System and method for controlling horizontally and focusing automatically silicon slice platform of photo-etching machine

An automatic focus and level control technology, which is applied in the direction of microlithography exposure equipment, optics, pattern surface photoplate making process, etc., can solve the problems that affect the detection accuracy, large focus depth, interference, etc., to improve detection accuracy and improve The effect of manufacturing process and equipment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

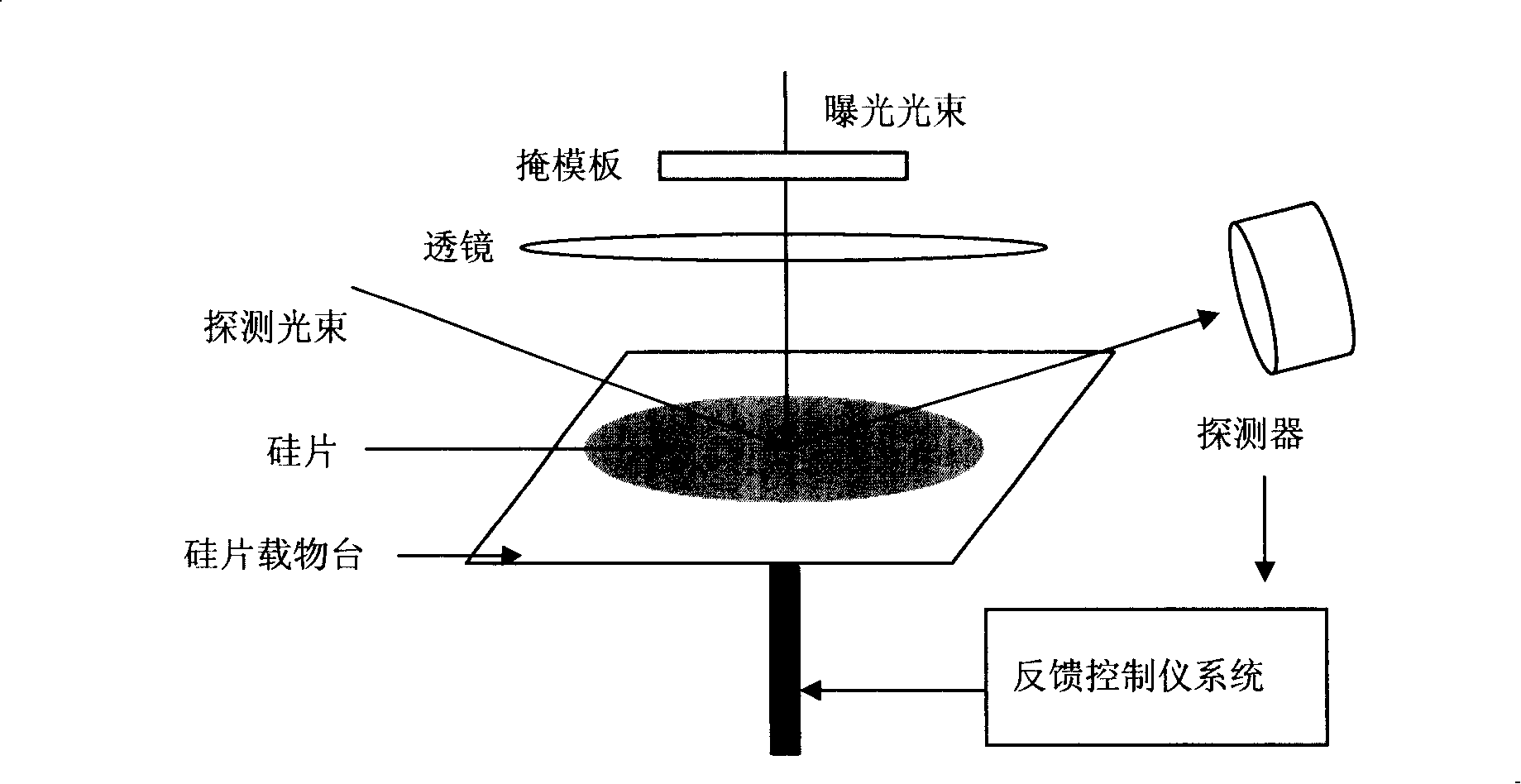

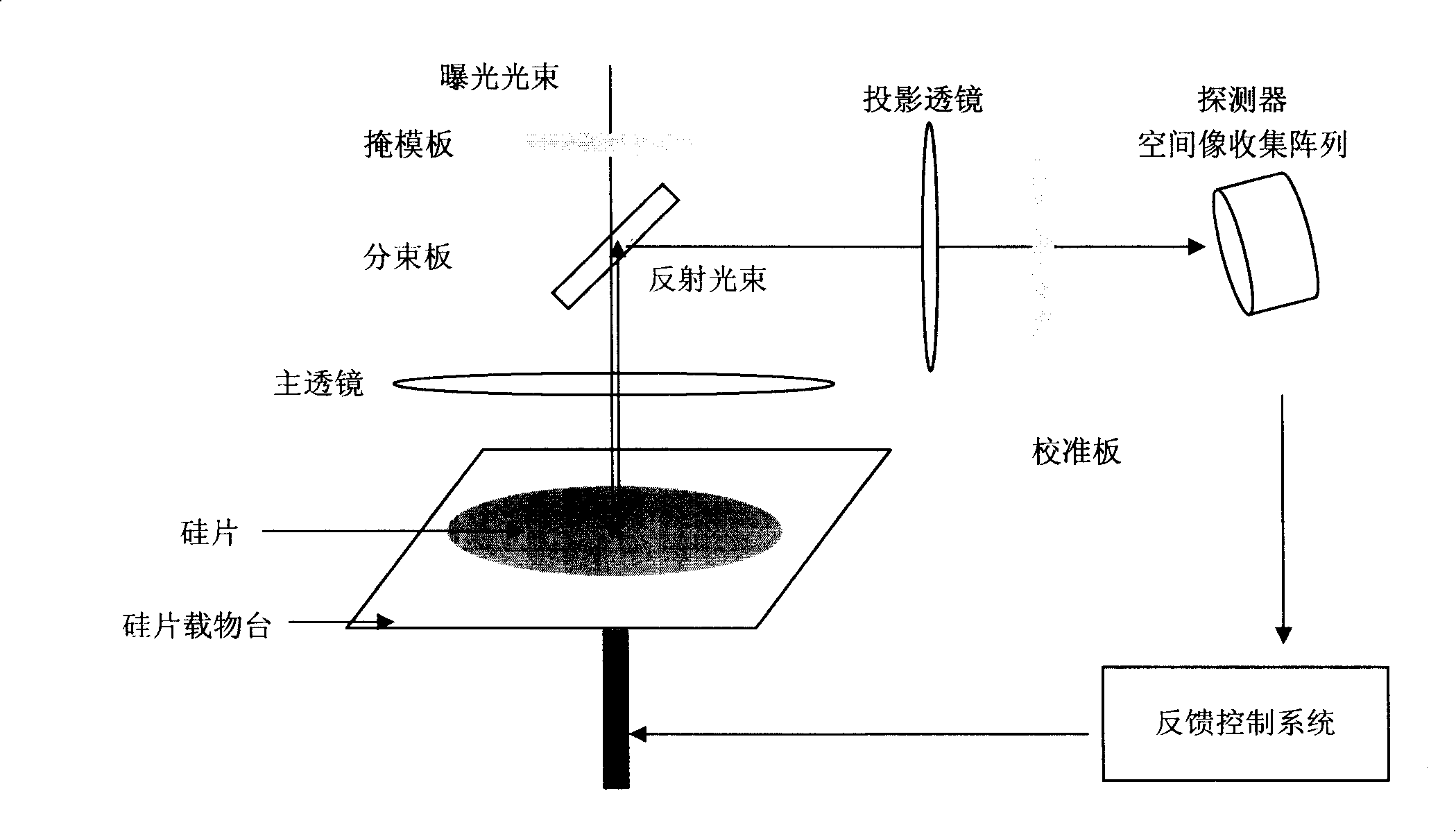

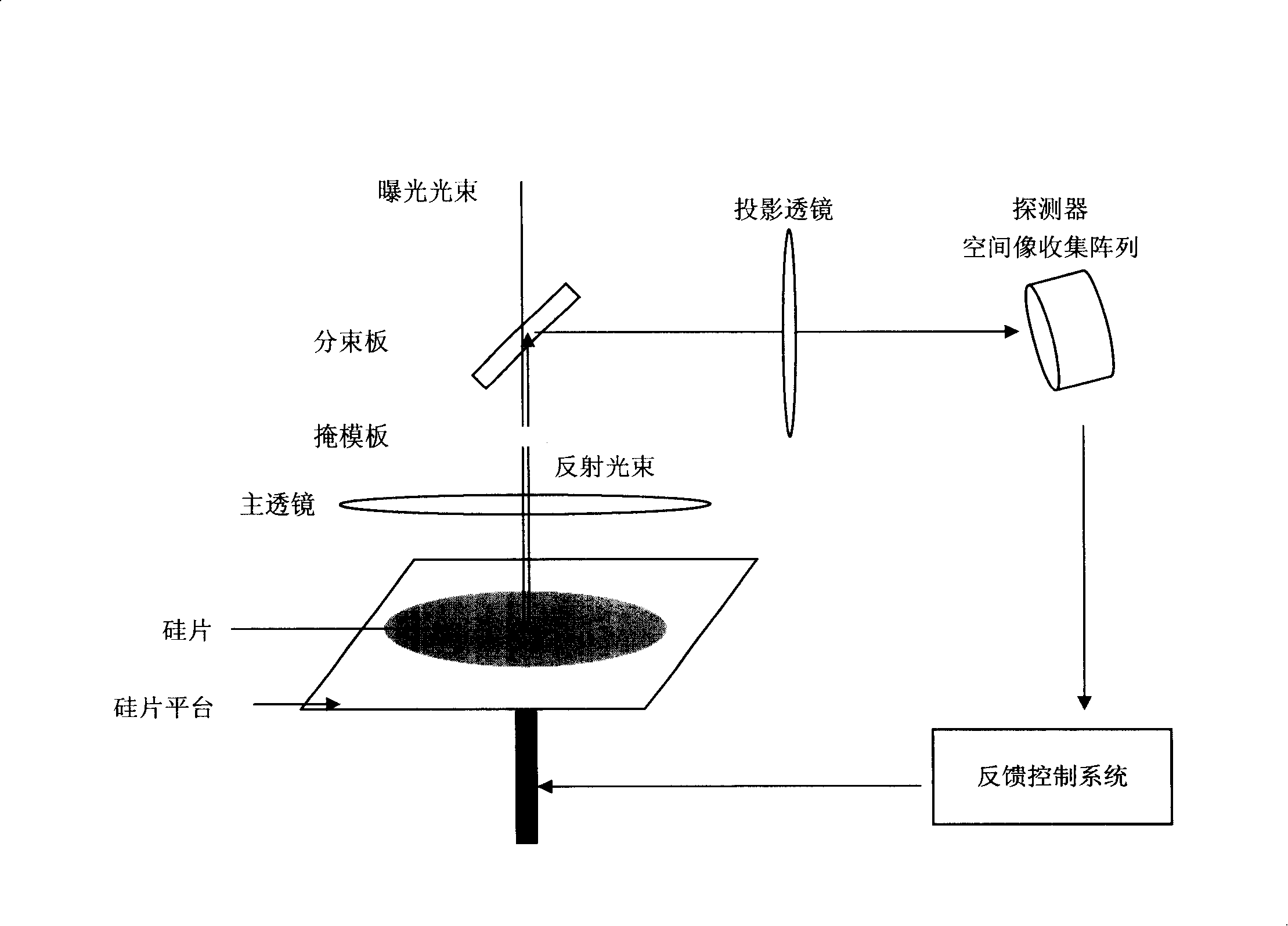

[0011] The invention is a silicon chip level control system of a photoetching machine used in projection photoetching for semiconductor integrated circuit printing, which uses the reflected beam of the exposure beam to confocal detection of the silicon chip position and real-time feedback control. As mentioned before (see figure 1 ), the silicon wafer stage control system in the prior art includes a mask, a lens, a silicon wafer stage, a focal plane spatial image collection detector array and a feedback controller system, etc. The feedback controller system can control the silicon The slide stage performs real-time feedback adjustment to automatically adjust the horizontal position of the silicon wafer and auto-focus; on this basis, the system of the present invention adds a projection lens and a beam splitting plate, the beam splitting plate can spl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com