Patents

Literature

76results about How to "Avoid affecting the sealing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

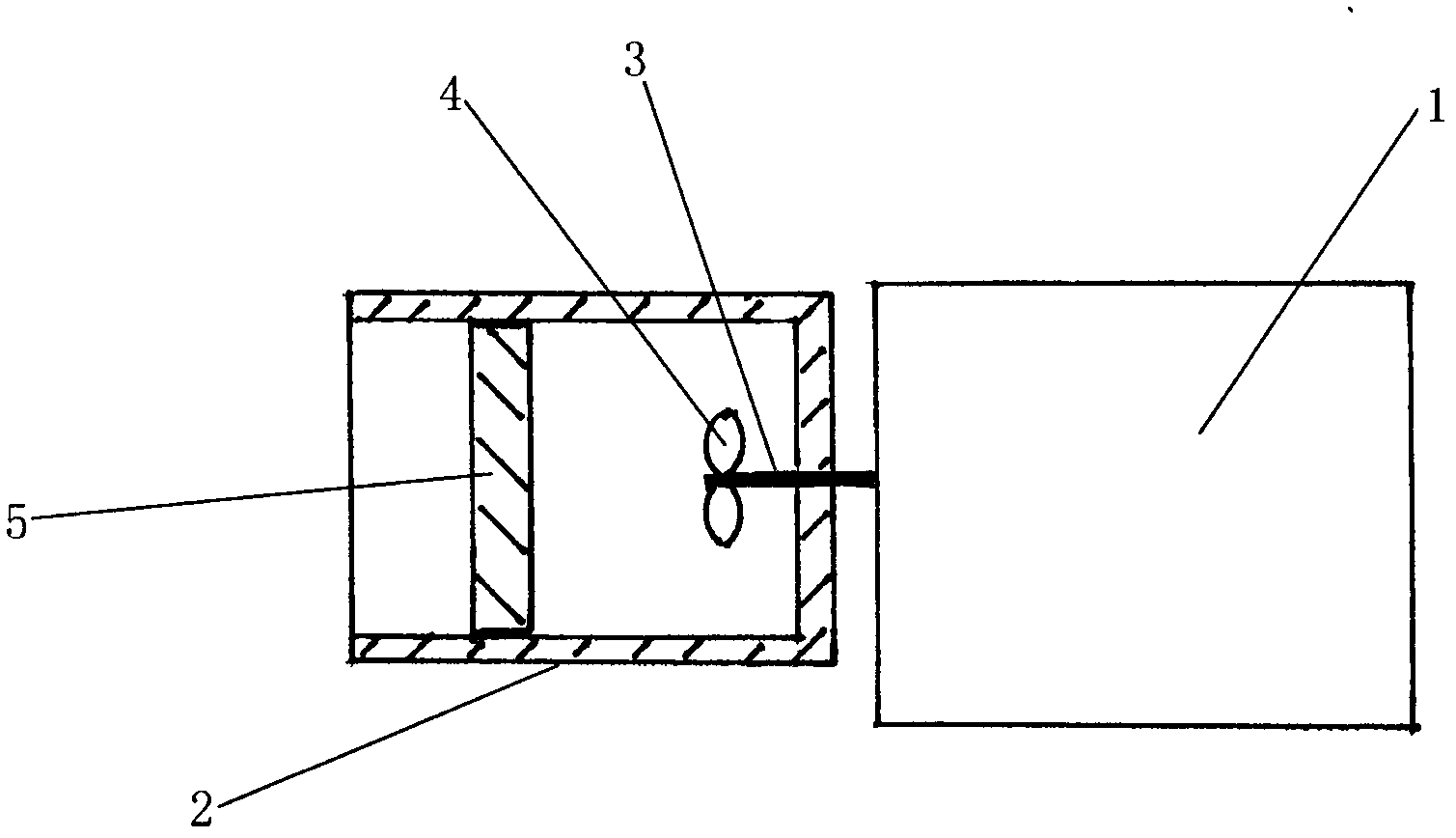

Positive-pressure type video camera lens protective cover

InactiveCN101135829AImprove sealingAvoid water seepageInstrument housingHermetically-sealed casingsCamera lensPositive pressure

Owner:杜永辉

Food processor with piston type sealing device

InactiveCN102578930AAvoid enteringReduce exposureVessels with intergral heatingMechanical engineeringControl circuit

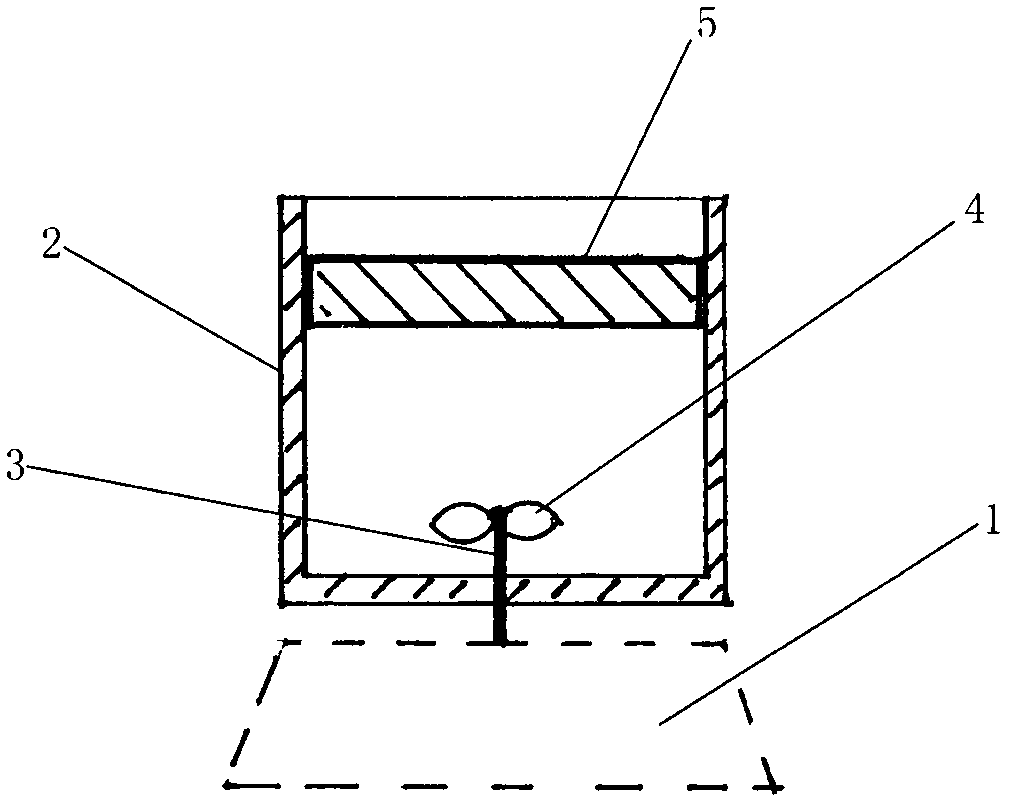

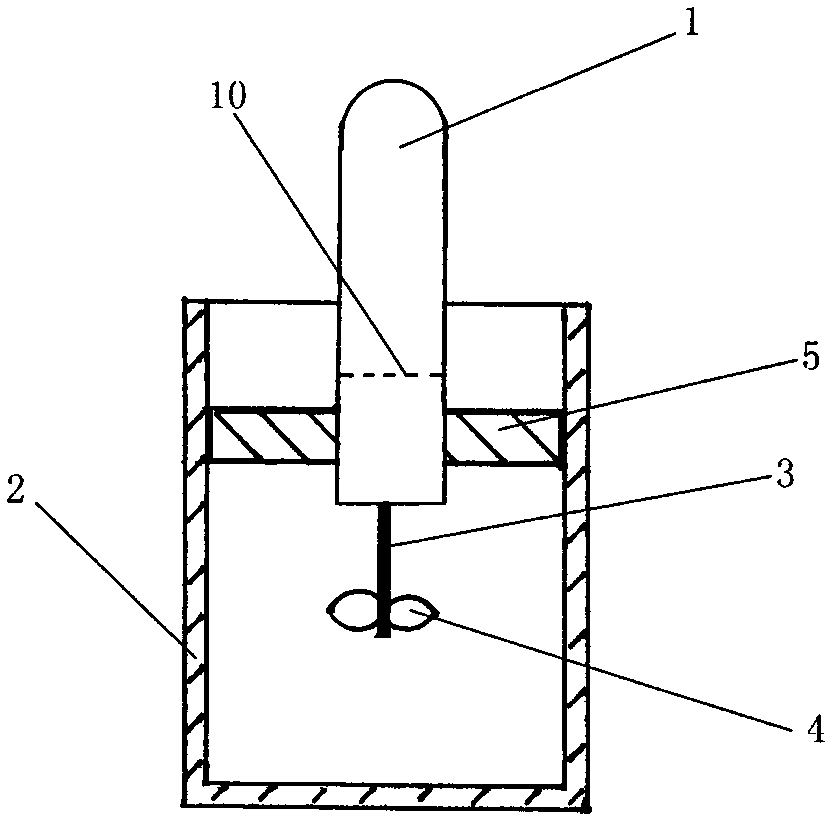

The invention relates to a food processor with a piston type sealing device. The food processor comprises a main food processor body consisting of a smashing device, a motor, a barrel body, a control circuit board and the like. A piston type sealing device is arranged in the barrel body, is in sliding fit or sliding seal with the inner wall of the barrel body, and can move along the longitudinal axis in the barrel body. The piston type sealing device comprises a main piston body which is provided with or not provided with a sealing ring, and is provided with a locking-positioning device, so as to be fixed in one position in the barrel body. In the food processor of the invention, according to the volume of the practical foodstuff liquid, the piston type sealing device is pushed to a position close to the foodstuff liquid level in the barrel body, air in the barrel body is discharged, simultaneously, the barrel body is sealed, air outside the barrel body is prevented from entering in the smashing process, the possibility of oxidization of foodstuff liquid processed by the food processor in the smashing process can be reduced and avoided, the nutrition loss is reduced, and the good mouthfeel and appearance color are kept.

Owner:王晓东

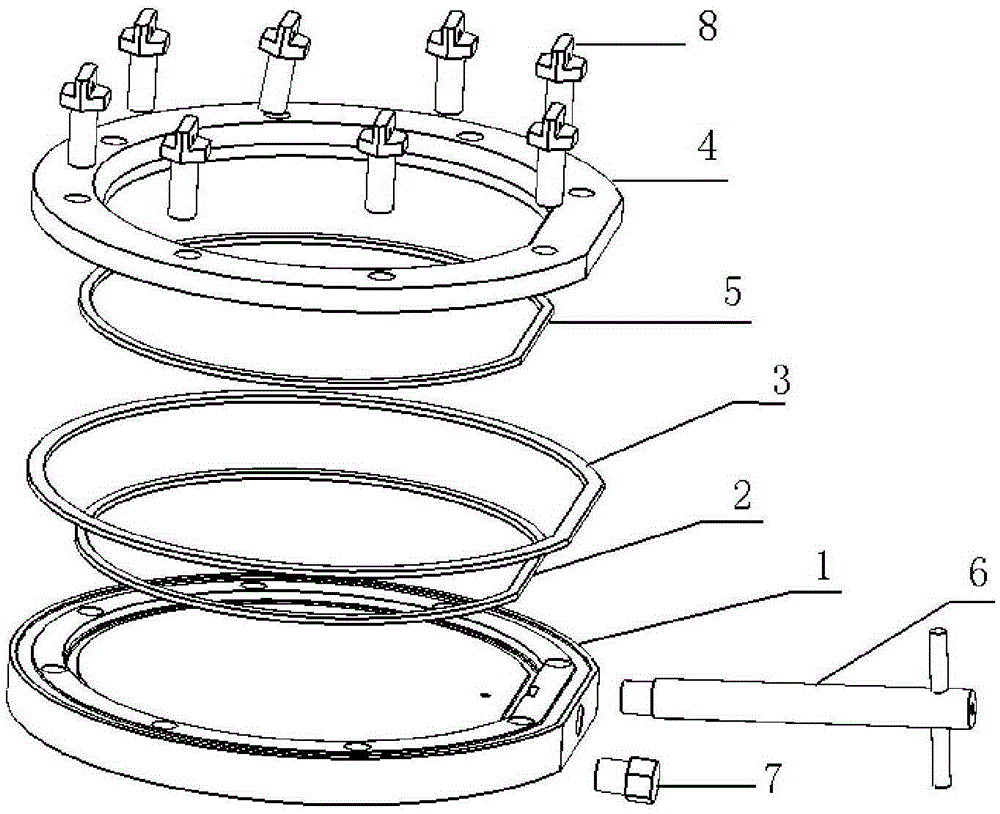

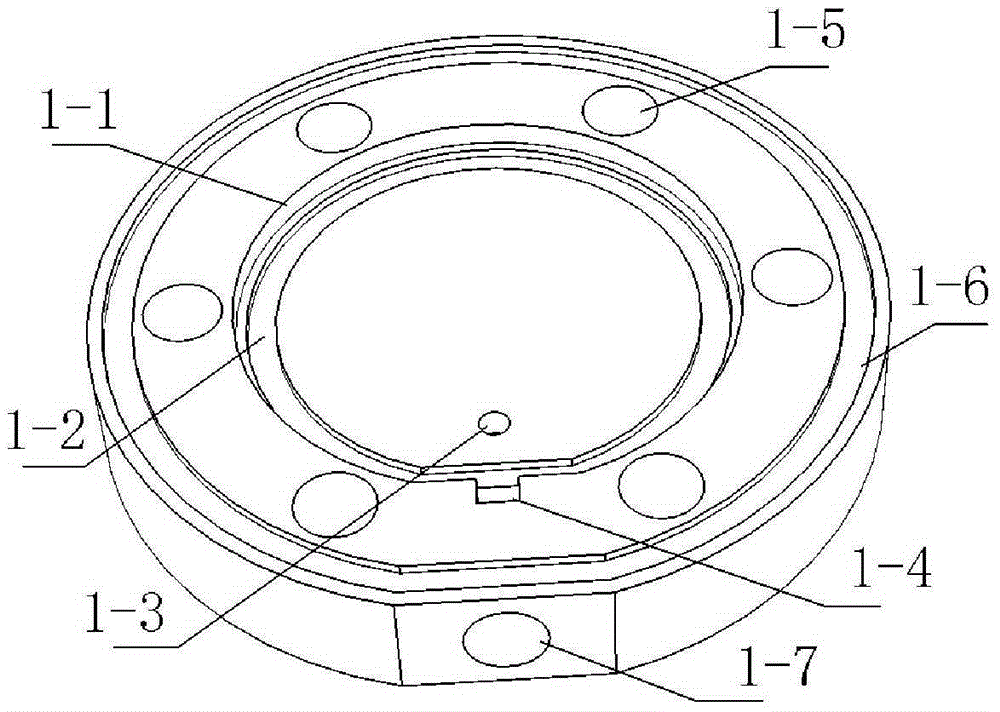

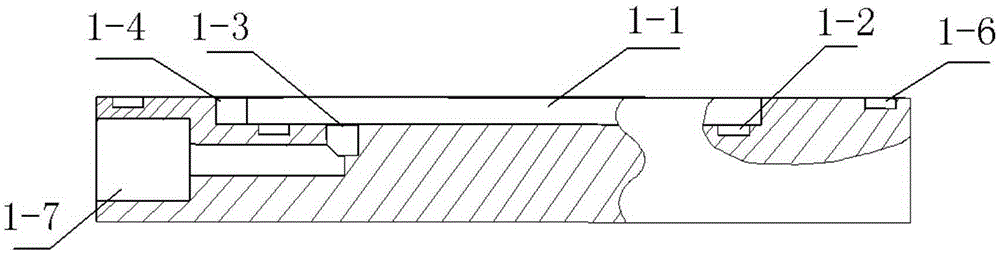

Wet etching protection clamp free of damage to wafer

InactiveCN105405802AAchieve perfect protectionAchieve the purpose of protectionSemiconductor/solid-state device manufacturingStress pointEngineering

The invention discloses a wet etching protection clamp free of a damage to a wafer. The wet etching protection clamp comprises a base and a head cover, wherein the base and the head cover are matched with each other to clamp the wafer; the wafer comprises a to-be-protected front surface and a to-be-corroded back surface; the base can accommodate and can wrap the front surface in a sealing manner; the head cover is in an annular shape and abuts on the edge part of the back surface; and the base and the head cover both are in contact with the wafer through elastic buffer sealing elements. The wet etching protection clamp has the advantages that due to a flexible clamping design, the wafer only contacts the flexible sealing element in use and the damage to the wafer caused by a rigid contact is reduced; due to a corresponding clamping design, clamping stress points of the upper and lower sealing elements correspond to each other, and the crack of the wafer caused by uneven stress is avoided; and due to the design of a corresponding shape of the protected surface, splitting caused by the uneven stress due to the fact that the wafer is twisted when the clamp is fastened is avoided.

Owner:ZHEJIANG UNIV

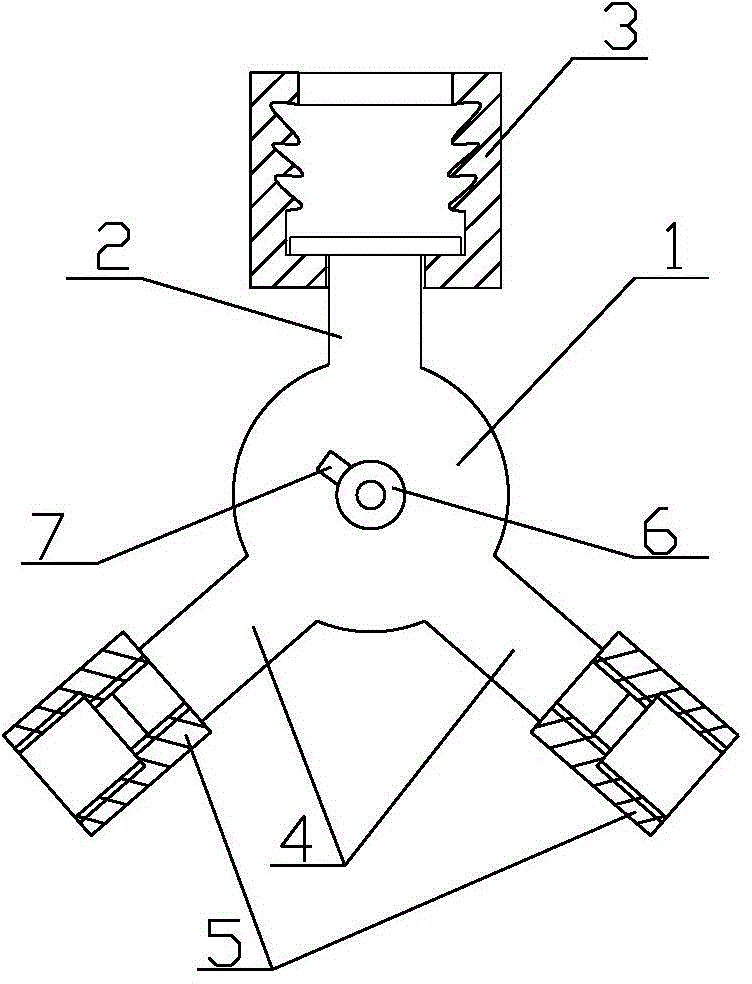

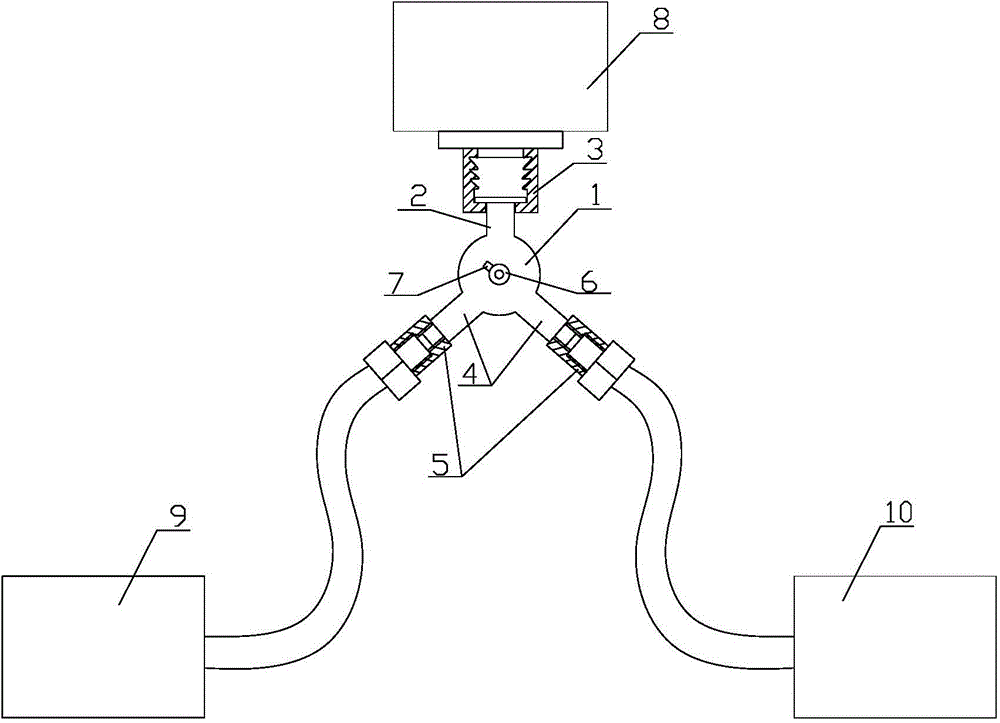

Special tee for test of sulfur hexafluoride gas and use method of tee

InactiveCN104315286ASimple structureEasy to usePipe elementsBranching pipesSulfur hexafluorideBrackish water

The invention relates to a special tee for the test of sulfur hexafluoride gas. The tee comprises a hollow body; the hollow body is provided with one air inlet pipe and two air outlet pipes; the end parts of the air inlet pipe and the air outlet pipes are provided with detachable adapters; the hollow body is also provided with a releasing valve; the use method comprises the steps of 1, selecting the adapters; 2, connecting electrical equipment filled with the sulfur hexafluoride gas and used sulfur hexafluoride gas brackish water and decomposer test equipment; 3, testing; 4, performing gas releasing operation after the test is finished; 5, wholly transferring to the next test point for performing the next around test. Compared with the prior art, the special tee for test of the sulfur hexafluoride gas and the use method of the tee have the beneficial effects that 1, the brackish water test and decomposer test of the sulfur hexafluoride gas can be finished at the same time; 2, the times for assembling and disassembling the adapters are reduced, and the influence to the sealing effect of the equipment due to multiple times of assembly and disassembly is avoided; 3, the work efficiency is improved, and the labor intensity of workers is relieved; 4, data is not influenced by residual gas, the test precision is improved and the harm to staff caused by overlarge gas pressure is prevented.

Owner:MAINTENANCE BRANCH STATE GRID LIAONING ELECTRIC POWER +1

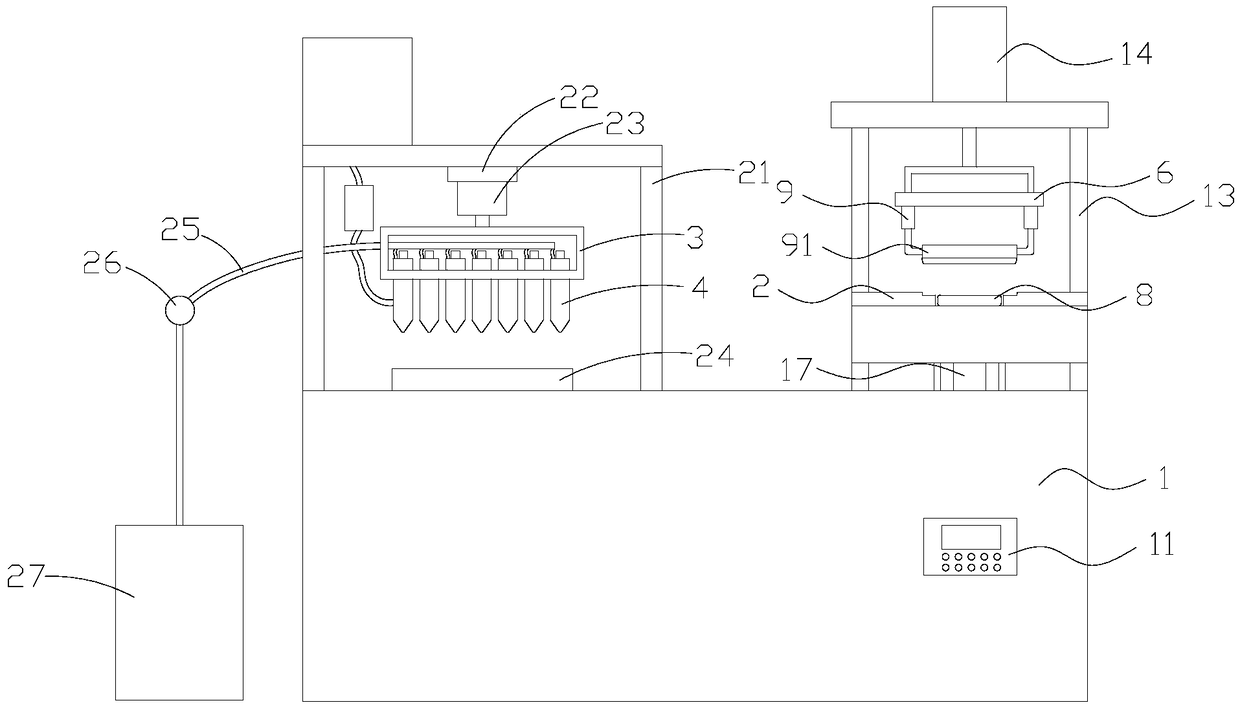

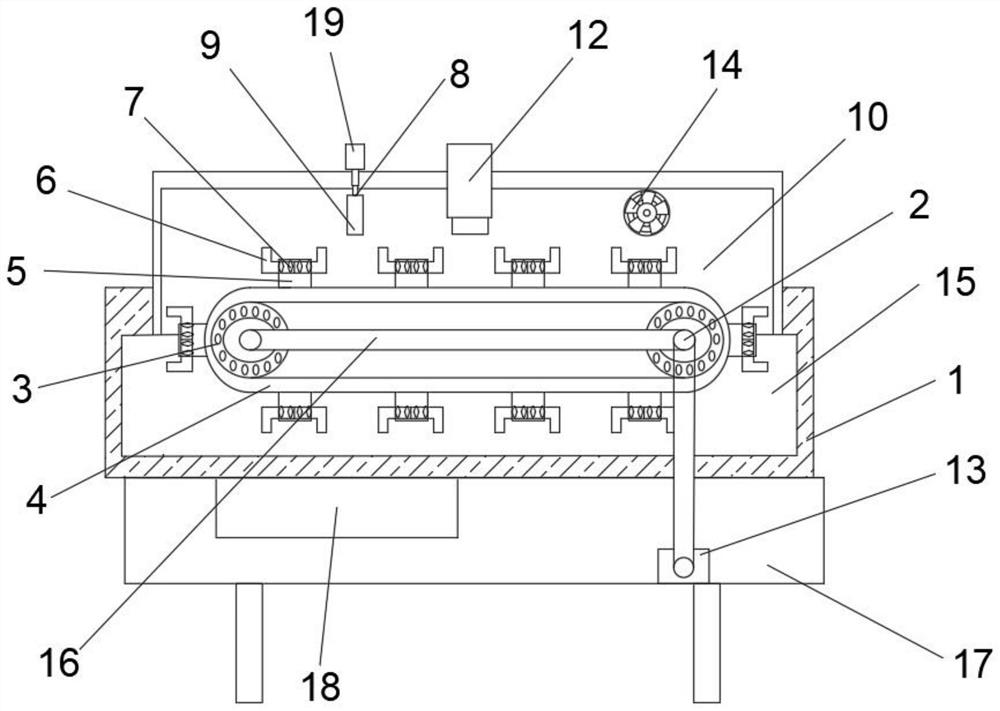

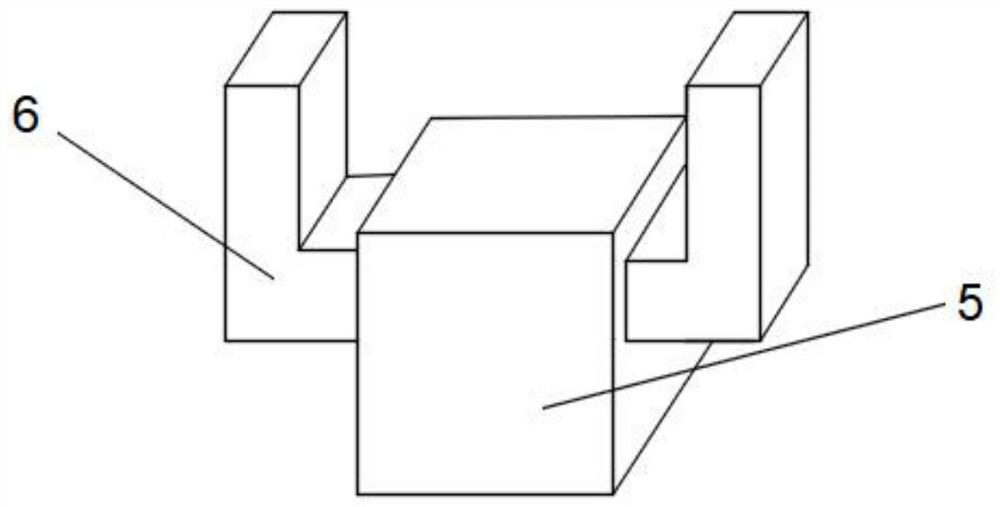

LED lamp processing device

InactiveCN109351559AAvoid cloggingGuaranteed to workLiquid surface applicatorsCoatingsLED lampMechanical engineering

The invention discloses an LED lamp processing device. The device comprises a base, a crystal expanding mechanism and a glue dispensing mechanism; the crystal expanding mechanism comprises a placementplatform, a crystal expanding part, an annular cutting part and a film pressing part, the glue dispensing mechanism comprises a glue gun frame, a glue gun and a feeding device, a fixed ring is arranged on the lower surface of the film pressing part, a first channel matched with the crystal expanding part is arranged on the annular cutting part, a second channel allowing the crystal expanding partto pass through is arranged on the film pressing part, a third channel the same with the crystal expanding part in size and shape is arranged on the placement platform, a glue dispensing head is detachably connected to the glue gun, a telescopic assembly is arranged in the glue dispensing head, and the glue gun is externally connected with a liquid inlet assembly. Through the liquid inlet assembly, glue in the glue gun can be kept at the proper concentration all the time, and the problem that due to solidification of glue in the glue gun, blockage is caused is solved.

