Patents

Literature

97 results about "Canned fish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Canned fish are fish which have been processed, sealed in an airtight container such as a sealed tin can, and subjected to heat. Canning is a method of preserving food, and provides a typical shelf life ranging from one to five years.

Canned abalones and production method thereof

The invention relates to canned abalones and a production method thereof. The canned abalones comprise 50 to 60 percent of abalone meat and 40 to 50 percent of flavoring soup blend. The manufacturing method comprises the following steps: removing mantles, horny jaw plates and melanin on peripheries of feet from the fresh and live abalones and washing the abalones; placing the abalones into 80 to 90 DEG C hot water and cooking the abalones for 3 to 8 minutes, taking meat, removing organs and rims and washing the meat; placing the meat in 0.1 to 0.5 percent solution of citric acid and performing color retention treatment at 75 to 85 DEG C for 20 to 30 minutes; soaking the meat in water for 2 to 2.5 hours; weighing pettitoes, lean pork, mutilated meat of old hens, pork large tripe, ginger, green onion, cooking wine and water to stew stock; mixing the stock, minor ingredients and pure water and heating the mixture to prepare the flavoring soup blend, wherein according to a standard of the weight of the pure water, the weight of the stock is 1 to 3 percent of that of the pure water and the minor ingredients comprise 0.6 to 1 percent of edible salt, 0.2 to 0.6 percent of sugar, 0.1 to 0.3 percent of abalone essence, 0.03 to 0.05 percent of iso-vitamin C sodium, 0.01 to 0.02 percent of citric acid, 0.03 to 0.06 percent of composite phosphate and 0.01 to 0.015 percent of nisin; and canning the abalone meat and the flavoring soup blend, exhausting air, and sealing and sterilizing the abalone meat and the flavoring soup blend. The canned abalones have rich nutrients, complete individuals, a yellow and bright color and a long shelf life. The manufacturing method of the canned abalones is reasonable in process and feasible in operation.

Owner:TAIXIANG GRP TECH DEV

Preparation method of canned sardines

The invention discloses a preparation method of canned sardines, comprising the steps of taking sardines as raw material, canning and cooking the sardines, filling soup and sealing, and finally, performing pre-sterilization and electron beam secondary sterilization so as to realize full sterilization on the basis of keeping the original taste. The canned sardines prepared by the preparation method of canned sardines, provided by the invention, the original rich nutrient contents of the seafood are kept and various nutrient contents are added, has no added preservative in the can and is a green health food, and can be preserved for a long time, thus satisfying the needs of human life.

Owner:ZHEJIANG MARINE DEV RES INST

Method for preparing blowfish can

InactiveCN101301092AAccelerateHigh temperature control accuracyFish washing/descalingMeat/fish preservation by heatingNutrientPre treatment

The invention relates to a method for making globe fish can, including the following steps: material preprocessing, cutting, soup stock production, mixing, canning, pre-boiling, sealing, sterilization, cooling, casing. The key technology of the method is adopting the wave-type hot water injection of an automatic spraying sterilizer and the temperature rise regulating sterilization in multi-stage. The making method has a strict and general sterilization to the globe fish materials, makes use of the advanced processing devices, temperature rise regulating sterilization in multi-stage and reasonable making technology. The can products are not only safe, nutrient, but also maintain the natural taste of the globe fish.

Owner:刘烈

Method for fabricating canned fish from tilapia wastes

InactiveCN103844282ARich industrialized productsImprove utilization of whole fishFood preparationChinFlavor

The invention discloses a method for fabricating canned fish from tilapia wastes. The method comprises the following steps: collecting raw materials; cleaning raw materials; pickling; frying; seasoning and softening; bagging and vacuum sealing; and sterilizing and packaging. By adopting the method disclosed by the invention, a traditional treatment mode of the tilapia wastes is broken through; the fish chin part is effectively separated from the tilapia wastes; the canned fish with a unique flavor is prepared by a series of treatment. Thus, the utilization rate of the overall fish is improved by 8%, the industrialized tilapia products are enriched, and a precedent is made for efficient utilization of the tilapia mossambica.

Owner:GUANGZHOU LUSHI FOOD CO LTD

Production method of air-dry fish can

InactiveCN101254002AUnique flavorNo effect on healthMeat/fish preservationFood preparationFish FlavorDried fish

The invention relates to a manufacturing method of an air-drying canned fish. The method is characterized in that the manufacturing method of the air-drying canned fish includes the following steps that are (1) fishes processing, (2) seasoning and salting, (3) air drying, (2) secondary seasoning, (5) can filling, (6) processing in vacuum, (7) ripening, (8) crisping, (9) sterilizing, and (10) packing. The manufacturing method of the air-drying canned fish has simple manufacture, green environmental protection, fish flavor maintenance, food safety, nutrition, and hygiene.

Owner:梁森德 +1

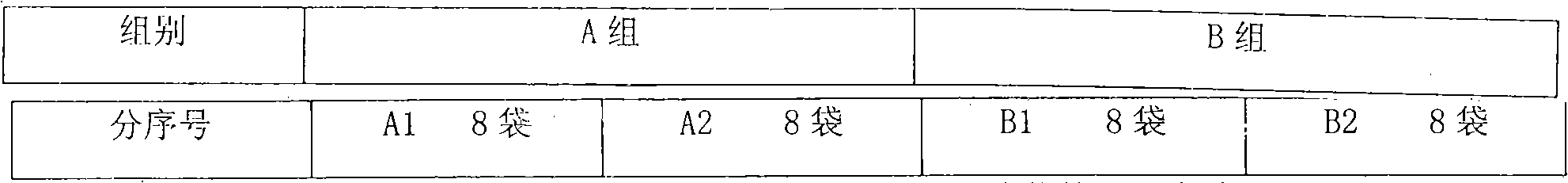

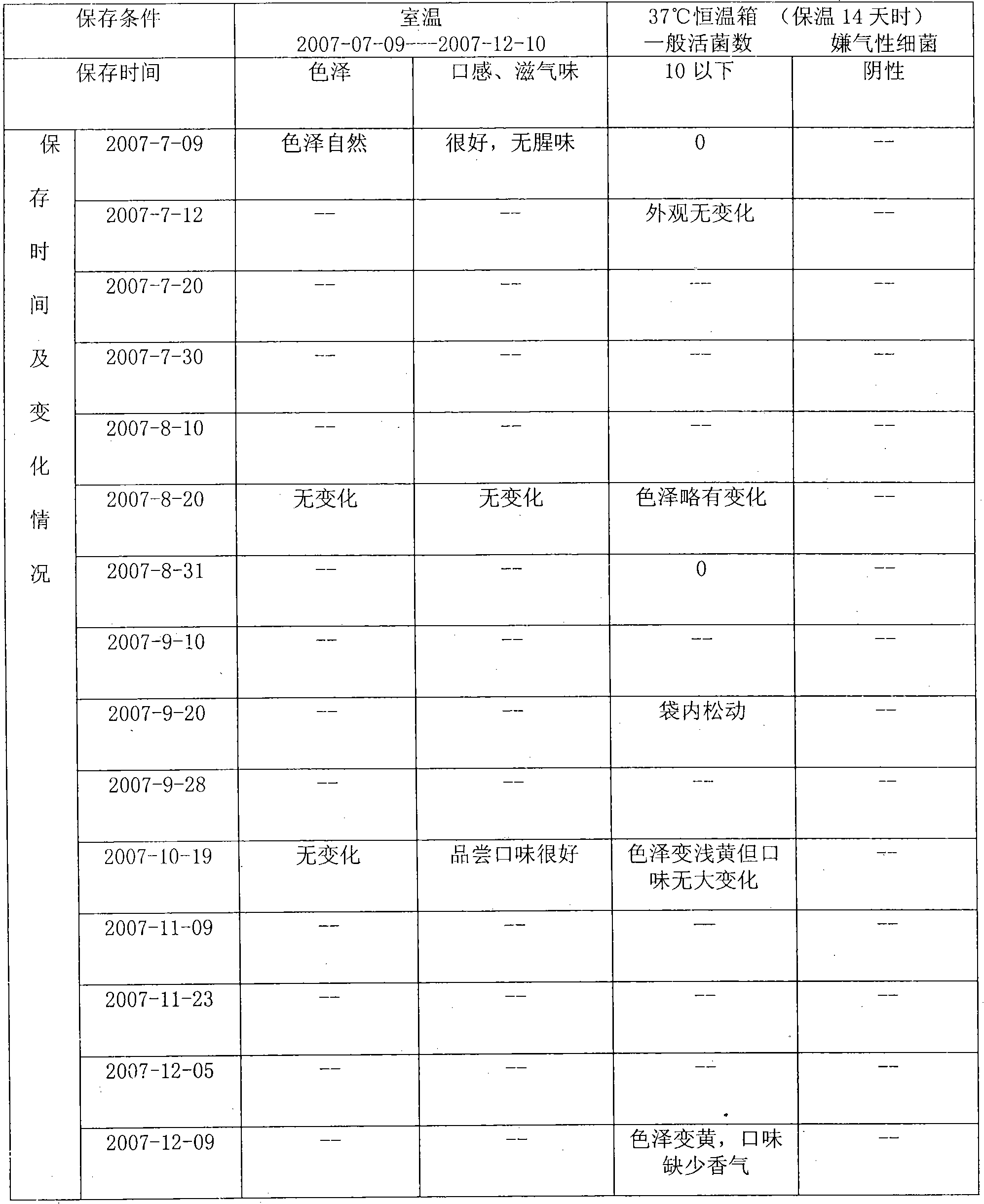

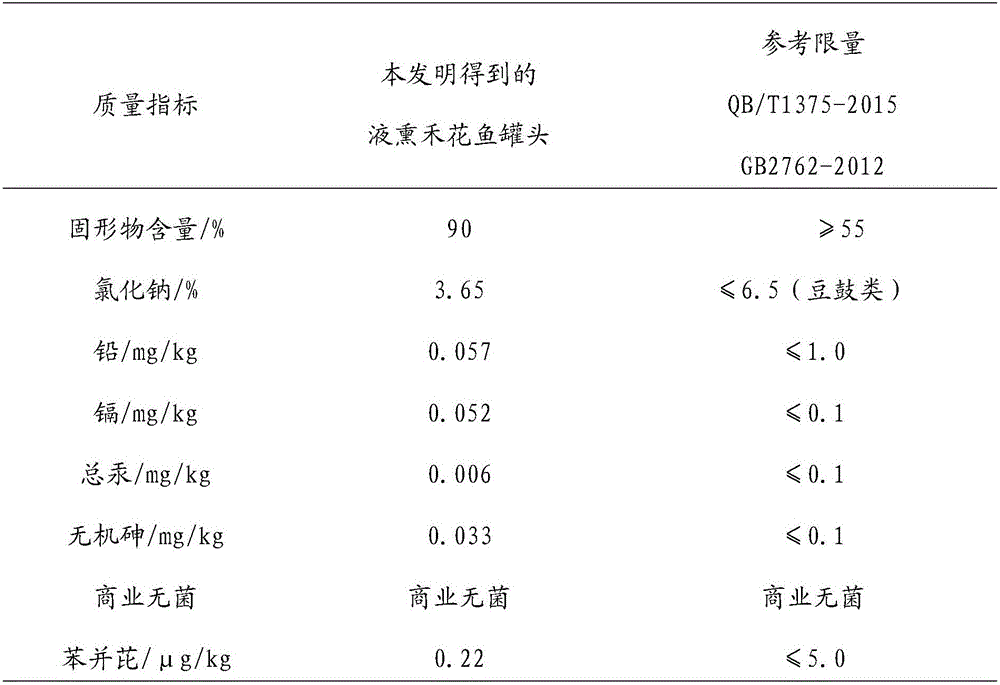

Preparation method of canned liquid-smoked procypris mera

InactiveCN105995628AAttractive smoky colorAttractive aromaFood ingredient as antioxidantFood ingredient as taste affecting agentTolerance limitLiquid smoke

The invention discloses a preparation method of canned liquid-smoked procypris mera and belongs to the technical field of processing of aquatic products. The preparation method comprises the following steps: (1) treatment of fish serving as a raw material; (2) liquid smoking; (3) frying; (4) canning and sealing; (5) sterilization; (6) cooling and packaging. The procypris mera is processed with a liquid smoking method, the attractive smoked color and fragrance can be obtained, and the functions of resisting bacteria, resisting oxidation and prolonging the guarantee period are realized; with the adoption of the smoking process, nutrients of the procypris mera are seldom damaged, processing is easy, time is saved, the efficiency is improved, the flavor of the product is good, and the canned liquid-smoked procypris mera has a golden color and a strong smoking flavor, is safe to take due to the fact that the content of residual BaP (benzopyrene) is lower than a national tolerance limit, and is very characteristic.

