Stamping device for waterproof tensile hardware circular hoop of LED lamp strip lamp plug

A technology of LED light strips and stamping equipment, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems that the stamping depth cannot be adjusted, the defective rate of pressed products is high, and there is no limit function, etc., so as to improve stamping High efficiency, good waterproof effect, and short pressing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the drawings and specific embodiments, but it is not a limitation of the present invention.

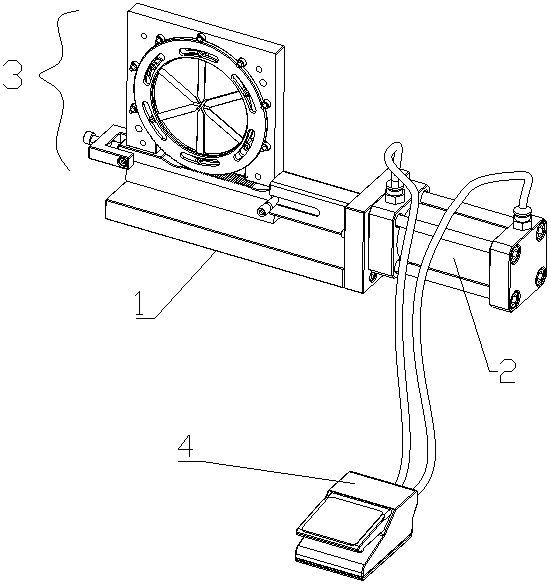

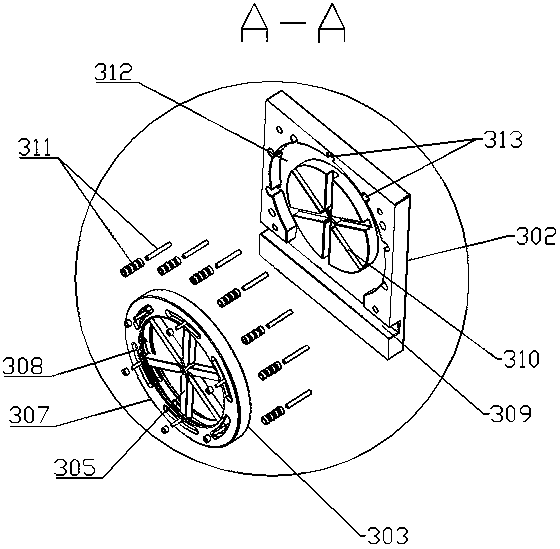

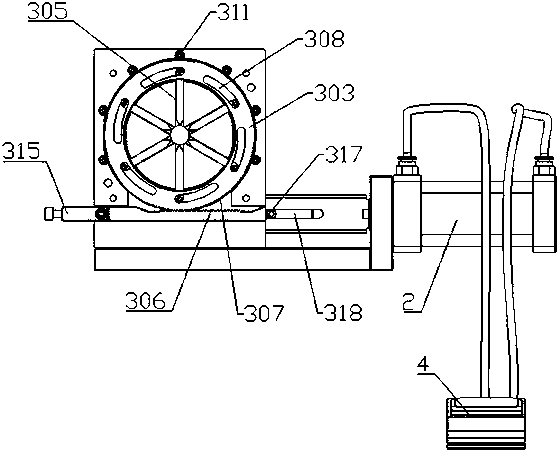

[0032] Such as figure 1 with figure 2 As shown, a stamping equipment for a waterproof and tensile metal hoop for an LED lamp with a lamp plug includes a base 1, a cylinder 2, and a pressing mechanism 3. The cylinder 2 is fixed on the base 1, and the pressing mechanism 3 includes The fuselage, the gear plate 303 that is rotatably connected with the fuselage, the gear rod 304 that drives the gear plate 303 to rotate, and the stamping top piece 305. The gear rod 304 is provided with a rack 306, which is arranged on the gear plate 303 The gear 307 meshes, the gear rod 304 is connected to the cylinder 2, the gear plate 303 is provided with a linkage groove 308 that matches the stamping top piece 305, and the body is provided for the gear rod 304 to move The first sliding groove 309 and the second sliding groove 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com