Patents

Literature

61results about How to "Play the role of limit movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

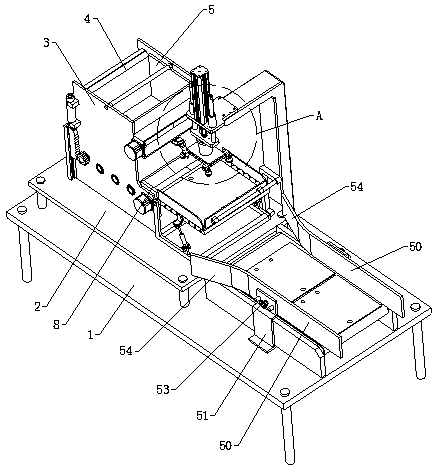

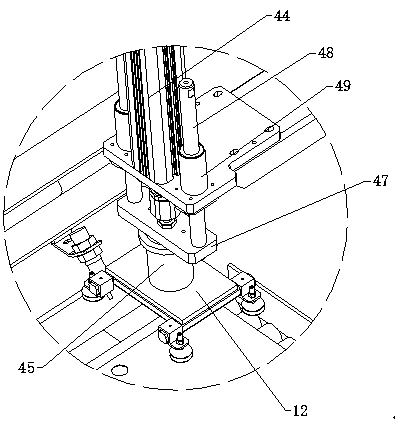

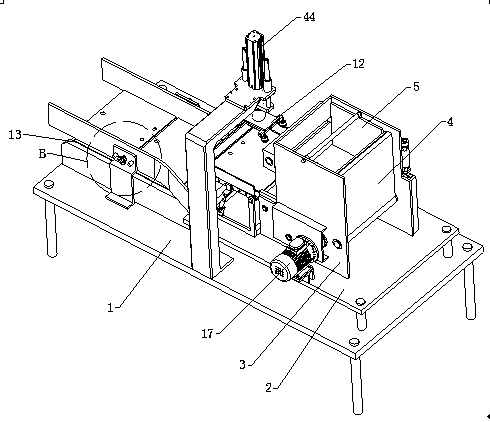

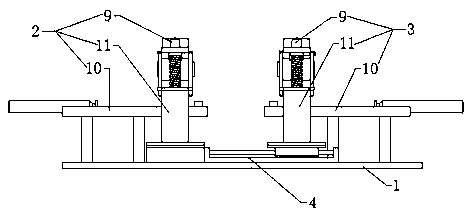

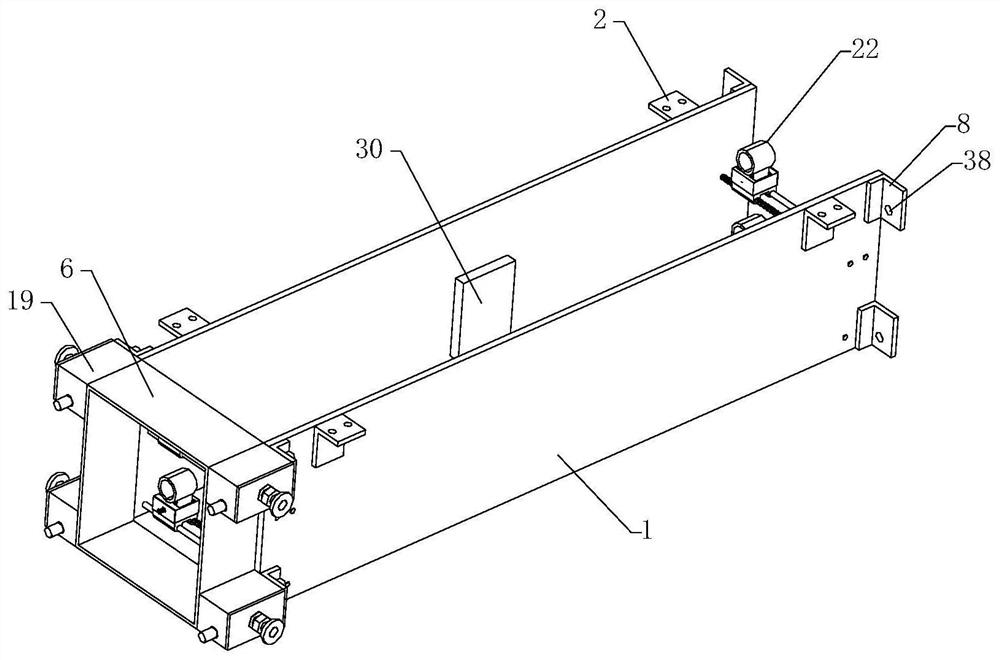

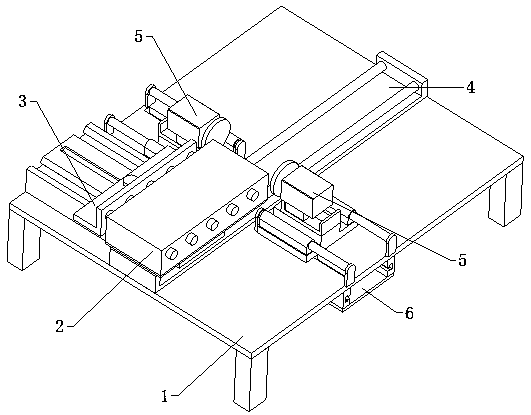

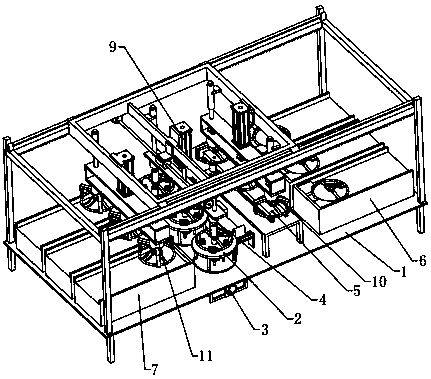

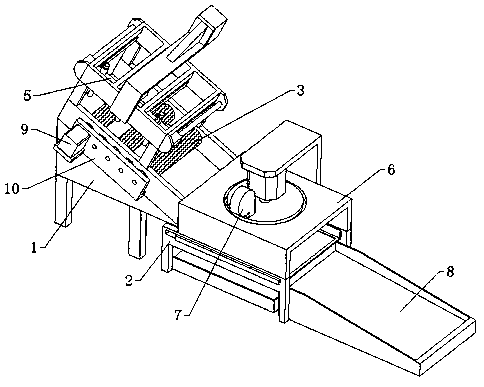

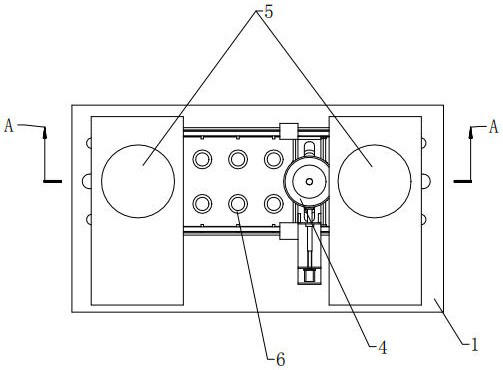

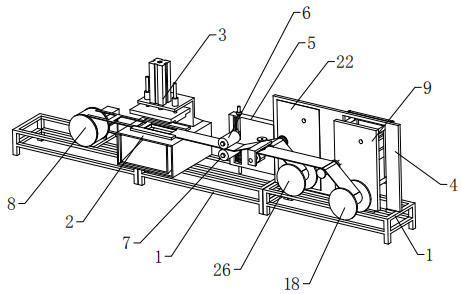

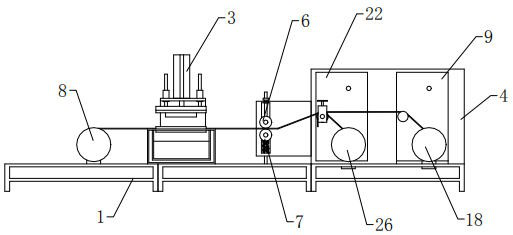

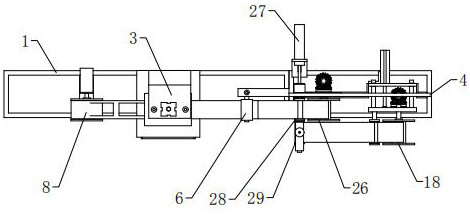

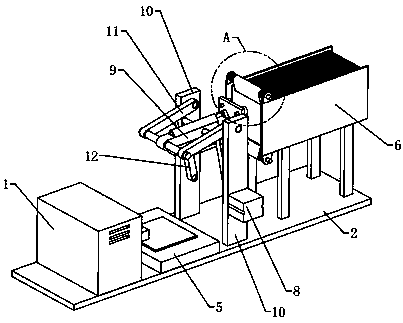

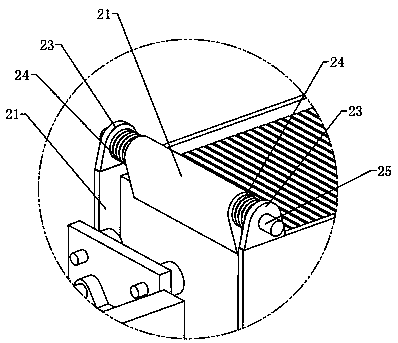

Plate directional arranging and conveying device for punch press

ActiveCN111498459APlay the role of limit movementPrevent slippingConveyor partsPunch pressStructural engineering

The invention relates to the technical field of plate machining, in particular to a plate directional arranging and conveying device for a punch press. The plate directional arranging and conveying device for the punch press comprises a base, and further comprises a placing and discharging mechanism, a directional correcting mechanism and a conveying mechanism, wherein the placing and dischargingmechanism comprises a supporting table and a rectangular placing box, a turnover door is arranged at the open end of one side of the placing box, abutting vertical plates are arranged on the two sidesof the interior of the placing box, three feeding rolling wheels are arranged at the lower end of the interior of the placing box, a discharging opening is formed in the lower end of the surface, away from the turnover door, of the placing box, extending vertical plates are arranged below the two sides of the surface, away from the turnover door, of the placing box, and opposite blocks are arranged between the two extending vertical plates; the directional correcting mechanism comprises a detection camera, a detection turnover slide way and a correcting assembly, and the correcting assembly comprises a pneumatic suction disc; and the conveying mechanism comprises a feeding conveyor and two material guiding assemblies. According to the technical scheme, the direction of plates can be automatically corrected, the plates are directionally arranged and conveyed, and the conveying efficiency is improved.

Owner:山东惠民鲁盛金属制品有限公司

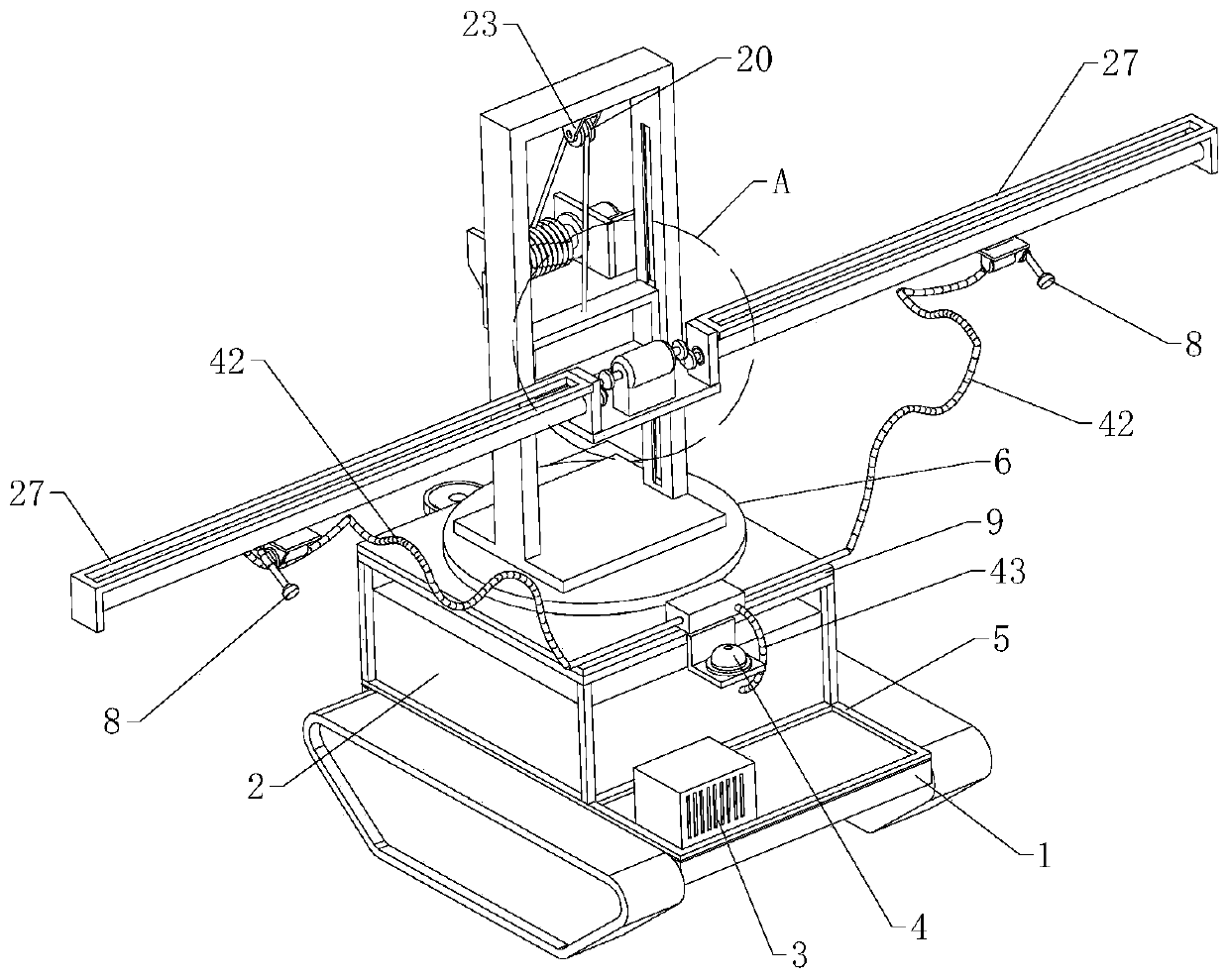

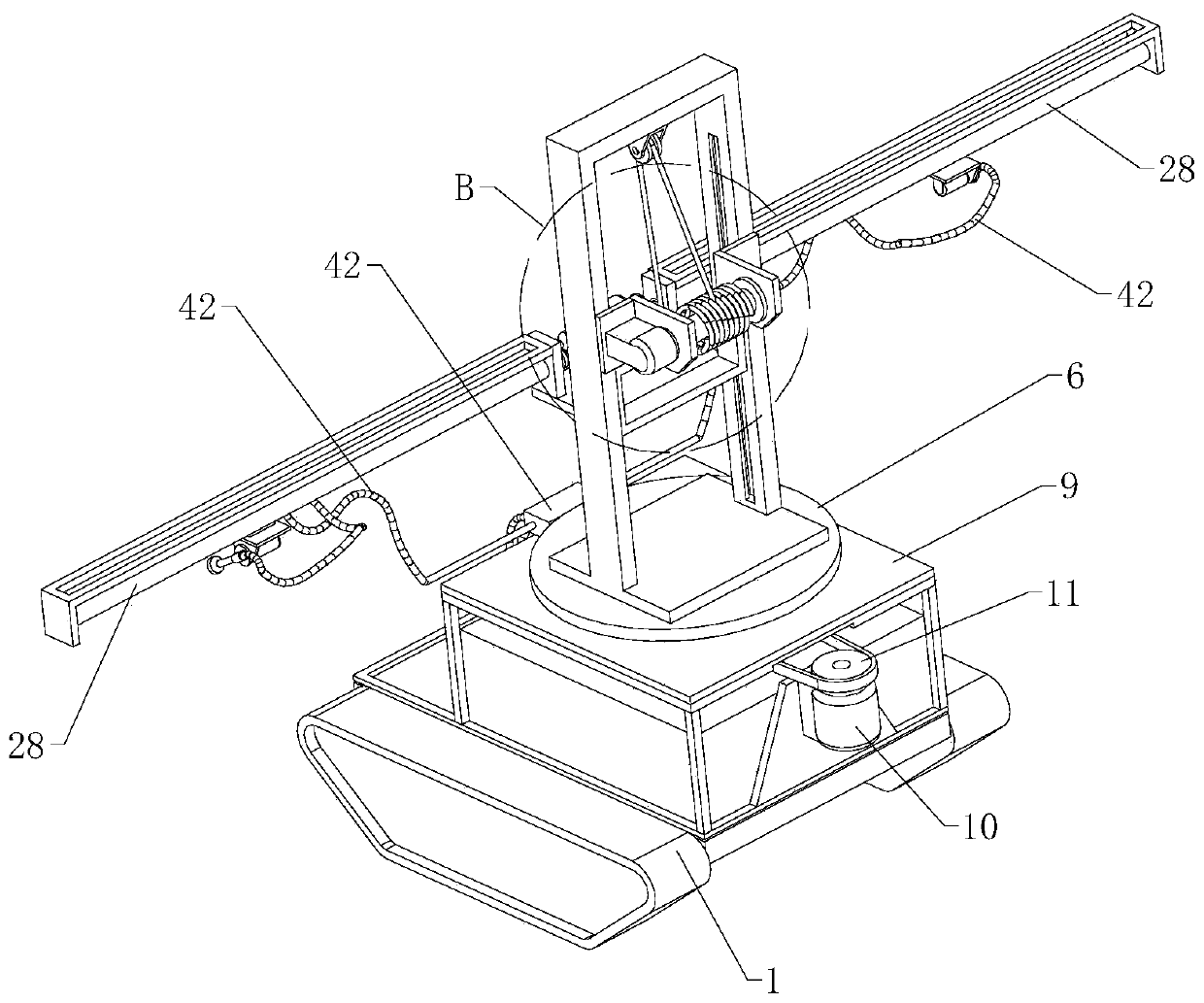

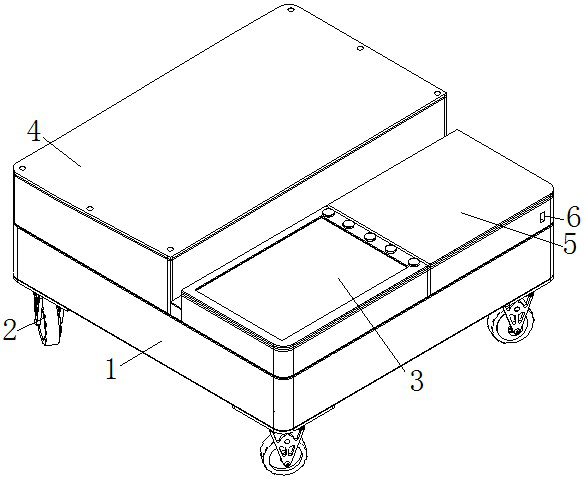

Agricultural irrigation robot

InactiveCN110999763APlay the role of limit movementEasy to driveWatering devicesCultivating equipmentsAgricultural scienceAgricultural irrigation

The invention relates to the technical field of agricultural robots and in particular relates to an agricultural irrigation robot which comprises a crawler track unit as well as a bottom rack, whereina water tank is arranged at one end of the top of the bottom rack; a controller is arranged at the other end of the bottom rack; a rotation adjusting component is arranged above the water tank; a camera is arranged at one end of the rotation component; the rotation adjusting component comprises a rotating disc; a lifting component is arranged at the top of the rotating disc; the lifting componentcomprises a lifting plate; horizontal moving components are respectively arranged on both sides of the top of the lifting plate; a turning component is arranged at the output end of each horizontal moving component; an irrigation nozzle is arranged at the output end of each turning component; and a bidirectional driving component is arranged between the two horizontal moving components. By adopting the technical scheme, irrigation height adjustment is solved, crops of different heights can be irrigated by using the irrigation robot, in addition, irrigation spraying angles can be adjusted, theflexibility of irrigation spraying can be improved, the irrigation range can be widened, water tube dragging and water injection are not needed, and the labor and time can be saved.