Owner:GUANGXI NORMAL UNIV

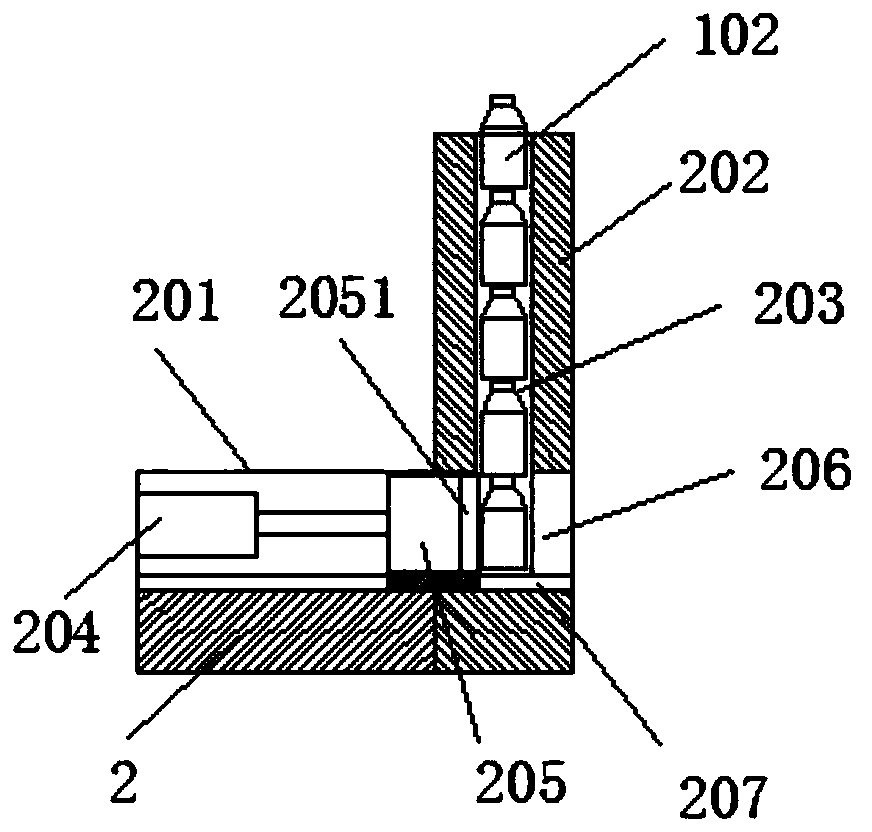

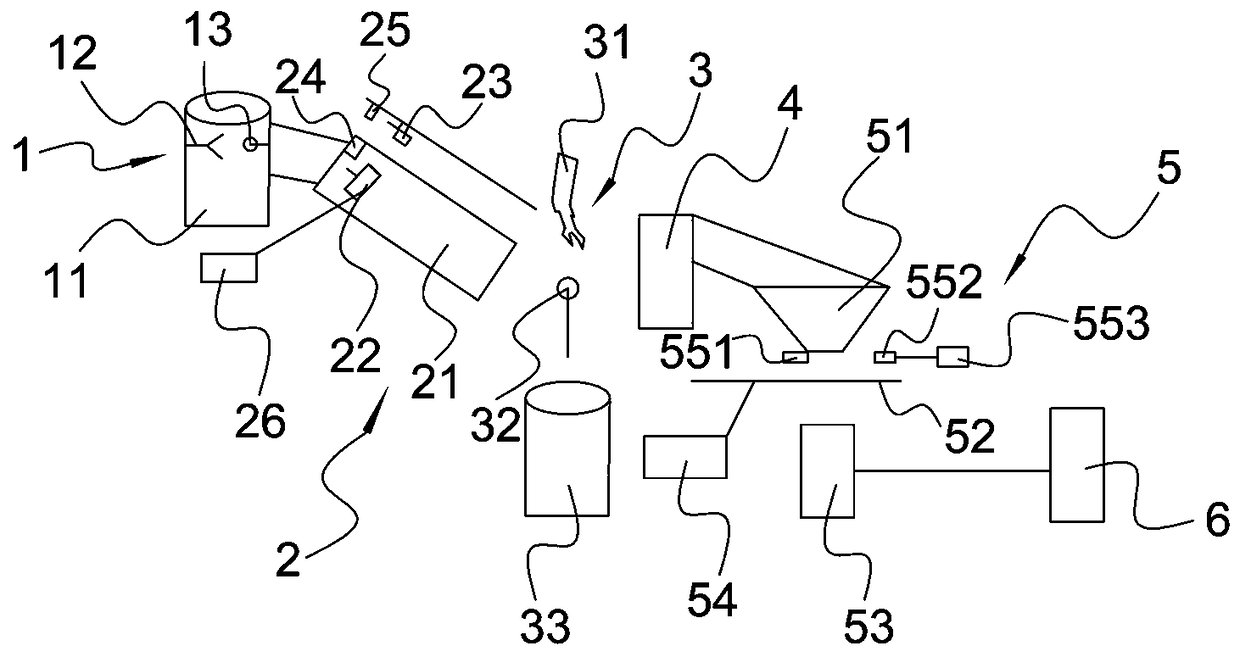

Production line for producing canned fish

InactiveCN102246846AEffective sterilizationExtended shelf lifeMeat/fish preservation by heatingProduction lineMicrowave

The invention discloses a production line for producing canned fish, relating to the technical field of processing of meat cans. A total process comprises the following steps of screening, abodominal organ cleaning, washing, pickling, washing, water removal, frying, seasoning, vacuum canning, sterilizing and packaging. The production line disclosed by the invention is simpler and can be used for producing canned fish with various tastes and different kinds; and by using microwave sterilizing, the sterilization in the canned fish is more effective, the shelf life is prolonged and the requirement of people can be better met.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

Canned fish and making method thereof

InactiveCN105123888ARich flavorBeautiful colorMeat/fish preservation using chemicalsFood preparationVegetable oilOyster

The invention discloses canned fish and a making method thereof, and belongs to the technical field of canned food processing. The canned fish is prepared from, by weight, 60-80 parts of fish, 20-30 parts of vegetable oil, 2-5 parts of starch, 1-4 parts of yellow wine, 1-3 parts of fermented blank beans, 0.8-1.2 parts of oyster sauce, 0.8-2 parts of dark soy sauce, 0.8-1.8 parts of mature vinegar, 0.8-1.5 parts of salt, 0.5-1.2 parts of aginomoto, 0.5-1 part of ginger powder, 0.5-1 part of white pepper, 0.2-1 part of rock candy, 0.2-0.5 part of pepper, 0.2-0.5 part of red pepper and 0.05-0.08 part of spice. The canned fish has the advantages of being good in color, aroma and taste and low in production cost, and the tasty ability of fish meat is good.

Owner:SICHUAN HUIQUAN CANNED FOOD

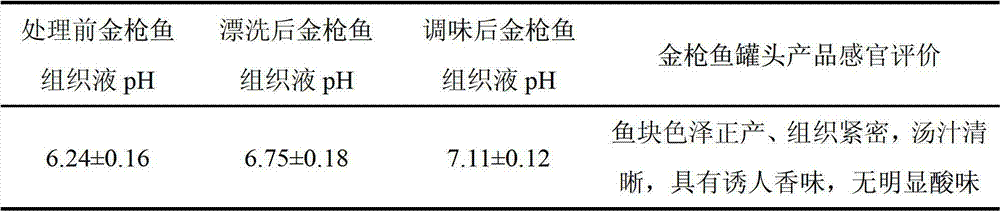

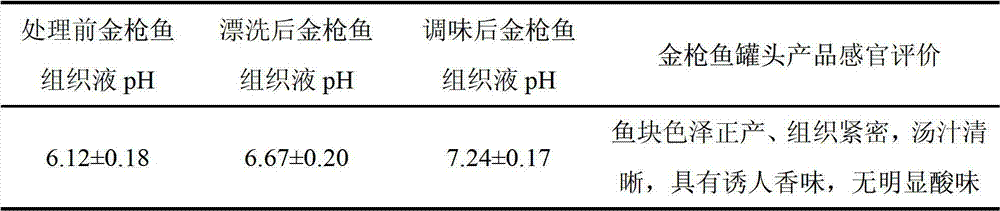

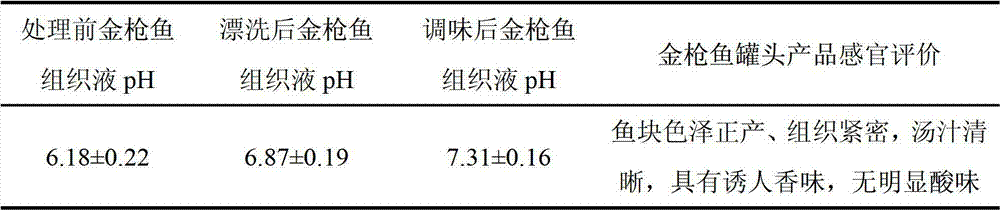

Method for removing sour flavor of tuna can products

InactiveCN103704540AKeep the tasteKeep the smellFood ingredient functionsFood preparationDipotassium hydrogen phosphateFlavor

The invention relates to a method for removing sour flavor of tuna can products, which comprises the following steps: preparing fish meat of the tun; preparing a rinsing solution containing 0.20-0.50g / L of tea polyphenol, 0.10-0.30g / L of dipotassium hydrogen phosphate and 0.10-0.30g / L of sodium acid pyrophosphate; placing the fish meat of the tuna in the rinsing solution for rinsing, wherein the proportion of the fish meat to the rinsing solution is 1.0kg tuna fish meat: 1.0-3.0L rinsing solution, rinsing for 1.0-4.0 minutes; during a seasoning process of an oil immersion tuna can and a seasoning tuna can, adding a flavor liquid containing 0.05-0.10g / L of sodium hexametaphosphate and 0.02-0.06g of sodium acid pyrophosphate in the canned fish meat, adding 10-15mL of flavor liquid in 100g of fish meat; during a brine adding process of a steamed tuna can, adding a salt aqueous solution containing 0.05-0.10g / L of sodium hexametaphosphate and 0.02-0.06g / L of sodium acid pyrophosphate in the canned fish meat, and adding 10-15mL of salt aqueous solution in 100g of fish meat. The method for removing sour flavor of tuna can products has the advantages of simple operation, low cost and good depickling effect, the problem of heavy sour flavour of the tuna can product is solved, the taste of the canned tuna product is effectively increased, and the business value of the tuna product is increased.

