Multi-roll continuous press dehydrator

A dehydrator and roller-type technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., to achieve the effects of increasing production and solid content, reducing tension requirements, and reducing machine volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

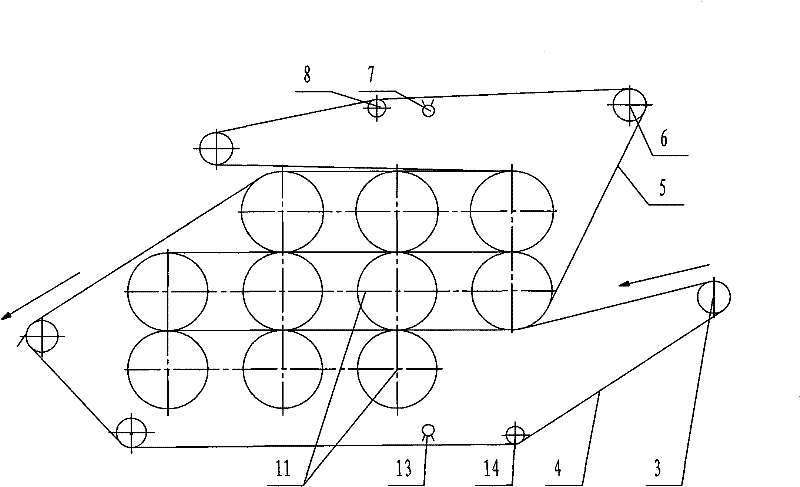

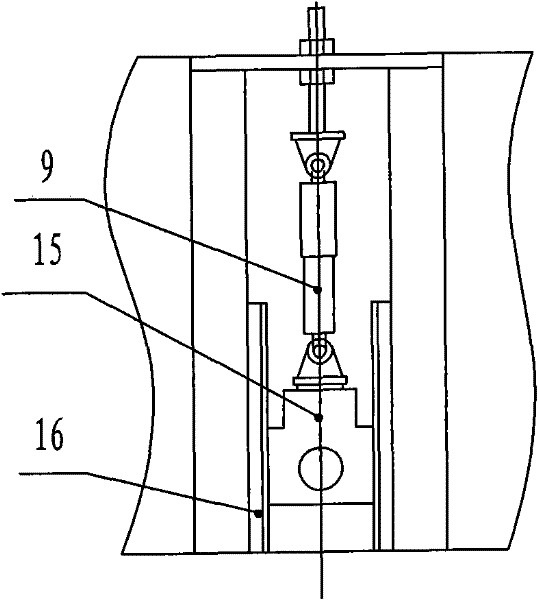

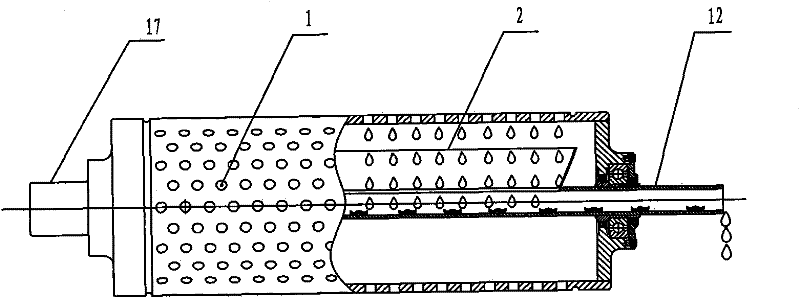

[0014] Example: According to figure 1 Shown, a kind of multi-roller type continuous pressure dewatering machine of the present invention is mainly made of frame, power unit, transmission device, pressure roller 11, upper filter cloth 5, lower filter cloth 4, upper tensioning device 6, upper flushing device 7. The upper deviation correction device 8, the lower tensioning device 3, the lower flushing device 13, and the lower deviation correction device 14 are composed, and all components are installed on the frame to form a whole. The transmission device is provided with an input shaft and three rows of output shafts arranged up and down, the input shaft is connected with the power device; the frame is provided with three rows of pressing rollers 11, and the positions of the pressing rollers 11 correspond to the output shafts, so The pressure roller 11 is connected with the output shaft. The transmission device is driven by the power device through the input shaft, and the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com