Rapid press-fitting locking mechanism

A technology of locking mechanism and pressing mechanism, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of reduced economic benefits, loose workpieces, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

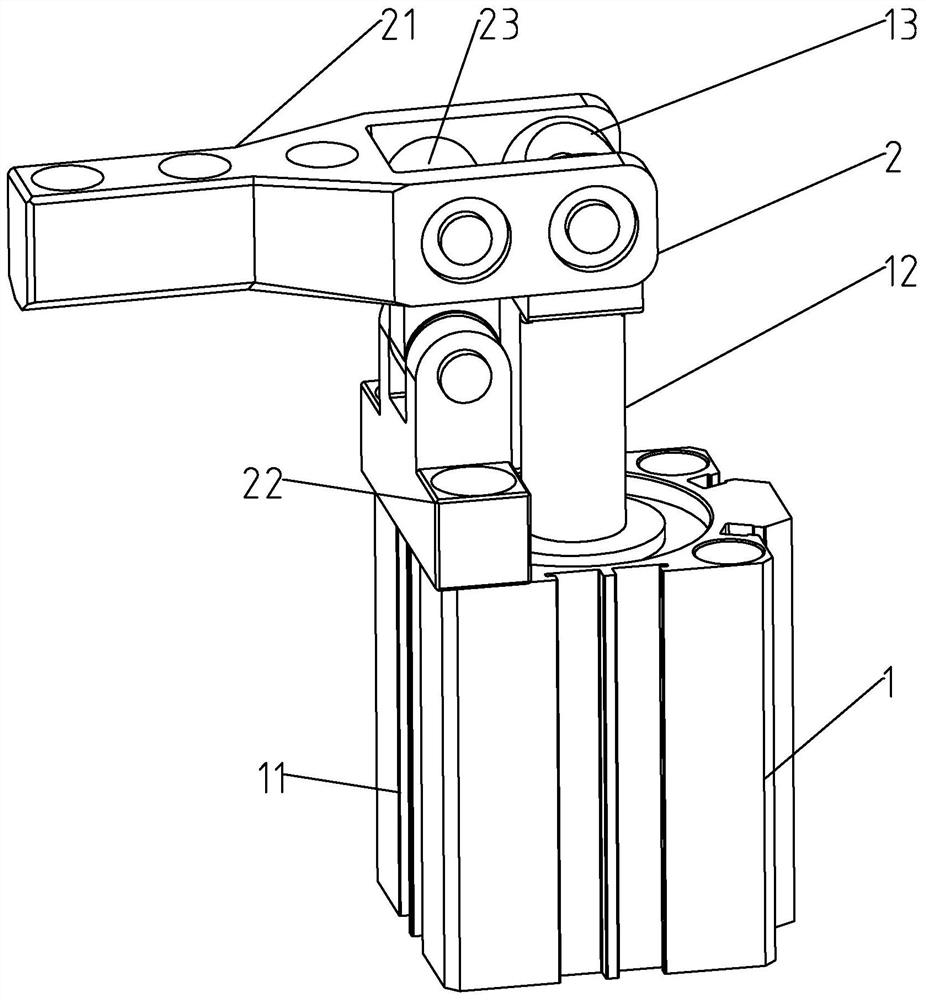

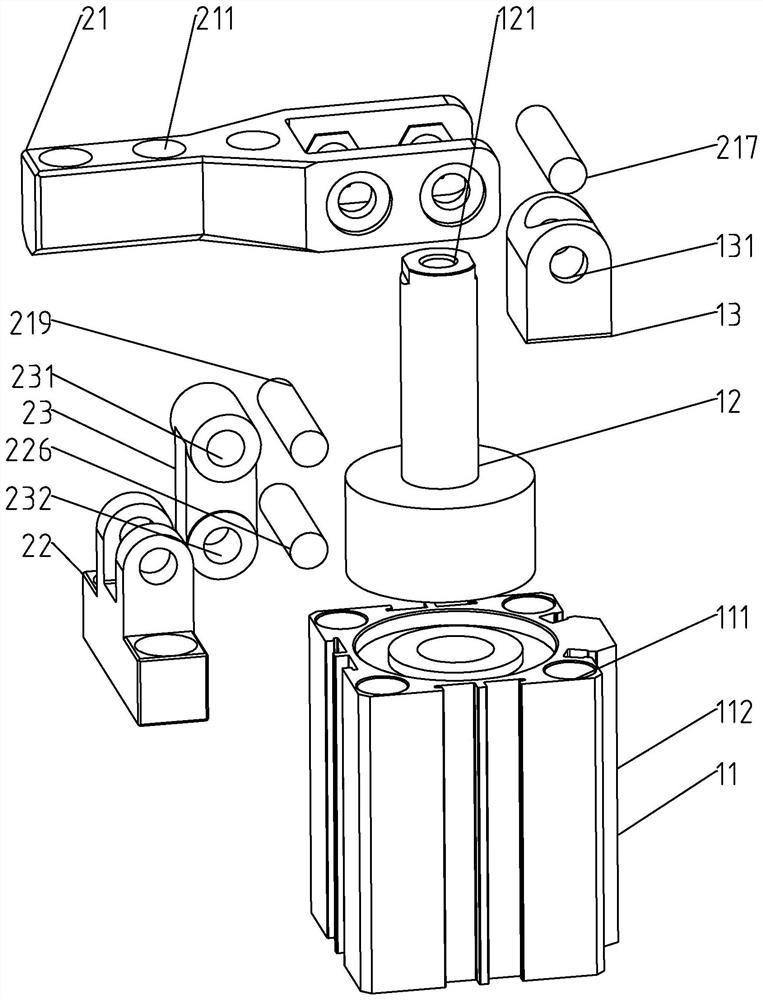

[0036] Such as figure 1 , figure 2 As shown, the present invention provides a technical solution, a fast press-fit locking mechanism, which is composed of a driving device 1 and a pressing mechanism 2. The driving device 1 includes a cylinder 11 and a piston rod 12, and one end of the piston rod 12 is located at Inside the cylinder 11, the other end stretches out from the top of the cylinder 11, and the top outer surface of the piston rod 12 is fixedly connected with a connecting pin 13; The seat 22 is fixedly installed on the top of the cylinder 11, and the mounting seat 22 is movably connected with the middle part of the compression rod 21 through the hinge arm 23, and the piston rod 12 is movably connected with the end of the compression rod 21 adjacent to the end of the cylinder 11 through the connecting pin 13. The end of the pressing rod 21 away from the connecting pin 13 is also provided with several positioning holes 211 .