Owner:ZHEJIANG OCEAN UNIV

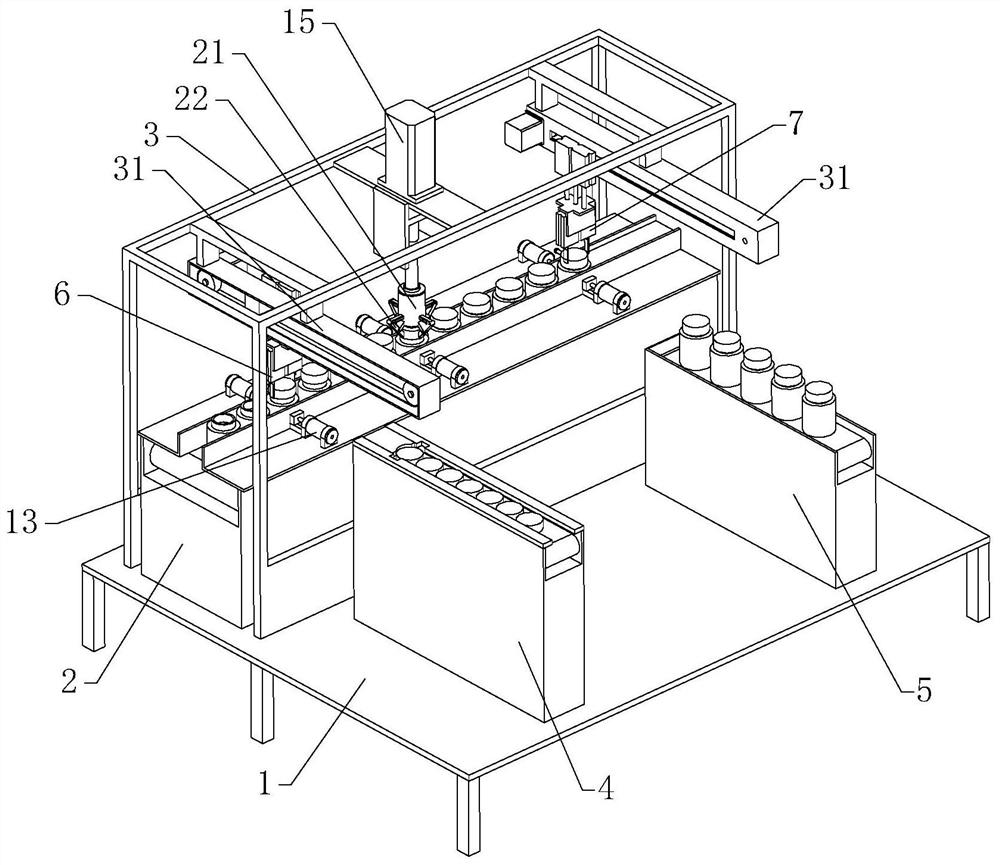

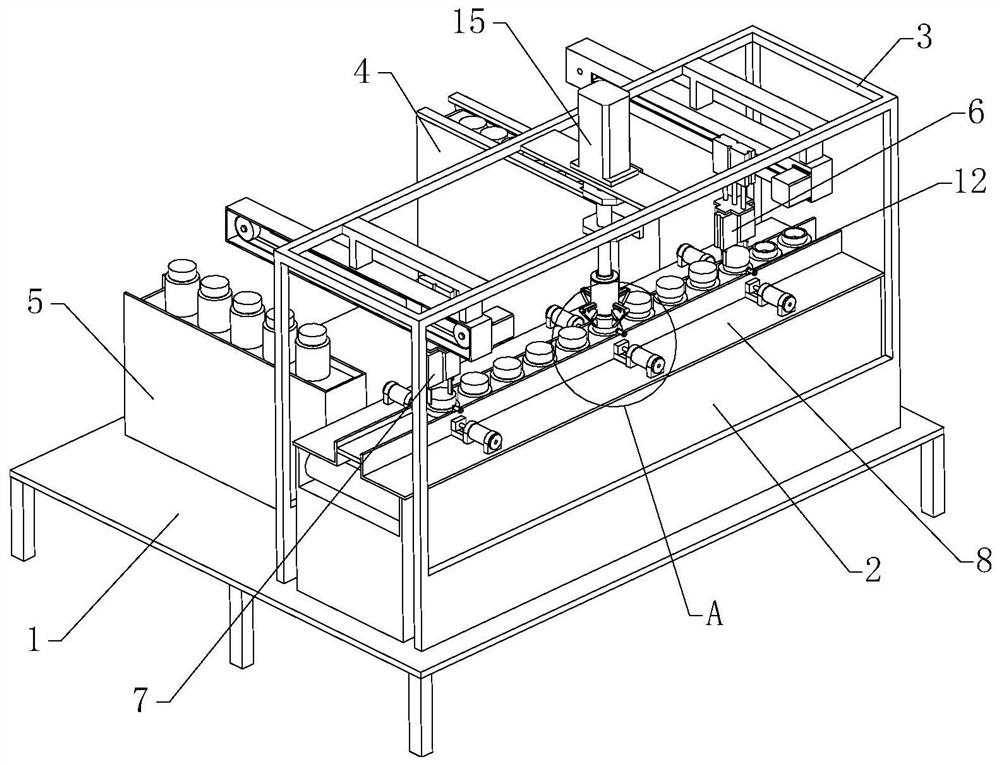

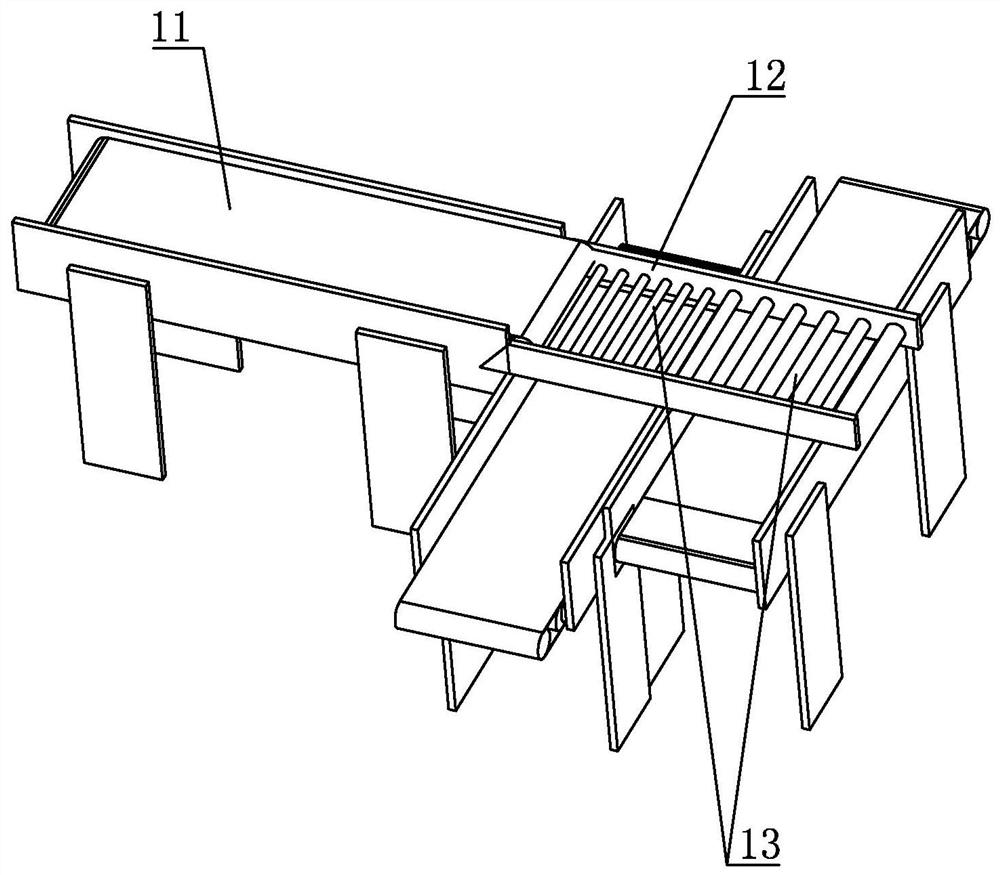

Full-automatic filling machine for canned abalones

ActiveCN111943122APlay the role of limit movementEasy to take outThreaded caps applicationSynchronising machinesBiotechnologyMechanical engineering

The invention relates to the technical field of canned abalone processing, in particular to a full-automatic filling machine for canned abalones. The full-automatic filling machine comprises a base, afeeding conveyor, a horizontal frame, a can cover feeding mechanism, a filling and sealing mechanism and a discharging mechanism, wherein positioning assemblies corresponding to the can cover feedingmechanism, the filling and sealing mechanism and the discharging mechanism in a one-to-one mode are arranged at the top of the feeding conveyor, a can cover conveyor and a discharging conveyor are arranged on one side of the feeding conveyor, one end of the can cover conveyor is in butt joint with one end of the interior of the can cover feeding mechanism, the can cover feeding mechanism comprises a first moving assembly, first clamping jaws are arranged at the working end of the first moving assembly, the discharging mechanism comprises a second moving assembly, and second clamping jaws arearranged at the working end of the second moving assembly. According to the technical scheme, the canned abalones can be automatically and efficiently filled, and the processing efficiency is improved.

Owner:FANGJIAPUZI PUTIAN GREEN FOOD

Preparation technology of canned abalones

InactiveCN110638000AGet rid of mucusEat clean and hygienicFood mechanical treatmentFood ingredient as taste affecting agentBiotechnologyAnimal science

The invention discloses a preparation technology of canned abalones. The preparation technology of the canned abalones comprises the following steps: selecting raw materials; removing impurities; preparing abalone meat; washing the prepared abalone meat; performing color retention on the washed abalone meat; pickling the color-retained abalone meat with salt; preparing soup; carrying out filling;and then, carrying out inspecting and packaging. In the step of selecting raw materials, namely the abalones, the abalones to be selected are rinsed with saline water of which the concentration is 1%for 3-5 days, so that inherent slime of the abalones can be effectively removed by the saline water; and moreover, parasites on surface of the abalones can be killed by the sterilization effect of thesaline water, and dirts in the stomachs of the abalones are promoted to be spitted out by the abalones due to soaking by the saline water, so that the finally prepared canned abalones become cleanerand more hygienic. In the step of preparing abalone meat, a sodium hypochlorite solution of which the concentration is 0.5% is added, so that low-temperature sterilization of abalone meat is realizedso as to improve water-holding capacity and texture of the abalone meat, thereby preventing water loss and retaining heat-sensitive nutrients to the maximum extent. In addition, in the step of performing ultrasonic washing on the prepared abalone meat, a compound salt solution is added, so that the purpose of ensuring excellent tenderness and meat elasticity of the canned abalones is achieved.

