Method for removing sour flavor of tuna can products

A technology for tuna and canned food is applied in the field of removing the sour taste of canned tuna products, can solve problems such as no definite and feasible reports, and achieve the effects of low cost, improved commercial value, and reduced sour taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

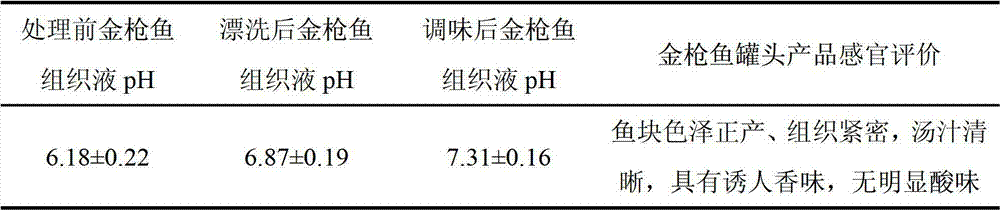

Examples

Embodiment 1

[0018] A method for removing the sour taste of canned tuna products, the steps are:

[0019] 1) After normal thawing, pretreatment and trimming of the frozen tuna, cut the muscle block into 4.0~8.0cm square meat pieces, and quickly rinse with water for later use;

[0020] 2) Preparation of rinse solution: containing 0.35g / L tea polyphenols, 0.20g / L dipotassium hydrogen phosphate and 0.20g / L sodium pyrophosphate;

[0021] 3) Put the tuna pieces in the above rinsing solution for rinsing: the ratio of tuna pieces to rinsing solution is 1.0kg tuna pieces: 2.0L rinsing solution, and the rinsing time is 2.5min;

[0022] 4) During the seasoning process of oil-soaked and seasoned canned tuna, seasoning liquid containing 0.075g / L sodium hexametaphosphate and 0.04g / L sodium pyrophosphate is added to the canned fish pieces, and the specific ratio is 100g of fish pieces. 12mL seasoning liquid; other operations follow the preparation requirements of GB / T24403-2009 canned tuna to produce c...

Embodiment 1

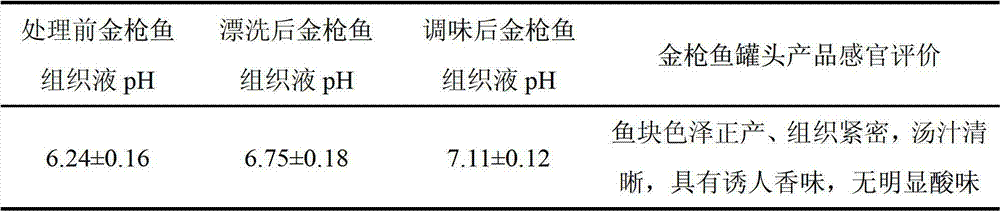

[0024] Embodiment 1 canned tuna deacidification effect

[0025]

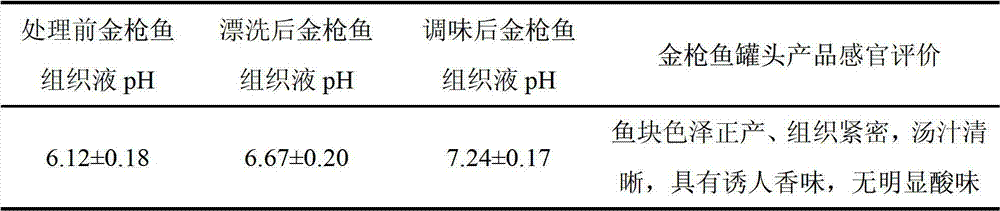

Embodiment 2

[0027] A method for removing the sour taste of canned tuna products, the steps are:

[0028] 1) After normal thawing, pretreatment and trimming of the frozen tuna, cut the muscle block into 4.0~8.0cm square meat pieces, and quickly rinse with water for later use;

[0029] 2) Preparation of rinse solution: (contains at the same time) 0.2g / L tea polyphenols, 0.30g / L dipotassium hydrogen phosphate, 0.10g / L sodium pyrophosphate;

[0030] 3) Put the above tuna meat pieces in the prepared rinsing solution: put the 1.0kg meat pieces in 1.0L rinsing solution, and the rinsing time is 1.0min;

[0031] 4) During the seasoning process of oil-soaked and seasoned canned tuna, seasoning liquid containing 0.05g / L sodium hexametaphosphate and 0.06g / L sodium pyrophosphate is added to the canned fish pieces, and the specific ratio is 100g of fish pieces. 15mL of seasoning liquid, and the rest of the operation shall be in accordance with the preparation process requirements of GB / T24403-2009 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com