Canned fish sealing device and production method of canned fish

The technology of a sealing device and production method is applied in the preservation of meat/fish, fish cleaning/descaling, heating and preserving meat/fish, etc., to achieve the effects of increasing calcium content, simple operation, and suitable for popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: a kind of production method of canned fish:

[0032] S1: Preprocessing:

[0033]Thaw the frozen fresh fish. After thawing, remove the head, tail and viscera of the fish, and then put the trimmed fish into the cleaning solution for cleaning; clean the frozen fresh fish Thawing until the central temperature of the fish body is 0 DEG C; the cleaning liquid contains 0.8-1% sodium chloride, 0.3-0.6% propylene glycol alginate and the rest is water.

[0034] S2: Canning

[0035] The cleaned fish are weighed according to standard weight and packed into tanks.

[0036] S3: aging

[0037] The process of pouring the tank filled with fish meat into the steamer for cooking, and drying the cooked fish meat; when cooking, the temperature is 80-90°C, and the time is 15-25min; when drying, the drying temperature is 100 -120℃, drying time is 5-10min.

[0038] S4: Pour sauce

[0039] Pour the seasoning sauce into the dried fish meat tank, and the seasoning sauce includ...

Embodiment 2

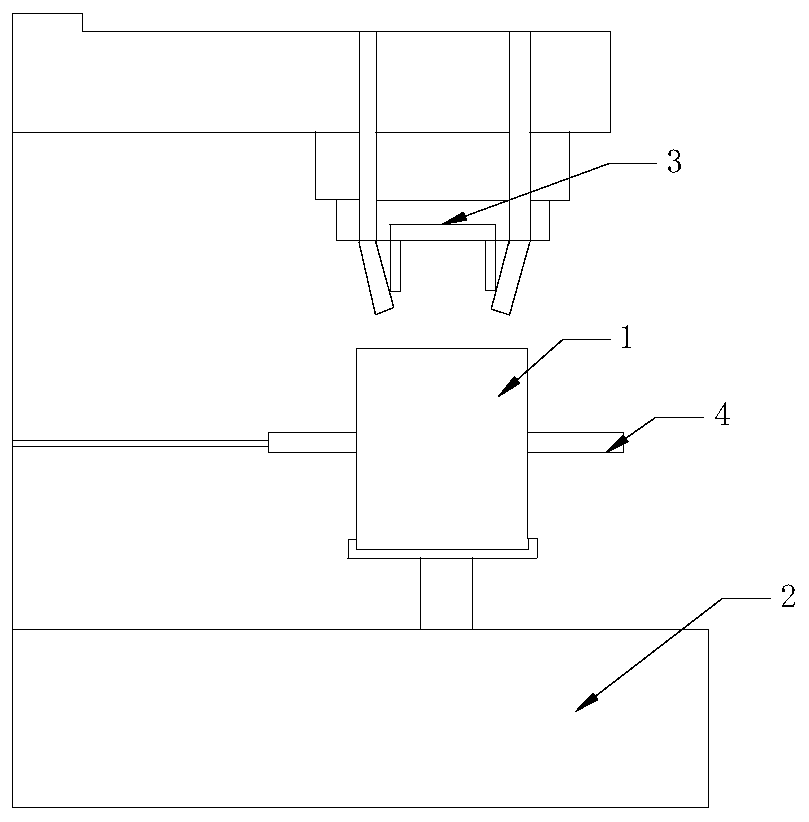

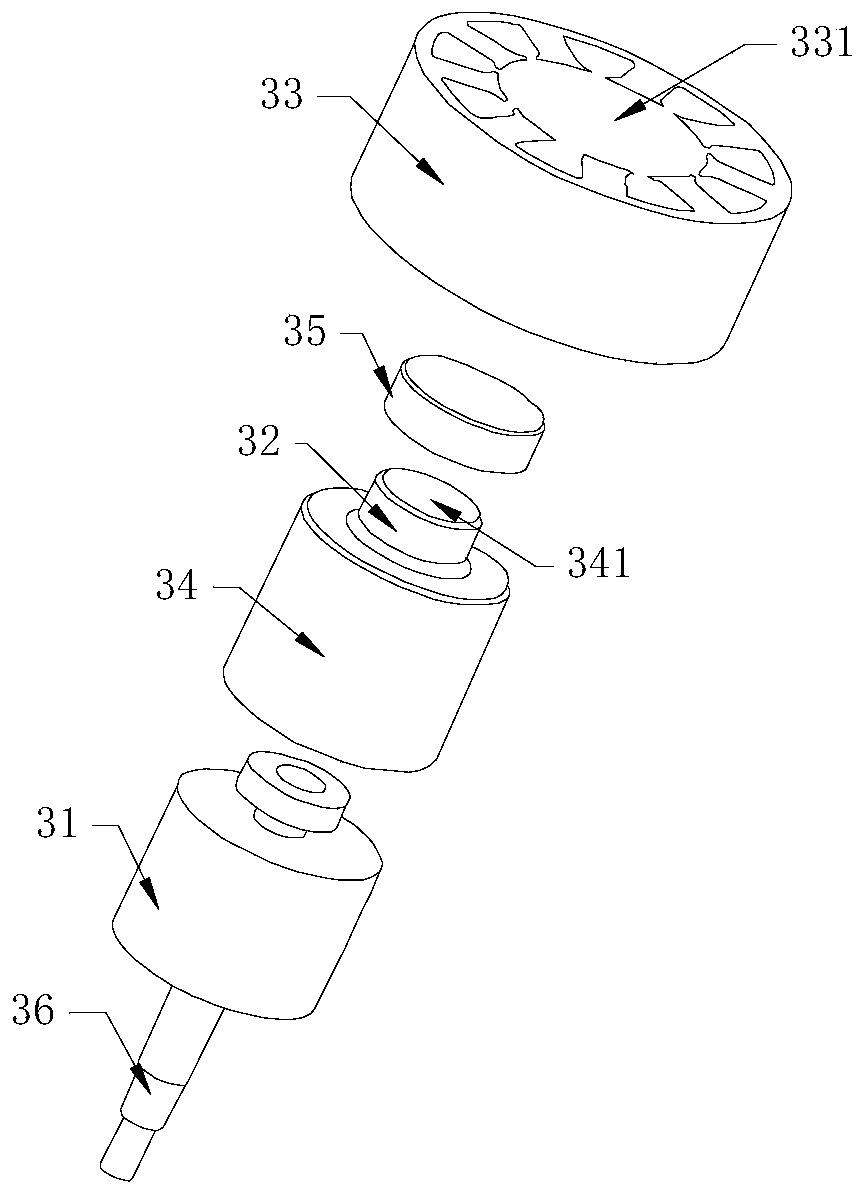

[0054] Embodiment 2: A kind of canned fish sealing device

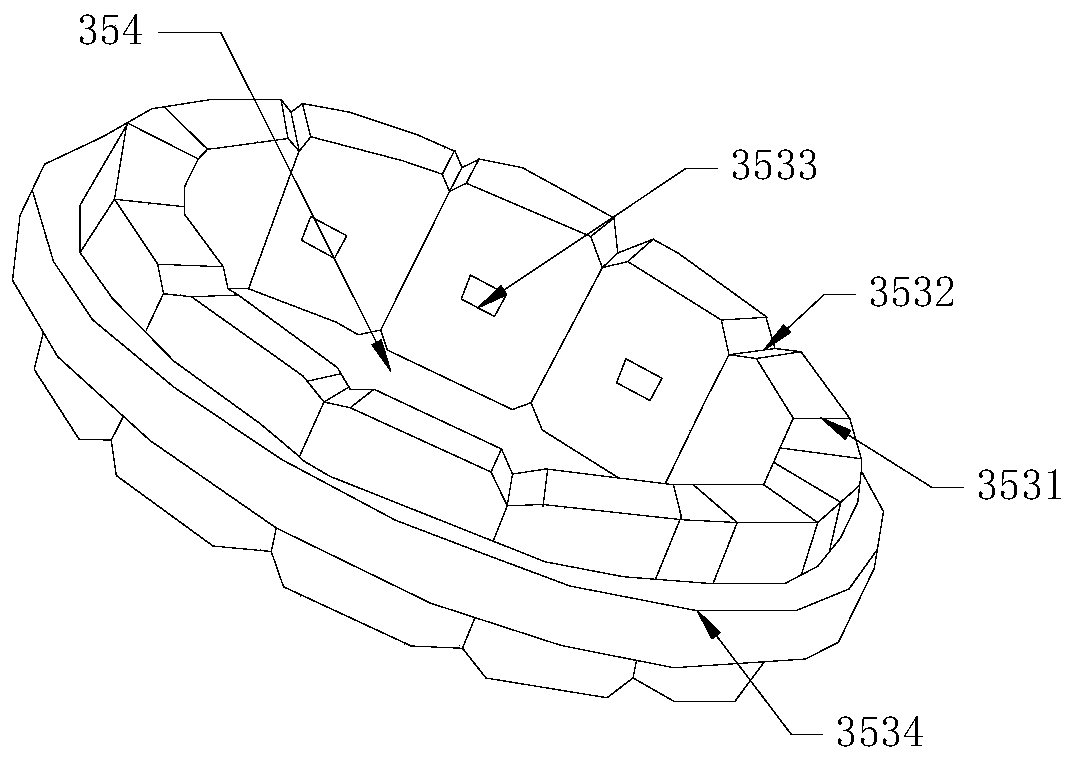

[0055] A sealing device for canned fish in this embodiment includes: a support fixed platform 2 for placing the can box body 1 and a sealing mechanism 3 located above the fixed platform. A pressing part 31, a second pressing part 32 and a third pressing part 33, the first pressing part 31 is flexibly connected to the second pressing part 32 through the first connecting part 34, and the second pressing part 32 is connected to the second pressing part 35 through the second connecting part 35 The three pressing parts 33 are movably connected. The sealing mechanism 3 also includes a rotating shaft 36 for the sealing part to rotate. The rotating shaft 36 is connected to the first pressing part 31. The first pressing part 31 is provided with a groove that is snap-fitted with the first connecting part 34. One end of the first connecting part 34 is connected with the first pressing part 31, and the other end of the first con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com