Owner:安徽艾可信网络科技有限公司

Production process of air-dried canned fish

The invention provides a production process of air-dried canned fish. The production process comprises the following steps: A, preprocessing and killing a fish, namely removing scales, belly nape, internal organs, fins, gills and teeth, and longitudinally and vertically cutting the back and thick meat part of the fish for 2-3 times; washing the fish, namely removing dirt and mucus of the fish and rinsing for 2-3 times by using clean water, wherein the water temperature is controlled to be 10-12 DEG C and the time is controlled to be within 30 minutes in a fish washing process; B, salting the fish, uniformly coating a fish body with prepared seasonings for salting, and emphatically coating the thick meat part with the seasonings to enable the fish to be tasty; C, air-drying, namely hanging the fish on an air-drying shelf, keeping the relative humidity of less than 57% and the temperature of 18-22 DEG C, and air-drying the fish body until the water content is 50%-57%; D, canning and sterilizing, namely canning the air-dried fish within 3 hours and sterilizing; or storing in a refrigeration house with temperature of 0-3 DEG C; quantitatively weighing soup and seasoning oil, adding the soup and the seasoning oil into a can, and sealing the can.

Owner:SICHUAN HUIQUAN CANNED FOOD

Preparation method of flexible package canned fish

InactiveCN103284224ARaw materials are easy to getHigh nutritional valueFood preparationOysterHigh pressure

The invention discloses a preparation method of a flexible package canned fish, which comprises the following steps: processing a fish: cleaning the fish, peeling, and cutting both sides of the fish body into mesh patterns with a knife; preparing a main material, wherein the main material comprises 800g of fish, 150-250g of vinegar, 80-120g of white sugar, 3-8g of salt, 30-60g of cooking wine, 30-60g of soybean sauce, 30-60g of seasoned sauce for seafood, 30-60g of oyster sauce and 20-30g of chicken broth; cooking: taking a small amount of edible oil with a frying dipper, pouring into a pan, putting seasonings into the pan after the edible oil is hot, and frying; after the seasonings are half-mature, putting the processed fish on the seasonings, and pouring the sauce on the fish until the fish body is immersed; packaging the stewed fish with a high-temperature-resistant boiling bag, vacuumizing, and sealing; and finally, sterilizing by using a full-automatic process retort according to the conventional canned food sterilizing operation method. The flexible package canned fish has the advantages of unique formula, good mouthfeel, simple process and abundant nutrition.

Owner:杨玉萍

Easily digestive canned fish bladders and preparation method thereof

InactiveCN107788419APromote absorptionReasonable ingredientsFood ingredientsVitamin CAdditive ingredient

The present invention discloses easily digestible canned fish bladders and a preparation method thereof, and belongs to the technical field of canned food processing. The easily digestible canned fishbladders contain the following ingredients: 20-60% of fish bladder raw materials, 5-10% of fruit fleshes, 0.2-1.2% of Chinese wolfberry fruits, 0.3-0.8% of white fungus, 0.3-0.6% of lotus seed, 0.5-1% of longan, 0.5-1.5% of red dates, 0.15-0.5% of vitamin C, 0.1-0.5% of citric acid, 0.01-0.05% of fruit essence and the balance sugar water. Compared with traditional fish bladder products, the preparation method solves a problem that the traditional fish bladder products are not instant. Secondly, the easily digestible canned fish bladders are low in production costs, scientific in used materials and balanced in nutrition. The fruit fleshes and fish bladders are combined, and the easily digestible canned fish bladders are multiple in nutrients and easily digested, have nutrients easily absorbed by human body and bring large convenience for people to eat the fish bladders.

Owner:镇江中一广告制品有限公司

Instant mushroom-flavored drunken-fish can and preparation method thereof

The invention discloses an instant mushroom-flavored drunken-fish can and a preparation method thereof. The instant mushroom-flavored drunken-fish can is prepared from the following raw materials in parts by weight: 35-45 parts of dried mushrooms, 45-60 parts of drunken fishes, 30-50 parts of pickled peppers, 20-30 parts of fresh ginger juice, 3-5 parts of white sugar, 10-20 parts of carrots, 10-20 parts of tender bamboo-shoot tips, 7-12 parts of soybean sauce, 3-8 parts of salt, 5-10 parts of edible oil, 30-50 parts of corns and 27-35 parts of milk. The preparation method comprises the following steps: processing the drunken fish, making pulp, brewing the pulp in a boiler and hot-packaging the brewed pulp. The instant mushroom-flavored drunken-fish can disclosed by the invention has the characteristics of appropriate salty flavor, fresh and tender texture, strong aroma, rich nutrition and chewy taste. The preparation method of the instant mushroom-flavored drunken-fish can is easy to operate, convenient to prepare, low in cost, small in environment pollution and suitable for industrial mass production.

Owner:XIHUA UNIV

Preparation method of canned and fried fish

InactiveCN105325935AEasy to keep freshImprove antioxidant capacityMeat/fish preservation by heatingFood ingredient as flavour affecting agentMarine fishNutrition

The invention discloses a preparation method of canned and fried fish. The preparation method mainly solves the problems of uniform flavor and heavy fishy smell of existing canned fish. The preparation method comprises steps as follows: fresh marine fish is taken as a raw material, heads, tails, fins and viscera are removed, then the fresh marine fish are washed clean, and fish blocks are prepared; the fish blocks are soaked in a fishy smell elimination solution to remove a fish smell; the fish blocks are put into salt water after being rinsed and then subjected to superhigh-pressure treatment; the fish blocks are washed and immersed into a flavoring liquid to be flavored; the fish blocks are fried, and the fried fish blocks are obtained; shiitake mushrooms, winter bamboo shoots, carrots, sesame, chilli powder, fermented black bean sauce, granulated sugar, salt and goat bone soup are selected to prepare auxiliary materials; the fried fish blocks and the auxiliary materials are canned, nisin is added for bacteriostasis, exhausting, sealing, can washing, sterilization and back pressure cooling are performed, then the canned fish is left to stand and cooled to the normal temperature, and the finished canned and fried fish is prepared after being detected to be qualified. The preparation method is technologically reasonable, materials are matched scientifically, and the operability is high. The canned and fried fish prepared with the method has rich nutrition, chewy meat quality, a unique flavor and a long guarantee time and tastes good and delicious.

Owner:荣成石岛广信食品有限公司

Method for preparing cat food phagostimulant by comprehensively utilizing fish leftovers

InactiveCN111557386AModerate hardnessFull of nutritionAnimal feeding stuffAccessory food factorsBiotechnologyFish paste

The invention discloses a method for preparing a cat food phagostimulant by comprehensively utilizing fish leftovers. The cat food phagostimulant is prepared from the following raw materials in partsby weight: 30-40 parts of fish viscera, 20-30 parts of fish paste, 5-10 parts of fish bone meal, 2-5 parts of edible gum, 10-20 parts of potatoes, 3-8 parts of protein powder, 1-3 parts of sugar and 2-4 parts of salt. The canned fish is prepared by taking the fish viscera, the fish paste and the fish bone meal as main raw materials, so that the nutritional ingredients in the raw materials are reserved to the maximum extent, and the obtained product has the advantages of moderate hardness and rich nutrition, and is beneficial to healthy growth of pets.

Owner:JIANGSU LIANYI BIOTECH

Microwave extraction method of canned fish seasoning liquid

The invention discloses a microwave extraction method of canned fish seasoning liquid, which comprises the following steps of mixing the following components in parts by weight: 1-5 parts of anise, 1-5 parts of pepper, 1-2 parts of fennel, 1-2 parts of clove, 1-2 parts of liquorice, 0.5-1.5 parts of radix angelicae, 0.5-1.5 parts of bay leaves, 0.5-1.5 parts of Bibo, 0.5-1.5 parts of cortex cinnamomi, 0.25-0.75 part of rhizoma kaempferiae, 0.25-0.75 part of radix aucklandiae, 0.25-0.75 part of kaempferia galangal, 0-3 parts of hawthorn and 0-3 parts of black pepper; grinding; and performing microwave extraction to obtain the canned fish seasoning liquid. According to the method disclosed by the invention, by adopting a microwave dynamic circulating reverse flow method to extract active ingredients in a Chinese herbal medicine, the prepared canned fish seasoning liquid integrates the essences of multiple traditional Chinese medicines, and has good nourishing and seasoning functions; and moreover, the canned fish seasoning liquid has a strong, pure and lasting aroma, and has the functions of strengthening the spleen and promoting appetite, removing the mutton smell and improving freshness and eliminating fishy smell and peculiar smell.

Owner:广州鹰金钱食品集团有限公司

Five-spice flavored yellow croaker and processing process thereof

The invention relates to a five-spice flavored yellow croaker can and a processing process thereof, belonging to the field of food processing. The processing process is realized by the following steps: preferably selecting a yellow croaker; after selecting and washing the materials, leaching and slicing; pickling, frying, pickling, boiling, adding soup and immersing; and sealing the slices in a can in vacuum, and statically storing to prepare the five-spice flavored yellow croaker can. The processing process has reasonable processing steps and design; the can prepared by the process has abundant nutrition; the fish is tender, dry and wet and has a strong five-spice flavor; and the five-spice flavored yellow croaker can is convenient to carry and eat and easy to store.

Owner:张庆之

Deep sea fish sauce and preparation technology thereof

The invention provides a preparation technology of a deep sea fish sauce. The preparation technology comprises the following steps of pretreating raw materials; performing steaming: steaming the cut fish meat blocks under the temperature condition of 95-100 DEG C until the fish blocks are fully cooked; performing dehydration: performing dehydration on the steamed fish meat; performing drying: baking the fish meat after the dehydration until the baked fish meat is brown and fragrance is generated; performing deep-frying: pouring oil in a deep-frying machine, heating the oil to 160-180 DEG C, putting the dried fish meat into the deep-frying machine, and deep-frying the fish meat until the deep-fried fish meat is brown; performing seasoning and decocting so as to obtain a fish sauce; performing filling: performing quantitation on a fish sauce, and performing filling on the fish sauce after quantitation to glass bottles; performing sealing: performing vacuum sealing on the bottled fish sauce; and performing sterilization; loading the processed glass bottles with the fish sauce into boxes, enabling the fish sauce loaded in the boxes to be preserved under room temperature conditions, and guaranteeing that the storage environment is ventilated. According to the production technology disclosed by the invention, the technologies of performing dehydration, drying and deep-frying are performed on the cooked fish meat, so that the whole canned fish meat is guaranteed to be fresh, fragrant and refreshing. In addition, the invention further provides a deep sea fish sauce prepared by the preparation technology.

