Squeezing type juicer

The technology of a juicer and a pressing block is applied in the direction of juice extraction, household machinery for filtering food, household appliances, etc., which can solve the problems of wasting juice, destroying the nutritional structure of food fiber, small pressing force, etc., and achieves short pressing time, The effect of retaining nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

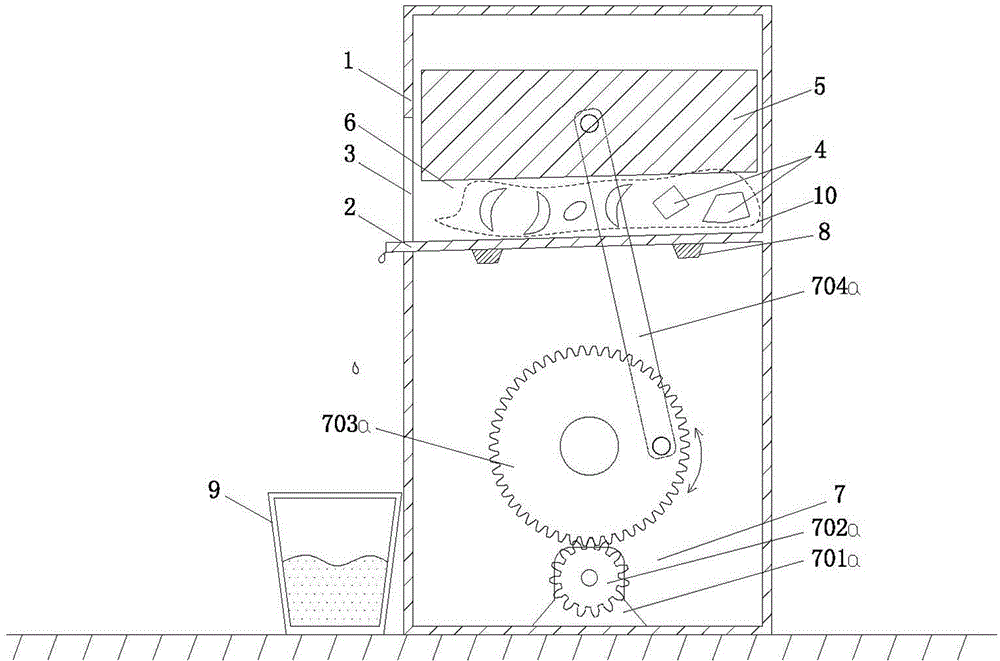

[0022] The first embodiment: as figure 1 As shown, a squeeze type juice extractor includes a body, which is characterized in that an inclined plate 2 is fixed inside the body 1, the inclined low end of the inclined plate 2 corresponds to the side of the body 1 to form a juice outlet 3, and the inclined plate 2. There is a pressing block 5 that slides up and down on the top. A pressing space 6 for placing the pressed material 4 is formed between the pressing block 5 and the inclined plate 2. A pressing driving device 7 is installed under the inclined plate 2. The pressing driving device 7 and the pressing block 5 The driving connection makes the pressing block 5 squeeze and slide toward the direction of the inclined plate 2, so that the squeezed material 4 in the squeezing space 6 is squeezed out and then flows out along the juice outlet.

[0023] In the squeeze type juice extractor with this structure, the squeeze block 5 is driven by the squeeze driving device 7, so that the ...