[0037] The above-mentioned fast press-fit...

Embodiment 2

[0039] Such as figure 1 As shown, the present invention provides another technical solution, a quick press-fit locking mechanism, which is composed of a driving device 1 and a pressing mechanism 2 .

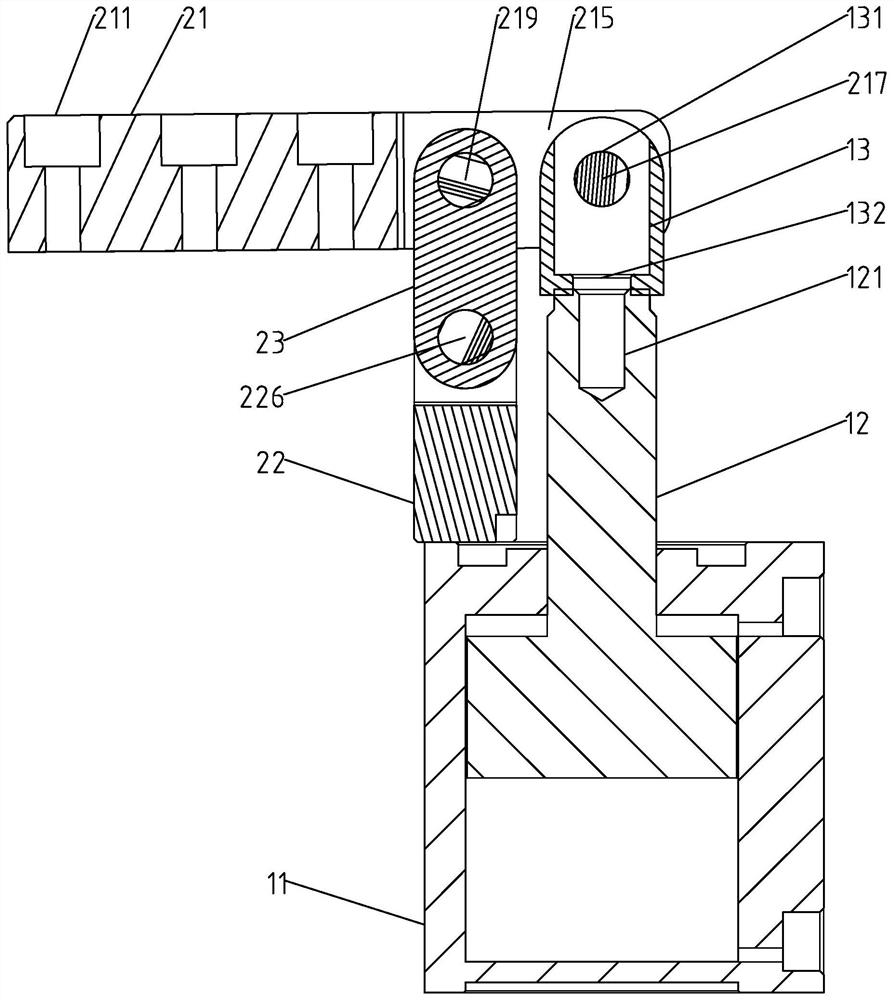

[0040] Such as image 3 , 4 As shown, the driving device 1 is composed of a cylinder 11 and a piston rod 12. The piston rod 12 is provided with one end of the piston located inside the cylinder 11, and the other end stretches out from the top of the cylinder 11. The pressure energy of the compressed gas in the cylinder 11 can be converted into a piston The mechanical energy of motion, and the top outer surface of piston rod 12 is fixedly connected with connecting pin 13; Figure 10 As shown, the connecting pin 13 is provided with a first mounting hole 132, and the top of the piston rod 12 is provided with a first threaded hole 121. The locking bolt (not shown in the figure) in the fixed connection. The piston rod 12 works through the cylinder 11 to drive one end of the compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com