Owner:青岛福富通食品有限公司

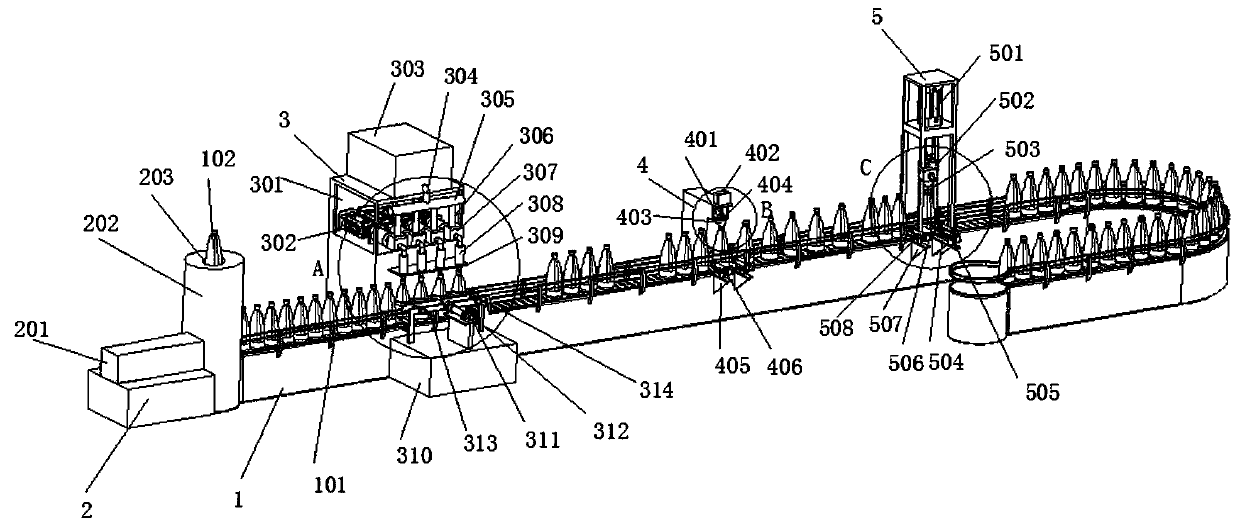

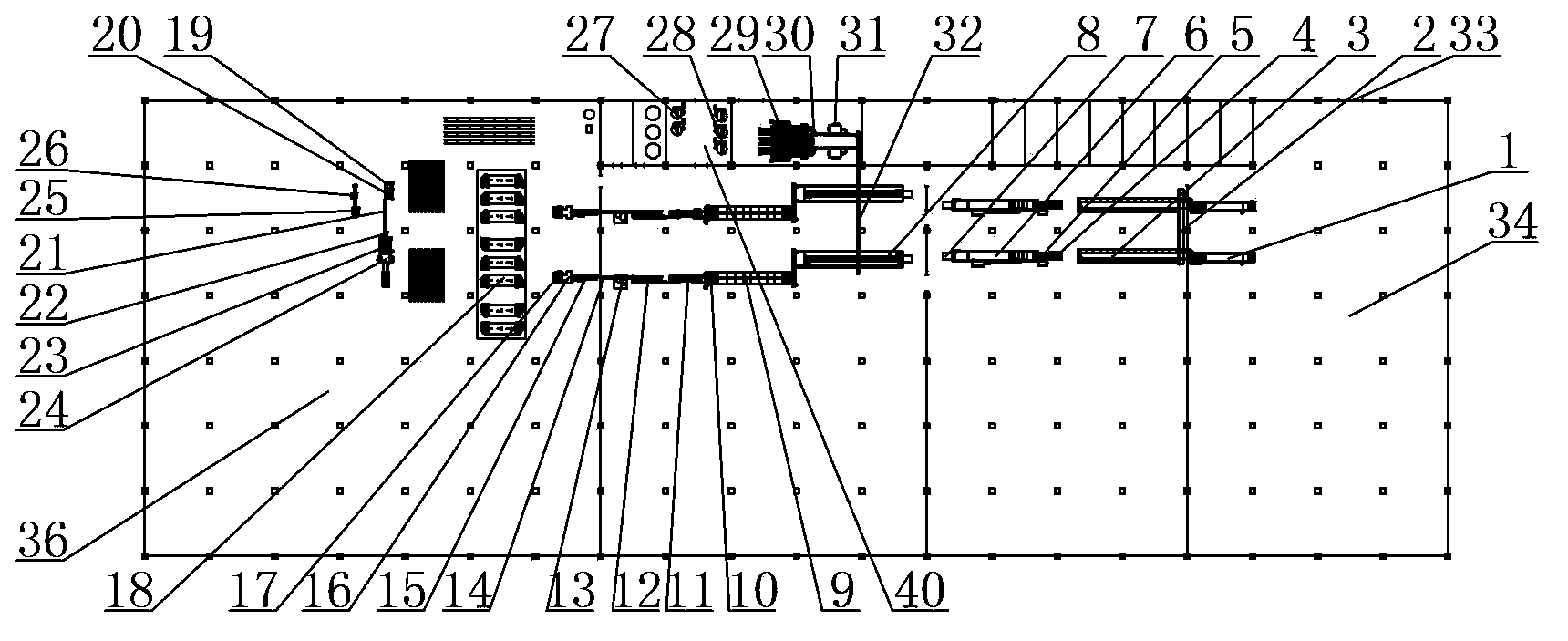

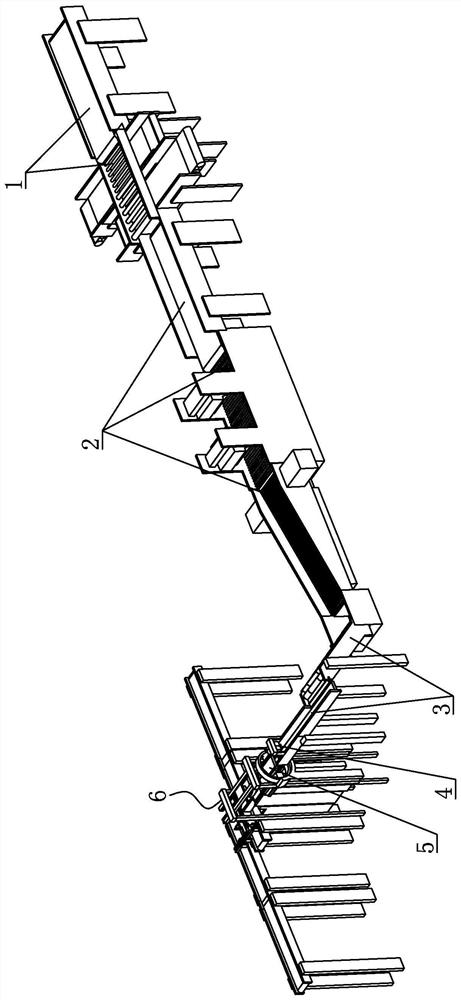

Canned fish production line

InactiveCN103380810AFully automatedImprove efficiencyMeat/fish preservation by dryingBiologyCanned fish

The invention relates to the field of canned fish production, in particular to a canned fish production line which comprises a raw material channel, a deicing cleaning machine, a waste belt conveyor, a head and tail removing and gutting conveyor, a secondary cleaning tank, an impurity remover, a salt water soaking hoister, a material receiving worktable, a can filling charge conveyor, an exhaust box, a can distributing chain plate conveyor, a can single draining device, a can soup adding machine, a can capping machine, a can inspection chute, a filled can cleaning machine, a can receiving platform, a hydraulic lifting cage loading machine, a horizontal sterilizer, a horizontal lifting cage unloading machine, a disk conveyer, a blow drying machine, a connecting chain plate conveyor, a material receiving chain plate conveyor, an automatic hydraulic lifting stacker, a labeling machine and a coding machine. The can filling charge conveyor is connected with an empty can cleaning machine, the disk conveyer, an empty can unstacking machine, a tomato sauce mixing can platform and a salt water mixing can, and a weighing room is connected with a control room. The canned fish production line has the advantages that automation is fully realized, efficiency is improved, and the canned fish production line is standard.

Owner:象山双鱼轻工机械有限公司

Canned edible fish for pets

The invention discloses canned edible fish for pets. The canned edible fish is prepared from the following raw materials in parts by weight and in a compounding ratio: 30-40 parts of internal organs of fishes, 20-30 parts of fish paste, 5-10 parts of fish bone meal, 2-5 parts of edible gelatin, 10-20 parts of potatoes, 3-8 parts of protein powder, 1-3 parts of sugar and 2-4 parts of salt. According to the canned edible fish disclosed by the invention, the internal organs of the fishes, the fish paste and the fish bone meal are used as main raw materials for making the canned fish, nutrient components in the raw materials are reserved to a maximum degree, obtained products have the advantages of being moderate in hardness of mouth feel and rich in nutrition, and the healthy growth of the pets is facilitated.

