Manufacturing method for bauxite direct flotation concentrate press-filtering and separation filter cloth

A technology of bauxite and filter cloth, which is applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the high level of filtrate floats, the need for secondary dehydration of refractory concentrates, and the filter cloth material of a single filter press And the production process and other issues, to achieve the effect of high work efficiency and short pressing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

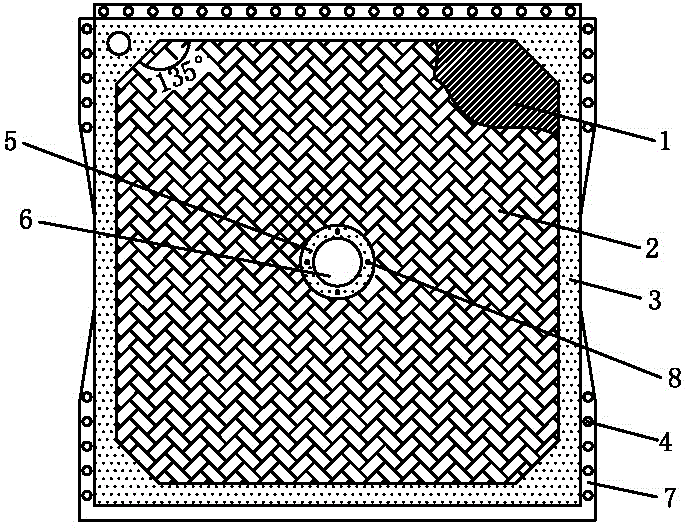

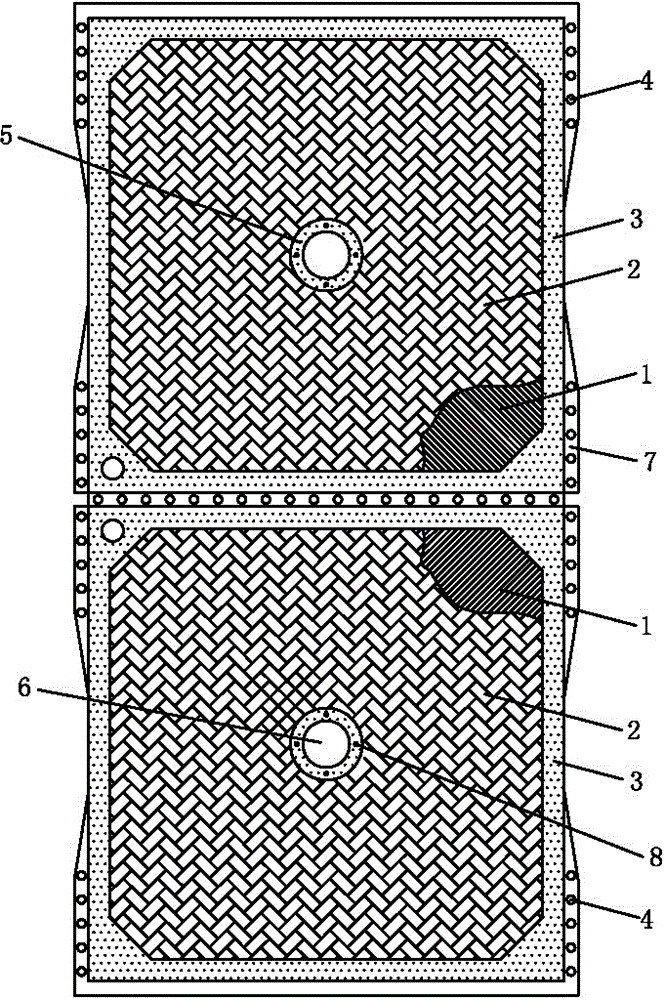

[0018] Depend on Figure 1-Figure 6 Given, the preparation method of the bauxite positive flotation concentrate ore press filter separation filter cloth of the present invention is: the first layer is polypropylene multifilament plain weave filter cloth 1, the second layer is monofilament plain weave polypropylene filter cloth 2, the third The first layer is a non-woven filter cloth 3, and the first layer and the second layer above are stacked together to form a composite layer. The size, structure and shape of the first layer and the second layer are the same, both are square, and the upper edge of the square, There are fixed edges 7 extending horizontally outwards on the lower edge and the edges on the left and right sides, and there are symmetrical trapezoidal grooves in the center of the fixed edges on the left and right sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com