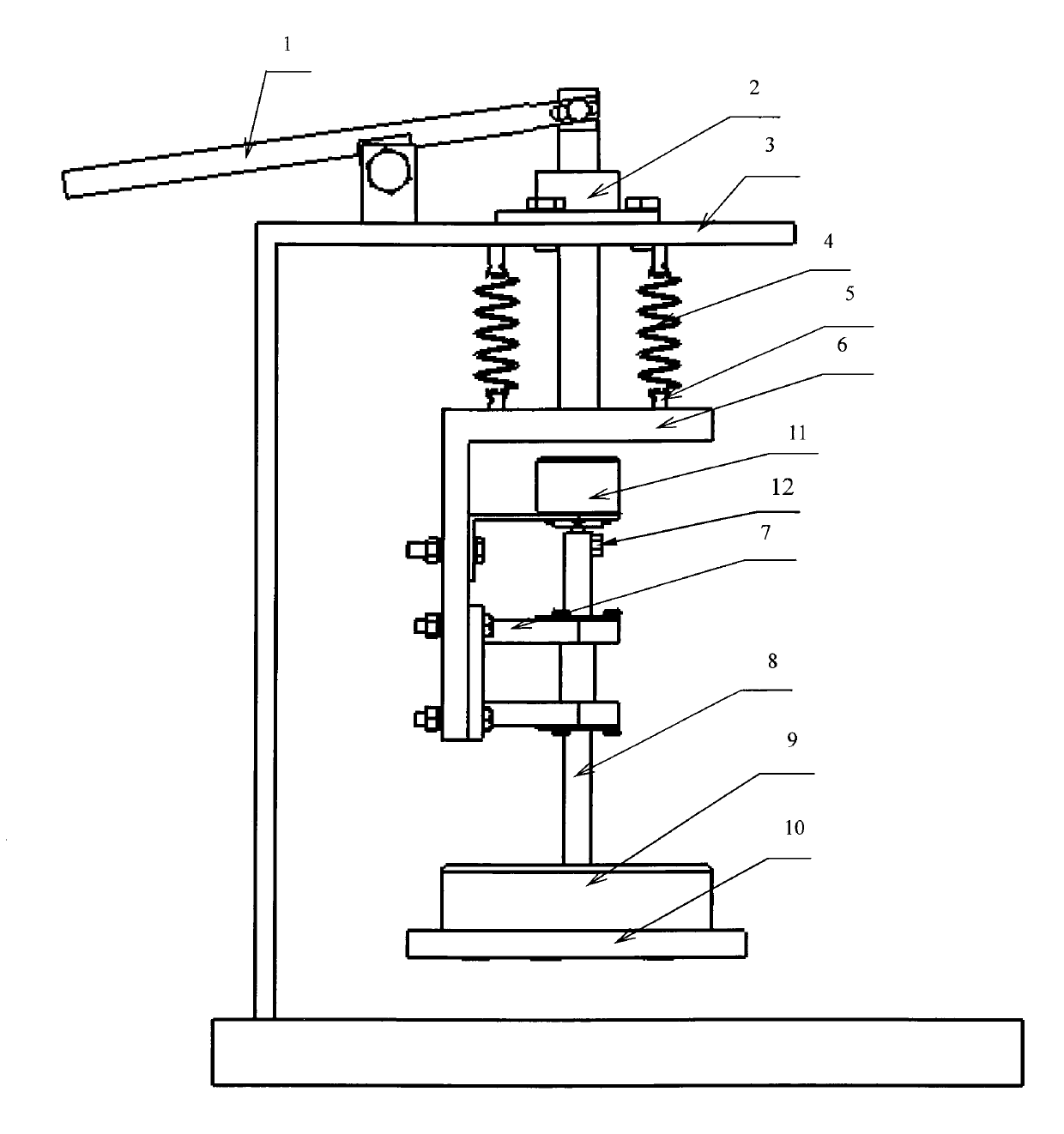

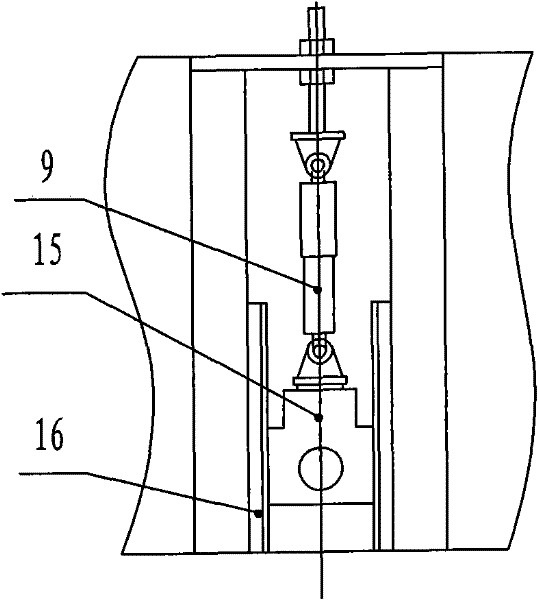

Quick calibrating apparatus for turning disc of automobile wheel positioning instrument

The invention discloses a quick calibrating apparatus for a turning disc of an automobile wheel positioning instrument, aiming at solving the problem that the turning disc of the automobile wheel positioning instrument can not be rapidly and accurately calibrated. The quick calibrating apparatus for the turning disc of the automobile wheel positioning instrument comprises a compression bar (1), asleeve (2), a base (3), a pressure spring (4), a stud (5) provided with a hole, a support seat (6), a bearing seat (7), a rotating shaft (8), a pressure plate (9), an elastic rubber pad (10), an encoder (11), a locating bolt (12), a bearing end cover (13) and a bearing (14). The quick calibrating apparatus can be used for completing the quick calibration for turning disc of the automobile wheel positioning instrument.

Owner:JILIN UNIV

Environment-friendly glue for silk-screen printing and lamination method of ceramic raw ceramic chip

InactiveCN110862785AImprove adhesionShort pressing timeNon-macromolecular adhesive additivesOil/fat/wax adhesivesScreen printingCellulose

Belonging to the technical field of semiconductor manufacturing, the invention relates to an environment-friendly glue for silk-screen printing and a lamination method of a ceramic raw ceramic chip. The environment-friendly glue for silk-screen printing is composed of the following components by weight: 60-100 parts of a solvent, 0.6-1 part of an adipic acid ether plasticizer, 0.1-1 part of hydrogenated castor oil, 0.2-1 part of lecithin and 2-6 parts of ethyl cellulose. The glue is mainly applied to a laminating link of a ceramic packaging base, the glue is uniformly coated on a raw ceramic chip in a silk-screen printing mode, and after normal-pressure fixation and lamination, firm bonding between a ceramic casting raw ceramic chip and a raw ceramic chip is realized. After silk-screen printing and normal-pressure plate pressing (only 4-6s) on the glue, automatic and continuous production of the ceramic packaging base can be realized, and the production efficiency is greatly improved.

Owner:瓷金科技(河南)有限公司

Process for producing rubber sheets, rubber mats or similar rubber products from rubber granules

ActiveUS8343290B2Short production timeGood value for moneyPlastic recyclingLaminationPolymer scienceRubber sheet

A rubber sheet is made from rubber-containing granules by first coating the rubber granules with a binder, then forming the coated rubber granules into a mat having a core layer with a low moisture level of less than 5% and a pair of outer surface layers, and then, without substantially increasing the low moisture level in the core layer, setting in at least one of the outer layers a high moisture level of 10% to 50% by weight and thereby imparting to the mat an inhomogeneous moisture profile. The mat with the inhomogeneous moisture level is then hot-pressed with pressure and heat so as to vaporize moisture in the one outer layer and drive steam into the core layer, and the hot-pressed mat is cured.

