Preparation process of peanut oil

A preparation process and technology of peanut oil, applied in the direction of fat oil/fat refining, fat production, fat oil/fat production, etc., can solve the problems of ineffective utilization of peanut protein, destruction of oil nutrients, affecting product nutritional quality, etc., to achieve aroma Better richness, reduced phospholipid content, flavor and nutrition retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

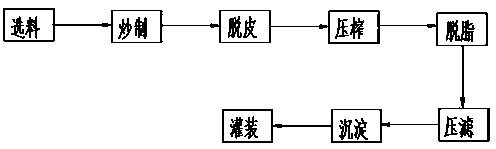

[0028] Such as figure 1 Shown, a kind of preparation technology of peanut oil comprises the following steps: material selection-frying-peeling-pressing-skimming-press filtration-precipitation-filling, specifically as follows:

[0029] Use a combination of mechanical and manual methods to remove impurities and defective products in peanut raw materials. Frying is carried out in a spiral electric frying furnace. The frying process adopts two-stage heating to avoid damage to the nutrients in the peanut raw materials. Among them, the temperature of the first stage is controlled at 80 ° C, and the constant temperature is heated for 10 minutes. The temperature is controlled at 100°C, heated at a constant temperature for 15 minutes, and the water content of the peanut raw material is controlled below 3.5%. The roasted peanut raw materials are placed at room temperature, and cooled rapidly by air flow with a temperature of 25°C and a humidity of 40%, so as to avoid the interior of th...

Embodiment 2

[0032] The same part of this embodiment and Embodiment 1 will not be described again, the difference is:

[0033] A preparation process of peanut oil, comprising the following steps: material selection-frying-peeling-pressing-degreasing-press filtration-precipitation-filling, specifically as follows:

[0034] Use a combination of mechanical and manual methods to remove impurities and defective products in peanut raw materials. Frying is carried out in a spiral electric frying furnace. The frying process adopts two-stage heating to avoid damage to the nutrients in the peanut raw materials. Among them, the temperature of the first stage is controlled at 90 ° C, and the constant temperature is heated for 8 minutes. The temperature is controlled at 110°C, heated at a constant temperature for 12 minutes, and the moisture content of the peanut raw material is controlled below 3.5%. The roasted peanut raw materials are placed at room temperature and rapidly cooled by air flow at a t...

Embodiment 3

[0037] The same part of this embodiment and Embodiment 1 will not be described again, the difference is:

[0038] A preparation process of peanut oil, comprising the following steps: material selection-frying-peeling-pressing-degreasing-press filtration-precipitation-filling, specifically as follows:

[0039] Use a combination of mechanical and manual methods to remove impurities and defective products in peanut raw materials. Frying is carried out in a spiral electric frying furnace. The frying process adopts two-stage heating to avoid damage to the nutrients in the peanut raw materials. Among them, the temperature of the first stage is controlled at 100 ° C, and the constant temperature is heated for 5 minutes. The temperature is controlled at 120°C, heated at a constant temperature for 10 minutes, and the water content of the peanut raw material is controlled below 3.5%. The roasted peanut raw materials are placed at room temperature, and cooled rapidly by air flow with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com