Underwater manifold connector

A connector and manifold technology, applied in flange connection, pipe/pipe joint/pipe fitting, fluid pressure actuating device, etc., can solve the problem of uneven force on the jaws, save material costs and improve service life and reliability and ease of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

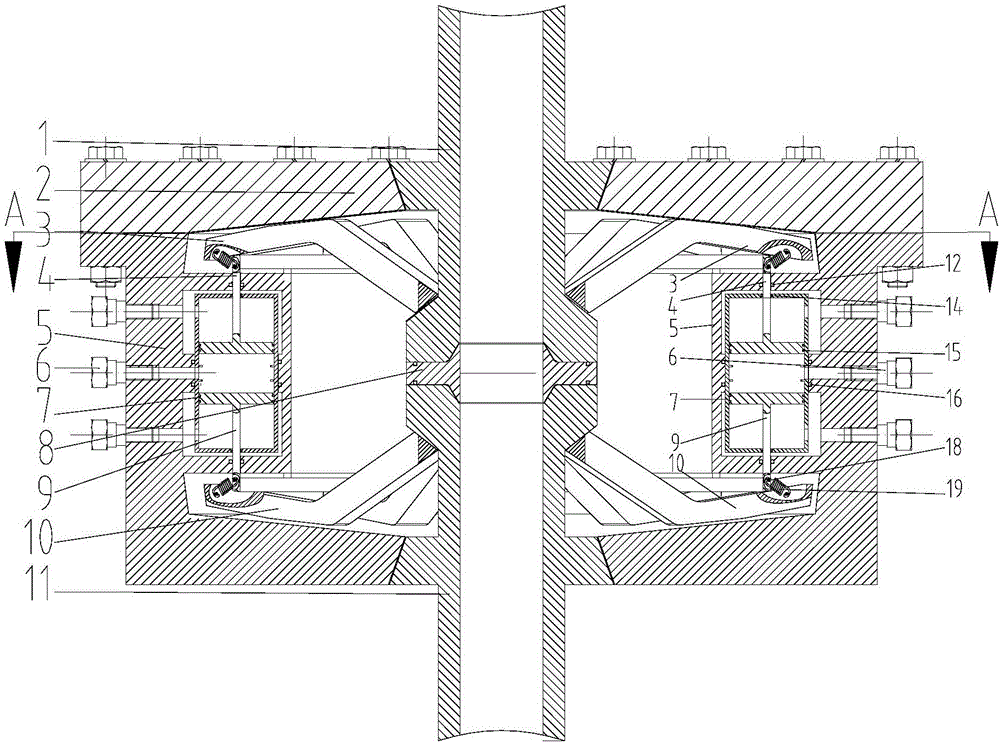

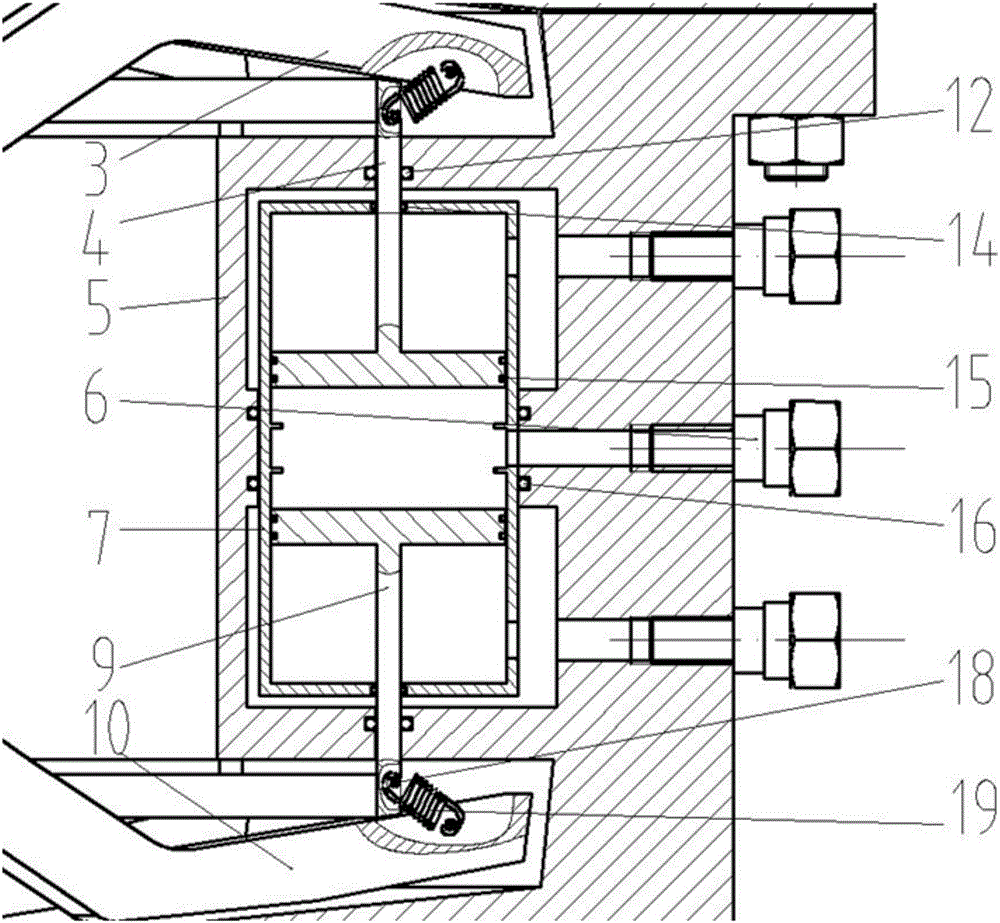

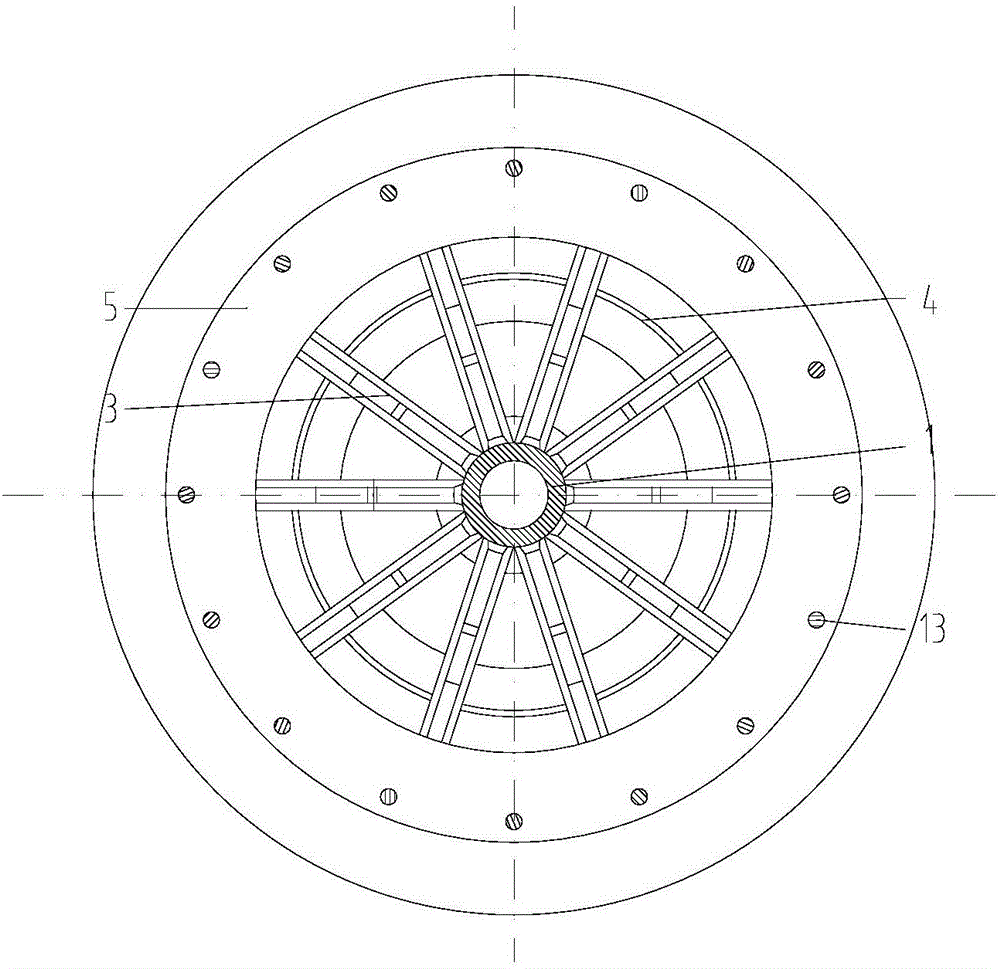

[0022] Such as Figure 1 to Figure 5 As shown, an underwater manifold connector of the present invention includes a base body 5, and a first cavity is provided in the base body 5, and the first cavity is connected to the connector end cover through 16 connecting bolts 13 2. Sealing. There is a floating hydraulic cylinder 7 in the first cavity. The floating hydraulic cylinder 7 is located in the second cavity extending from the base body 5. The second cavity is circular, and the liquid level of the floating hydraulic cylinder 7 is circular. , the floating hydraulic cylinder 7 is provided with several groups of upper piston rods 4 and lower piston rods 9, and the connecting pipe 1 and the connected pipe 11 to be connected are arranged in the base body 5, and the ends of the connecting pipe 1 and the connected pipe 11 The upper part of the conical boss and the lower conical boss are respectively provided, and a sealing ring is provided between the connecting pipe 1 and the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com