Production method of cotton non-ironing cool garment

A non-iron cool feeling and production method technology, applied in textiles and papermaking, fiber treatment, plant fiber, etc., can solve the problems of damaging the strength of fabrics, fabrics feel hard, high baking temperature, etc., to reduce yellowing, low-pressure ironing temperature , the effect of short baking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of embodiment 1 cotton non-ironing cool feeling garment is:

[0031] S1: Configure non-iron cooling finishing liquid, which is composed of 145g / L ethylene urea resin non-ironing finishing agent, 135g / L cooling feeling finishing agent, 30g / L non-ironing catalyst, 25g / L softener and water; The non-iron cooling finishing liquid is atomized and sprayed on the cotton garments until the cotton garments are evenly covered with liquid, and the liquid retention rate is 90%;

[0032] S2: Pre-dry the garment at 70±2°C until the liquid-carrying rate is 42%;

[0033] S3: Iron cotton garments with a steam iron at 100°C, until the suture part has a liquid retention rate of 17%, and the body part has a liquid retention rate of 12%, and then press each part of the cotton garment with a press at 130±2°C Pressing pressure is 4kg / cm 2 , the pre-ironing time is 10s; the pre-ironing and pressing are all ironed in the order of the seam first and then the center of the...

Embodiment 2

[0035] The preparation method of embodiment 2 cotton non-ironing cool feeling clothing is:

[0036] S1: Configure no-ironing finishing liquid, which is composed of ethylene urea resin non-ironing finishing agent 130g / L, cooling feeling finishing agent 150g / L, non-ironing catalyst 20g / L, softener 40g / L and water; The non-iron cooling finishing liquid is atomized and sprayed on the cotton garments until the cotton garments are evenly covered with liquid, and the liquid retention rate is 93%;

[0037] S2: Pre-dry the garment at 70±2°C until the liquid-carrying rate is 45%;

[0038] S3: Iron the cotton garment with a steam iron at 100°C, until the suture part has a liquid retention rate of 15%, and the body part has a liquid retention rate of 11%, and then press the cotton garment with a pressing machine at 120±2°C, Pressing pressure is 3.5kg / cm 2 , the pressing time is 15s; the pre-ironing and pressing are all ironed in the order of the seam first and then the center of the gar...

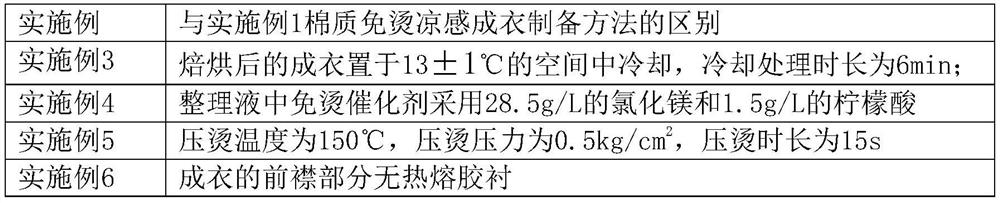

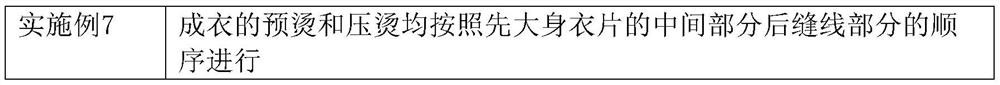

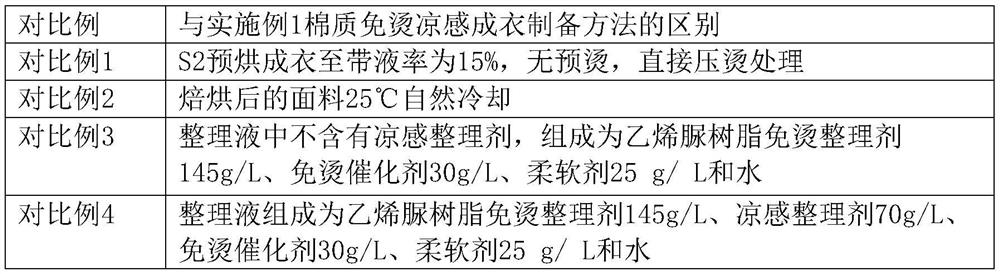

Embodiment 3-7

[0041] Embodiment 3-7 is based on embodiment 1, and the difference of process parameter sees the following table:

[0042]

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com