Degumming process of tuna oil

A technology of tuna oil and tuna, which is applied in the direction of fat oil/fat refining and fat production, which can solve the problems of deep color of degummed oil and low degumming rate, and achieve the effect of color improvement, good degumming effect and mild reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

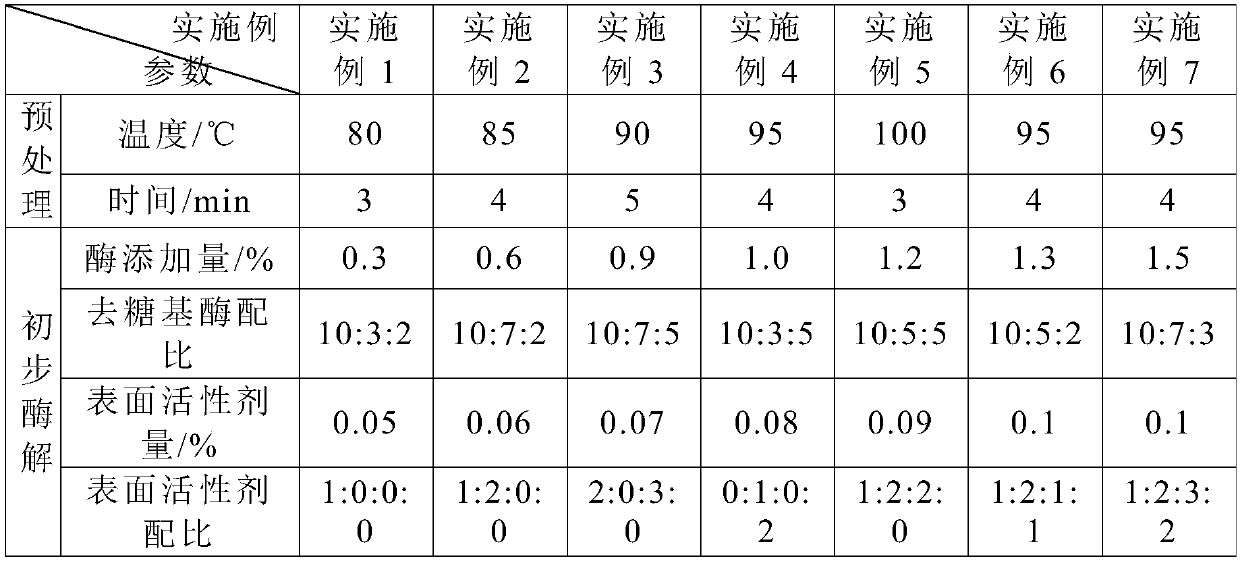

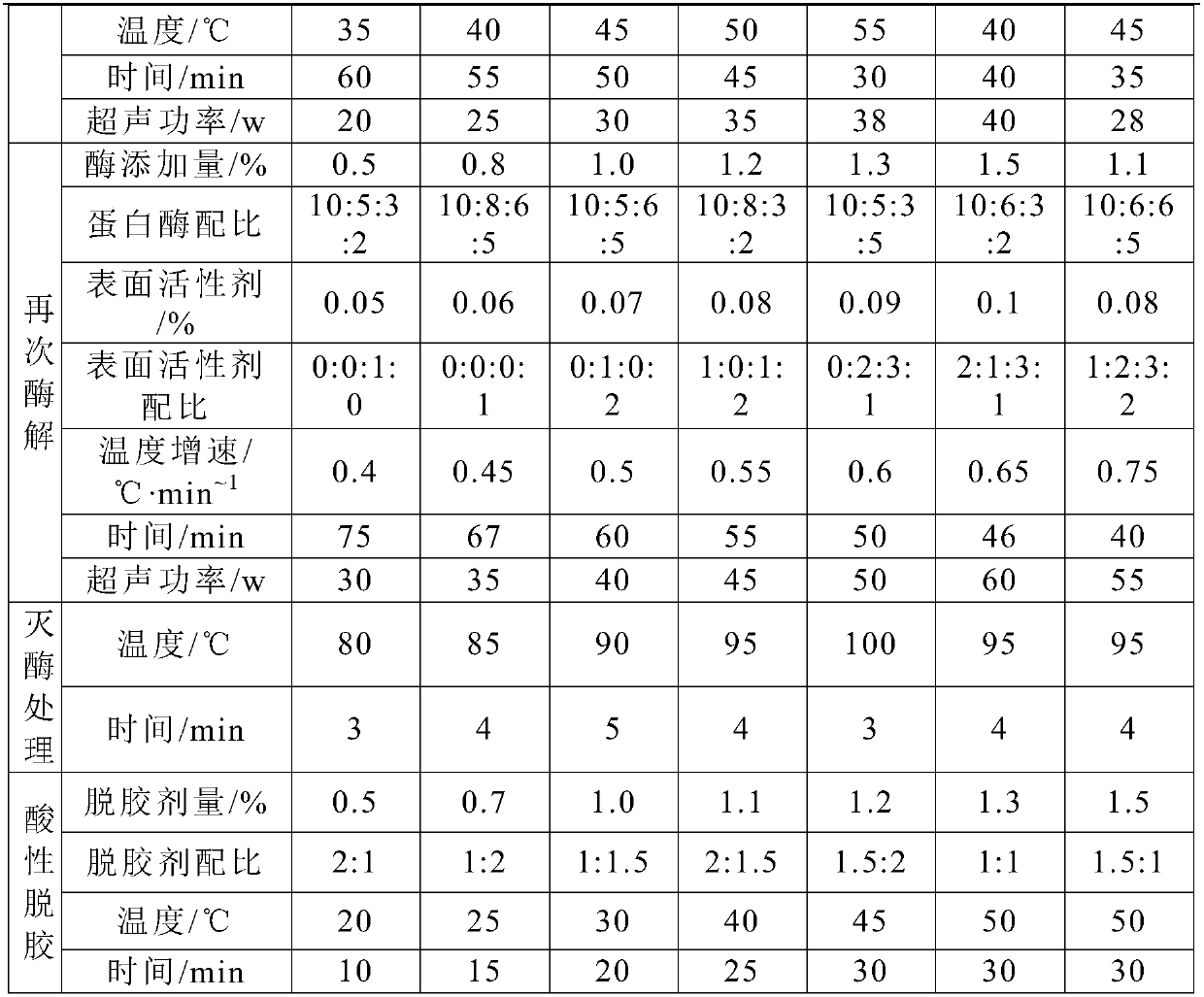

[0040] Degumming process among the present invention comprises the following steps:

[0041] Heat the crude tuna fish oil to 80-100°C for pretreatment for 3-5 minutes, add distilled water to the crude tuna fish oil at a volume ratio of 1:(1-3), and stir evenly;

[0042] Then add 0.3-1.5% compound deglycosylase and 0.05-0.1% surfactant based on the weight of tuna crude fish oil, and carry out preliminary enzymolysis with ultrasonic-assisted stirring for 30-60 minutes at 35-55°C to obtain preliminary enzymolysis fish oil , the compound deglycosylase is a mixture of exoglycosidase, endoglycosidase and glucosaminidase with a weight ratio of 10:(3~7):(2~5), the ultrasonic frequency is 26KHz, and the ultrasonic power is 20~ 40w;

[0043] Add 0.5-1.5% compound protease and 0.05-0.1% surfactant to the preliminary enzymatic hydrolysis fish oil, and control the temperature to rise from 35°C to 65°C at a speed of 0.4-0.75°C / min, assisted by ultrasound Stir and carry out enzymolysis aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com