Owner:HANGZHOU XIAOCHENG IND DESIGN CO LTD

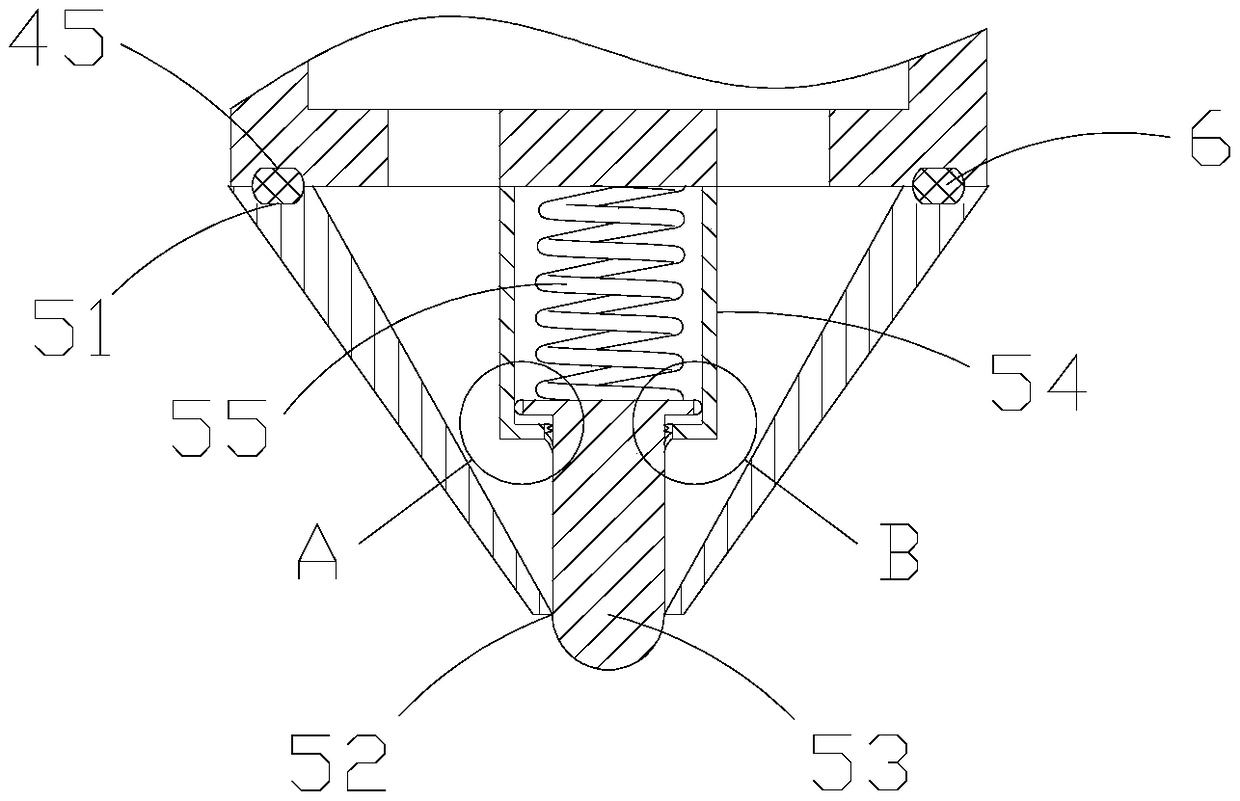

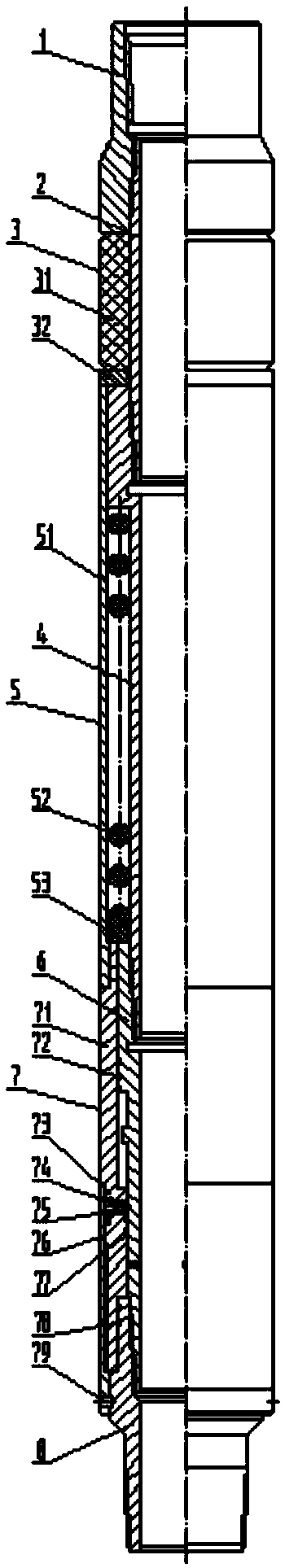

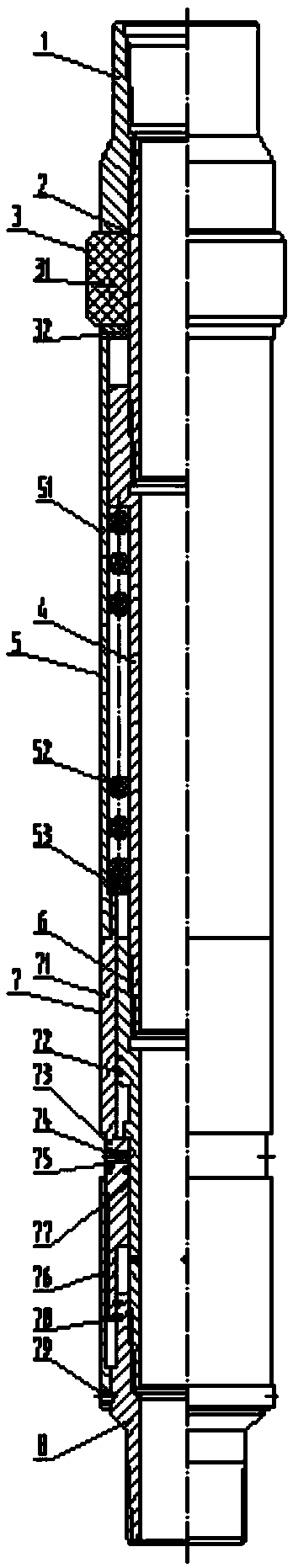

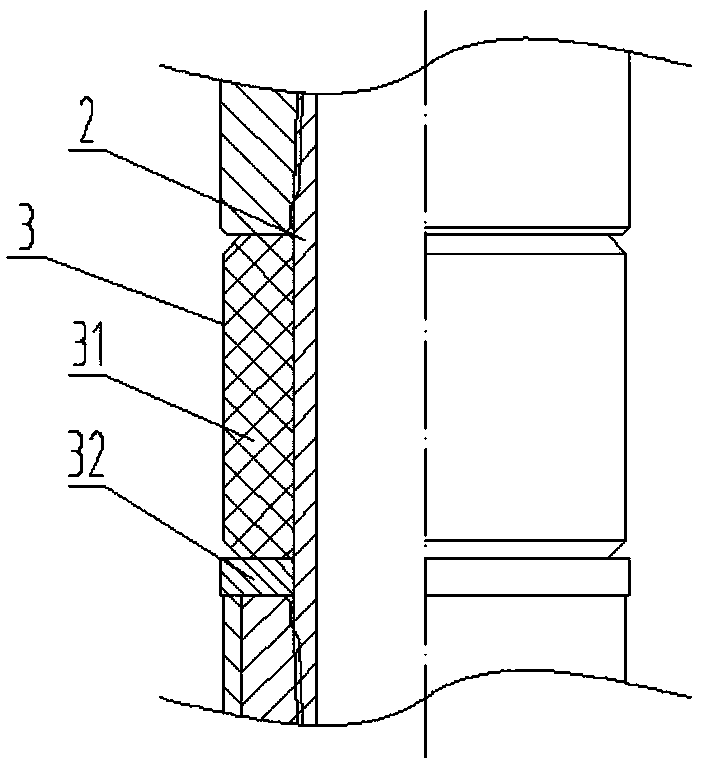

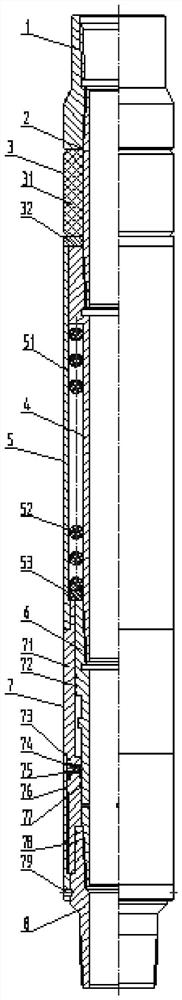

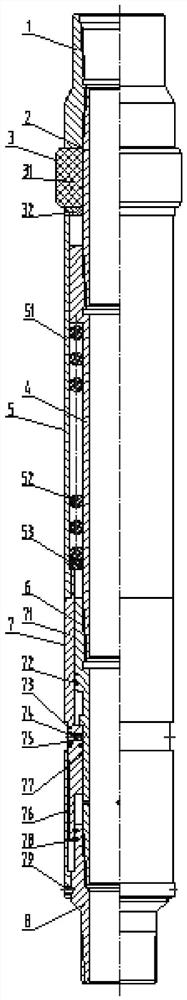

Non-throttling self-service unsealed packer

InactiveCN109538182AEasy to controlWithstand large pressure differenceFluid removalSealing/packingDual effectEngineering

The invention discloses a non-throttling self-service unsealed packer which comprises an upper connector, an upper central pipe, a sealing mechanism, a spring central pipe, a spring self-service unsealing mechanism, a lower central pipe, a setting-dissoluble unsealing mechanism and a lower connector. No throttling or setting needs to be conducted for the non-throttling self-service unsealed packer, and the setting process is convenient to control; limiting steps are arranged in the packer, it is avoided that the sealing effect is affected by the excessive compression of a rubber cylinder; by means of the compressed rubber cylinder, the borne pressure difference is large, and the setting effect is good and stable; large-discharge and large-scale cracking construction refitting can be realized; by means of the spring self-service unsealing mechanism, unnecessary advanced setting generated in the pipe column put-down process is avoided; after cracking construction ends, the rubber cylinder of the packer is rapidly unsealed under the dual effects of the rebound force of the rubber cylinder and the self-service unsealing force of a spring; by means of the setting-dissoluble unsealing mechanism, under the high pressure in a well, the rapid unsealing of the packer can still be ensured.

Owner:CNPC BOHAI DRILLING ENG

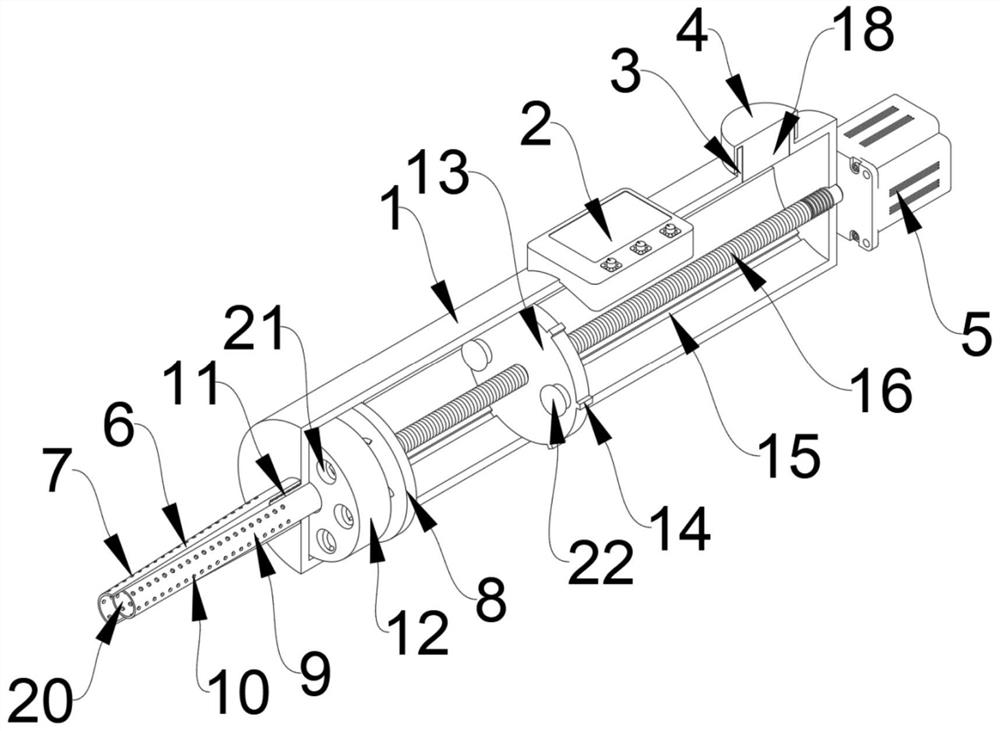

Fuel-rod end plug pressing machine and application method

ActiveCN106531260ASimplified assembly stepsImprove sealingNuclear energy generationReactors manufactureControl systemEngineering

The invention discloses a fuel-bar end plug pressing machine and an application method. The device comprises a base, a driving system and a control system. A fixing mechanism, an operating chamber, a sealing mechanism and a pushing mechanism are arranged on the base, an air feeding and discharging mechanism is connected to the operating chamber, and the control system controls the driving system to drive the pushing mechanism and the air feeding and discharging mechanism. The application method of the device includes the steps that vacuumizing and inflating are carried out in the sealed operating chamber, and after the proportion of inflated inert gas reaches a preset proportion, plug pressing is directly carried out till a plug is tightly pressed. By means of the device, the sealing effect of a fuel bar can be improved, sealing leakage detection is facilitated, operating is more convenient, the mixing possibility of other air ingredients is reduced, contact of a core block in the fuel bar and a shell covering pipe is effectively delayed, and the performance and the safety of the fuel bar are improved. By means of the application method, the volume ratio of the inflated gas can be accurately controlled, the plug pressing step is simplified, the performance and the safety of the fuel bar are improved, the cost is reduced, and the production efficiency is improved.

Owner:CNNC JIANZHONG NUCLEAR FUEL +1

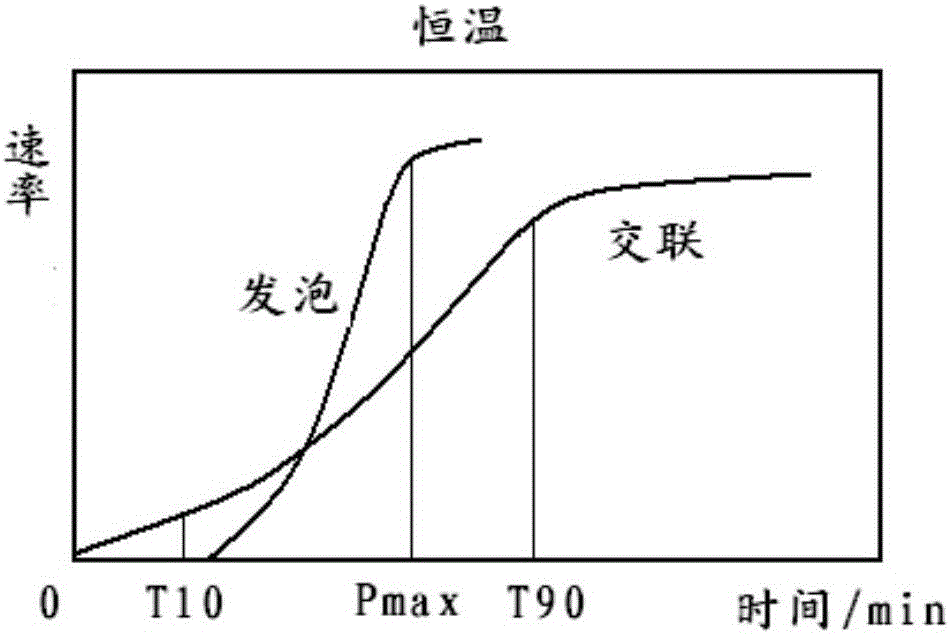

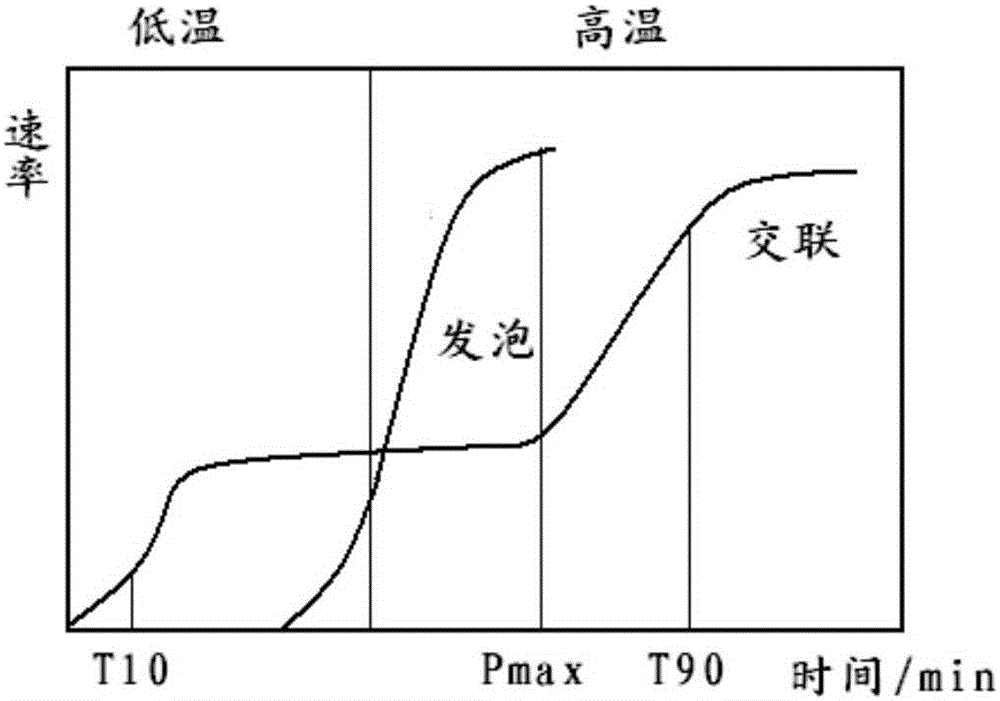

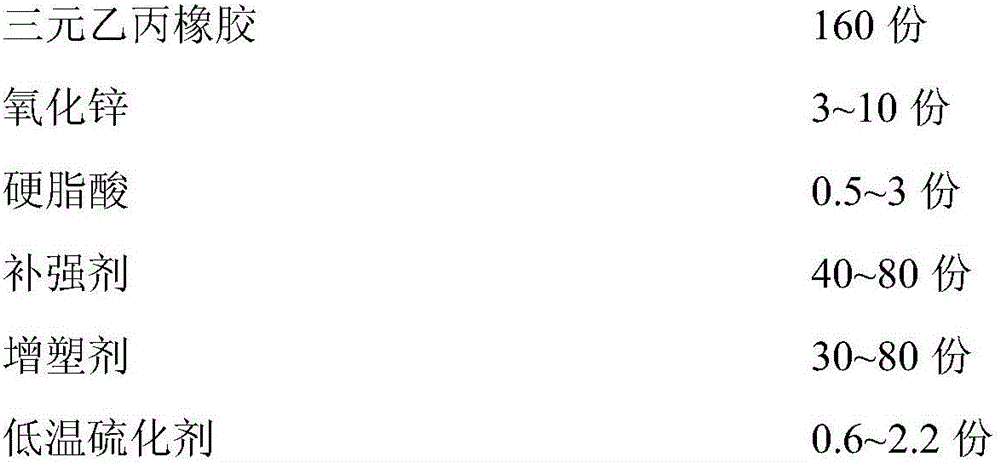

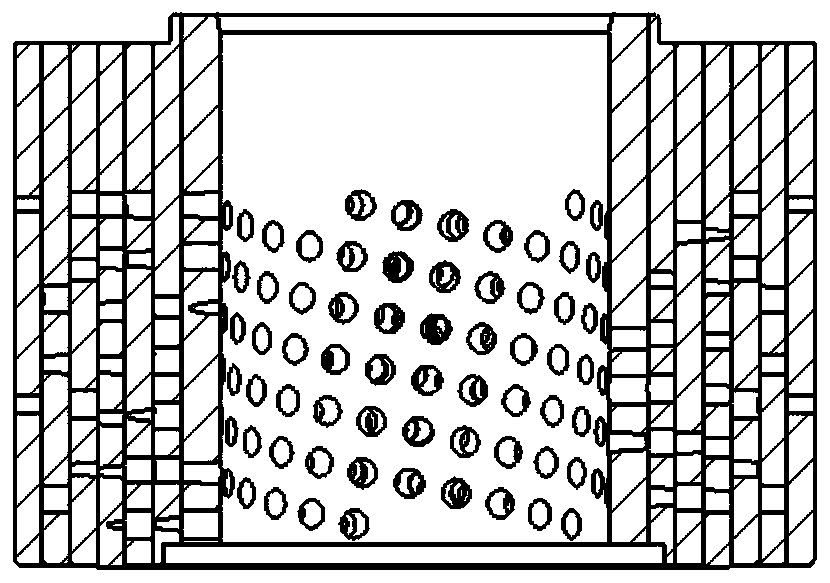

EPDM rubber foaming material and moulding method

The invention belongs to the technical field of high-molecular materials. Through combination of high-temperature foaming system and a low-temperature foaming system and two-stage vulcanization technology of pressure vulcanization and non-pressure foaming vulcanization, micro-foaming micro-nucleuses and high-temperature foaming vulcanization are realized. The EPDM rubber foaming material at least comprises the following ingredients (by weight): 160 parts of EPDM rubber, 3-10 parts of zinc oxide, 0.5-3 parts of stearic acid, 40-80 parts of a strengthening agent, 30-80 parts of a plasticizer, 0.6-2.2 parts of a low-temperature vulcanizing agent, 0.8-2.4 parts of a high-temperature vulcanizing agent, and 0.8-2.2 parts of a foaming agent. The EPDM rubber foaming material has advantages as follows: foaming is uniform; surface state is good; pressure change, hardness and low-temperature performance of the material can be designed and regulated according to requirements; and the product has good dimensional stability and high controllability. The moulding method is suitable for whole compression moulding of large-size foam sealing rings with low pressure change, low hardness and low temperature resistance and having requirements on dimension and appearance.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

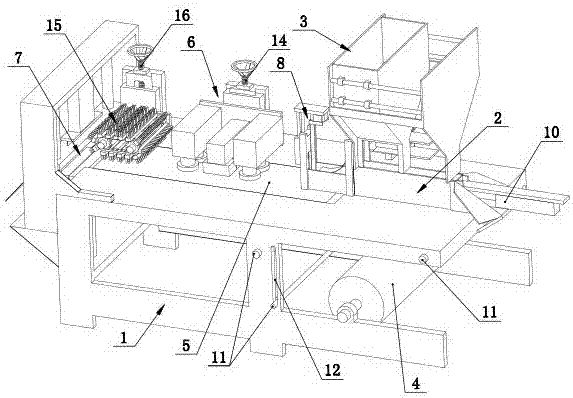

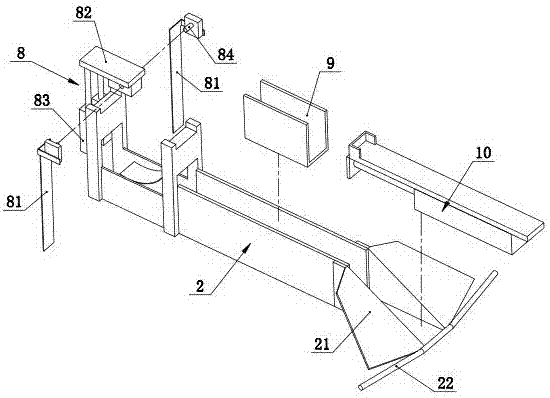

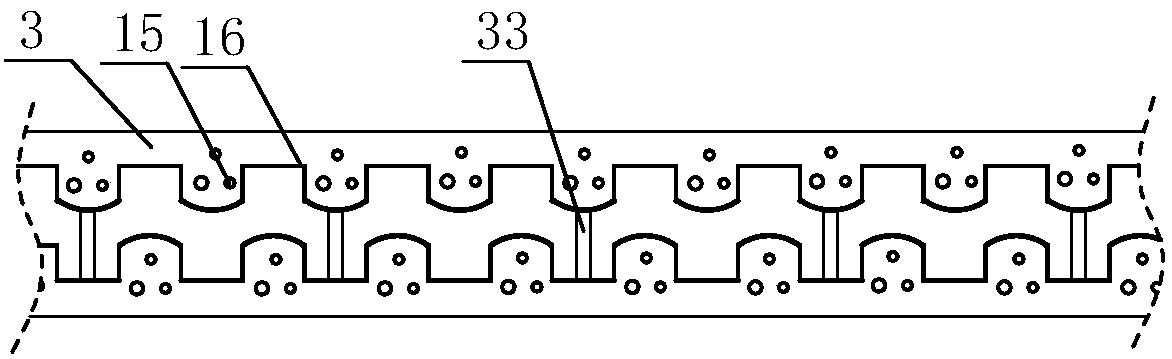

Bamboo stick type product packing machine

InactiveCN106938711AAutomate the packaging processImprove processing efficiencyWrapper twisting/gatheringRod-shaped articlesEngineeringSurface heat

The invention discloses a bamboo stick type product packing machine which comprises a rack; a loading bin, a feeding funnel, a packing bag output roll and a conveying belt are arranged on the rack; the loading bin is strip-shaped; the cross section of the loading bin is U-shaped; the front end of the loading bin is connected with the packing bag output roll; the rear end of the loading bin is connected with the input end of the conveying belt; the feeding funnel is located above the middle part of the loading bin; a side surface heat sealing mechanism for carrying out folding and heat sealing on the two sides of a packing bag is arranged above the conveying belt; and a sealing and cutting mechanism for finally sealing and cutting the packing bag is arranged at the output end of the conveying belt. With the adoption of the scheme, the automatic packing machine is applicable to the packing of strip-shaped products like bamboo sticks, toothpicks and chopsticks.

