Patents

Literature

49results about How to "Low in phospholipids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing process for rapeseed oil

ActiveCN103666749ALow in phospholipidsReduce crude fiber contentFatty-oils/fats refiningFatty-oils/fats productionFlavorFood safety

The invention discloses a processing process for rapeseed oil. The process comprises the following steps of (1) carefully selecting rapeseeds of the year, drying the rapeseeds in the sun until the water content is 9 to 11 percent, and removing impurities, wherein the oil content of the rapeseeds is 36 to 39 percent; (2) crushing the rapeseeds, and performing flasking to obtain rapeseed flakes; (3) steam-roasting the rapeseed flasks for 70 to 80 minutes by utilizing the natural water of the flasks; (4) placing the steam-roasted rapeseeds in an oil press, and pressing the rapeseeds to extract crude oil at low temperature of 60 to 70 DEG C; (5) filtering the crude oil by using a conventional method, and performing refining to obtain a rapeseed oil finished product. According to the process, the rapeseeds with the oil content of 36 to 39 percent are taken as raw materials, and are subjected to the steps of drying in the sun, steam-roasting, low-temperature pressing and the like, the obtained rapeseed oil is a non-transgenic product, the intrinsic flavor, aroma and nutrient substances of the rapeseed oil are maximally maintained, the oil yield is over 35 percent, the requirements of green processing are met, and the food safety is ensured.

Owner:贵州侗乡生态农业科技发展有限公司

Method for extracting tea seed oil by using enzymatic hydrolysis method

ActiveCN102061217AHigh purityLight colorFatty-oils/fats productionOil and greaseEnzymatic hydrolysis

The invention discloses a method for extracting tea seed oil by using an enzymatic hydrolysis method, which comprises the following steps of: airing, unshelling, husking and pulverizing tea seeds; carrying out enzymolysis on the tea seeds in the material-liquid ratios of 1:3 to 1:5 at the extraction temperature of 40-60 DEG C for 1-5h with the enzyme quantity of 40-600U under the pH natural condition; centrifugally layering; adding an organic solvent into centrifugal liquid and extracting; and rotating and evaporating to obtain an oil sample. By adopting the scheme, the method has the advantages of low temperature for equipment operation, low energy consumption, high purity of extracted oil, low content of phospholipid, low acid value and low peroxide value, shallow color, low BOD (Biochemical Oxygen Demand) and COD (Chemical Oxygen Demand) values, easiness of treatment and less pollution, and the oil yield ratio is up to 23.1 percent.

Owner:HUAQIAO UNIVERSITY

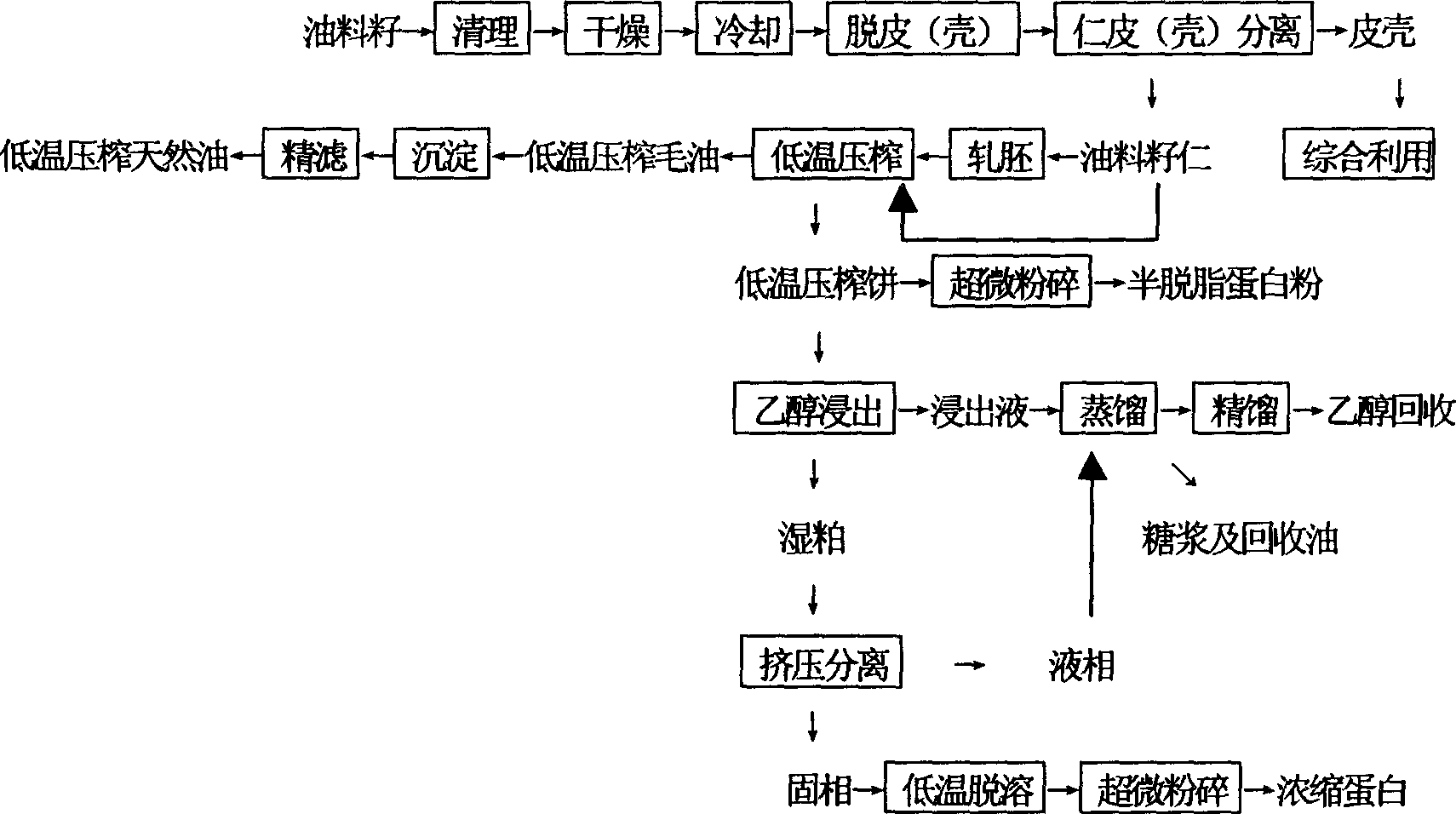

Low temperature oil preparation and protein in oil-bearing materials preparation method

InactiveCN1840623ALow in phospholipidsLight colorProtein composition from vegetable seedsFatty-oils/fats productionMaterials preparationLeachate

The related preparation method for oil and oil protein comprises: cleaning material, drying till water content in 2-10%; cooling to ambient temperature, peeling or shelling more than 90%, separating core and seedcase to obtain the oiling seed with 0.5-10% seedcase; after rolling or not, expressing with low-temperature device at 20-70Deg to obtain crude oil and cake; depositing, fine filtering to obtain the objective oil; super grinding the cake to prepare semi-degreased protein powder, or soaking to obtain leachate for recovery and wet dreg to recover ethanol and grind for protein powder.