Owner:SIEMPELKAMP MASCH & ANLAGENBAU GMBH & CO KG

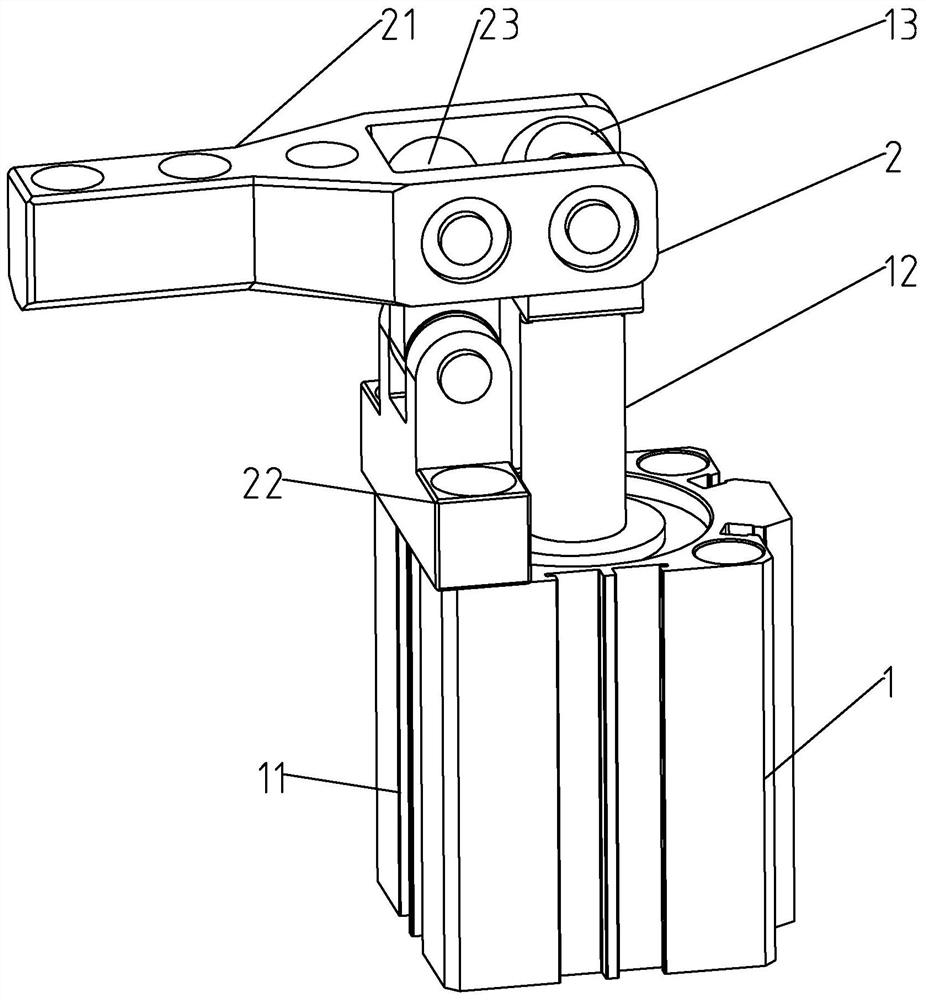

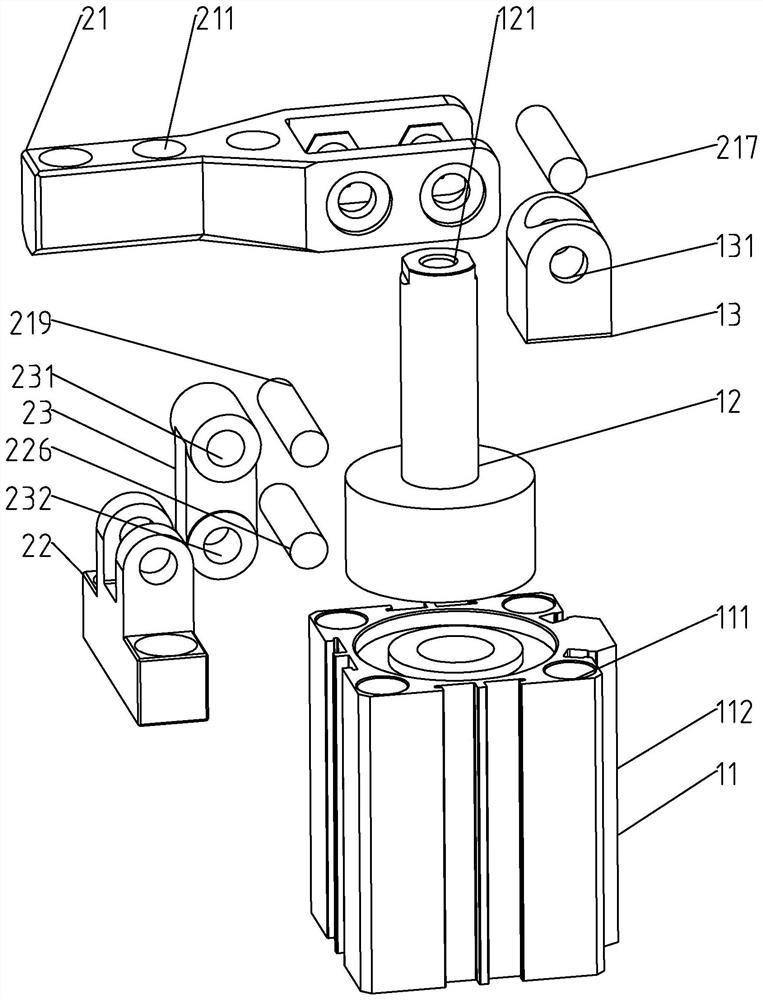

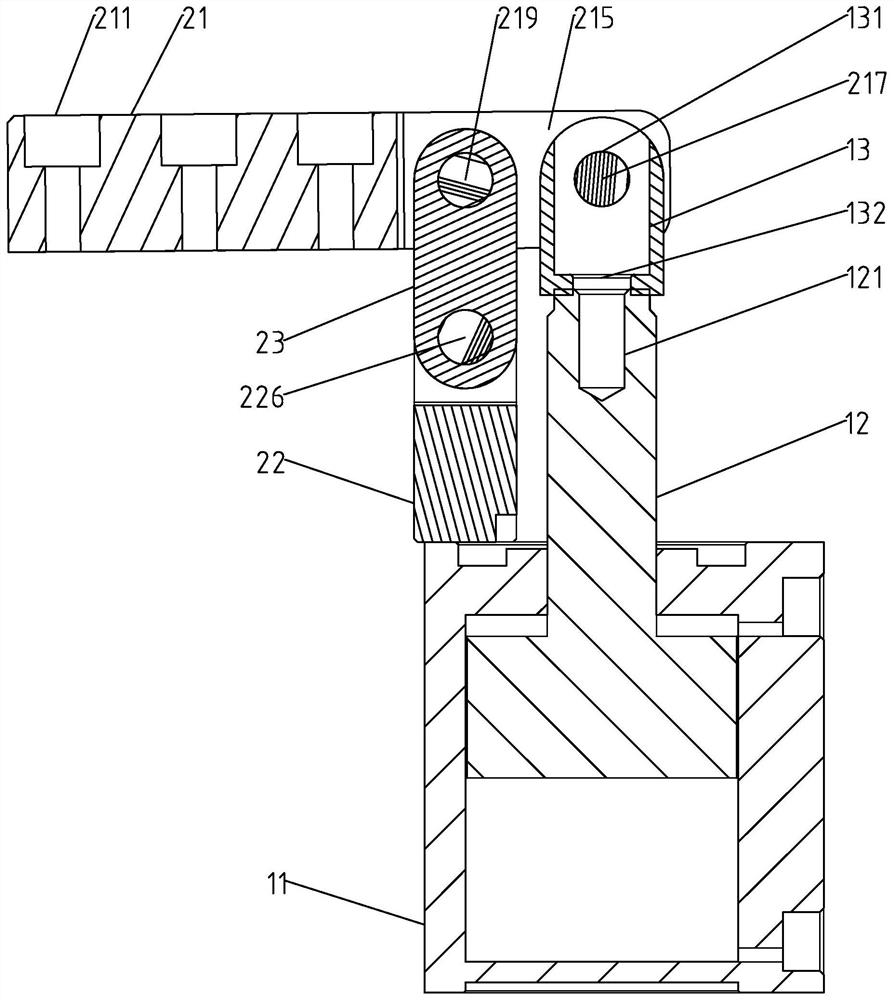

Rapid press-fitting locking mechanism

The invention relates to a rapid press-fitting locking mechanism which comprises a driving device and a pressing mechanism. The driving device comprises an air cylinder and a piston rod, one end of the piston rod is located in the air cylinder, the other end of the piston rod extends out of the top of the air cylinder, and the outer surface of the top of the piston rod is fixedly connected with a connecting pin; and the pressing mechanism comprises a pressing rod, a mounting seat and a hinge arm, the mounting seat is fixedly mounted at the top of the air cylinder and movably connected with the middle of the pressing rod through the hinge arm, the piston rod is movably connected with the end, close to the air cylinder, of the pressing rod through the connecting pin, and a plurality of positioning holes are formed in the end, away from the connecting pin, of the pressing rod. The rapid press-fitting locking mechanism has the beneficial effects that the pressing force is improved, the operation accuracy is improved, and the operation efficiency is improved.

Owner:YONGKANG LINGYING ELECTRICAL APPLIANCES

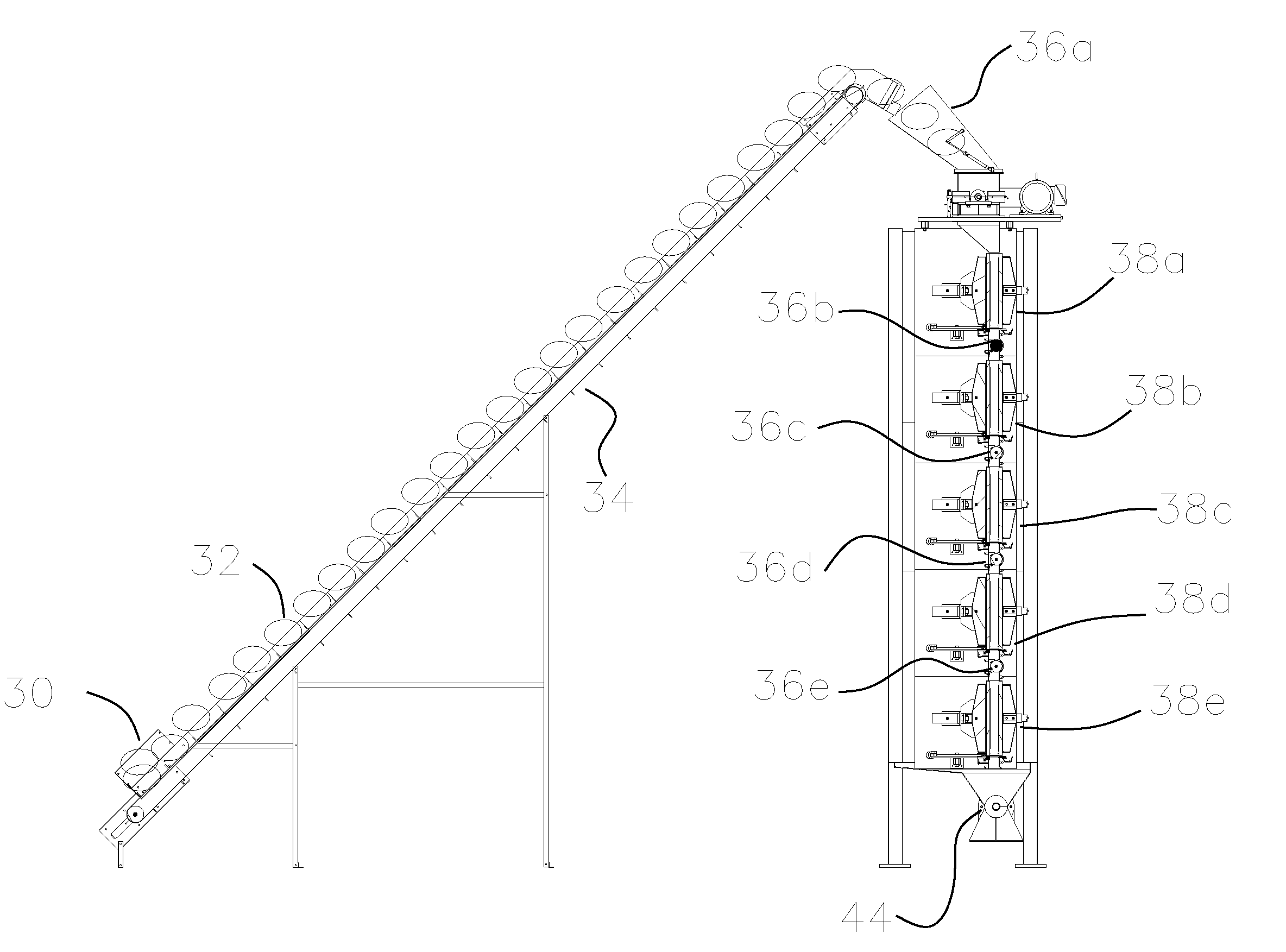

Apparatus and method for multi-stage cutting and juice pressing

Juice extraction using multiple pairs of juice extractors and comminutors which reduce the food pieces into successively smaller pieces with juice extraction occurring after each comminuting step. Coarse food pieces are pressed with extracted juice directed to a juice holding tank. The pressed coarse chop food pieces fall into the hopper of a second comminutor which performs a medium chop on the now pressed but still coarse chopped food pieces. The medium chopped food pieces are then fed from the second comminutor into the juice extraction chamber of a second juice extractor whereupon the medium chopped food pieces are pressed with extracted juice directed to a juice holding tank. Any number of comminutor and juice extraction pairs may be used in serial fashion to optimize the percentage of juice extracted in a minimum amount of time.