Owner:HENAN UNIVERSITY

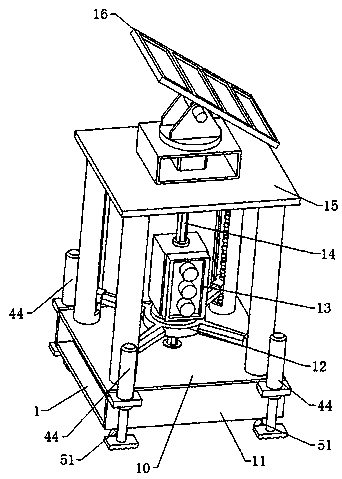

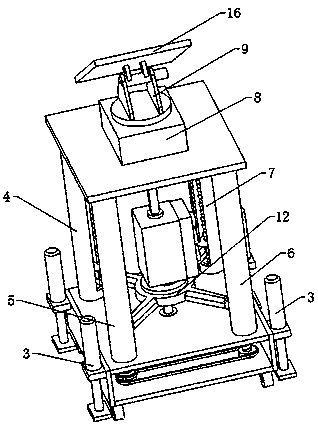

Mobile adjustable traffic lights with built-in solar panel

ActiveCN110444034APlay the role of limit movementPrecise positioningBatteries circuit arrangementsRoad vehicles traffic controlEngineeringMechanical engineering

The invention relates to the field of rail transit, and in particular to mobile adjustable traffic lights with a built-in solar panel. The traffic lights comprise a mobile bottom plate, and further comprise a lifting mechanism, a first rotating mechanism, a second rotating mechanism and a turning mechanism, wherein the first rotating mechanism comprises a gap rotating assembly, the top of the gaprotating assembly is provided with a fixed horizontal plate, both sides of the fixed horizontal plate are respectively fixedly connected to both sides of the mobile bottom plate through support plates, one side of each support plate is respectively provided with two positioning assemblies spaced at intervals, the lifting mechanism comprises four vertically arranged thread lifting assemblies and alifting plate, the lifting plate is provided with the vertically arranged traffic lights, the gap rotating assembly comprises a vertically arranged rotating shaft, the second rotating mechanism comprises a top plate and a deceleration rotating assembly, and the turning mechanism comprises an adjusting turning assembly and a solar panel. The equipment is powered by solar energy, supports automaticadjustment of height and four-sided direction, and can stably position to improve safety.

Owner:苏州因知成新能源有限公司

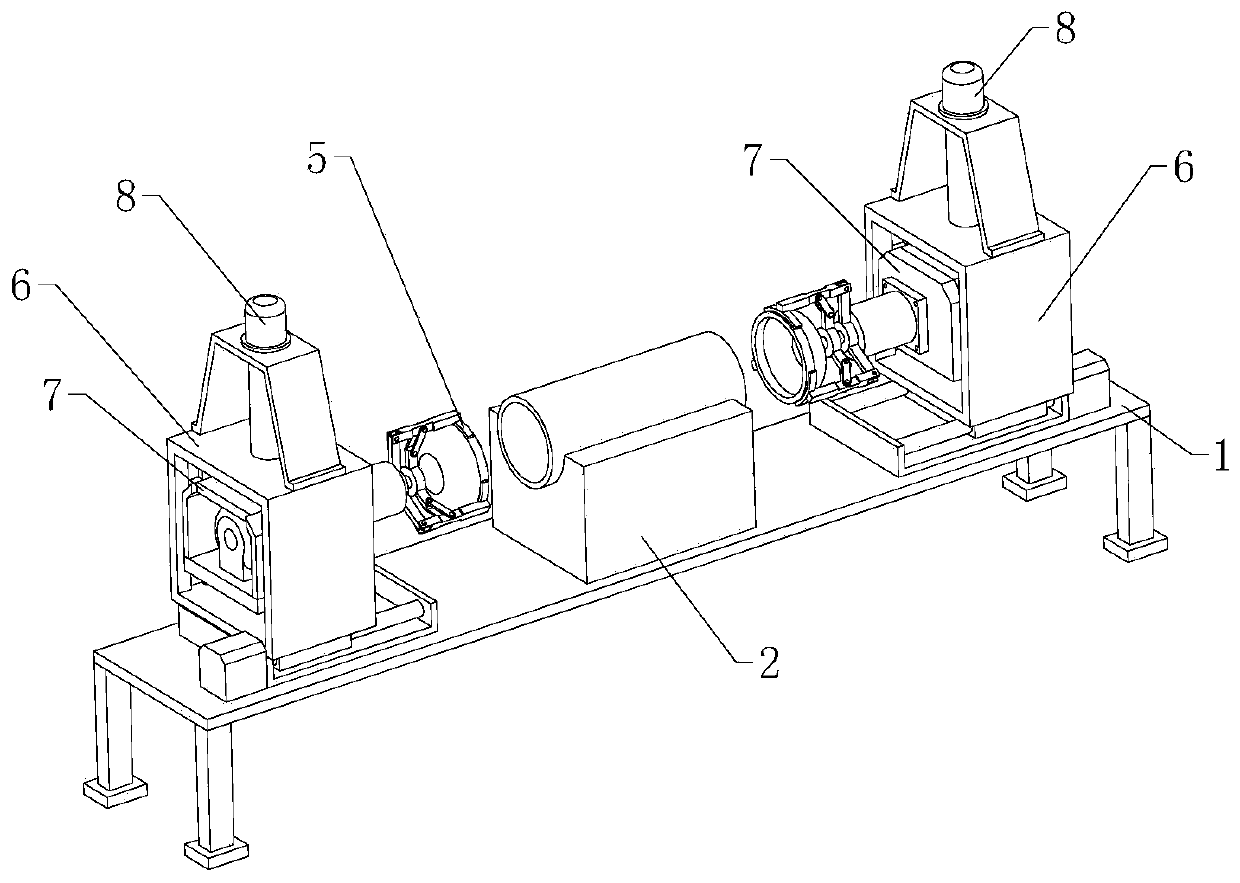

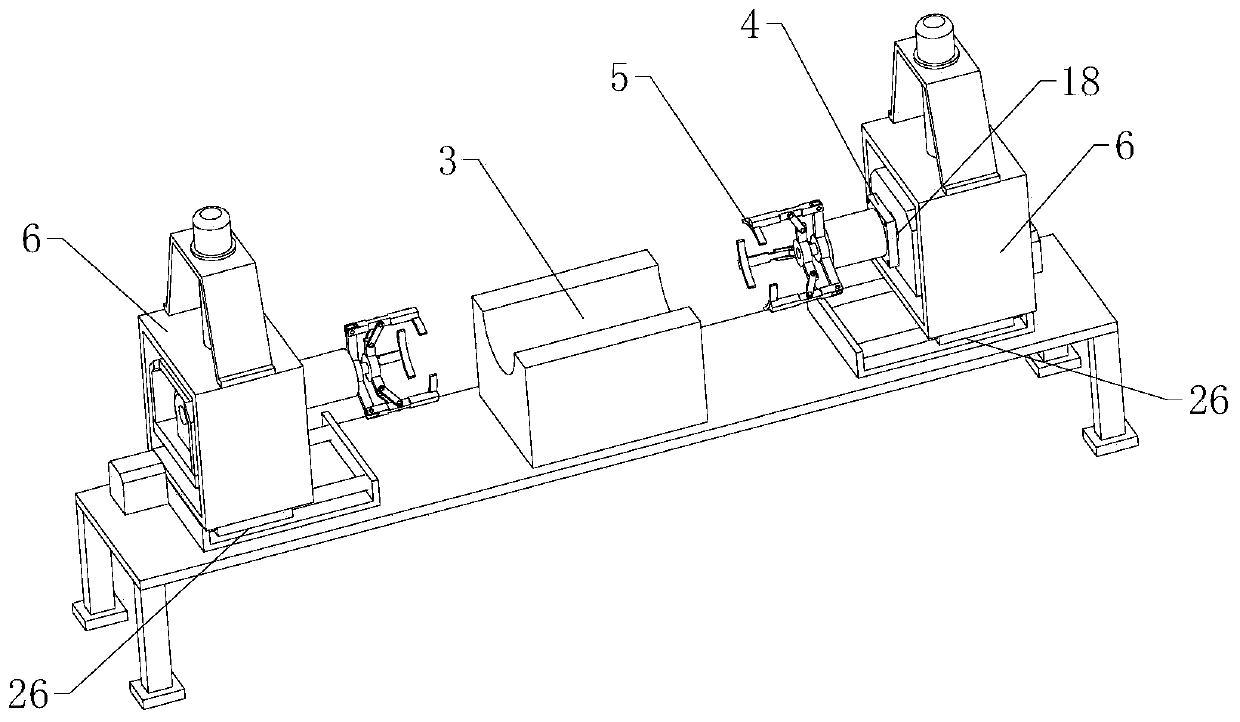

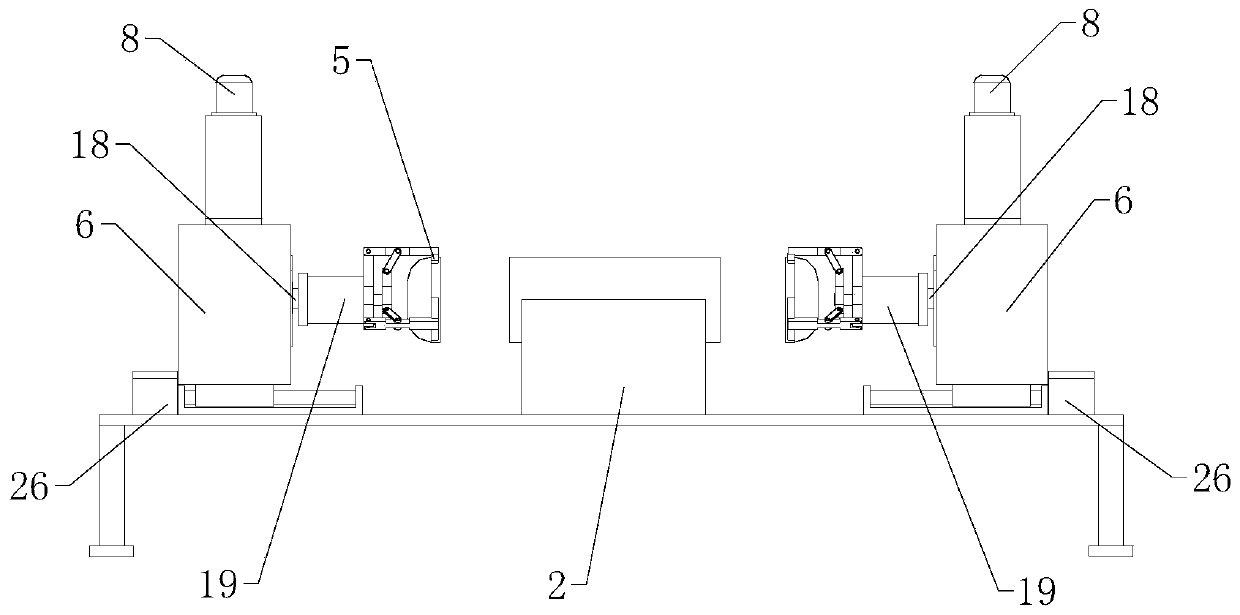

Improved end cover welding tool for barrel

InactiveCN110757085ANot easy to moveScratch protectionWelding/cutting auxillary devicesAuxillary welding devicesMachiningPhysics

The invention relates to the technical field of end cover machining, in particular to an improved end cover welding tool for a barrel. The tool comprises a machining table and a barrel support, and further comprises two positioning adjustment stepping mechanisms, wherein the barrel support is fixedly mounted at the center of the top of the machining table, the barrel support is provided with an arc-shaped accommodating groove capable of accommodating the barrel, and the two positioning adjustment stepping mechanisms are arranged at the two ends of the barrel support correspondingly; and each positioning adjustment stepping mechanism comprises a height adjusting assembly, a rotating assembly, a positioning clamping assembly, and a horizontal moving assembly, each horizontal moving assemblyis fixedly mounted on the machining table, each height adjusting assembly is located above the corresponding horizontal moving assembly, the bottom of each height adjusting assembly is fixedly connected with the working end of the corresponding horizontal moving assembly, and each rotating assembly is located inside the corresponding height adjusting assembly. Each end cover needing to be welded can be stably clamped by the device, the height of each end cover can be adjusted, and the accuracy of welding between each end cover and the barrel is improved.

