Water stop device for layered water pumping tests and water pumping testing device and method

A technology of pumping test and water stop device, which is applied in the direction of earthwork drilling, mining fluid, wellbore/well parts, etc. Shorten the water distance and other problems, to achieve the effect of simple and efficient pumping test, convenient and simple operation of pumping test, and protection of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

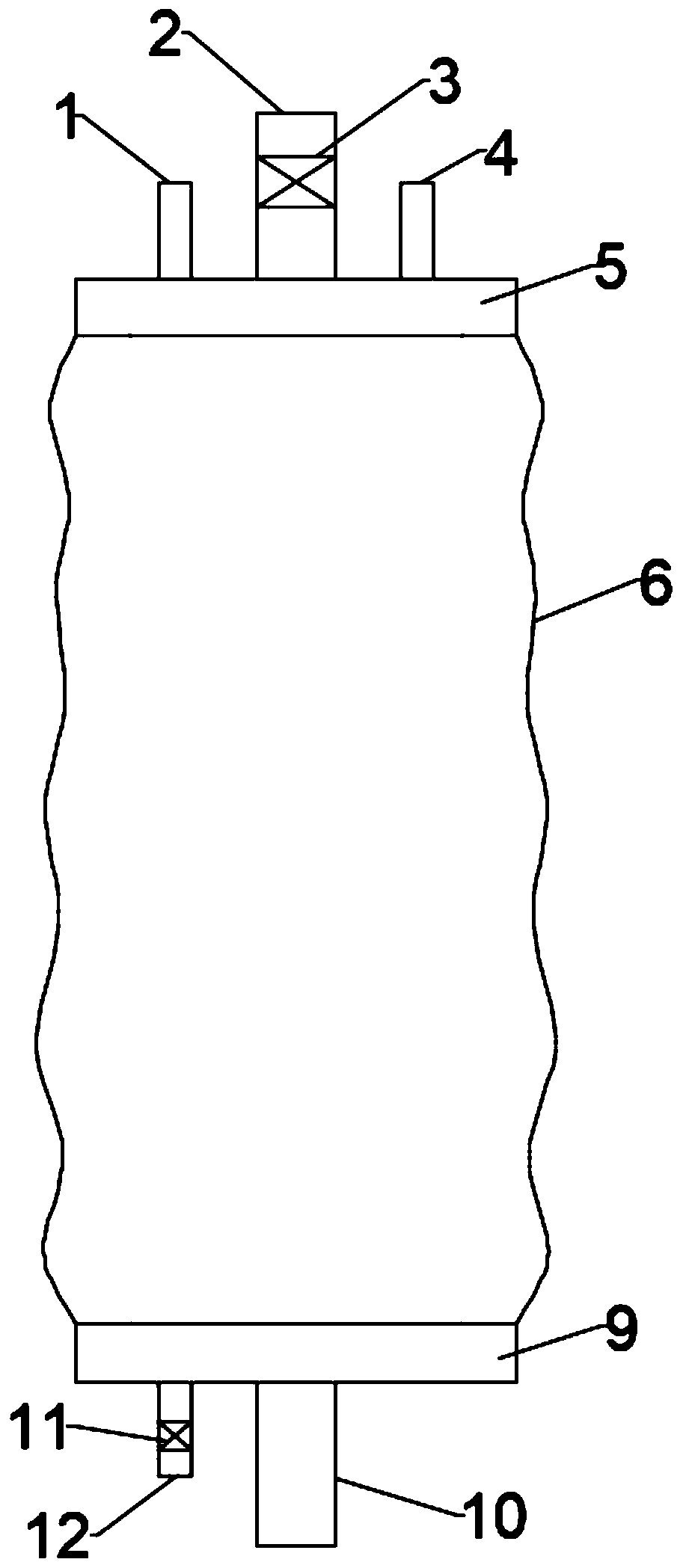

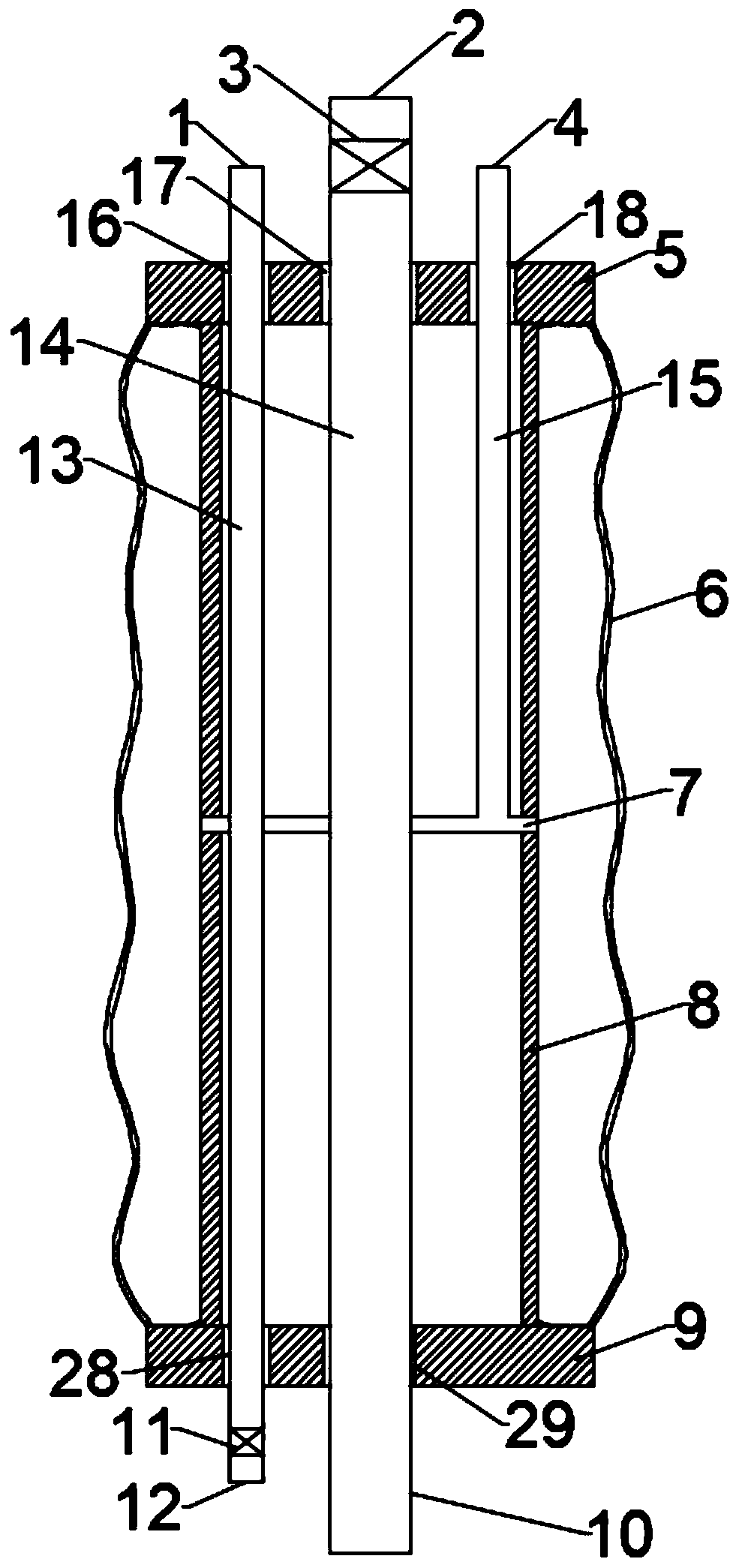

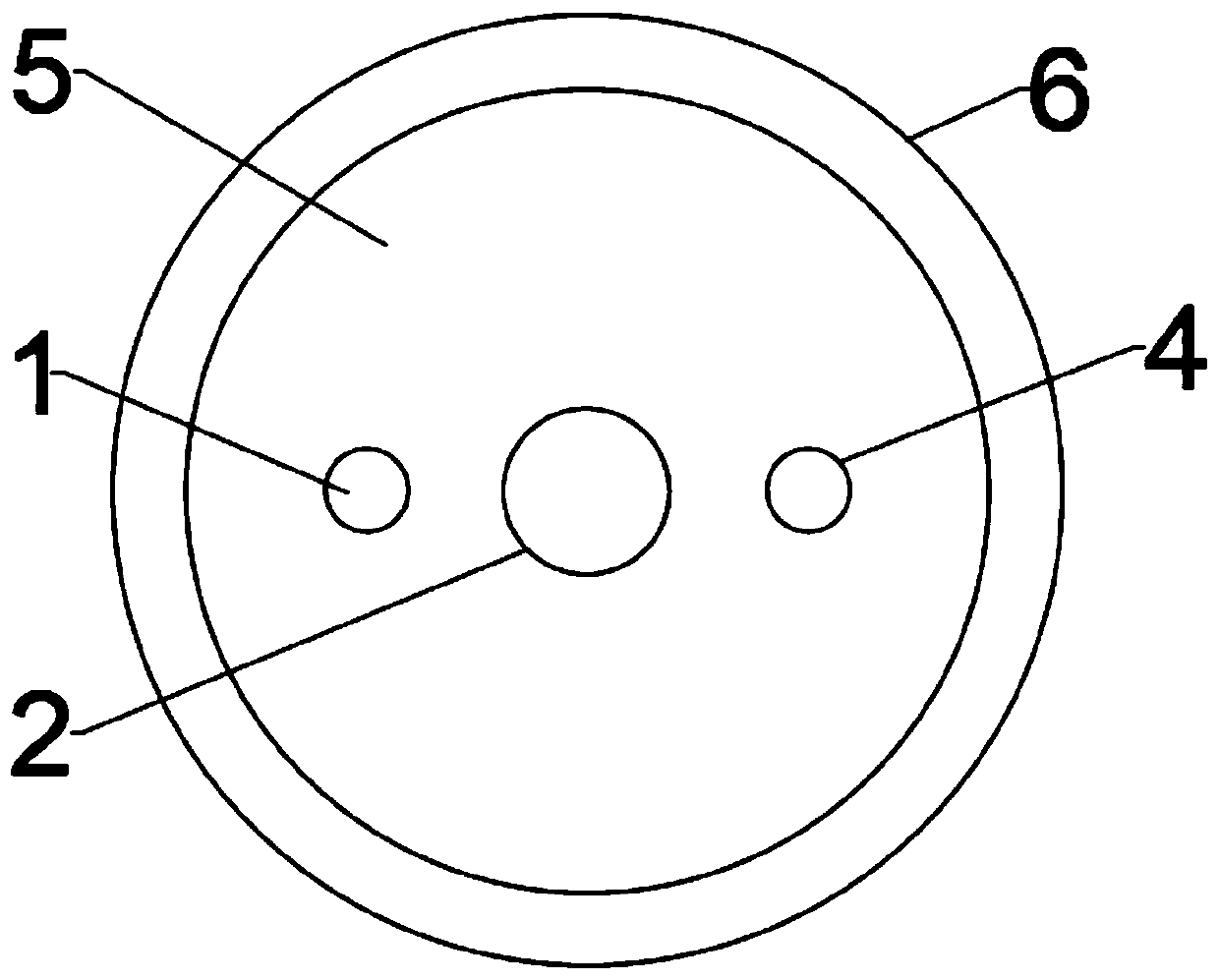

[0059] Such as Figure 1-Figure 3 As shown, a water stop device 24 for stratified water pumping test includes: a body, a rubber air bag 6, an air pressure pipe 15 and a water outlet pipe 14.