Owner:周忠学

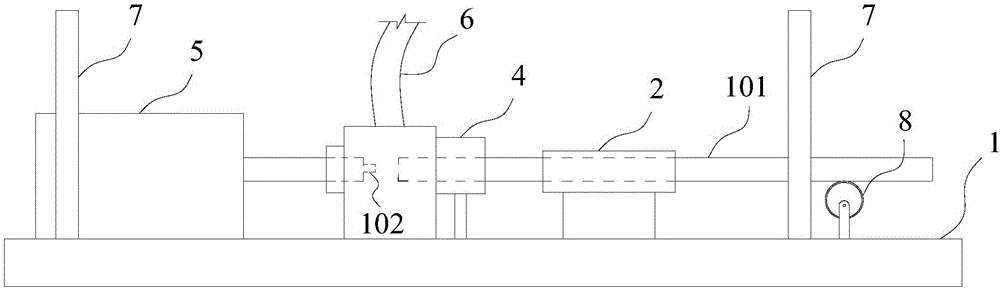

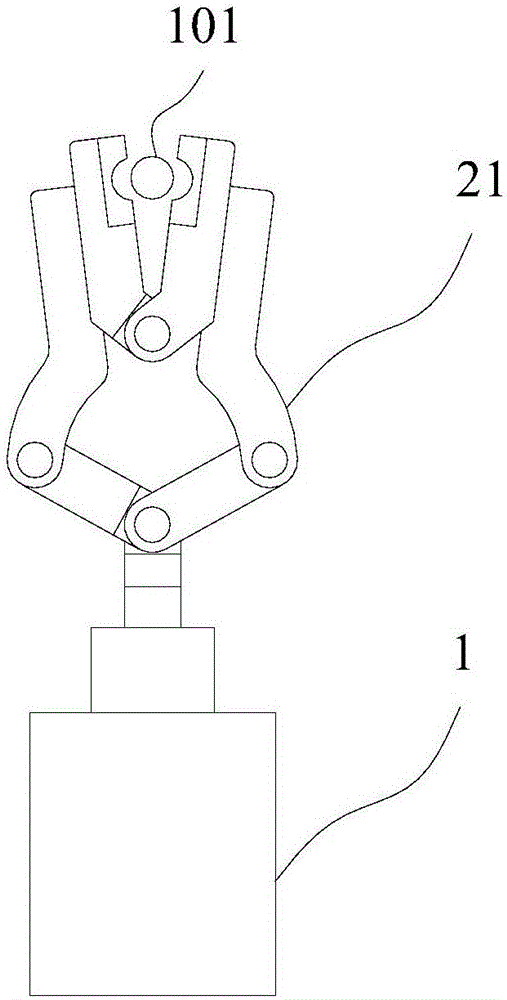

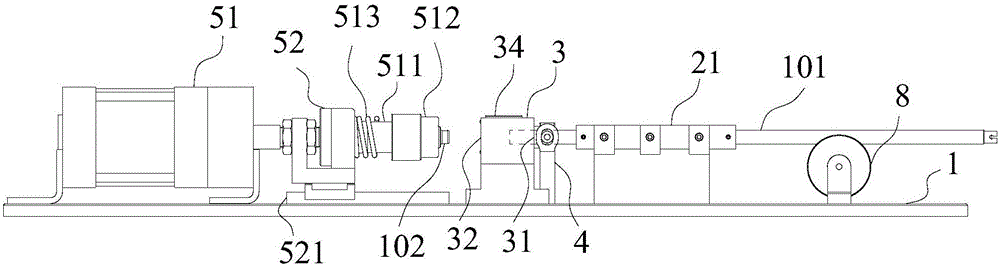

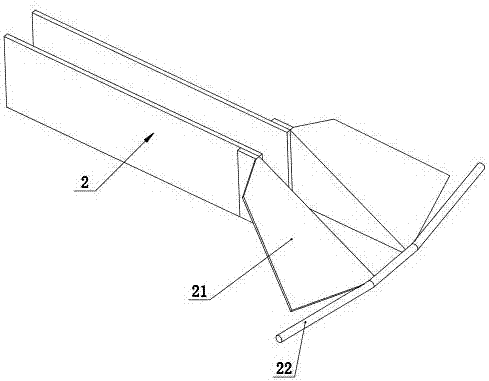

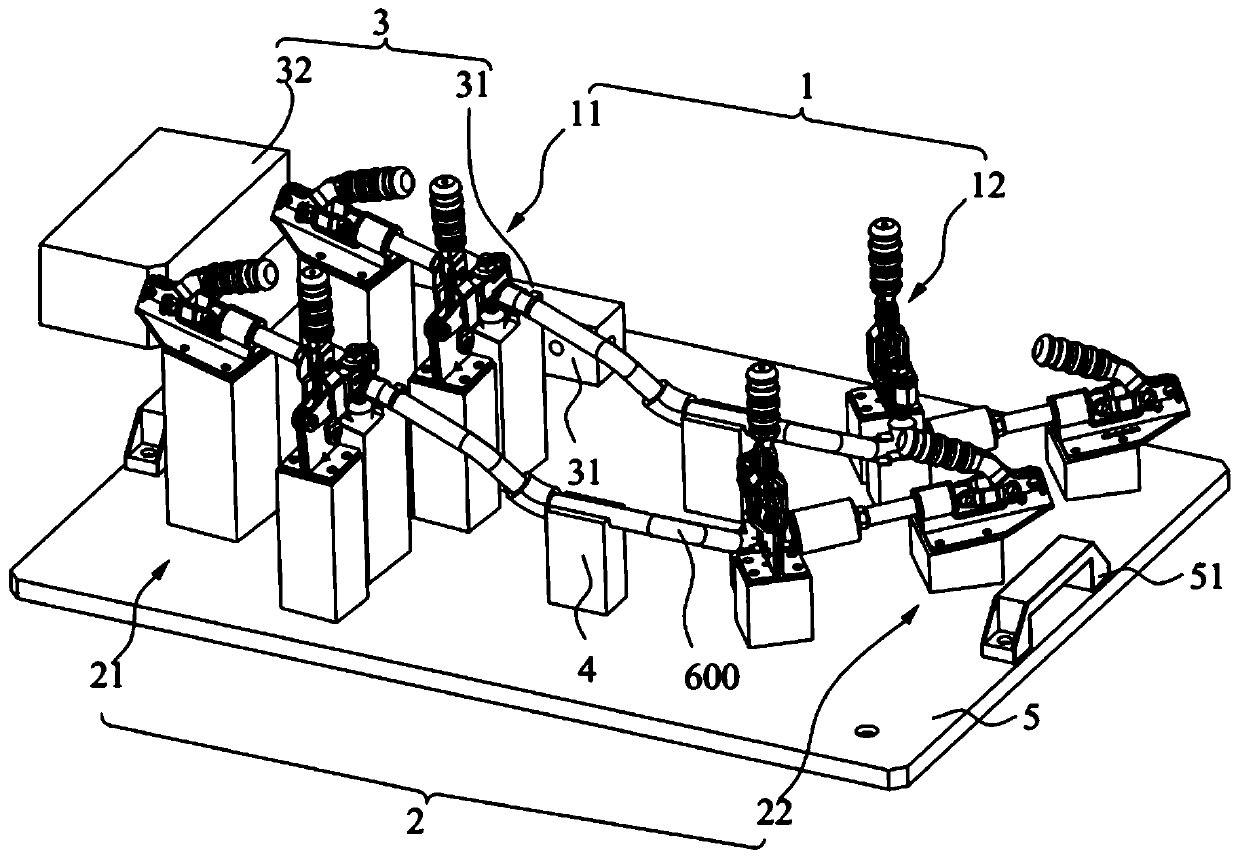

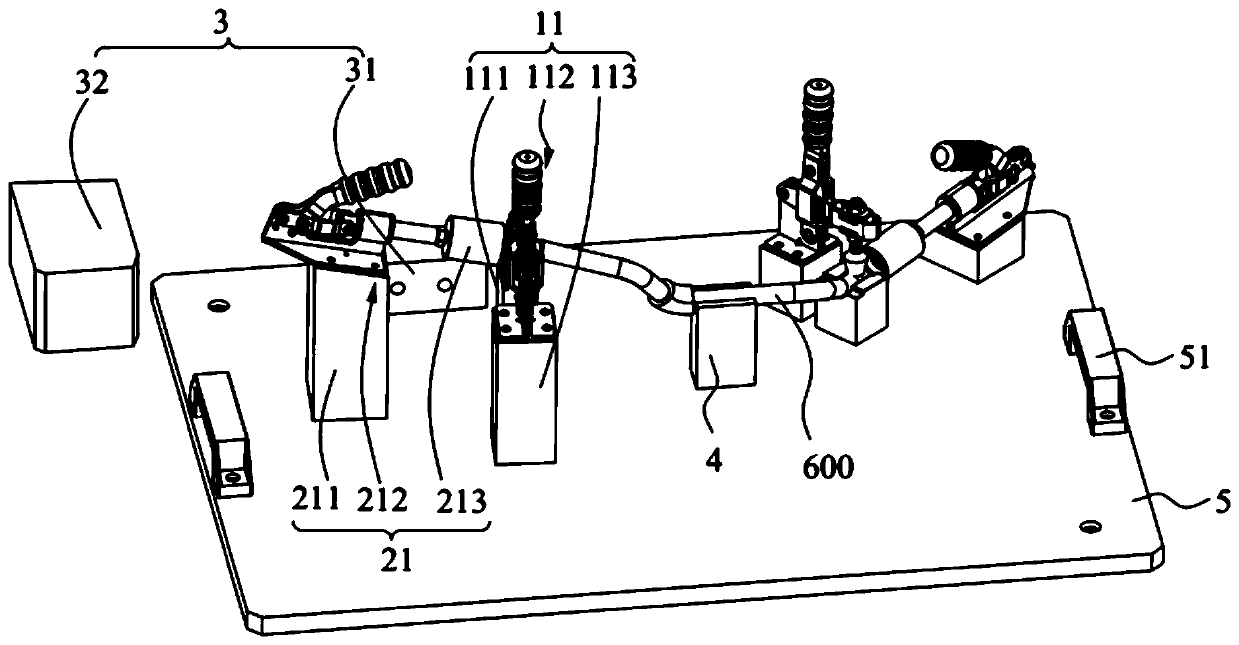

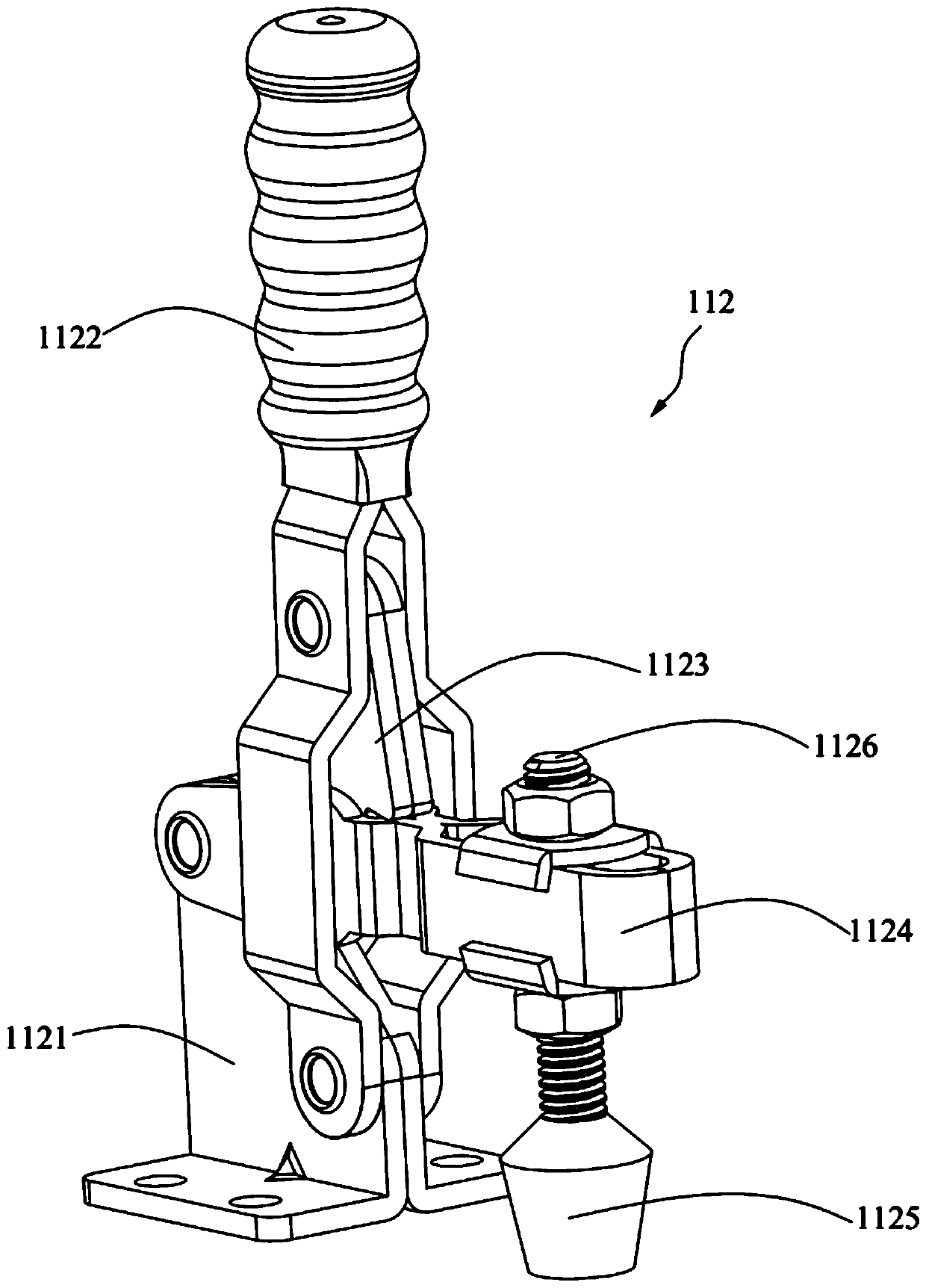

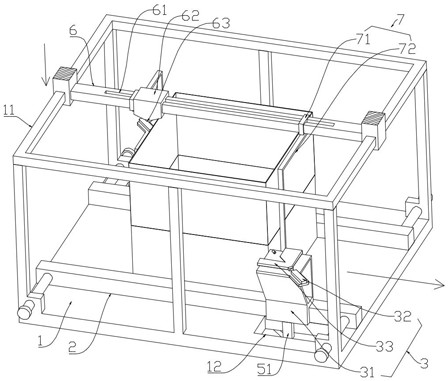

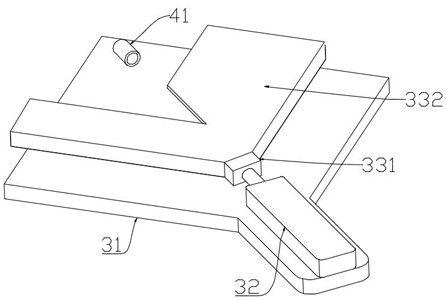

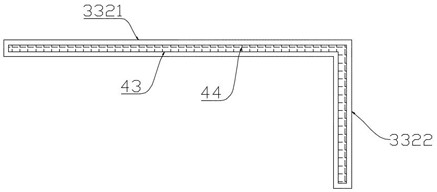

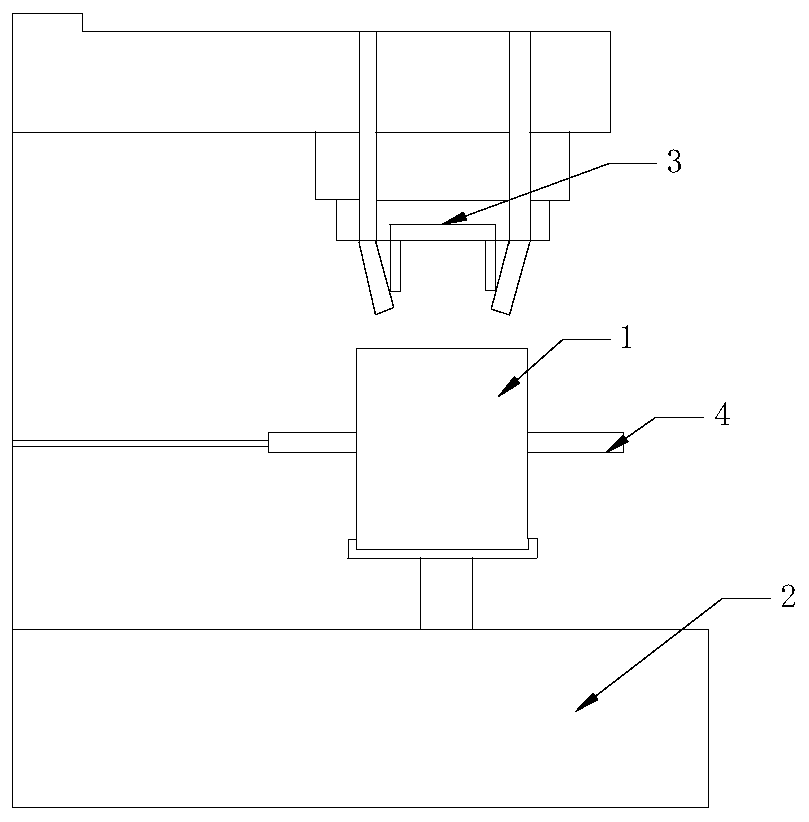

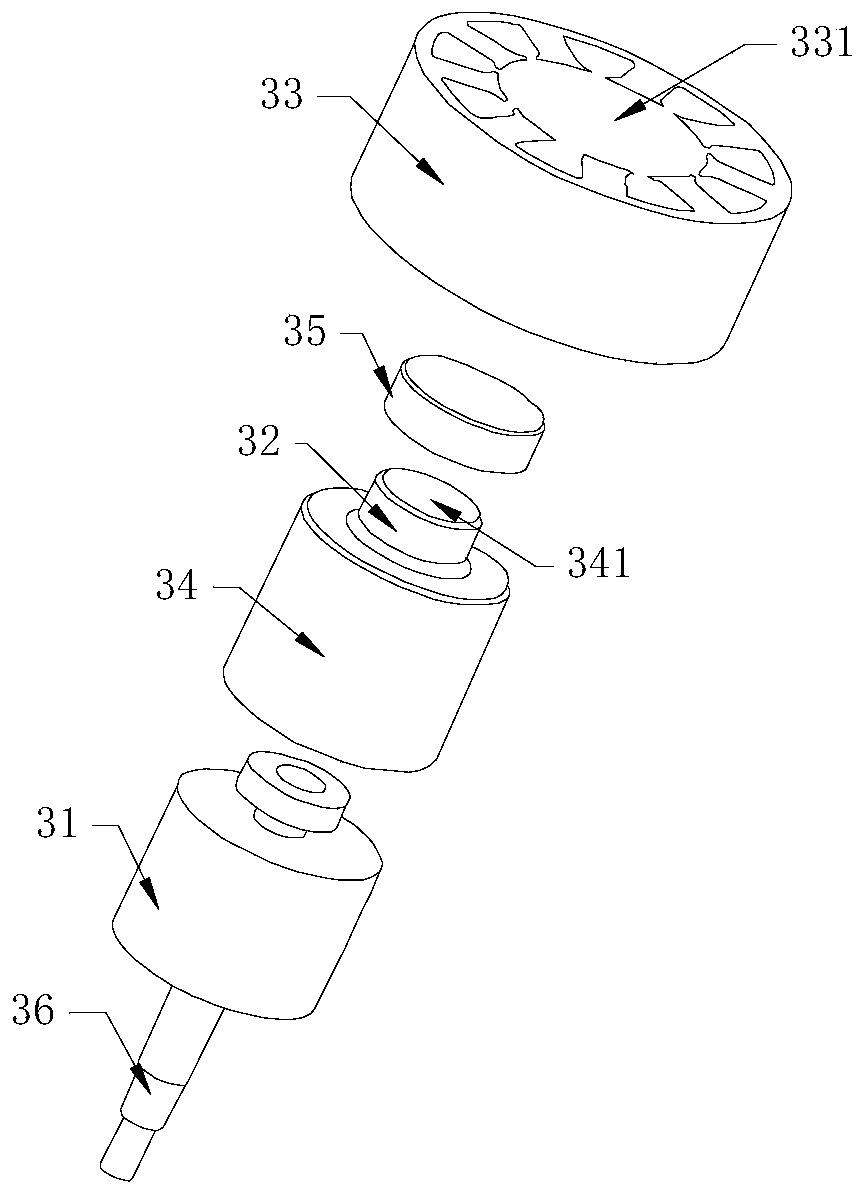

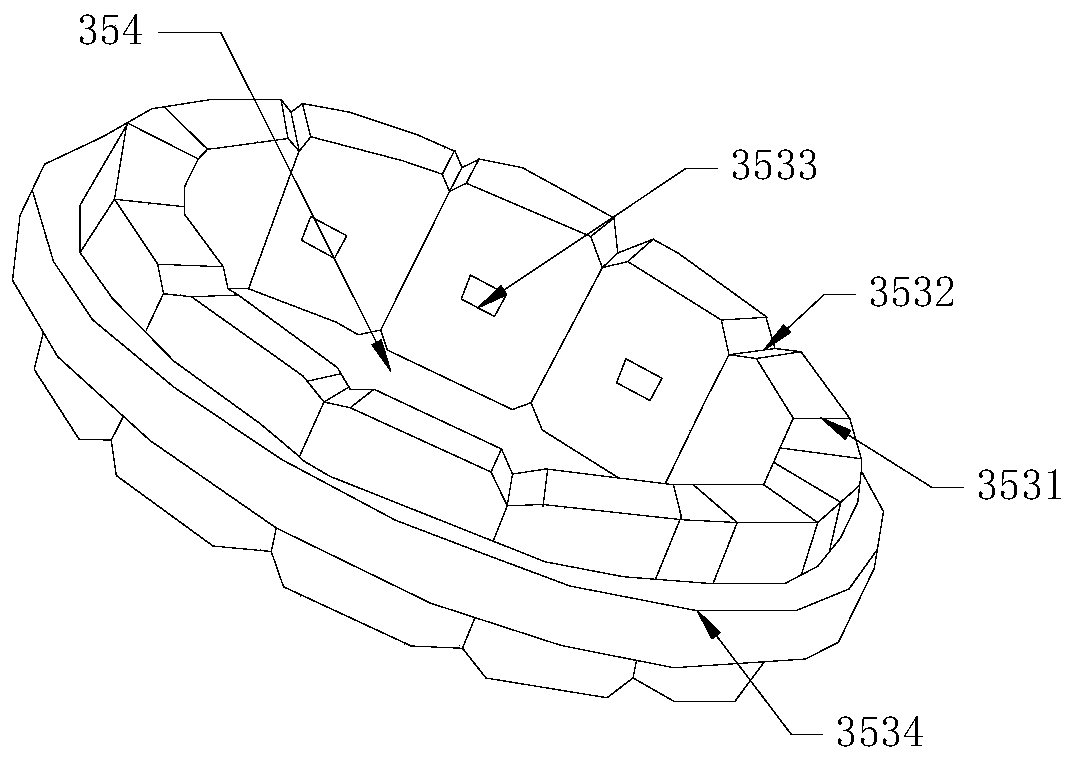

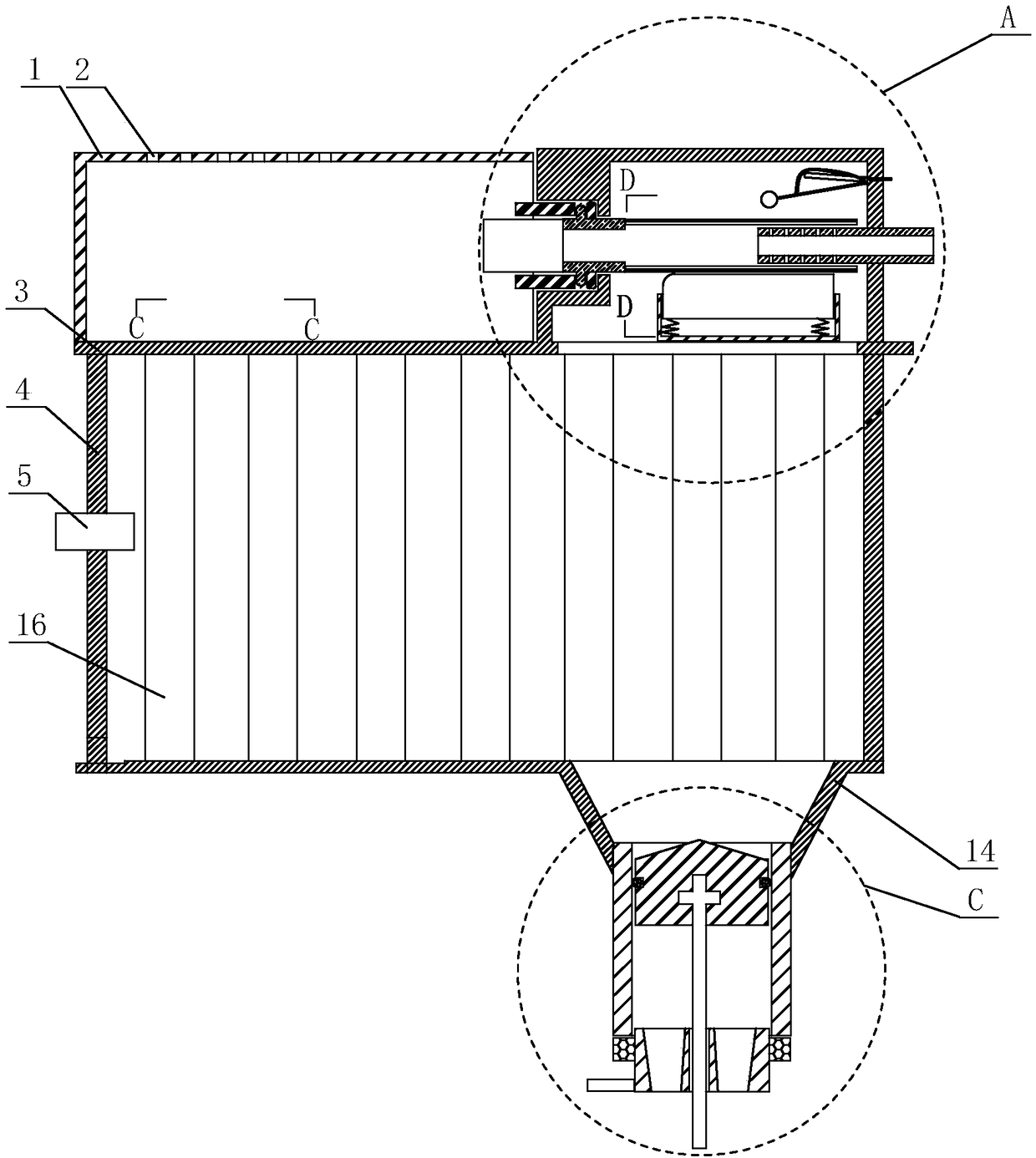

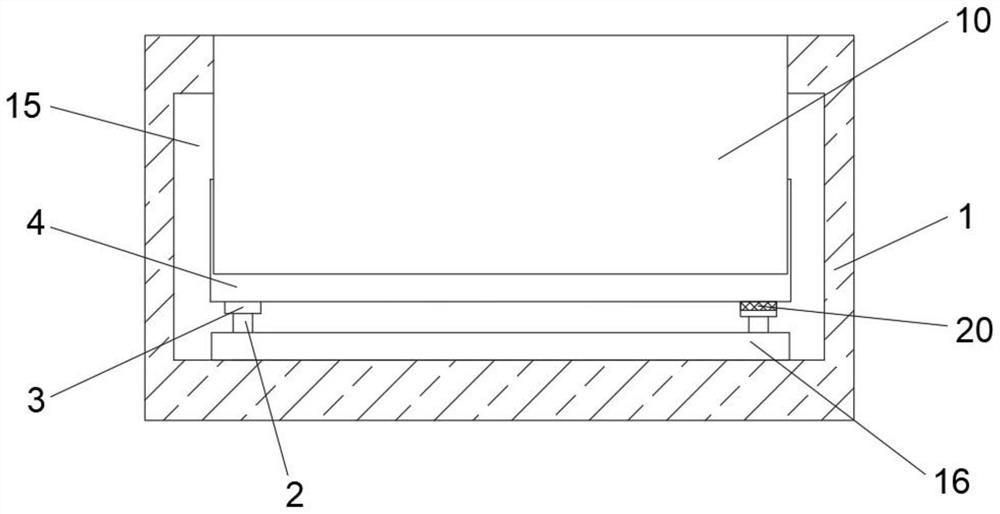

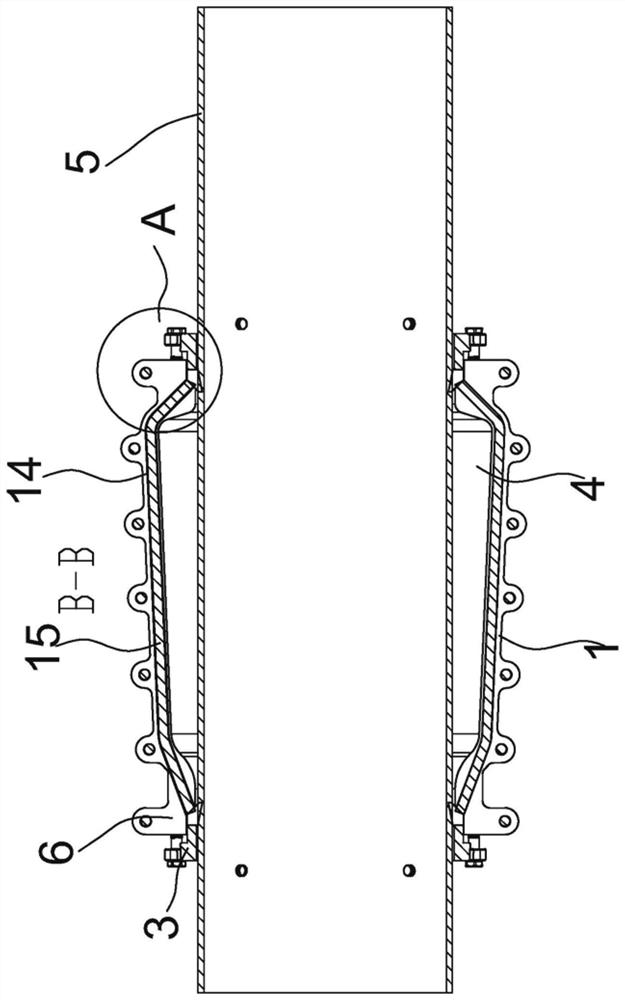

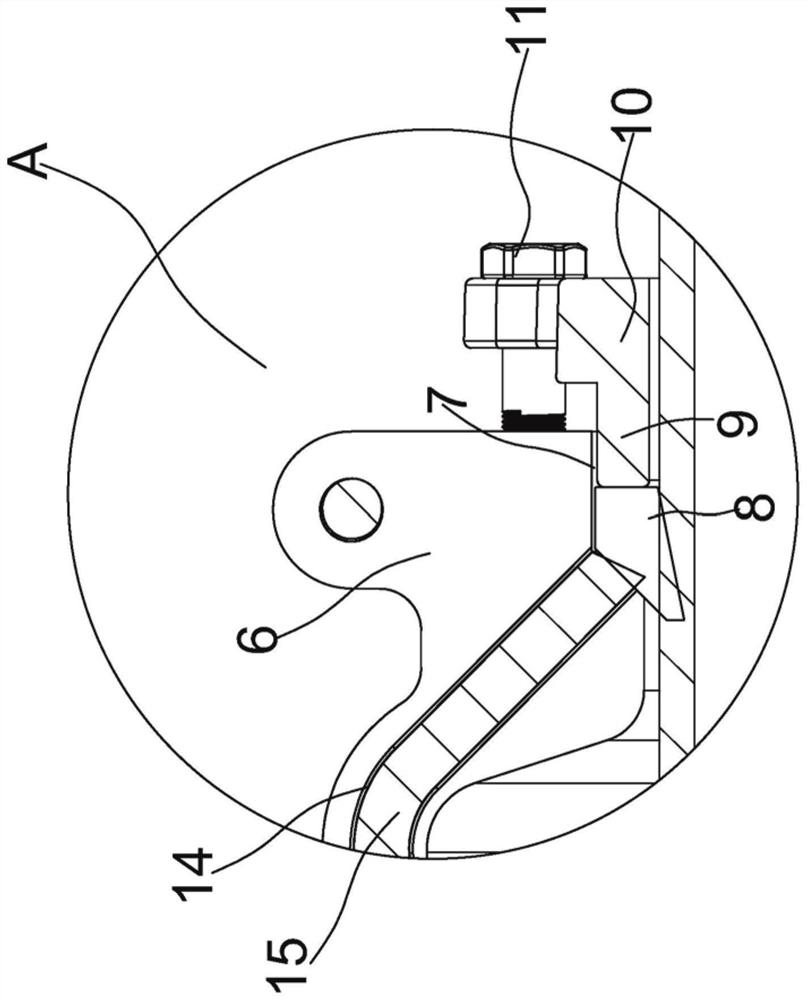

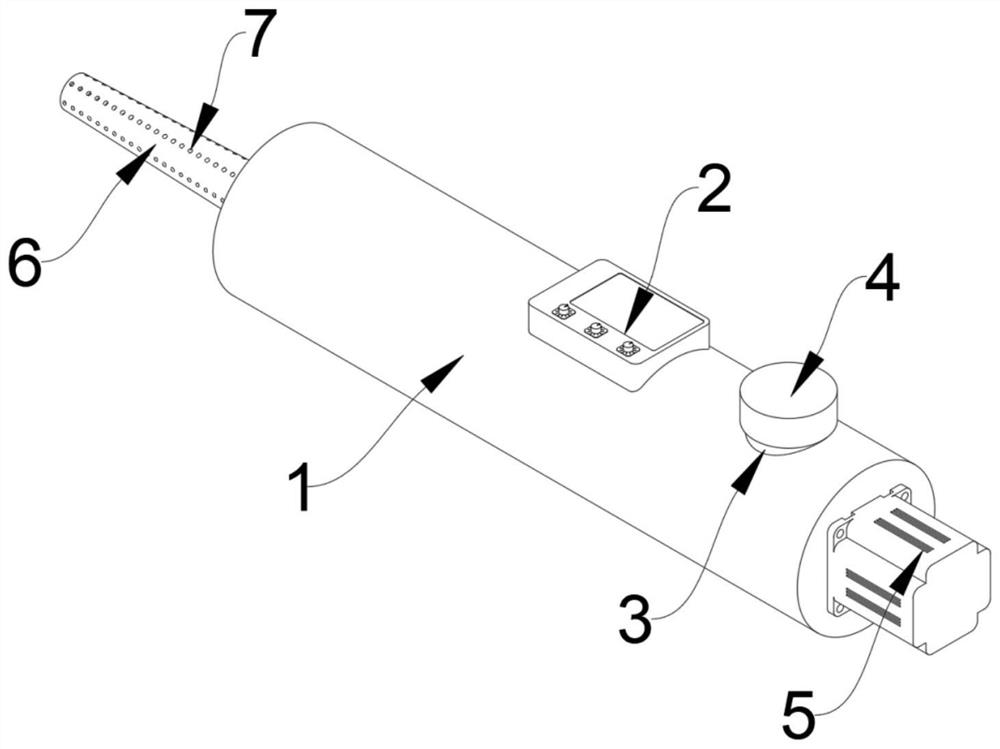

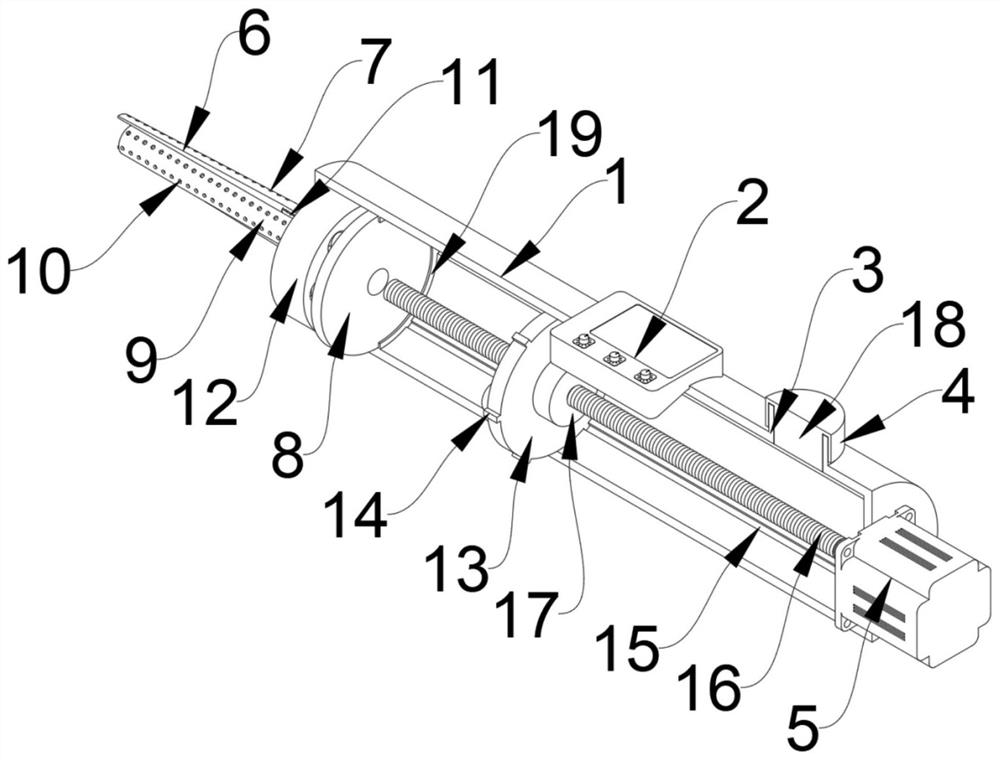

Air tightness detection device

PendingCN110823464AAvoid affecting the sealing effectThe detection structure is accurateMeasurement of fluid loss/gain rateMotor vehicle partEngineering

The invention belongs to the technical field of automobile part production and manufacturing, and discloses an air tightness detection device that comprises a clamping mechanism, a plugging mechanismand a detection mechanism. The clamping mechanism can selectively clamp the two ends of a workpiece. The plugging mechanisms are located on the two sides of the clamping mechanism and can selectivelyseal and plug the two ends of the workpiece. The detection mechanism is communicated with one end of the plugging mechanism, introduces gas into the plugging mechanism and is used for detecting the air tightness of the workpiece. The clamping mechanism, the plugging mechanism and the detection mechanism are matched with one another; the workpiece can be fixed through the clamping mechanism; the sealing and plugging effect of the plugging mechanism is prevented from being affected by movement of the workpiece when the plugging mechanism moves in the direction close to the workpiece and plugs the workpiece, so air tightness detection can be achieved on the workpiece in a sealed state through the detection mechanism; the detection structure is more accurate, and therefore the detection precision is improved.

Owner:SHANGHAI JINGZHI IND CO LTD

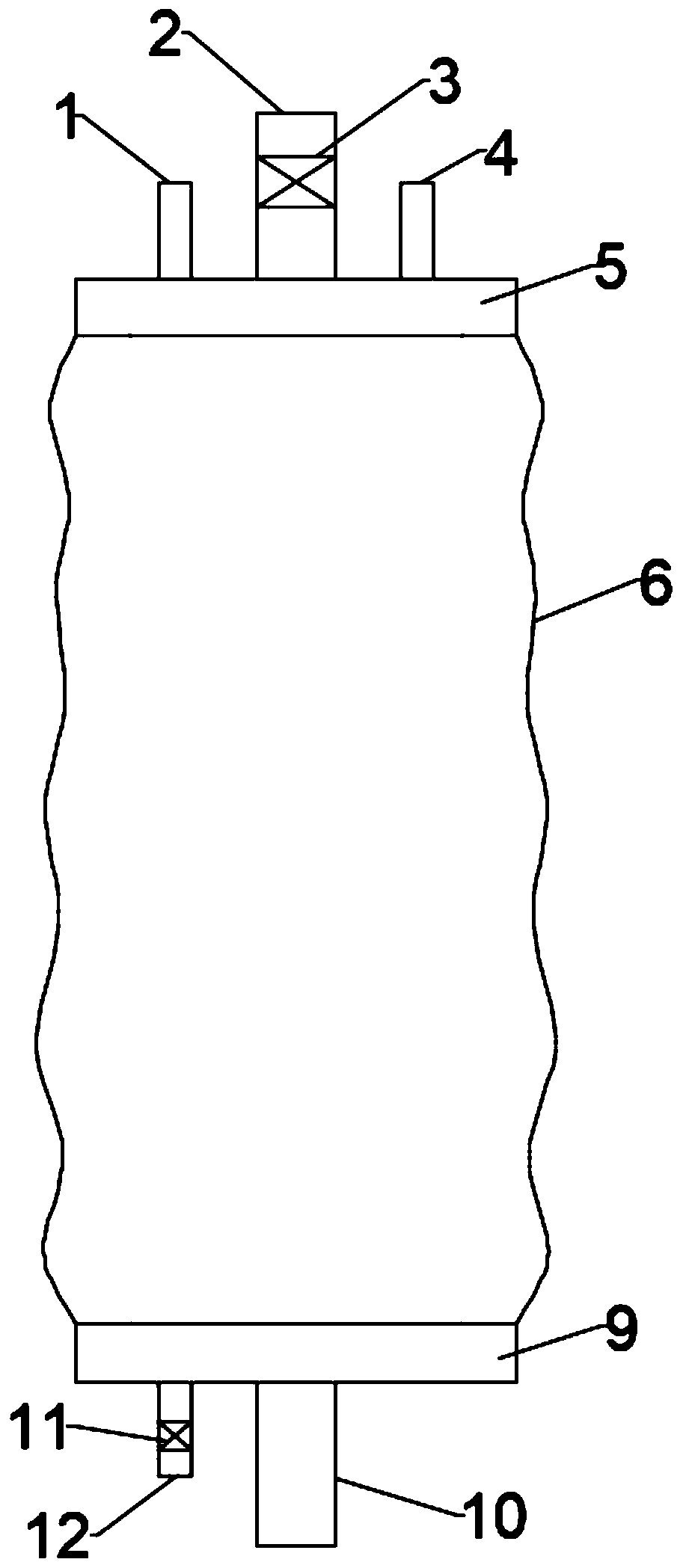

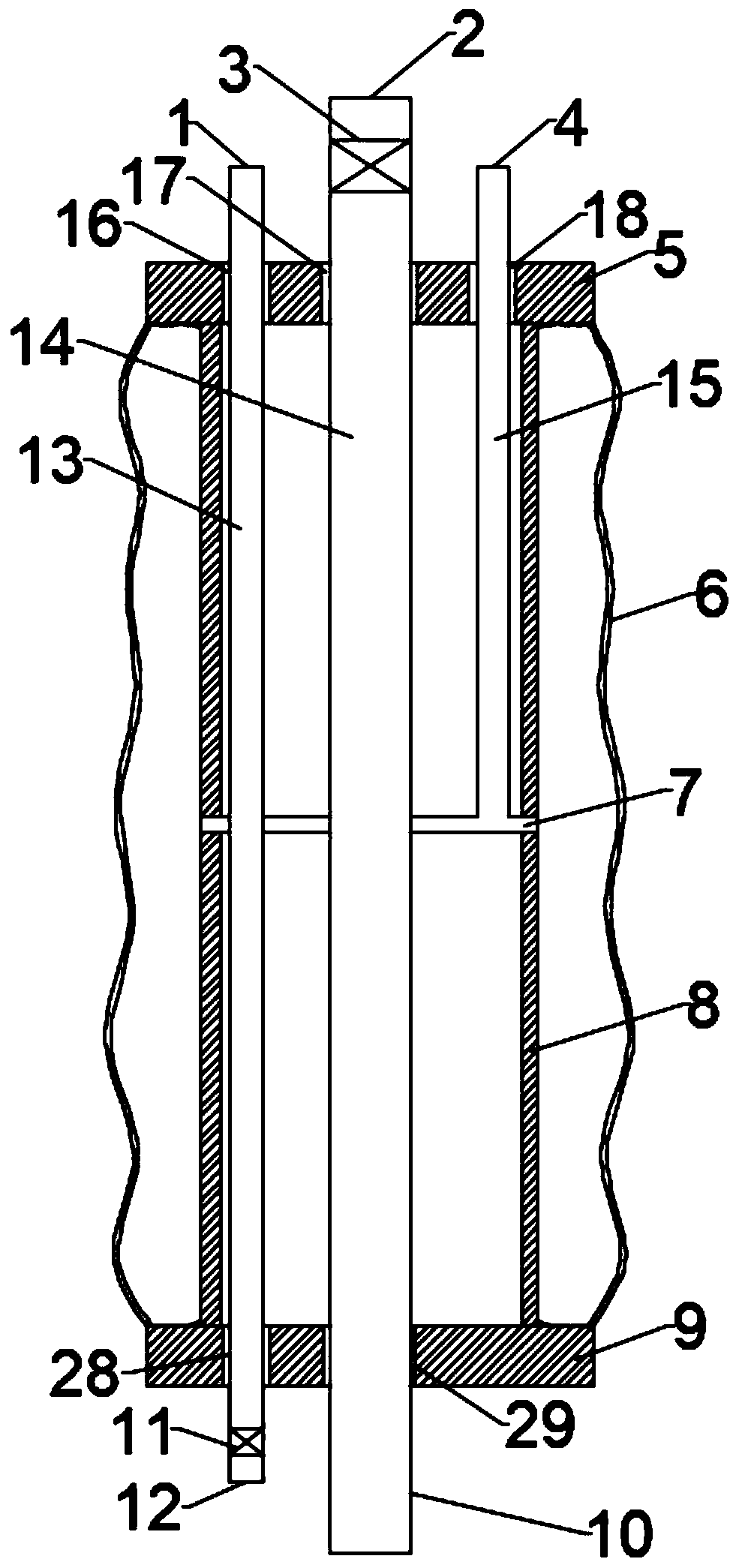

Water stop device for layered water pumping tests and water pumping testing device and method

PendingCN111173474ASolve the problem of air leakageMeet the needs of engineering multi-caliber testsFluid removalSealing/packingWater stopEngineering