Owner:丽水市莲都区贝亿乐信息技术服务有限责任公司

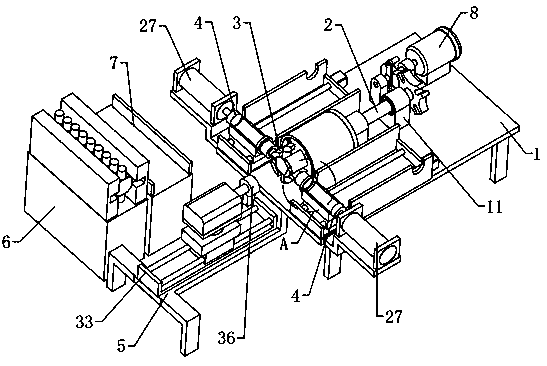

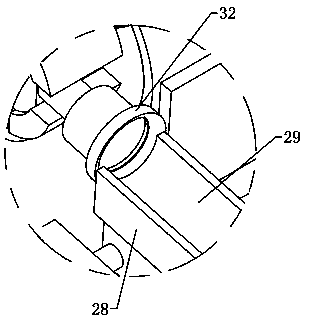

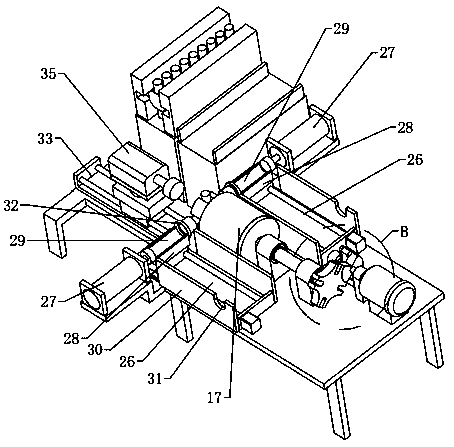

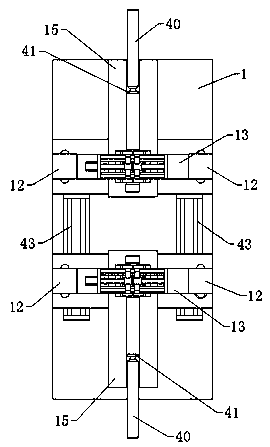

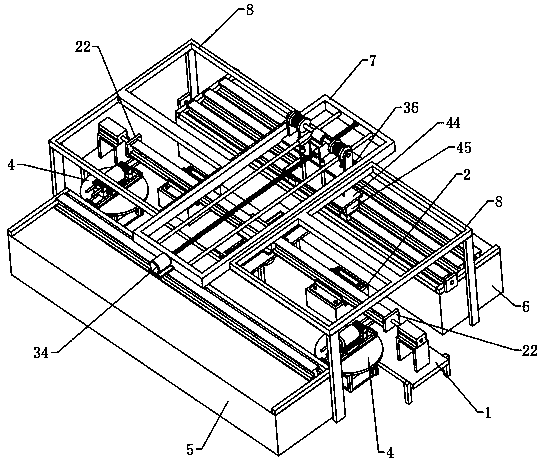

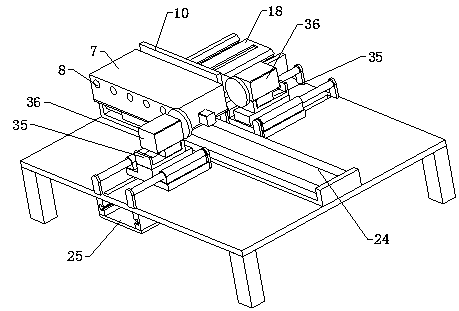

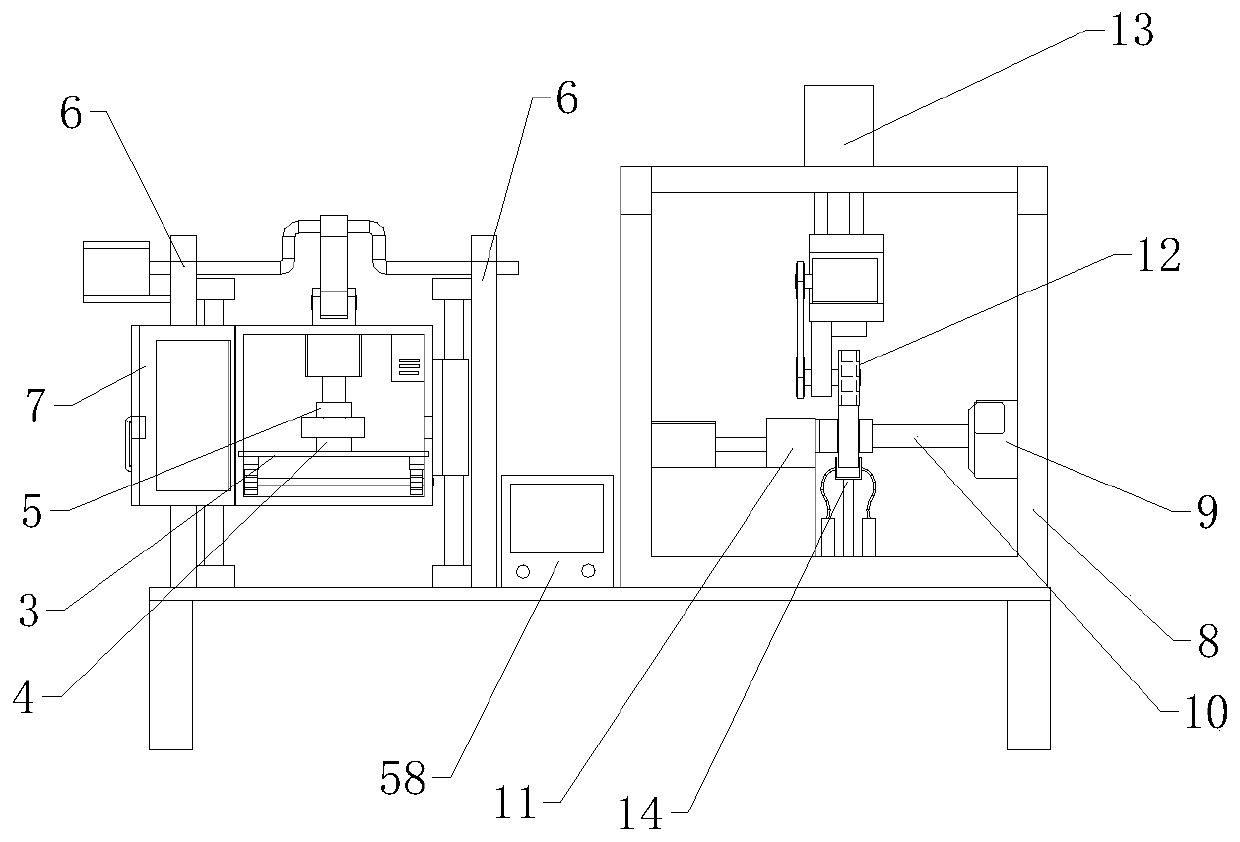

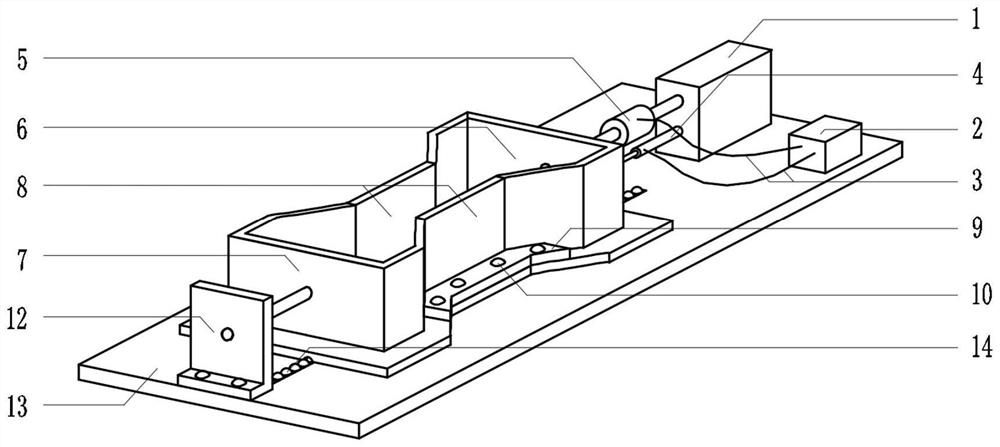

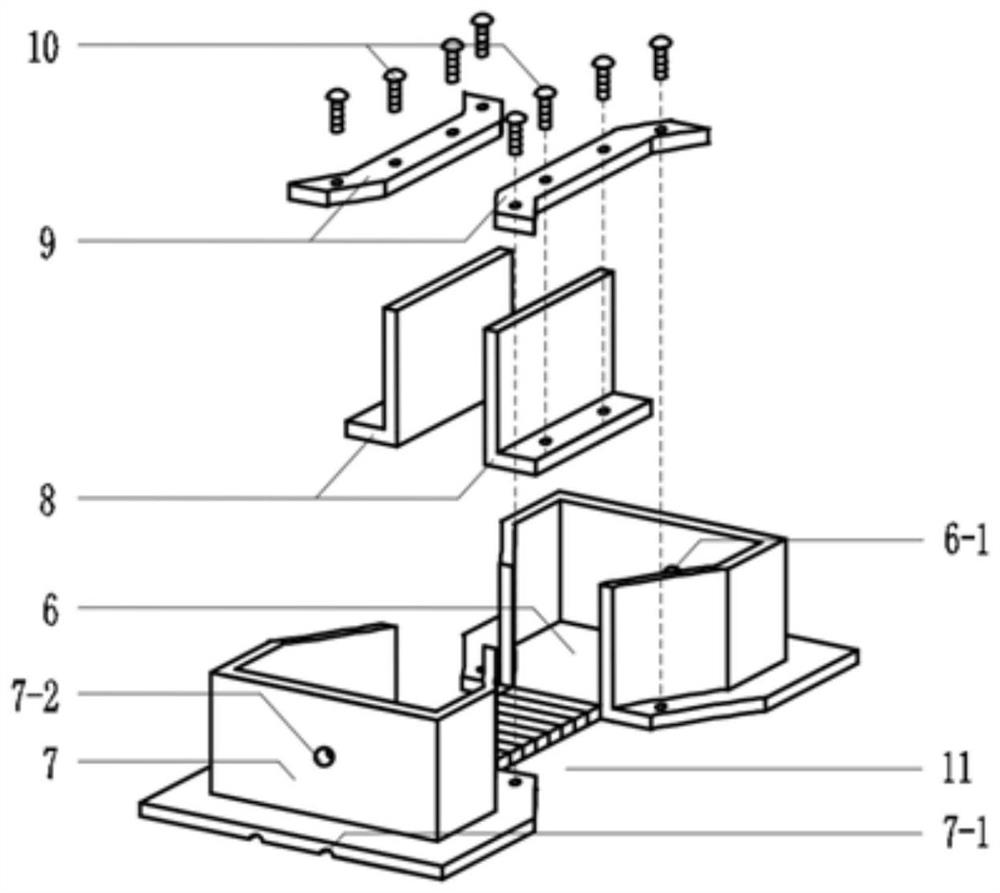

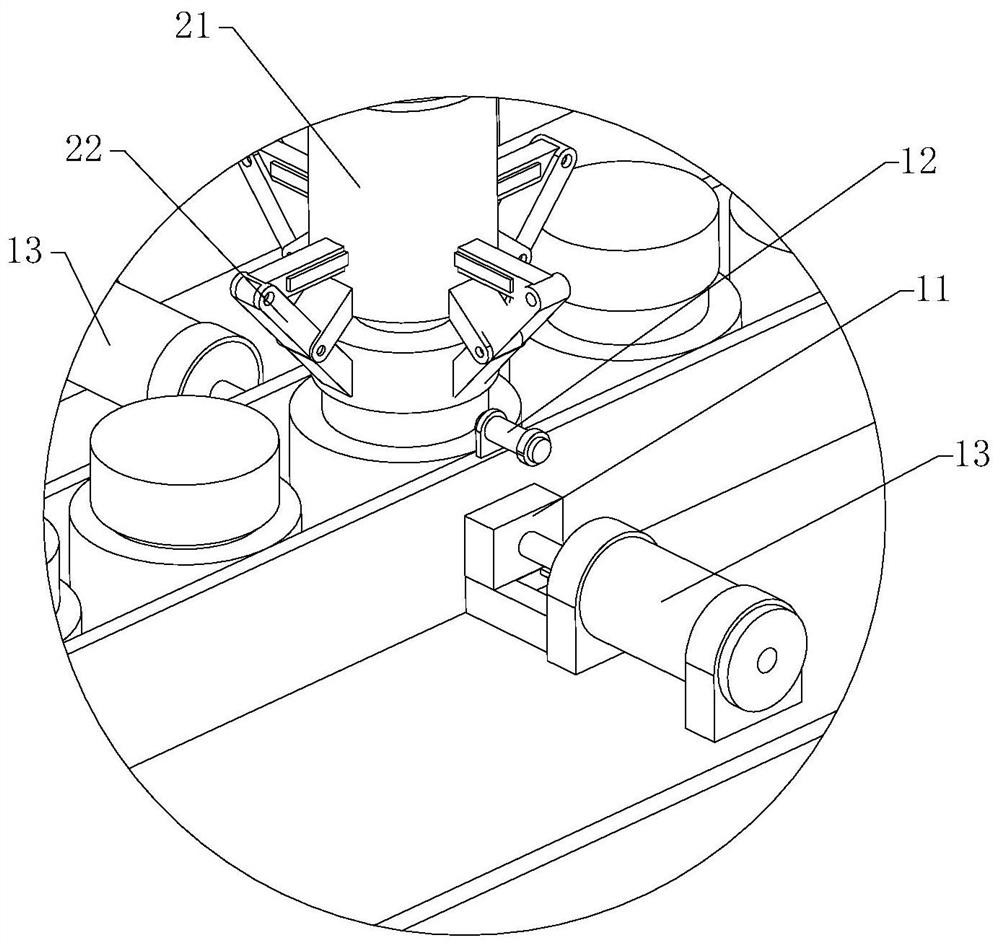

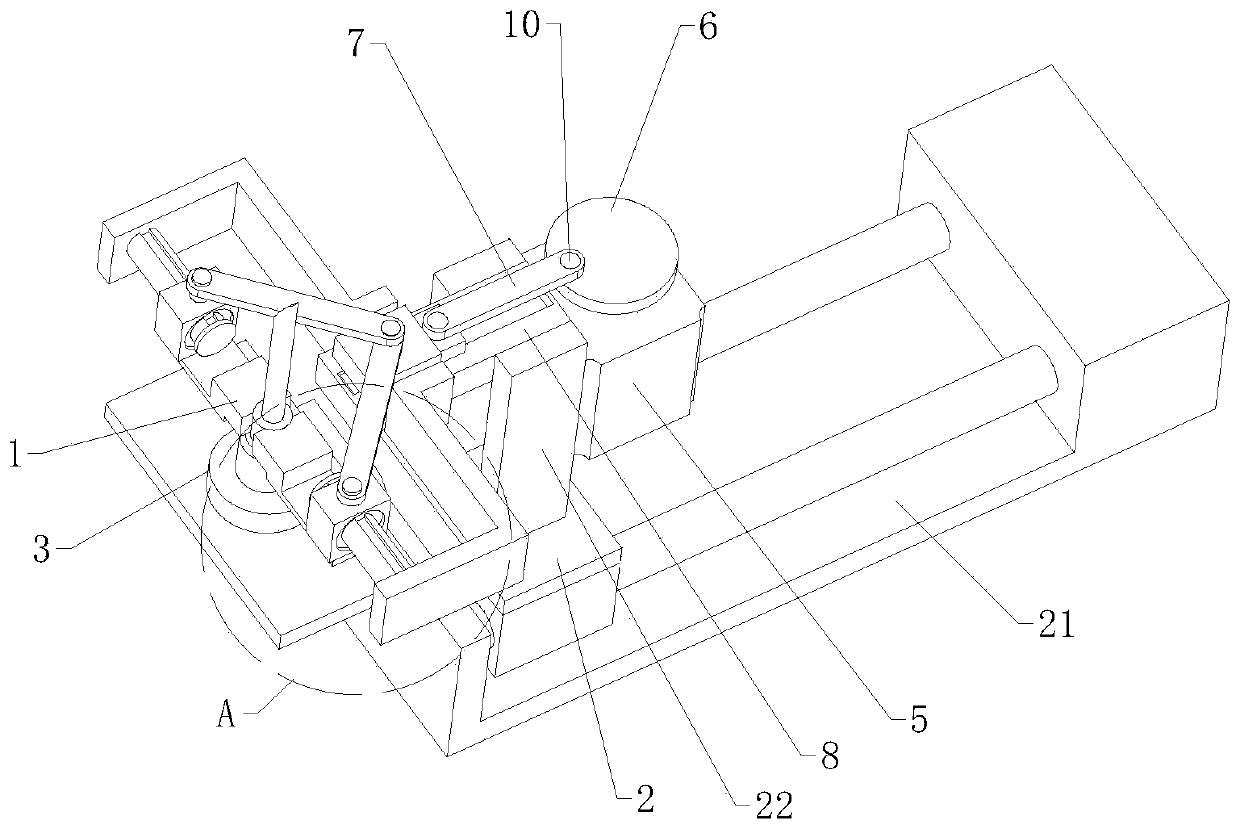

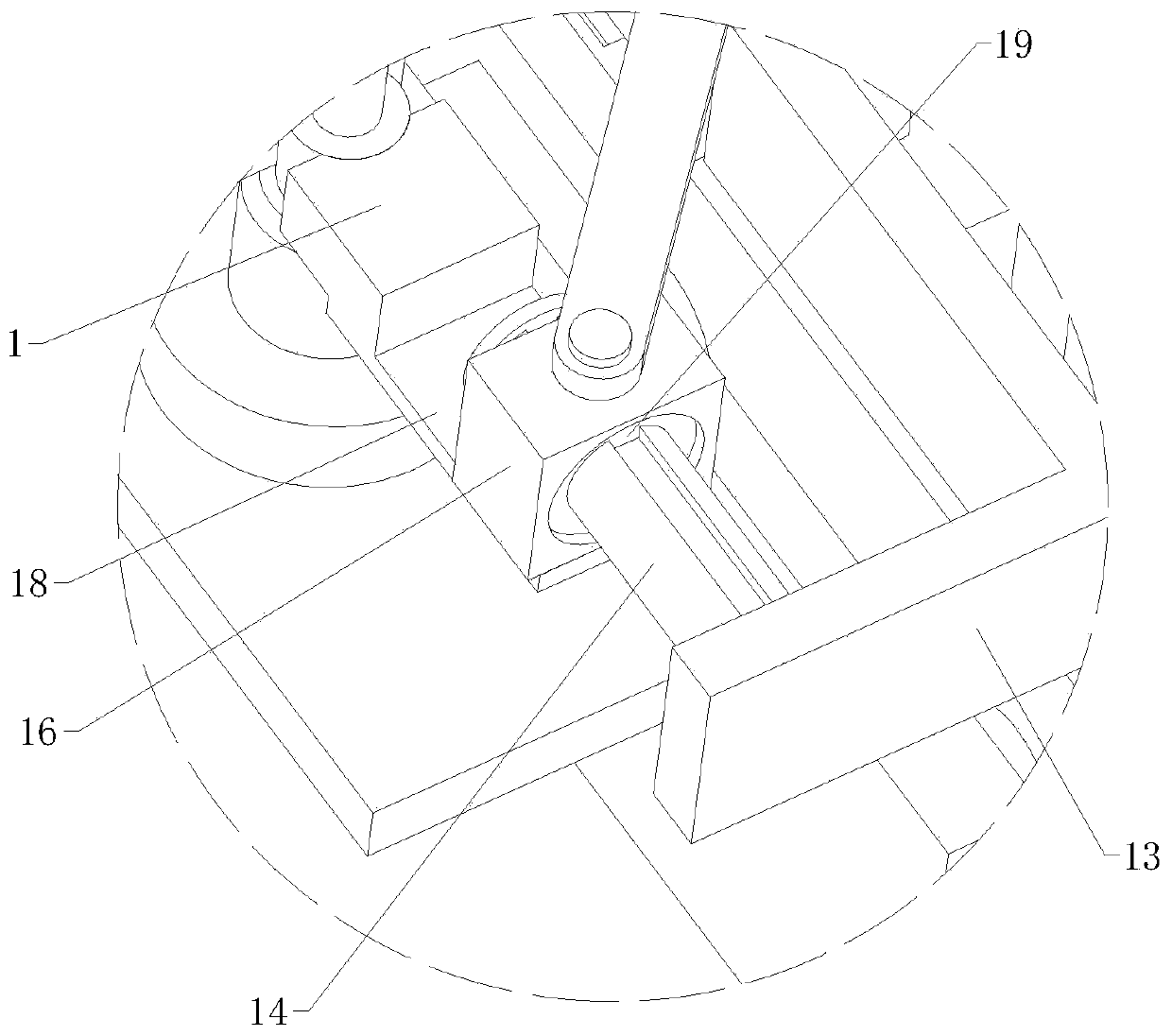

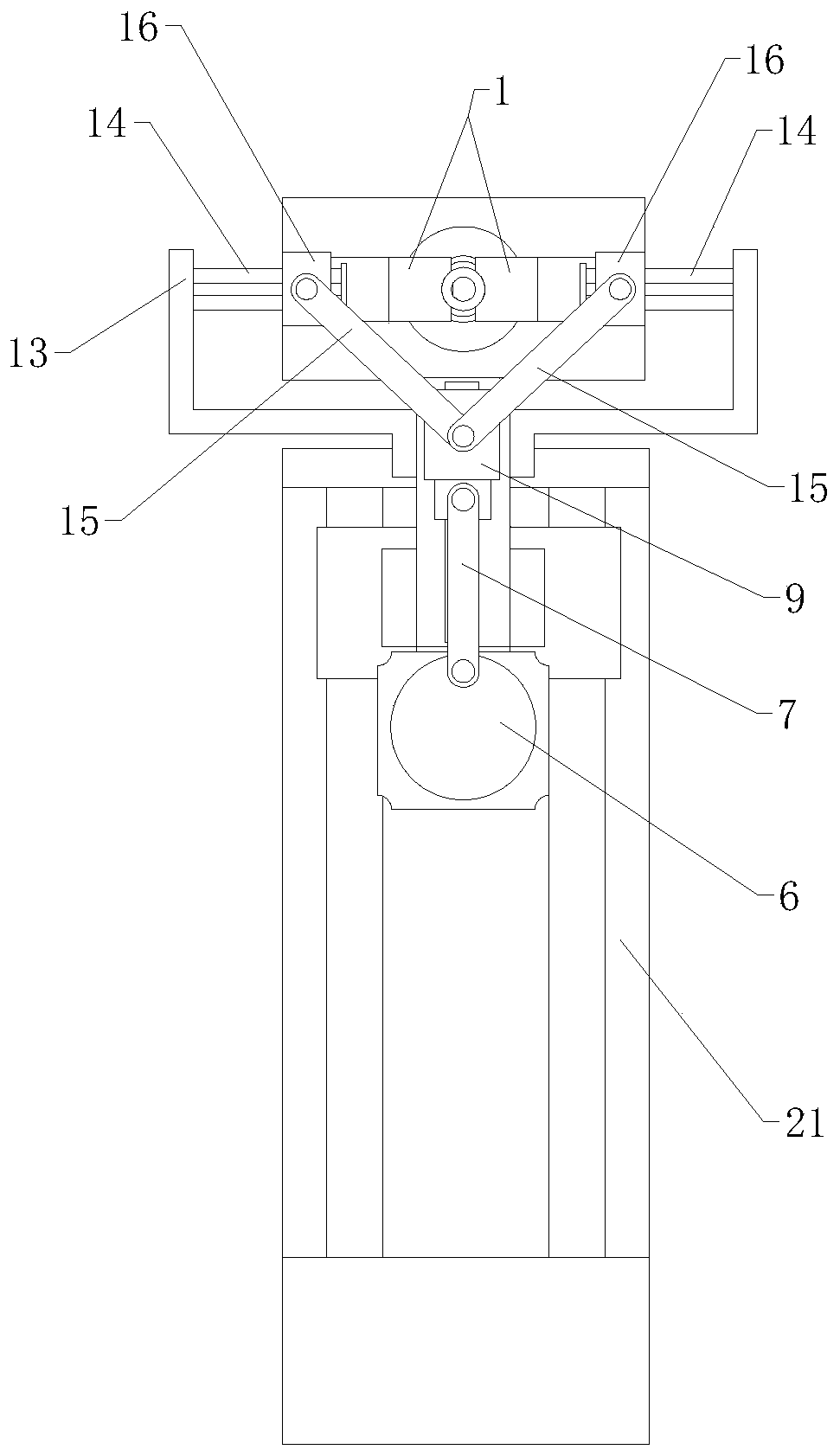

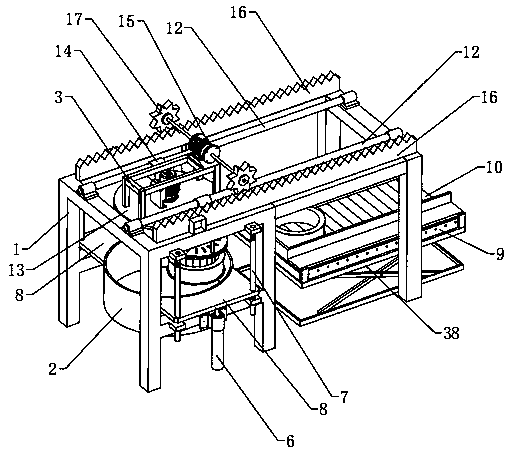

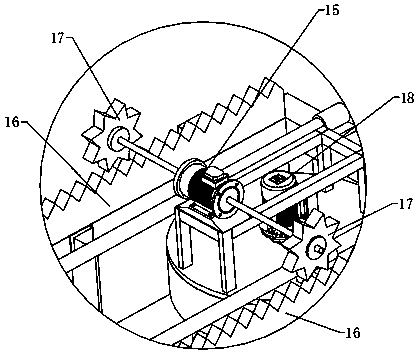

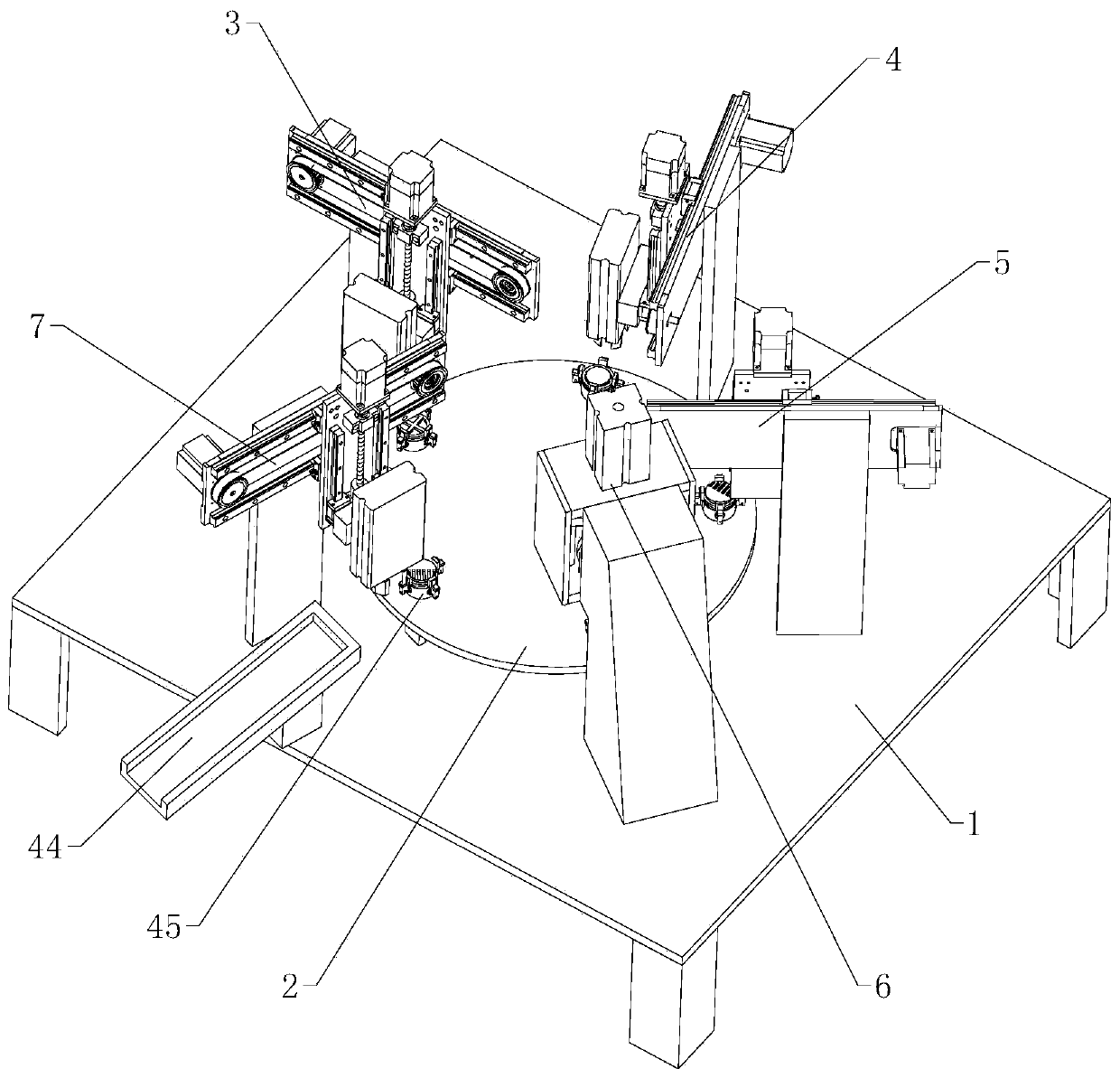

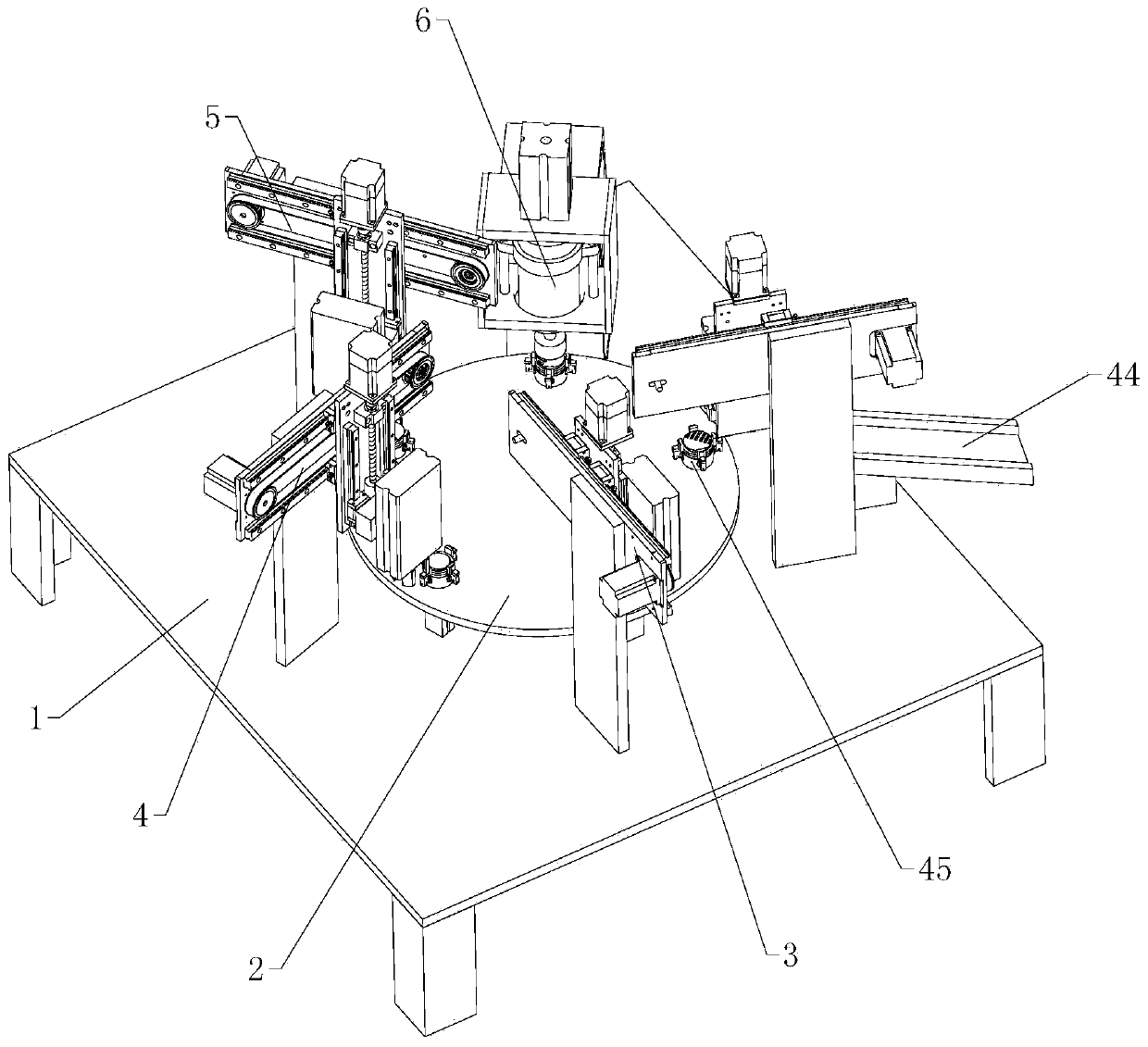

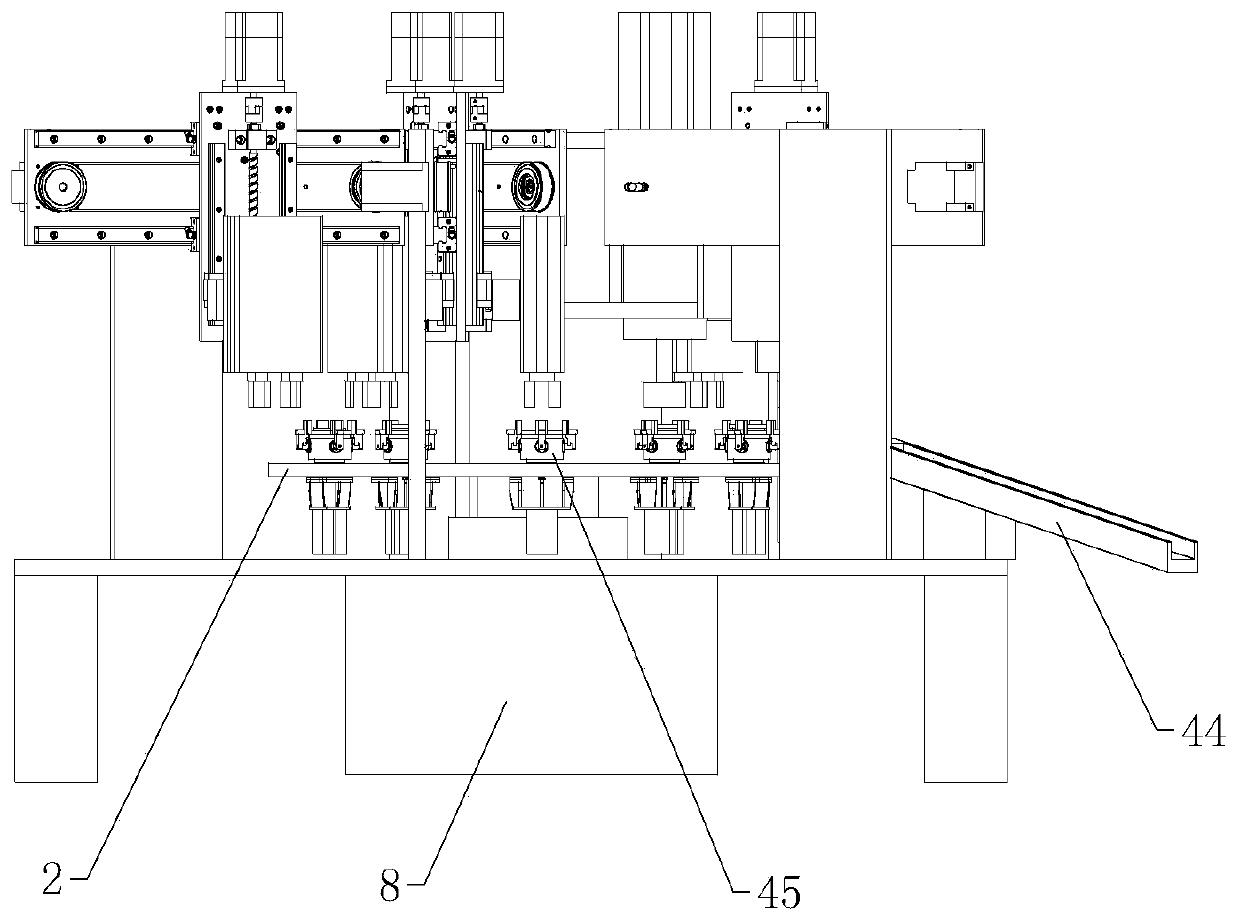

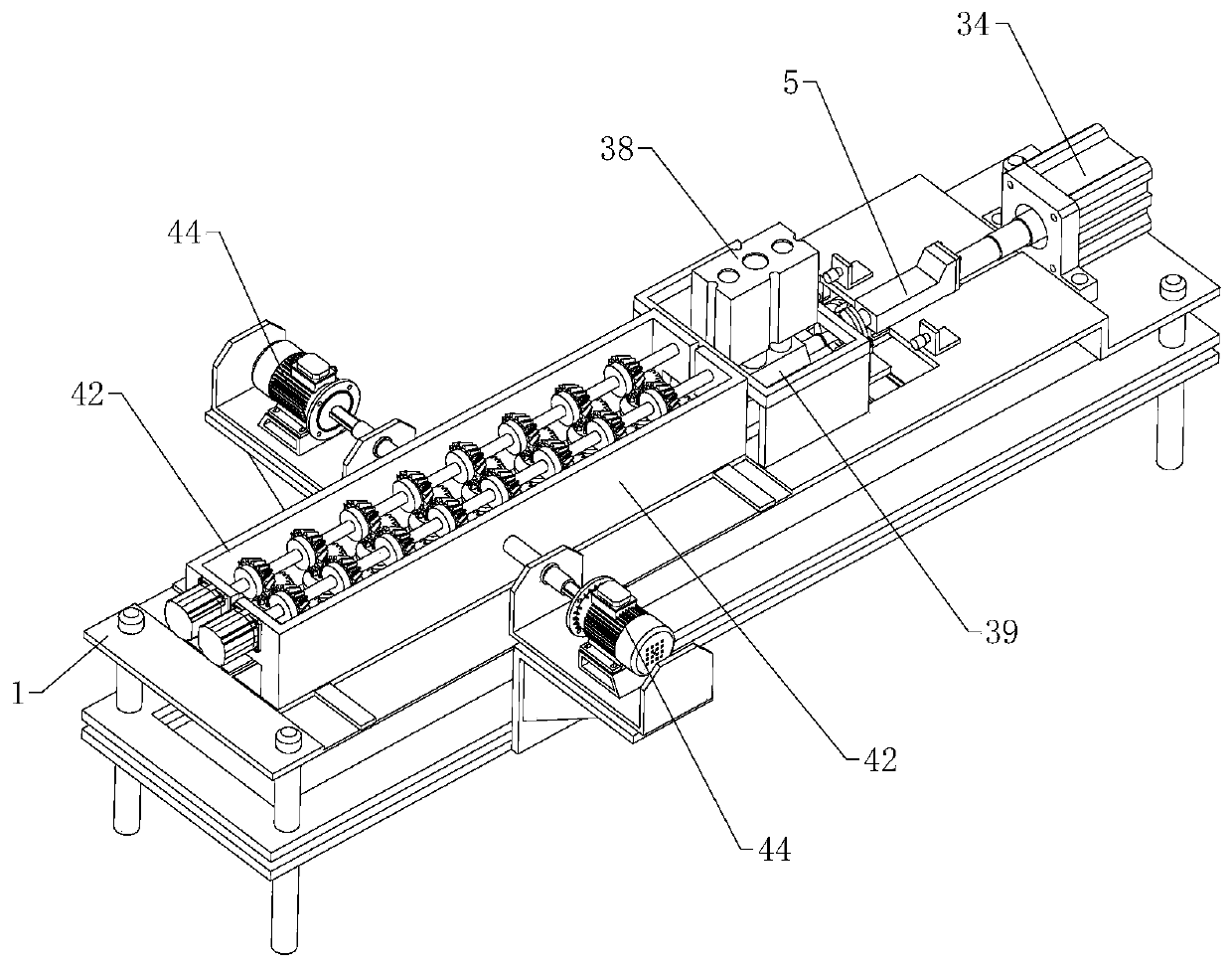

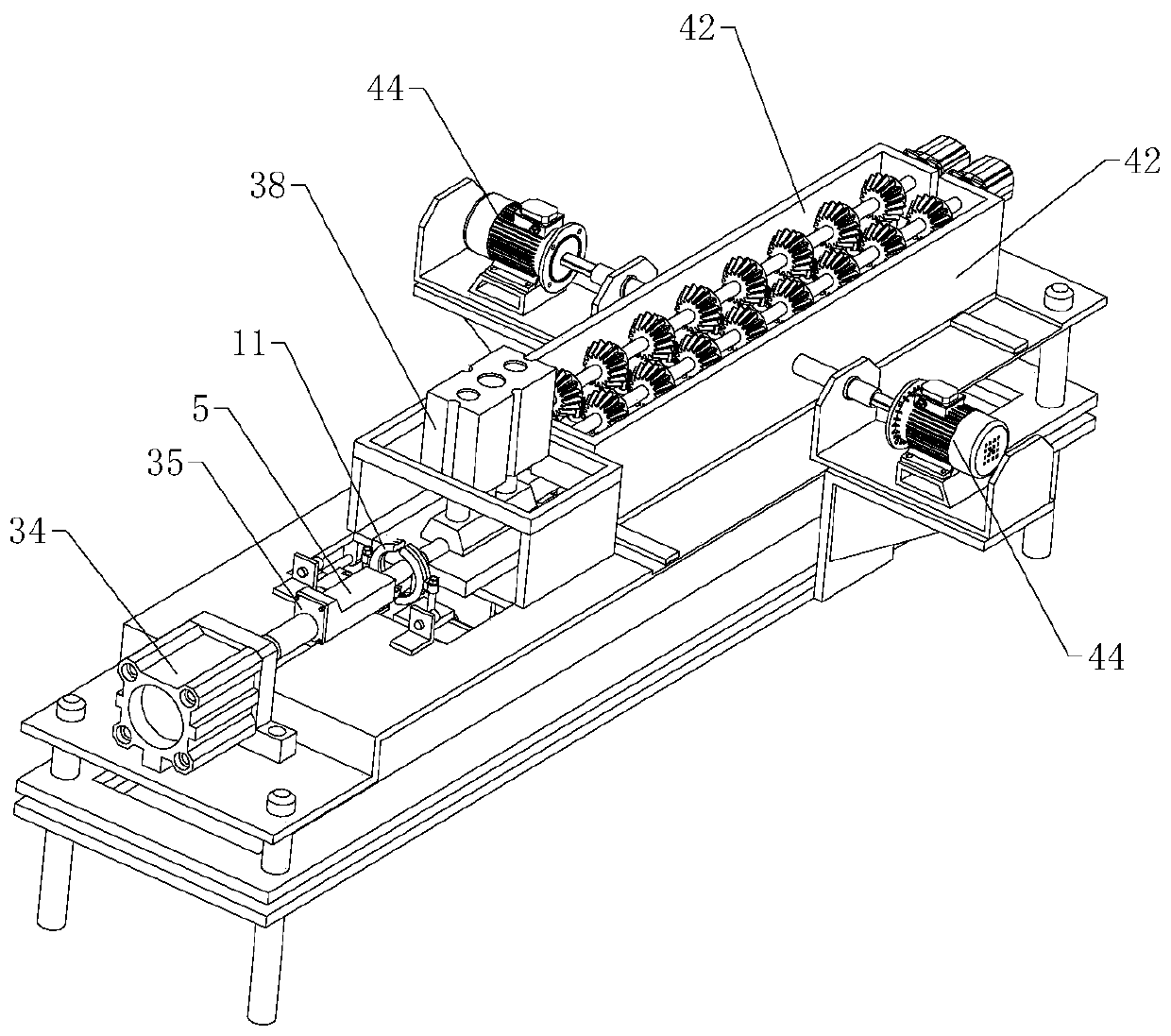

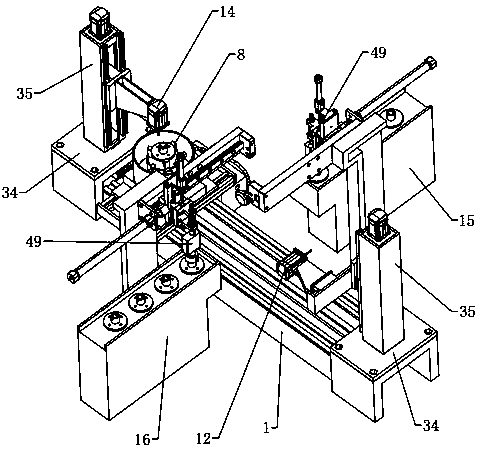

Automatic tool device for cross shaft bearing

InactiveCN110712035APlay the role of limit movementPrevent slippingAssembly machinesMetal working apparatusRotational axisEngineering

The invention relates to the technical field of bearing assembly, and specifically relates to an automatic tool device for a cross shaft bearing. The automatic tool device comprises a machining table,and further comprises a clearance rotation driving assembly, a jig positioning assembly, a left side material guide assembly and a right side material guide assembly, wherein the clearance rotation driving assembly comprises a rotating shaft which is horizontal and can rotate in a clearance mode, the jig positioning assembly comprises four clamping plates capable of abutting against a cross shaft, the left side material guide assembly and the right side material guide assembly are the same in structure, the left side material guide assembly and the right side material guide assembly each comprise a pressing block, a material guide frame is arranged at the end, positioned on the jig positioning assembly, of the machining table, a cross shaft feeding conveyor and a cross shaft discharging conveyor are arranged on one side of the material guide frame, and an upper material guide assembly and a lower material guide assembly which can move among the cross shaft feeding conveyor, the crossshaft discharging conveyor and the jig positioning assembly are arranged on the material guide frame. According to the automatic tool device, automatic feeding and discharging can be realized, each lug shaft of the cross shaft can be automatically assembled, and the production efficiency and the assembly quality are improved.

