A kind of preparation method of high-quality nylon 6 mother silk

A high-quality, master yarn technology, applied in the directions of drawing spinning, melt spinning, filament/thread forming, etc., can solve the problems of affecting the spinning speed, low monofilament strength, complicated process, etc. The effect of reducing friction and tension requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

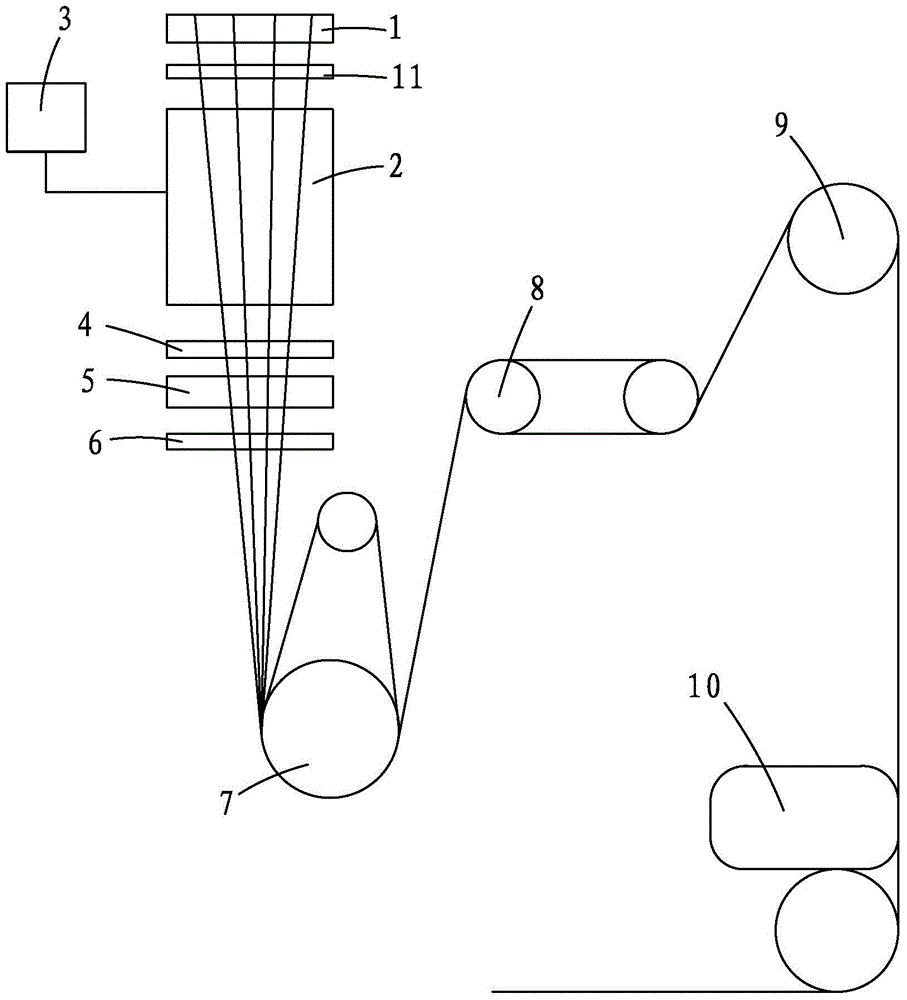

[0019] See figure 1 , The present invention is a method for preparing high-quality nylon 6 mother yarn, which includes the following specific operations: the tow ejected from the spinning box assembly is cooled by the wind blown from the side blowing window, and the spinning assembly A slow cooling device with a temperature of 160~200℃ is installed between the side blowing window and the slow cooling device is used to initially and slowly cool the tow; the tow enters the spinning tunnel 2 after being cooled by the side blowing, and humidification is adopted The device 3 sprays the tow entering the spinning tunnel 2 with a moisture spray rate of 0.8~1.2kg / h. The tow is guided to the upper tanker 5 through the guide wire 4 to be evenly spread; then the tow passes through After the guide wire hook 6 reaches the cold roller group 7, the hot roller group 8 and the tension roller 9 in sequence (specifically, reaches the cold roller group 7, the tow passes through the splitting and tu...

Embodiment 1

[0023] The tow ejected from the spinning box assembly is initially slowly cooled by the slow cooling device 1 whose temperature is controlled at 200°C; then the tow is cooled by the side blower and then enters the spinning shaft 2, and the humidifier 3 is used to enter the spinning shaft The tow in 2 is sprayed, and the wet amount of each tow is 1.2kg / h. The tow is guided to the upper tanker 5 through the guide wire rod 4 for uniform spreading; then the tow passes through the guide wire hook 6 and reaches the cold roll Group 7, after the tow is divided and turned by the cold roller group 7, the stretching ratio of the cold roller group 7 is between 1.2 and 1.5, and reaches the hot roller group 8, and the heat roller group 8 sets the tow and the shaping temperature The temperature is 180℃, and the tension between the cold roller group 7 and the hot roller group 8 is controlled to 50cN, and then it reaches the tension roller 9, which stabilizes the tension of the tow, and the yarn...

Embodiment 2

[0025] The tow ejected from the spinning box assembly is initially slowly cooled by the slow cooling device 1 whose temperature is controlled at 180°C; then the tow is cooled by the side air blower and then enters the spinning shaft 2, and the humidifier 3 is used to enter the spinning shaft The tow in 2 is sprayed, and the wet amount of each tow is 1.0kg / h. The tow is guided to the upper tanker 5 through the guide wire rod 4 for uniform spreading; then the tow passes through the guide wire hook 6 and reaches the cold roll Group 7, after the tow is divided and turned by the cold roller group 7, the stretching ratio of the cold roller group 7 is between 1.2 and 1.5, and reaches the hot roller group 8, and the heat roller group 8 sets the tow and the shaping temperature The temperature is 160℃, and the tension between the cold roller group 7 and the hot roller group 8 is controlled to 30cN, and then reaches the tension roller 9, the tension roller 9 stabilizes the tension of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com