The invention relates to a water stop device for layered water pumping tests and a water pumping testing device and method. The water stop device comprises a vertical body, a rubber air bag, an air pressure pipe and a vertical water outlet pipe, wherein the rubber air bag sleeves the outer wall of the body; the air pressure pipe is located in the body, one end of the air pressure pipe stretches the top end of the body to form an air pressure connector, an air outlet is formed in the other end of the air pressure pipe, and the air outlet is communicated with the rubber air bag; a water inlet isformed in the lower end of the water outlet pipe, the lower end of the water outlet pipe penetrates through the body, and an air outlet is formed in the upper end of the air outlet pipe. The water stop device greatly avoids the phenomenon that on the current market, a water stop device with a water-stop rubber air bag is shrunk due to expansion to cause air leakage, no influence on the stabilityof a sand and gravel well wall can be caused, the water stop device can be reused, and the engineering cost is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

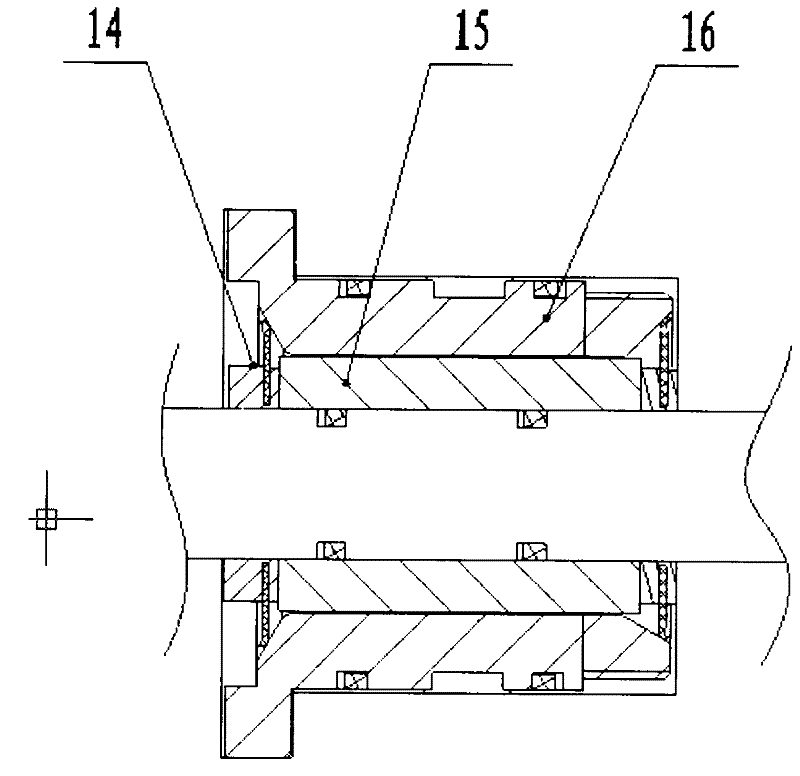

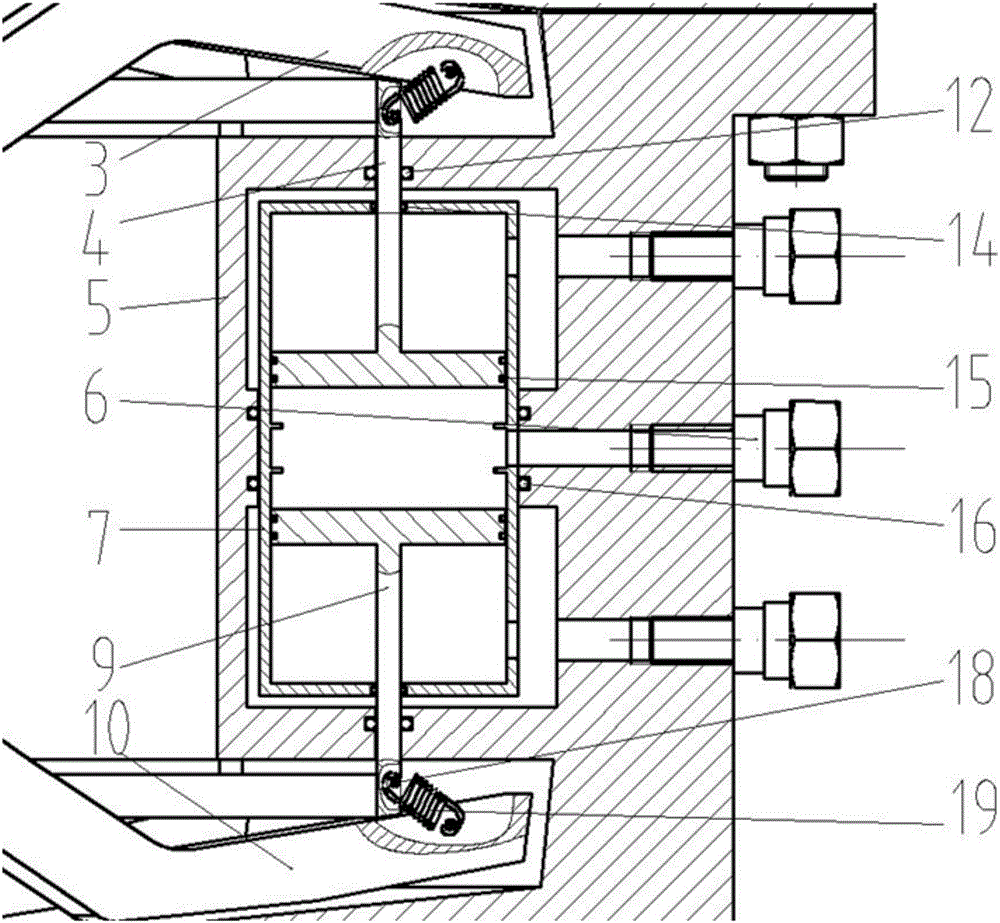

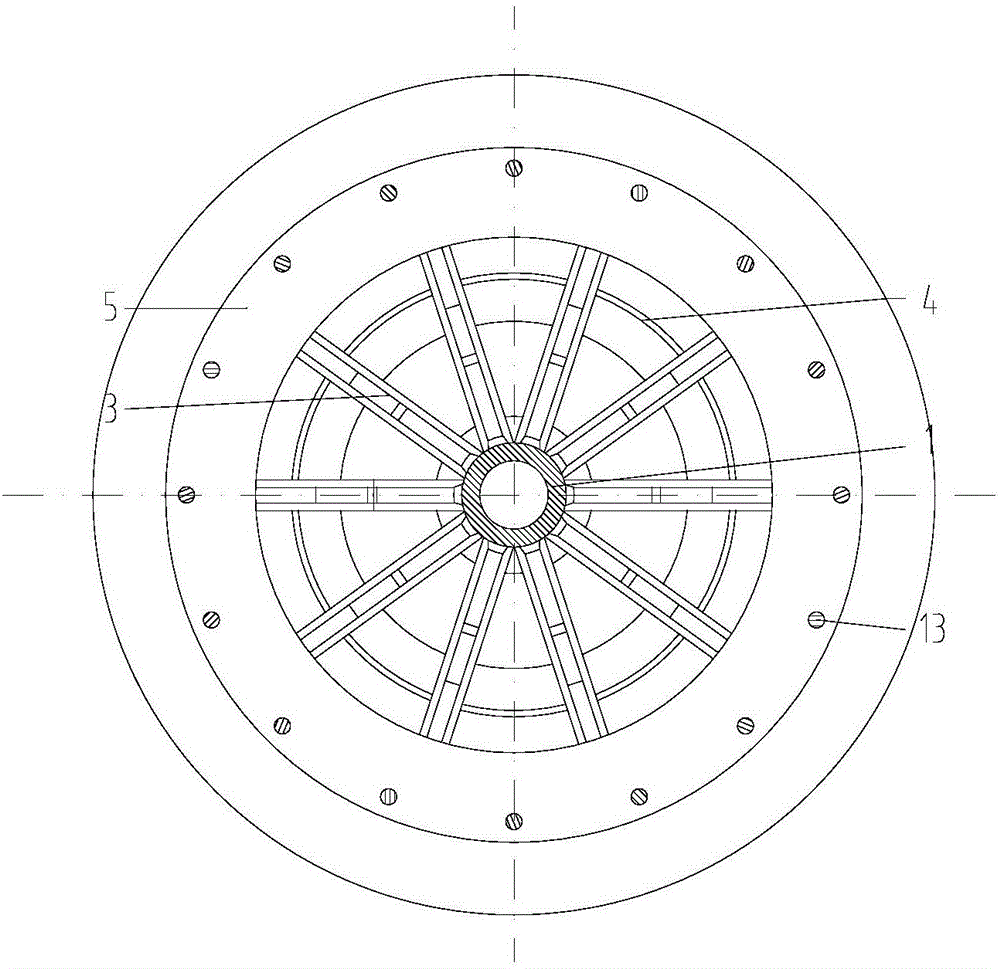

Sealing structure for pumping oil cylinder rod

InactiveCN104912870AEasy dischargeAct as a primary sealEngine sealsFluid-pressure actuatorsEngineeringMechanical engineering

The invention discloses a sealing structure for a pumping oil cylinder rod. The sealing structure comprises an oil cylinder body, a piston rod and a rod end chamber. One end of the oil cylinder body is connected with a guide sleeve, and the piston rod is sleeved with the guide sleeve. In the direction from one end, close to the rod end chamber, of the guide sleeve to the other end of the guide sleeve, a Sitefeng seal, a U-shaped sealing ring, a BA sealing ring and a dustproof ring are arranged between the guide sleeve and the piston rod in sequence, a first guide ring is arranged between the Sitefeng seal and the U-shaped sealing ring, a second guide ring is arranged between the U-shaped sealing ring and the BA sealing ring, a ring tank is arranged between the U-shaped sealing ring and the second guide ring, the ring tank is connected with a one-way valve, the ring tank is communicated with an inlet of the one-way valve, and an outlet of the one-way valve is communicated with the rod end chamber. According to the sealing structure for the pumping oil cylinder rod, trapped oil between sealing elements can be conveniently discharged in time, and the situation that trapped oil pressure is excessively high and consequently the sealing effect is affected is avoided.