Owner:JIANGSU YIHE PET PROD CO LTD

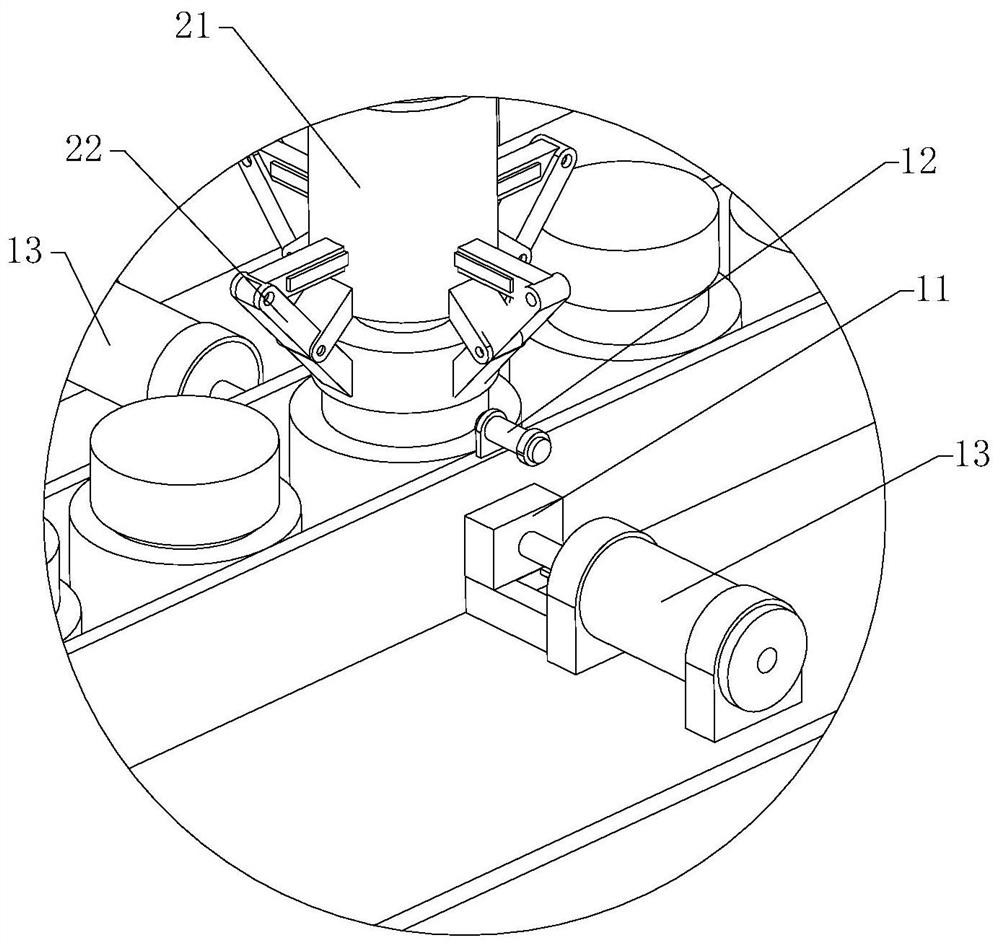

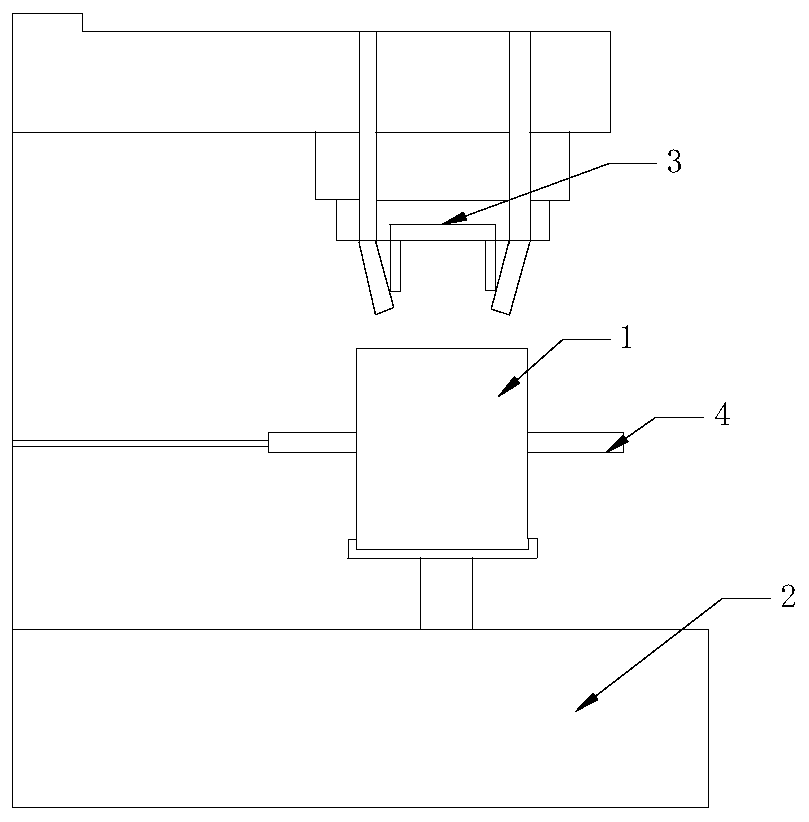

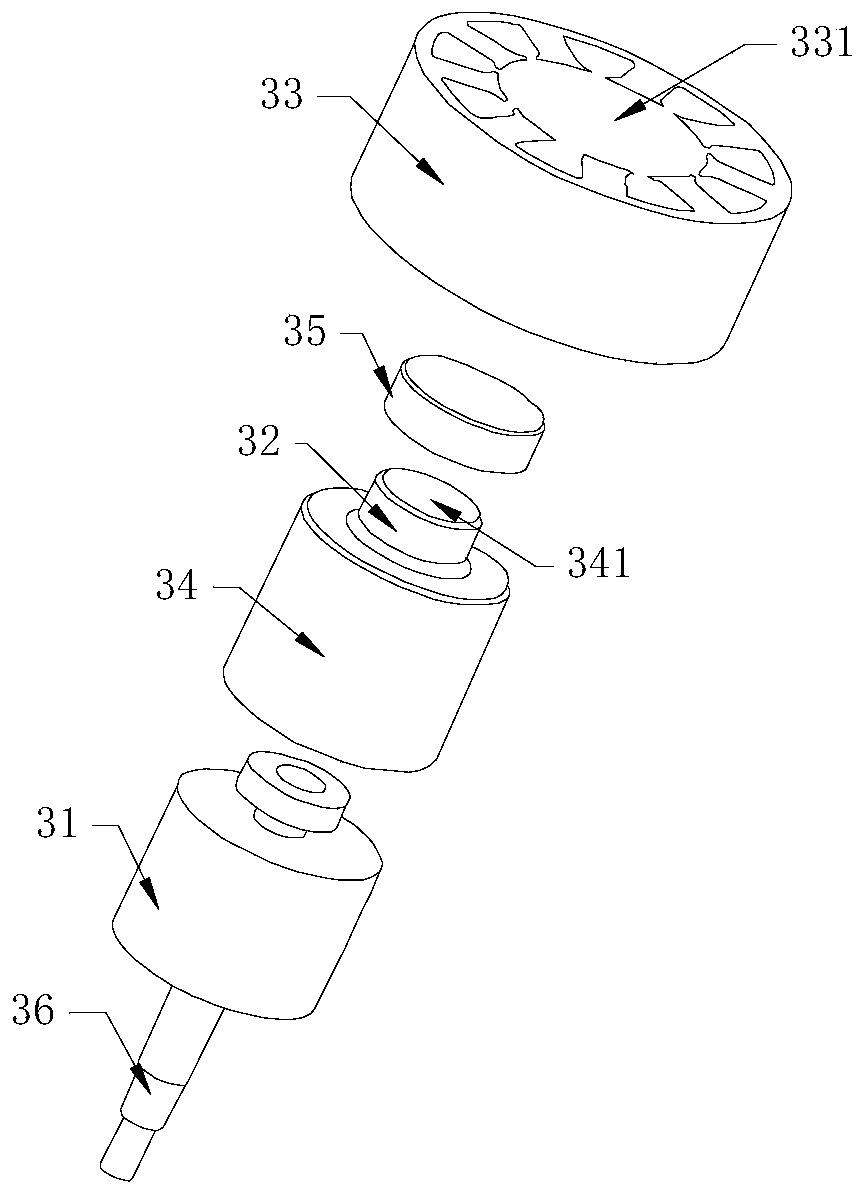

Canned fish sealing device and production method of canned fish

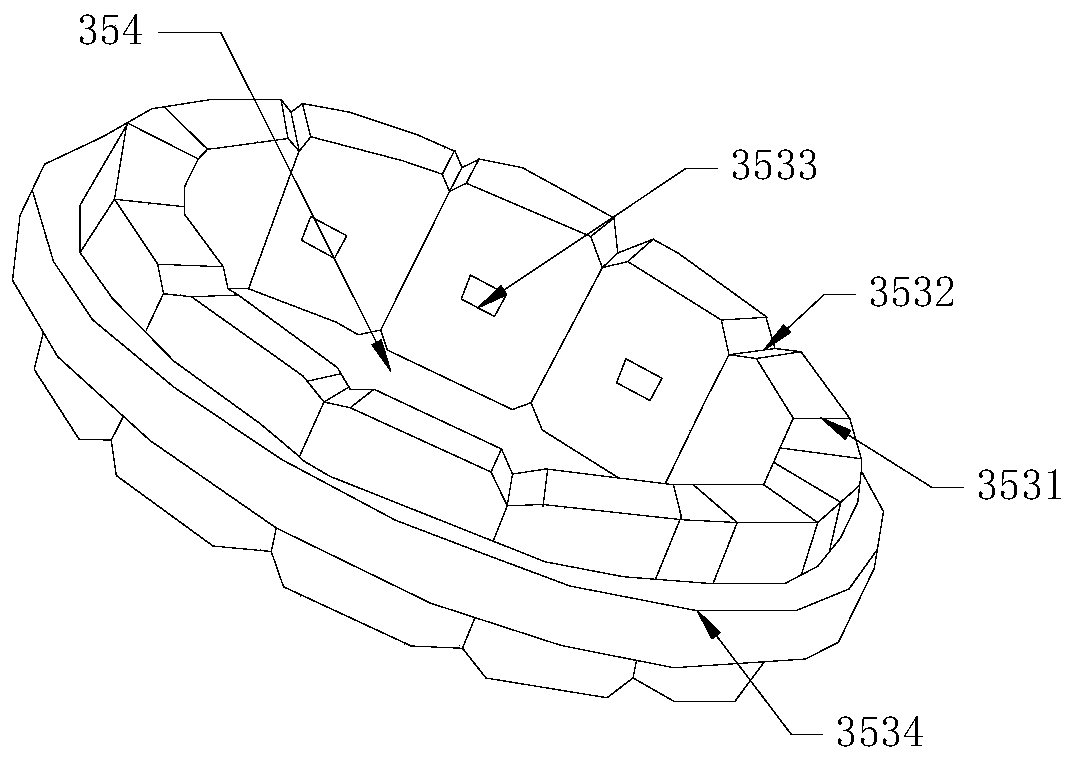

ActiveCN109928346AMeet various sealing requirementsAvoid affecting the sealing effectFish washing/descalingMeat/fish preservation by heatingEngineeringCalcium content

The invention provides a canned fish sealing device and a production method of canned fish. The canned fish sealing device comprises a supporting fixing table and a sealing mechanism, wherein the supporting fixing table is used for holding a can body, and the sealing mechanism is located above the supporting fixing table; and the sealing mechanism comprises a sealing part, the sealing part comprises a first pressing part, a second pressing part and a third pressing part which are arranged in a matched mode, the first pressing part is movably connected to the second pressing part through a first connecting part, and the second pressing part is movably connected to the third pressing part through a second connecting part. According to the canned fish sealing device, the plurality of pressingparts are matched with one another, so that the sealing device can be suitable for multiple types of sealing cans and capable of meeting various sealing requirements; and the production method of thecanned fish can improve the calcium content in the canned fish and effectively reduce the histamine component.

Owner:RONGCHENG TAIXIANG FOOD

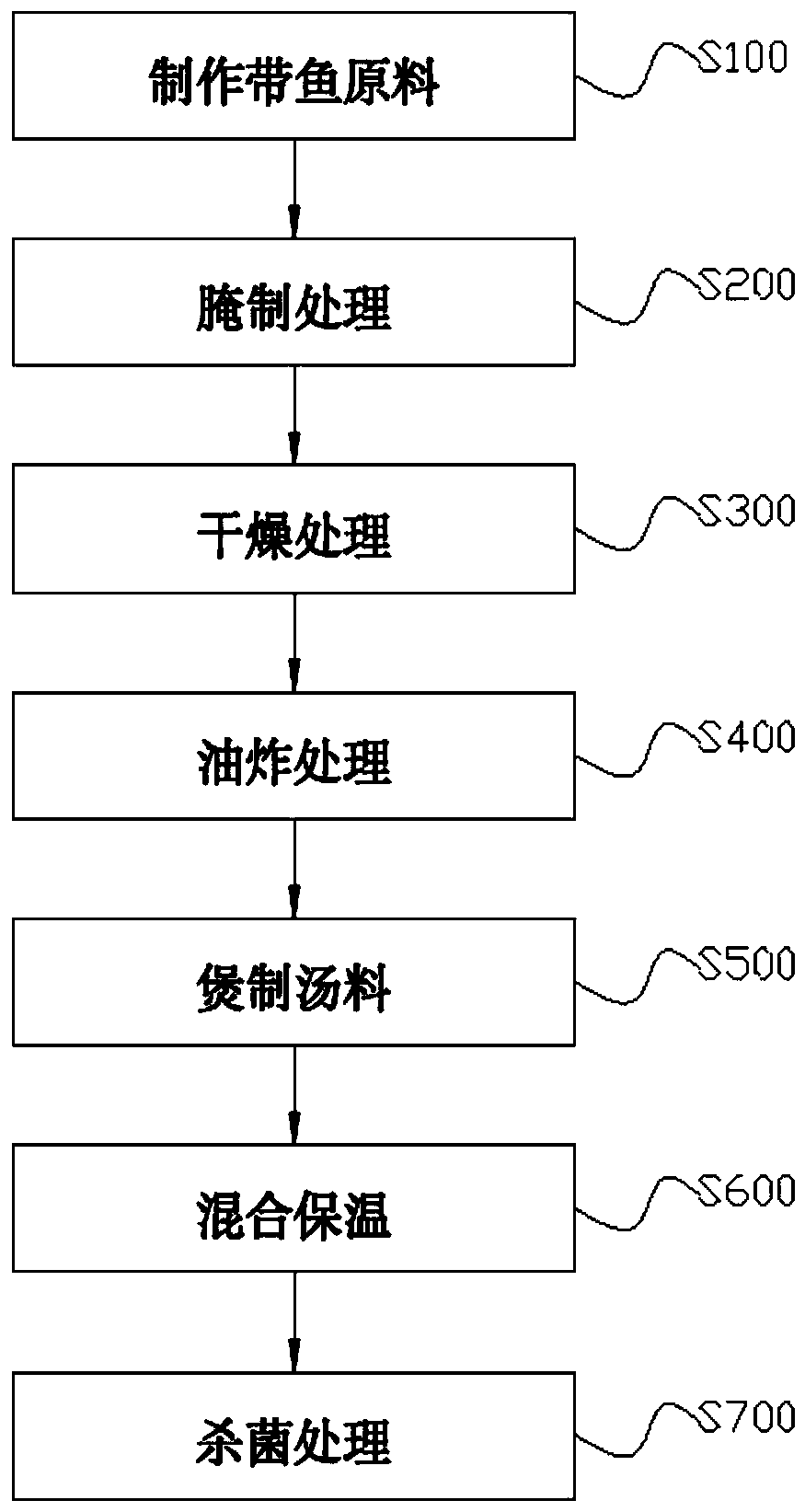

Method for manufacturing canned ribbonfish

InactiveCN110839838AEasy to carryExtended shelf lifeMeat/fish preservation by heatingNutritionEngineering