Owner:WUHAN POLYTECHNIC UNIVERSITY +1

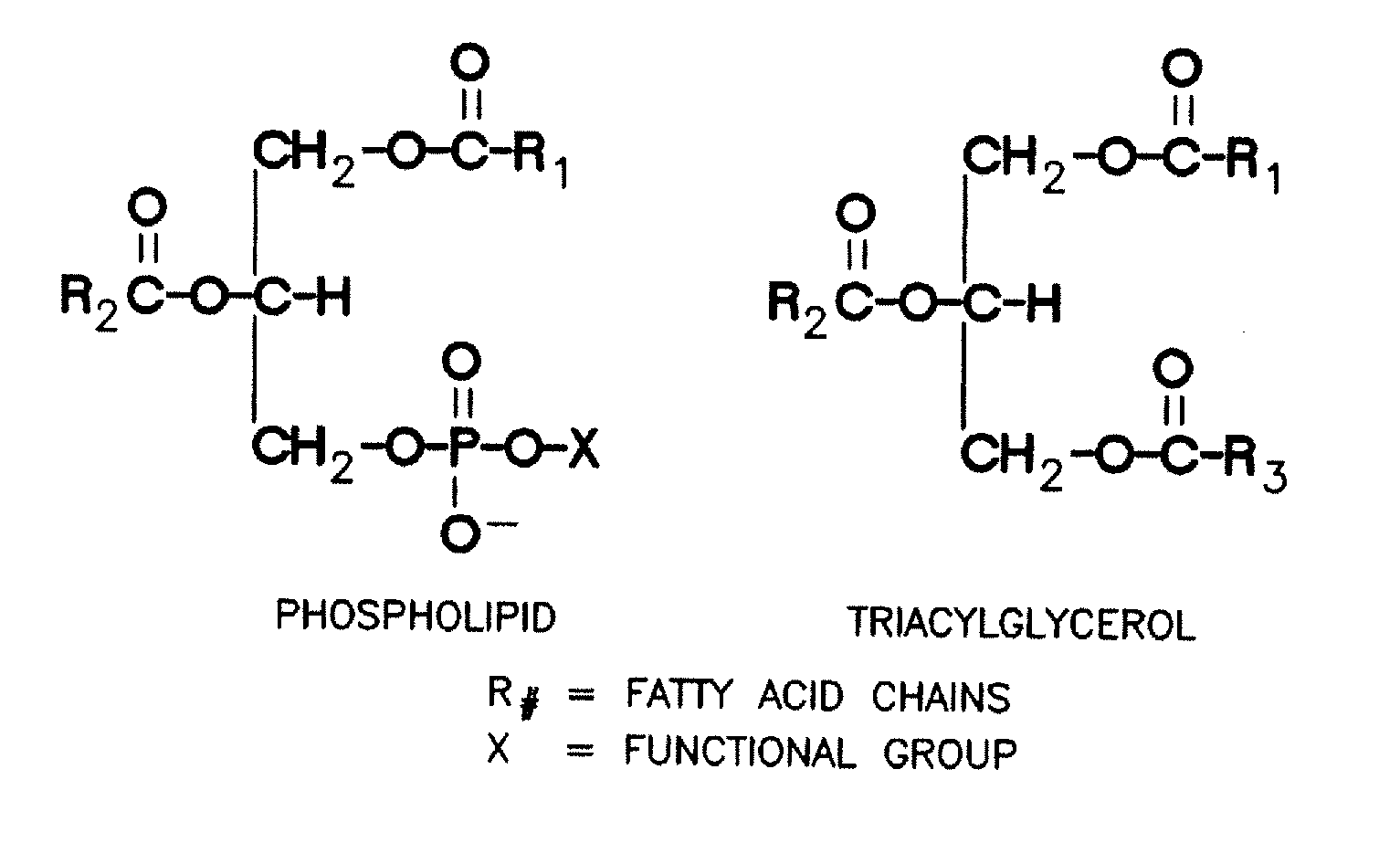

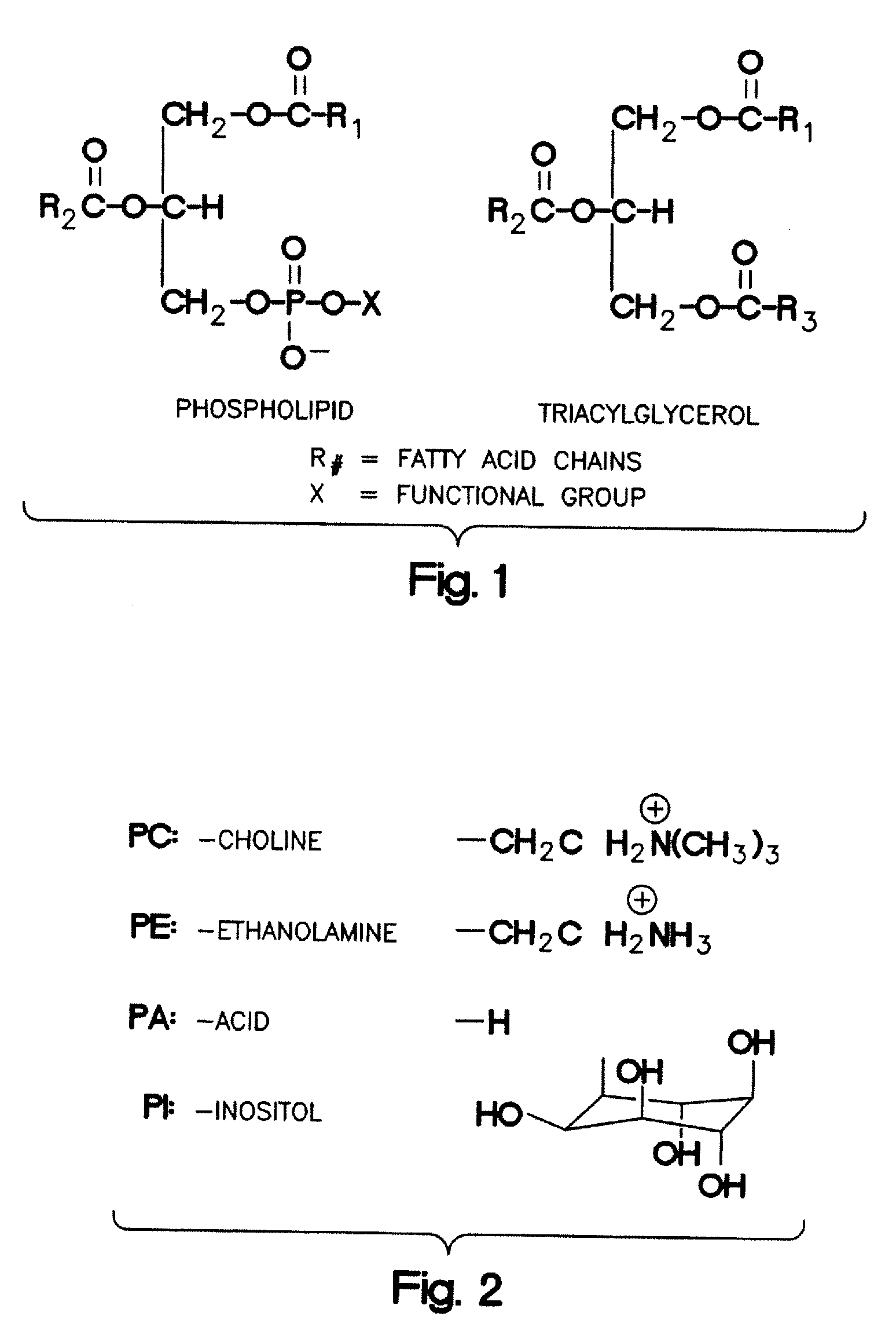

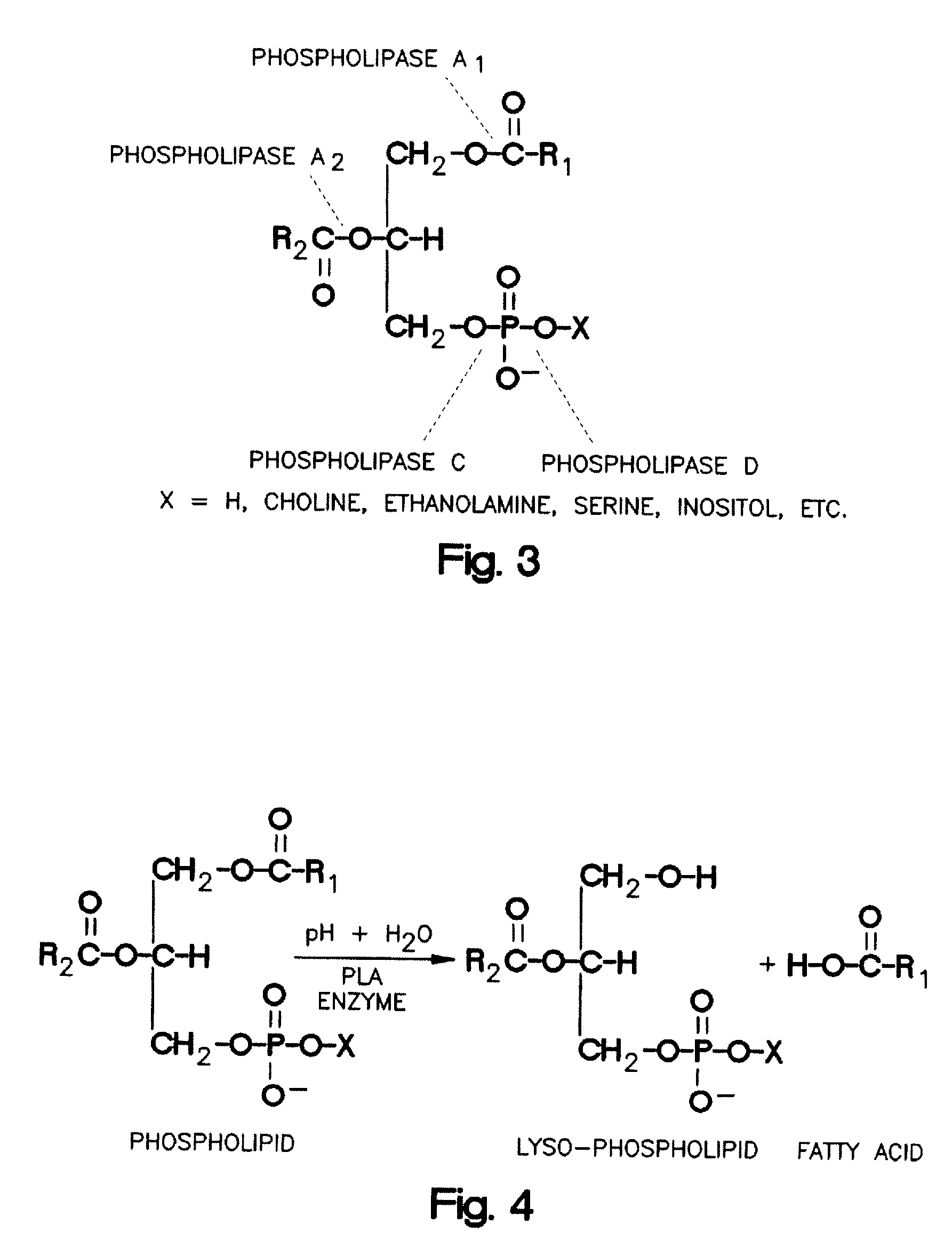

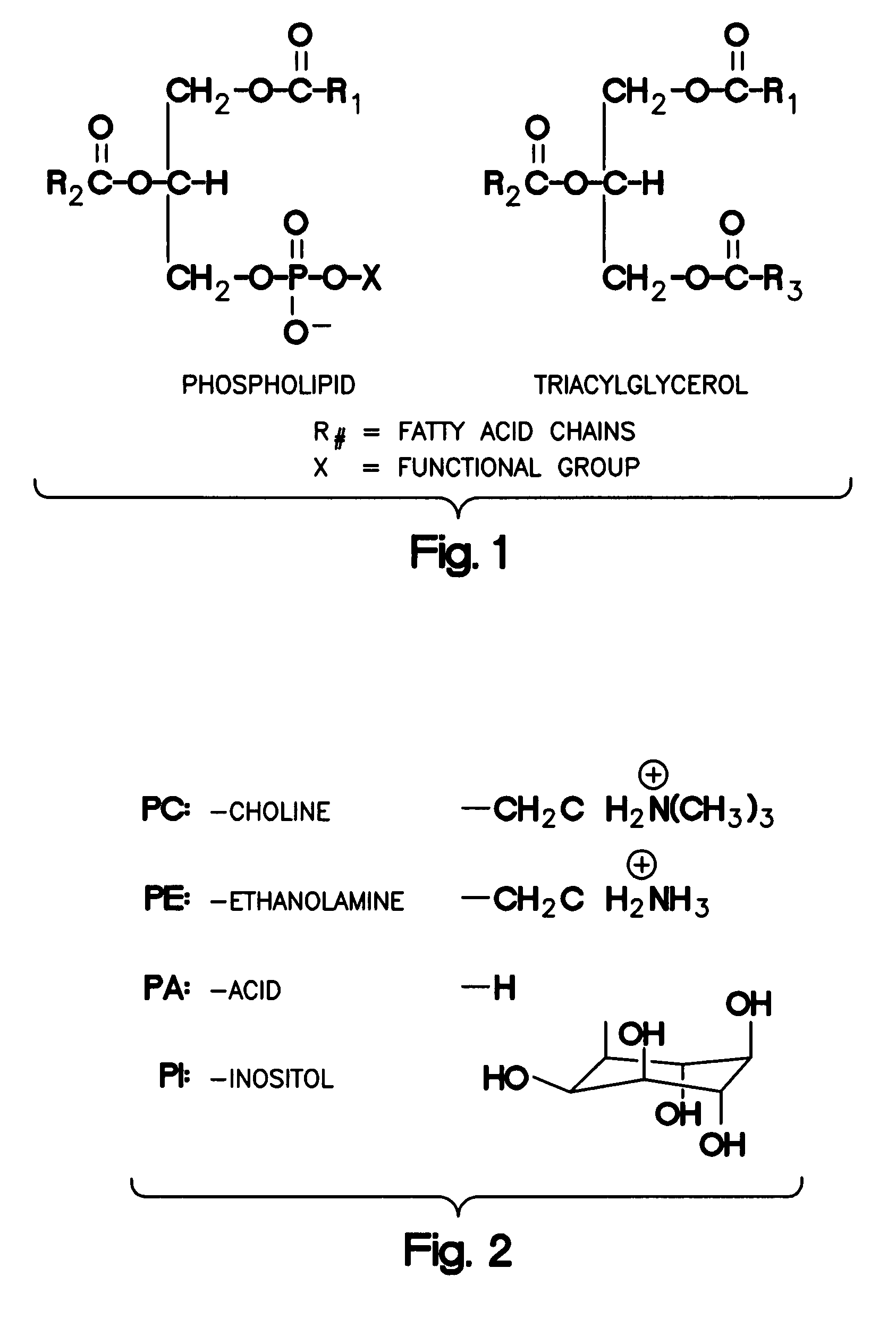

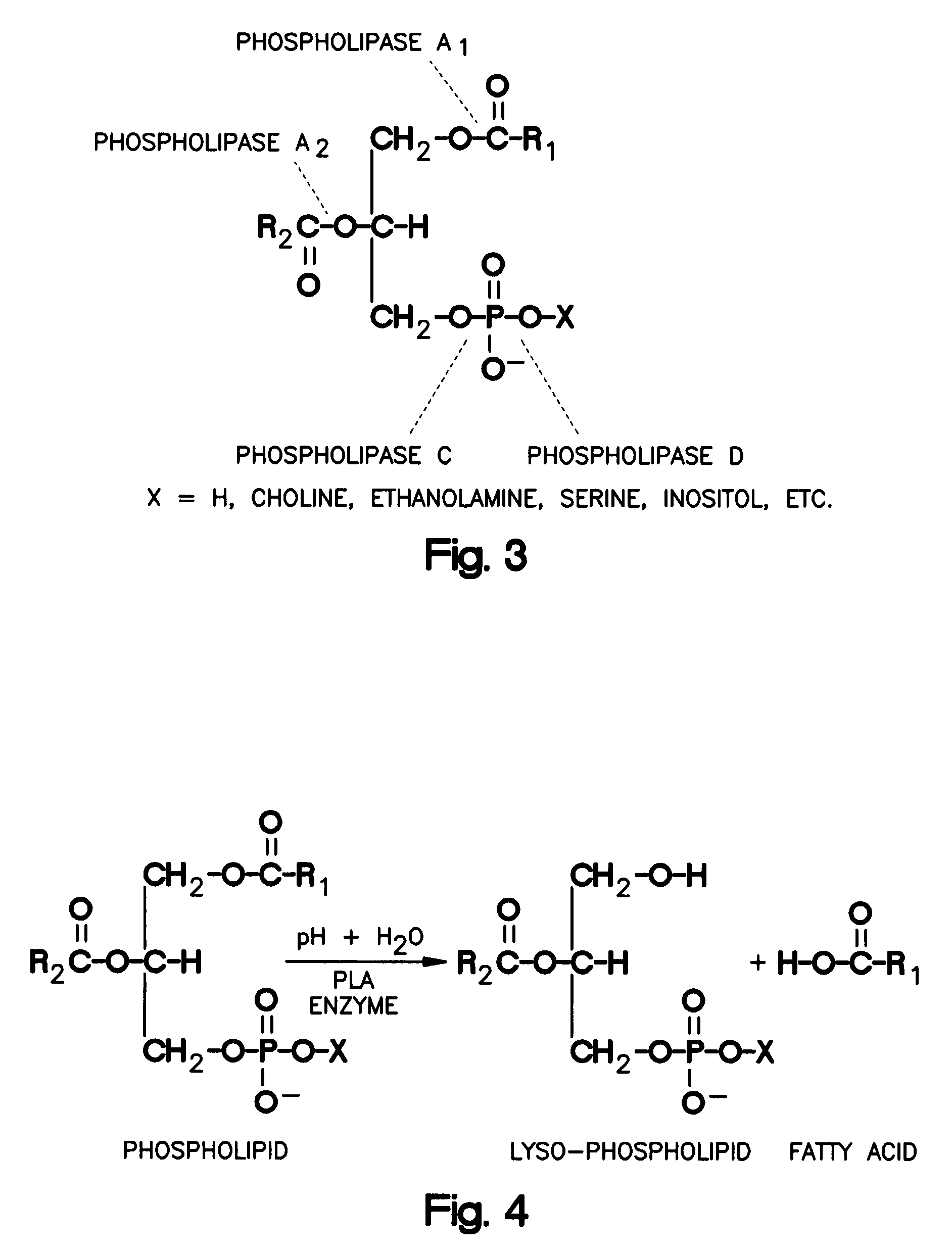

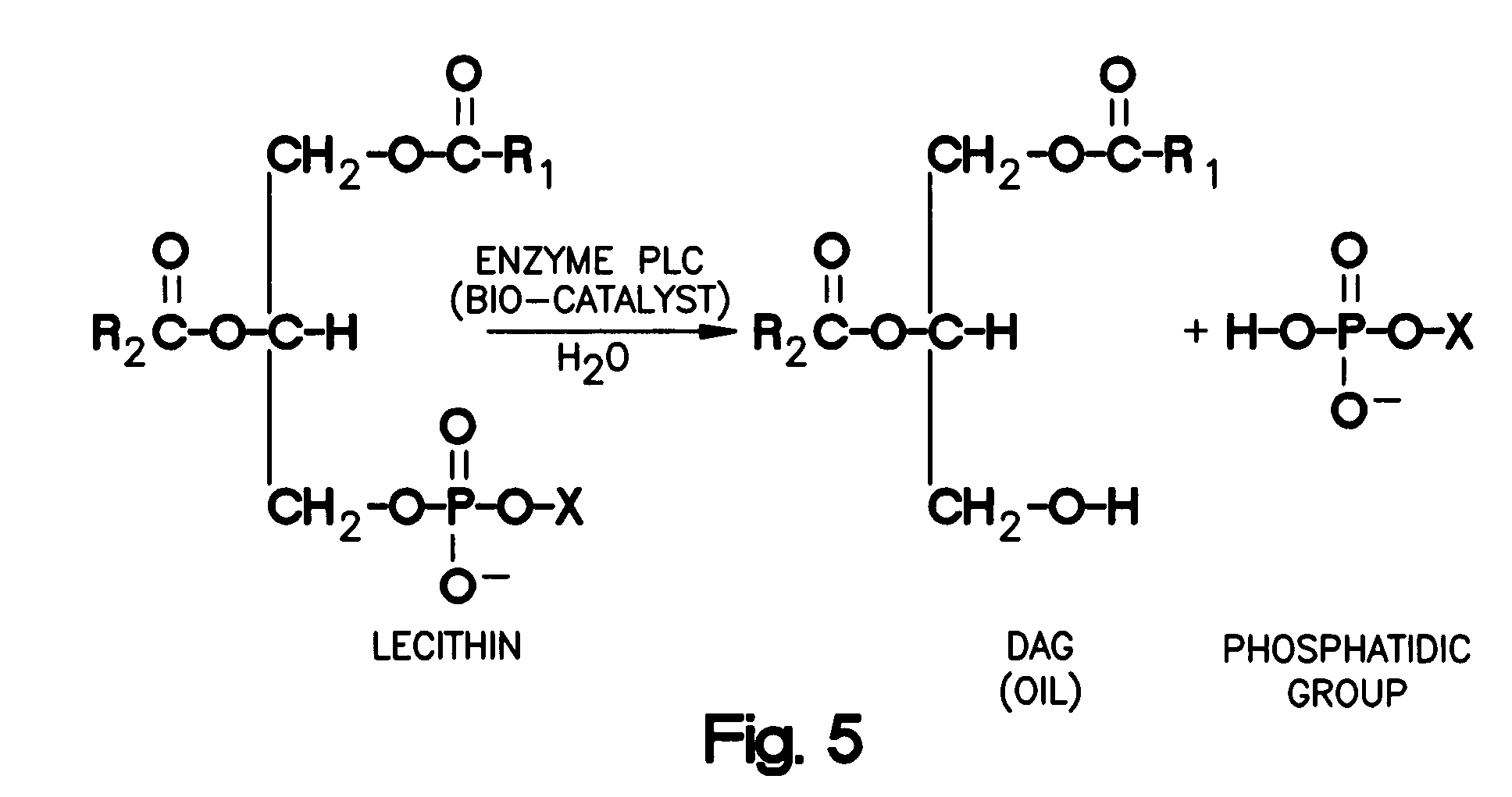

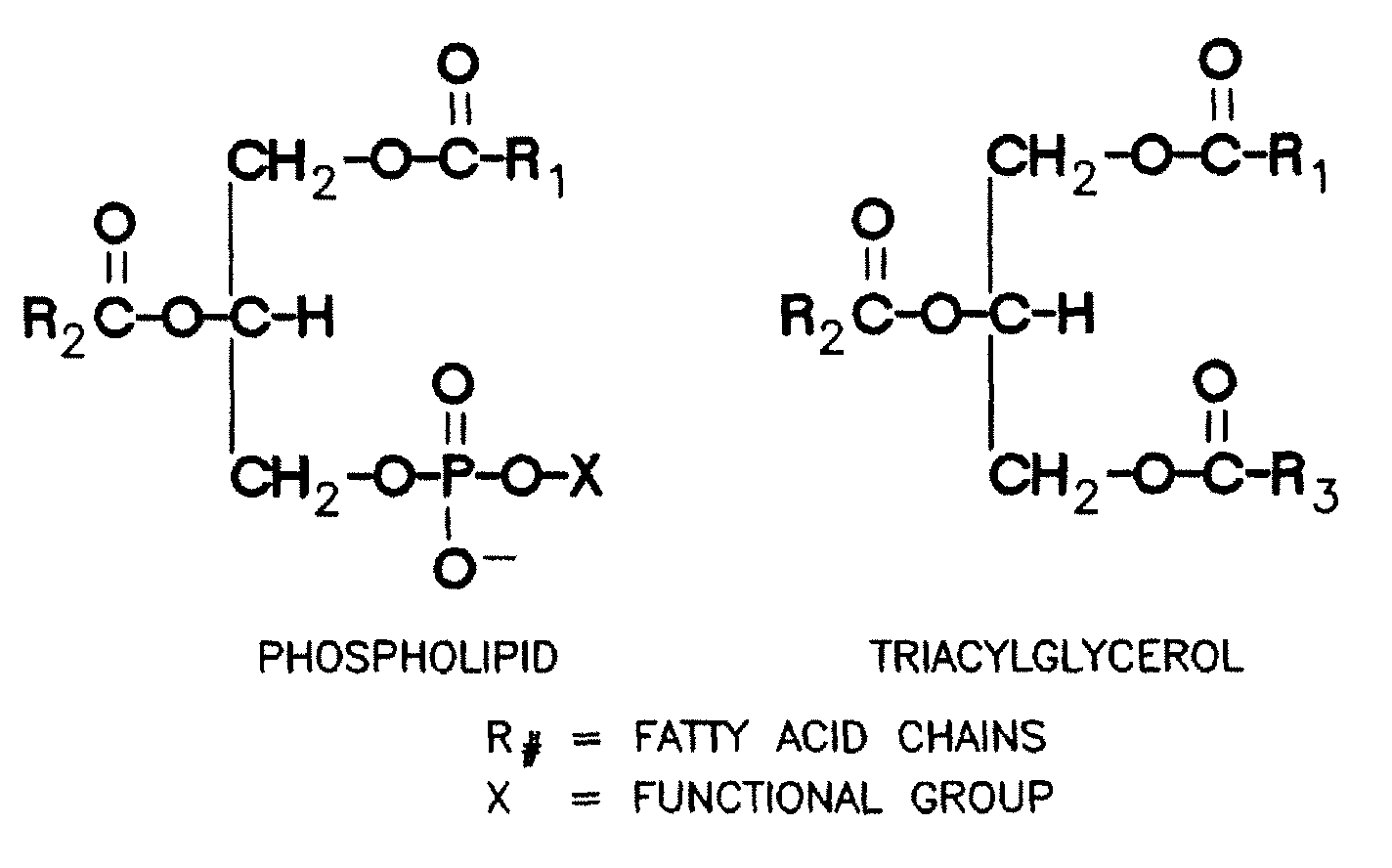

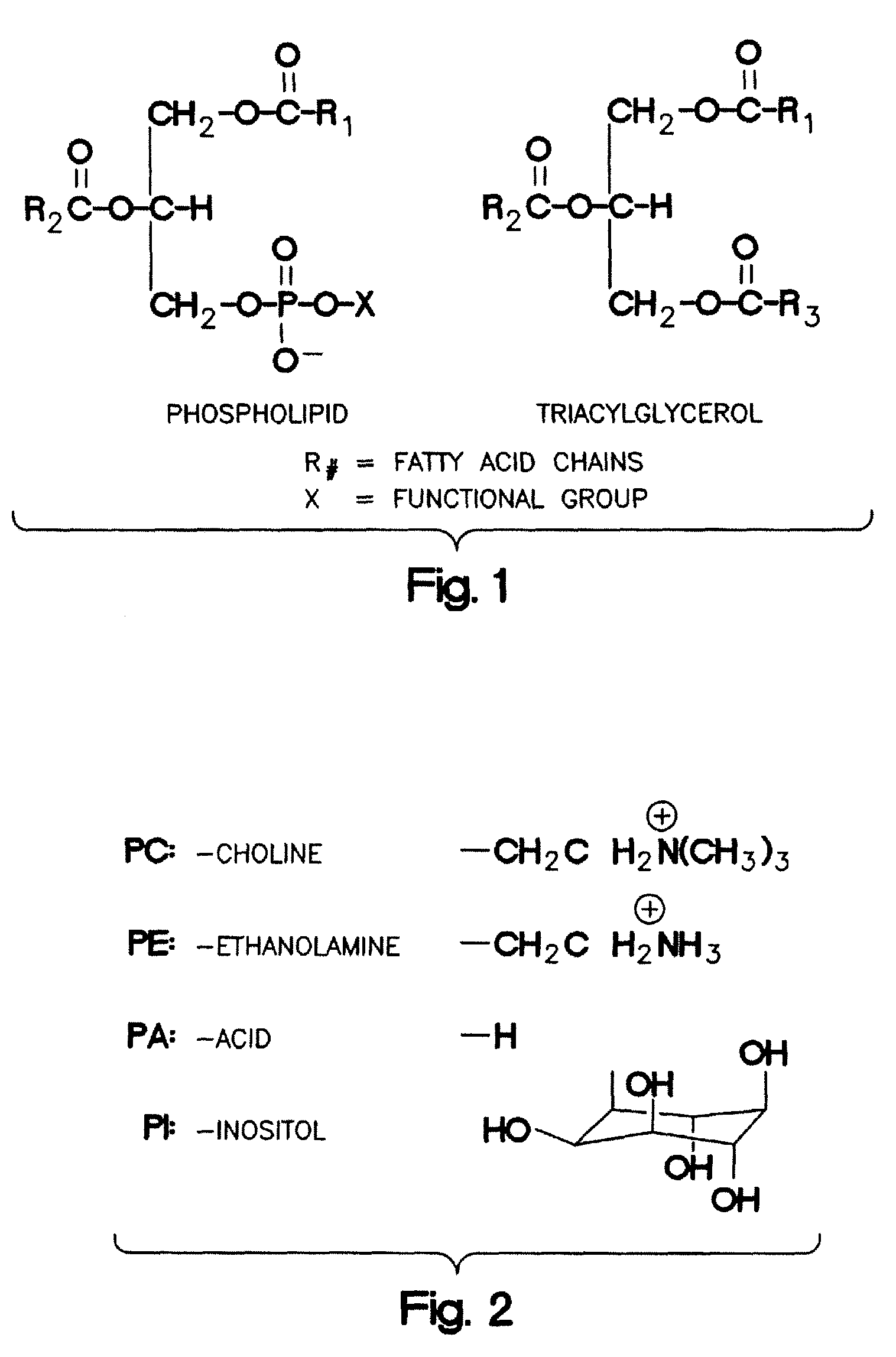

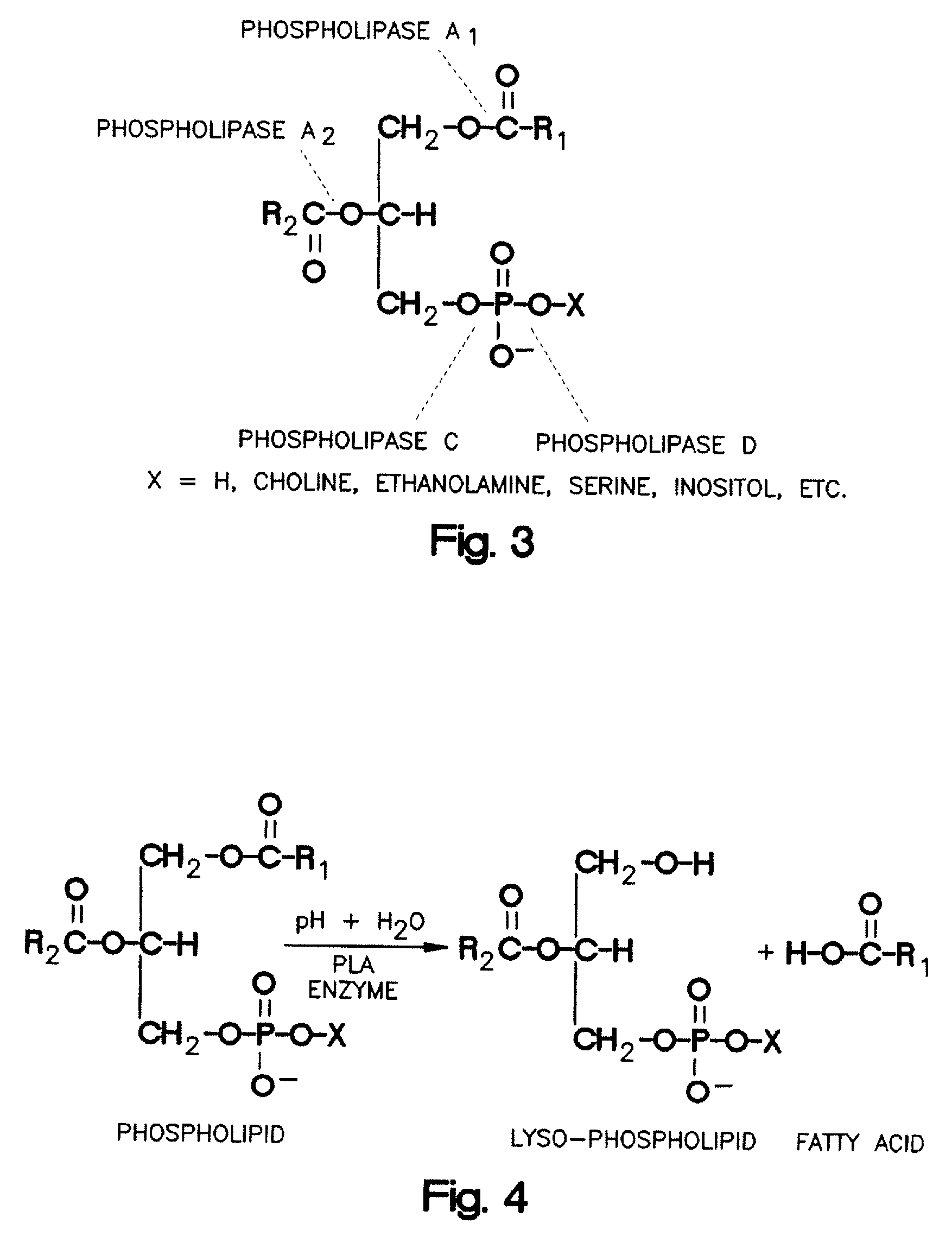

Enzymatic Degumming Utilizing a Mixture of PLA and PLC Phospholipases with Reduced Reaction Time

ActiveUS20090069587A1Suitable for useReduced phospholipid contentFatty oils/acids recovery from wasteBiocidePhospholipases CPhospholipases A

A method for degumming an oil composition comprises the steps of (a) providing an oil composition containing a quantity of phospholipids, (b) contacting said oil composition simultaneously with one or more phospholipase A enzymes and one or more phospholipase C enzymes, under conditions sufficient for the enzymes to react with the phospholipids to create phospholipid reaction products, and (c) separating the phospholipids reaction products from the oil composition, the remaining oil composition after the separation being a degummed oil composition, whereby during step (b) the reaction of said one or more phospholipase A enzymes proceeds at a faster rate than it would in the absence of said one or more phospholipase C enzymes, and wherein the reaction of step (b) continues for a duration of less than about one hour.

Owner:BUNGE OILS INC

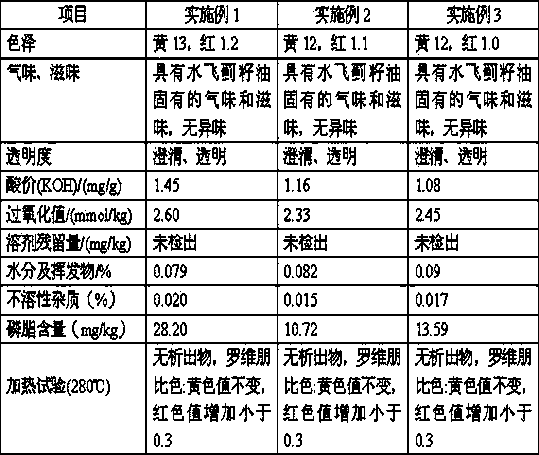

Rapeseed oil and preparation method thereof

InactiveCN103184098AReduce redReduced phospholipid content and impuritiesFatty-oils/fats refiningFatty-oils/fats productionChemistryOil and grease

The invention discloses a preparation method of rapeseed oil. The preparation method comprises the steps as follows: rapeseeds are squeezed and filtered to obtain crude oil and an oil squeezed cake; the crude oil is put into an oil refining caldron and stirred till no bubbles exist, and the temperature of the oil refining caldron is in a range from 50 EDG C to 95 DEG C; warm water with the crude oil weight of 5-10% and edible non-iodized salt with the crude oil weight of 4-5% are added into the crude oil for hydration; after hydration, sedimentation is performed, and water and colloidal impurities subsided at the bottom of the crude oil are removed to obtain raw oil; the raw oil is dried, and water in the raw oil is removed; the temperature and the vacuum degree for drying are maintained, an adsorbent and fennel are added in the raw oil for decoloration, and the total adding amount of the adsorbent and the fennel accounts for 1-3% of the mass of the raw oil; and the decolored raw oil is filtered to obtain the rapeseed oil. The invention further discloses the rapeseed oil prepared with the preparation method. All indexes of the rapeseed oil all meet the international requirements of the four-level rapeseed oil, and intense original rapeseed oil fragrance can be maintained.

Owner:湖南盈成油脂工业有限公司

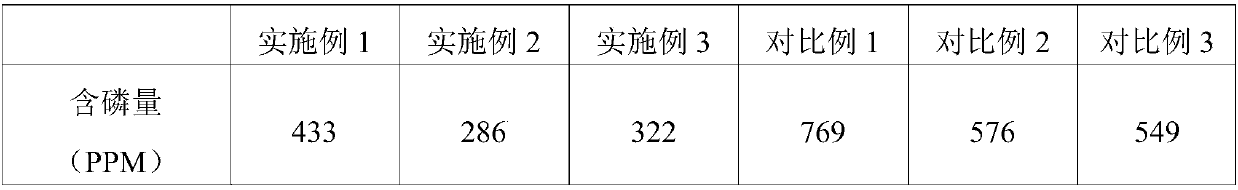

Grease refining method based on enzymatic degumming technology

InactiveCN105907466ALow in phospholipidsQuality improvementFatty-oils/fats refiningPhospholipidChemistry