[0060] The main body is arranged vertically, and the main body is used to support the rubber bladder to avoid the instantaneous shrinkage of the rubber bladder when it shrinks. The rubber airbag 6 is sheathed on the outer wall of the body, wherein the rubber airbag 6 is ring-shaped. The air pressure tube 15 is located in the body, and one end of the air pressure tube 15 protrudes from the top of the body to be the air pressure interface 4, and the other end of the air pressure tube 15 is an air outlet 7, which communicates with the rubber air bag 6, and the other end of the air pressure tube 15 is provided There are two branch air outlets 7, and the two air outlets 7 pass through the body to communicate with the rubber air bag 6, thereby communicating with the external air compressor eq...

Embodiment 2

[0098] The structure of the water-stopping device 24 adopted in this embodiment is the same as that of Embodiment 1, the difference is that this embodiment provides a pumping test device, including the water-stopping device 24 for layered pumping tests as described above, The pumping test device also includes a submersible pump 25 , and the top of the submersible pump 25 is connected to the water inlet port 10 . It also includes a water level monitoring connecting pipe, an air pressure connecting pipe 20 and a water outlet drill pipe 19, wherein the water level monitoring connecting pipe is vertically arranged, the upper end of the water level monitoring connecting pipe is connected with the second water level monitoring interface 12, and the water level monitoring connecting pipe is provided with evenly spaced The drilled holes can facilitate water to enter the water level monitoring connecting pipe through the drilled holes. The height of the borehole is 10m. Wherein the ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com