no. 2 example

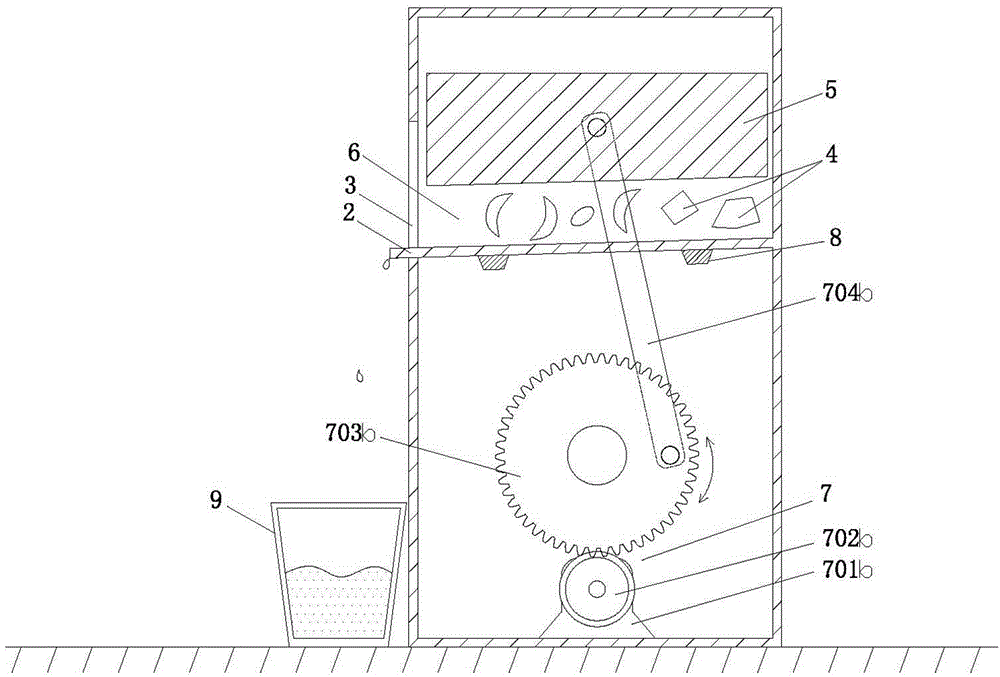

[0028] The second embodiment: as figure 2 As shown, it is similar to the first embodiment, the difference is that the press driving device 7 includes a worm motor 701b, a worm 702b, an eccentric gear 703b and a transmission link 704b, and the worm motor 701b is fixed on the body below the inclined plate 2 1. At the bottom, the rotating shaft on the worm motor 701b is connected with a worm 702b, the worm 702b meshes with the eccentric gear 703b, the eccentric gear 703b is eccentrically connected with a transmission link 704b, and the other end of the transmission link 704b is connected with a pressing block 5 that slides up and down, Squeeze and slide the squeezing block 5 towards the direction of the inclined plate 2, so that the squeezed material 4 in the squeezing space 6 is squeezed out and then flows out along the juice outlet 3; the transmission mode of this scheme is similar to the previous scheme, the difference is that a worm motor is used 701b drives the worm 702b to...

no. 3 example

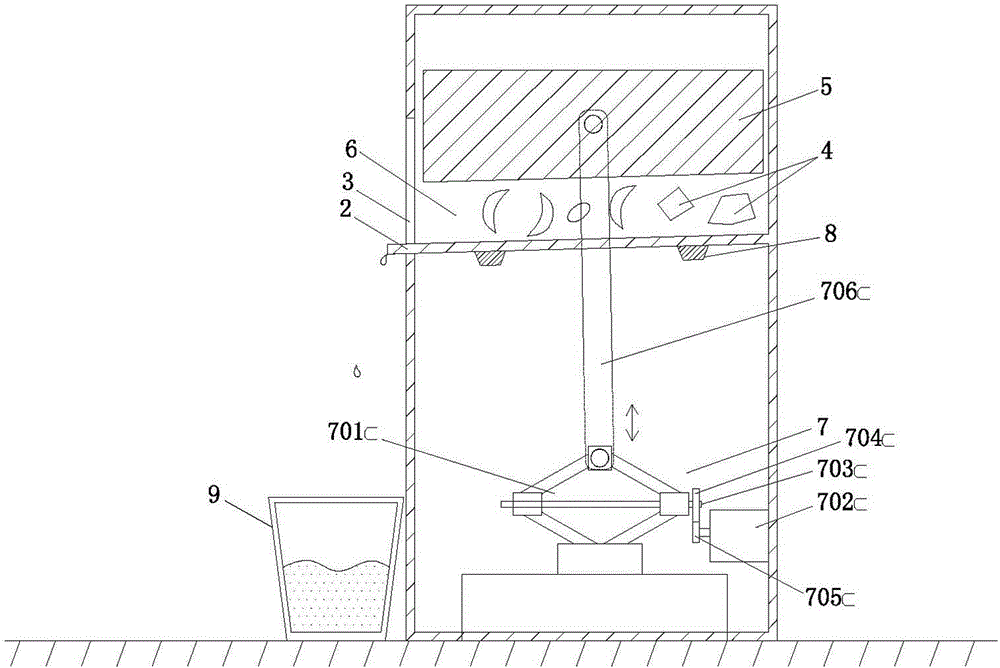

[0030] The third embodiment: as image 3 As shown, similar to the first embodiment, the difference is that the press driving device 7 includes a scissor jack 701c and a jack motor 702c, and a driving gear 704c is sleeved on one end of the driving screw 703c on the scissor jack 701c, and the jack motor The output shaft of 701c is sleeved with a motor gear 705c meshing with the drive gear 704c, and the top of the scissor jack 701c is driven and connected with the press block 5 through the push rod 706c, so that the press block 5 presses and slides in the direction of the inclined plate 2, making the press space The squeezed material 4 in 6 is squeezed out and flows out along the juice outlet 3; the transmission mode of this scheme uses the principle of a scissor jack 701c (that is, a jack for a vehicle, such as Chinese patent 201010243368.2, etc.), and is driven by a jack motor 702c. The screw rod 703c makes the scissor jack 701c drive the push rod 706c to make the pressing bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com