The invention discloses a grease refining method based on the enzymatic degumming technology. Grease is subjected to acid reaction, then enzymatic degumming is conducted, and degummed oil is obtained through colloid separation, wherein the phosphorus content of the degummed oil is not higher than 30 mg / kg; the degummed oil is subjected to alkali refining to obtain desaponification oil, the desaponification oil is subjected to decoloration and deodorizing, and refined oil is prepared. The method reduces the phospholipid content in soapstock and improves quality of acidic oil; the desaponification oil with lower phosphorus content can be obtained; phospholipid in grease is separated independently, and high-value application is further facilitated.

Owner:SOUTH CHINA UNIV OF TECH

Method for extracting tea seed oil from oil-tea camellia seeds

InactiveCN106544152AEasily brokenHigh purityFatty-oils/fats refiningFatty-oils/fats productionCamellia oleiferaAdditive ingredient

The invention provides a method for extracting tea seed oil from oil-tea camellia seeds. The method comprises the following steps that 1, husked tea seed kernels are taken as raw materials to be subjected to freezing treatment with liquid nitrogen and then crushed immediately after treatment, and crushed tea seed kernels are obtained; 2, the crushed tea seed kernels are added into 50-60-DEG C water immediately and then subjected to ultrasonic wave-microwave treatment to break tea seed kernel cells, wherein the process is conducted according to the process parameters that the power of ultrasonic waves is 30-50 W, the power of microwaves is 10-200 W, and the time is 20-60 min; 3, a compound enzyme of which the weight accounts for 0.02%-0.1% of that of the tea seed kernels is added into the crushed tea seed kernels obtained in the step 2, enzymolysis is conducted under the conditions that the temperature ranges from 50 DEG C to 60 DEG C and the pH is 6-7.5, separation is conducted, and the tea seed oil is obtained. According to the method, the oil yield of the tea seed oil is increased, the oil quality of the tea seed oil is improved, and the defects of low oil yield, high temperature, high pressure, organic solvent residues and more nutrient ingredient losses which exist in a traditional technology are fundamentally overcome.

Owner:合肥观云阁科技发展有限公司

Enzymatic degumming utilizing a mixture of PLA and PLC phospholipases

ActiveUS8956853B2Suitable for useLow in phospholipidsFatty oils/acids recovery from wasteOrganic compound preparationPhospholipidPhospholipases A

A method for degumming an oil composition comprises the steps of (a) providing an oil composition containing a quantity of phospholipids, (b) contacting said oil composition simultaneously with one or more phospholipase A enzymes and one or more phospholipase C enzymes, under conditions sufficient for the enzymes to react with the phospholipids to create phospholipid reaction products, and (c) separating the phospholipids reaction products from the oil composition, the remaining oil composition after the separation being a degummed oil composition, whereby during step (b) the reaction of said one or more phospholipase A enzymes proceeds at a faster rate than it would in the absence of said one or more phospholipase C enzymes.