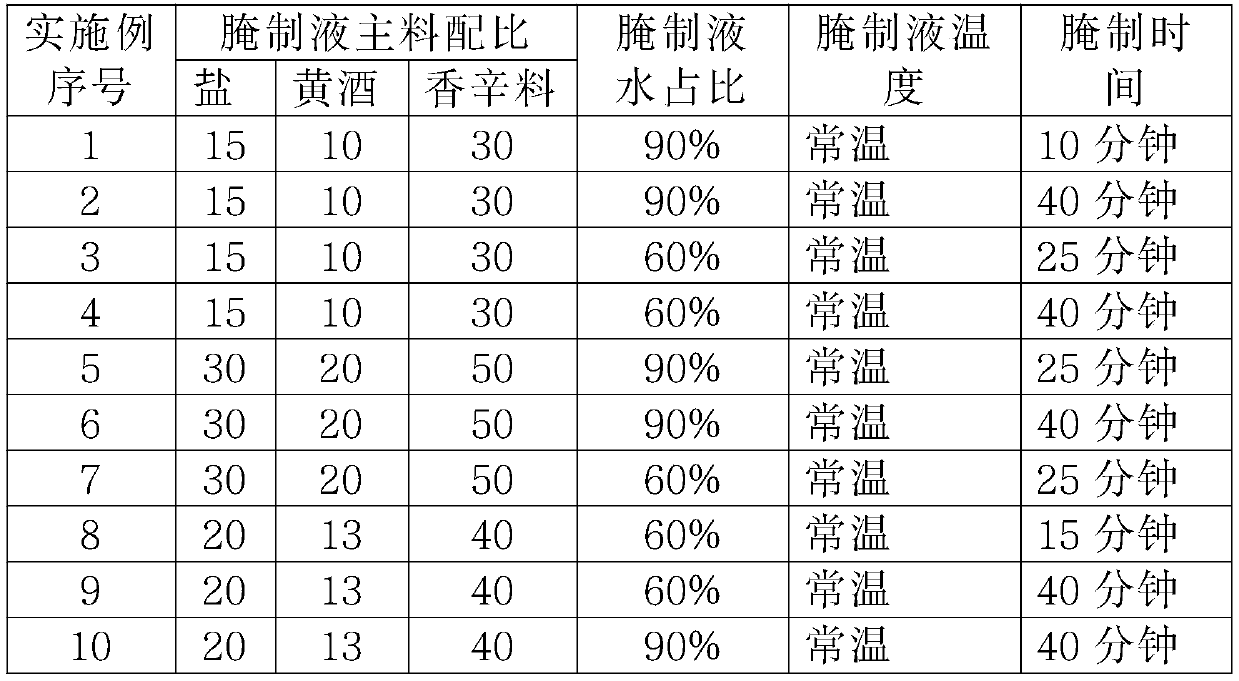

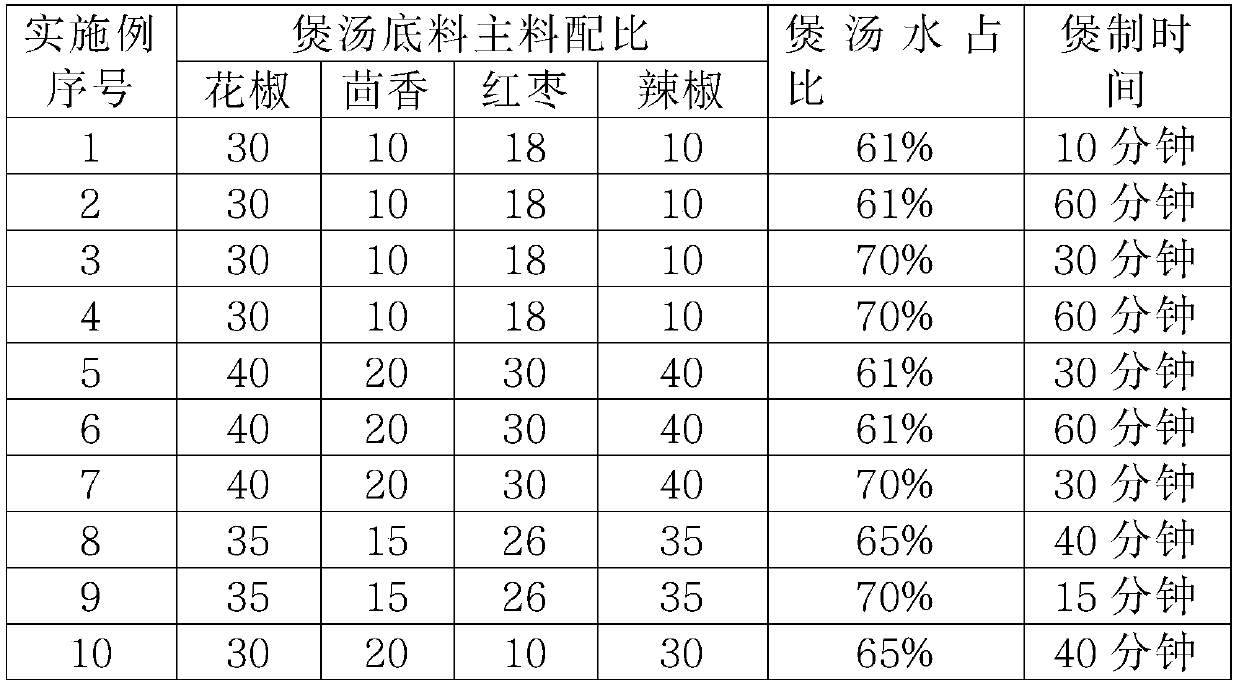

The invention provides a method for manufacturing canned ribbonfish, which comprises the steps of providing a ribbonfish material; preparing a marinating liquid, and marinating the prepared ribbonfishmaterial with the marinating liquid to form a marinated ribbonfish material; drying the marinated ribbonfish material; deep-frying the marinated ribbonfish material to form a deep-fried ribbonfish material; preparing a stewing stock material, and stewing the stewing stock material and water in an earthen pot for 30 to 60 minutes so as to form earthen pot-cooked ribbonfish soup; mixing the prepared earthen pot-cooked ribbonfish soup with the deep-fried ribbonfish material, and holding the temperature of 60-80 DEG C for 20-30 minutes. The canned ribbonfish is convenient to carry and long in shelf life, and also has the advantages of good nutrition, fineness, crispy bone and tender flesh.

Owner:山东亚圣食品有限公司

Processing method of canned fish for keeping complete fish flesh

The present invention discloses a processing method of canned fish for keeping complete fish flesh. The processing method comprises the following steps: pretreatment: frozen fish is thawed with tap water, a fish head, a fish tail and fish internal organs are removed, and the treated fish is washed clean to obtain fish segments; compound additive solution preparing: a compound additive is dissolved in water to obtain a compound additive solution; the compound additive comprises 5-20 wt% of transglutaminase, 5-25 wt% of curdlan, 10-30 wt% of soluble starch, 0.1-5 wt% of sodium hydroxide, 25-50 wt% of edible salt, 5-25 wt% of potassium dihydrogen phosphate and 5-20 wt% of sodium polyphosphate; soaking treatment: the fish segments are soaked in the compound additive solution; and the fish segments are taken out, the taken out fish segments are drained, the drained fish segments are canned, seasoning juice is added, the fish segments are sealed, the sealed fish segments are sterilized, and the sterilized fish segments are cooled to obtain finished products. The processing method avoids broken fish flesh, a large amount loss of fish flesh juice, and soup turbidity of the canned fish.

Owner:JIMEI UNIV

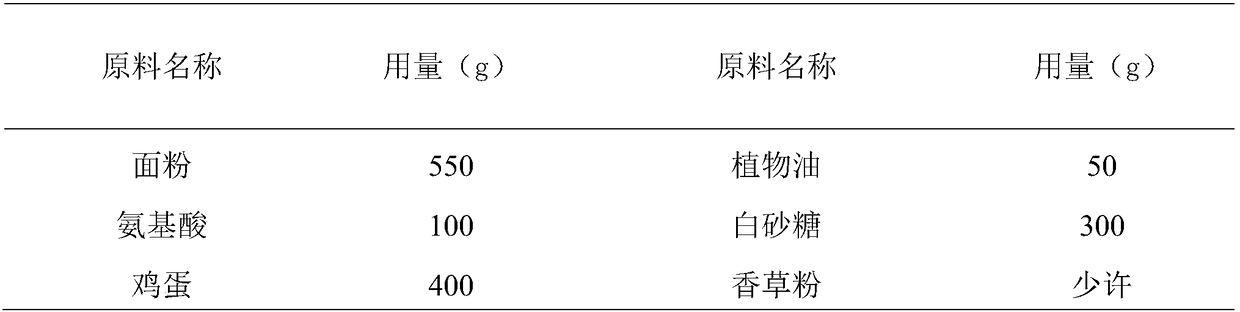

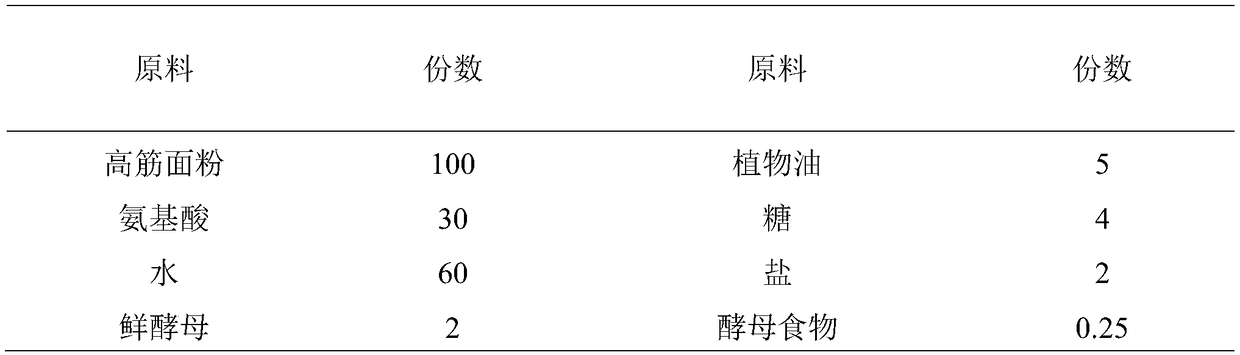

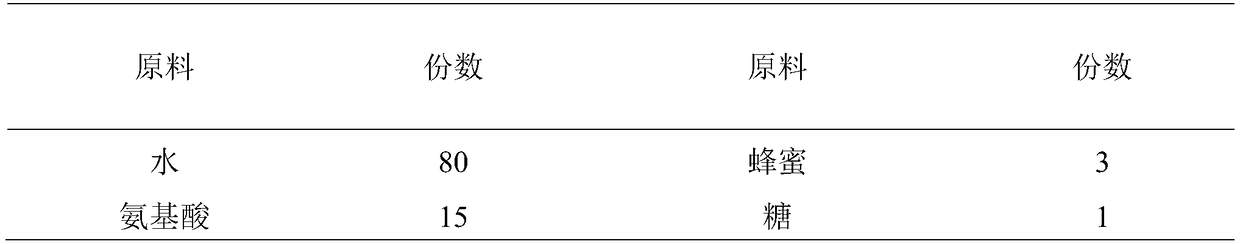

Method for recovering amino acids in canned sardine processing fish soup waste liquid and application thereof