Owner:GOODNATURE PROD INC

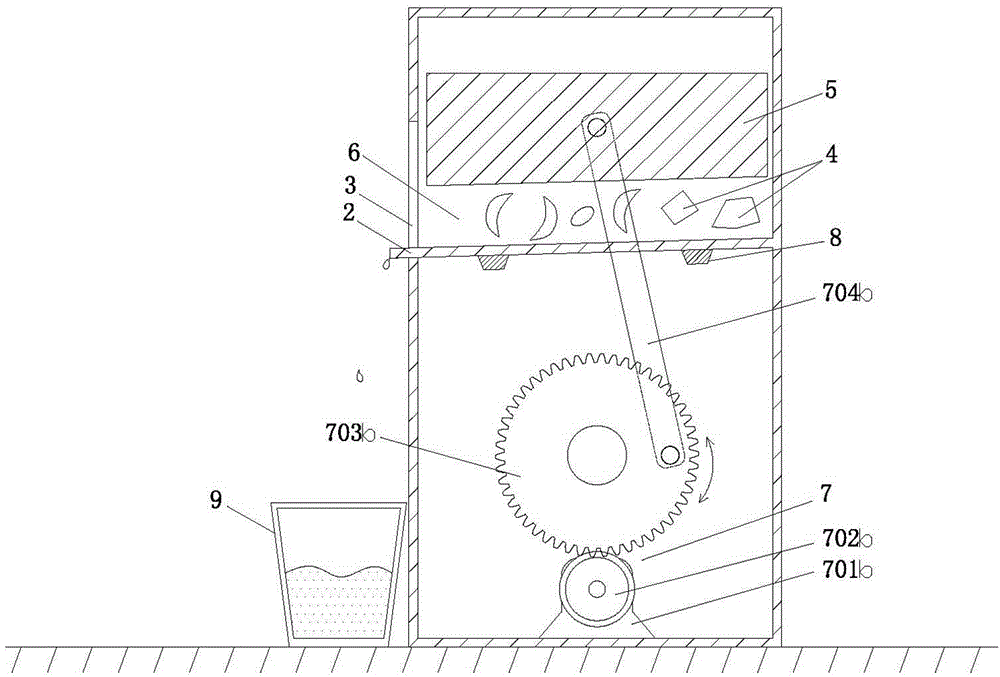

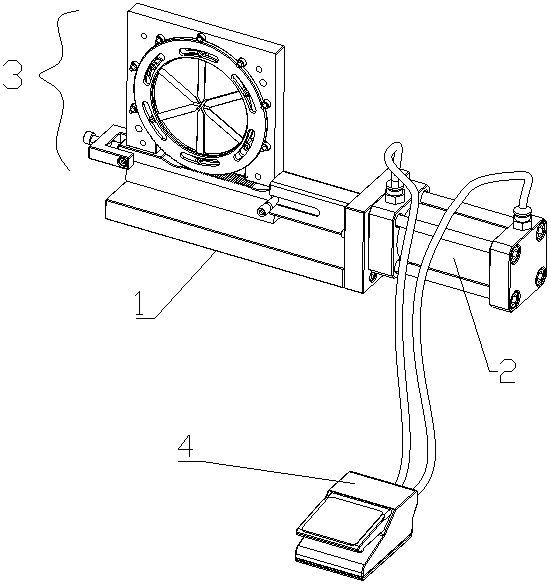

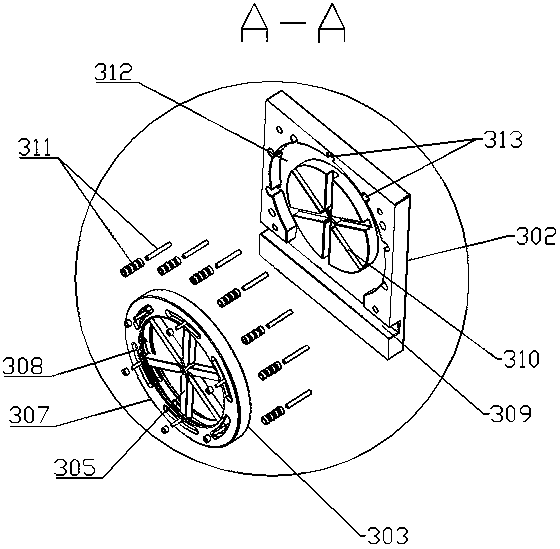

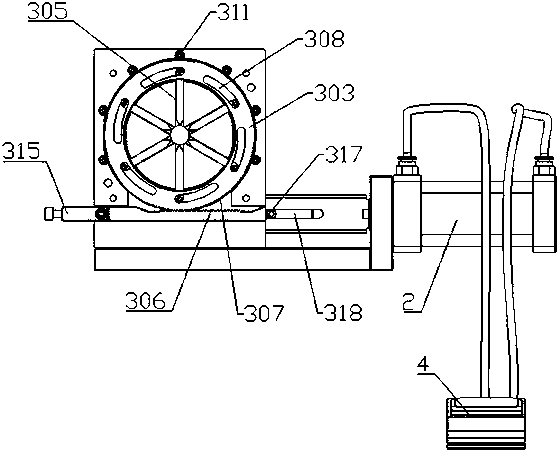

Stamping device for waterproof tensile hardware circular hoop of LED lamp strip lamp plug

PendingCN110524222AShort pressing timeImprove stamping efficiencyMetal working apparatusEngineeringLED lamp

The invention relates to a stamping device for a waterproof tensile hardware circular hoop of an LED lamp strip lamp plug. The device comprises a base, a power mechanism and a pressing mechanism, thepower mechanism is fixed on the base, and the pressing mechanism comprises a machine body, a gear disc rotationally connected with the machine body, a gear rod for driving the gear disc to rotate anda stamping ejection piece. The gear rod is provided with a rack, the rack is meshed with a gear arranged on the gear disc, and the gear rod is connected with the power mechanism; the gear disc is provided with a linkage groove matched with the stamping ejection piece, one end of the stamping ejection piece is matched with the linkage groove, and the other end of the stamping ejection piece is usedfor forming a plug circular hoop to be stamped. The stamping device is driven by the power mechanism, and matches with a pedal, so that the pressing time is short, and the stamping efficiency is improved. The power mechanism drives the multiple stamping ejector pieces to contract or expand at the same time, a pressed section is of an angular star structure, the structure is regular, the plug circular hoop is evenly stressed, and the circular hoop and the plug are pressed tightly, so that the waterproof effect of a product is good.

Owner:吴雪祥

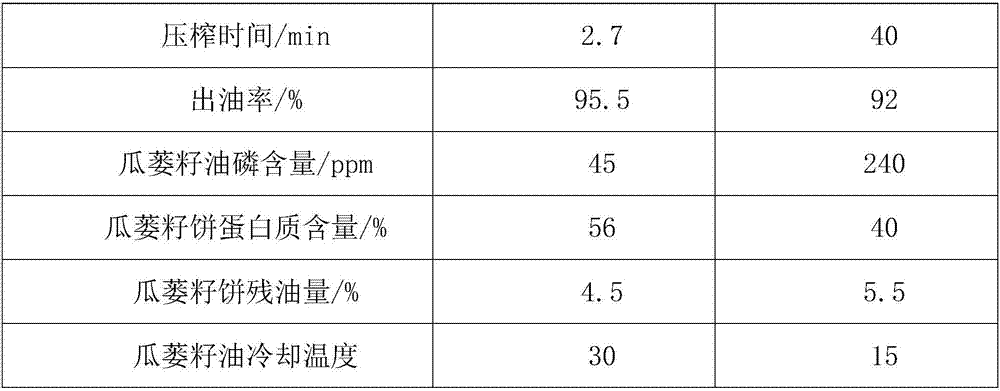

Processing method for Trichosanthes kirilowii seed oil

InactiveCN107541333AImprove extraction efficiencyShort pressing timeFatty-oils/fats refiningFatty-oils/fats productionWater contentChemistry

The invention discloses a processing method for Trichosanthes kirilowii seed oil. The processing method comprises the following steps that firstly, crushing and enzymolysis are conducted, wherein thewater content of Trichosanthes kirilowii seeds is controlled to be, by weight, 8-12%, and the Trichosanthes kirilowii seeds are crushed and mixed with a mixing solution A for an enzymolysis reaction;secondly, screw pressing is conducted, wherein the material obtained in the first step is pressed, and Trichosanthes kirilowii seed cakes and pressed oil are obtained; thirdly, filtration and separation are conducted, wherein the pressed oil is filtered, cooled and filtered, and the Trichosanthes kirilowii seed oil is obtained. The processing method for the Trichosanthes kirilowii seed oil has theadvantages that the extraction rate of the Trichosanthes kirilowii seed oil is high, energy conservation and environment protection are achieved, no pollution is produced, the pressing time is short,the instantaneous pressing pressure is low, the Trichosanthes kirilowii seed oil does not need to be subjected to chemical refining, and the production cost is low, and the large-scale, industrial and continuous production of the Trichosanthes kirilowii seed oil is achieved.

Owner:安徽嘉旗粮油工程技术有限公司

Method used for low-temperature cold-pressing screw-type extraction of full-fat wheat germ oil

InactiveCN105112150AIncrease enzyme activityShorten the enzymatic digestion timeFatty-oils/fats productionEdible oils/fatsEnzymatic hydrolysisPre treatment

The invention relates to a method used for low-temperature cold-pressing screw-type extraction of full-fat wheat germ oil. According to the method, under weak basic conditions, a single enzyme is adopted for enzymatic hydrolysis, enzyme deactivation and drying are carried out at the same time, and a low-temperature double-screw cold-pressing expeller is adopted for cold pressing so as to obtain transparent clear full-fat wheat germ oil. The method can be used for solving problems of the prior art that oil yield is low, and nutrients are destroyed because of excessively high temperature in cold pressing processes; the single enzyme is adopted for pretreatment, oil materials are softened quickly under weak basic conditions, hot wind cooking is adopted, cold pressing can be carried out directly, operation steps are simplified, and production efficiency is increased. Oil yield of the method is high; and the quality of the obtained full-fat wheat germ oil accords with industrial standards.

Owner:HEILONGJIANG HUIMINXING BIOTECH

A thin key switch

ActiveCN106783326BImprove the uniformity of forceExtended service lifeElectric switchesComputingEngineeringLight transmission

The invention discloses a thin type key switch. The thin type key switch comprises a panel shell and a base, wherein the panel shell is buckled on the base; a first slot position used for placing a contact chip and a second slot position used for placing a sounding part are arranged in the base; and the first slot position and the second slot position are both positioned in the side part of the base. The thin type key switch has the advantages of low height, uniform stress, long service life, bottom light transmission, good user experience and the like.

