Method for preparing blowfish can

A production method and technology for puffer fish, which are applied in the directions of processing fish, peeling fish, food preparation, etc., can solve the problems of difficulty in maintaining the delicious taste of puffer fish, difficulty in maintaining freshness for a long time, and impact on eating effect, and achieve shortening time. The effect of heating time, avoiding cooking odor, and food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] According to the above-mentioned canned puffer fish production process, a certain manufacturer tested and produced canned products with significantly better quality and taste than traditional products. The details are as follows:

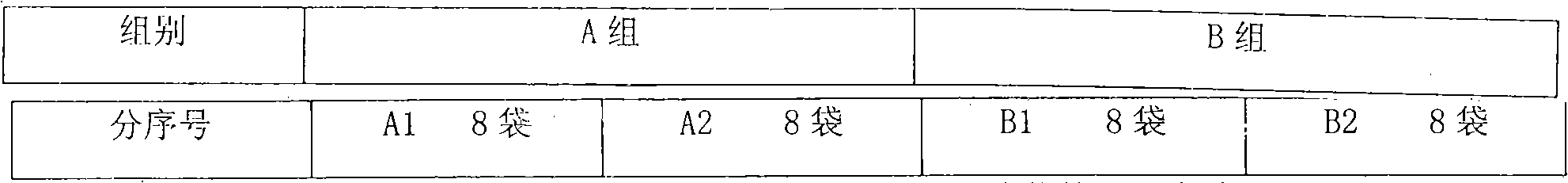

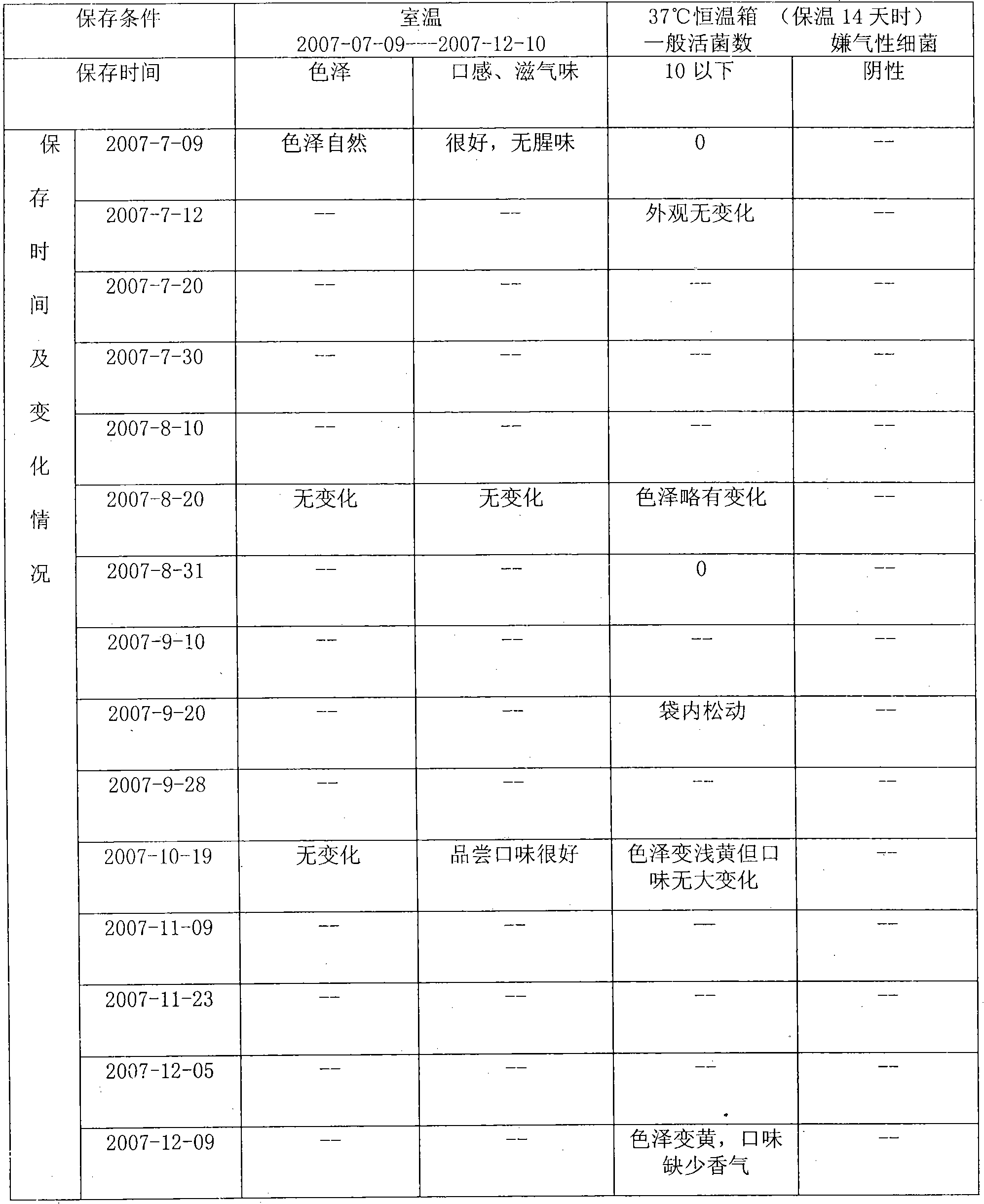

[0049] The selected raw materials were 32 boy puffer fish, divided into two groups A and B with different test conditions, 16 in each group, 8 were stored at room temperature, and 8 were stored at a constant temperature of 37°C, and 4 of them were vacuum-sealed in transparent high-temperature cooking bags. Two bags at room temperature and two bags at constant temperature were used for color observation, and the changes are shown in the table below:

[0050]

[0051] 2007-07-09-2007-12-08 Observation results of microbiological testing on puffer fish samples

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com