Silica gel sealing strip production process and production line thereof

A production process and sealing strip technology, applied in the field of silicone sealing strip production process and its production line, can solve the problems of weak seal, high labor cost, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

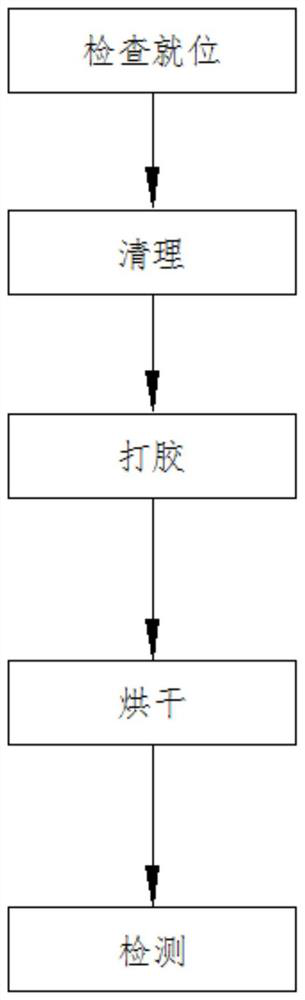

Method used

Image

Examples

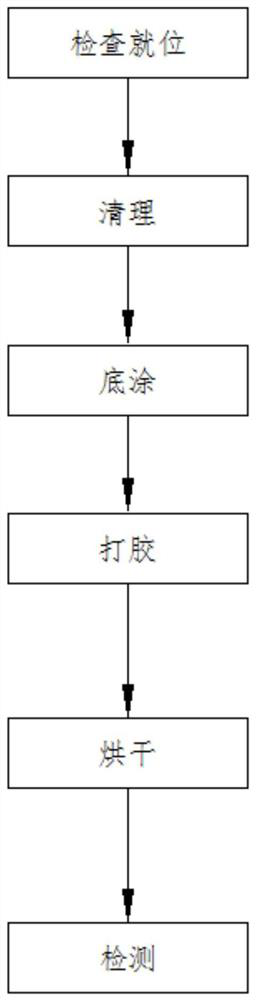

Embodiment 2

[0044]Embodiment 2, insert the primer process between step 2 and step 3 in the above embodiment 1 to form this embodiment, for the shell made of SMC, after the alcohol is volatilized and dried on the shell, use the primer Apply the paint pen evenly for a week along the position where the sealing strip needs to be installed on the housing, and let it dry. The primer material is specifically TEROSON SB 450.

[0045] Specifically, after the primer coating process is completed, it is naturally dried at an ambient temperature of 18-25° C. for 10-180 minutes.

[0046] By applying primer material on the sealing flange surface of the SMC housing, it can ensure that the silicone sealing strip is bonded to the position where the sealing strip needs to be installed on the housing, avoiding falling off during transportation and installation, which will affect the sealing effect.

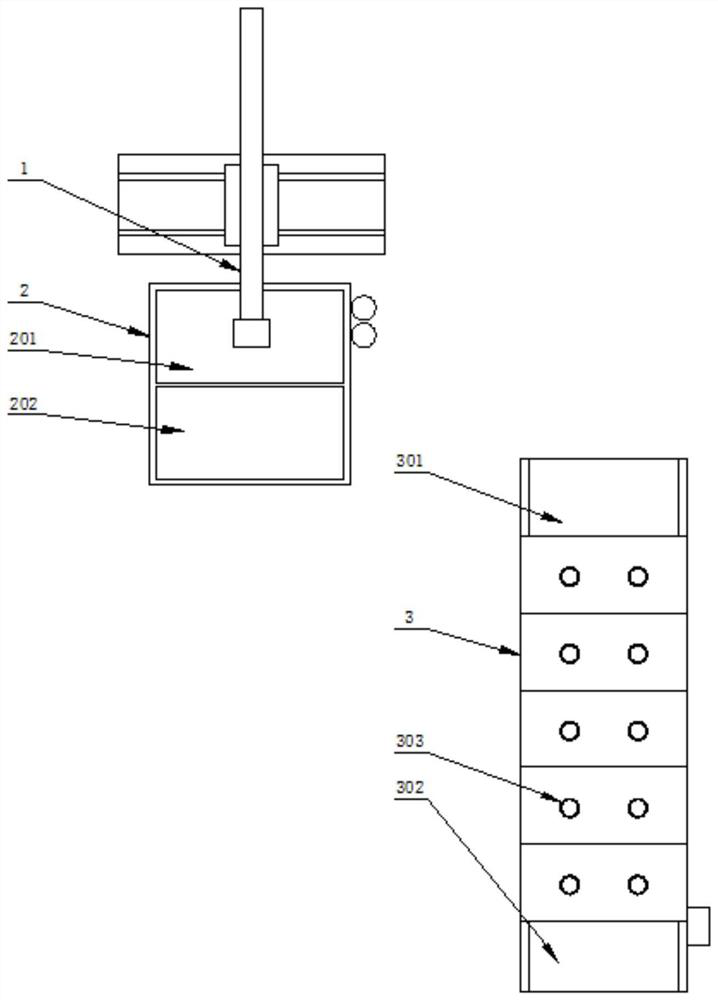

[0047] The invention also discloses a silicone sealing strip production line, such as image 3 As shown, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com