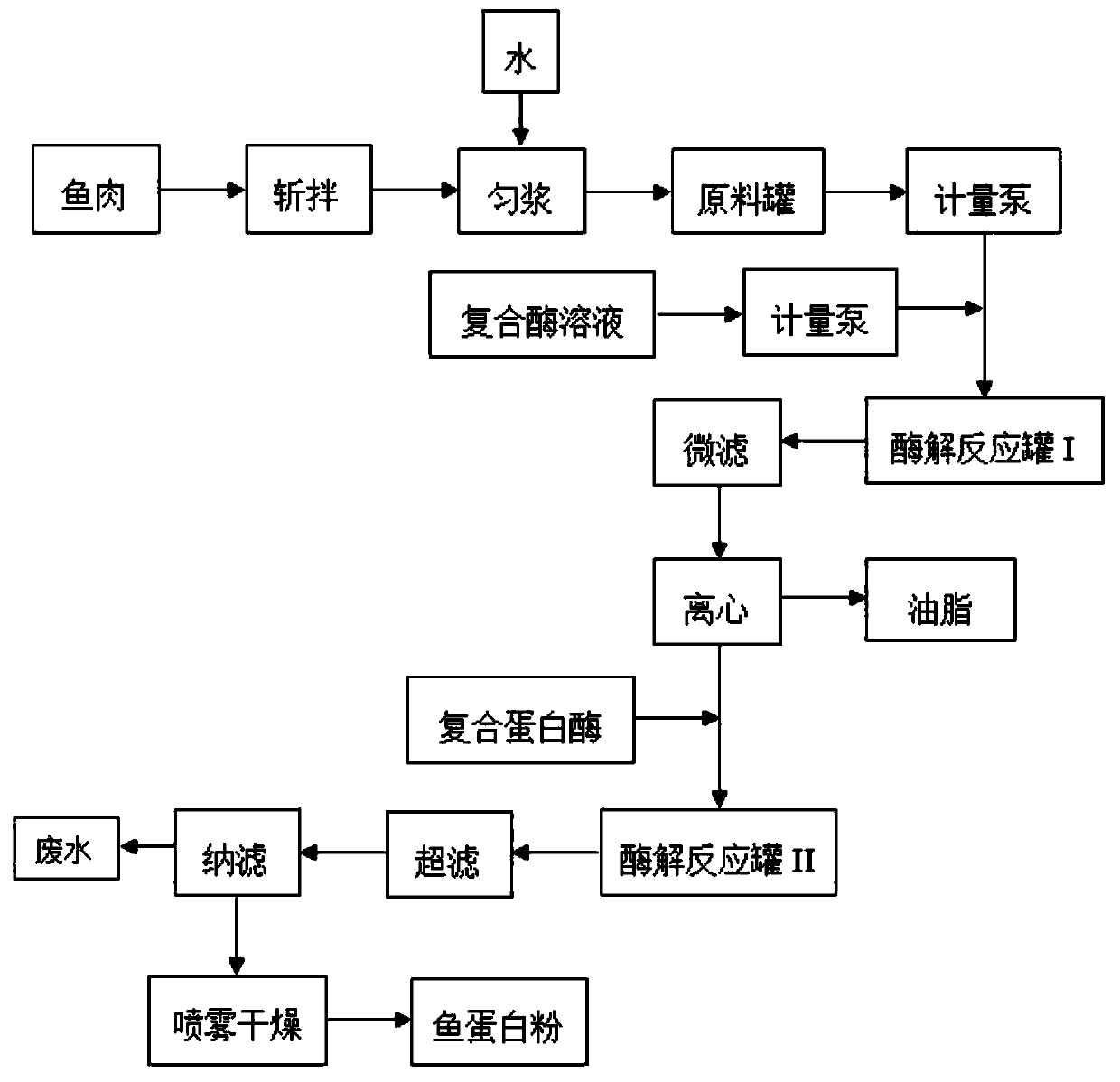

Method for preparing fish protein powder through continuous enzymolysis

A technology of fish protein powder and enzymatic hydrolysis, which is applied in the field of preparation of fish protein powder, can solve the problems of incomplete oil separation, large amount of organic solvent and acid and alkali, high content of bitter peptide and hydrophobic amino acid, and achieve uniform distribution and safety High, soluble protein molecular weight controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 400 kg of minced white meat was chopped and mixed, 1100 kg of water was added, and 5000 rpm high-speed shearing was used for homogenization. Transfer the minced meat homogenate to the raw material tank to adjust pH 7.0, heat to 35°C, transfer the minced meat homogenate to the enzymolysis reaction tank I at a flow rate of 100mL / min, and continuously feed and compound at a flow rate of 5mL / min Enzyme solution I (wherein pancrelipase 30U / mL, dispase 200U / mL), open microfiltration equipment (microfiltration membrane aperture is 50 μ m), adjust its effluent discharge speed to maintain reaction tank I reaction liquid volume about 50L, The operating pressure is 0.7kPa.

[0031] The continuously discharged permeate is centrifuged to remove fat, and the water phase and the precipitate are remixed in the enzymatic reaction tank II for homogenization. Control the reaction temperature at 45°C, add compound protease II once every 12 hours (add 500 grams of trypsin, 100 grams of neu...

Embodiment 2

[0034] 200 kg of minced white meat was chopped and mixed, 300 kg of water was added, and 6000 rpm high-speed shearing was used for homogenization. Transfer the minced meat homogenate to the raw material tank to adjust the pH to 7.5, heat to 40°C, transfer the minced meat homogenate to the enzymolysis reaction tank I at a flow rate of 50 mL / min, and continuously feed and compound at a flow rate of 5 mL / min Enzyme solution I (including pancreatic lipase 30U / mL, papain 200U / mL, neutral protease 100U / mL), turn on the microfiltration equipment (microfiltration membrane pore size is 10μm), adjust its effluent discharge speed to maintain the reaction tank I The volume of the reaction solution is about 50L, and the operating pressure is 7kPa.

[0035] The continuously discharged permeate is centrifuged to remove fat, and the water phase and the precipitate are remixed in the enzymatic reaction tank II for homogenization. Control the reaction temperature at 50°C, add compound protease...

Embodiment 3

[0038] 200 kg of minced red meat was chopped and mixed, 600 kg of water was added, and 8000 rpm high-speed shearing was used for homogenization. Transport the minced meat homogenate to the raw material tank to adjust the pH to 6.5, heat to 30°C, transport the minced meat homogenate to the enzymolysis reaction tank I at a flow rate of 50 mL / min, and continuously feed and compound at a flow rate of 5 mL / min Enzyme solution I (including pancreatic lipase 50U / mL, papain 200U / mL, neutral protease 200U / mL), turn on the microfiltration equipment (microfiltration membrane pore size is 30μm), adjust its effluent discharge speed to maintain the reaction tank I The volume of the reaction solution is about 50L, and the operating pressure is 3kPa.

[0039] The continuously discharged permeate is centrifuged to remove fat, and the water phase and the precipitate are remixed in the enzymatic reaction tank II for homogenization. Control the reaction temperature at 50°C, add compound protease...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com