Owner:刘军方

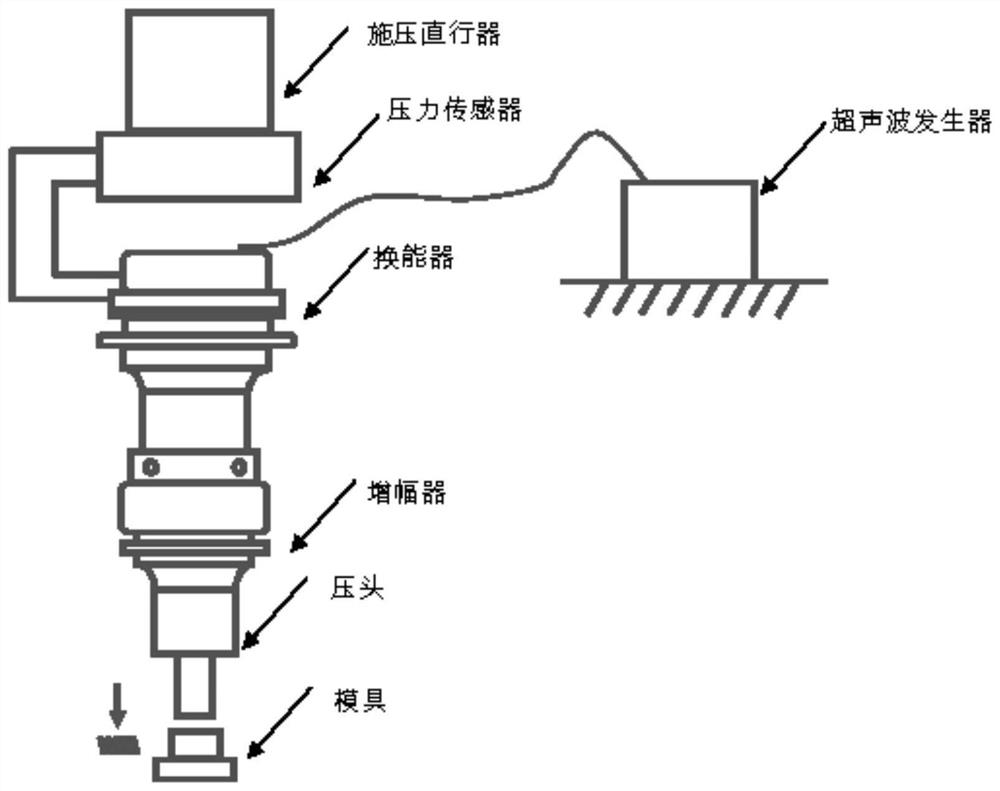

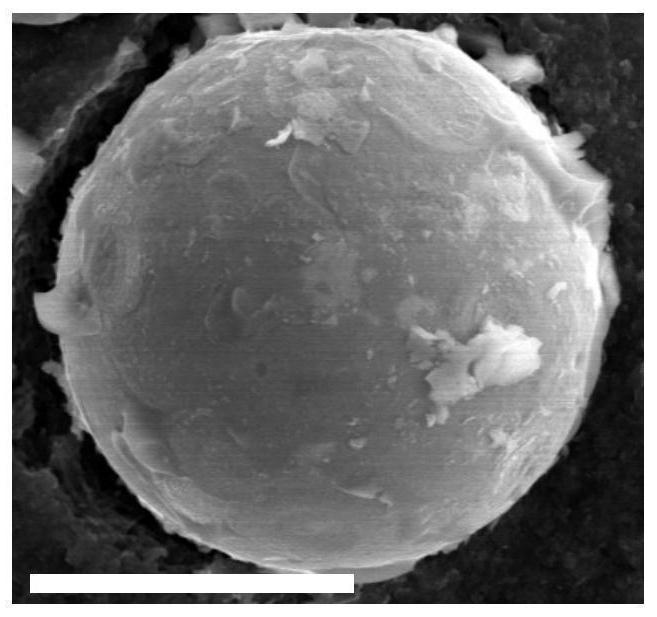

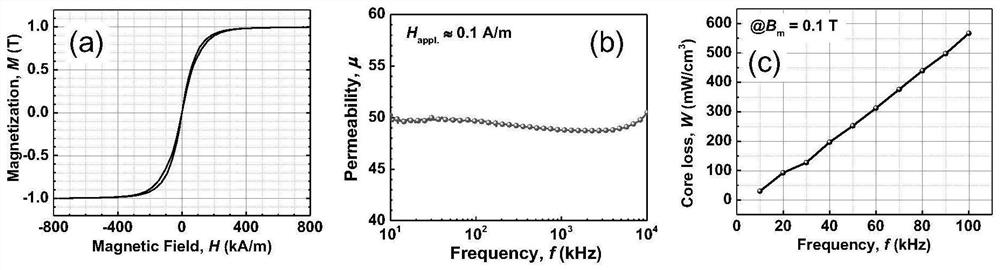

Ultrasonic-enhanced magnetic powder core compression molding method and compressed powder magnetic core

PendingCN113871179APromote sportsFacilitate rearrangementInorganic material magnetismInductances/transformers/magnets manufactureCompression moldingInitial permeability

The invention discloses an ultrasonic-enhanced magnetic powder core compression molding method and a compressed powder magnetic core. The invention discloses an ultrasonic enhanced magnetic powder core compression molding method which comprises the following steps: placing soft magnetic powder (coated) in ultrasonic compression molding equipment, setting the ultrasonic frequency to be 15-60kHz and the vibration amplitude to be 70-90%, and simultaneously starting a pneumatic system to pressurize, wherein the pressure is 0.3-0.9 MPa, the compression time is 0.1-10s and the dwell time is 3-5s, and completing the compression molding of a magnetic powder core. The method / process has the advantages of being small in required pressure, short in completion time, high in powder forming density, simple and efficient. The invention further discloses the magnetic powder core prepared by the ultrasonic enhanced magnetic powder core compression molding method, the magnetic powder core has high saturation flux density, low iron loss and high initial magnetic conductivity, and the magnetic conductivity of the magnetic powder core shows good high-frequency stability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Technique for manufacturing decorative boards

A decorative board is prepared from the used fabric blocks (60-80 wt.%), waste plastics (20-40 wt.%), and thermofusible fibres (0-20 wt.%) through preparing plastic fibres from waste plastics, mixing with others, making felt, heating in oven, and cold pressing. Its advantages are short period and low energy consumption.

Owner:CHONGQING CHANGPENG IND GRP CO LTD

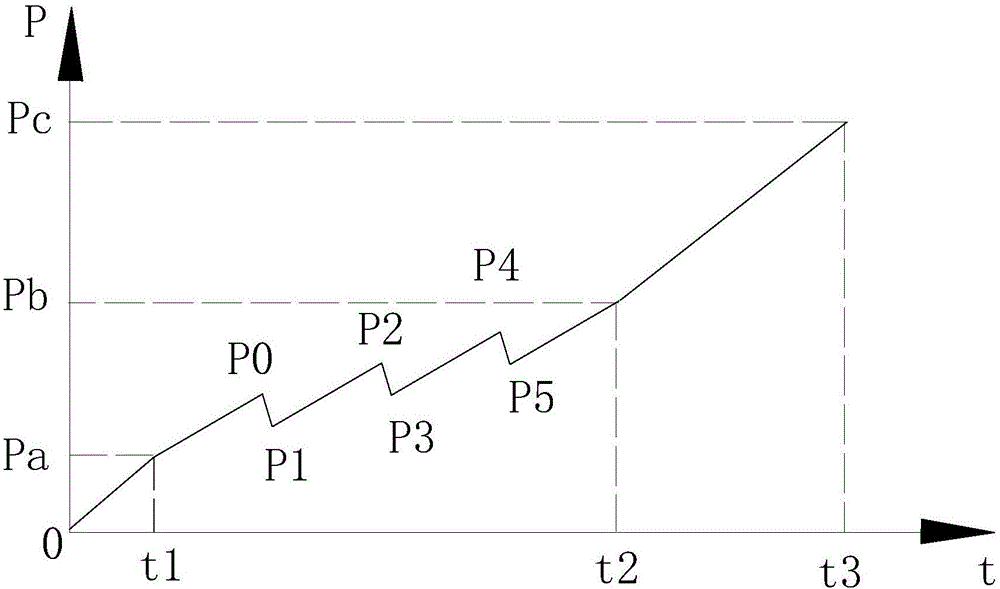

High-dryness squeezing method for sludge

InactiveCN106587563AReduce moisture contentShort pressing timeSludge treatment by de-watering/drying/thickeningSludge cakeCapillary water

The object of the invention is to provide a high-dryness squeezing method for sludge. The method has the advantages that the moisture content of sludge cakes is effectively lowered, and the squeezing time is short. According to the method, mud, which is obtained through carrying out modification treatment on sludge, is subjected to high-dryness dehydration by adopting a press filter, wherein a pressure value P applied by the press filter is firstly subjected to linear increase, then, undulatory changes and then linear increase along with time t. According to the method, the pressure value P of the press filter is firstly subjected to the linear increase, so that part of water in the sludge is squeezed out rapidly; then, the pressure value P is subjected to the undulatory changes, so that the sludge is in a periodic compressed and loosened state, the separation of the sludge from capillary water and pore water and the squeezing-out of the capillary water and the pore water are facilitated, and thus, the moisture content of the interior of the sludge cakes and the moisture content of the outside surfaces of the sludge cakes tend to be consistent; finally, the pressure value P is subjected to the linear changes again, so that water in the sludge cakes is squeezed out. According to the method, the squeezing time is short, the entire process needs 18 minutes only, and the moisture content of the finally obtained sludge cakes is 56% to 60%, so that the dehydration effect is good.