Owner:HUNAN XIELI HYDRAULIC

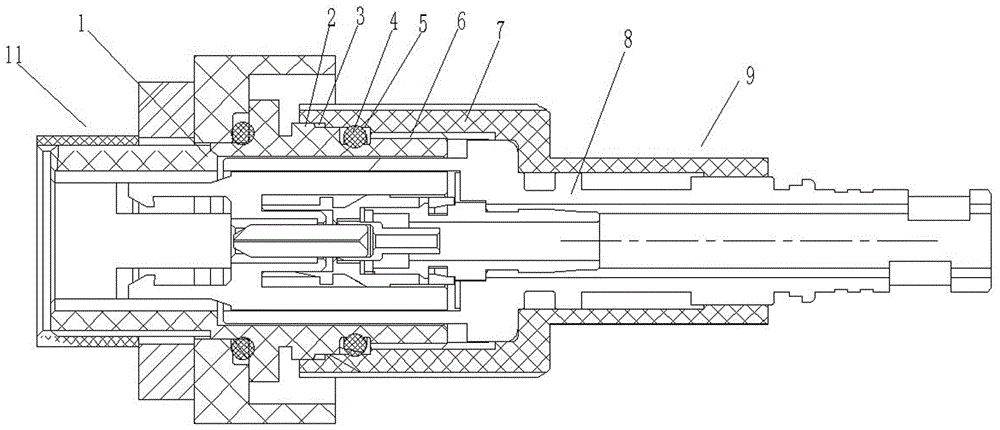

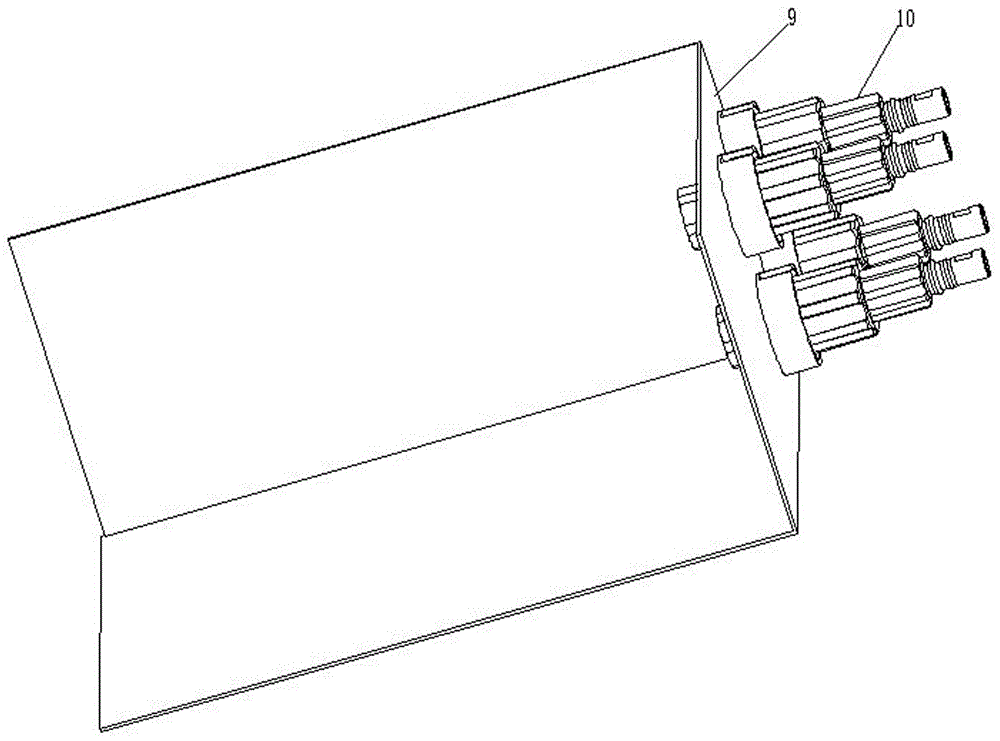

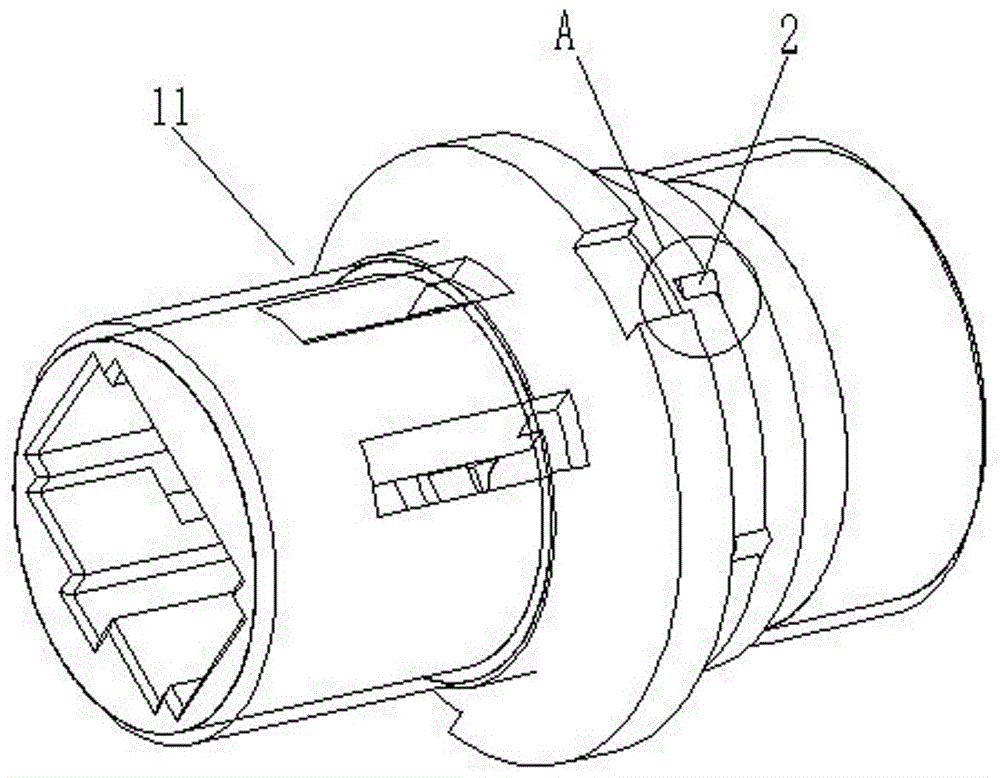

Connector, adaptive connector and anti-loose connector assembly

ActiveCN105932484AAchieve sealingRealize anti-looseningEngagement/disengagement of coupling partsCouplings bases/casesLoose toothMechanical engineering

The invention relates to a connector, an adaptive connector and an anti-loose connector assembly. The anti-loose connector assembly comprises the connector and the adaptive connector, the front ends of which are in plug connection mutually when used. The connector comprises a connector housing provided with an external thread. The adaptive connector comprises a nut provided with an internal thread. The connector housing is provided with connector anti-loose teeth. The nut is provided with nut anti-loose teeth cooperated with the connector anti-loose teeth. The outer circumference of the connector housing is provided with a seal ring. The inner circumference of the nut is provided with a seal matching surface for being in seal matching with the seal ring. The invention provides the anti-loose connector assembly capable of realizing both anti-loosening and seal effects, and the connector and the adaptive connector used in the anti-loose connector assembly.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Carton packaging machine with pneumatic automatic cover sealing function

ActiveCN113501154AAvoid affecting the sealing effectAvoid creasesWrapper twisting/gatheringVertical edgeCarton

The invention discloses a carton packaging machine with a pneumatic automatic cover sealing function, and relates to the technical field of packaging machines. The carton packaging machine comprises a workbench, wherein a conveying device is arranged on the workbench, the conveying device conveys cartons placed on the conveying device in a gap mode, limiting frames are fixedly connected to the two sides of the workbench, the cartons to be sealed are placed in the two limiting frames, a cover sealing mechanism is connected to the two limiting frames, the cover sealing mechanism comprises a mounting frame, a driving air cylinder and a cover sealing block, and the mounting frame is connected to the limiting frames in a sliding mode. According to the carton packaging machine, when the cartons are sealed, two driving mechanisms are started, the output ends of the driving mechanisms extend to push the cover sealing block to get close to the two vertical edges of the cartons, and are in contact with carton covers on the four sides of the cartons in sequence, so that the cartons are folded and kept in a folded state; and compared with a traditional mode that the carton covers are folded through guide rods, the situation that the carton covers are folded and folded marks are generated due to the fact that the carton covers rebound after being bent can be avoided, so that the sealing effect of the cartons is prevented from being influenced.

Owner:南通市通州区茂润包装制品有限公司

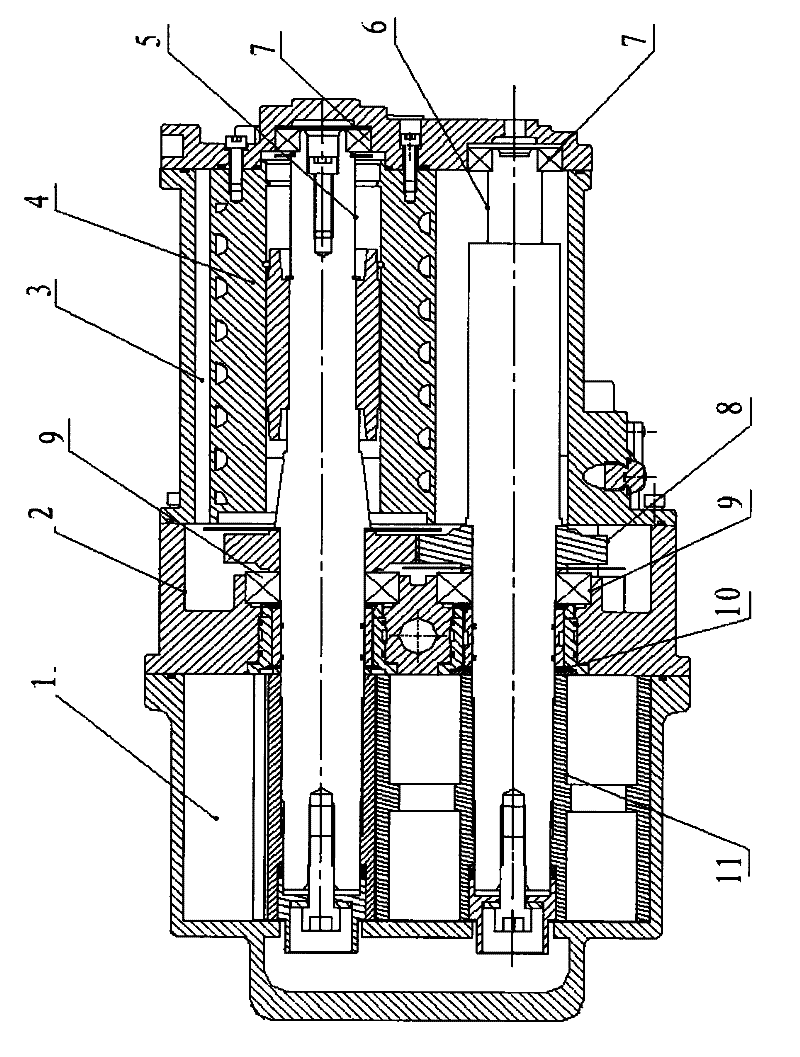

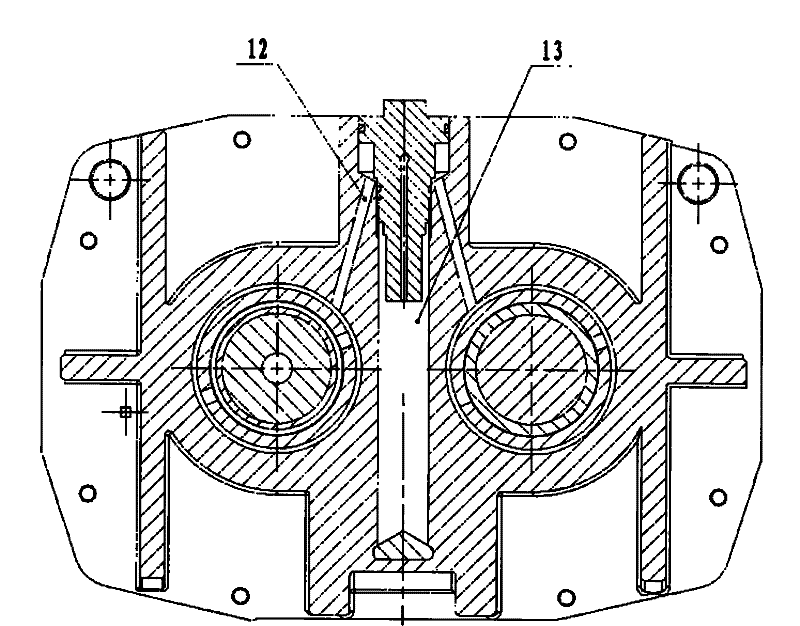

A vacuum pump structure

InactiveCN102278309APrevent leakageReduce chance of damageMachines/enginesPumpsGear transmissionMotor shaft

The invention discloses a vacuum pump structure, which is composed of a vacuum chamber, a gear box, a motor chamber, a shielded motor, a shaft seal structure, a motor main shaft, a driven shaft, a Roots rotor and the like. The vacuum pump is driven by a shielded motor, which is completely inside the motor cavity. The main shaft and driven shaft of the vacuum pump motor are partly cantilevered in the vacuum chamber without bearing support, which reduces the difficulty of processing and assembly, and reduces the chance of the bearing being damaged by the transmission medium in the pump during the working process. The shaft seal assembly structure is installed in the gearbox, which can block the diffusion of lubricating oil in the motor cavity to the vacuum cavity. The gas passage in the gear box allows gas to enter the shaft seal assembly, preventing excessive temperature rise or dust from entering the shaft seal. The transmission device of the vacuum pump is a gear with a transmission ratio of 1:1.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

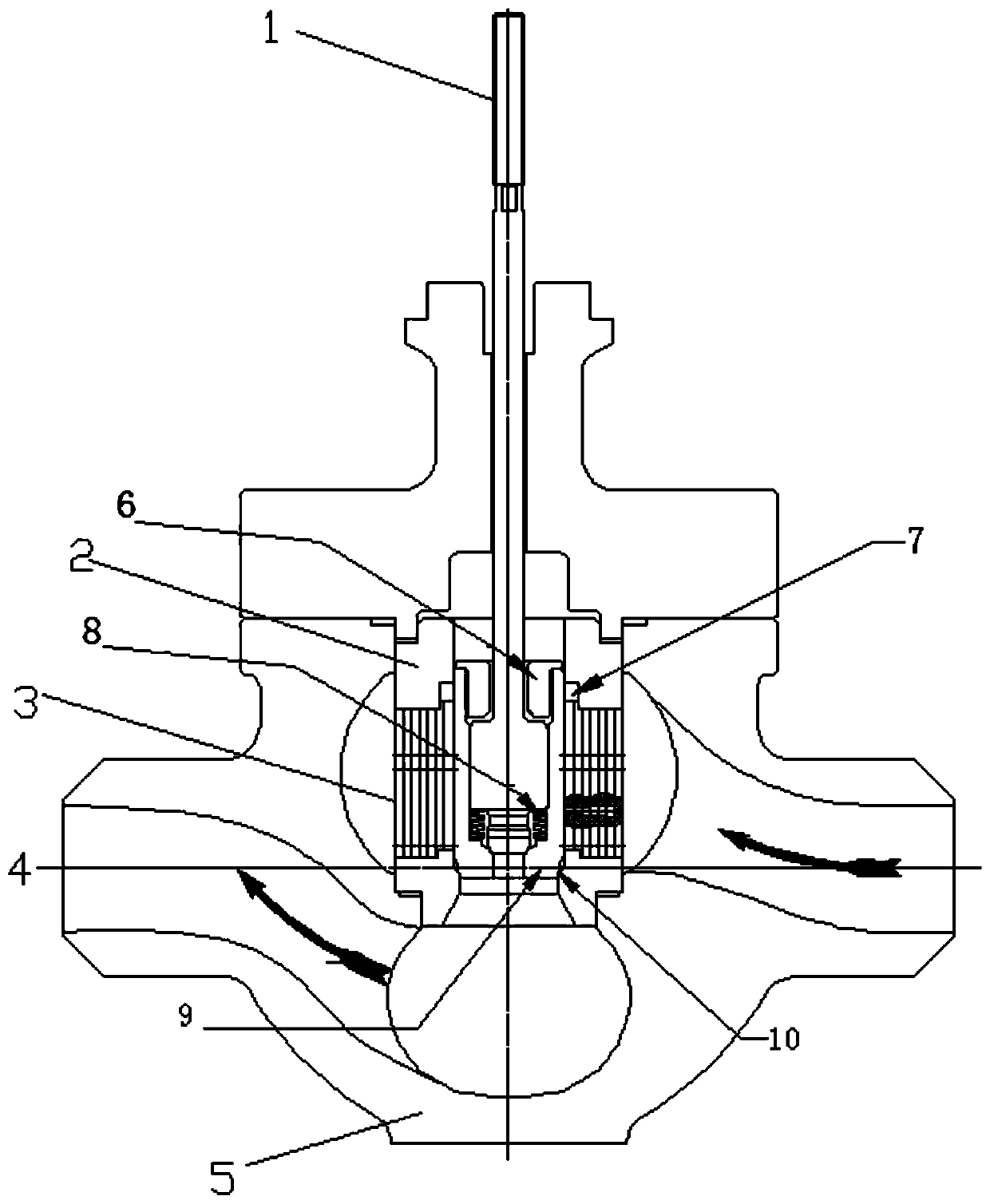

Small-flow and large-pressure-difference adjusting valve

InactiveCN111473156AGuaranteed tightnessSealing effectValve members for absorbing fluid energySlide valveEngineeringVALVE PORT

The invention discloses a small-flow and large-pressure-difference adjusting valve which comprises a valve element, a valve cover, a multi-layer shutoff reducing valve cage, a valve body, a valve headand a valve seat. The valve element and the valve rod are integrated, and the bottom of the valve element is mounted in the valve head. The multi-layer shutoff reducing valve cage is assembled in thevalve body, and the upper end of the valve seat is connected with an execution mechanism. A supporting ring is arranged above the multi-layer shutoff reducing valve cage, and a valve head seal is arranged in the multi-layer shutoff reducing valve cage. A valve head nut is arranged above the valve head. A butterfly spring is arranged below the valve head nut. According to the small-flow and large-pressure-difference adjusting valve, the influence of impurities in a pipeline on the sealing effect is effectively avoided, a sealing pair in the valve is protected better, the service life of the valve is prolonged, and the reliability of the valve is also improved.

Owner:YICHUAN TECH CHENGDU CO LTD

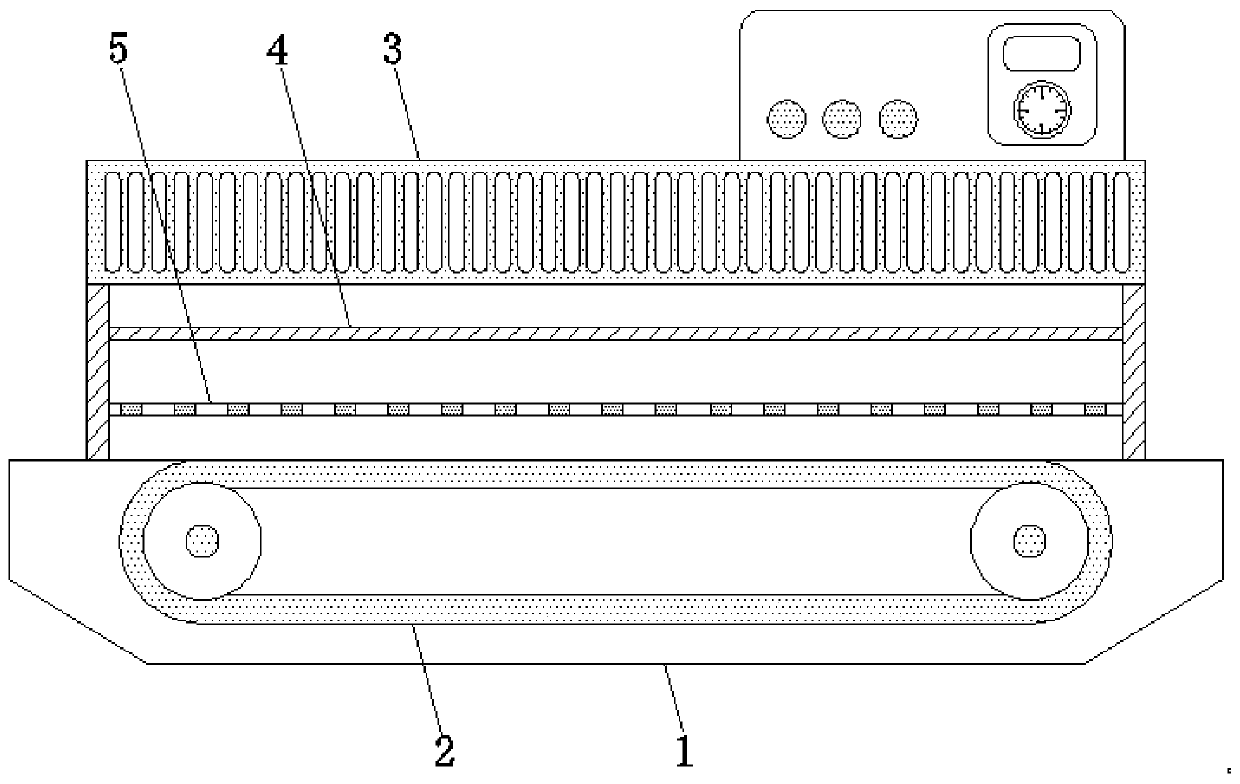

Intelligent sealing machine capable of ensuring heat sealing stability based on intermittent reciprocating motion

InactiveCN111268210AHeat-sealed firmlyThe time of heat welding is consistentWrapper twisting/gatheringReciprocating motionGear wheel

The invention relates to the technical field of automatic packaging, and discloses an intelligent sealing machine capable of ensuring heat sealing stability based on intermittent reciprocating motion.The intelligent sealing machine comprises a base, wherein a conveyor belt is movably connected inside the base, packaging bags are conveyed by the conveyor belt, a support plate is fixedly connectedabove the base to support the whole device, hot welding wires are movably connected to the repair of the support plate, through use of the hot welding wires, it is ensured that the hot welding time ofthe hot welding wires is equal, the packaging heat sealing time is kept consistent, and the situation that the sealing effect is affected due to insufficient heat sealing or excessive heat sealing isavoided; through cooperative use of a push rod and a supporting bin, the packaging bags subjected to heat sealing are fixed through pressure intensity changes, and the heat sealing effect is prevented from being influenced by movement of the packaging bags in the heat sealing process, through cooperative use of a rotary disc, a connecting rod, a gear and a sliding block, so that the connecting rod is driven to intermittently move, the linkage of the whole device is improved, and operation is more intelligent and simpler.

Owner:杨兴

Canned fish sealing device and production method of canned fish

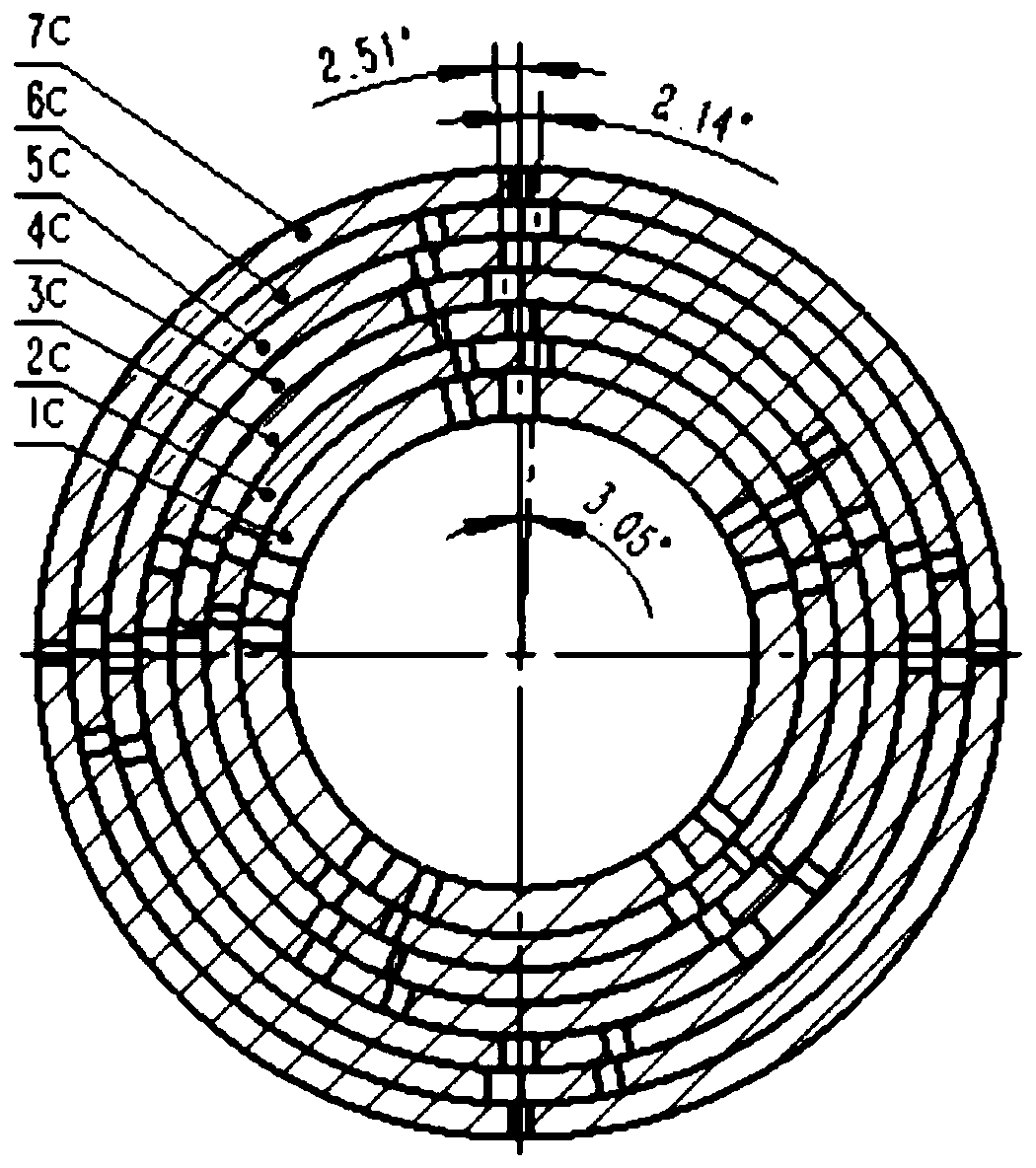

ActiveCN109928346AMeet various sealing requirementsAvoid affecting the sealing effectFish washing/descalingMeat/fish preservation by heatingEngineeringCalcium content

The invention provides a canned fish sealing device and a production method of canned fish. The canned fish sealing device comprises a supporting fixing table and a sealing mechanism, wherein the supporting fixing table is used for holding a can body, and the sealing mechanism is located above the supporting fixing table; and the sealing mechanism comprises a sealing part, the sealing part comprises a first pressing part, a second pressing part and a third pressing part which are arranged in a matched mode, the first pressing part is movably connected to the second pressing part through a first connecting part, and the second pressing part is movably connected to the third pressing part through a second connecting part. According to the canned fish sealing device, the plurality of pressingparts are matched with one another, so that the sealing device can be suitable for multiple types of sealing cans and capable of meeting various sealing requirements; and the production method of thecanned fish can improve the calcium content in the canned fish and effectively reduce the histamine component.

