Copper clad laminate glue drying device

A drying device and a technology for copper clad laminates, which are used in lamination devices, devices for coating liquid on surfaces, and other household appliances, etc., can solve the problems of high defect rate and slow gluing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

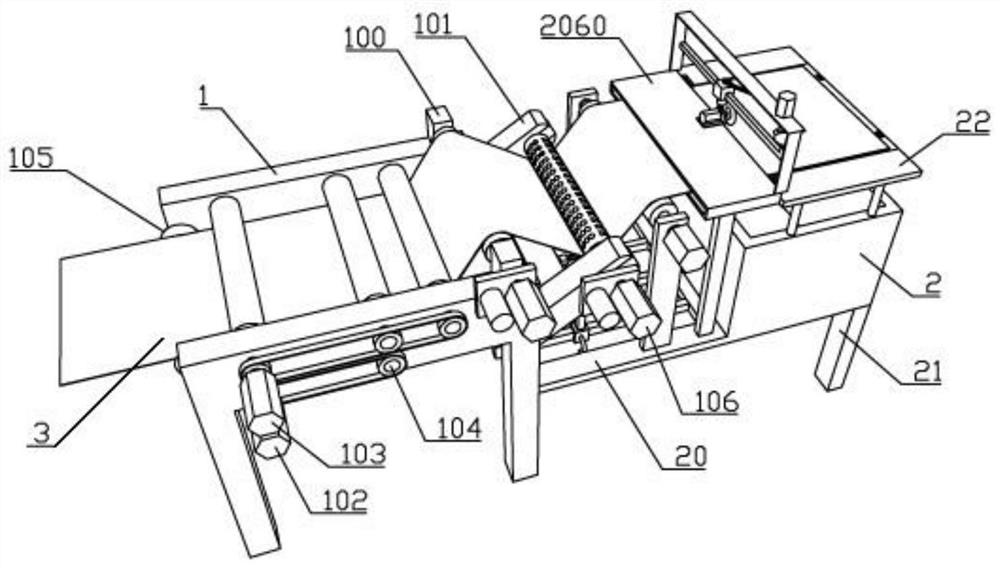

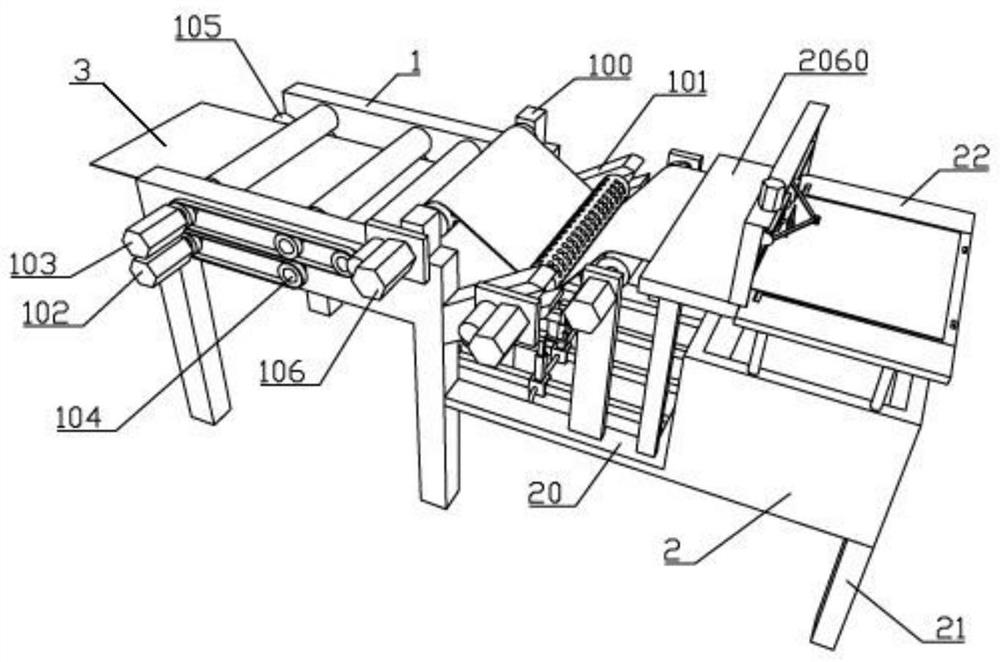

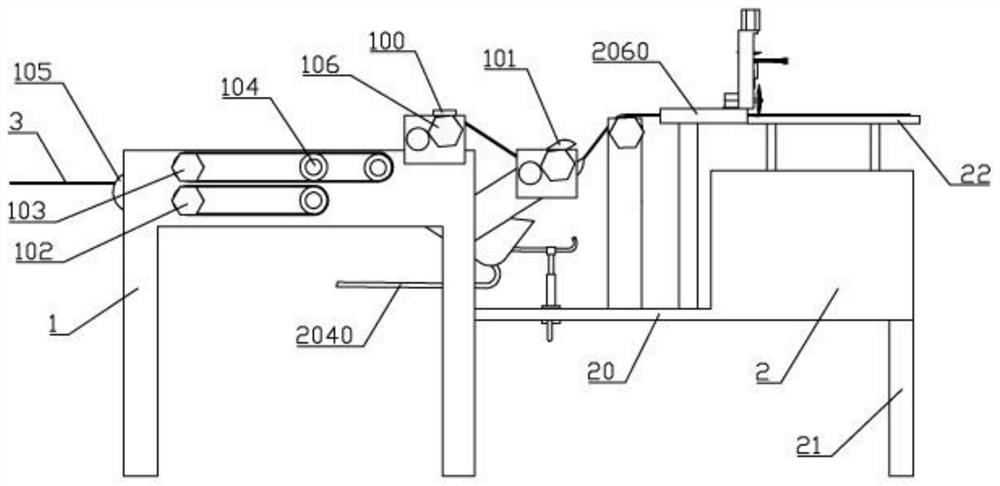

[0059] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0060] Such as Figure 1-Figure 9 As shown, the glue drying device for copper clad laminates of the present invention comprises the following steps:

[0061] Step 1, preparing glue;

[0062] Step two, glass fiber cloth glue:

[0063] Put the glue solution prepared in step 1 into the glue storage box 1061, and then pull the glass fiber cloth into it to realize gluing;

[0064] Step 3, surface drying treatment:

[0065] Transfer the semi-finished product after gluing in step 2 to the surface drying box 2060 for surface drying. The surface drying time is 5 seconds to 30 seconds. The temperature of the surface drying box 2060 is controlled between 80 ° C and 150 ° C to achieve surface drying ;

[0066] Step 4, cropping:

[0067] The semi-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com