The invention discloses a method for recovering amino acids in canned sardine processing fish soup waste liquid and application thereof and belongs to the technical field of foods. The compound aminoacids in the fish soup waste liquid are obtained by using an ion exchange resin method, and the method has the advantages of simple technology and easy industrial production. The obtained compound amino acids can be used for being processed into an amino acid oral liquid, or being added in foods such as biscuits, breads, cakes and condiments as nutritional ingredients, and the food nutrition and flavor are enhanced. The method can greatly improve the utilization rate of resources, reduce environmental pollution, increase the added value of the fish soup waste liquid, and increase the profit ofan enterprise.

Owner:QUANZHOU NORMAL UNIV

Aquatic product processing device

InactiveCN108739959ALong storage timeEasy to carryFish washing/descalingMeat/fish preservation by freezing/coolingCooking & bakingDried fish

The present invention provides an aquatic product processing device and belongs to the technical field of aquatic products. The aquatic product processing device comprises a scale removing member, a block cutting member, a viscus removing member, a baking chamber, a canning member and a refrigerating chamber; the scale removing member comprises a first fish barrel, a first fixing structure, a first hair brush and a first spraying nozzle; and the viscus removing member comprises a second fixing structure, a second hair brush and a second spraying nozzle. The scale removing member removes fish scales; the first hair brush scrapes off the fish scales; the first spraying nozzle removes the fish scales; the fish scale removing effect is better; the block cutting member cut the scale-removed fish into fish blocks with a preset length; the viscus removing member removes viscera in the fish blocks; the second hair brush scrapes off the viscera; the second spraying nozzle removes the viscera; the viscus removing effect is better; the fish blocks are baked in a second baking chamber into dried fish blocks for preset time; the canning member cans the dried fish blocks into canned fish; the canned fish is convenient for users to carry; the canned fish is refrigerated in the refrigerating chamber, so that the canned fish is longer in preservation time; and the aquatic product processing device has a simple structure and is convenient to operate.

Owner:福建省连江县宏裕水产有限公司

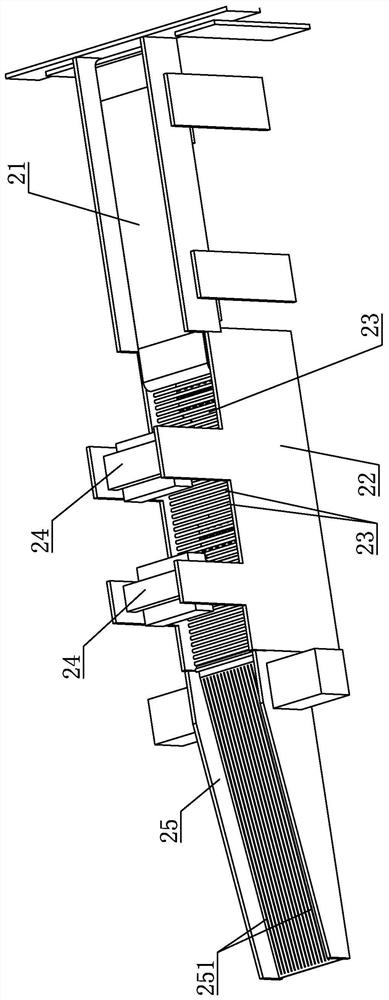

Canned abalone preparation device and method

ActiveCN113142288AEasy to processHigh degree of automationClimate change adaptationShellfish/bivalves grading/classificationAnimal scienceZoology

The invention discloses a canned abalone preparation device. The device comprises a can making device and an abalone processing device, wherein the abalone processing device comprises a first filtering mechanism, a first cleaning mechanism, a first row-dividing and single-dividing mechanism, a first detecting mechanism, a first overturning mechanism and a first shelling mechanism; the first detecting mechanism comprises a detection rod for detecting hardness; the first shelling mechanism comprises a first cutting assembly and a first shelling assembly; and the first cutting assembly comprises an adsorption head, a first telescopic assembly, a sliding portal frame and a cutting saw belt for cutting abalone shells. The device is accurate in shelling and can reduce cost and labor intensity. The canned abalone preparation method comprises the following steps: screening sizes of abalones; cleaning the abalones; dividing the abalones into rows and sizes; detecting front and back sides of the abalones; turning over the abalones of which flesh is not upward; shelling the abalones; and collecting abalone flesh, and performing ingredient canning. The method can be used for processing the abalones conveniently and quickly and shelling accurately.

Owner:诏安海联食品有限公司

Method for producing canned yellow croaker

The invention discloses a method for making canned yellow croaker, which belongs to the technical field of canned food processing. The production method comprises: the first step of raw material pretreatment; the second step of pickling; the third step of frying; the fourth step of boiling; the fifth step of packaging and sterilization. This production method enriches the taste of canned fish through the selection and ratio design of raw materials, especially the addition of oyster sauce, dark soy sauce, and mature vinegar in the formula, and by adding a specific proportion of raw materials such as ginger powder, rice wine, and spices. The invented canned fish has the advantages of complete color, fragrance and taste.

Owner:ZIGONG CITY TIANJING FOOD CO LTD

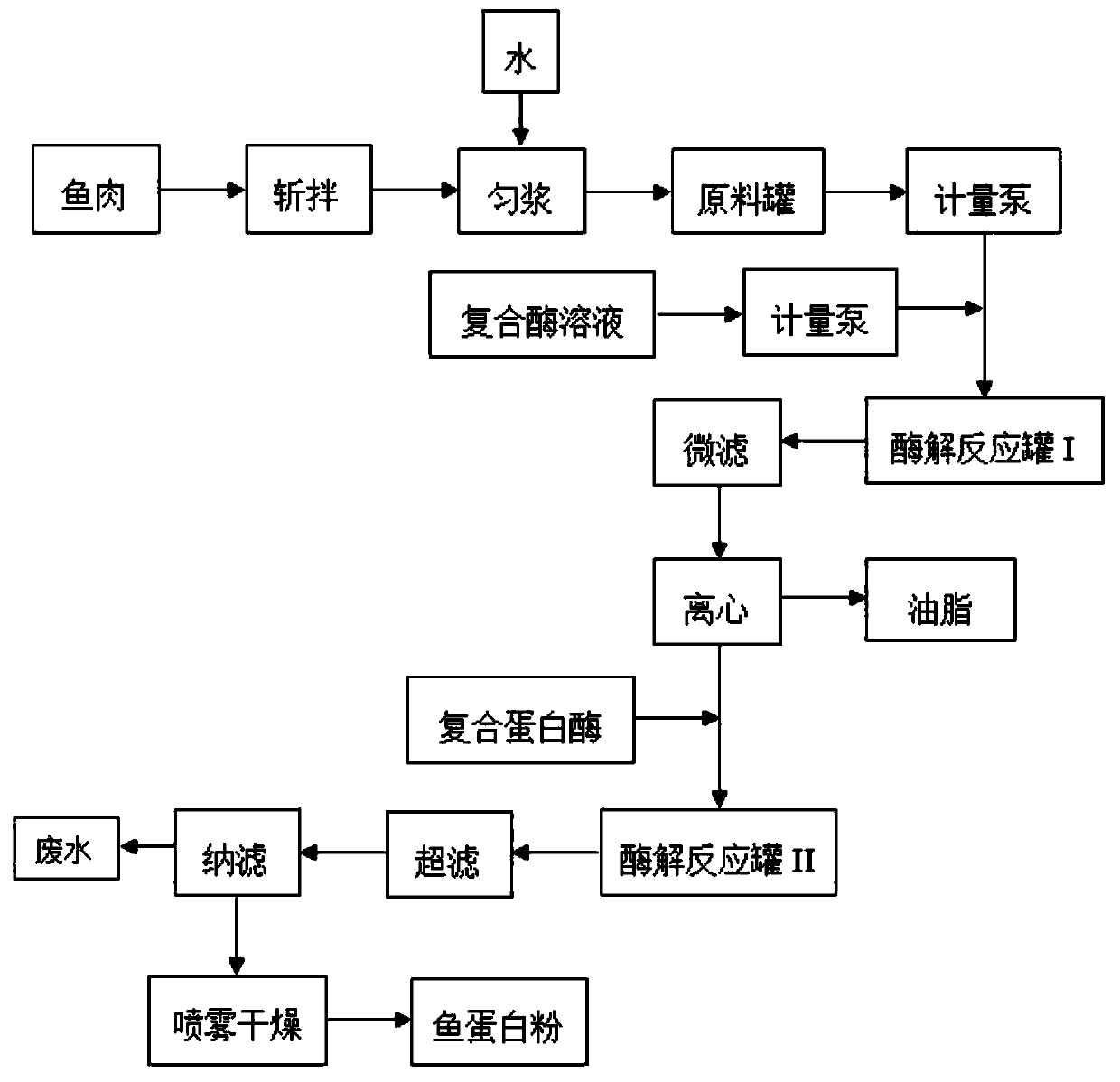

Method for preparing fish protein powder through continuous enzymolysis

PendingCN110353084AImprove qualityImprove securityProtein composition from fishProtein solutionHydrolysis

The invention discloses a method for preparing fish protein powder through continuous enzymolysis. With processed minced flesh of canned fishes as a raw material, the method comprises the following steps that the minced flesh is cut and mixed, and water is added for homogenization to obtain a homogenized solution; a complex enzyme is added for hydrolysis, an oily fish flesh protein pulp is separated out through a coupled microfiltration process, and oil is removed through centrifugation; the protein pulp continues to be subjected to enzymolysis after a complex protease is supplemented, and soluble protein with the molecular weight less than 15 KDa is obtained through coupled ultrafiltration separation; through nanofiltration, the protein solution is desalted, and small-molecular amino acids and peptides are removed; mist spraying and drying are conducted to obtain the fish protein powder with the water content of 3%. The method is suitable for preparing the aquatic protein powder, andespecially suitable for the continuous production of the fish protein powder. According to the method, through coupling of a combined membrane technology and the enzymolysis process, the fish flesh protein is simultaneously deoiled, separated, desalted and concentrated, the quality and safety of the protein powder are high, the production process is environmentally friendly and safe, and the energy consumption is low.

Owner:ZHEJIANG UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com