Owner:束宇晨

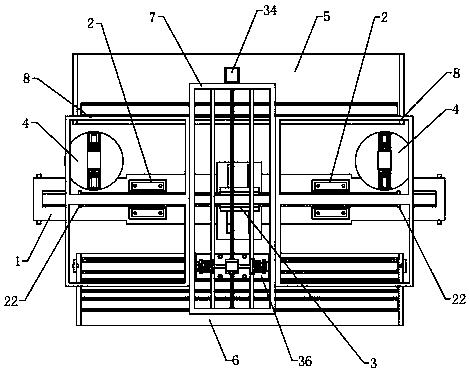

Welding equipment for automobile pipe fitting machining

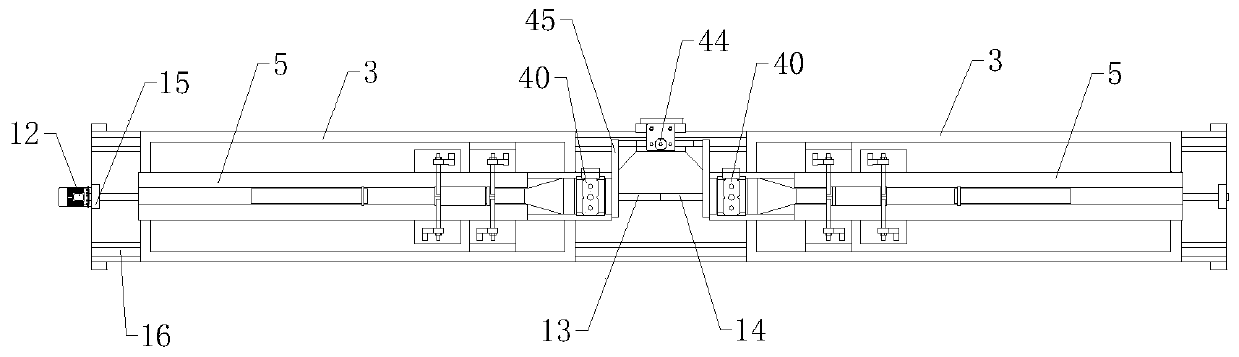

ActiveCN110170795APlay the role of limit movementPrecision weldingWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingMachining

The invention relates to the field of welding equipment, in particular to welding equipment for automobile pipe fitting machining. The welding equipment comprises a workbench, and further comprises aleft end positioning mechanism, a right end positioning mechanism and a right end moving mechanism. The left end positioning mechanism and the right end positioning mechanism are symmetrically arranged above the workbench. The left end positioning mechanism is fixedly arranged on a table top of the workbench through a fixing bracket. The right end moving mechanism is positioned below the right endpositioning mechanism. The right end positioning mechanism is arranged on the top of a horizontal bottom plate. The right end positioning mechanism and the left end positioning mechanism respectivelycomprise a base, a synchronous driving assembly, a positioning assembly, a feeding positioning assembly and two lifting assemblies, wherein each lifting assembly is provided with a lifting plate; each positioning assembly comprises a fixing cross plate and two clamps; each feeding positioning assembly comprises a feeding rail; and each feeding rail is provided with avoidance slots for avoiding the movement of the corresponding two clamps. By means of the welding equipment, the height of each welding pipe fitting can be adjusted separately, so that more precise welding of automobile pipe fittings can be realized, and the welding efficiency can be improved.

Owner:极能电气(苏州)有限公司

Cable bridge

ActiveCN111817223APlay the role of limit movementFast dismantlingElectrical apparatusAlarmsCable trayElectric cables

The invention relates to the technical field of cable bridges, in particular to a cable bridge. The cable bridge comprises a main bridge frame, mounting plates are respectively arranged at the upper ends of two sides of the main bridge frame; an alarm mechanism is arranged at the middle end in the main bridge frame; distance adjusting mechanisms are arranged at the two ends of the interior of themain bridge frame respectively; each distance adjusting mechanism comprises an adjusting assembly; each adjusting assembly comprises two moving plates capable of moving horizontally and oppositely. Each moving plate is provided with a cable clamping head. A detachable connecting mechanism is arranged at each tail end of the main bridge frame; each connecting mechanism comprises a connecting framecapable of being in butt joint with the corresponding tail end of the main bridge frame and locking assemblies installed at the upper end and the lower end of the two sides of the corresponding connecting frame respectively. The two sides of the main bridge frame are each provided with a connecting plate capable of being detachably connected with the corresponding locking assembly, the cable bridge can adjust a fixed cable, the installation practicability is improved, each hinge frame can be efficiently and independently disassembled, and the later-period maintenance efficiency is improved.

Owner:天津龙鼎熙石化新能源科技有限公司

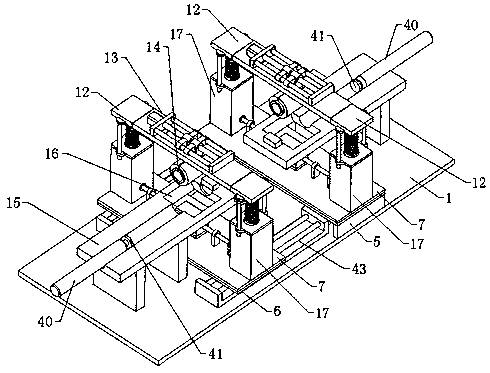

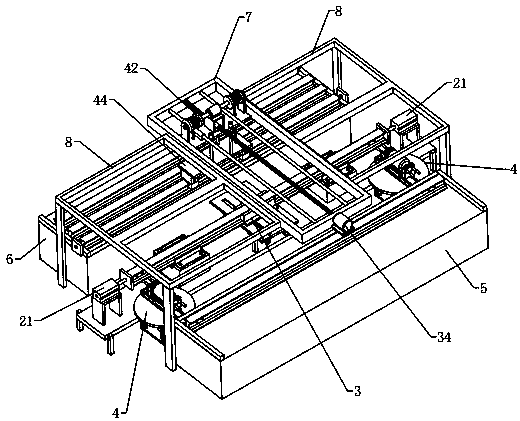

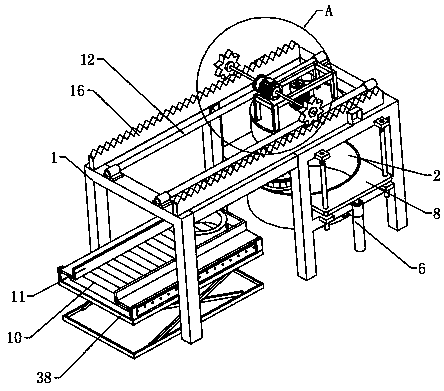

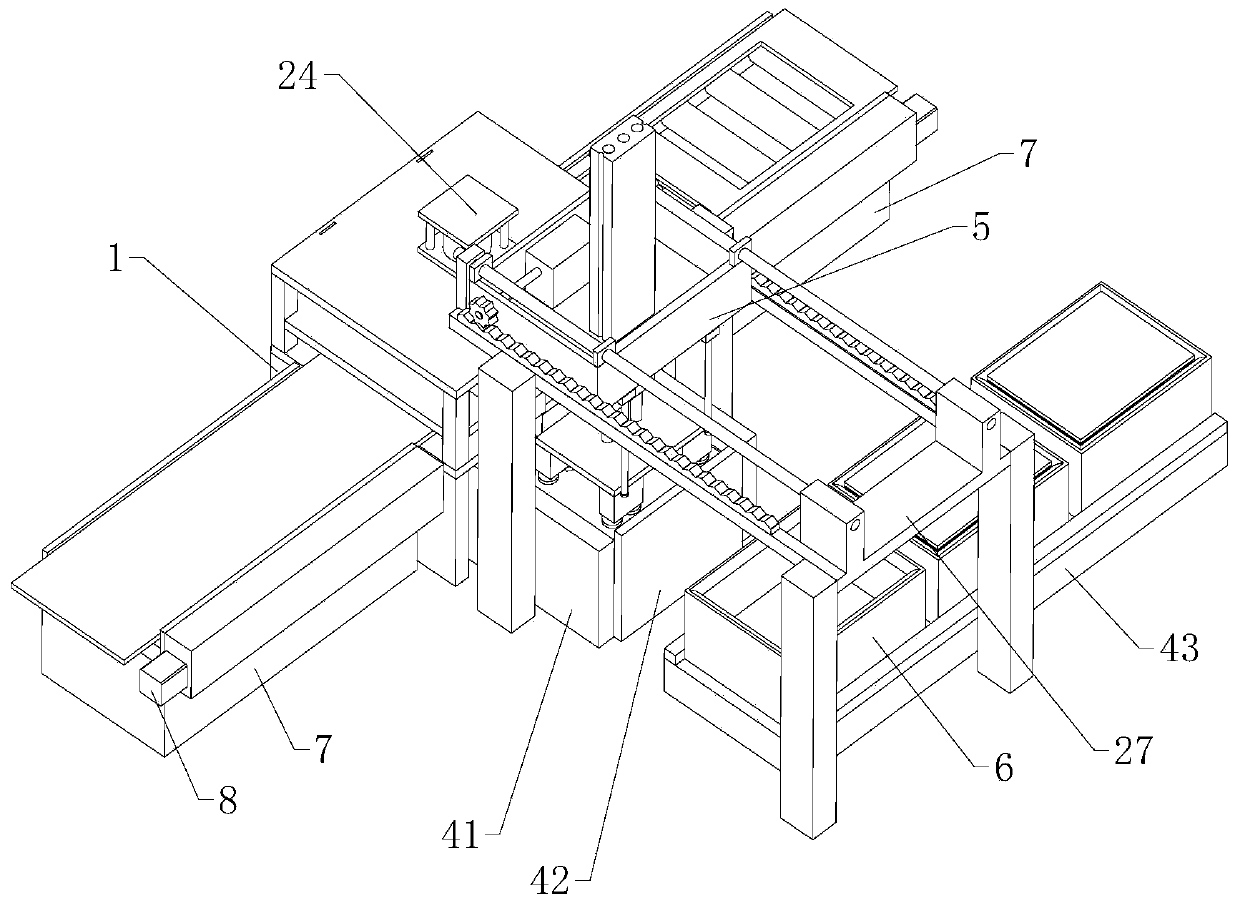

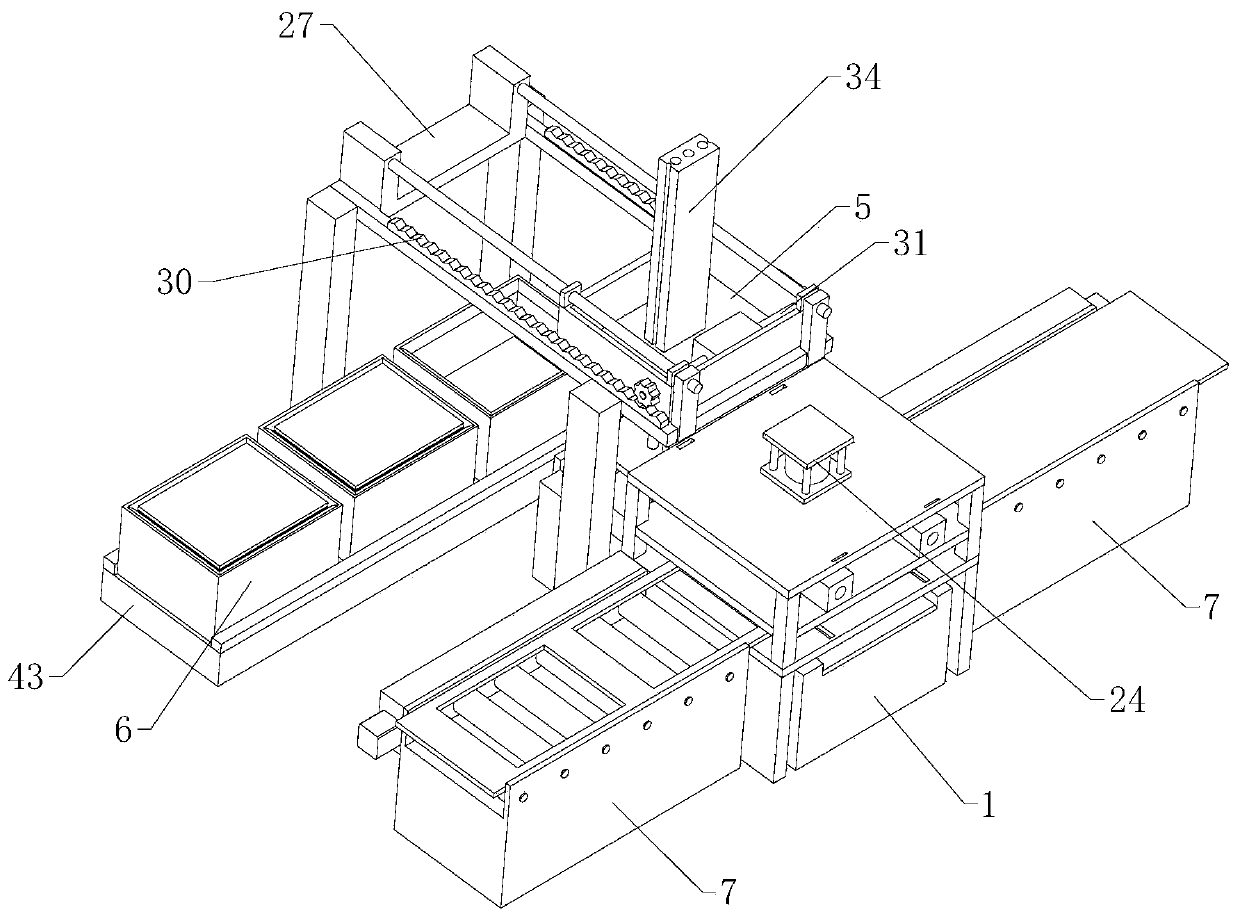

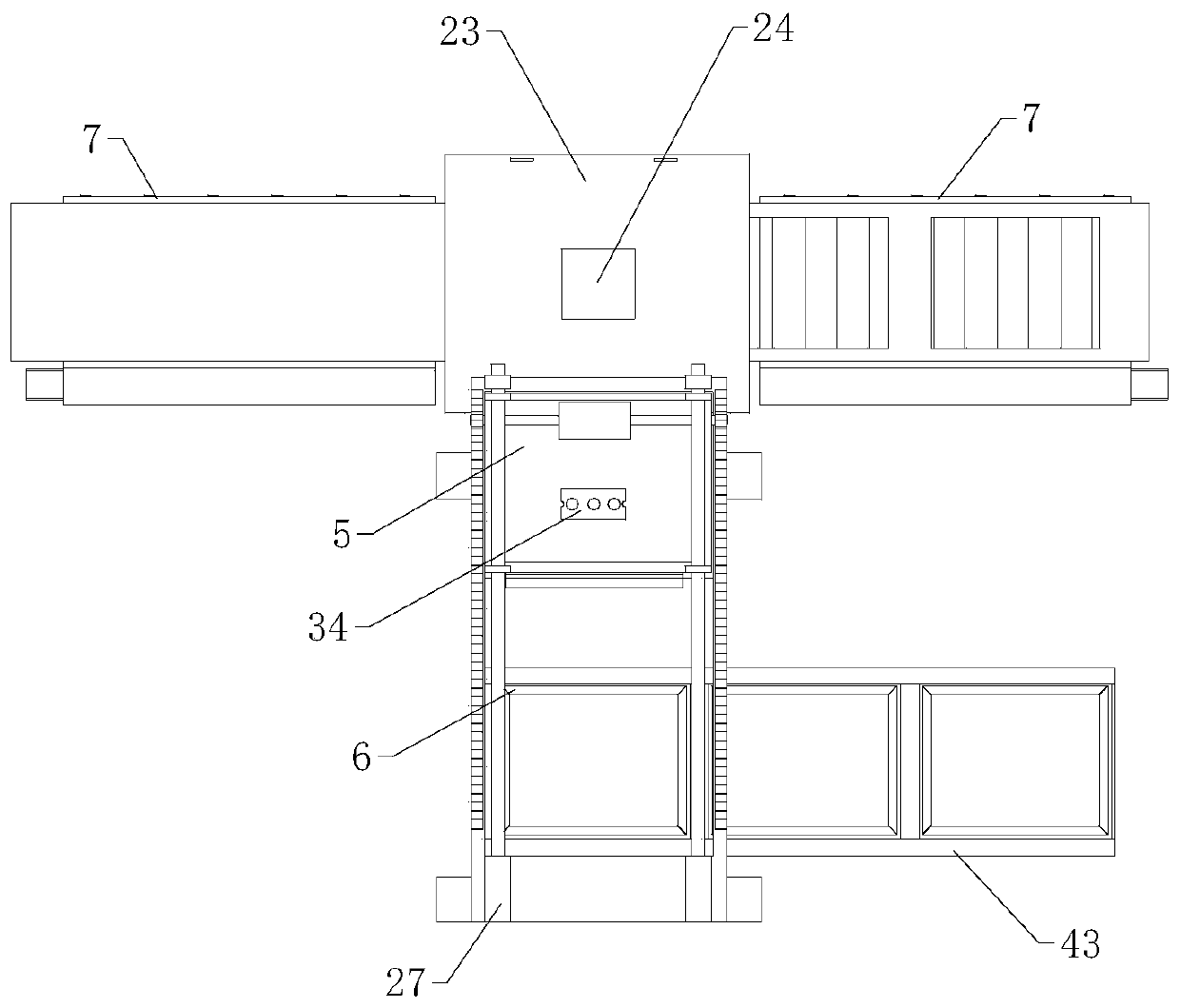

Steel rail kidney hole machining device used for rail traffic

The invention relates to the technical field of rail traffic, in particular to a steel rail kidney hole machining device used for rail traffic. The steel rail kidney hole machining device comprises amachining table. A carrying table is arranged on the top of the machining table. End portion positioning assemblies are arranged at the two ends of the machining table correspondingly. A side portionpositioning assembly is arranged below the carrying table. The side portion positioning assembly comprises two side portion clamping blocks, and rotating tables are arranged on one sides of the two ends of the machining table correspondingly. Each rotating table is provided with a drilling assembly. A discharging table and a feeding table are arranged on the two sides of the machining table correspondingly, and a hollow rectangular frame which is horizontally arranged is arranged above the machining table. Fixing supports used for fixing are arranged on the two sides of the rectangular frame correspondingly. A horizontal moving assembly is arranged in the rectangular frame. The horizontal moving assembly comprises a clamping claw which can move among the feeding table, the carrying table and the discharging table and can clamp a steel rail. By means of the device, the steel rail can be automatically adjusted with multiple angles and positioned, in addition, automatic feeding and discharging can be achieved, and the machining efficiency is improved.