Owner:安徽省通源环保科技有限公司

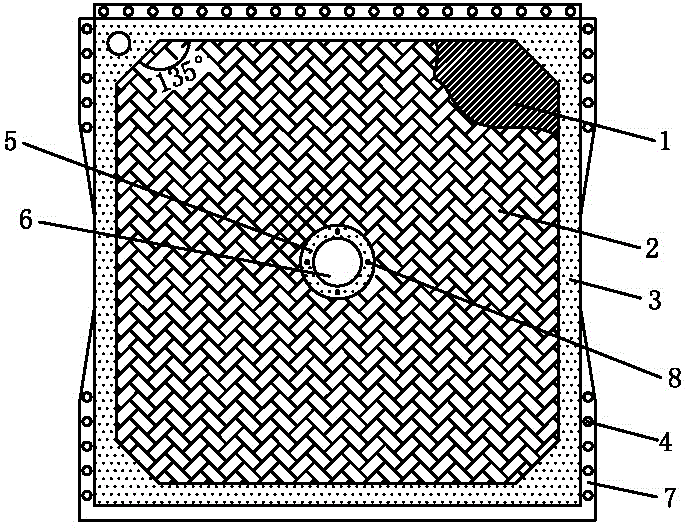

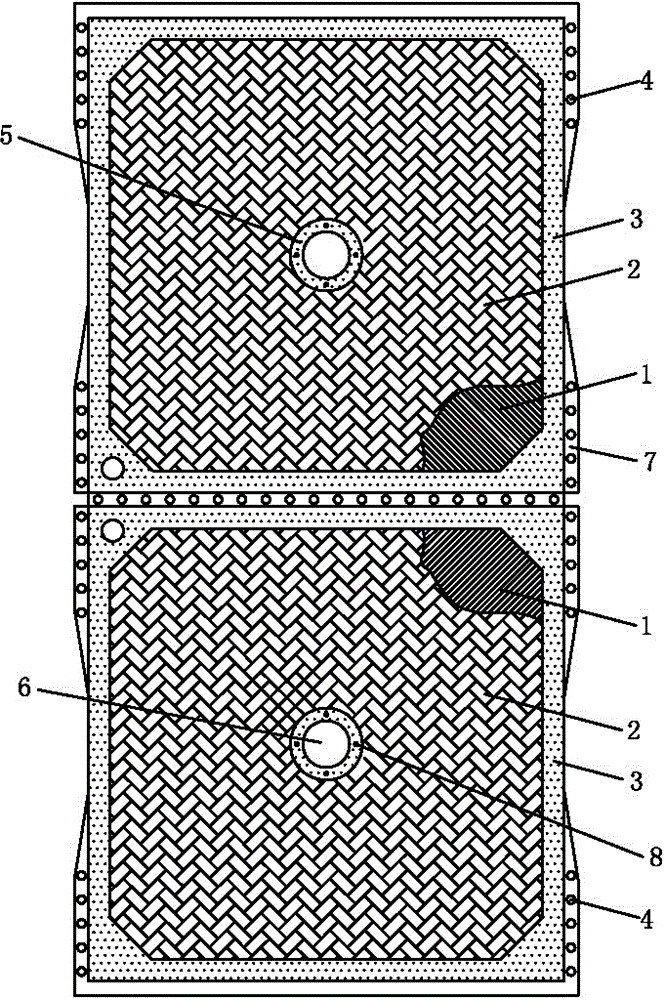

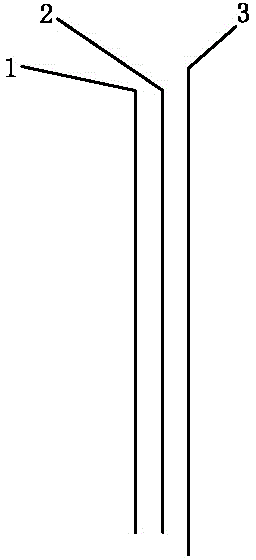

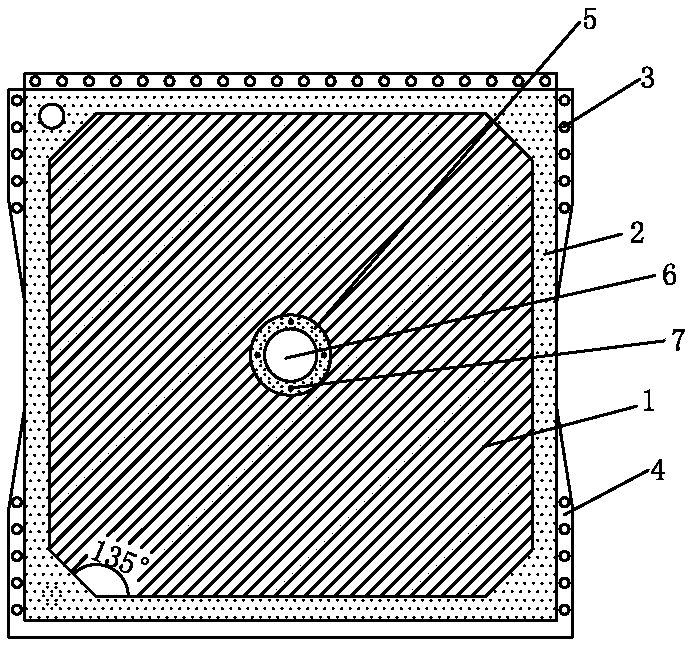

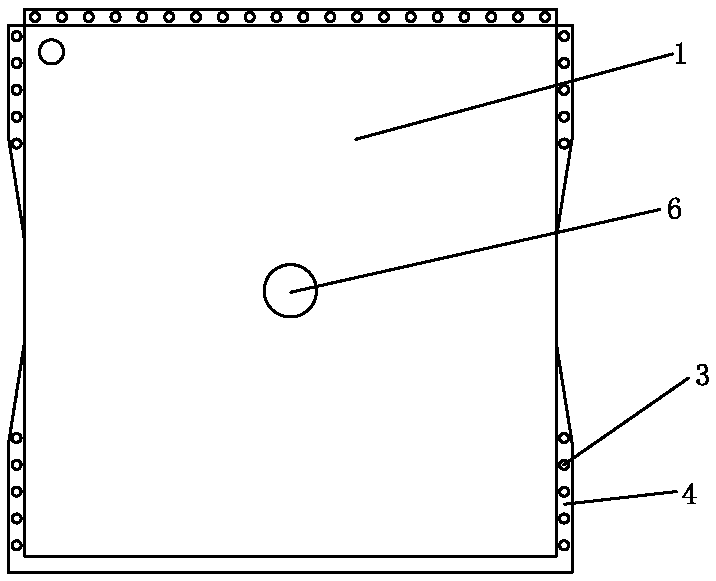

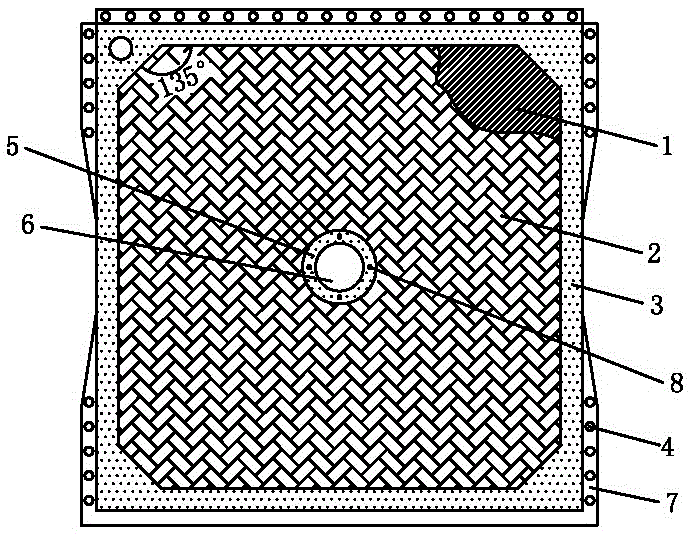

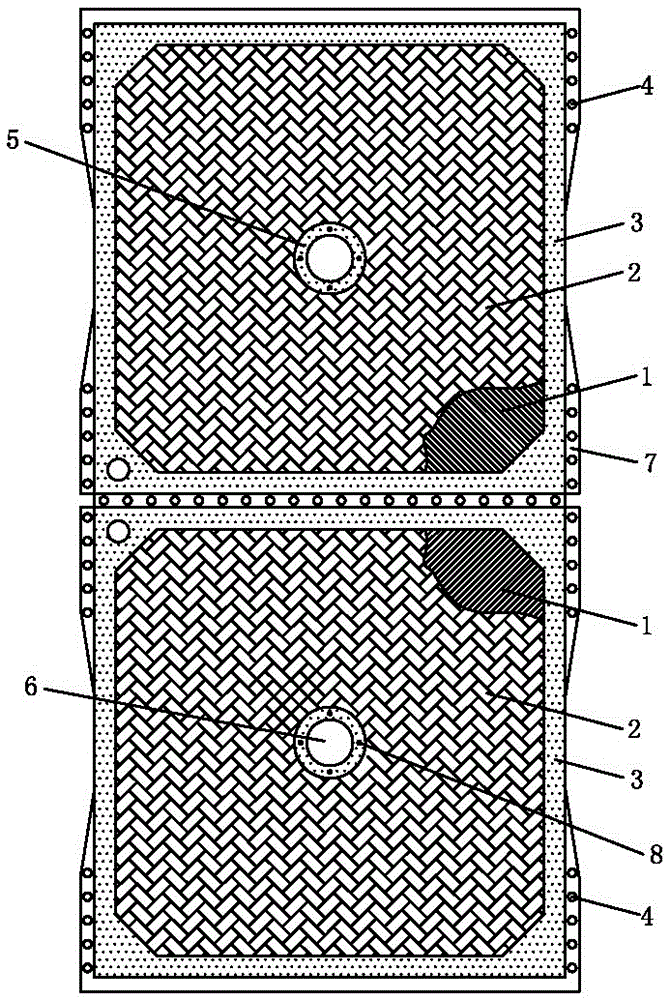

Manufacturing method for bauxite direct flotation concentrate press-filtering and separation filter cloth

ActiveCN104689640ASolve the problem of highMeet production requirementsSynthetic resin layered productsFiltration separationEngineeringSuspended matter

The invention relates to a manufacturing method for bauxite direct flotation concentrate press-filtering and separation filter cloth, and aims at effectively solving the problem that the contents of moisture and filtrate suspended matters are too high. A first layer and a second layer on the first layer are overlapped together and are square; fixed edges are arranged at the upper and lower side edges and left right side edges of the square shape; trapezoid grooves are formed in the centers of the fixed edges of the left and right sides; fixed holes are formed in the upper fixed edge and the fixed edges of the left and right sides; a round central hole is formed in the center of the square shape; a third layer is arranged on the second layer and is composed of inner and outer parts; the outer part of the third layer is in a square annular shape, and the inner part of the third layer is a circular ring arranged at the center of the outer part; the first layer and the second layer are aligned to the edge of the third layer, and are sewed by a four-line sewing machine; and the circular ring of the third layer is located on the periphery of the round central hole of the second layer and is sewed by a three-line sewing machine. By virtue of the manufacturing method, the problem that the contents of the moisture and the filtrate suspended matters of concentrate are too high is solved, the squeezing time is short and the working efficiency is high.

