Sealing structure for pumping oil cylinder rod

A sealing structure and oil cylinder rod technology, which is applied to the sealing of engines, fluid pressure actuators, engine components, etc., can solve the problems that trapped oil cannot be discharged smoothly, affecting the normal operation of concrete pumps, and the sealing effect of easily damaged seals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

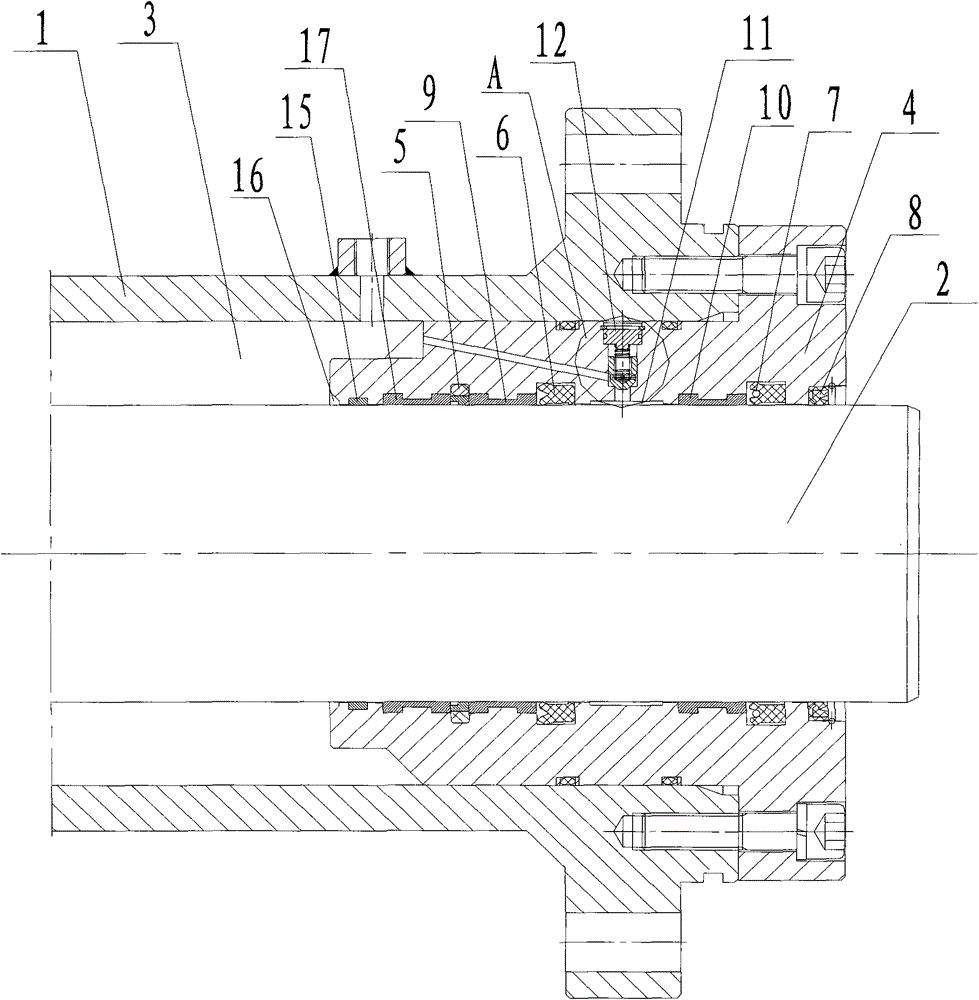

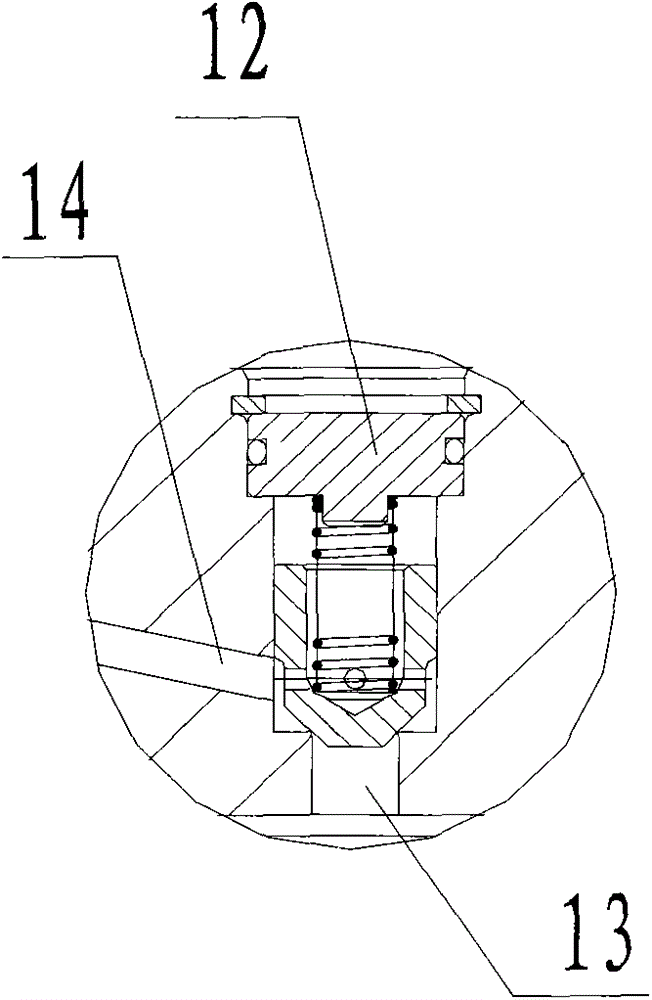

[0020] combine figure 1 , figure 2 , a pumping cylinder rod sealing structure, comprising a cylinder body 1, a piston rod 2 and a rod cavity 3, one end of the cylinder body 1 is connected with a guide sleeve 4, the guide sleeve 4 is set outside the piston rod 2, along the guide sleeve 4 In the direction from one end of the rod cavity to the other end of the guide sleeve, a Ster seal 5, a U-shaped seal ring 6, a BA seal ring 7 and a dust-proof ring 8 are sequentially arranged between the guide sleeve 4 and the piston rod 2, and the Ster seal 5 and the U-shaped sealing ring 6 is provided with a first guide ring 9, between the U-shaped sealing ring 6 and the BA sealing ring 7 is provided with a second guide ring 10, between the U-shaped sealing ring 6 and the second guide ring 10 A ring groove 11 is provided, and a check valve 12 is connected to the ring groove 11. The ring groove 11 communicates with the inlet 13 of the check valve, and the outlet 14 of the check valve communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com