LED lamp processing device

A technology of processing equipment and LED lamps, which is applied in the direction of coating and liquid coating on the surface, etc., can solve the problems of too tight arrangement of chips, blockage of glue guns, increase of chip spacing, etc., so as to facilitate production and avoid over sticking Thick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

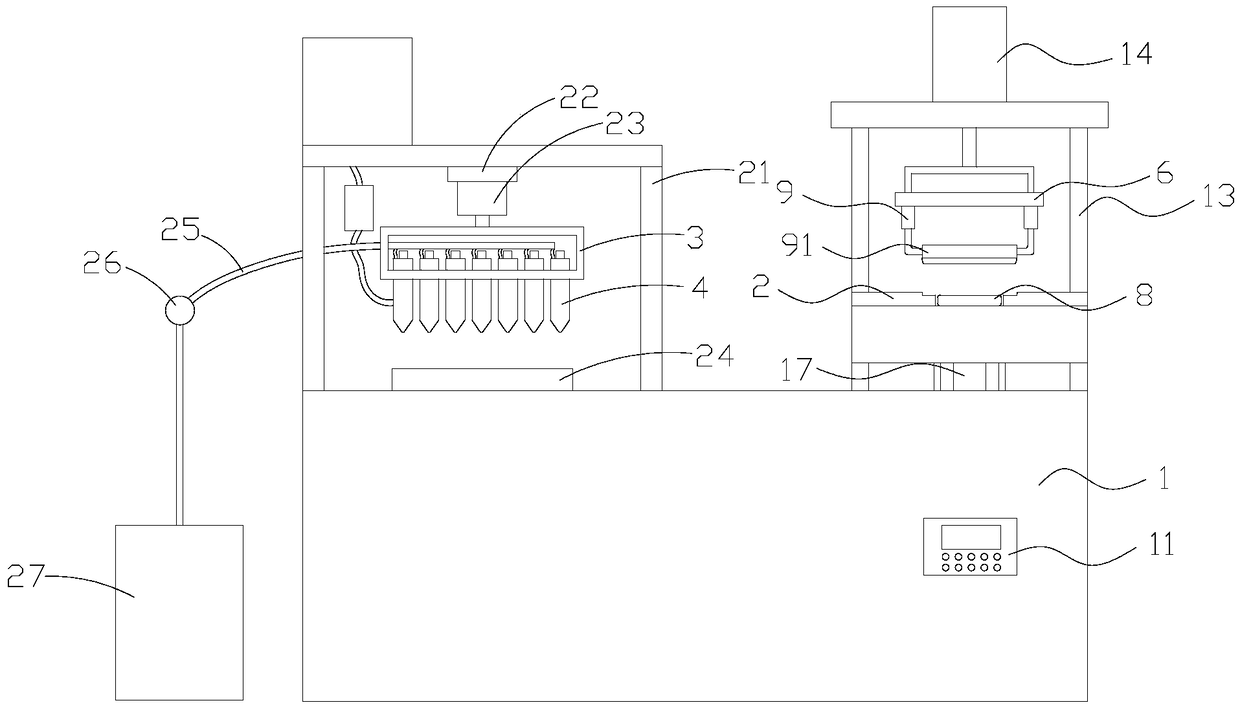

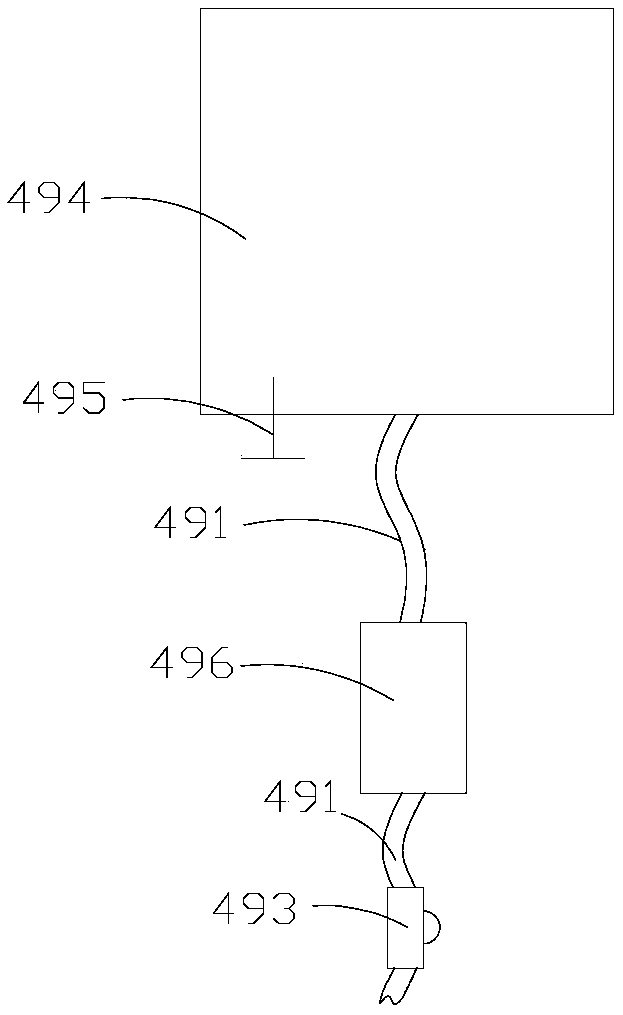

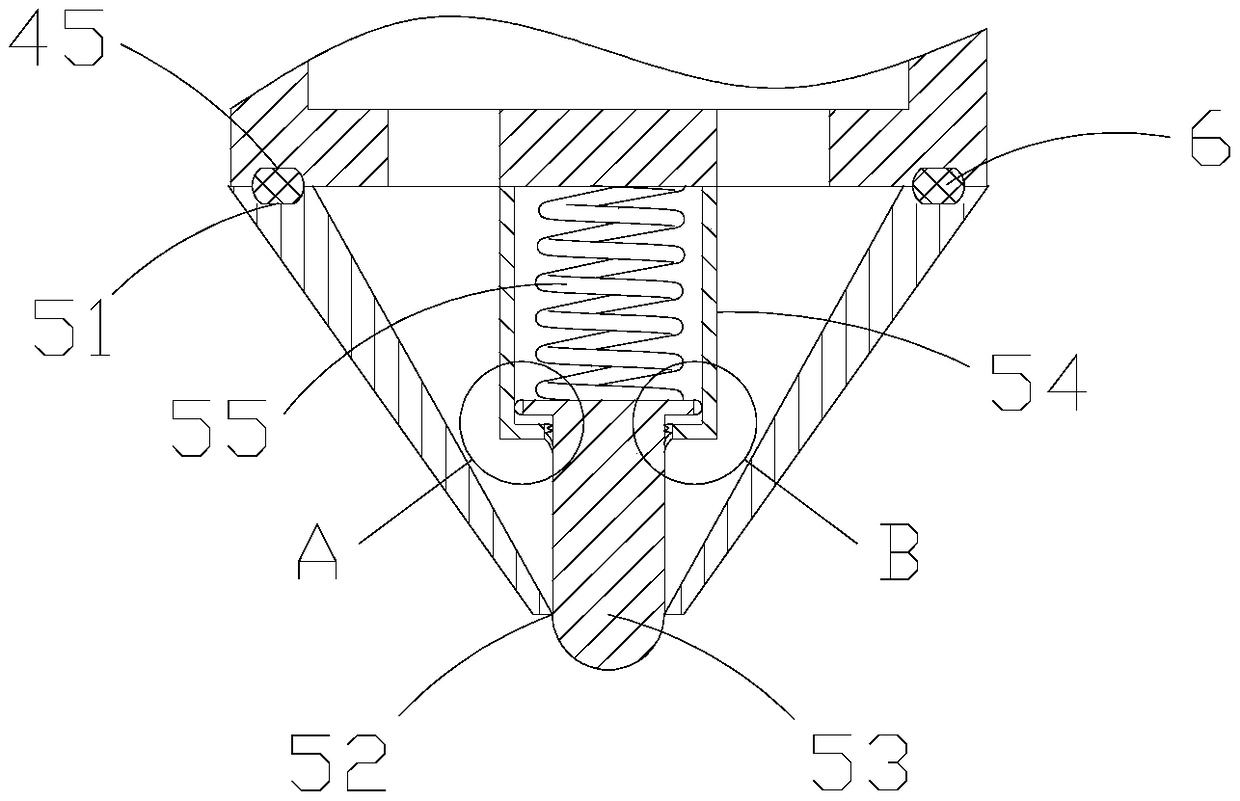

[0029] like Figure 1-12 As shown, a kind of LED lamp processing equipment, LED lamp processing procedures are complex, including crystal expansion process, cleaning process, warming process, dispensing process, solid crystal process, baking process, wire bonding process, assembly process and testing process ; Emphasis of the present invention is crystal expansion process and dispensing process, comprises base 1, the crystal expansion mechanism that is located on described base 1 and the dispensing mechanism that is located on described base 1; Wherein crystal expansion mechanism is used for pulling For stretching the chip film, because when the chip film just came out, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com