Owner:BUNGE OILS INC

Refining method for fourth-grade rapeseed oil

ActiveCN105087155AThe processing method is simple and feasibleEnvironmental pollutionFatty-oils/fats refiningChemistryQuality standard

The invention discloses a refining method for fourth-grade rapeseed oil. The refining method comprises the following steps: (1) carrying out pre-acidification; (2) carrying out post-acidification; (3) carrying out hydration; (5) carrying out centrifugal degumming; (5) carrying out oxidative decolorization; and (6) carrying out vacuum dehydration and desolvation. According to the method disclosed by the invention, two acids are separately used for two-time acidifying hydrated phospholipid and non-hydrated phospholipid in crude oil, so that the phospholipid content in the fourth-grade rapeseed oil is reduced to meet the qualified requirement of a heating test, and therefore, the problem that four-grade rapeseed oil produced from imported rapeseed oil cannot meet the quality standards in a heating test is solved.

Owner:厦门银祥油脂有限公司

Enzymatic degumming utilizing a mixture of PLA and PLC phospholipases with reduced reaction time

ActiveUS8460905B2Suitable for useLow in phospholipidsFatty oils/acids recovery from wasteBiocidePhospholipidPhospholipases C

A method for degumming an oil composition comprises the steps of (a) providing an oil composition containing a quantity of phospholipids, (b) contacting said oil composition simultaneously with one or more phospholipase A enzymes and one or more phospholipase C enzymes, under conditions sufficient for the enzymes to react with the phospholipids to create phospholipid reaction products, and (c) separating the phospholipids reaction products from the oil composition, the remaining oil composition after the separation being a degummed oil composition, whereby during step (b) the reaction of said one or more phospholipase A enzymes proceeds at a faster rate than it would in the absence of said one or more phospholipase C enzymes, and wherein the reaction of step (b) continues for a duration of less than about one hour.

Owner:BUNGE OILS INC

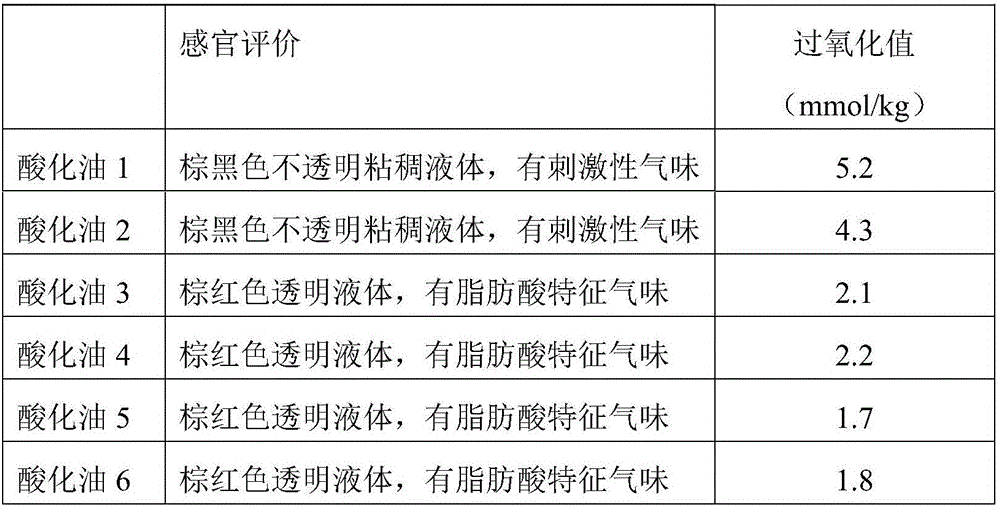

Method for preparing acidic oil by using soapstock

InactiveCN109554230ALow in phospholipidsReduce dosageFatty oils/acids recovery from wasteFatty substance recoveryAcid waterWastewater

The invention provides a method for preparing acidic oil by using soapstock. The preparation method comprises the following steps: heating soapstock to 88-92 DEG C, adding an acid and acid water to carry out a primary acidification reaction, and carrying out separation to obtain primary acidic oil; and heating the primary acidic oil to 88-92 DEG C, adding concentrated sulfuric acid to carry out asecondary acidification reaction, and carrying out separation to obtain the acidic oil, wherein the acid water is acidic water obtained by separation after the secondary acidification reaction. According to the method for preparing the acidic oil by using the soapstock, the content of phospholipid in the acidic oil can be directly reduced through the secondary acidification reaction, and the usageamount of the acid in the primary acidification reaction is reduced, so that the generation amount of acidification wastewater is reduced; the concentrated sulfuric acid is added in the secondary acidification reaction, and the generated acid water is reused in the primary acidification reaction, so that the usage amount of sulfuric acid and water can be reduced again; the acidification wastewater obtained after the primary acidification reaction does not need to be treated with addition of alkali liquor, so that generation of sewage is further reduced, and production cost is saved. The method can be widely applied to industrial production of acidic oil, and is economic and environmentally friendly.

Owner:嘉里粮油(营口)有限公司

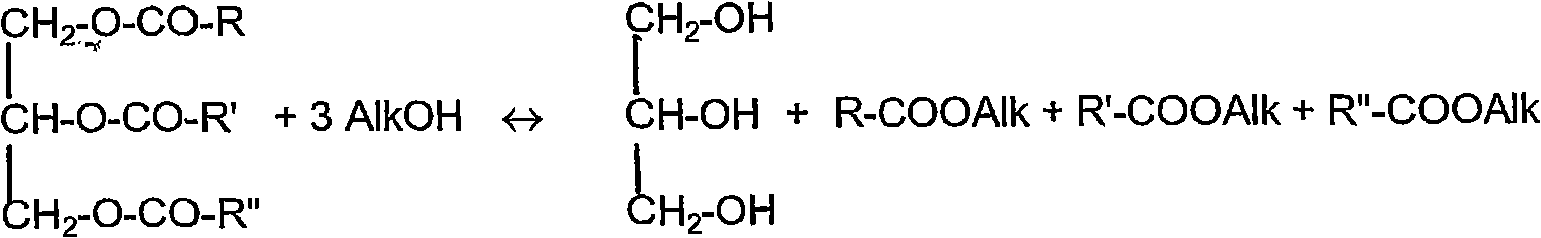

Transesterification of vegetable oils

ActiveCN101952403ARapid responseEasy to separateFatty acid esterificationPreparation by ester-hydroxy reactionAlcoholVegetable oil

A method for producing diesel grade fuel of plant origin by transesterifying a refined vegetable oil with a charge of a C1-C4 alcohol in the presence of a catalyst and at least 0.2 parts by volume, related to unit volume of refined vegetable oil, of an aliphatic hydrocarbon solvent with a boiling point of -42 DEG C to 200 DEG C, comprises mixing the oil, alcohol, catalyst and solvent in a single reaction vessel under homogeneous conditions which promote transesterif ication to 95-98% completion and which suppress reverse glycerolysis, without stopping transesterif ication to remove by- product polar glycerol, and without subjecting the oil / fuel mixture to a further transesterif ication step with a fresh charge of alcohol and catalyst.