Owner:RONGCHENG TAIXIANG FOOD

Inner lining stainless steel pipe fitting joint

The invention discloses an inner lining stainless steel pipe fitting joint. The inner lining stainless steel pipe fitting joint comprises pipe bodies, a first clamping plate, a second clamping plate and a sealing ring, wherein a first connecting hole is formed in the front face of the first clamping plate; a first connecting block is transversely and fixedly connected to the left side of the outersurface of the first clamping plate; and a first fixing block is transversely and fixedly connected to the right side of the outer surface of the first clamping plate. Through the cooperation of thefirst clamping plate, the second clamping plate, the sealing ring, the first connecting block, a first sealing gasket, a first placing groove, the first fixing block, a second sealing gasket, a secondplacing groove, a second fixing block, a second connecting hole, a semi-threaded bolt, a nut and a third through hole, the joint of the two pipe bodies can be effectively connected and sealed, and the maintenance of a pipeline by a maintainer is facilitated; and meanwhile, the problems that a joint of a traditional flange connection mode cannot be reused and resources are wasted are solved, and the inner lining stainless steel pipe fitting joint has the advantage of secondary utilization and is worth popularizing.

Owner:JIANGSU SHUNLONG PIPE TECH CO LTD

Energy-saving-type heating device and work method thereof

InactiveCN108332278AReduce wasteGuaranteed water temperatureLighting and heating apparatusSpace heating and ventilation detailsEngineeringHeat sink

The invention relates to an energy-saving-type heating device and a work method thereof and belongs to the field of machines. The energy-saving-type heating device comprises two cooling fins with thesame specification, the two sides of the cooling fins are fixedly connected with two connecting plates, and sealing plates are fixedly connected to the upper sides and the lower sides of the cooling fins correspondingly. The sealing plates, the cooling fins and the connecting plates form a closed space, a water inlet pipe is arranged on the connecting plate on the left side, an iron water pipe canbe used, and impurities in water can be filtered; and meanwhile the impurities can be conveniently taken out and cleared, pollution discharge is convenient, heating plates do not need to be dismounted for cleaning, using is convenient, the heat exchange efficiency of the heating plates is improved, and energy is greatly saved.

Owner:范蕾

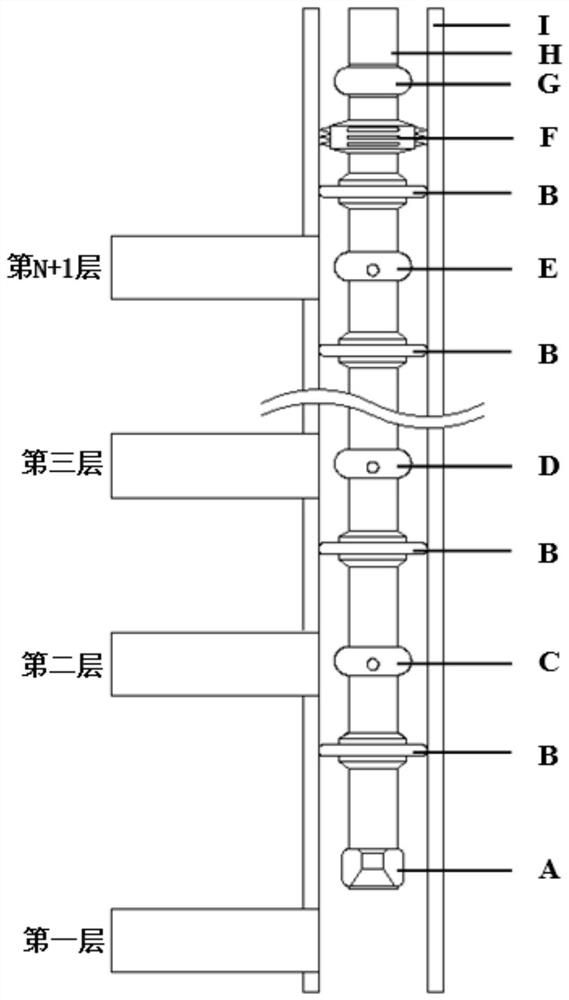

Throttling-free multistage layered fracturing pipe column and multistage layered fracturing construction method

The invention discloses a throttling-free multistage layered fracturing pipe column and a multistage fracturing construction method. The pipe column comprises a horn mouth, a plurality of throttling-free self-service deblocking packers, throttling-free sand blasting sliding sleeves, sand prevention hydraulic anchors and hydraulic safety joints which are sequentially connected through oil pipes from bottom to top. In each throttling-free sand blasting sliding sleeve, a plurality of sand blasting holes are formed in a sand blasting sliding sleeve body, a throttling-free inner sliding sleeve is fixed in each sand blasting sliding sleeve body through a plurality of shear pins and seals the sand blasting holes, and comprises an outer cylinder and an inner cylinder with the axial length smallerthan that of the outer cylinder, and the inner cylinder sleeves the inner side of the bottom end of the outer cylinder through a connecting part in a manner that a gap exists; and the inner diameter of the inner cylinder of each stage of throttling-free sand blasting sliding sleeve is gradually increased from bottom to top. According to the non-throttling multistage layered fracturing pipe column,the purpose of completing multistage layered fracturing and layer combining production solving by tripping in the pipe column once can be achieved, bottom-to-top step-by-step fracturing constructionis achieved, and the sand conveying efficiency and the fracturing construction safety can be remarkably improved through the corresponding fracturing construction method.

Owner:CNPC BOHAI DRILLING ENG +1

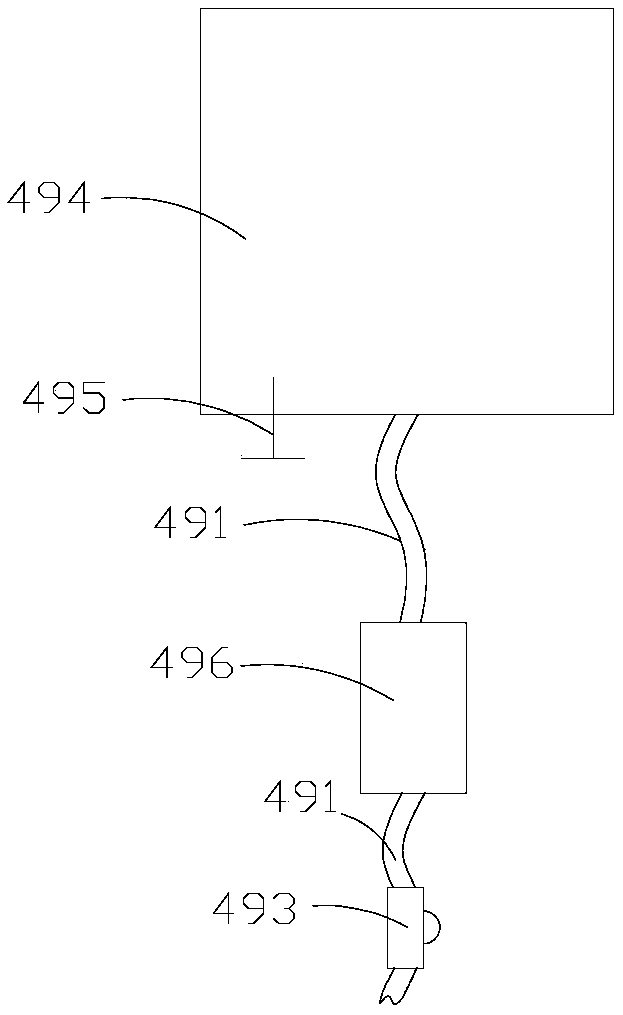

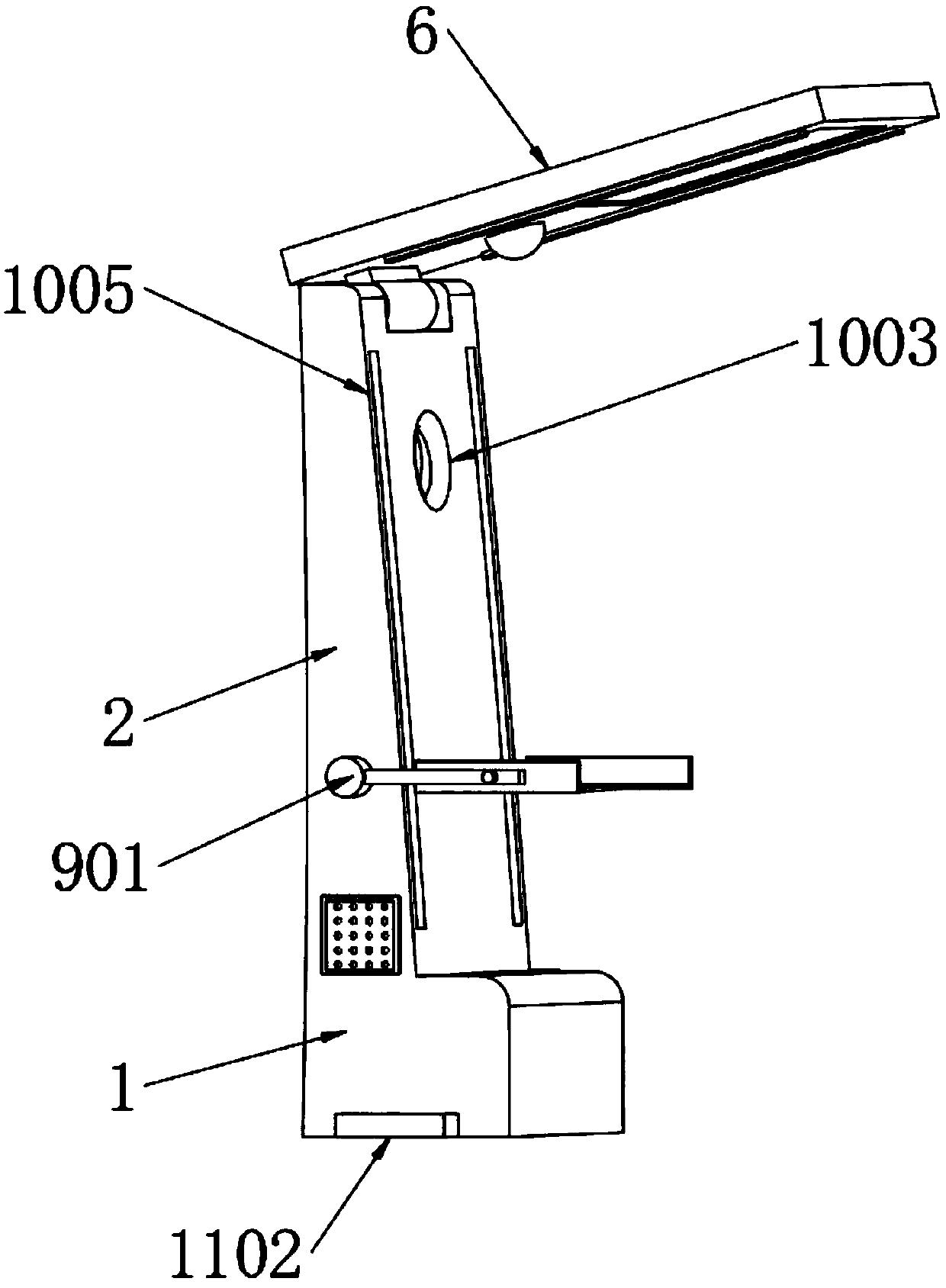

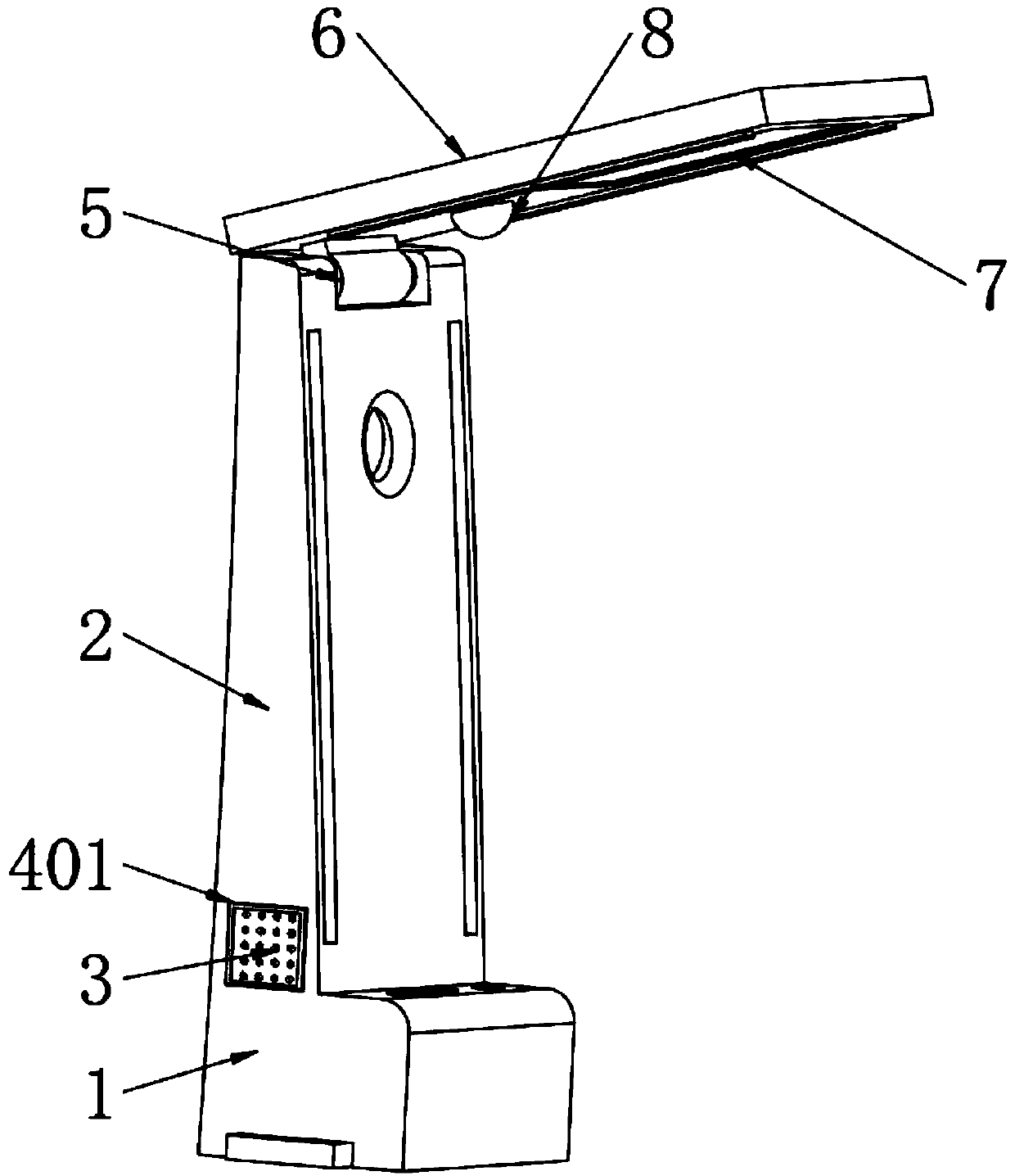

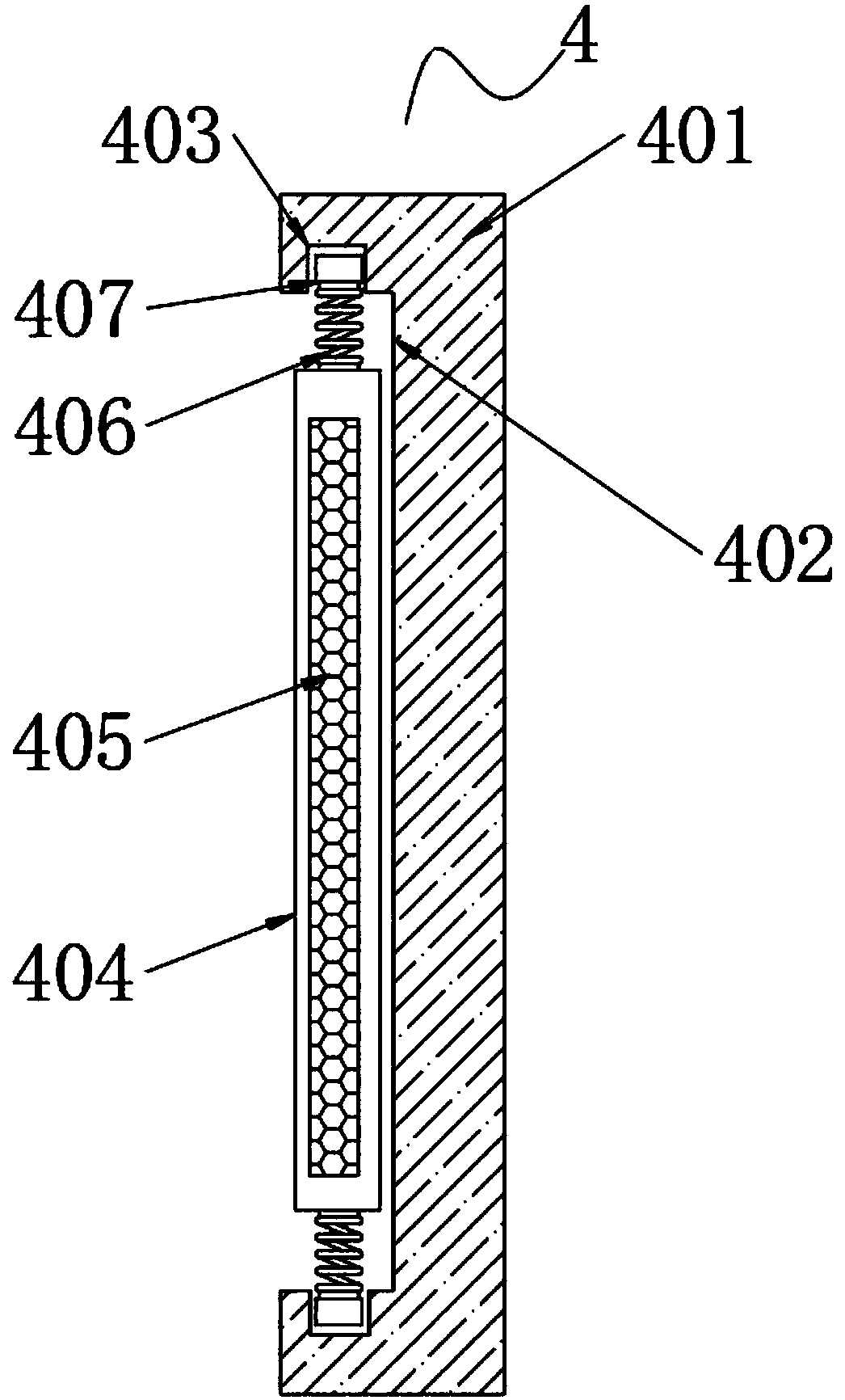

Multifunctional AI education table lamp

PendingCN111207319AScientific and reasonable structureEasy to useTelevision system detailsLighting support devicesComputer hardwareEngineering

The invention discloses a multifunctional AI education table lamp. The table lamp comprises a table lamp base, and a table lamp arm is mounted at the top end of the table lamp base; and a movable plate is mounted at the top end of the table lamp arm. According to the invention, the table lamp is scientific and reasonable in structure, and is safe and convenient to use; the table lamp is provided with a movable plate; through the effects of a camera and a broadcasting hole, the books below the lamp panel can be conveniently scanned; therefore, the characters on the book are identified, and thecharacters are broadcasted through the broadcasting hole; therefore, the knowledge memory effect of the user is enhanced; through the arrangement of the dustproof assembly, the effects of a shieldingplate and a dustproof net; the broadcast hole can be shielded conveniently; the external dust is prevented from entering the broadcasting hole to cause blockage; through the effects of fixing springs,limiting blocks and limiting grooves, the dustproof net can be conveniently fixed through the elastic effect of the fixing springs, the situation that the sealing effect is affected due to the fact that the dustproof net shakes back and forth when the device works is avoided; meanwhile, the dustproof net can be conveniently disassembled, and therefore cleaning work can be conducted, and the use is more convenient.