Owner:FUSHIKOU RAILWAY EQUIP ZHEJIANG CO LTD

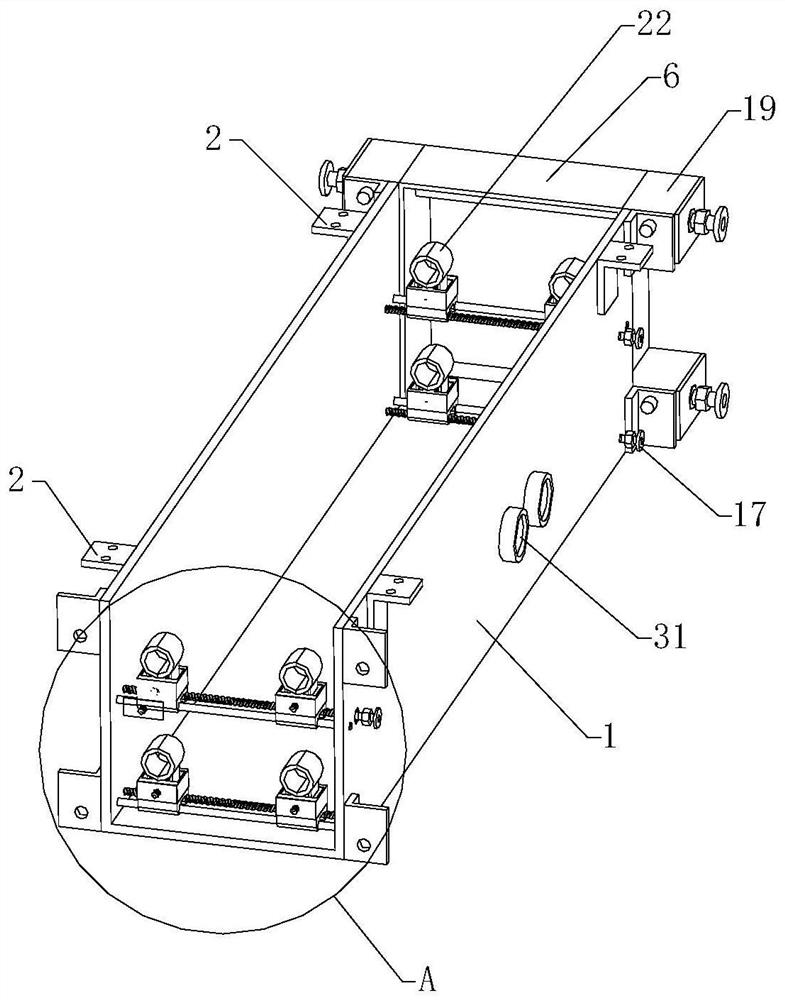

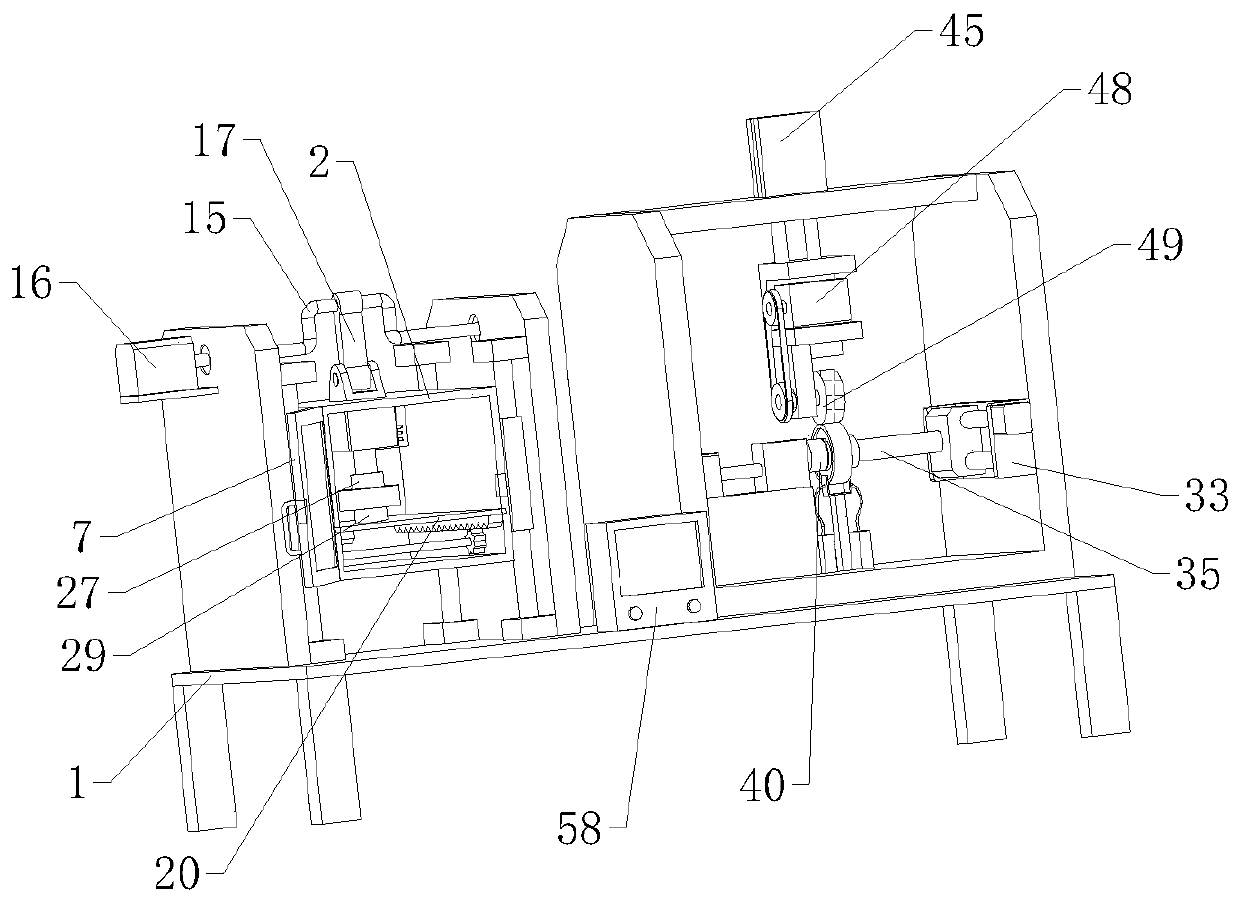

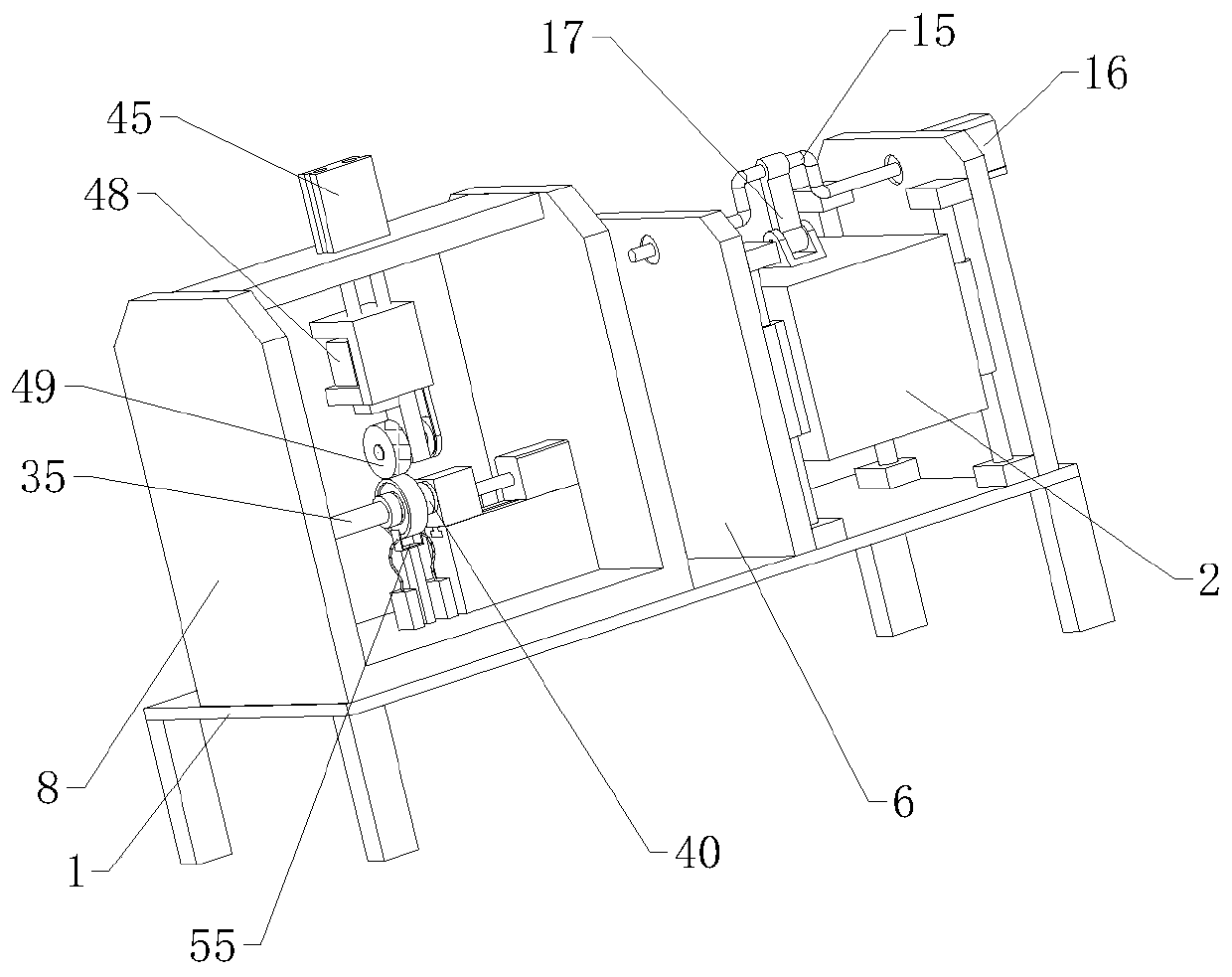

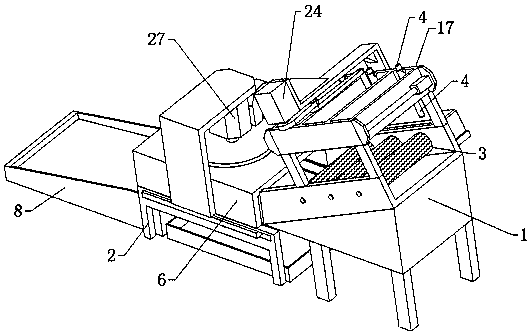

Shaft workpiece end part grinding device

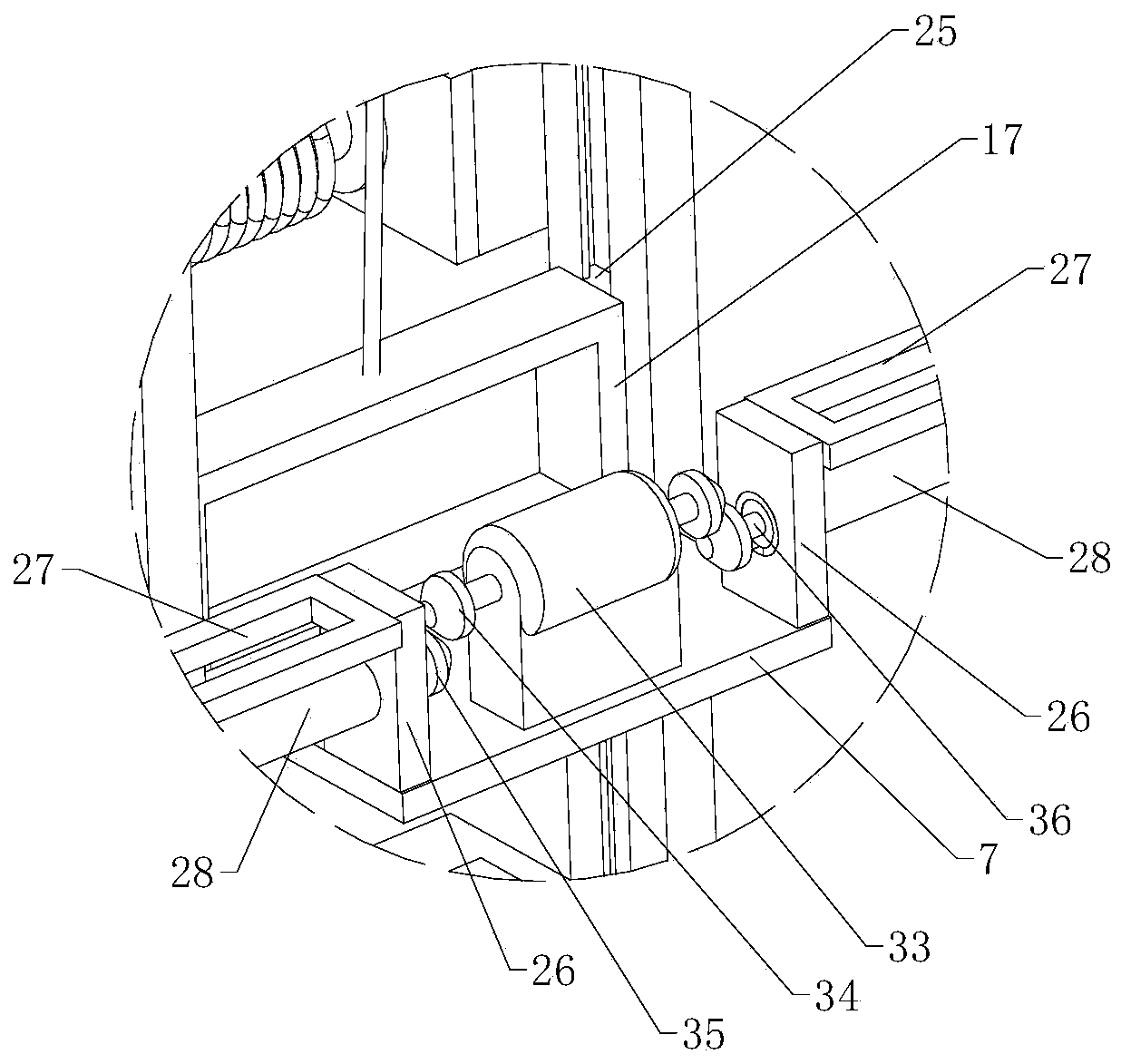

InactiveCN110421427APlay the role of limit movementPlay the role of guide limitGrinding drivesGrinding work supportsEngineeringTransfer mechanism

The invention relates to the field of shaft workpiece machining, in particular to a shaft workpiece end part grinding device. The device comprises a workbench, and further comprises a material discharging and transferring mechanism and a grinding mechanism, wherein the material discharging and transferring mechanism comprises a material discharging and clamping assembly, a positioning assembly anda horizontal material transferring assembly, the material discharging and clamping assembly comprises a material discharging bin, a plurality of containing penetrating holes are formed in one side ofthe material discharging bin, one side of the interior of each containing penetrating hole is provided with an abutting pressing block capable of abutting against a shaft workpiece, the positioning assembly comprises a positioning baffle plate, the grinding mechanism comprises two grinding assemblies and a opposite direction driving assembly, the two grinding assemblies are symmetrically arrangedon the two sides of the center of the horizontal material transferring assembly, the opposite direction driving assembly is positioned at the bottom of the workbench, and the interiors of the two grinding assemblies penetrate through the top of the workbench and are fixedly connected with the working end of the opposite direction driving assembly. The device can grind shaft workpieces with different lengths, and can simultaneously grind the two ends of several shaft workpieces, so that the efficiency is improved.

Owner:云和县凯毅德电子设备厂

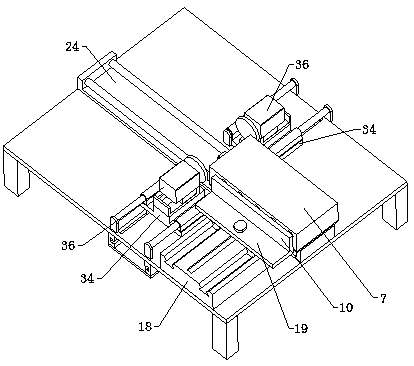

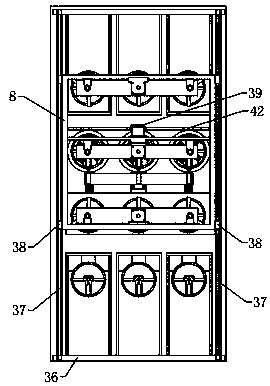

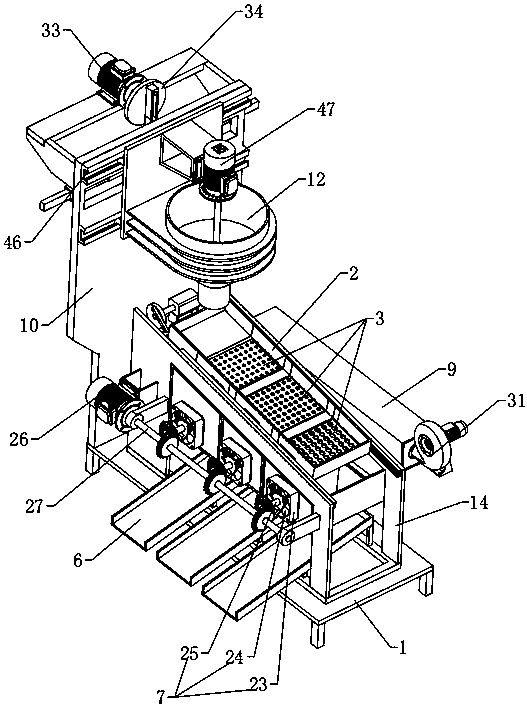

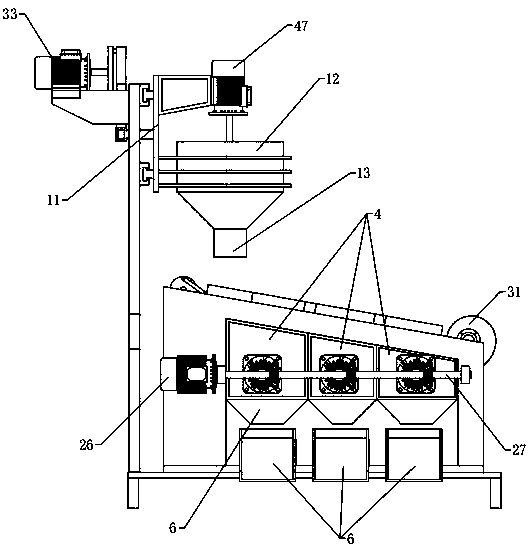

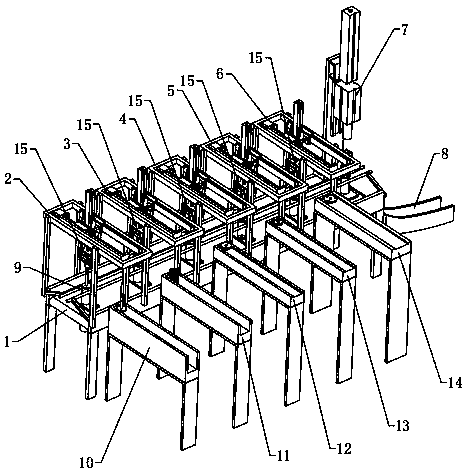

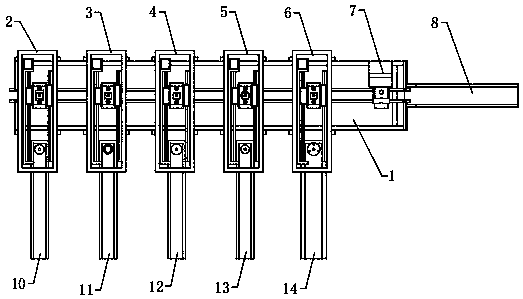

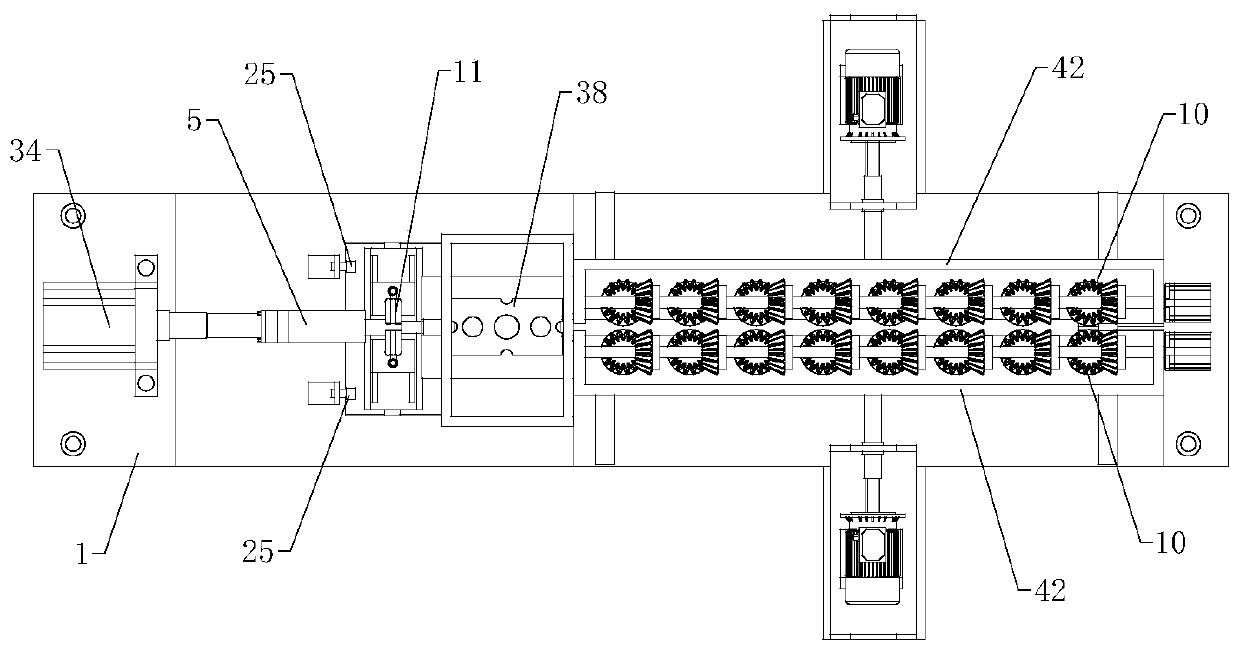

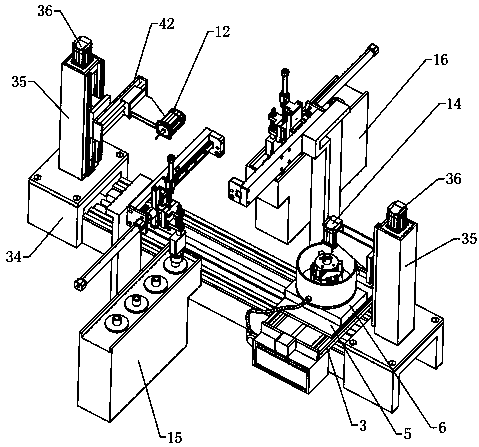

Batch grinding equipment for automobile steering wheel frameworks

ActiveCN111070041APlay the role of limit movementEasy to take outGrinding carriagesGrinding drivesSteering wheelControl engineering

The invention relates to the technical field of automobile steering wheel machining, in particular to batch grinding equipment for automobile steering wheel frameworks. The batch grinding equipment comprises a machining table, a positioning mechanism, a rotating mechanism, a grinding mechanism, a detecting mechanism, a horizontal moving mechanism, a feeding mechanism, a discharging mechanism, a guiding mechanism, a feeding grabbing mechanism and a discharging grabbing mechanism, wherein the positioning mechanism, the rotating mechanism, the grinding mechanism, the detecting mechanism, the horizontal moving mechanism, the feeding mechanism, the discharging mechanism, the guiding mechanism, the feeding grabbing mechanism and the discharging grabbing mechanism are installed on the machining table; the positioning mechanism comprises a plurality of positioning assemblies; the rotating mechanism comprises a rotating assembly; the grinding mechanism comprises grinding knives corresponding torotary tables; a correcting mechanism comprises a detecting table and detecting heads located on the detecting table and corresponding to the positioning assemblies; the feeding mechanism comprises feeding conveyors corresponding to the positioning assemblies; the discharging mechanism comprises discharging conveyors corresponding to the positioning assemblies; the horizontal moving mechanism comprises a moving frame; and the guiding mechanism, the feeding grabbing mechanism and the discharging grabbing mechanism are installed in the moving frame. The batch grinding equipment can automatically conduct machining in batches, feeding and discharging can be achieved, and the machining efficiency is improved.