Owner:QS BIODIESEL

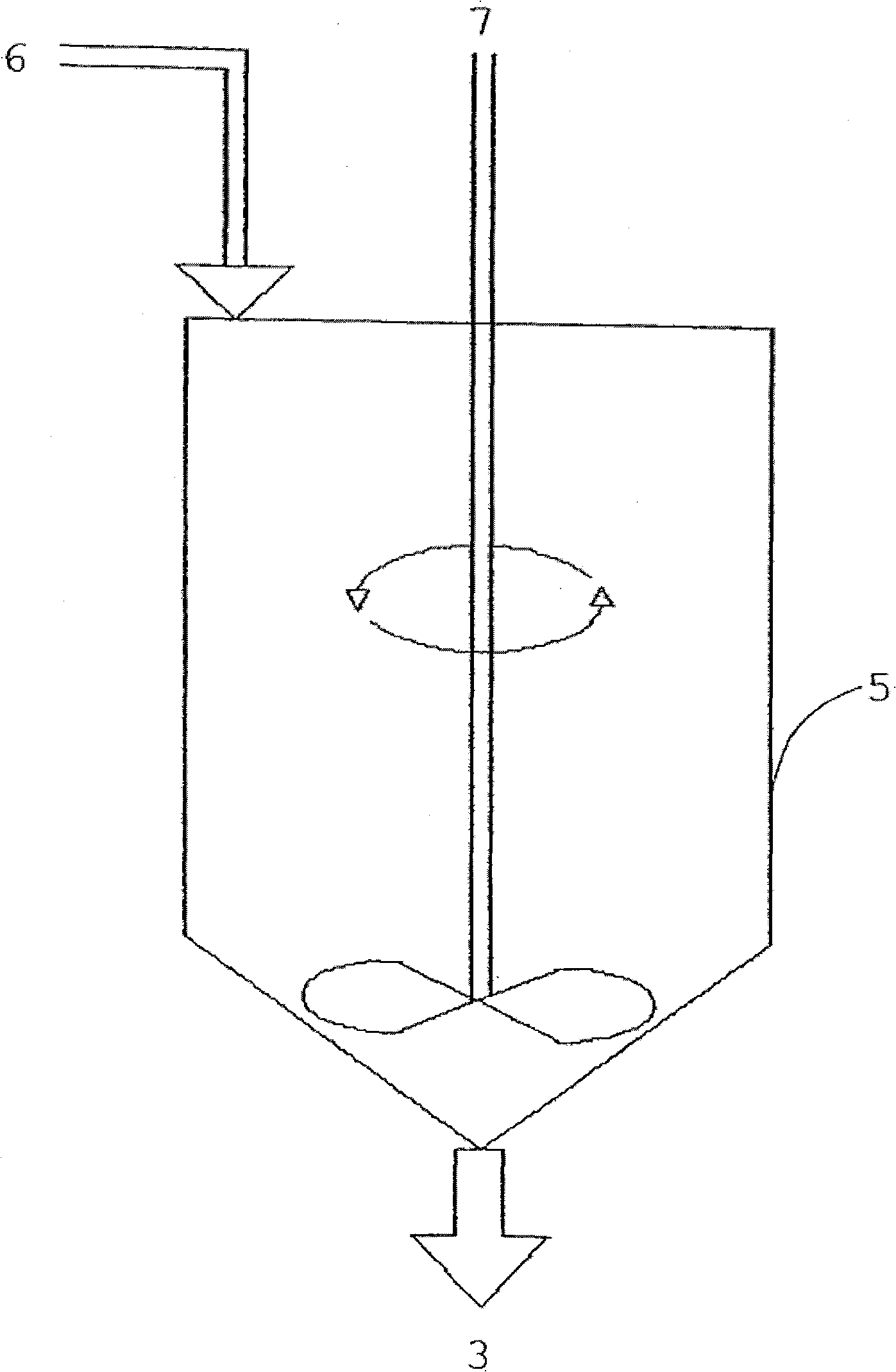

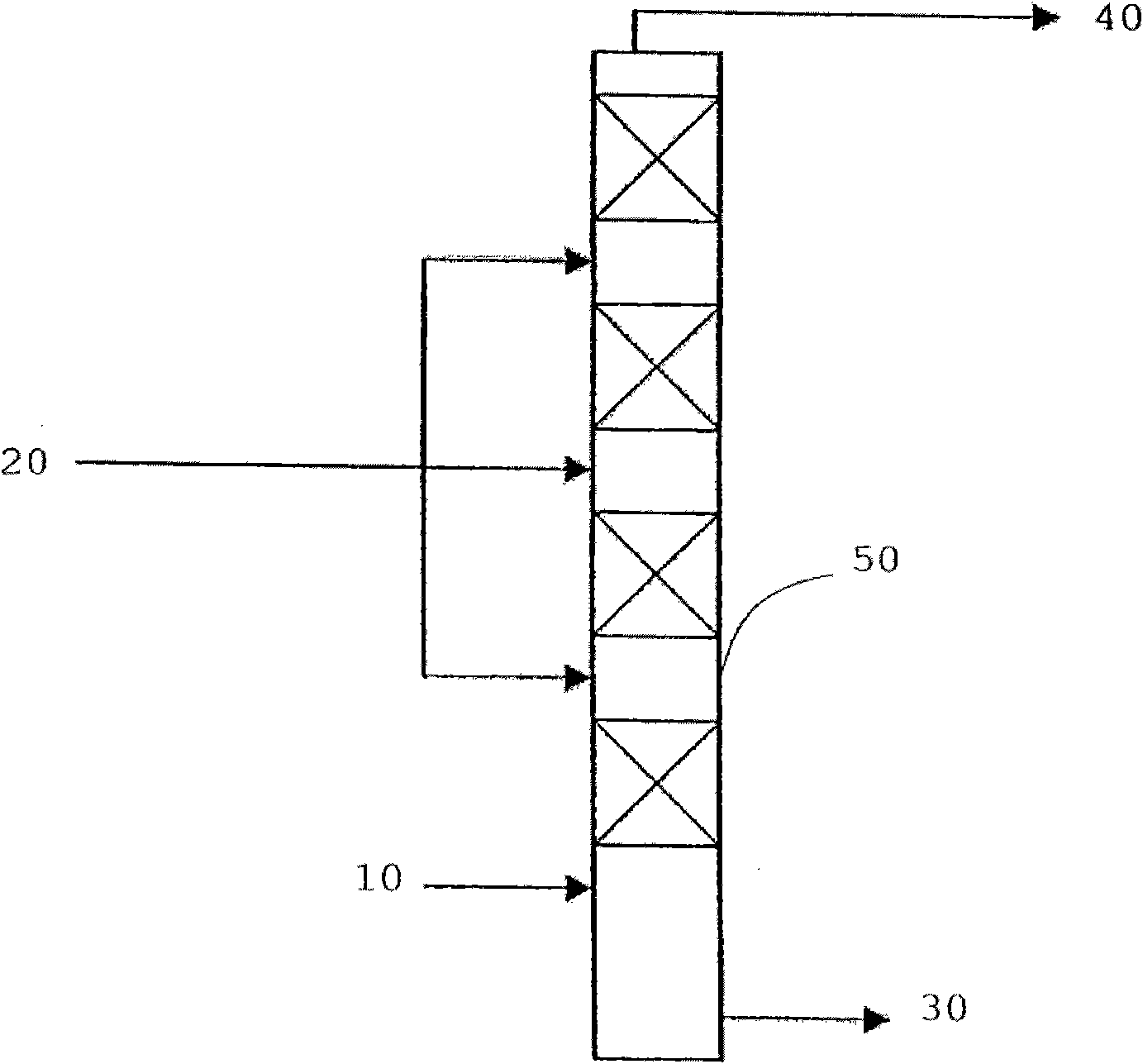

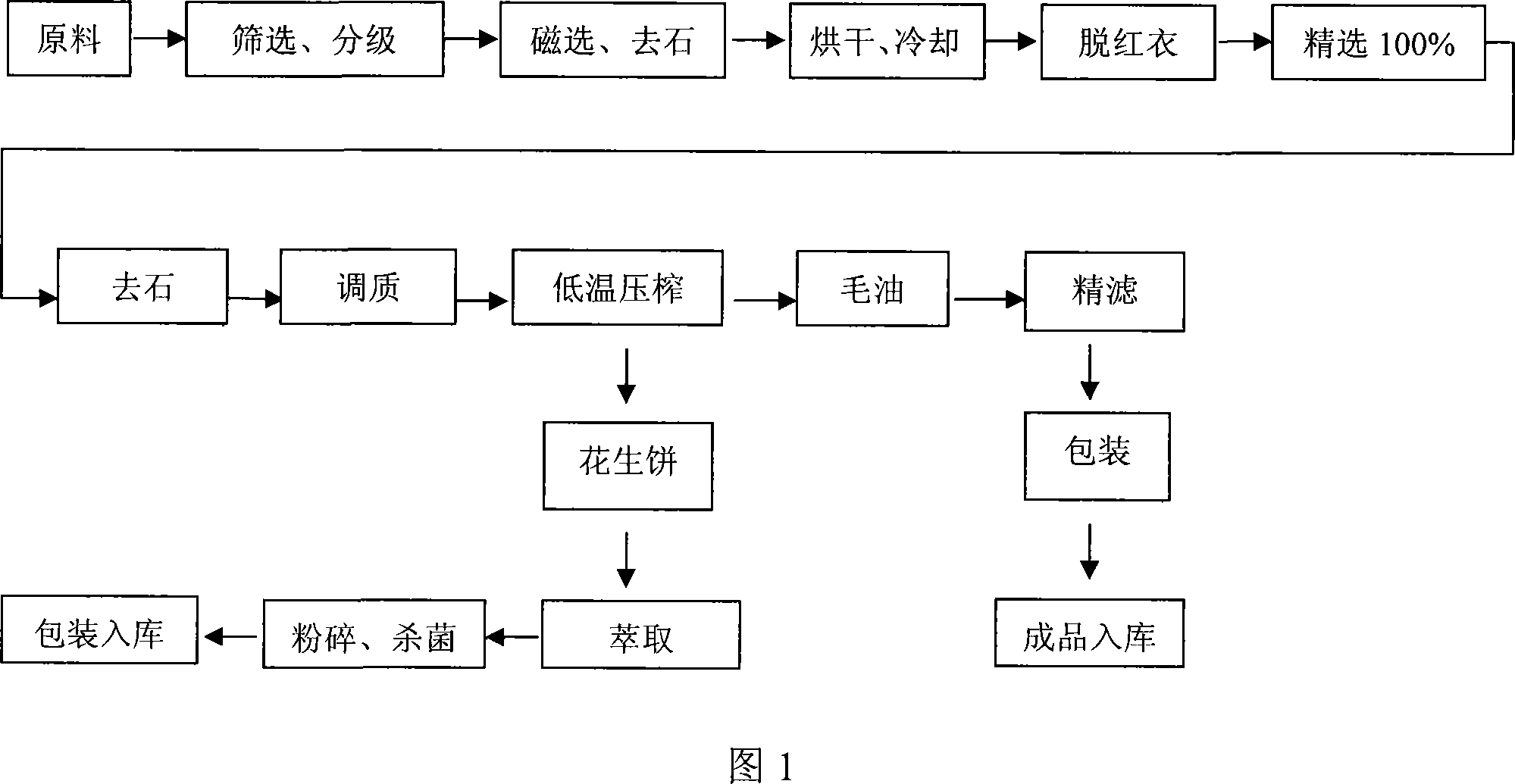

Process for preparing peanut oil and peanut protein powder synchronously

ActiveCN101095435AAflatoxin removalEfficient removalProtein composition from vegetable seedsEdible oils/fatsChemical compositionAdditive ingredient

The invention relates to a method for preparing peanut oil and peanut protein powder simultaneously, which comprises following steps: treating peanut at low temperature, pressing with oil expeller at low temperature and getting crude oil and cake; fine filtering the crude oil and getting peanut oil; extracting said cake at low temperature, ultra-micro disintegrating, disinfecting and getting peanut protein powder. The invention is characterized in that the process is carried out at low temperature, so the nutrition can be maximum retained, and the peanut oil is rich in unsaturated fatty acid, contains no cholesterol, color is light, the phosphatide content is low, and there is no toxic chemical component and residual. The protein is not degenerated, the residual oil content is lower than 1.5%, protein content is more than 55%, and the water and oil retaining property, emulsifying and gel performance are better. The application is wider.

Owner:SHANDONG GAOTANG LANSHAN GRP CORP +1

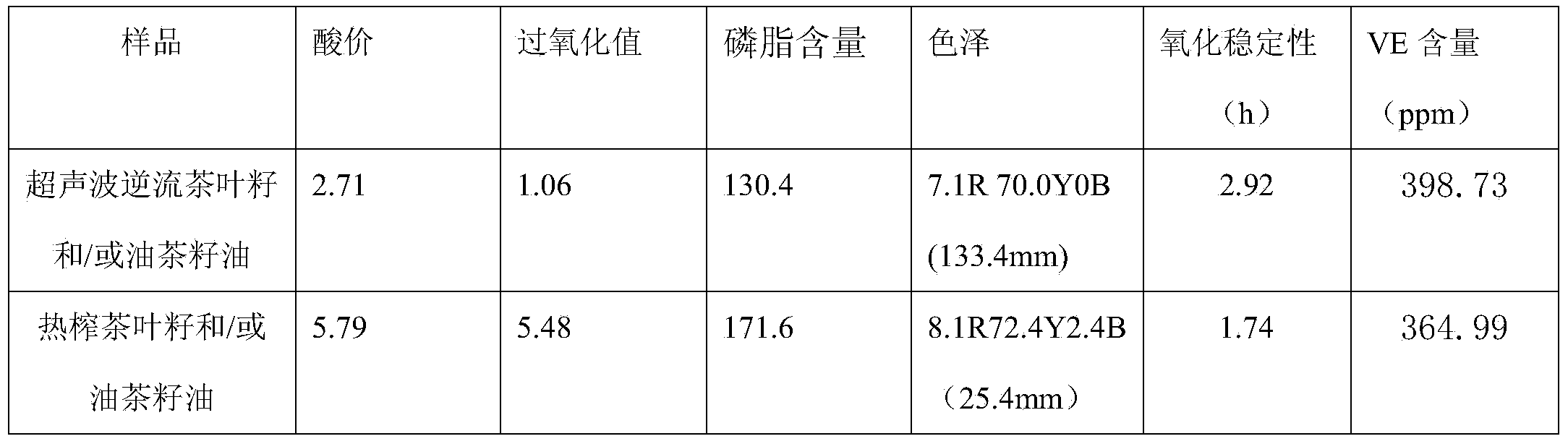

Method for ultrasonic countercurrent extraction of tea seed and/or camellia seed soil

InactiveCN103756783AReduce consumptionReduce energy consumptionFatty-oils/fats productionEdible oils/fatsSlagUltimate tensile strength

The invention discloses a method for ultrasonic countercurrent extraction of tea seed and / or camellia seed soil, and the method comprises the following steps: putting the raw material treated tea seed and / or camellia seed oil into a feed device of a continuous countercurrent ultrasonic leacher, and inputting an extraction agent into the leacher from a slag outlet at the other end, and inputting the material and extraction liquid at the same time, wherein the ultrasonic frequency is 20-25KHz, the ultrasonic intensity is 50-600W, the extraction temperature is 30-60 DEG C, the material-liquid mass ratio is (1:2)-(1:12), and the leaching time is 10-30 minutes; separating to obtain tea seed and / or camellia seed residue and extract liquid; obtaining the tea seed and / or camellia seed raffinate from the slag outlet, and conveying to a solvent recycling system to recycle the extraction agent; obtaining the extraction liquid from a liquid outlet of the continuous countercurrent ultrasonic leacher; separating the tea seed and / or camellia seed crude oil from the extraction liquid while recycling the extraction agent. By adopting the continuous countercurrent ultrasonic technology to extract the tea seed and / or camellia seed crude oil, the method disclosed by the invention has the advantages of simple equipment, low energy consumption, high oil yield, short extraction time, low solvent consumption and the like, and is suitable for large-scale production.

Owner:JIANGNAN UNIV +1

Method for preparing peanut oil by baking and squeezing at low temperature

InactiveCN106883929AGood and strong fragranceStrong fragranceFatty-oils/fats productionFlavorHeat sensitive

The invention provides a method for preparing peanut oil by baking and squeezing at low temperature. The method comprises the following steps: screening, baking at low temperature, squeezing at low temperature, purifying and the like. Through reasonable screening, and baking for deoiling, the quality safety of the peanut oil is improved, and the prepared peanut oil is nutritional, healthy, and better and stronger in fragrance; through strict control over the process temperature, the influence on the heat-sensitive substances in peanuts is relatively small, and the flavor and the nutrition of the peanuts are effectively retained.