Owner:深圳市安信祥和科技有限公司

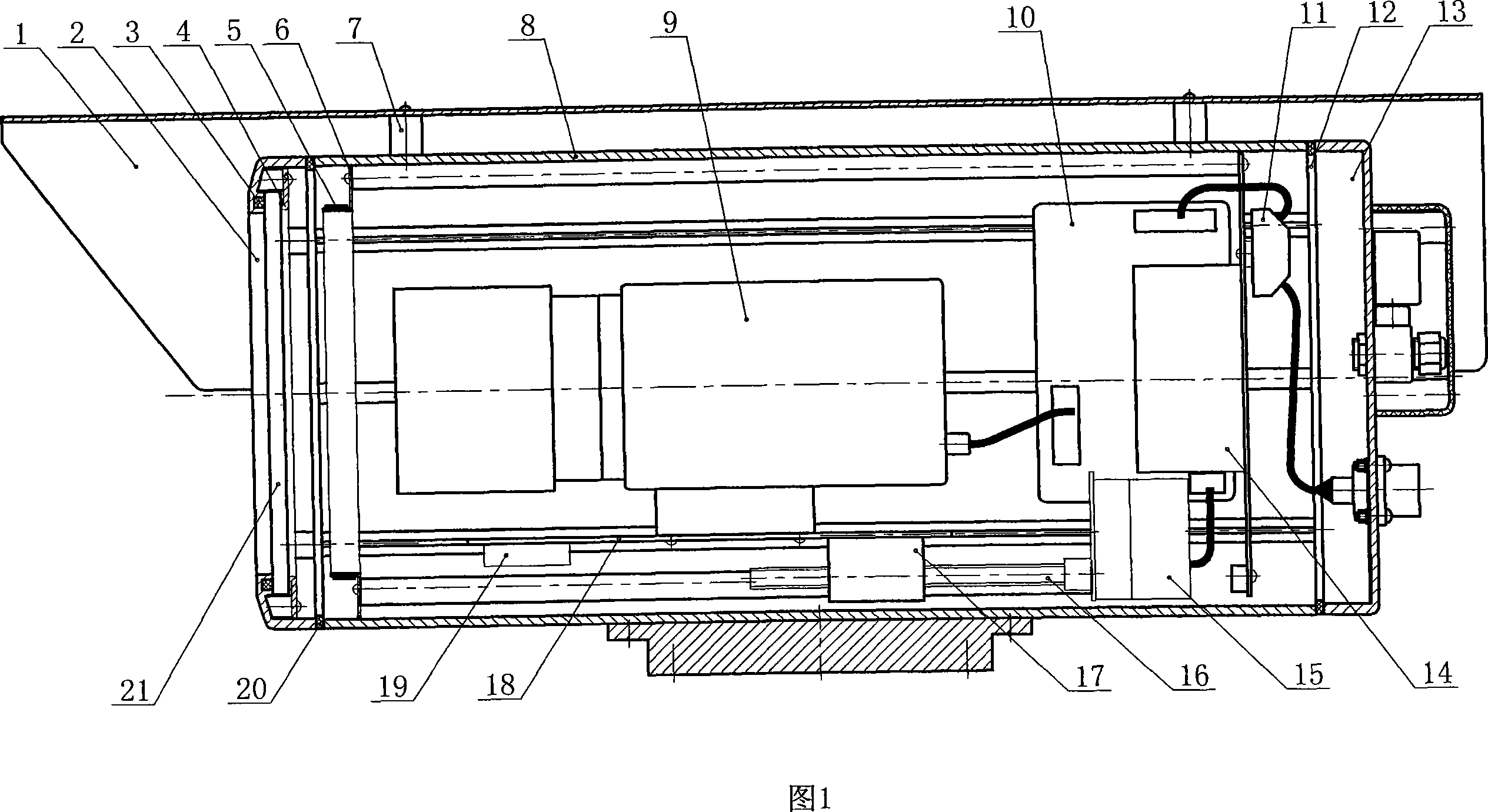

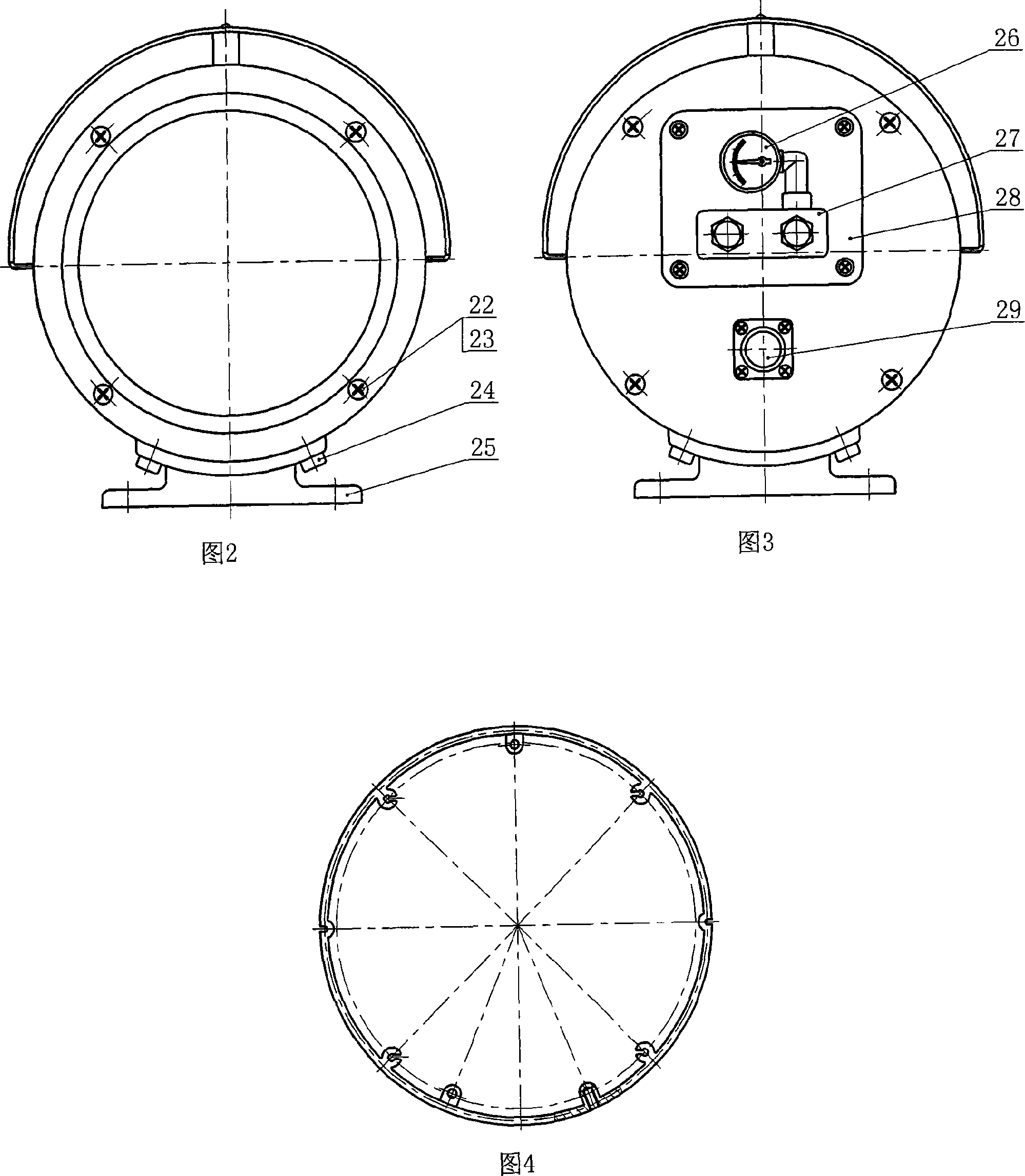

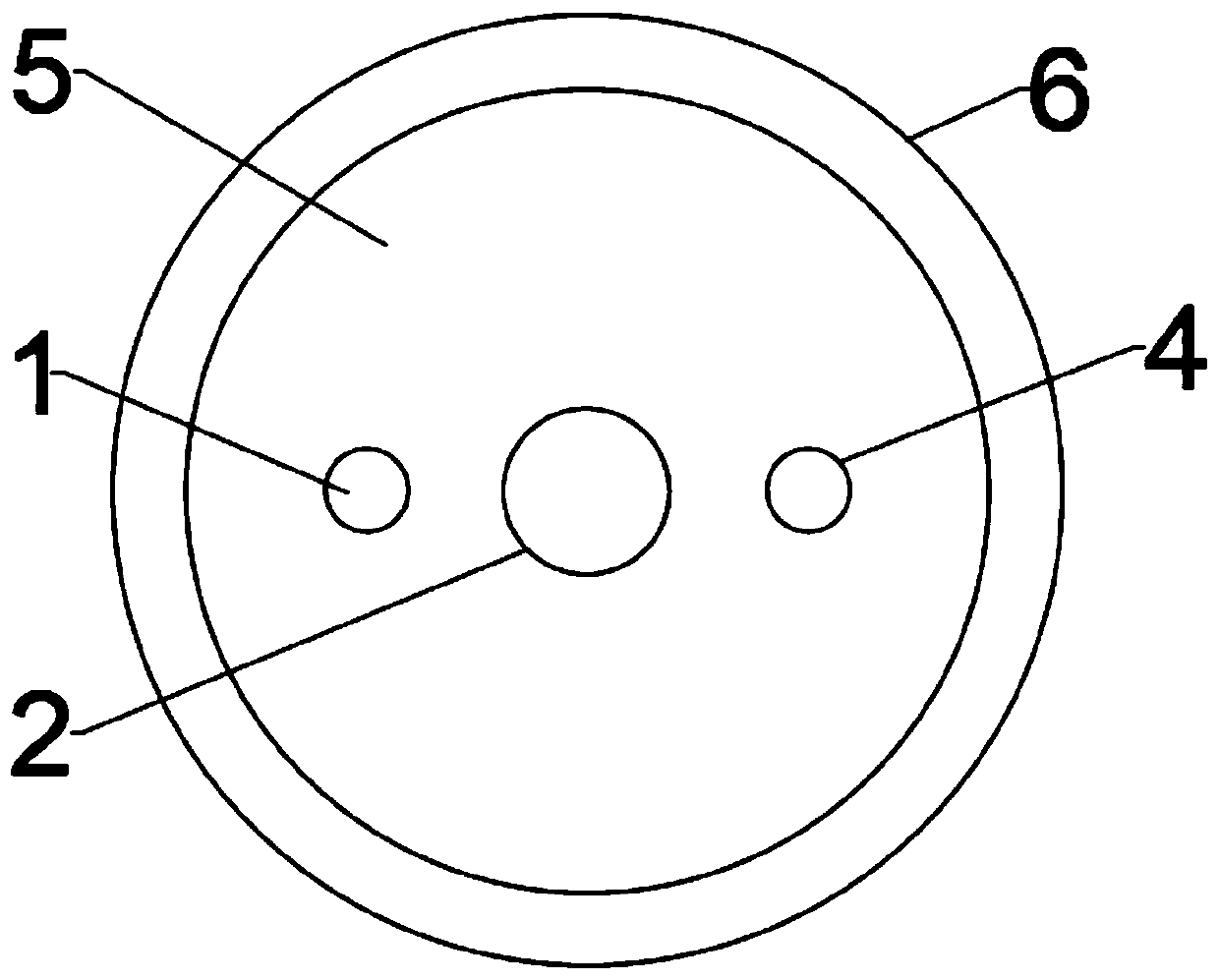

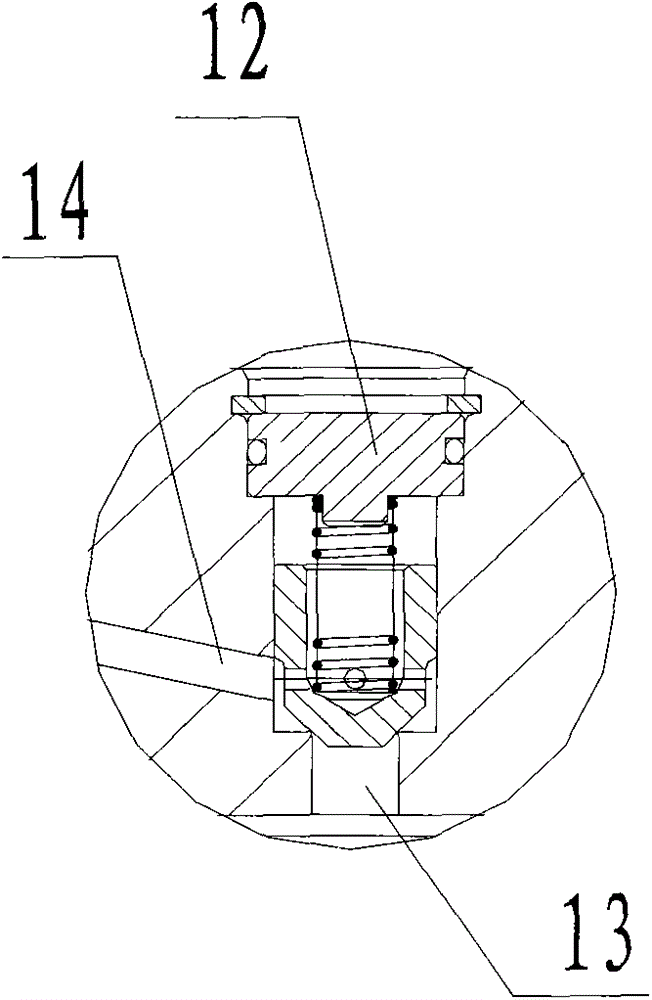

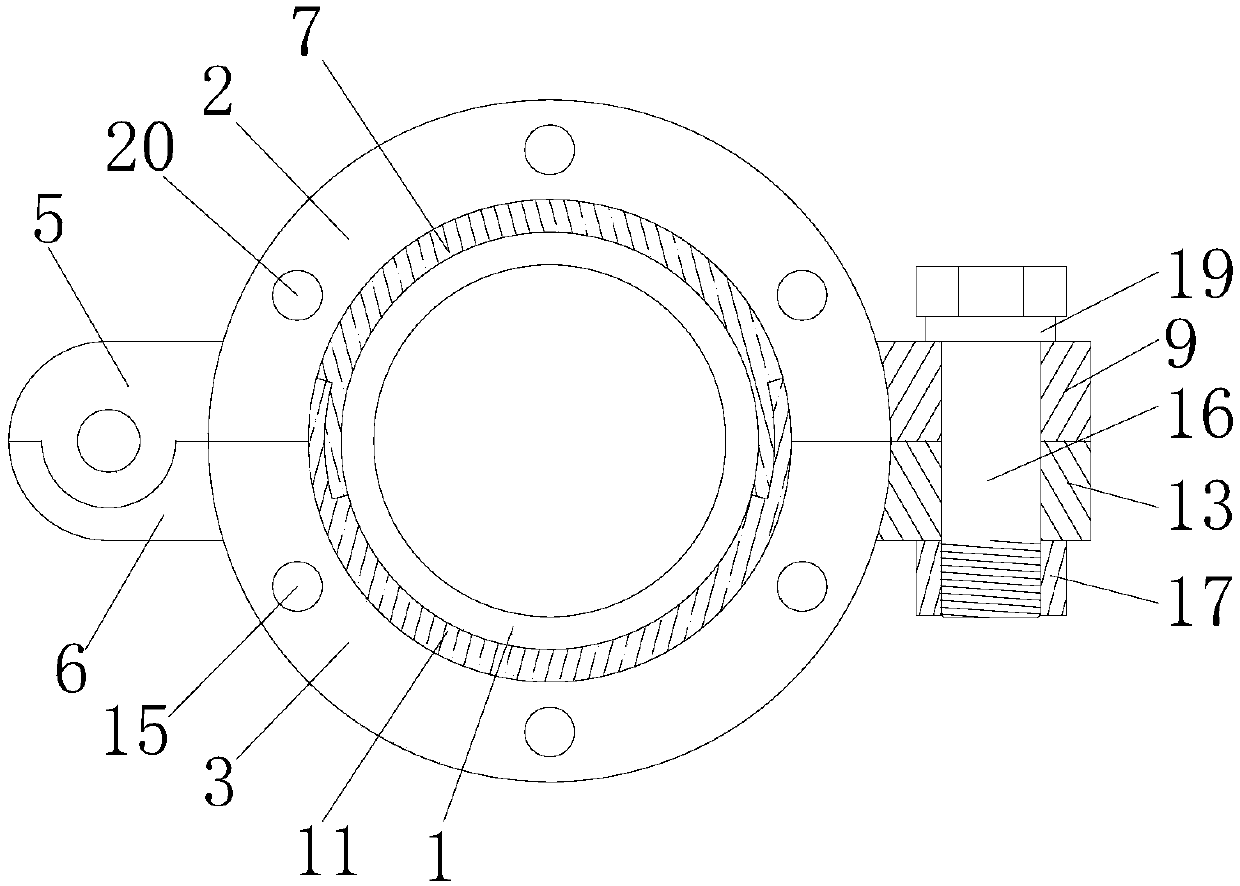

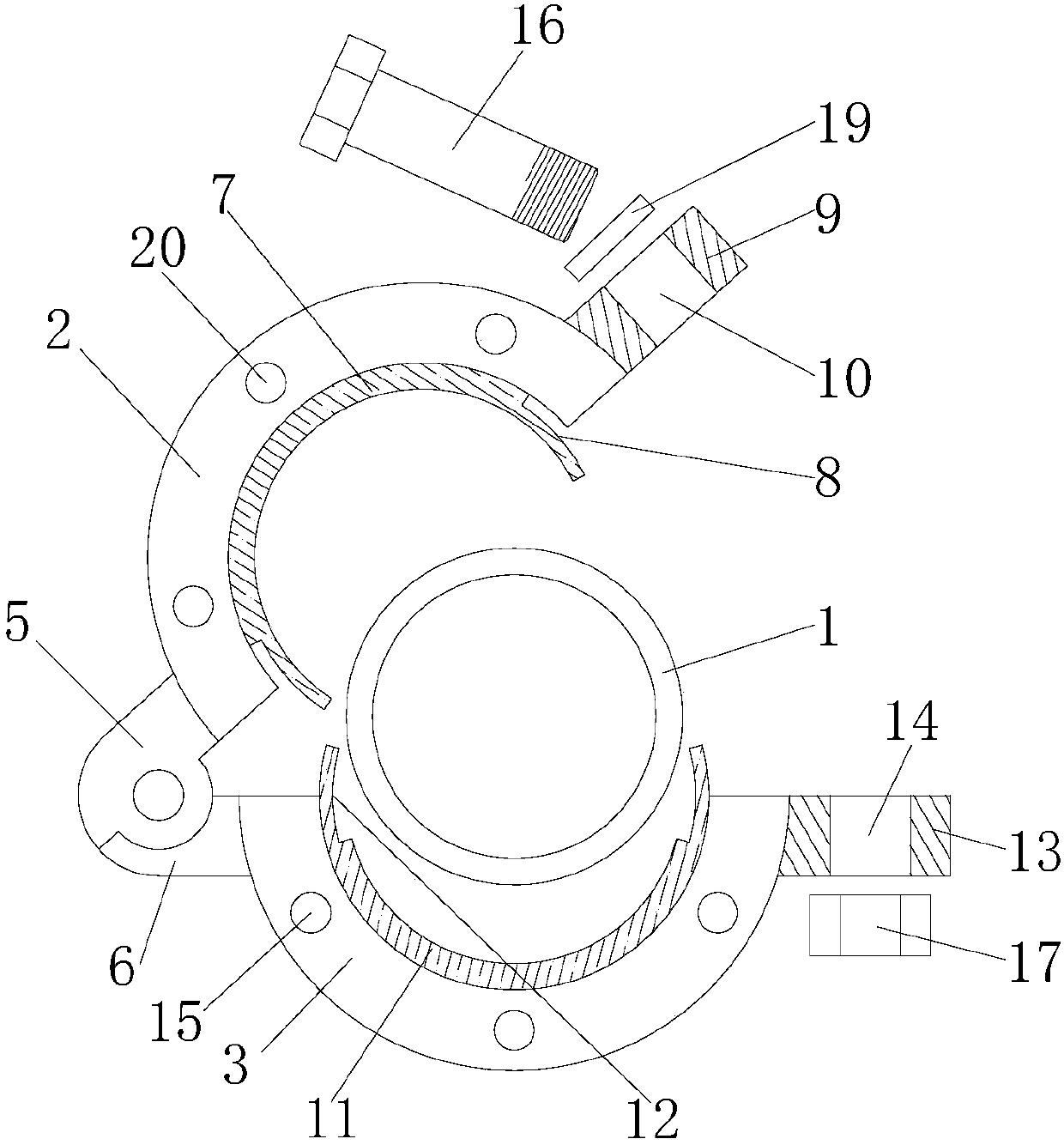

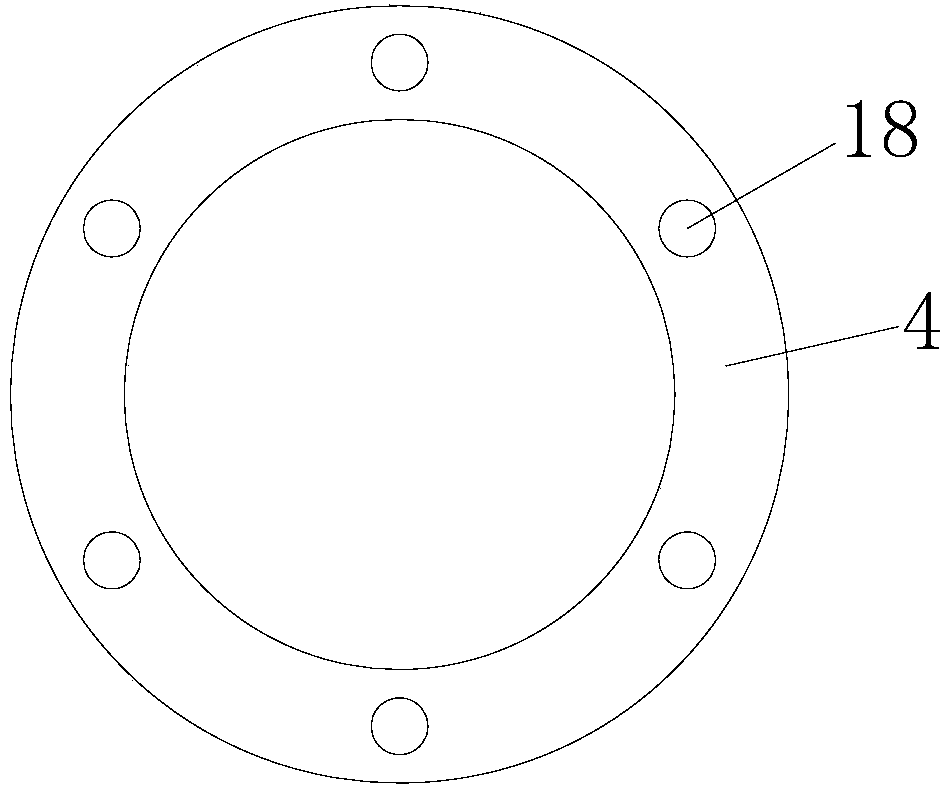

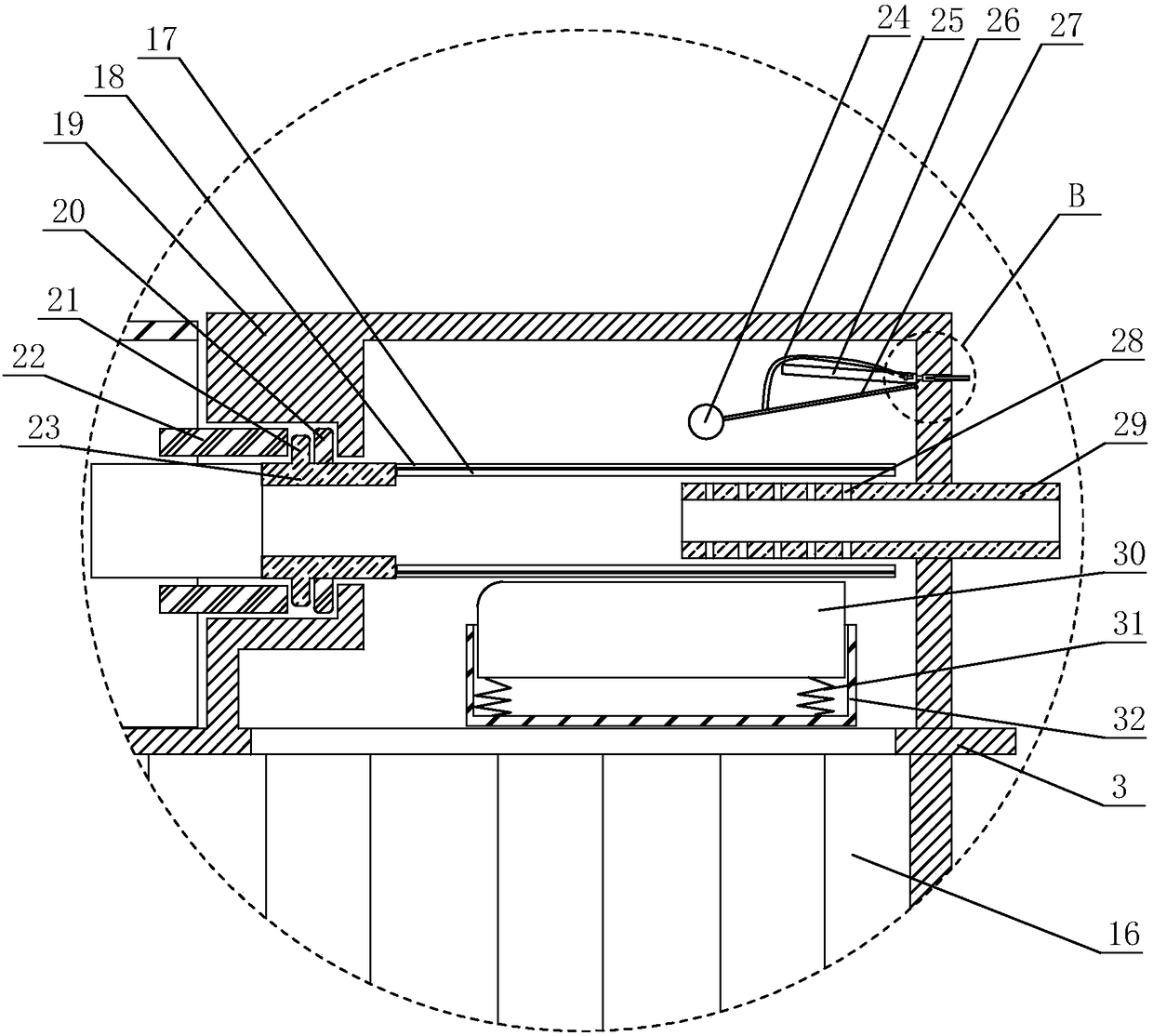

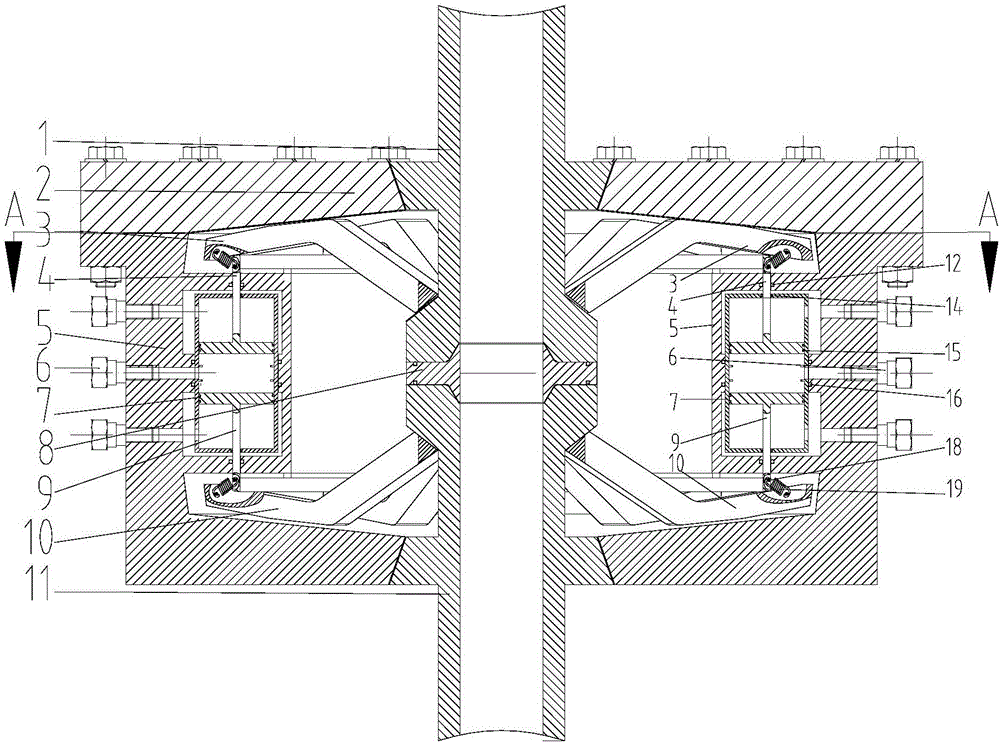

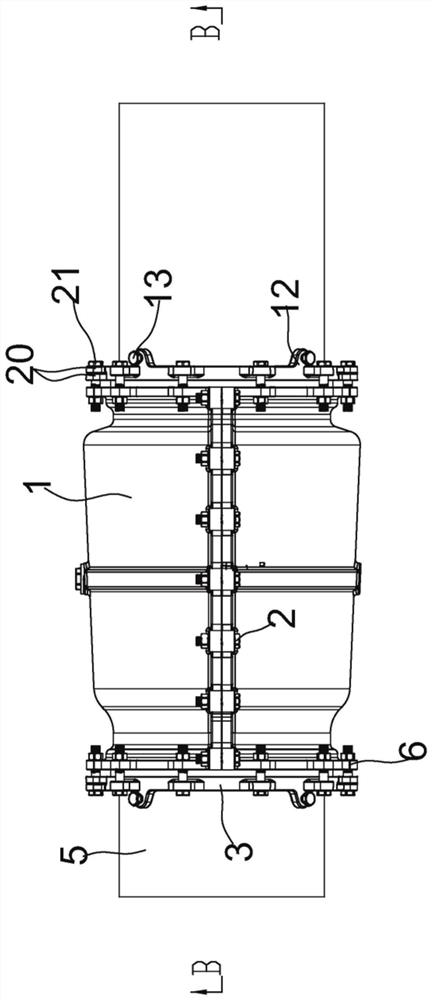

Underwater manifold connector

ActiveCN106352177AAchieving autofocusEasy to installFlanged jointsFluid-pressure actuatorsHydraulic cylinderUnderwater

The invention discloses a underwater manifold connector which comprises a base body, wherein a first cavity is formed in the base body and sealed by an end cover of the connector, a floating hydraulic cylinder is arranged in the first cavity and located in a second cavity extended by the base body, an upper piston rod and a lower piston rod are arranged in the floating hydraulic cylinder, a connection pipe required for connection and a connected pipe are arranged in the base body, an upper conical boss and a lower conical boss are arranged at the end parts of the connection pipe and the connected pipe respectively, a sealing ring is arranged between the connection pipe and the connected pipe, a plurality of upper clamping jaws are circumferentially distributed on the upper conical boss, and a plurality of lower clamping jaws are circumferentially distributed on the lower conical boss. According to the underwater manifold connector, a conical block is arranged on a manifold and has guiding and alignment functions, the installation is convenient, disassembly and replacement are convenient, and the defect that the clamping jaws bear stress unuiformly due to fatigue wear of mechanical parts can be overcome while uniform distributing of the clamping jaws is ensured by hydraulic driving.

Owner:JIANGSU UNIV OF SCI & TECH

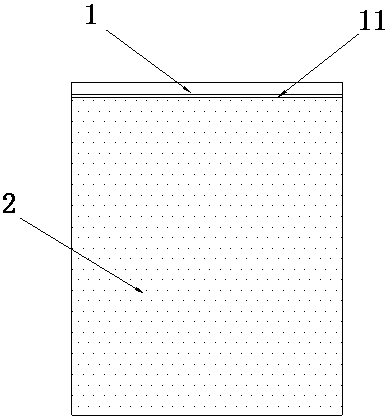

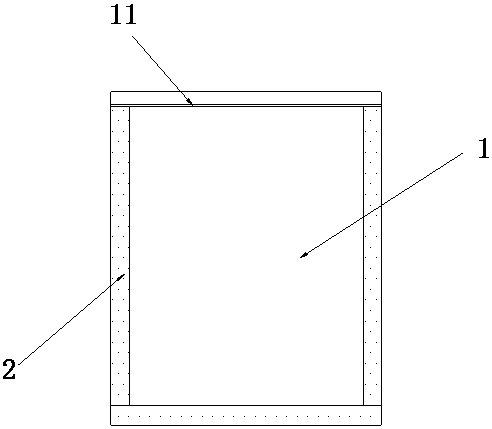

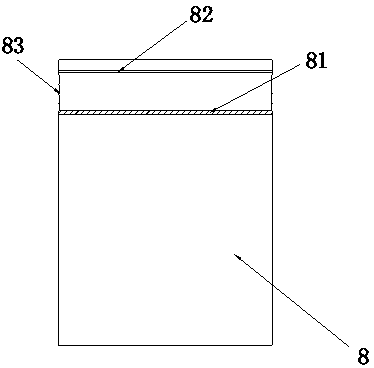

Dual-layer sealing bag for storing hot melt coating

InactiveCN109229816AQuality impactTo achieve the purpose of moisture-proofDomestic cooling apparatusLighting and heating apparatusHot melt coatingEngineering

The invention provides a dual-layer sealing bag for storing hot melt coating. The dual-layer sealing bag comprises an external bag and an internal bag in the external bag, the external bag is internally provided with an external bag body, a damp-proof decoration layer is closely glued to the outer layer of the external bag body through a first glue layer, an aluminum foil layer is glued to the inner layer of the external bag body through a second glue layer, and a sponge layer is arranged on the inner surface of the aluminum foil layer. According to the dual-layer sealing bag for storing the hot melt coating, the external bag is provided with the papery damp-proof decoration layer, so that the damp-proof aim can be achieved when the whole external bag is reversely placed; the inner layer is provided with the aluminum foil layer with the sponge layer, the heat-insulation effect can be achieved, and the influence of the external environment on the quality of the hot melt coating is reduced. A sealing strip is arranged on the internal bag, a high sealing effect can be achieved, storage of the hot melt coating is facilitated, and the rain-proof and damp-proof aims can be achieved. A bending section is arranged on the internal bag, the drop-resistant effect can be achieved, and the situation is avoided that under violent impact, the sealing strip in the internal bag is pulled out, and the sealing effect is affected.