Owner:广州中谷自动化设备有限公司

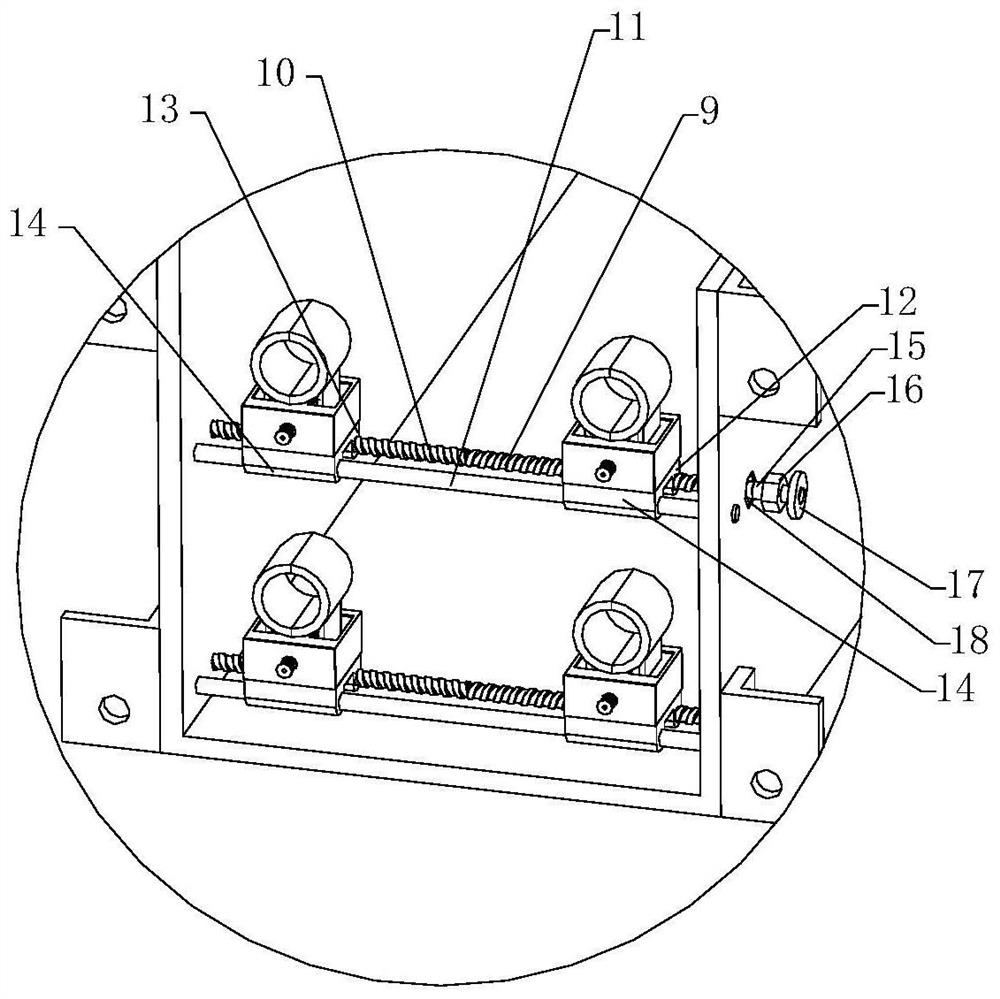

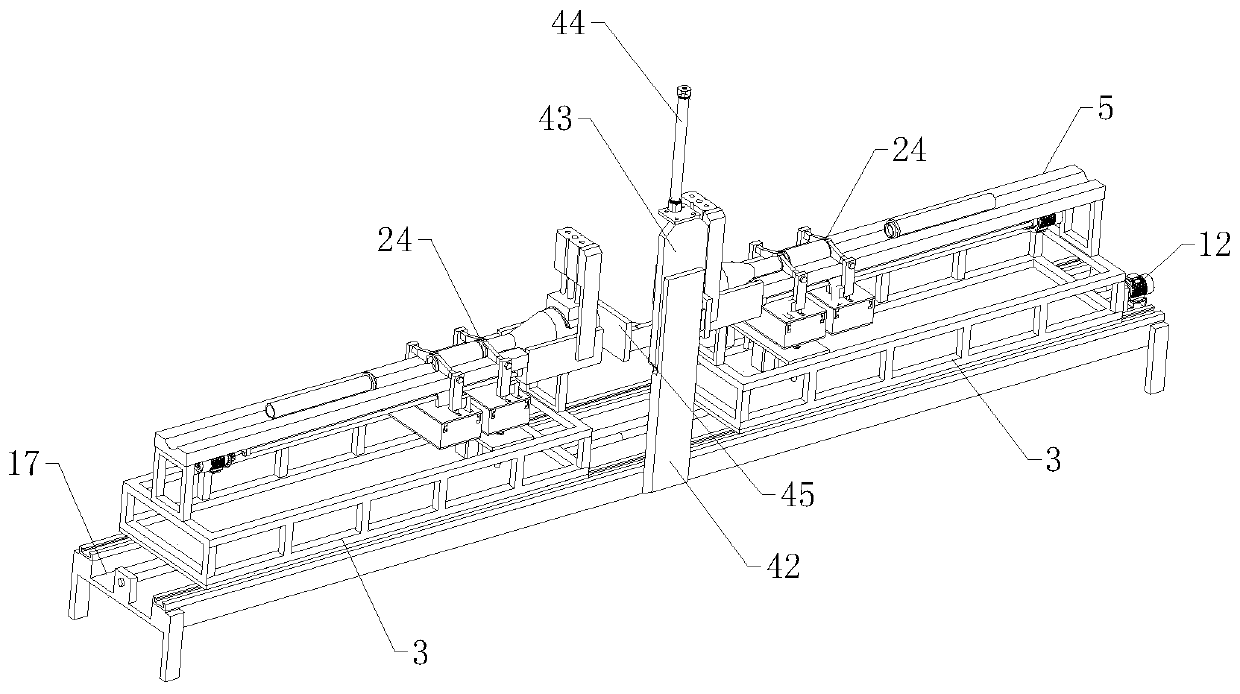

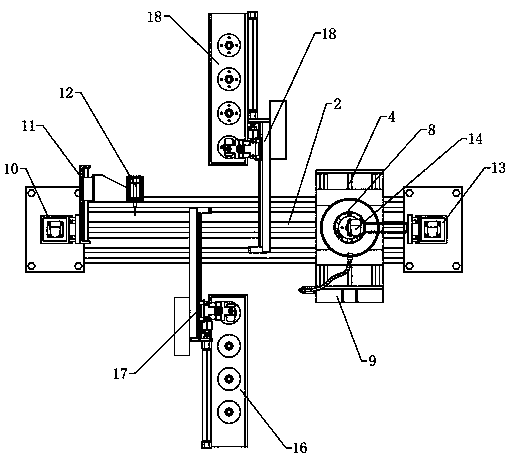

Aero-engine rotor rolling bearing longitudinal and radial shake detection device

ActiveCN110501162APlay the role of limit movementReduce detection errorMachine part testingRolling-element bearingAero engine

The invention relates to the technical field of bearing detection, and particularly relates to an aero-engine rotor rolling bearing longitudinal and radial shake detection device, which comprises a processing table. The device also comprises a longitudinal shake detection mechanism and a radial shake detection mechanism. A controller is arranged between the longitudinal shake detection mechanism and the radial shake detection mechanism. The longitudinal shake detection mechanism comprises a shake seal box, a horizontal material moving assembly, a bottom positioning assembly, a top positioningassembly and two vertical supports. One end of the shake seal box is provided with a folding door. The radial shake detection mechanism comprises a hollow U-shaped base, a material moving assembly, aright positioning assembly, a left positioning assembly, an analog rotation assembly, a lifting assembly and a radial detection assembly. The device only needs to place a detected product in the device and can realize longitudinal and radial automatic accurate detection, thereby reducing detection errors and improving detection efficiency.

Owner:NANCHANG HANGKONG UNIVERSITY

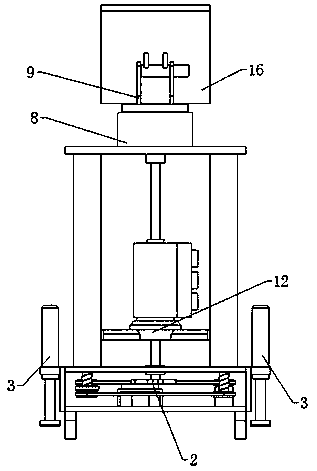

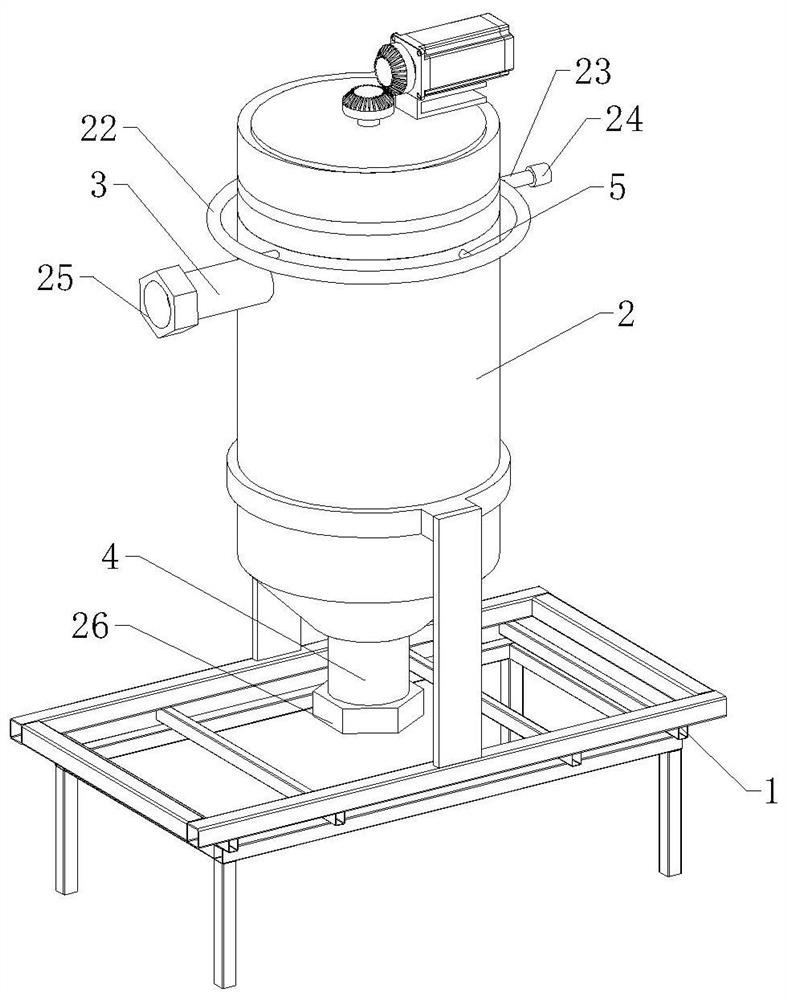

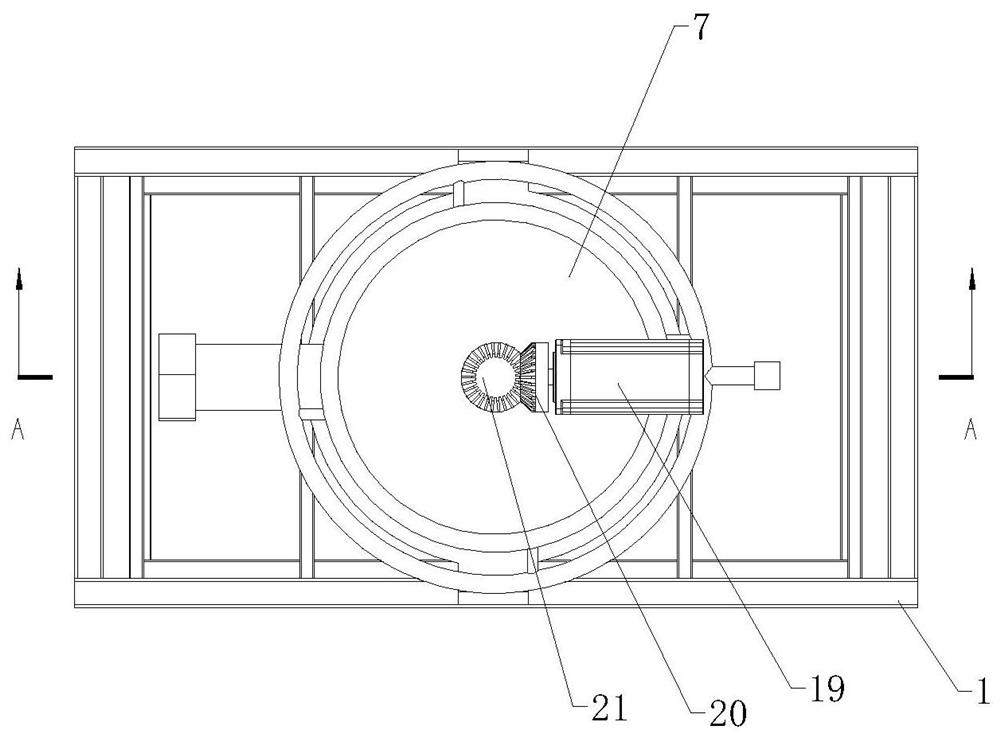

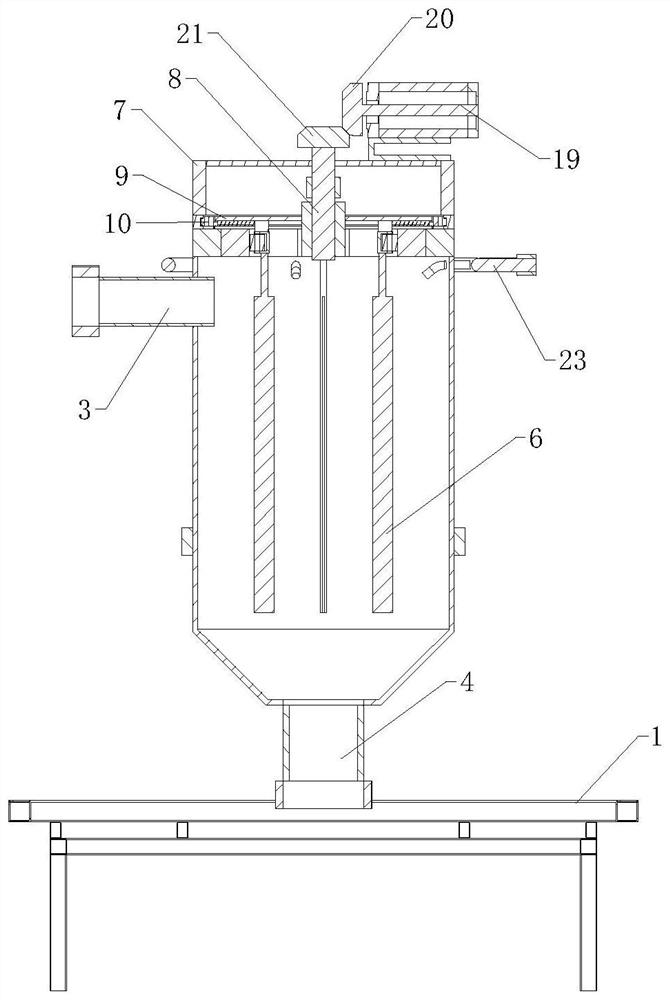

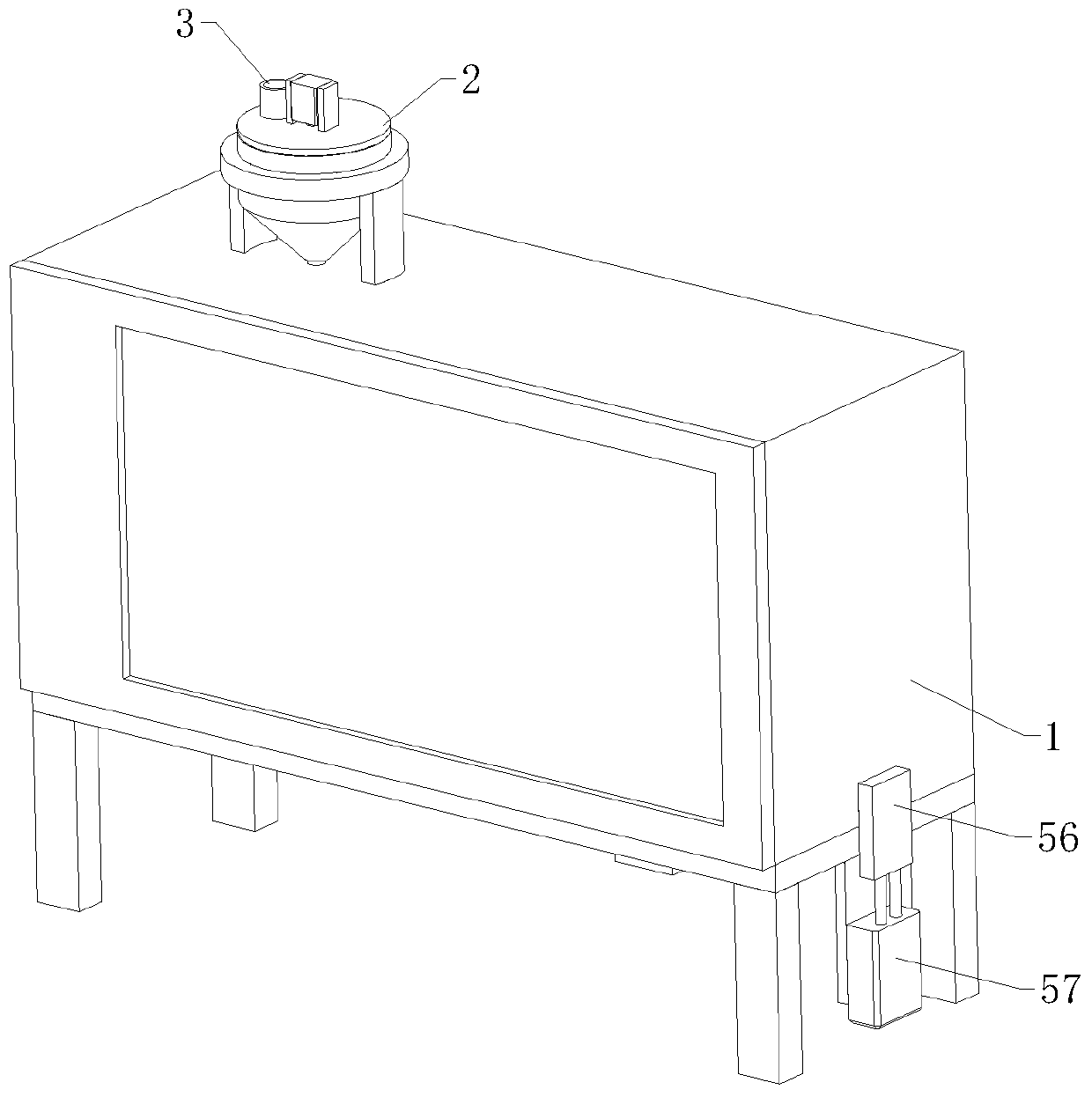

Stirring mechanism for chili sauce production

InactiveCN111888988AStir wellPlay the role of limit movementRotary stirring mixersTransportation and packagingChilli con carneMechanical engineering