Owner:HENAN DONGDA TECH CO LTD

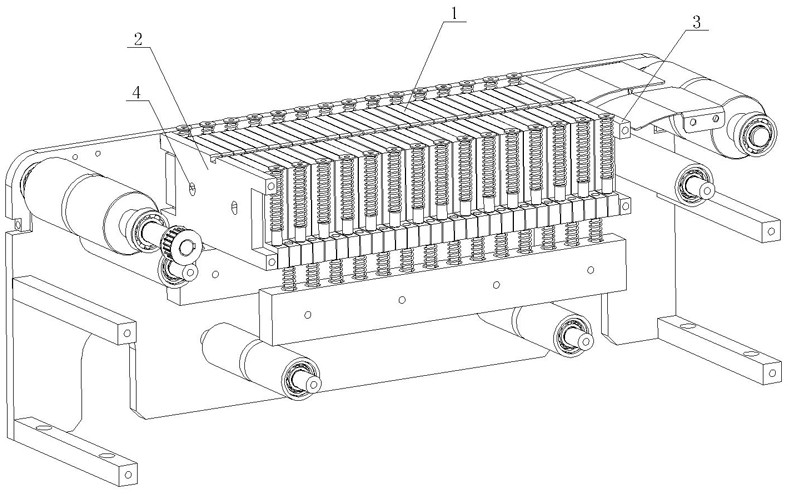

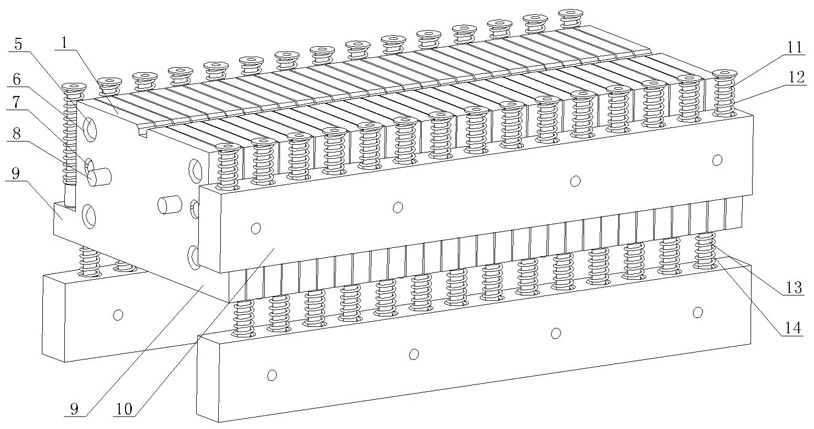

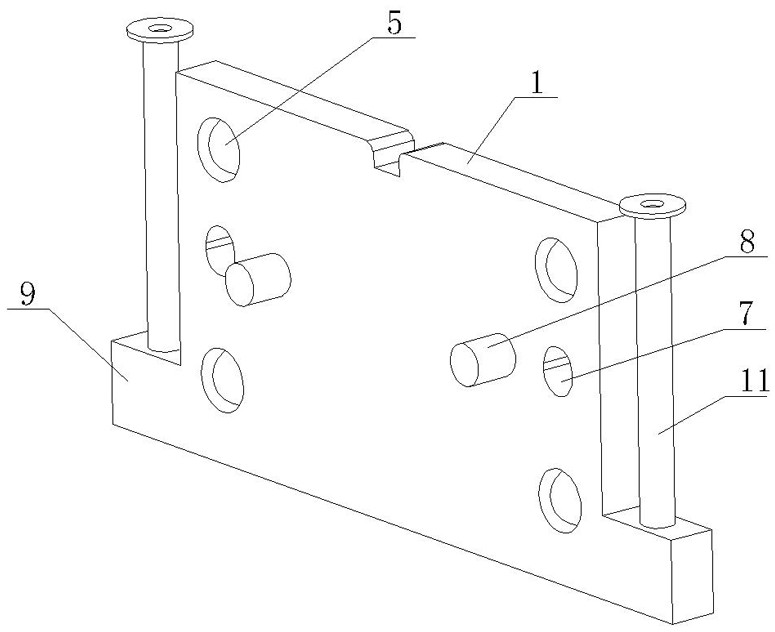

Upper and outsole press-fit workbench

PendingCN112656090ARapid automated productionHigh compression support strengthShoe gluingEngineeringWorkbench

The invention discloses an upper and outsole press-fit workbench which is characterized in that the press-fit workbench comprises a platform support and a floating block set arranged on the platform support, the floating block set is formed by connecting a plurality of longitudinally-arranged floating blocks front and back, the adjacent floating blocks move up and down relatively, and the floating blocks are supported by springs in a floating mode. The workbench is used for fixing and pressing uppers and rubber outsoles in the shoemaking process, the press-fit quality is better guaranteed, degumming is prevented, and automatic production of a press-fit machine at a higher speed is achieved.

Owner:温州市德立智能科技有限公司

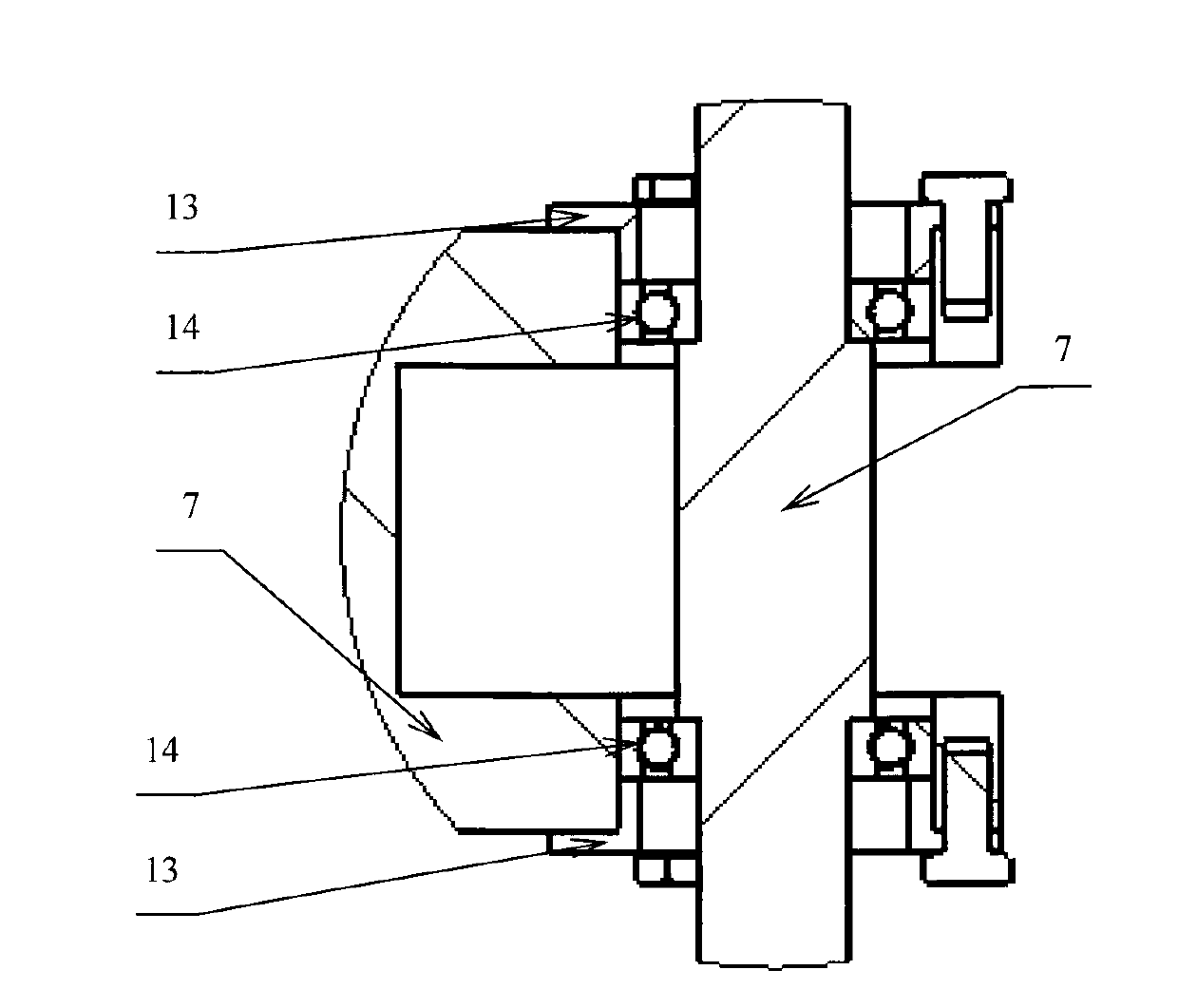

Quick calibrating apparatus for turning disc of automobile wheel positioning instrument

The invention discloses a quick calibrating apparatus for a turning disc of an automobile wheel positioning instrument, aiming at solving the problem that the turning disc of the automobile wheel positioning instrument can not be rapidly and accurately calibrated. The quick calibrating apparatus for the turning disc of the automobile wheel positioning instrument comprises a compression bar (1), asleeve (2), a base (3), a pressure spring (4), a stud (5) provided with a hole, a support seat (6), a bearing seat (7), a rotating shaft (8), a pressure plate (9), an elastic rubber pad (10), an encoder (11), a locating bolt (12), a bearing end cover (13) and a bearing (14). The quick calibrating apparatus can be used for completing the quick calibration for turning disc of the automobile wheel positioning instrument.

Owner:JILIN UNIV

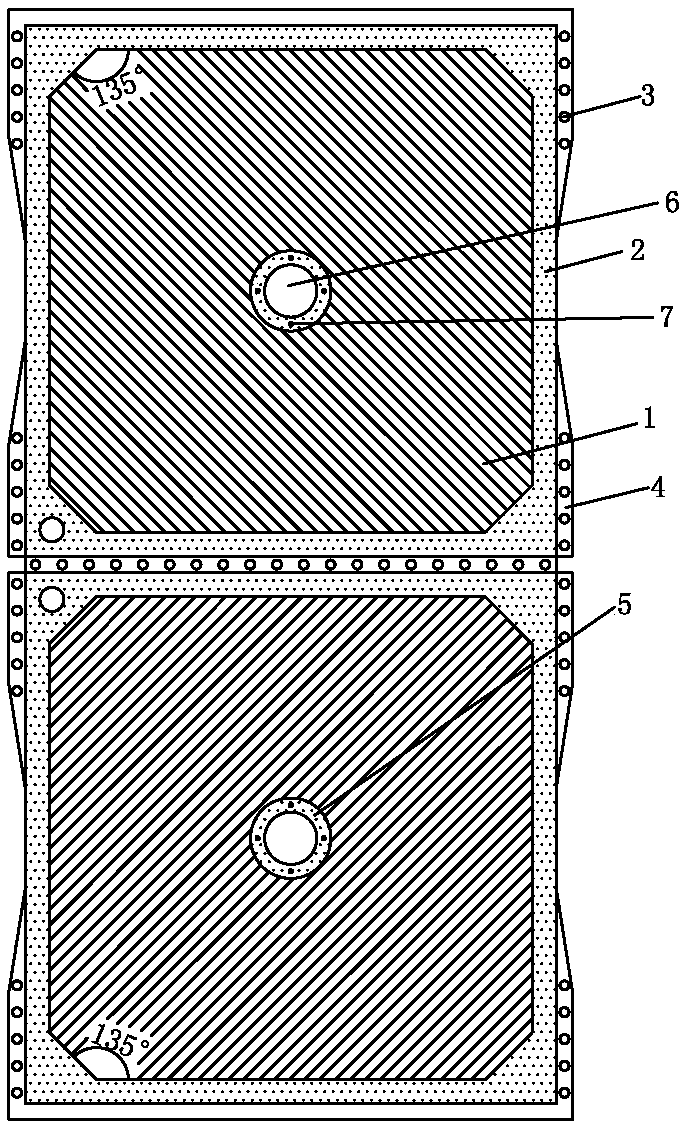

A kind of preparation method of bauxite positive flotation tailings pressure filtration separation filter cloth