Owner:南京鑫亮交通设施有限公司

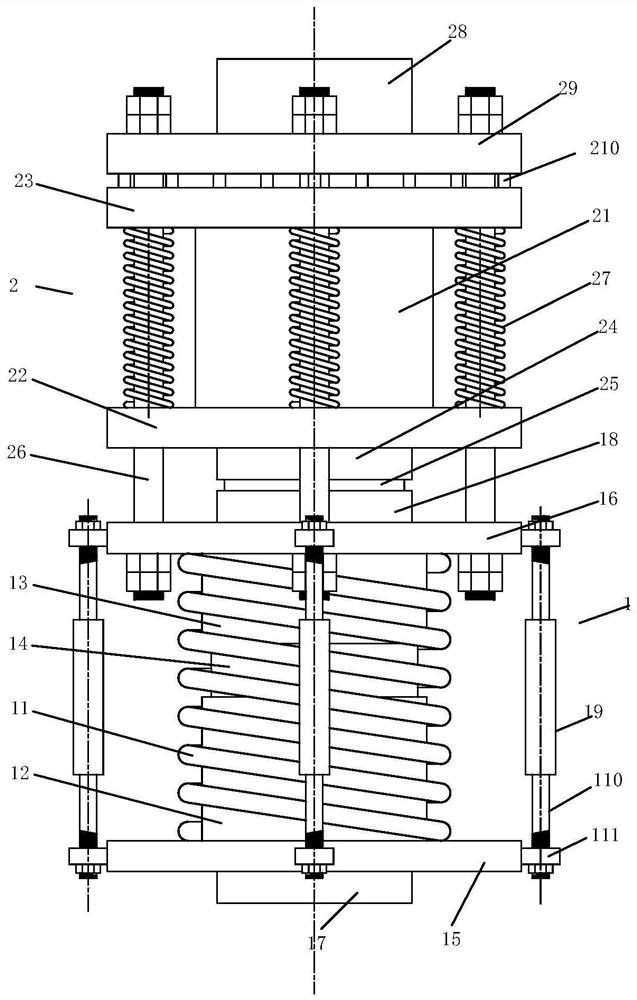

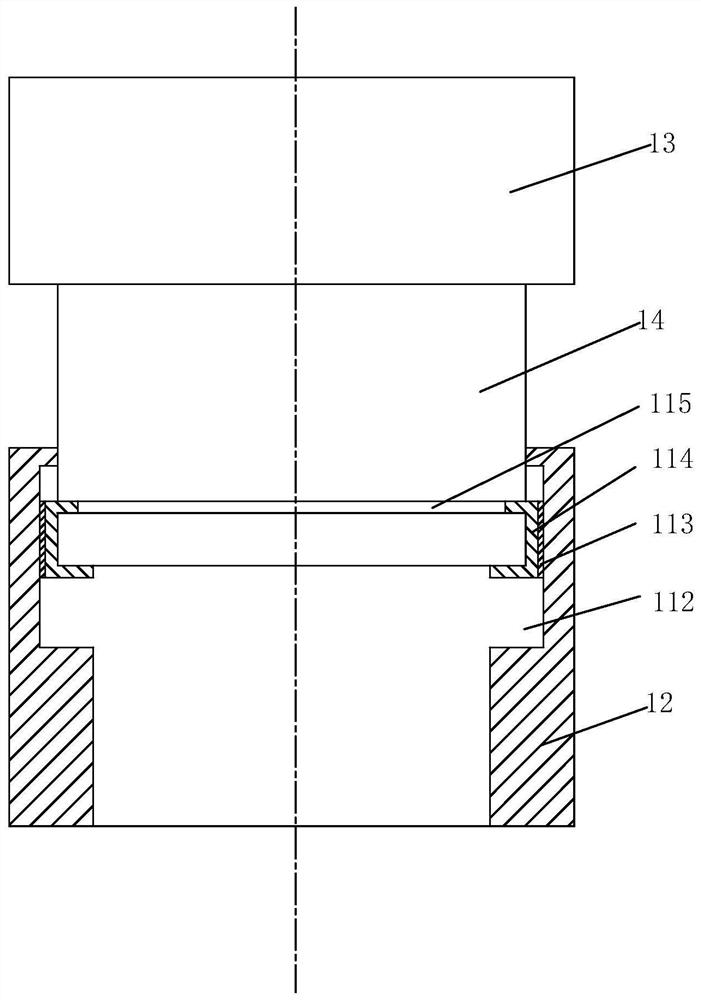

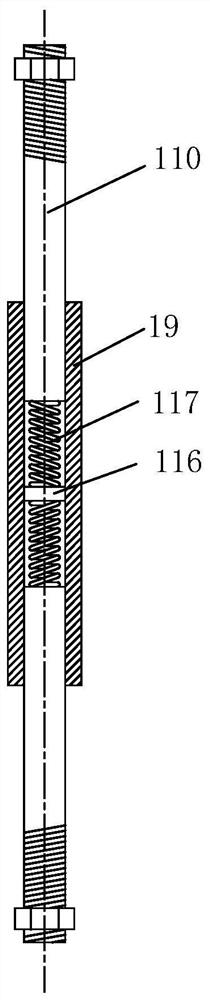

a compensator

ActiveCN110657310BImprove stabilityAvoid thermal expansion and contractionPipeline expansion-compensationAxial displacementEngineering

The invention relates to the field of compensators, specifically a compensator, including an axial displacement compensation mechanism and a lateral displacement compensation mechanism. A lateral displacement compensation mechanism is arranged directly above the axial displacement compensation mechanism. , an outer sleeve and an inner sleeve, the present invention sets an axial displacement compensation mechanism, utilizes the cooperation between a plurality of piston bolt rods and the piston tube, and the telescopic sliding between the outer sleeve and the inner sleeve, which can It is suitable for the displacement change between the pipes and realizes the adjustment of the axial distance. By setting the lateral displacement compensation mechanism and setting the silicone rubber tube and the pipe cover between the inner and outer cylinders, it can prevent the large gap between the outer cylinder and the inner cylinder. The axial movement of the pipe can avoid the damage of the inner cylinder and the outer cylinder caused by the expansion of the pipeline, and at the same time, it can reduce the mutual friction and affect the sealing effect, thereby greatly increasing the service life of the lateral displacement compensation mechanism and improving the utilization rate.

Owner:江苏星光波纹管有限公司

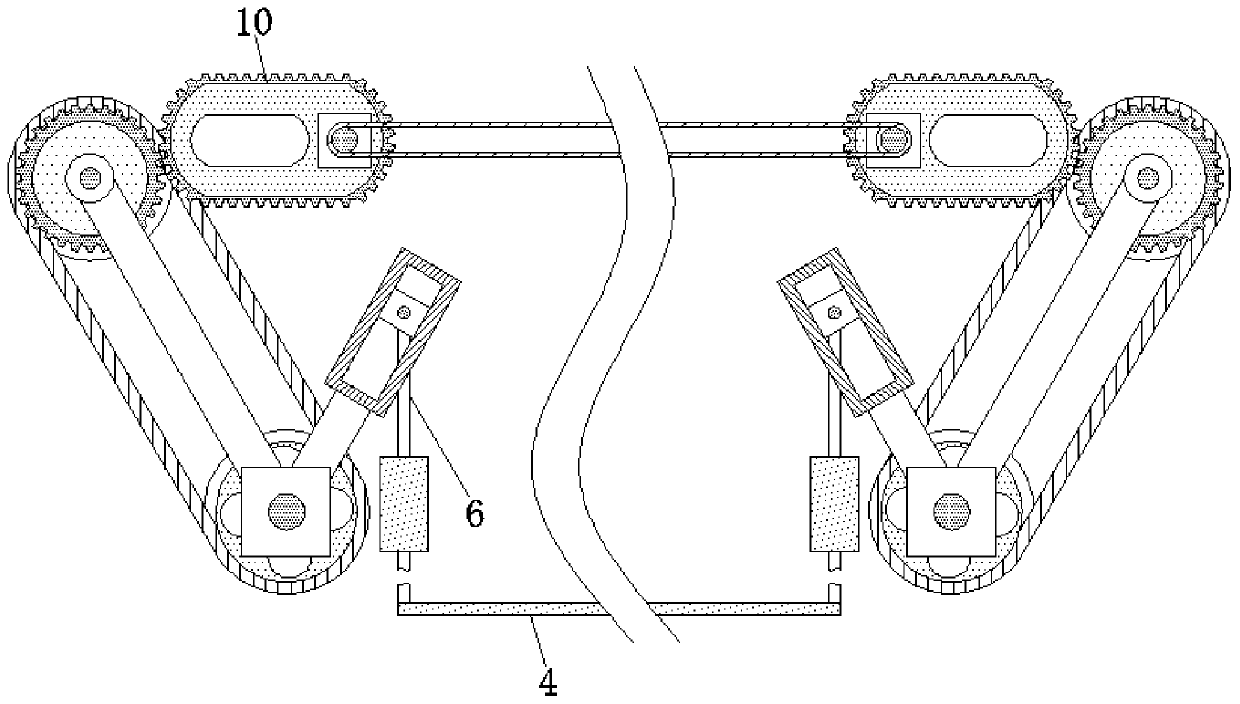

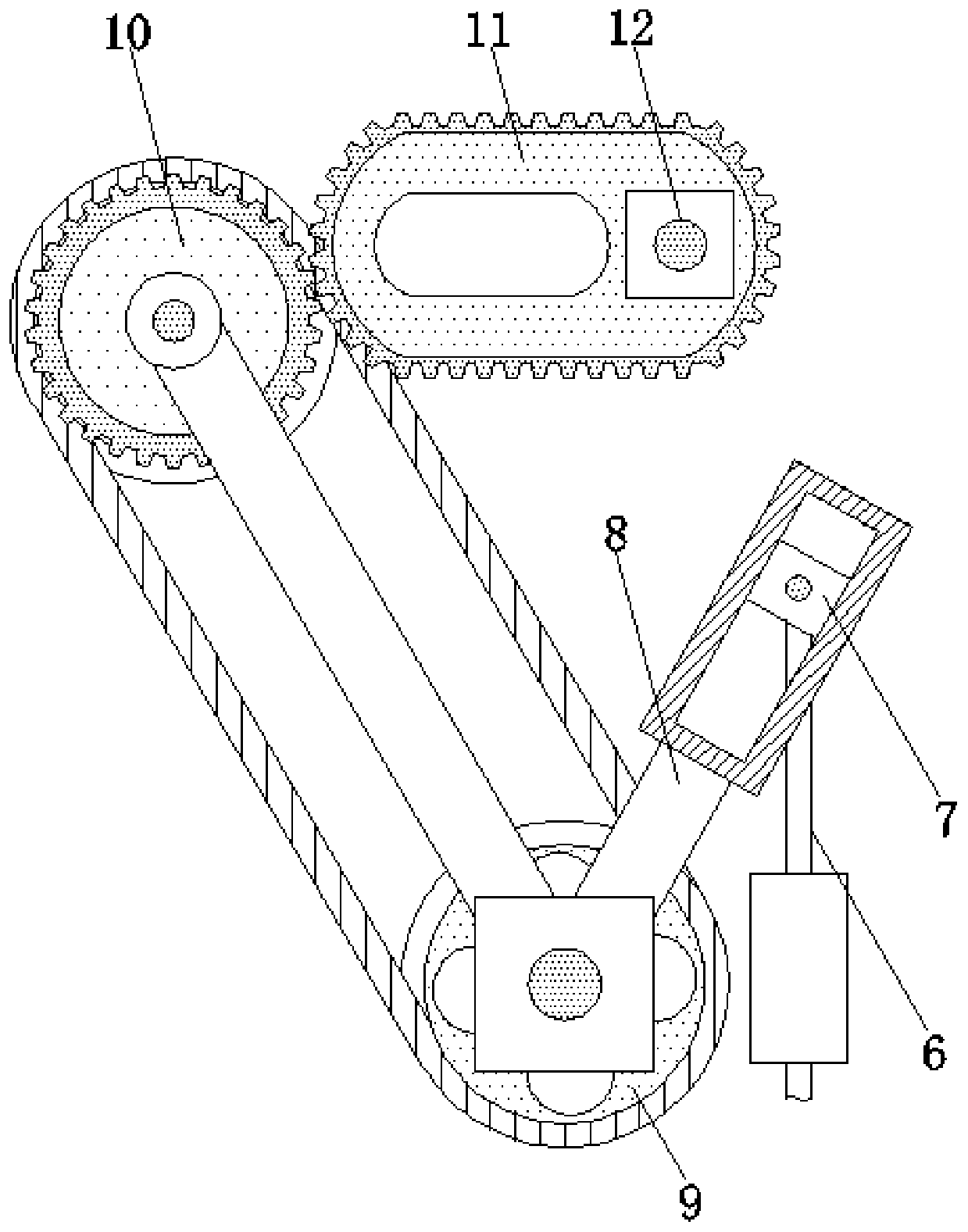

Multifunctional carton packaging machine

InactiveCN111731567AImprove work efficiencyAvoid affecting the sealing effectPackagingEngineeringDust particles

The invention discloses a multifunctional carton packaging machine. The multifunctional carton packaging machine includes a workbench. An accommodating groove is formed in the workbench. The inner walls of two sides of the accommodating groove are fixedly connected with positioning rods. Bearings are arranged on the two sets of positioning rods in a sleeving mode, and fixing plates are fixedly connected two ends of the positioning rods in a sleeving mode. According to the multifunctional carton packaging machine, the positioning blocks are arranged, conveyor belts are connected with clamping plates through the positioning blocks, a fixing function is achieved, the clamping plates movably connected into the positioning blocks are arranged, the width of the clamping plates can be adjusted according to built-in springs fixed to two ends of the clamping plates, products of different sizes are placed and fixed at the same time, an air box can perform blowing and remove floating dust particles through evenly arranged air outlets before the products are packaged so as to prevent the situation that the sealing effect is affected due to the fact that the subsequent package is not tightly sealed due to dust, a cooling fan is arranged, and the package can be cooled in time after the package is heated by a retractable packaging machine to avoid burns caused by the touch of the staff.

Owner:浙江慧诚包装材料有限公司

Improved leakage-proof universal half joint assembly

PendingCN112747179AVersatilityAvoid displacementSleeve/socket jointsFlanged jointsClassical mechanicsStructural engineering

The invention provides an improved leakage-proof universal half joint assembly. The improved leakage-proof universal half joint assembly comprises two half joint half bodies, and further comprises at least one socket joint, wherein accommodating cavities for allowing a pipeline to pass through are formed in the two half joint half bodies; a first connecting flange is fixedly arranged on at least one end part of the two half joint half bodies; a first mounting slot is formed in the first connecting flange; a first sealing part is arranged in the first mounting slot; the socket joint is adjacent to the first connecting flange and is arranged on the outer wall of the pipeline in a sleeving mode; one end, close to the first connecting flange, of the socket joint is equipped with a positioning lug boss which can be inserted into the first mounting slot; the positioning lug boss can abut against the first sealing part; one end, away from the first connecting flange, of the socket joint is fixedly equipped with a connector; and the first connecting flange is connected with the connector. The half joint assembly provided by the invention is simple in structure, is convenient to mount, is good in sealing performance and is strong in universality.

Owner:SOUTHEAST PIPE VALVE CO LTD

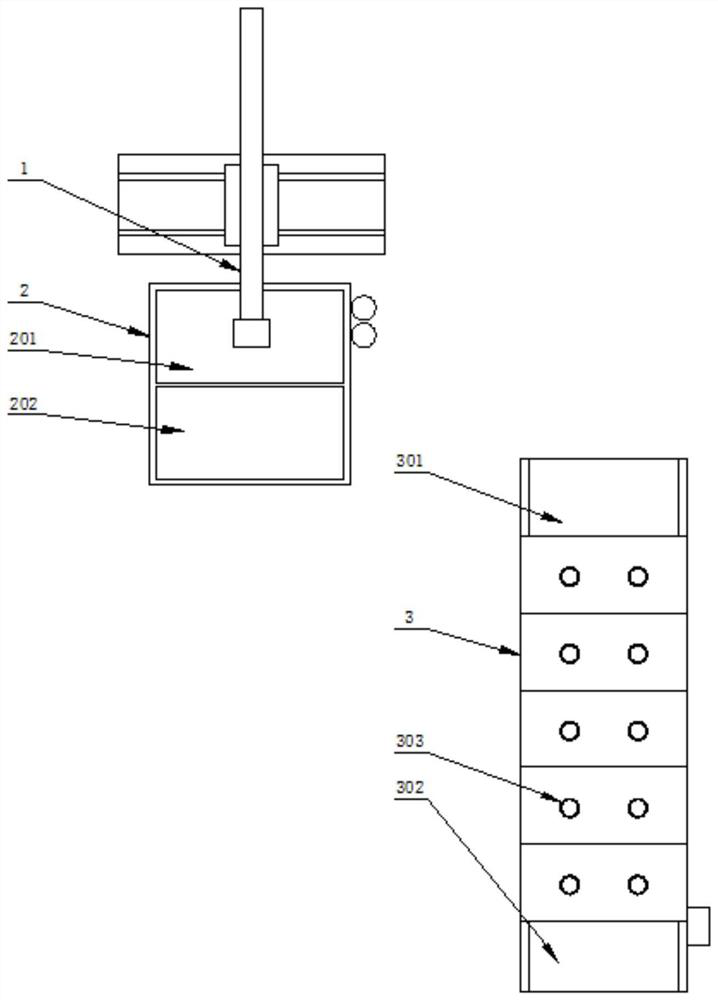

Wall seam glue sealing device for buildings

ActiveCN113605651AUniform dischargeAvoid affecting the sealing effectBuilding constructionsHouse buildingSizing

The invention discloses a wall seam glue sealing device for buildings, and relates to the technical field of house buildings. The device comprises a sizing material storage shell used for storing sizing materials, an inner pipe adjusting plate is slidably connected to the interior of the sizing material storage shell, the inner pipe adjusting plate is made of magnets, one end of the inner pipe adjusting plate is fixedly connected with a sizing material discharging inner pipe, the sizing material discharging inner pipe penetrates through the sizing material storage shell, a plurality of first inner pipe sizing material holes are formed in the peripheral side of the sizing material discharging inner pipe, the first inner pipe sizing material holes are divided into a plurality of groups, each group of first inner pipe sizing material holes are annularly and uniformly distributed in the peripheral side of the sizing material discharging inner pipe, and second inner pipe sizing material holes are formed in the end, away from the inner pipe adjusting plate, of the sizing material discharging inner pipe. According to the wall seam glue sealing device, through cooperation of all accessories, glue sealing treatment can be evenly conducted on the interior of a wall seam, the situation that gaps appear when the wall seam is subjected to glue sealing, consequently, part of positions are not filled with the sizing materials, and the glue sealing effect is affected is avoided, and the sizing materials can be discharged at a constant speed.

Owner:SHANGHAI GREENLAND CONSTR GRP

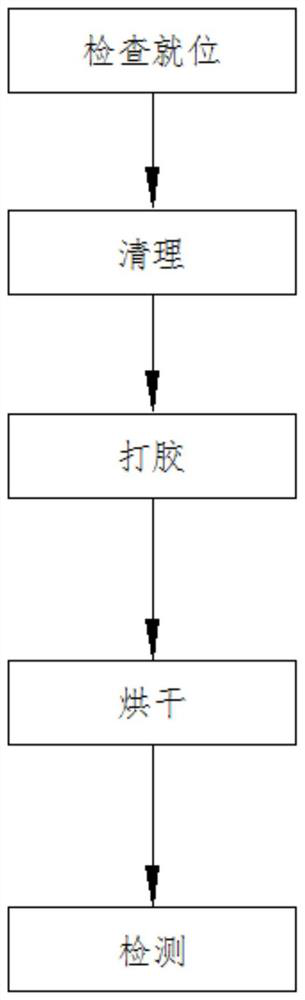

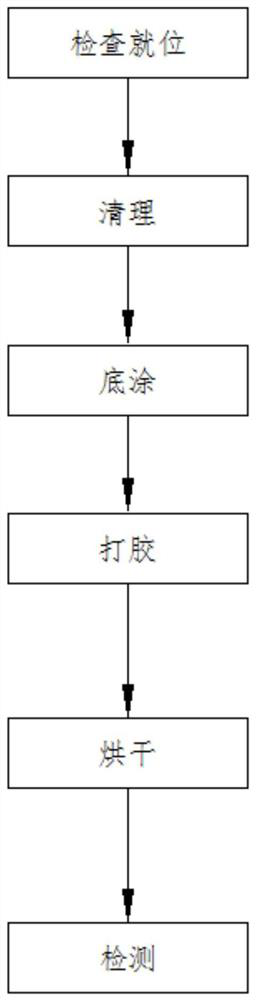

Silica gel sealing strip production process and production line thereof

InactiveCN111804528AIncrease widthGuaranteed sealing qualityEngine sealsPretreated surfacesAlcoholProcess engineering

The invention discloses a silica gel sealing strip production process. The silica gel sealing strip production process comprises the steps that 1, in-place inspection is conducted, specifically, the appearance of a shell is inspected, oil stain pollution is avoided, and clashing, scratching and deformation are avoided; 2, cleaning is conducted, specifically, cotton cloth or tissue paper is dippedin alcohol, the position, where a sealing strip needs to be mounted, of the shell is wiped, and no dirt exists; 3, gluing is conducted, specifically, continuous gluing is conducted along the position,where the sealing strip needs to be mounted, of the shell, glue discharging is uniform, and the whole circle of foamed silica gel sealing strip is formed; 4, drying is conducted, specifically, the shell with the foamed silica gel sealing strip is integrally dried; and 5, detection is conducted, specifically, the section size and the position size of the foamed silica gel sealing strip are inspected, and that the appearance is compact and free of roughness is inspected. According to the silica gel sealing strip production process, the whole circle of foamed silica gel sealing strip is formed by directly conducting gluing on the shell, the production efficiency is improved, the material and labor cost is reduced, and the sealing quality is ensured. The invention further discloses a silica gel sealing strip production line used in the process.

Owner:保定市宏腾科技有限公司

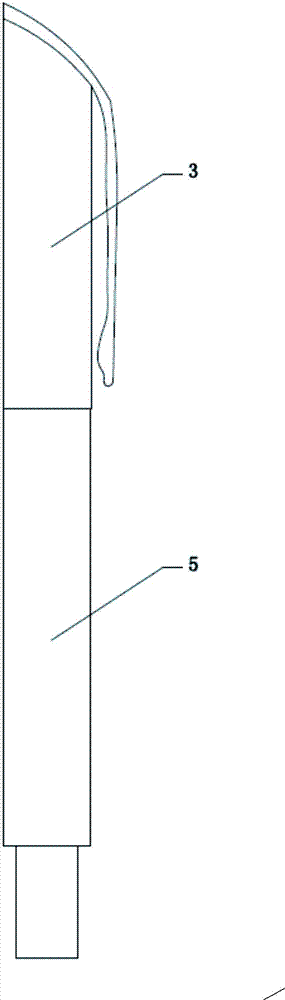

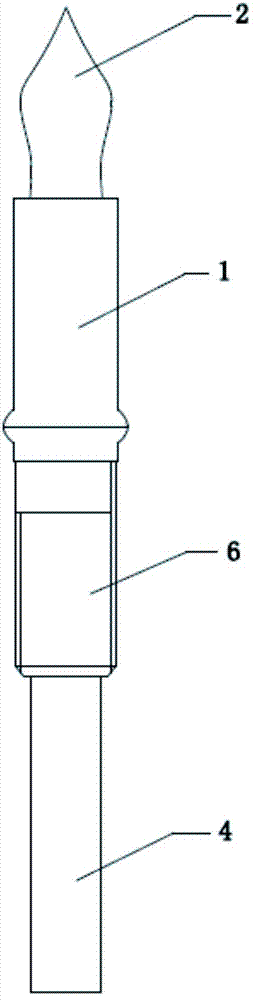

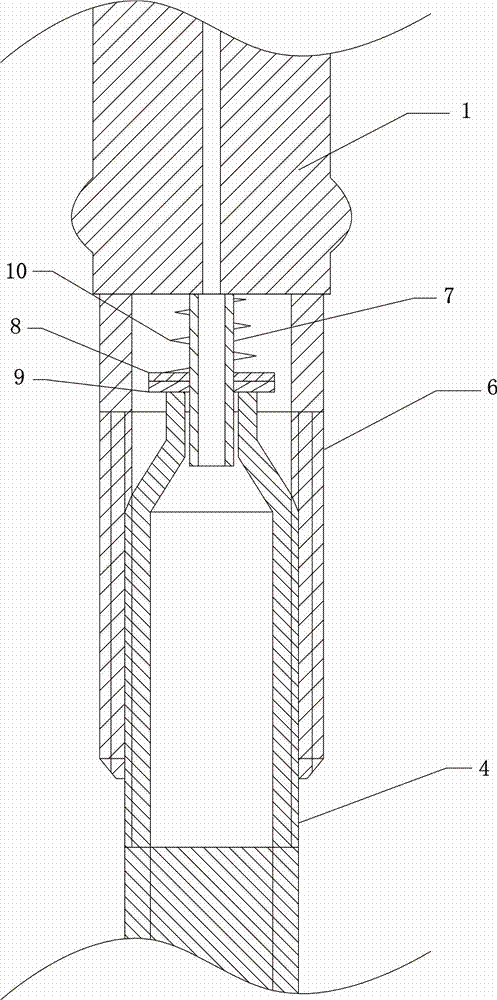

Pen with replaceable ink bag

The invention belongs to the technical field of stationery, and in particular relates to a pen with a replaceable ink bag. The pen includes a nib. One end is closed, the opening end of the ink bag is provided with an external thread, the rear end of the nib is provided with a connecting pipe, and the connecting pipe is threadedly connected with the ink bag, and the rear end of the nib is located in the connecting pipe and is provided with a leading part for extending into the opening end of the ink bag. When installing and replacing the ink bag in the present invention, it is only necessary to screw the ink bag on the connecting pipe of the nib, and during the screwing process, the conducting part will extend into the ink bag to seal the diaphragm of the ink in the film bag It is very convenient to use, and the ink bag is connected with the connecting pipe on the nib. The structure is simple, the parts are less worn, and the sealing effect is good. The ink bag can be replaced many times. The ink sac and the nib are sealed and connected to avoid ink leakage, and the use cost is low.

Owner:王梓

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com