Owner:ANHUI HUAYU FLAVORING FOOD

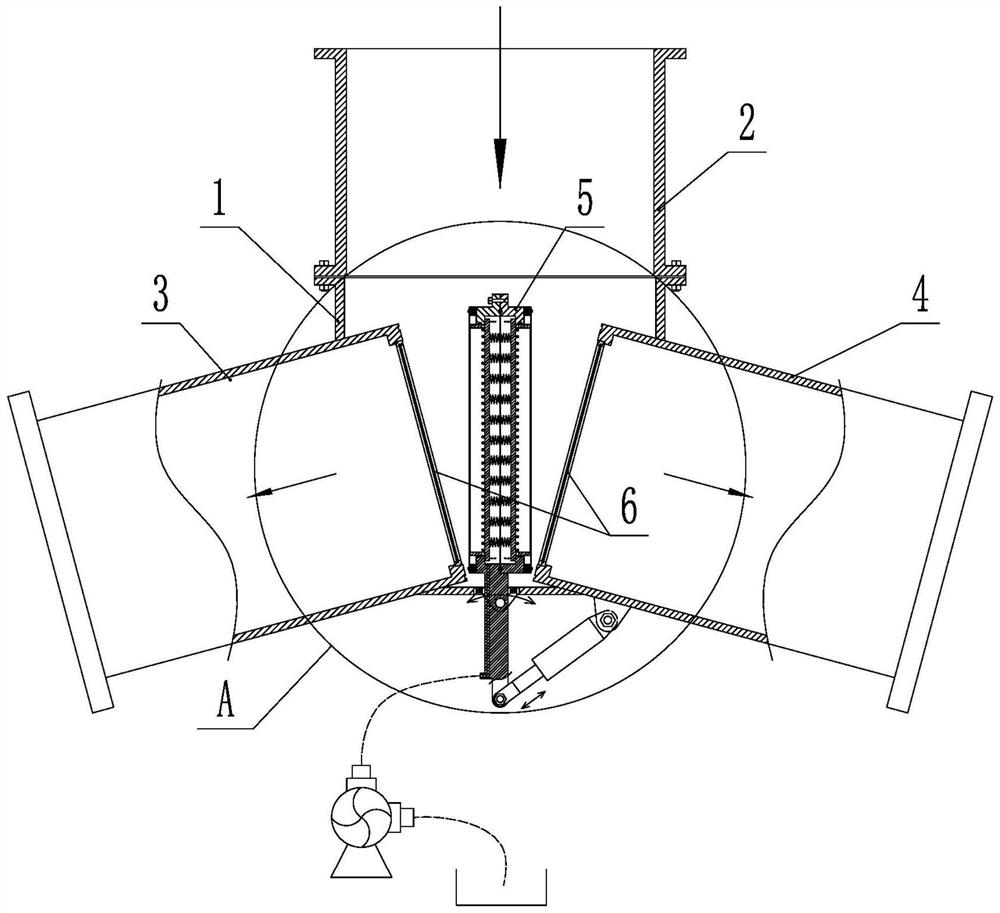

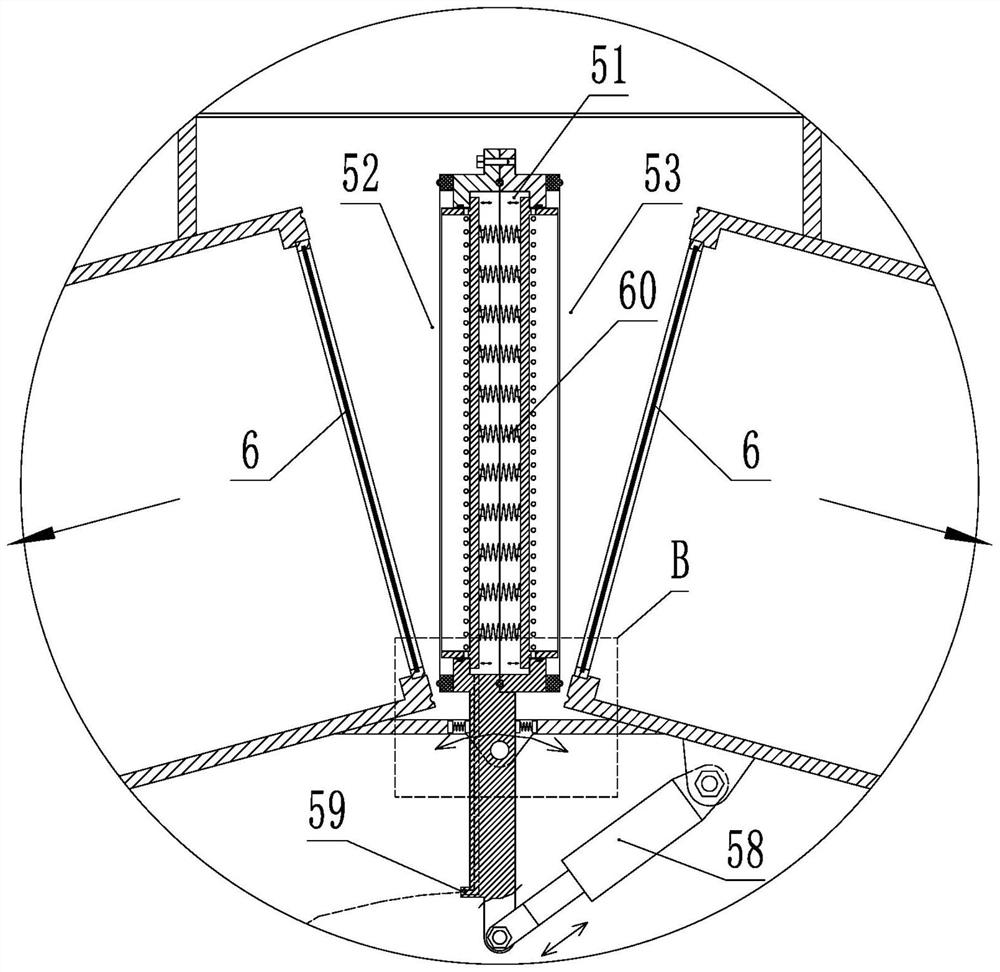

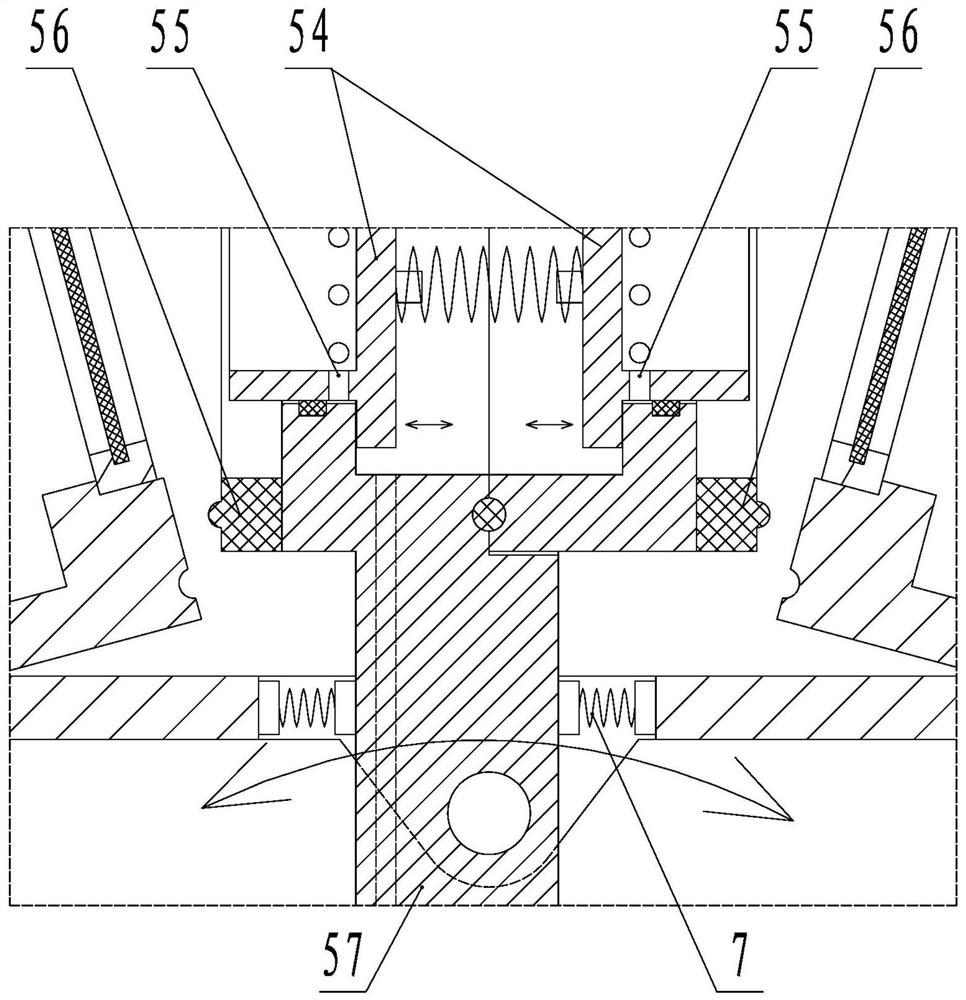

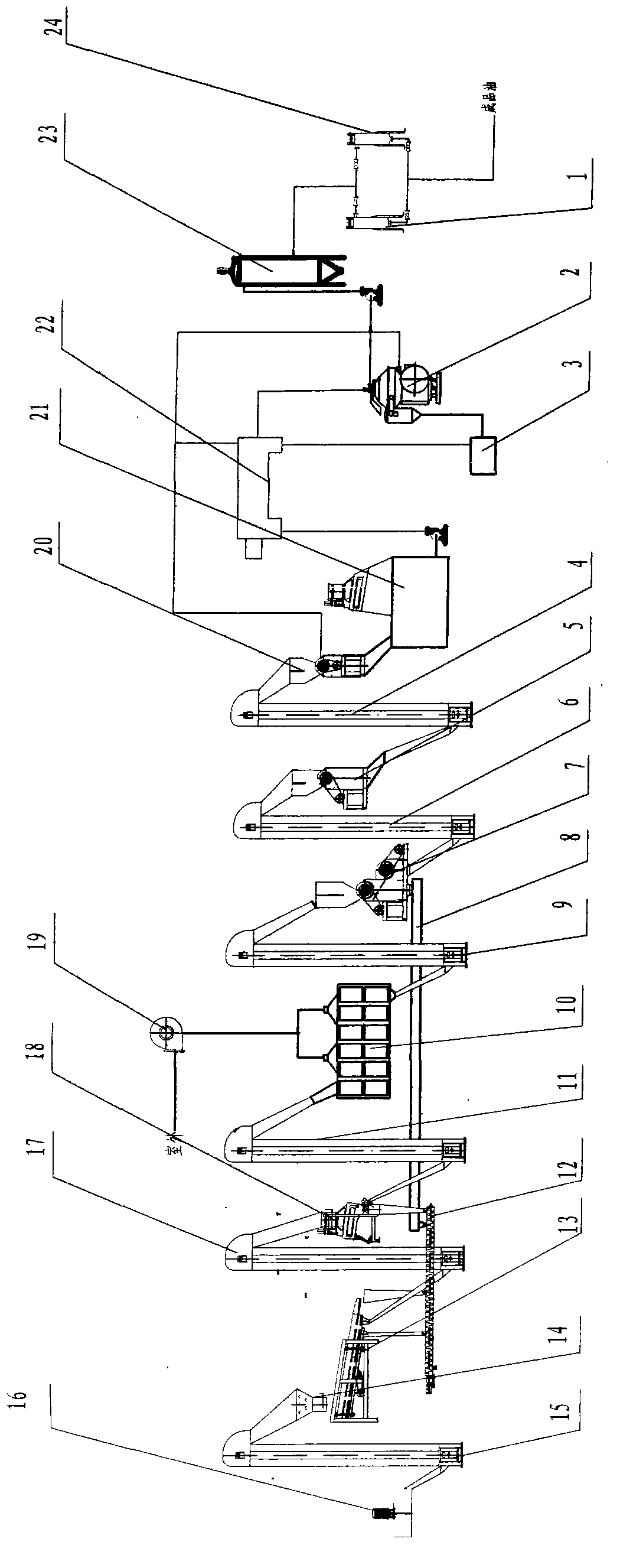

Device and process for purifying fried food waste oil based on continuous mode

ActiveCN111632420AEnsure safetyEasy to recycleFatty-oils/fats refiningMembrane filtersDeep fryingWaste oil

The invention provides a device and process for purifying fried food waste oil based on a continuous mode, and relates to the technical field of edible oil treatment. The device comprises a shell, anoil inlet pipe, a first oil outlet pipe, a second oil outlet pipe, an overturning body located in the shell, and an overturning mechanism; filters are arranged at the oil inlet ends, located in the shell, of the first oil outlet pipe and the second oil outlet pipe; an oil suction cavity is formed in the overturning body, a first oil suction port and a second oil suction port which are communicatedwith each other are formed in the two ends of the overturning body respectively, and valve mechanisms in a normally-closed state are arranged at the first oil suction port and the second oil suctionport respectively; when the overturning body acts, the first oil suction port is attached to the filter at the oil inlet end of the first oil outlet pipe, the valve mechanism at the position is opened, or the second oil suction port is attached to the filter at the oil inlet end of the second oil outlet pipe, and the valve mechanism at the position is opened; and the oil suction cavity is communicated with an external negative pressure pump pipeline. Edible waste oil obtained after deep frying of food is used is subjected to efficient impurity removal treatment, so recycling of the edible waste oil is facilitated.

Owner:湖南银城湘味食品有限公司

Aqueous enzymatic camellia oil extraction method

InactiveCN103805332AStrenuous exerciseHigh purityFatty-oils/fats refiningFatty-oils/fats productionAcid valueWastewater

The invention discloses an aqueous enzymatic camellia oil extraction method. According to the aqueous enzymatic camellia oil extraction method, mechanization of camellia seed unshelling can be realized; camellia seed oil content is high, and reaches 35.0 to 60.0%; camellia seed raw material is subjected to mechanical pulverization, and is mixed with water with a water to camellia seed raw material ratio of 3:1ml / g; extraction temperature is 40 DEG C; and extraction time is 90min. Operation temperature is low; energy consumption is low; the obtained oil is high in purity, low in phospholipid content, light in color, and low in acid value and peroxide value; generated waste water is low in BOD and COD, and is convenient for treatment, and less pollution is caused; the aqueous enzymatic camellia oil extraction method is capable of meeting with demands of 'high efficient, safe, and green'.

Owner:BEIJING ZHONGTIAN JINGU GRAIN OIL ENG TECH

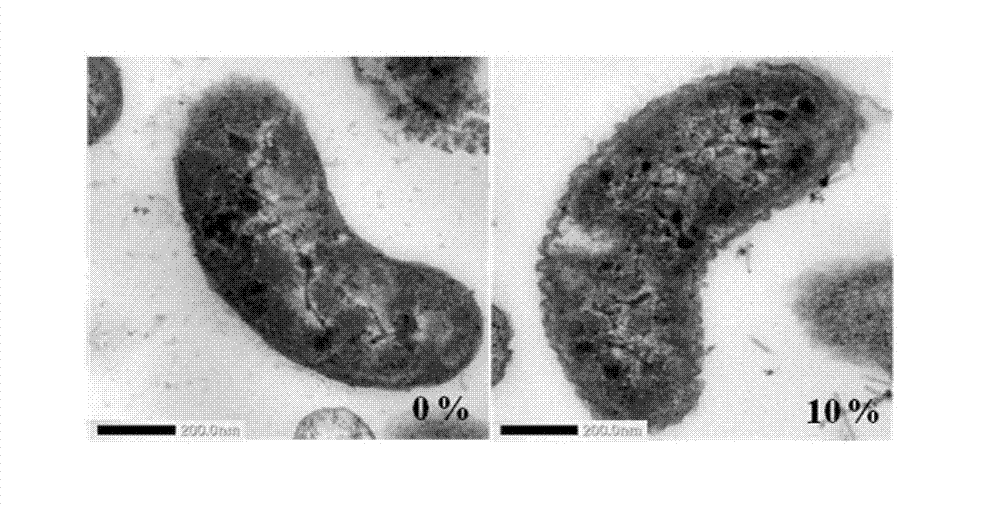

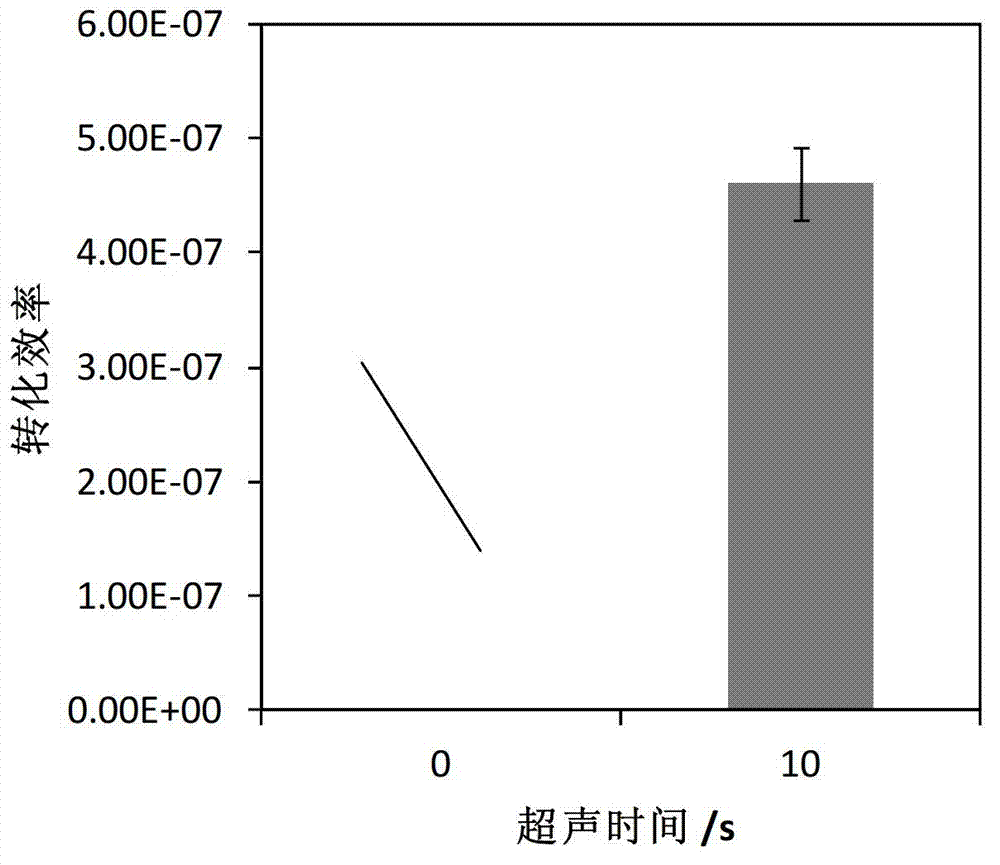

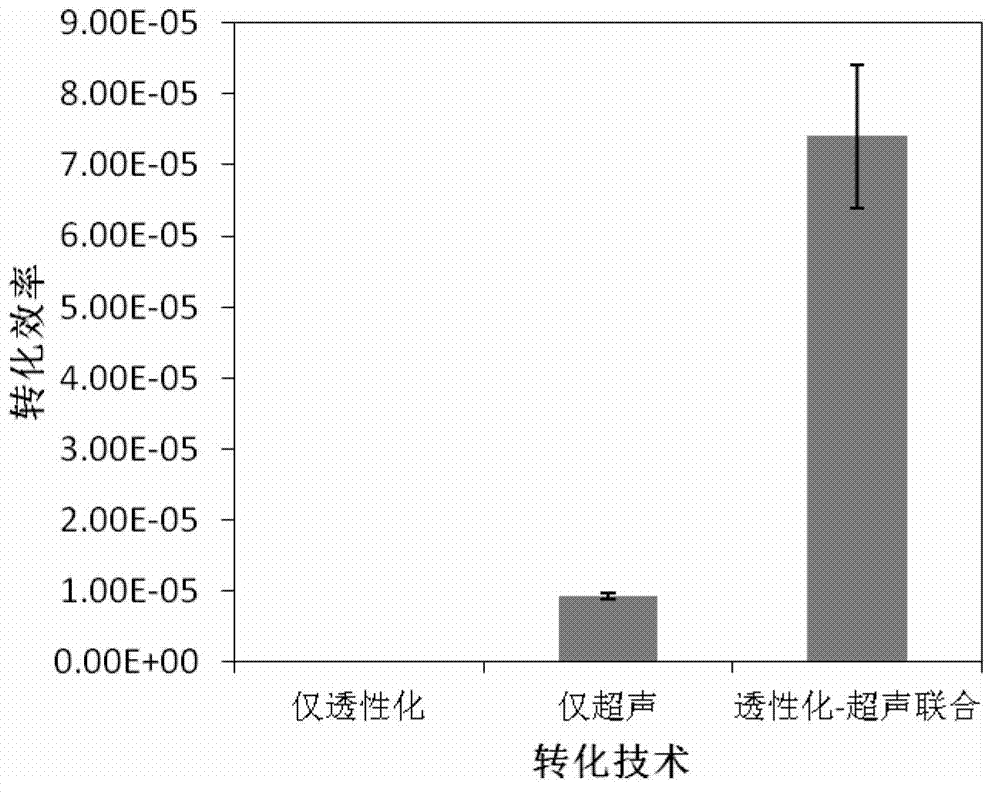

Functional microbial transformation method with combination of permeabilization and ultrasound

InactiveCN103088045ALow in phospholipidsEasy to expandVector-based foreign material introductionMicrobial transformationTransformation efficiency

The invention discloses a functional microbial transformation method with combination of permeabilization and ultrasound. The method comprises the following steps of: permeabilizing microbial cells by a Decon solution to reduce the content of phospholipids in cell walls and cytoplasmic membranes; adding calcium ions to a system during the permeabilization so as to facilitate the sedimentation and the transportation of exogenous DNA (Deoxyribonucleic Acid); and then exerting low-frequency ultrasonic waves of 20-80 kHz to transport the DNA and ribonucleic acid (RNA) to be transformed into the cells. By virtue of the Decon permeabilization, the power of the ultrasound in the ultrasonic transformation can be relatively reduced, the ultrasound time is short, and the damage of the ultrasound to the cells is alleviated; by reasonably choosing a permeabilization reagent and determining corresponding concentration, a medium solution simultaneously meeting the requirements of the permeabilization and the ultrasonic transformation is obtained; and exogenous nucleic acid molecule transformation of host bacteria in a larger range can be realized, and the transformation efficiency is enhanced, so that an effective technological way for genetic engineering transformation and new functional microbial culture is provided, the efficiency is enhanced, and the cost and the operation difficulty are reduced.

