Intelligent welder for large ship steel plate

A welding machine and hull technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high price and low efficiency of cleaning equipment, and achieve low price, simple and efficient design, and obvious effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and embodiment.

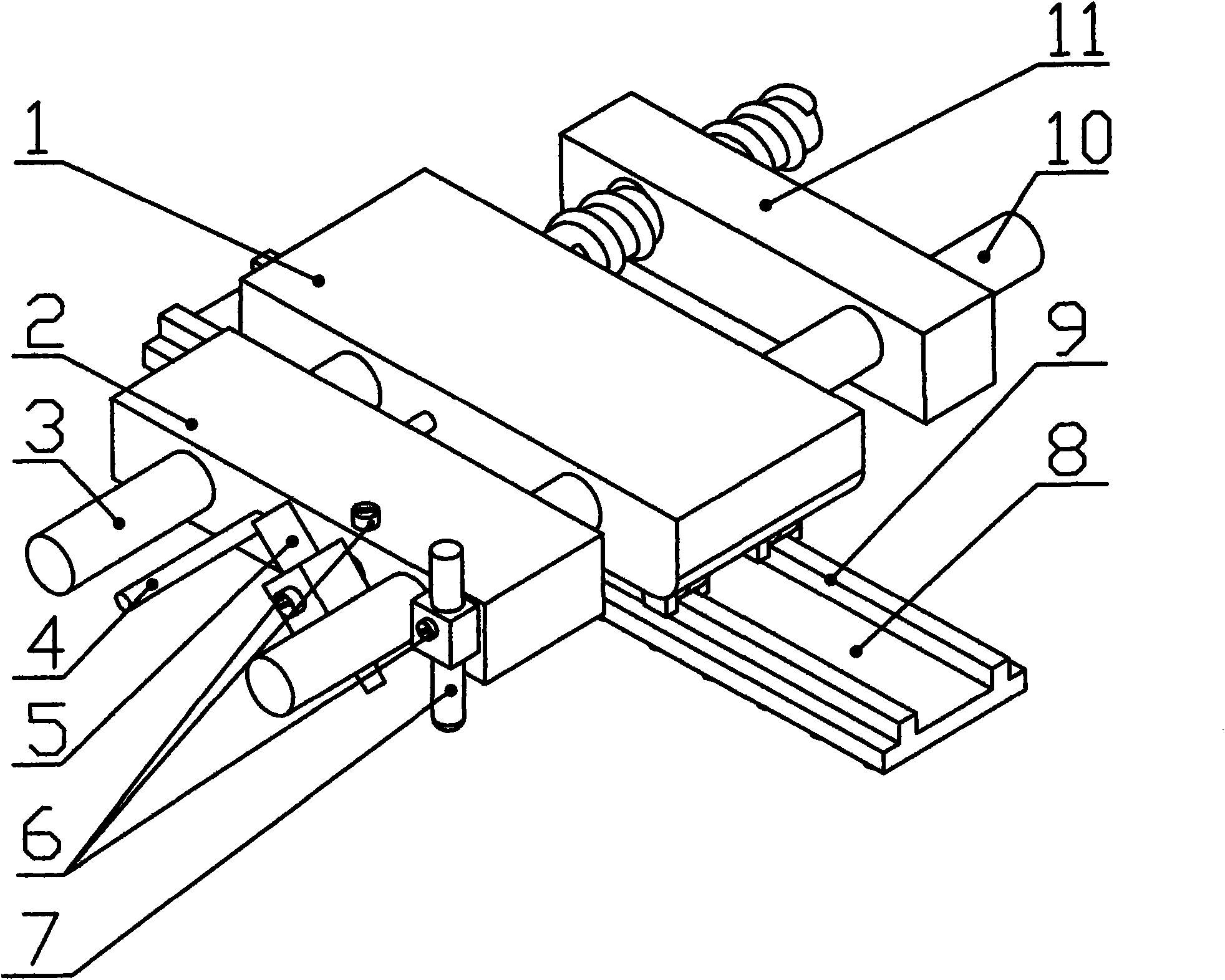

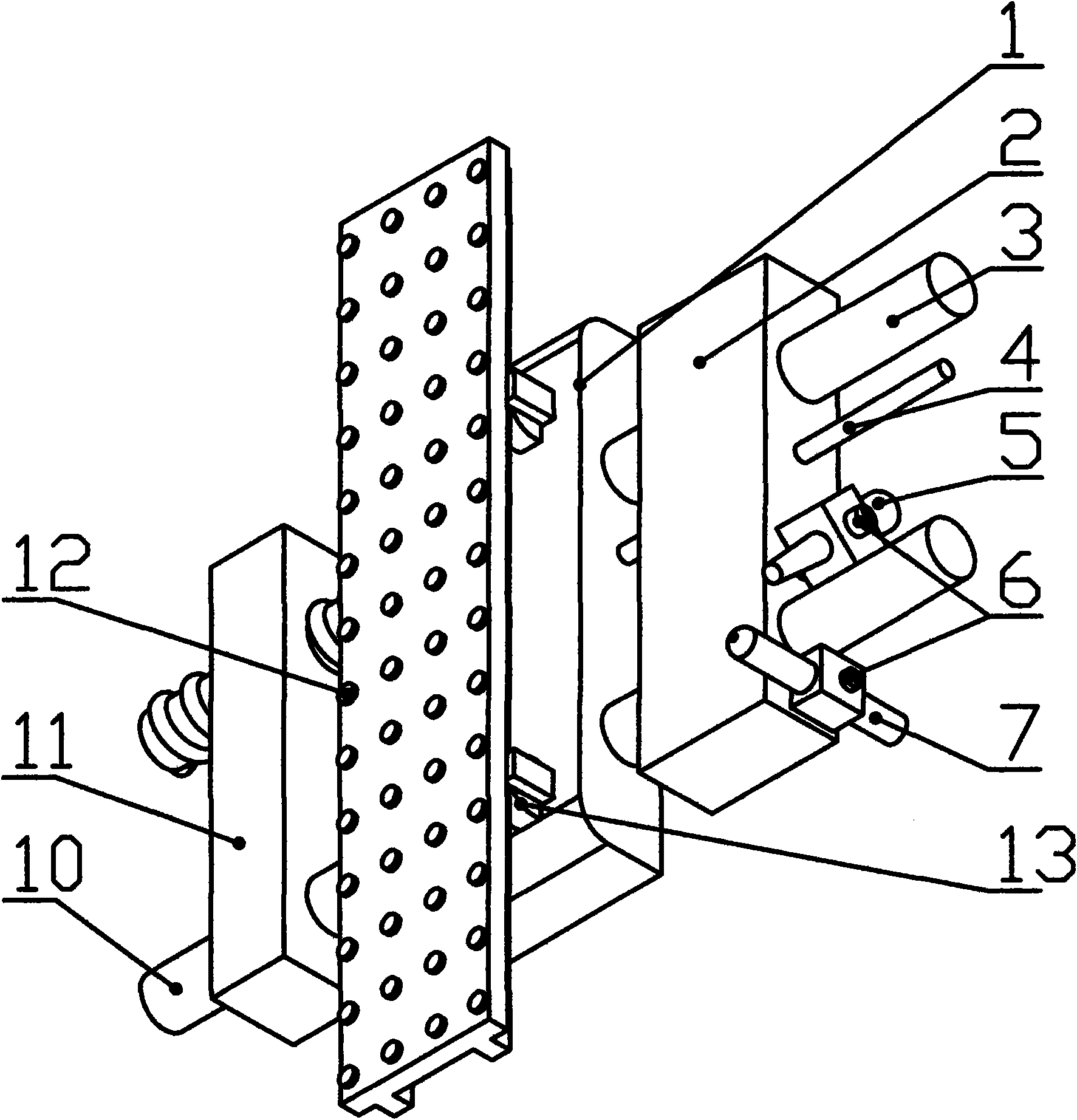

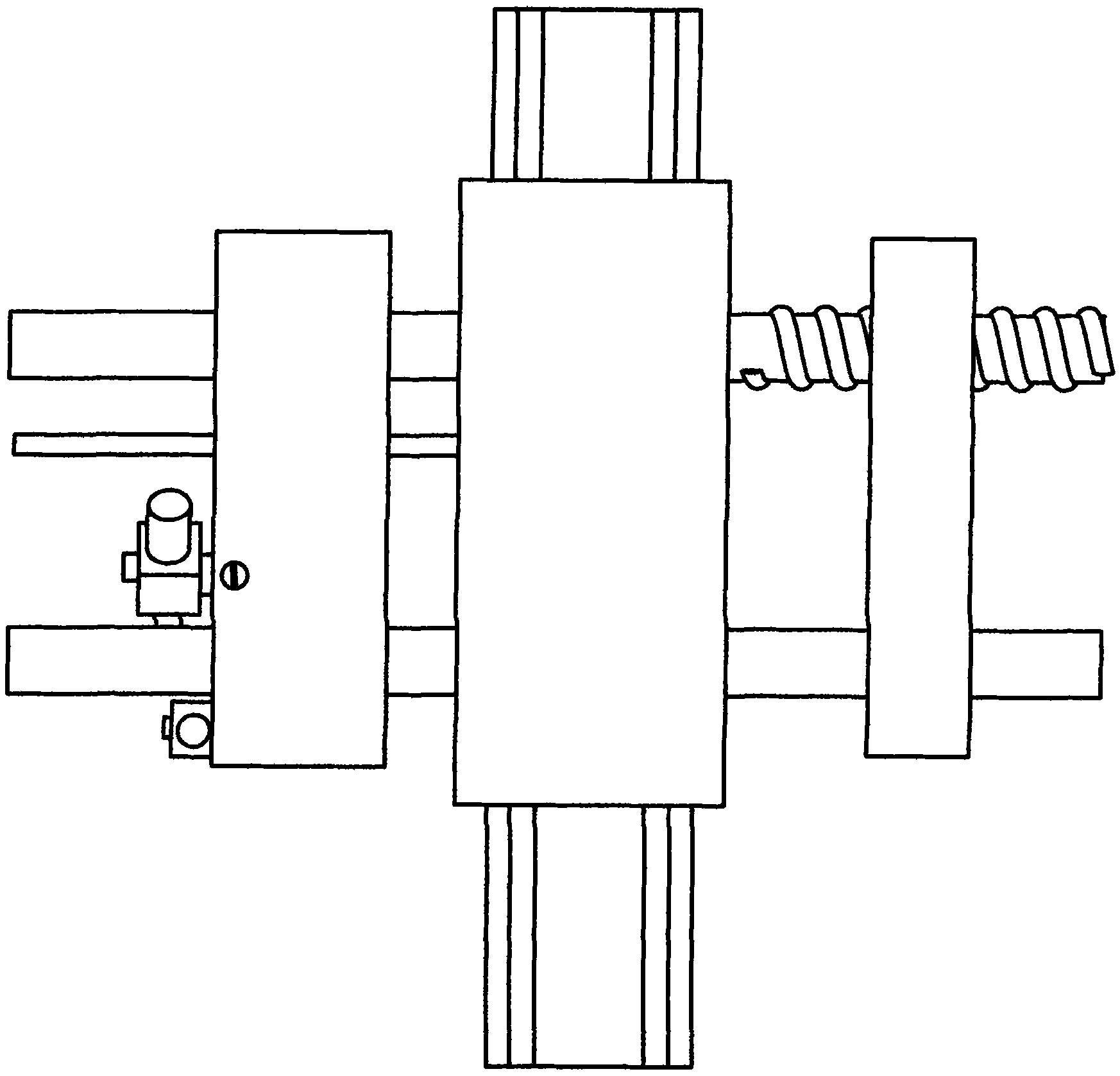

[0016] Such as Figure 1-4 As shown, the intelligent welding machine for large-scale hull steel plates of the present invention consists of a controller carrier 1, a slider 2, a rotating rod 3, a displacement sensor 4, a welding torch head 5, a fastening screw 6, a positioning rod 7, a rubber plate 8, a guide rail 9, The fixed rod 10, the counterweight 11, the sucker 12, the track wheel 13, and the convex point 14 are formed. The track wheel 13 is installed on the bottom of the controller carrier 1, and the rotating rod 3 and the fixed rod 10 are installed on both sides of the controller carrier 1. The slider 2 is installed on the left side of the rotating rod 3 and the fixed rod 10, and can slide freely under the action of the positioning rod 7, and the displacement sensor 4 is installed on the left side of the controller carrier 1 for transmitting the displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com