ActiveCN104645713BSolve the problem of highImprove work efficiencySynthetic resin layered productsFiltration separationFiltrationEngineering

The invention relates to a manufacturing method of pressure filtration separation filter cloth for direct flotation separation tailings for bauxite and aims at solving the problem that the amounts of suspended matter in water and a filtrate of the separation tailings are large. A first layer is polypropylene multifilament plain woven filter cloth which is a square, fixed edges are formed in the upper and lower edges and the left and right side edges of the square respectively, trapezoidal grooves are formed in the centers of the fixed edges at the left and right sides respectively, fixed holes are formed in the upper fixed edge and the fixed edges at the left and right sides respectively, a circular center hole is formed in the center of the square, a second layer is arranged on the first layer and consists of interior and exterior parts, the exterior part is a square ring, the interior part is a circular ring arranged in the center of the exterior part, the edges of the square of the first layer and the edges of the square ring of the second layer are aligned to each other and sewn together by virtue of a four-wire sewing machine, and the circular ring of the second layer is arranged on the periphery of the circular center hole of the first layer and is sewn together with the periphery of the circular center hole of the first layer by virtue of a three-wire sewing machine. According to the manufacturing method disclosed by the invention, the amounts of suspended matters in the water and the filtrate of the separation tailings both meet the production requirements, the squeezing time is short, and the working efficiency is high.

Owner:HENAN DONGDA TECH CO LTD

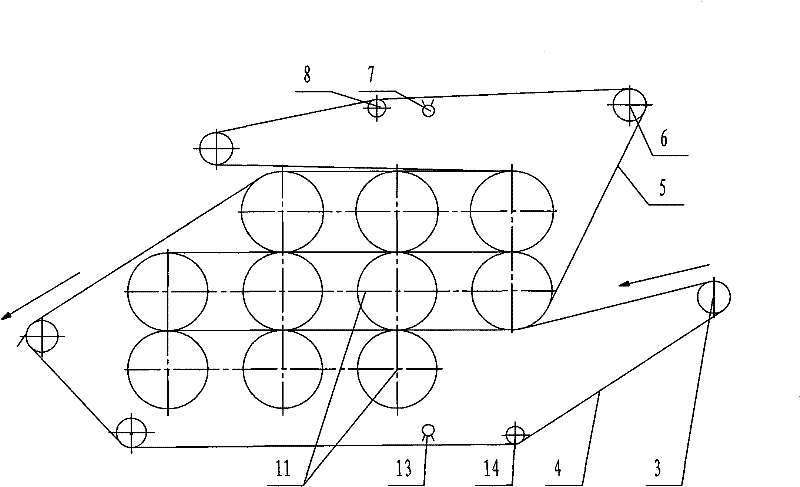

Multi-roll continuous press dehydrator

ActiveCN101863607BLow tension requirementGuaranteed lifeSludge treatment by de-watering/drying/thickeningEngineeringPower apparatus

The invention discloses a multi-roll continuous press dehydrator which comprises a stander, a power device and a transmission device, wherein the transmission device is provided with an input shaft and more than two rows of output shafts which are arranged up and down; the input shaft is connected with the power device; the stander is provided with more than two rows of pressing rolls (11) corresponding to the output shafts; the pressing rolls (11) are connected with the output shafts; and the upper and the lower rows of pressing rolls which are adjacent to each other are in rolling in a roll-to-roll rotating relay way. The multi-roll continuous press dehydrator can be used for reasonably rolling for a plurality of times by a limited number of pressing rolls. As the contact area between the two rolls is small, the multi-roll continuous press dehydrator has the advantages of high pressing force and short pressing time, leads the discharge moisture content to be lower, improves the mud cake content and the solid content, lowers the tension requirement for filter cloth, prolongs the service life of the filter cloth, reduces the volume of a machine, and ensures the structure to be more compact.

Owner:HUATIAN ENG & TECH CORP MCC

Copper clad laminate glue drying device

ActiveCN110370781BFast productionPrecision requirements are not highLamination ancillary operationsLayered product treatmentElectric machineStructural engineering

The invention belongs to the technical field of copper-clad laminate preparation, and in particular relates to a glue drying device for copper-clad laminates, including a traction bracket and a drying box; There are protrusions integrally formed, and the top of the right side of the traction bracket is integrally formed with oblique support blocks with low left and high right. Gluing components are installed between the two front and rear facing protrusions, and the two front and rear facing oblique support blocks There is also a gluing assembly installed between them. The gluing assembly includes a gluing motor, a gluing roller, a fixing plate and a glue storage box. The fixing plate is fixed on the power output shaft of the gluing motor, and the glue storage box is installed on the fixing plate. , the rear end of the power output shaft of the gluing motor is driven with a sleeve shaft, the gluing roller is sleeved on the sleeve shaft and fixed with the sleeve shaft, and the first bearings are fixedly installed at both ends of the sleeve shaft.

Owner:黄瑞有

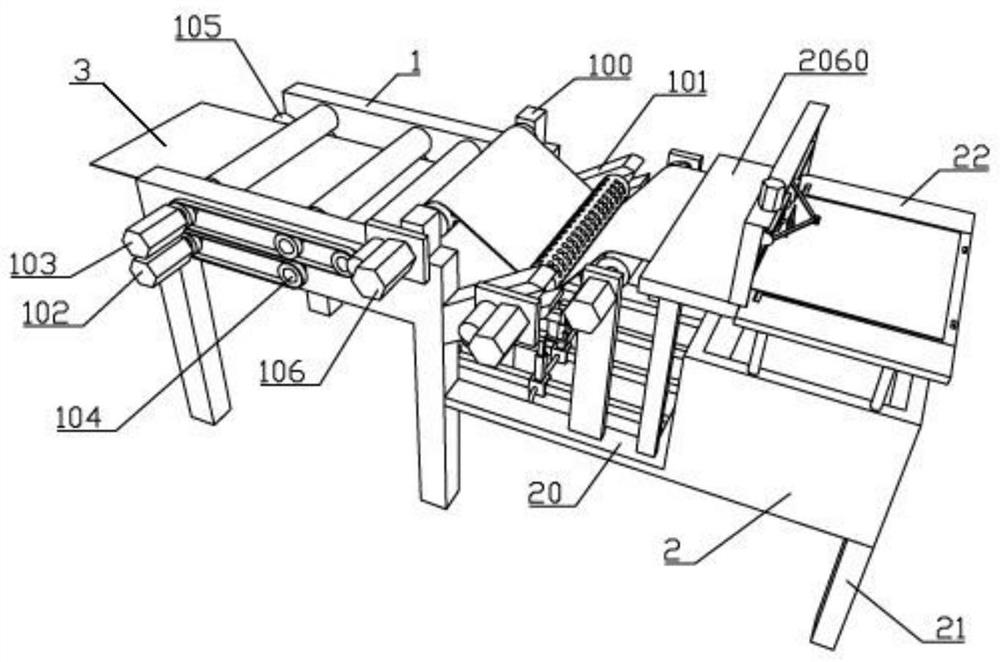

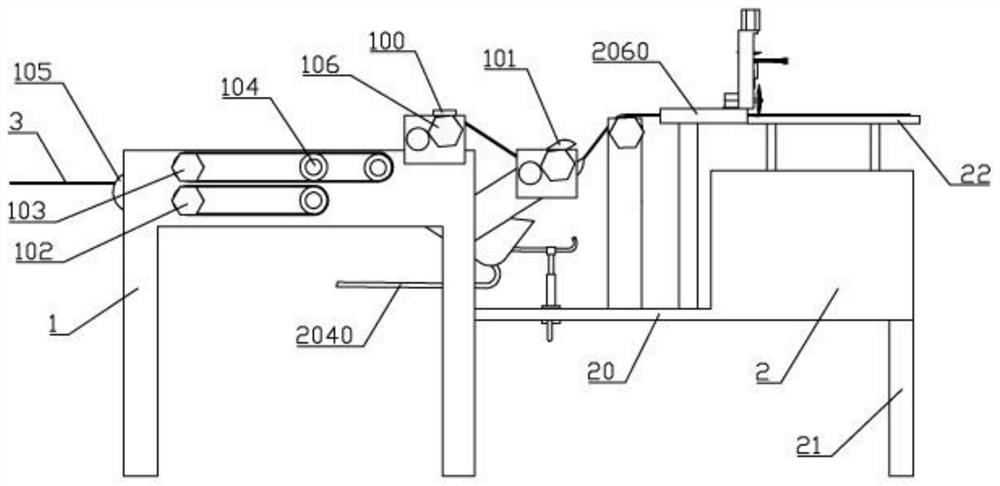

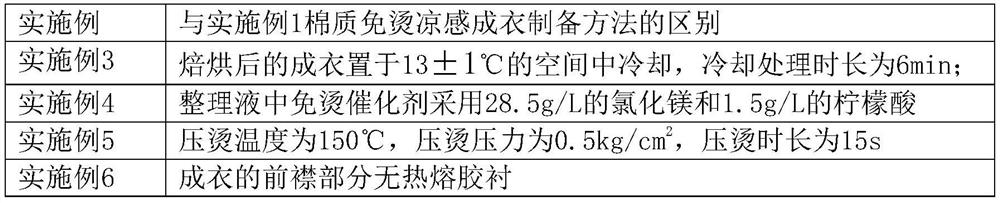

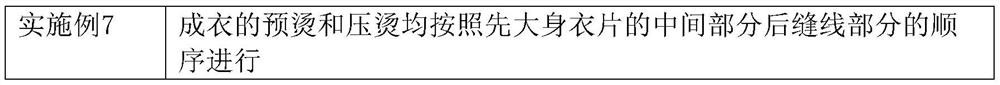

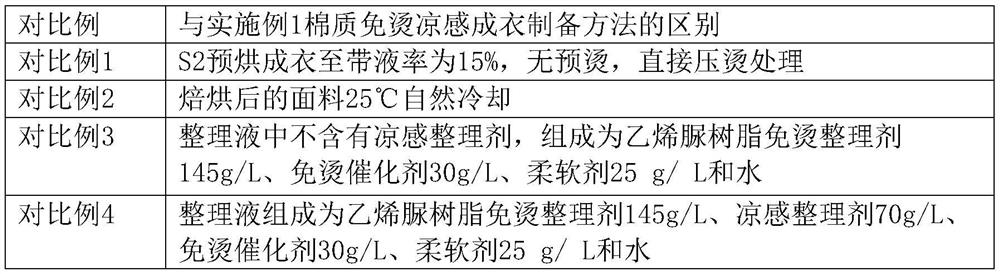

Production method of cotton non-ironing cool garment

PendingCN114134711AEfficient use ofExcellent cooling sensationWrinkle resistant fibresVegetal fibresPolymer scienceEthylene urea

The invention discloses a production method of a cotton non-ironing cool-feeling garment, which comprises the following steps: S1, preparing a non-ironing cool-feeling finishing liquid, and uniformly applying the non-ironing cool-feeling finishing liquid to the cotton garment until the liquid carrying rate of the cotton garment is 85-95%; s2, pre-drying the ready-made clothes until the liquid carrying rate is 35%-50%; s3, the cotton garment is pre-ironed until the liquid carrying rate of the sewing thread part is 15-20% and the liquid carrying rate of the body part is 10-15%, and then the cotton garment is pressed and ironed; s4, baking and shaping, cooling and moisture regaining, and washing; the finishing liquid is mainly composed of 130-160 g / L of an ethylene urea resin non-ironing finishing agent, 120-150 g / L of a cool feeling finishing agent, 20-40 g / L of a non-ironing catalyst, 10-40 g / L of a softening agent and water, and the cool feeling finishing agent is composed of silk protein and xylitol. Through one-step finishing by selecting the preferable non-ironing finishing agent and the preferable cool-feeling finishing agent, the obtained fabric has good and durable non-ironing and cool-feeling effects.