Owner:宋一之

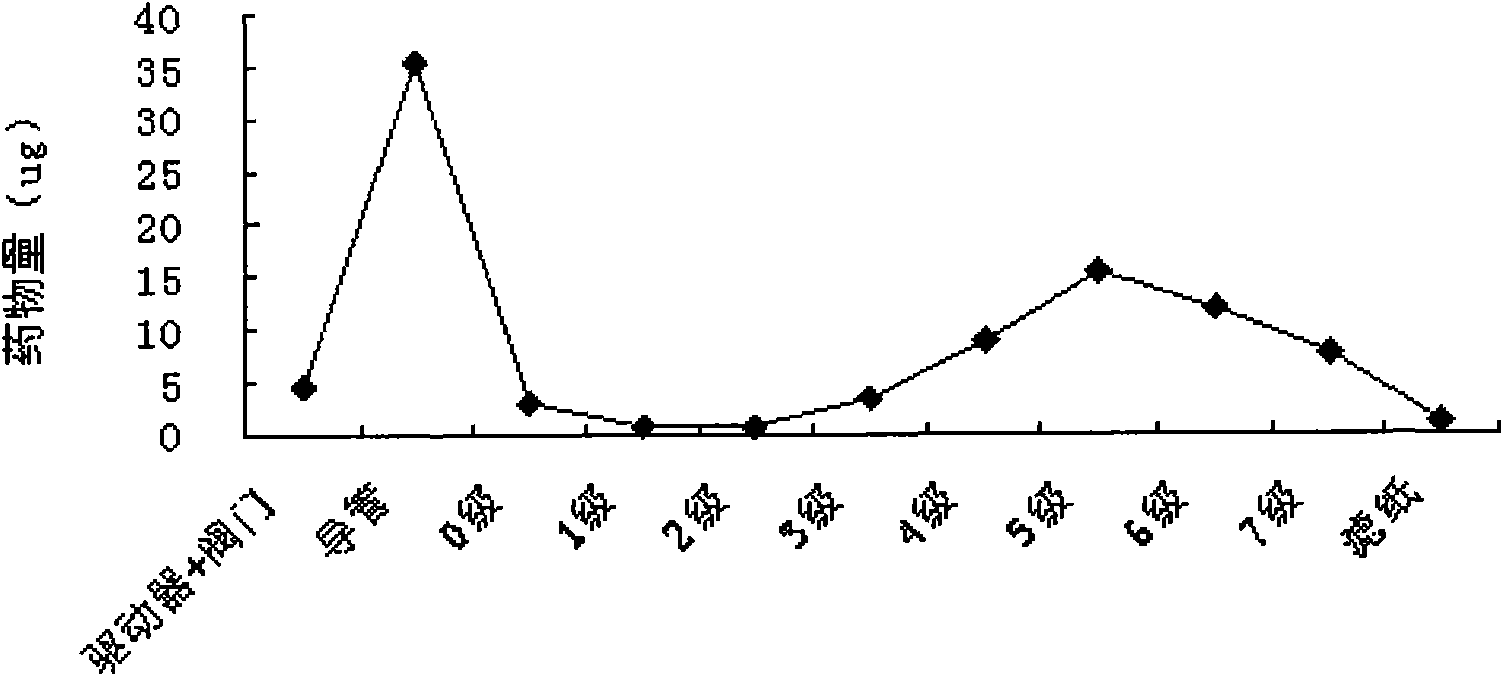

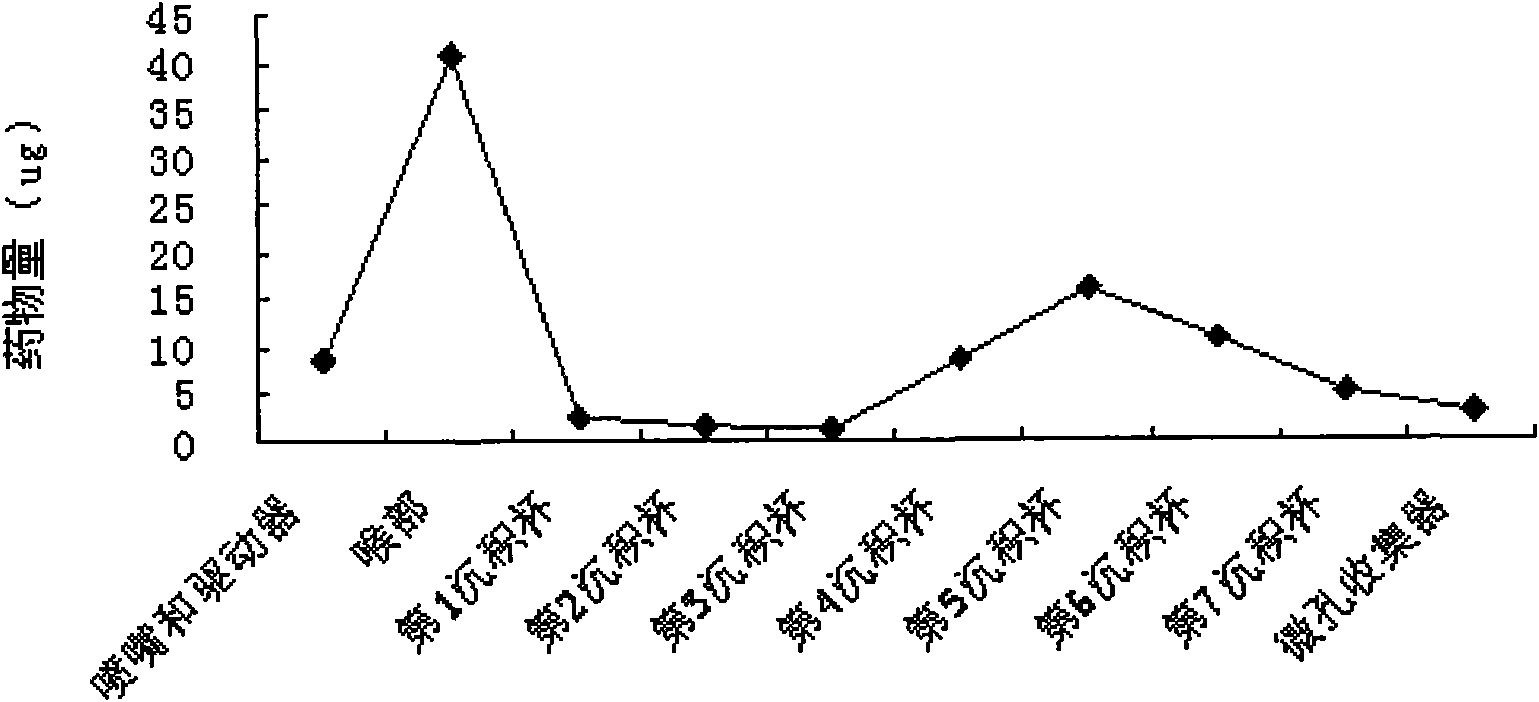

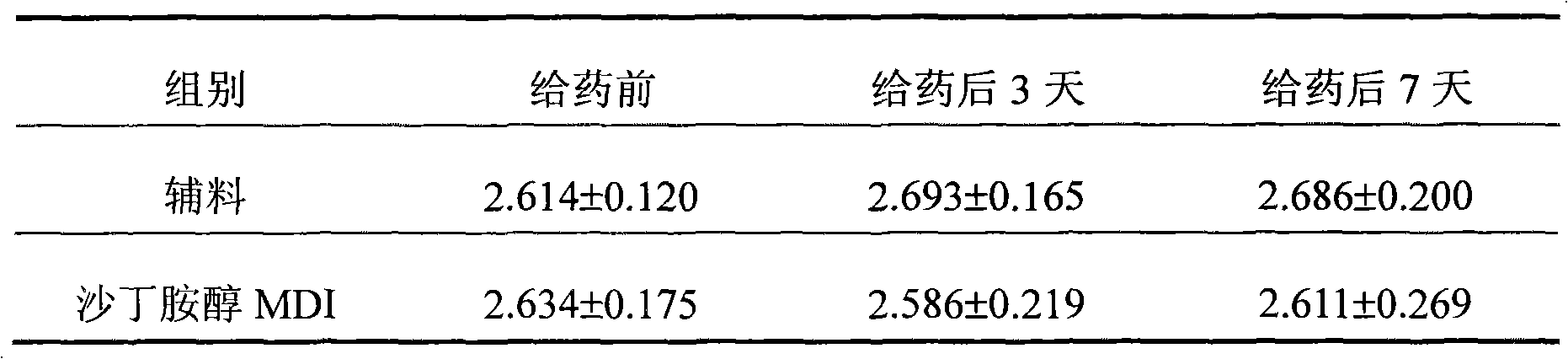

Surface-modified salbutamol suspension type non-Freon inhalation aerosol and preparation method thereof

InactiveCN101889993AGood treatment effectSmall side effectsOrganic active ingredientsAerosol deliverySalbutamolMedicine

The invention discloses a surface-modified salbutamol suspension type non-Freon inhalation aerosol and a preparation method thereof. The surface-modified salbutamol suspension type non-Freon inhalation aerosol contains 0.001%-3% of salbutamol with surface modified by using phospholipid by total weight of the aerosol. The surface-modified salbutamol suspension type non-Freon inhalation aerosol hasthe advantages of convenient use, safety and nonirritant because natural nontoxic phospholipid is used as a surface active agent has great low content, and higher clinical application value.

Owner:扬州市三药制药有限公司 +1

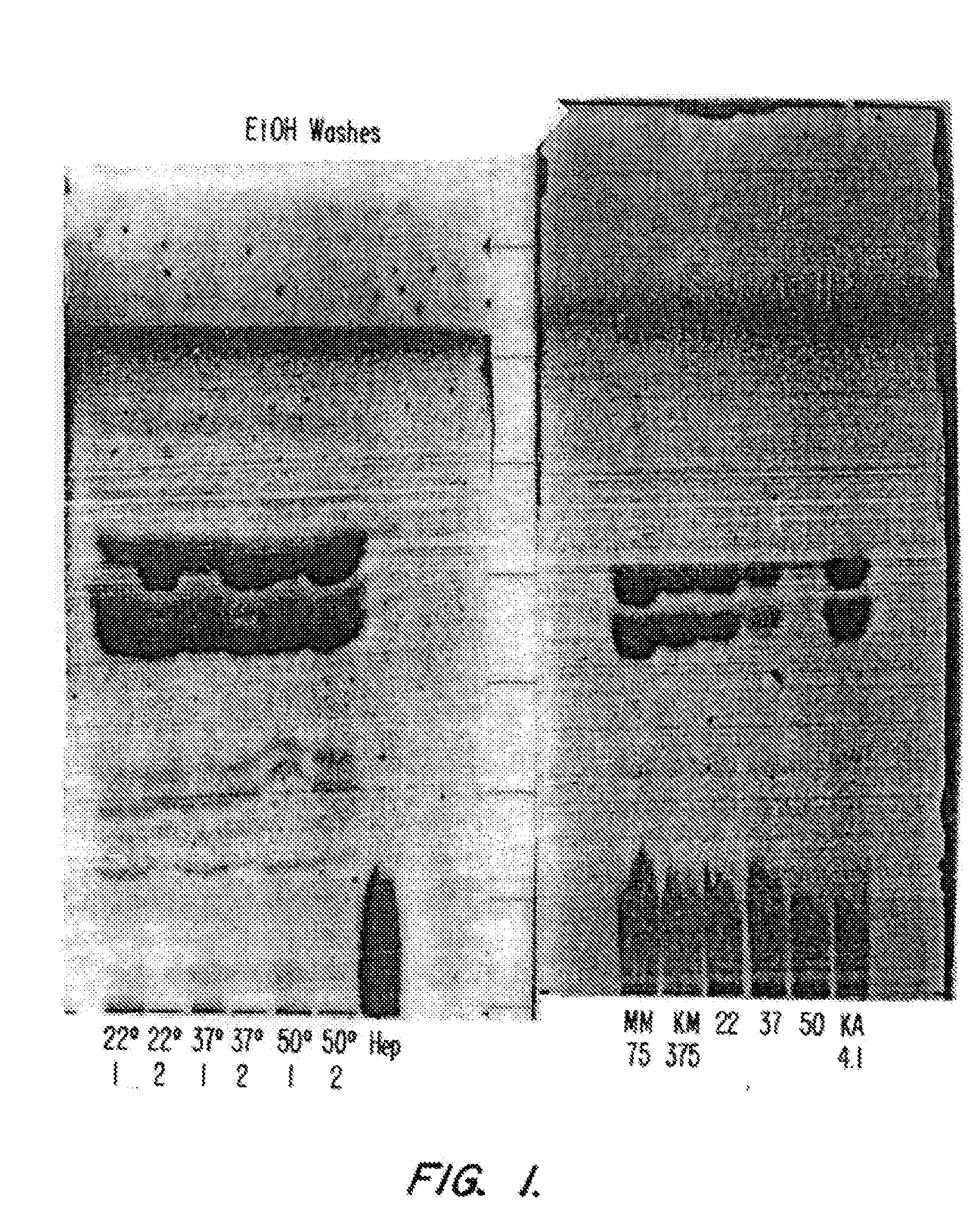

Methods for the production of 3-o-deactivated-4'-monophosphoryl lipid a (3d-mla)

InactiveUS20070212758A1Low in phospholipidsSimple and inexpensive stepEsterified saccharide compoundsOrganic active ingredientsBiotechnologyAcyl group

Herein is disclosed a method for producing lipopolysaccharide (LPS), comprising: (a) growing a culture of deep rough mutant bacterial strain in a medium; (b) maintaining the culture in stationary phase for at least about 5 hr; (c) harvesting cells from the culture; and (d) extracting LPS from the cells. The method allows for the production of an LPS which can be used to produce a 3-O-deacylated monophosphoryl lipid A (3D-MLA) having at least about 20 mol % of the hexaacyl congener group. Also herein is disclosed a method of extracting lipopolysaccharide (LPS) from a culture of deep rough mutant bacterial strain cells, comprising: (a) extracting the cells with a solution consisting essentially of at least about 75 wt % of an aliphatic alcohol having from 1 to 4 carbon atoms and the balance water, thereby producing cells with reduced phospholipid content; and (b) extracting the cells with reduced phospholipid content with a solution comprising chloroform and methanol, thereby yielding a solution of LPS in chloroform and methanol (CM). This method provides LPS solutions in CM that have reduced phospholipid content and are produced by relatively simple and inexpensive process steps.

Owner:CORIXA CORP

Strong-flavor oil enzymatic-process degumming process

The invention discloses a strong-flavor oil enzymatic-process degumming process, is used for solving the problems of relatively large oil product loss, relatively high water content, relatively long degumming time, non-thorough degumming, relatively high phosphorus content, not easy long-term preservation and the like in the prior art, and is characterized in that trace active phospholipase is added in crude oil for degumming, and the process comprises the following specific process steps: measuring the quantity of oil products in a hydration tank with a ruler, calculating the mass of an enzyme required to be added and the mass of soft water required to be added, measuring the temperature of the crude oil, then adding the soft water and the active phospholipase in a stirring heating-up process, stopping stirring, then naturally settling for 2-4 hours, discharging oil foots, starting up a refrigerating unit for cooling hydration oil, starting to filter oil when the temperature is dropped to about 25 DEG C, and completing the process after the oil filtration is completed. The process has the advantages of advanced process, thorough degumming, resource saving, quality improving and the like, and can be widely applied for degumming in a strong-flavor oil production workshop.

