Processing method for Trichosanthes kirilowii seed oil

A technology of Trichosanthes seed oil and processing method, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems of high labor intensity of workers, low oil extraction rate, harsh production environment, etc., and achieve shortening of pressing Time, low production cost, and the effect of solving high pressing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

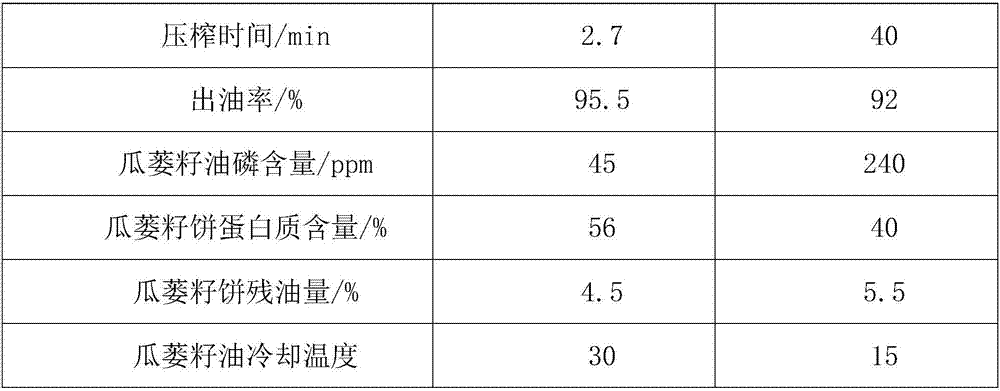

Image

Examples

Embodiment 1

[0029] A kind of processing method of Trichosanthes quince seed oil that the present invention proposes, comprises the following steps:

[0030] S1. Broken enzymolysis: control the water content of Trichosanthes seeds at 8-12wt%, crush them, mix with mixed solution A, and carry out enzymolysis reaction;

[0031] S2, screw pressing: pressing the material obtained in S1 to obtain Trichosanthes seed cake and pressed oil;

[0032] S3. Filtration and separation: filter the pressed oil, cool down, and filter to obtain Trichosanthes seed oil.

Embodiment 2

[0034] A kind of processing method of Trichosanthes quince seed oil that the present invention proposes, comprises the following steps:

[0035] S1, crushing enzymatic hydrolysis: control the water content of Trichosanthes seeds at 8wt%, use a crusher to crush the Trichosanthes seeds, the crusher is a toothed or hammer crusher, and crush the Trichosanthes seeds to the maximum diagonal length It is 3mm granular, mixed with the mixed solution A in a continuous homogenizer for 30min, the mixing temperature is 40°C, and the enzymolysis reaction is carried out; wherein, the raw materials of the mixed solution A include by weight: demineralized water: 80 parts, citric acid: 15 parts, Phospholipase A1: 0.001 parts, Sclare essential oil: 0.5 parts, Sclareol: 2 parts.

[0036] S2, screw pressing: the material obtained in S1 is pressed with a double-screw oil press, the pressing time is 180s, the compression ratio of the press chamber of the oil press is 18:1, and the instantaneous maxi...

Embodiment 3

[0042] A kind of processing method of Trichosanthes quince seed oil that the present invention proposes, comprises the following steps:

[0043] S1, crushing enzymatic hydrolysis: control the water content of Trichosanthes seeds at 12wt%, use a crusher to crush the Trichosanthes seeds, the crusher is a toothed or hammer-type crusher, and crush the Trichosanthes seeds to the maximum diagonal length It is 2mm granular, mixed with mixed solution A in a continuous homogenizer for 15 minutes, and the mixing temperature is 60°C, and the enzymolysis reaction is carried out; wherein, the raw materials of mixed solution A include by weight: demineralized water: 85 parts, citric acid: 20 parts, Phospholipase A1: 0.002 parts, Sclare essential oil: 1 part, Sclareol: 1 part.

[0044]S2, screw pressing: the material obtained in S1 is pressed by a double-screw oil press, the pressing time is 150s, the compression ratio of the press chamber of the oil press is 25:1, and the instantaneous maxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com