Owner:JIANGSU SUNSHINE GRP CO LTD

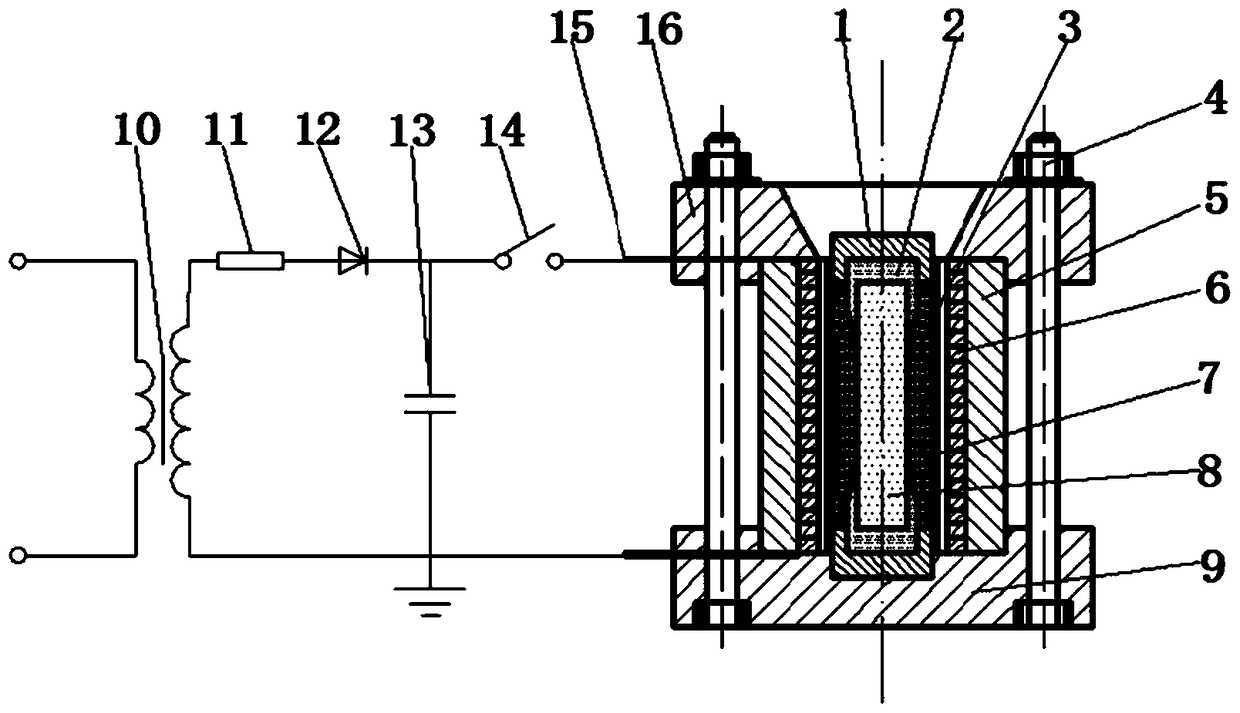

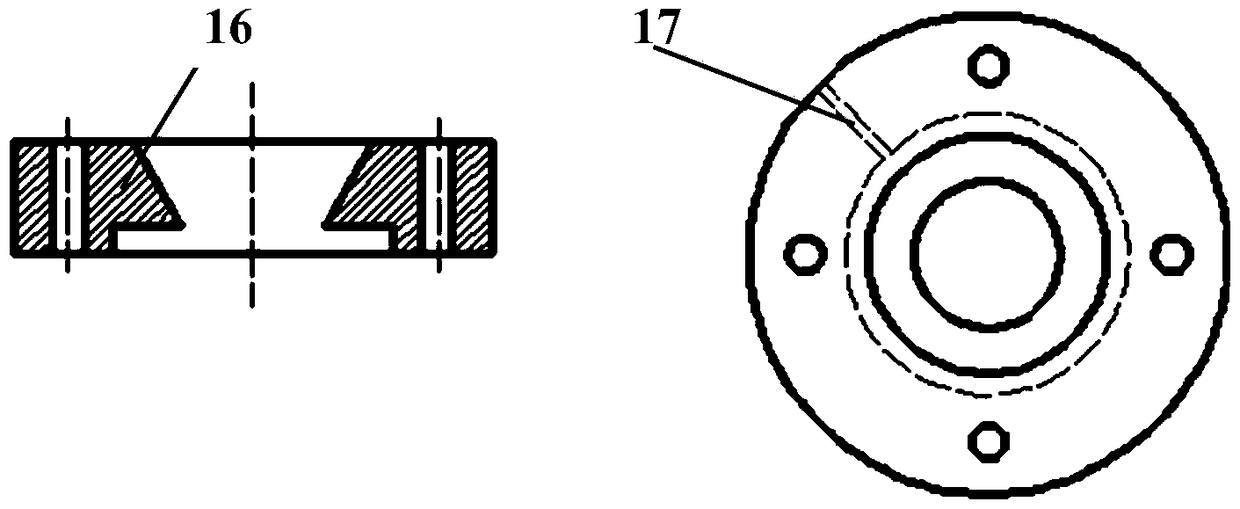

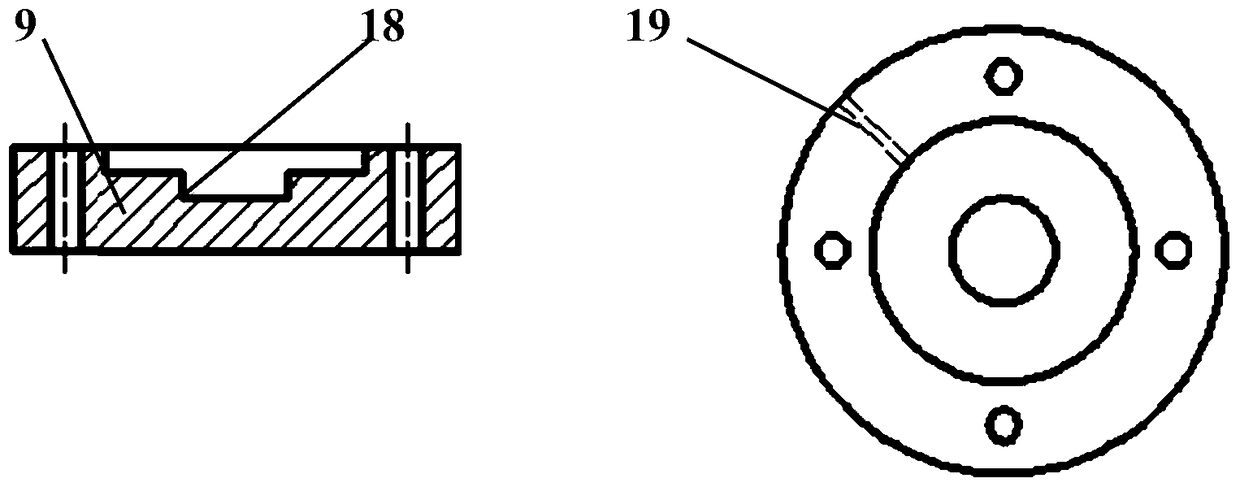

An electromagnetic pulse radial powder compaction device and compaction method

ActiveCN105436500BCircumferential uniformLarge discharge energyElectrical resistance and conductanceElectromagnetic pulse

The invention relates to a powder compacting device based on electromagnetic pulses. The powder compacting device comprises a power supply unit, a fixing unit and a compacting unit. The powder compacting device is characterized in that the power supply unit is composed of a charging circuit and a pulse discharging circuit, the charging circuit is composed of a high-voltage transformer (10), a charging resistor (11) and a high-voltage rectifier (12), and the pulse discharging circuit is composed of a capacitor set (13). Since pressure used in the electromagnetic pulse radial powder compacting process is radial force distributed evenly and is evenly distributed in the circumferential direction and the axial direction, the powder compacting device is suitable for forming axisymmetric shaft parts, pipe parts and gear parts.

Owner:HUNAN UNIV

A method for making bauxite positive flotation concentrate filter press filter cloth

ActiveCN104689640BSolve the problem of highMeet production requirementsSynthetic resin layered productsFiltration separationEngineeringSuspended matter

The invention relates to a manufacturing method for bauxite direct flotation concentrate press-filtering and separation filter cloth, and aims at effectively solving the problem that the contents of moisture and filtrate suspended matters are too high. A first layer and a second layer on the first layer are overlapped together and are square; fixed edges are arranged at the upper and lower side edges and left right side edges of the square shape; trapezoid grooves are formed in the centers of the fixed edges of the left and right sides; fixed holes are formed in the upper fixed edge and the fixed edges of the left and right sides; a round central hole is formed in the center of the square shape; a third layer is arranged on the second layer and is composed of inner and outer parts; the outer part of the third layer is in a square annular shape, and the inner part of the third layer is a circular ring arranged at the center of the outer part; the first layer and the second layer are aligned to the edge of the third layer, and are sewed by a four-line sewing machine; and the circular ring of the third layer is located on the periphery of the round central hole of the second layer and is sewed by a three-line sewing machine. By virtue of the manufacturing method, the problem that the contents of the moisture and the filtrate suspended matters of concentrate are too high is solved, the squeezing time is short and the working efficiency is high.

Owner:HENAN DONGDA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com