Owner:中粮粮油工业(黄冈)有限公司

Degumming process of tuna oil

InactiveCN107699343ALow in phospholipidsGood colorFatty-oils/fats refiningEnzymatic hydrolysisFish oil

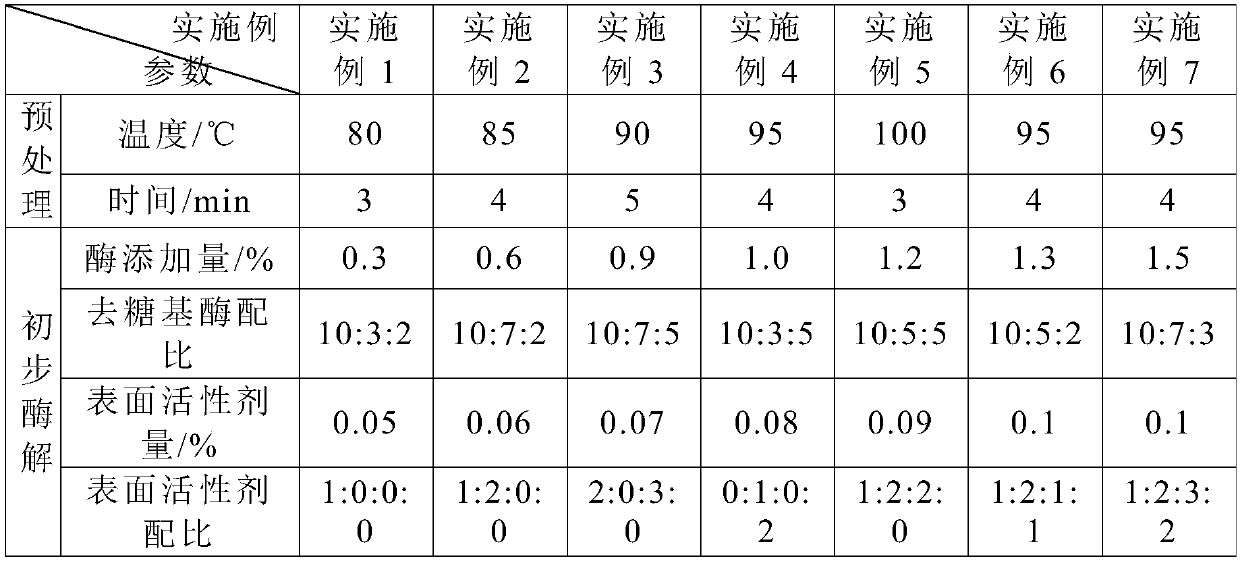

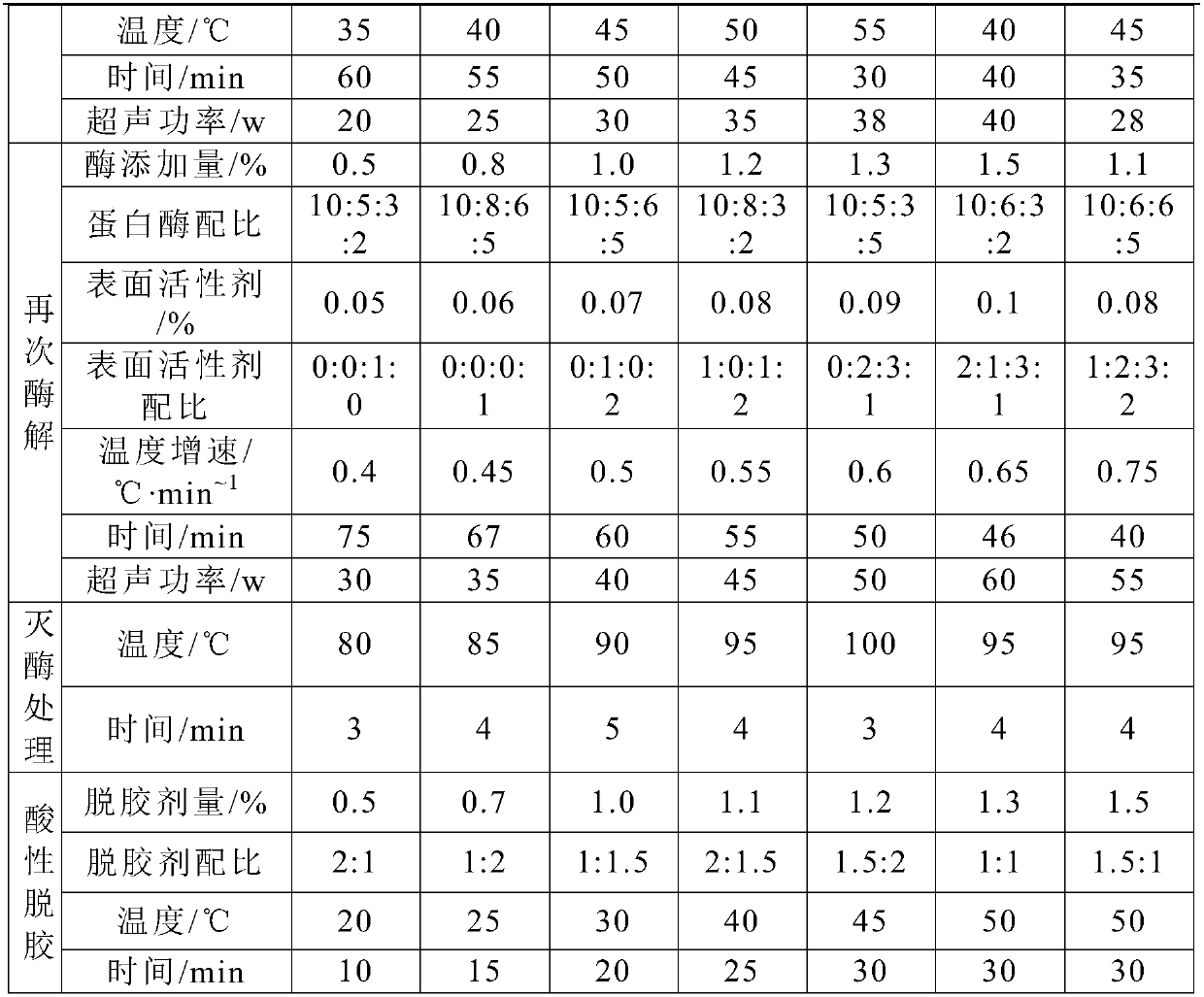

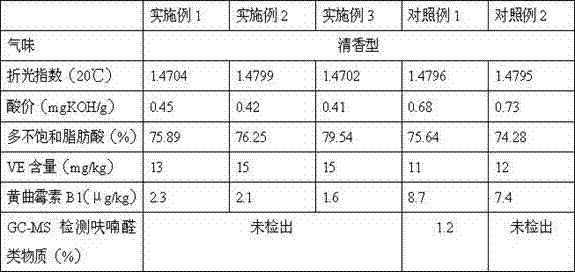

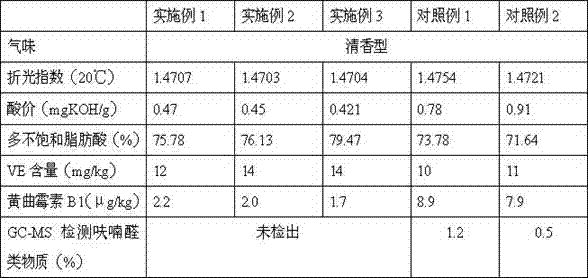

The invention relates to a degumming process of tuna oil, and belongs to the technical field of aquatic product processing. The degumming process comprises the following steps: pretreating tuna crudeoil; adding distilled water into the tuna crude oil after pretreatment, stirring evenly, then adding a compound deglycosylation enzyme, and carrying out preliminary enzymatic hydrolysis, to obtain primary enzymatic hydrolysis fish oil; adding a compound proteinase into the primary enzymatic hydrolysis fish oil, and carrying out enzymatic hydrolysis again, to obtain enzymatic hydrolysis fish oil; heating the enzymatic hydrolysis fish oil, carrying out enzyme inactivation treatment, then cooling to room temperature, centrifuging, and taking an upper floating oily matter, namely the primary degummed fish oil; and adding an acid degumming agent into the primary degummed fish oil, carrying out acid degumming, and then centrifuging to take a supernatant, namely degummed tuna oil. The degumming process has the advantages of mild reaction process, easy control, good degumming effect and high efficiency, and does not destroy the effective nutrient substances in the tuna oil.

Rapeseed oil hydration degumming method

The invention discloses a rapeseed oil hydration degumming method. The method comprises the following steps: heating raw oil of rapeseed oil, which is obtained by performing filtration to remove the residual cake meal, to 80-90 DEG C, storing the heated raw oil in an oil storage tank, and keeping the oil temperature at 80-90 DEG C; preparing a saline solution of 10-15 wt%, heating the saline solution to 80-90 DEG C, storing the heated saline solution in a saline solution tank, and keeping the saline solution temperature at 80-90 DEG C; delivering the raw oil in the oil storage tank to a hydration storage tank at the speed of 0.01-0.03m / s through an oil delivery pipe, adding the saline solution in the saline solution tank to the center of the oil delivery pipe which is 4.0-5.0m away from the hydration storage tank, allowing the raw oil and saline solution to be mixed, and enabling the mixture of the raw oil and saline solution to continuously flow into the hydration storage tank, wherein the speed of addition of the saline solution into the oil delivery pipe is 0.01-0.03m / s; and performing centrifugal separation on the mixture of the raw oil and saline solution in the hydration storage tank to remove gum deposits, thereby obtaining hydration-degummed oil. According to the rapeseed oil hydration degumming method, the saline solution is added to the center of the oil delivery pipe, so the saline solution and oil are uniformly mixed in the pipe, thereby greatly enhancing the hydration efficiency, shortening the hydration time, and greatly reducing the content of phospholipid in the hydration-degummed rapeseed oil.

Owner:成都市新兴粮油有限公司

Processing method for antioxidant fen-flavor peanut oil

InactiveCN107057826AClear colorLow in phospholipidsFatty substance preservation using additivesFatty-oils/fats refiningFlavorMicrowave

The invention relates to a processing method for antioxidant fen-flavor peanut oil and belongs to the technical field of peanut oil finish machining. The processing method comprises the following steps: removing red skins of peanuts, crushing the peanuts, then squeezing peanuts, obtained through microwave treatment, in a low-temperature squeezer to obtain crude oil, and sequentially performing filtering, pickling, low-temperature de-gumming, filtering, vacuum dehydration and anti-oxidation substance adding to obtain antioxidant fen-flavor peanut oil. The peanut oil obtained through the processing method for the antioxidant fen-flavor peanut oil has the advantages that the color is clear, the content of phosphatide is low, and the quality has low probability of changing after long-time storage.

Owner:许星星

Method for extracting suaeda salsa seed oil by adopting deionized water

InactiveCN103756776AReduce pollutionEasy to operateFatty-oils/fats productionEdible oils/fatsCatalytic pyrolysisWater baths

The invention discloses a method for extracting suaeda salsa seed oil by adopting deionized water. The method is operated according to the following steps: 1) grinding, namely grinding suaeda salsa seeds into 60-150 meshes; 2) soaking, namely fully mixing the uniformly-grinded suaeda salsa seed powder with deionized water by a material liquid weight-to-volume ratio of 1:3-1:10, and soaking; 3) pH regulation, namely regulating the pH value to 4.0-6.0; 4) catalytic pyrolysis, namely putting a solid and liquid mixture of which the pH value is regulated into a water bath at 40-65 degrees centigrade for catalytic pyrolysis for 1-5 hours; and 5) centrifugation. After the catalytic pyrolysis reaction, the solid and liquid mixture is centrifuged at a rotating speed of 4000-10000 rpm / min for 10-30 minutes; a centrifuged supernatant oil layer is sucked out, and then the required suaeda salsa seed oil is obtained. The method disclosed by the invention has the advantages of high oil yield, good quality, simple and safe process, high operability and low cost.

Owner:YANCHENG TEACHERS UNIV

Method for extracting acer truncatum fruit edible oil

PendingCN111961525AImprove qualitySimple and fast operationFatty-oils/fats refiningFatty-oils/fats productionBiotechnologyVegetable oil

The invention discloses a method for extracting acer truncatum fruit edible oil, and relates to the technical field of vegetable oil processing. The method comprises the steps: shelling the acer truncatum fruits to obtain acer truncatum seeds, putting the acer truncatum seeds into a low-temperature freezer, carrying out freezing treatment for 30-60 minutes at the temperature from -130 DEG C to -160 DEG C, then, carrying out unfreezing for 2 hours at normal temperature, carrying out drying, then carrying out crushing to 30 meshes, then carrying out enzyme deactivation and enzymolysis, carryingout high-speed centrifugation for 15 minutes at a rotating speed of 9800 r / min, and carrying out separation to obtain the acer truncatum edible oil. The extraction method disclosed by the invention isenvironment-friendly, pollution-free, short in time and high in crude oil quality; the oil extraction process is simple and convenient to operate, oil extraction conditions are mild, protein cannot be damaged, the acid value, the phospholipid content and the peroxide value of the extracted oil product are low, a water layer and residues obtained after centrifugal separation contain recyclable substances such as soluble polysaccharide, protein and tea saponin, and compared with a traditional process, the method reduces sewage and waste.

Owner:中科广化(重庆)新材料研究院有限公司 +1

Modified cocoa product and process for its manufacture

InactiveUS8197877B2Improved wettability factorLow in phospholipidsCocoaFood preparationPhospholipidFood science

Owner:NESTEC SA

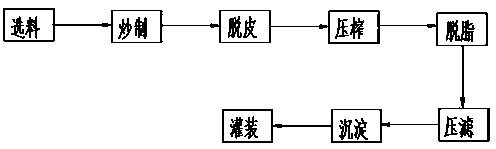

Preparation process of peanut oil

InactiveCN109294728APreserve the flavorRetain nutritionFatty-oils/fats refiningFatty-oils/fats productionFlavorVegetable oil

The invention relates to a preparation process of peanut oil and belongs to the technical field of plant oil preparation. The preparation process of the peanut oil comprises the following steps of material selection, frying, peeling, squeezing, degreasing, press-filtering, settling and filling. The preparation process of peanut oil combines low-temperature squeezing with sectional intermittent pressurizing, the obtained peanut oil can retain thermosensitive functional active materials, effectively preserve flavor and nutrition of peanuts and improve the quality of the peanut oil; the peanut oil is nutritive, healthful and rich in flavor; after peanuts are fried, low-temperature airflow is applied to accelerating cooling and meanwhile replenishing water content to reduce influence of subsequent hot roller pressing, effectively reduce lecithin content, improve the oil extraction rate, accelerate cooling and meanwhile replenish part of the moisture content, thereby reducing influence of pressing in a heating roller crusher; besides, by combining physical mixing and multiple filtering, the lecithin content can be effectively reduce, and the oil extraction rate can be improved; during preparation, no chemical agent is added, so that good safety and high quality of the peanut oil can be achieved.

Owner:青岛佳禾味真源食品有限公司

Method for refining silybum marianum seed oil by enzymic-method degumming

InactiveCN102936533BLow degumming temperatureQuality improvementFatty-oils/fats refiningSILYBUM MARIANUM SEED OILPhospholipin

The invention discloses a method for refining silybum marianum seed oil by enzymic-method degumming and relates to the technical field of oil refining. The method includes the following steps: squeezing or leaching silybum marianum seeds to prepare silybum marianum seed oil, utilizing the principle that suspension impurities and oil have different densities to separate the impurities and the oil under the standing state or placing the silybum marianum seed oil into a 50 DEG C drying box for 1h, filtering to prepare crude oil, degumming the silybum marianum seed oil through phospholipase and conducting deacidification, decoloration and deodorization to obtain the refined silybum marianum seed oil. The enzymic-method degumming method adopts key technology for refining of the silybum marianum seed oil, remarkably reduces phospholipid content in the degummed silybum marianum seed oil, and is high in degumming efficiency, mild in reaction condition, low in energy consumption and easy to control. Silica gel is utilized as adsorbent to conduct decoloration and deodorization processing, high temperature vacuum decoloration and high temperature vacuum deodorization processing in the prior art are avoided, loss of effective components in the silybum marianum seed oil is reduced, and process flow is shortened.

Owner:JIANGSU UNIV

Method for extracting tea seed oil by using enzymatic hydrolysis method

ActiveCN102061217BHigh purityLight colorFatty-oils/fats productionOil and greaseEnzymatic hydrolysis

The invention discloses a method for extracting tea seed oil by using an enzymatic hydrolysis method, which comprises the following steps of: airing, unshelling, husking and pulverizing tea seeds; carrying out enzymolysis on the tea seeds in the material-liquid ratios of 1:3 to 1:5 at the extraction temperature of 40-60 DEG C for 1-5h with the enzyme quantity of 40-600U under the pH natural condition; centrifugally layering; adding an organic solvent into centrifugal liquid and extracting; and rotating and evaporating to obtain an oil sample. By adopting the scheme, the method has the advantages of low temperature for equipment operation, low energy consumption, high purity of extracted oil, low content of phospholipid, low acid value and low peroxide value, shallow color, low BOD (Biochemical Oxygen Demand) and COD (Chemical Oxygen Demand) values, easiness of treatment and less pollution, and the oil yield ratio is up to 23.1 percent.

Owner:HUAQIAO UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com