Crawler blotter press

A technology of crawler type and filter press, which is applied in the direction of filtration separation, mobile filter element filter, separation method, etc. It can solve the problems of unfavorable dehydration, reduced vehicle speed, wear of filter belt, etc., and achieves high dehydration efficiency and reduced tension requirements , the effect of prolonging the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

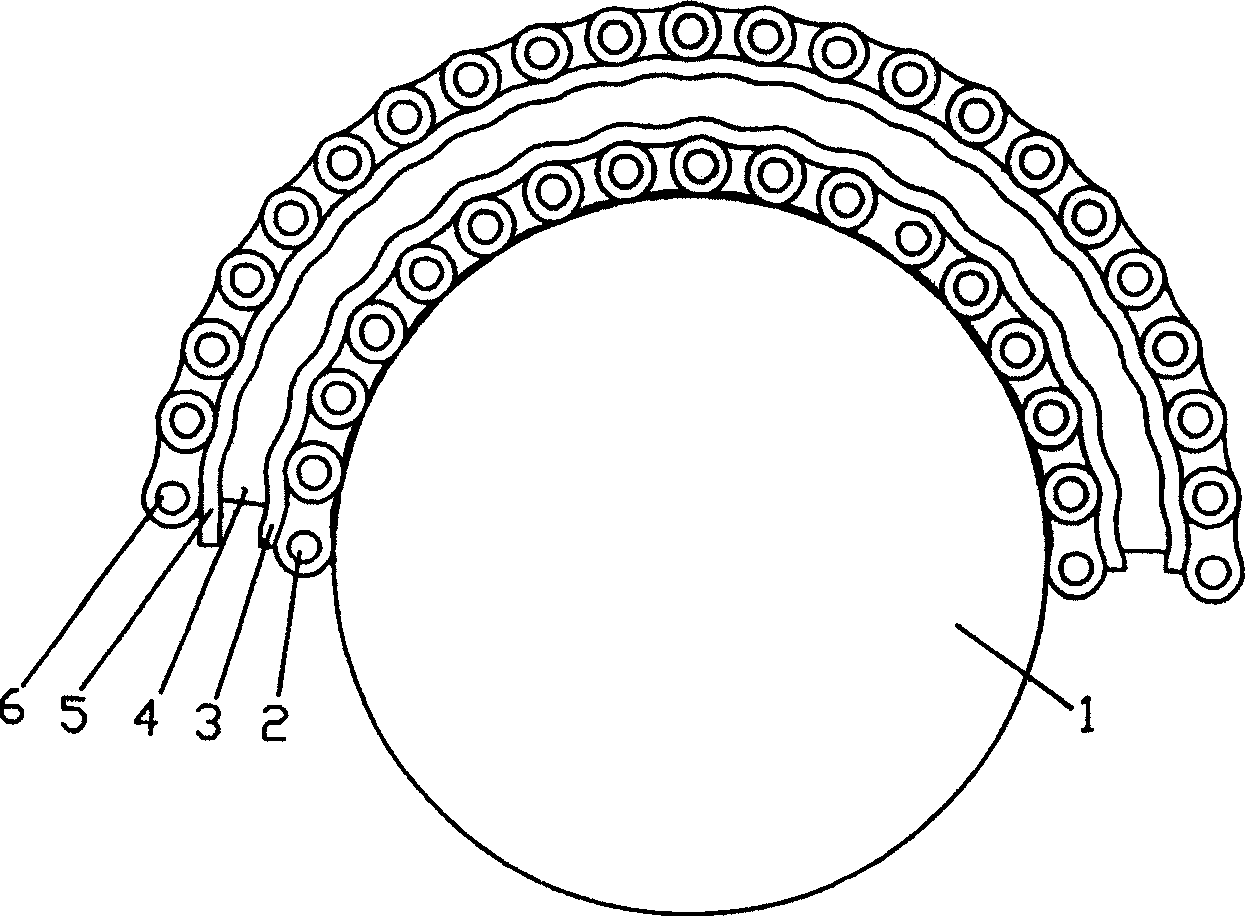

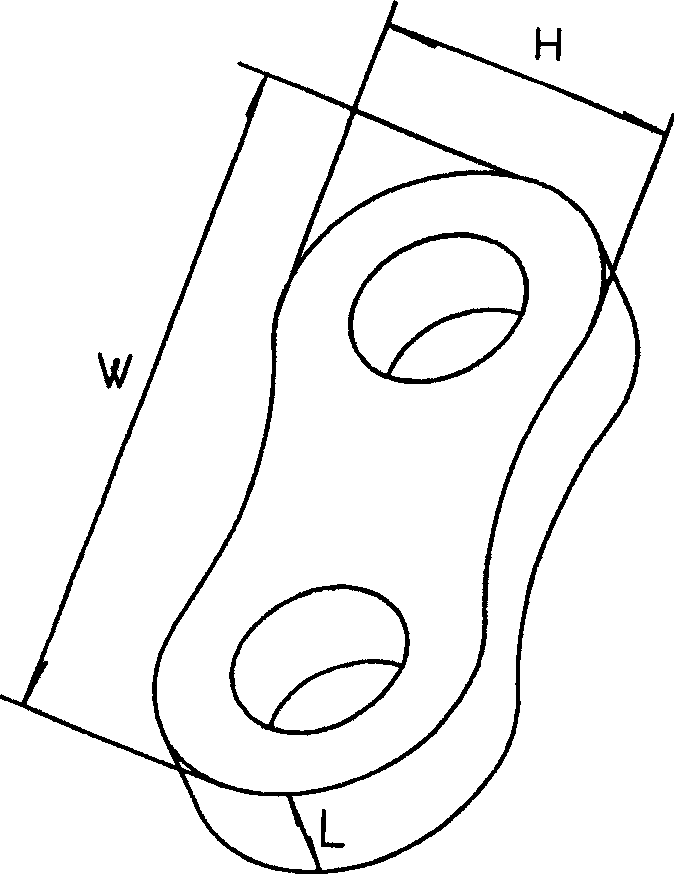

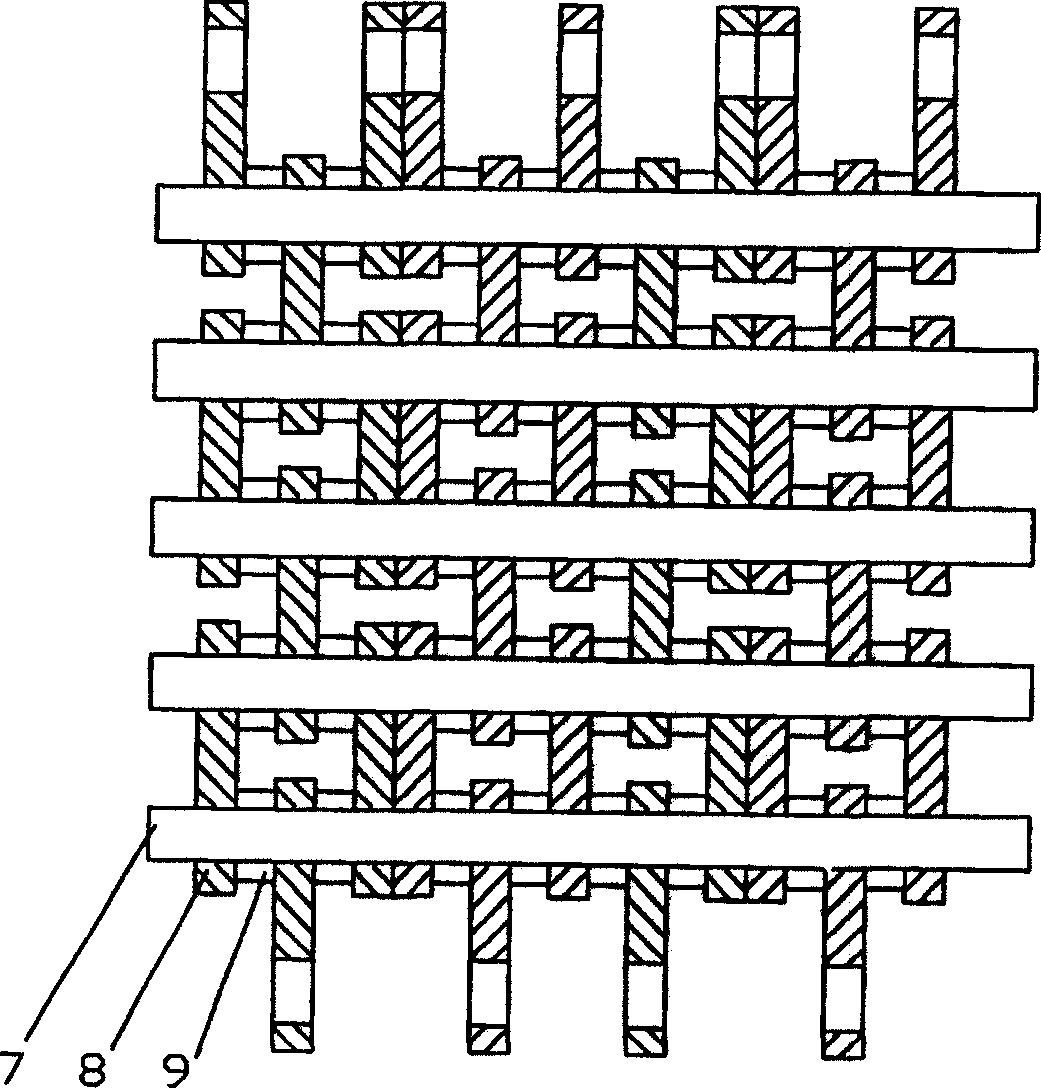

[0022] Embodiments The crawler filter press is mainly composed of a frame, a driving device, a feeding device, a pressing area and auxiliary devices. The press area includes filter press rollers, pressure belts, filter belts and crawler tension belts; the driving device includes motors and gearboxes; the auxiliary devices include tension rollers, scraper devices, water receiving devices, deviation correction devices and filter belt cleaning devices. The press area is installed on the frame, the driving device is connected with the filter press roller, the caterpillar tension belt, the pressure belt and the filter belt are overlapped and wrapped around the press roller in parallel, and the feeding device faces between the press belt and the filter belt. The pressure belt and the filter belt enclose the filter cake, the pressure belt and the filter belt in the press area are separated by a scraper device, the filter belt cleaning device is installed facing the filter belt, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com