Multifunctional carton packaging machine

A packaging machine and multi-functional technology, applied in the direction of packaging, etc., can solve the problems of lack of cooling, low packaging accuracy, and inability to accurately adjust the position of fixed products, so as to avoid burns and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

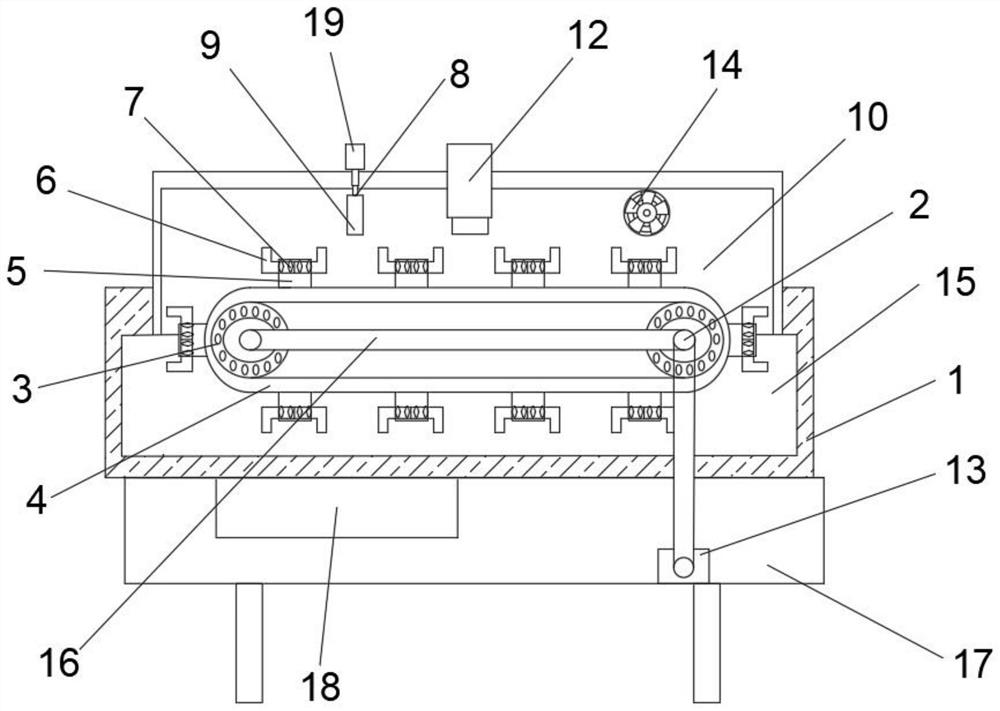

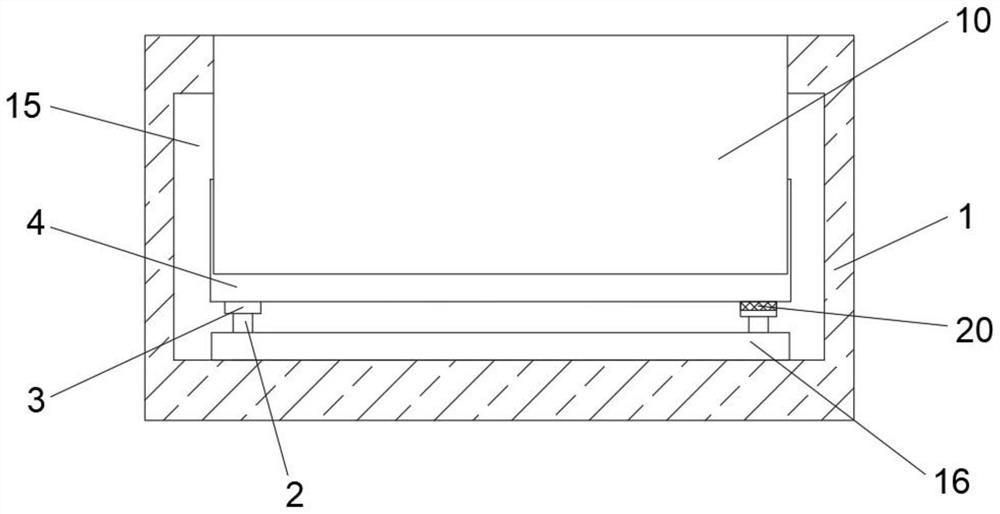

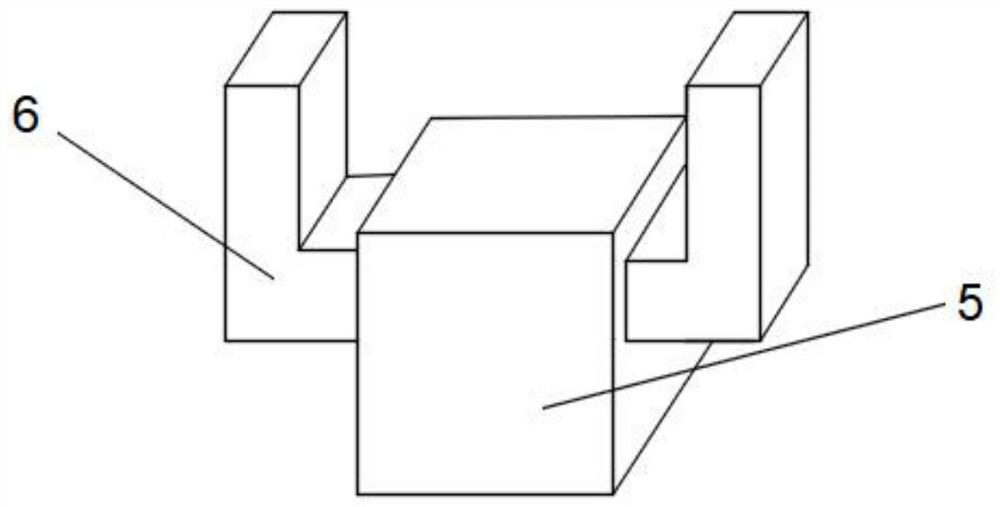

[0030] Such as Figure 1-4 As shown, a multifunctional carton packaging machine includes a workbench 1, and the inside of the workbench 1 is provided with a receiving groove 15, and the inner walls of both sides of the receiving groove 15 are fixedly connected with positioning rods 2, and two sets of positioning rods 2 are provided with The bearing 3 and the two ends of the positioning rod 2 are fixedly sleeved with a fixed plate 16, and one side of the fixed plate 16 is located on the inner wall of the receiving groove 15, and the outer surface of the upper end of the bearing 3 is covered with a conveyor belt 4, and several groups of positioning plates are evenly distributed on the outer surface of the conveyor belt 4. Block 5.

[0031] A splint 6 is installed through the center of the positioning block 5 , and a spring 7 is fixedly installed inside the bottom of the splint 6 , and the spring 7 is located inside the positioning block 5 .

[0032] By adopting the above-mentio...

Embodiment 2

[0034] Such as Figure 1-4 As shown, a multifunctional carton packaging machine includes a workbench 1, and the inside of the workbench 1 is provided with a receiving groove 15, and the inner walls of both sides of the receiving groove 15 are fixedly connected with positioning rods 2, and two sets of positioning rods 2 are provided with Both ends of the bearing 3 and the positioning rod 2 are fixedly connected with a fixed plate 16, and the fixed plate 16 is sleeved on both ends of the positioning rod 2, and one side of the fixed plate 16 is located on the inner wall of the receiving groove 15, and the outer surface of the upper end of the bearing 3 is sleeved There is a conveyor belt 4, and several groups of positioning blocks 5 are evenly distributed on the outer surface of the conveyor belt 4.

[0035] The upper end of the workbench 1 is provided with an operation table 10, and the upper end of the inner wall of the operation table 10 is provided with a telescopic packaging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com