The invention relates to the technical field of chili processing, particularly to a stirring mechanism for chili sauce production. The stirring mechanism comprises a rack, a stirring tank, a driving assembly, a cleaning assembly and an opening-closing rotating assembly, wherein the stirring tank is vertically arranged on the rack, a feeding pipe is arranged on one side of the upper end of the stirring tank, a discharging pipe is arranged at the bottom of the stirring tank, the cleaning assembly comprises a plurality of spray heads distributed at the upper end of the stirring tank at equal intervals, the opening-closing rotating assembly comprises a plurality of stirring blades which are opened and closed in the circumferential direction in the stirring tank and rotate, each stirring bladeis vertically arranged, the driving assembly is arranged at the top of the opening-closing rotating assembly, and the driving assembly is used for driving each stirring blade to rotate along the innercircumference of the stirring tank. According to the invention, the equipment adopts a plurality of stirring blades for stirring, and all the stirring blades can be opened and closed during stirring,so that chili raw materials are stirred uniformly.

Owner:林海云

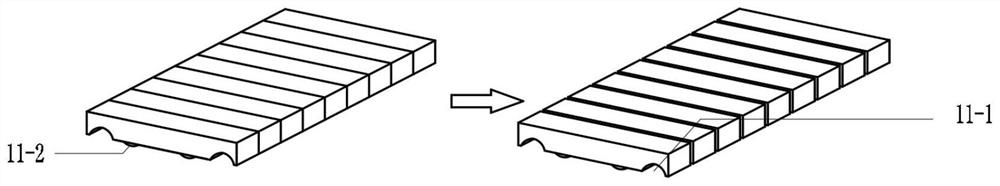

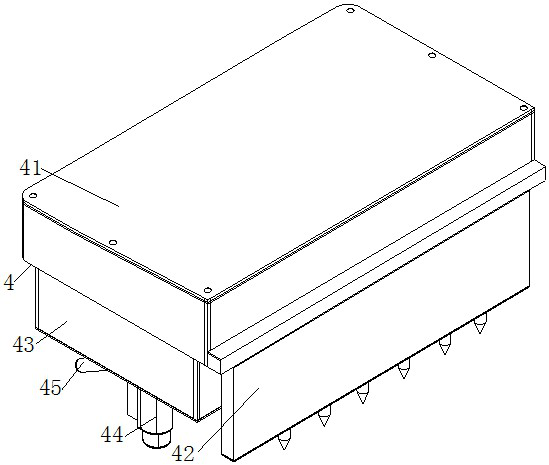

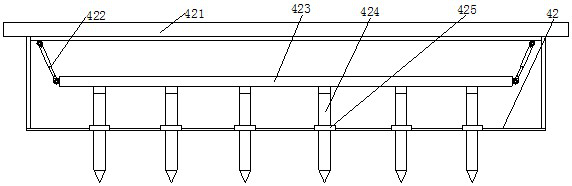

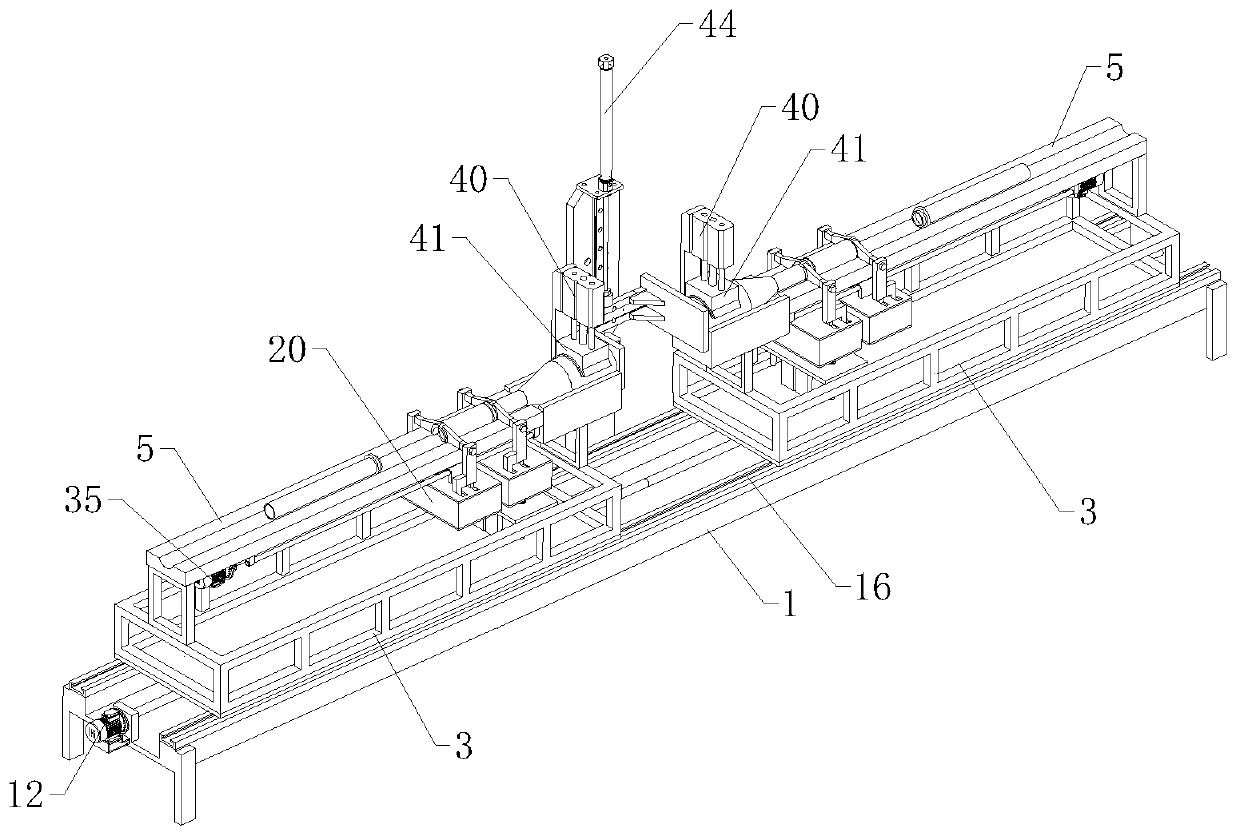

Test method of integral soil body uniaxial tension device

ActiveCN111982675APlay the role of limit movementPlay a supporting rolePreparing sample for investigationMaterial strength using tensile/compressive forcesUniaxial tensionSoil science

The invention discloses a test method of an integral soil body uniaxial tension device. The test method comprises the following steps: 1, assembling a visual integrated mold; firstly assembling the mold bottom plate, and then assembling the detachable L-shaped plate; 2, preparing a sample, namely filling a soil body sample by adopting a layered compaction method; 3, installing a shaft pulling device, specifically, stretching the die to be half connected with an oil pressure chest expander; 4, disassembling the L-shaped plate; 5, stretching; 6, breaking the sample: further stretching by using an oil pressure chest expander, and breaking the tensile deformation part of the soil body sample after the tensile deformation part reaches the maximum bearing force; meanwhile, separating the slidingstrips located under the fracture part from each other under the driving of the fracture sample above, so that the fracture position of the sample is recorded; and 7, drawing a tensile stress-time curve and a tensile displacement-time curve. A mold used for sample preparation is directly transformed into the movable clamp, integration of the mold and the movable clamp is achieved, demolding is omitted, and the specific fracture position can be observed.

Owner:HOHAI UNIV

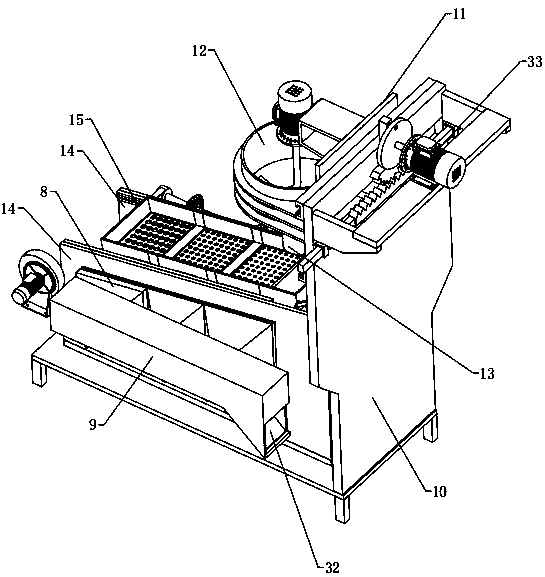

Integrated corn kernel impurity removal and screening device

InactiveCN111389724APlay the role of limit movementAdjust speedSievingGas current separationAgricultural engineeringStructural engineering

The invention relates to the technical field of corn processing, in particular to an integrated corn kernel impurity removal and screening device. The device comprises a base, wherein a bracket tableis arranged at the top of the base, a screening frame is arranged above the bracket table, a screening driving mechanism is arranged at the top of the bracket table, and three screens are arranged inside the screening frame; an impurity removal channel is formed below each screen; a discharge port is formed in the bottom of each impurity removal channel; a discharge slideway is arranged below eachdischarge port; a fan is arranged on the side wall of each impurity removal channel; a synchronous driving mechanism is arranged on the side wall of the bracket table, and an impurity removal channelis arranged on one side, away from a synchronous driving assembly, of the bracket table; and a vertical plate is arranged at one end of the top of the base, and an opposite moving mechanism is arranged on the vertical plate, and comprises an opposite plate, and a feeding hopper is arranged on the opposite plate. The device can automatically classify corn kernels and remove impurities, and processing efficiency is improved.

Owner:芜湖挺优机电技术有限公司

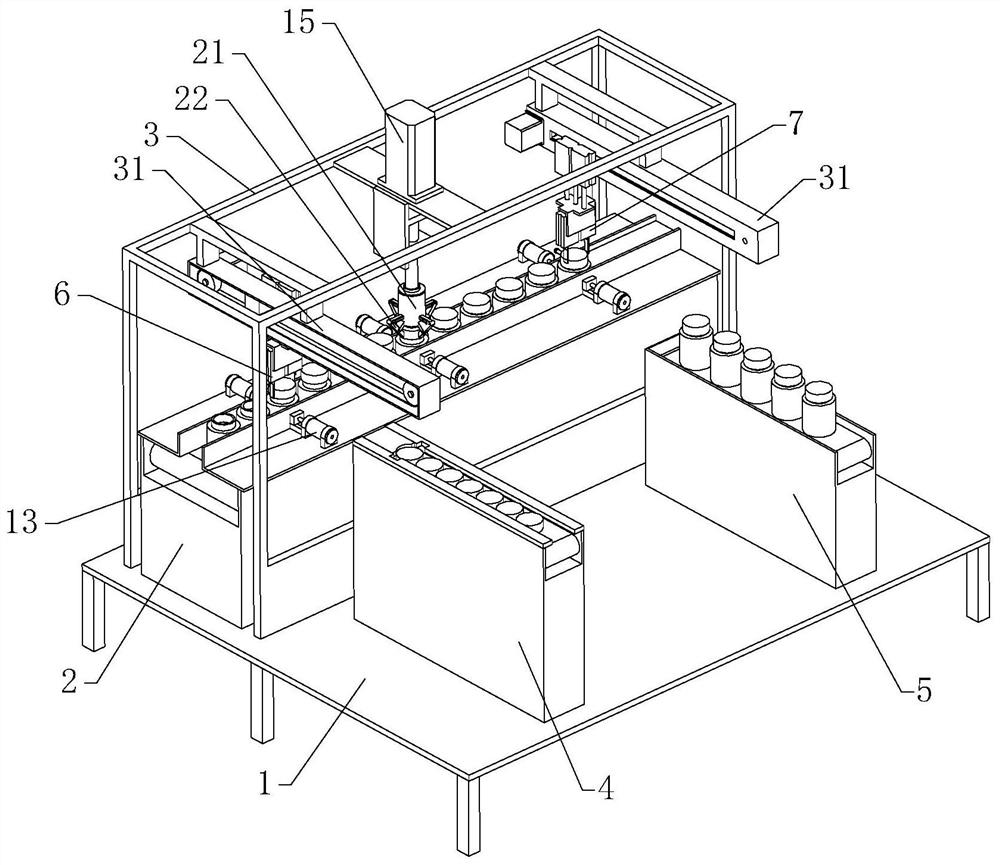

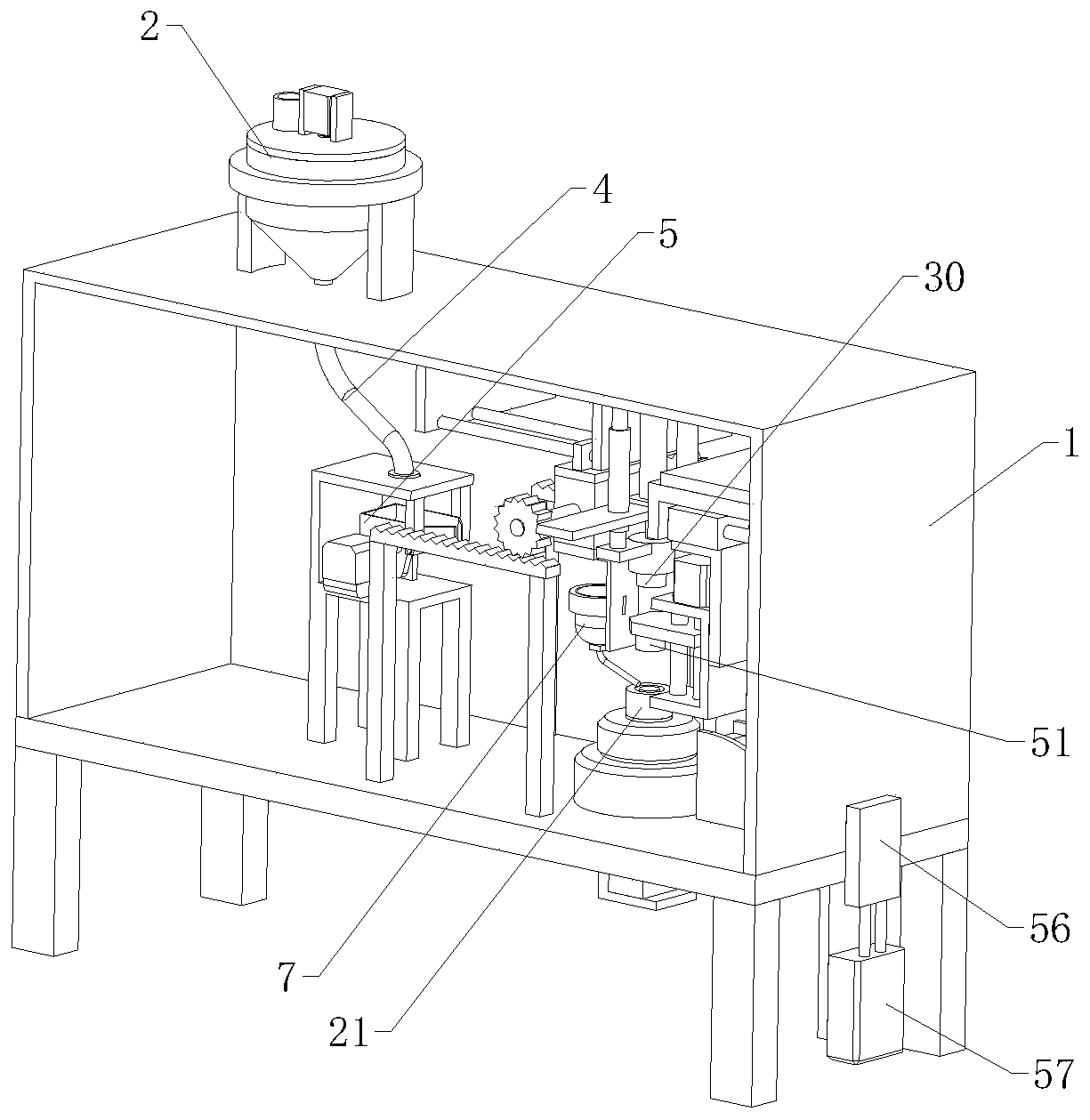

Full-automatic filling machine for canned abalones

ActiveCN111943122APlay the role of limit movementEasy to take outThreaded caps applicationSynchronising machinesBiotechnologyMechanical engineering

The invention relates to the technical field of canned abalone processing, in particular to a full-automatic filling machine for canned abalones. The full-automatic filling machine comprises a base, afeeding conveyor, a horizontal frame, a can cover feeding mechanism, a filling and sealing mechanism and a discharging mechanism, wherein positioning assemblies corresponding to the can cover feedingmechanism, the filling and sealing mechanism and the discharging mechanism in a one-to-one mode are arranged at the top of the feeding conveyor, a can cover conveyor and a discharging conveyor are arranged on one side of the feeding conveyor, one end of the can cover conveyor is in butt joint with one end of the interior of the can cover feeding mechanism, the can cover feeding mechanism comprises a first moving assembly, first clamping jaws are arranged at the working end of the first moving assembly, the discharging mechanism comprises a second moving assembly, and second clamping jaws arearranged at the working end of the second moving assembly. According to the technical scheme, the canned abalones can be automatically and efficiently filled, and the processing efficiency is improved.

Owner:FANGJIAPUZI PUTIAN GREEN FOOD

Cleaning equipment for automobile part production

InactiveCN110201927AEasy to movePlay the role of limit movementDrying gas arrangementsDrying chambers/containersButt jointEngineering

The invention relates to the field of cleaning equipment, in particular to the cleaning equipment for automobile part production. The cleaning equipment comprises a cleaning table, a drying table, a cleaning mechanism and a drying mechanism, wherein the cleaning mechanism is arranged on the cleaning table; the upper surface of the cleaning table is obliquely arranged; the cleaning mechanism comprises a cleaning wheel assembly and a flushing assembly; the cleaning wheel assembly comprises three roller shafts arranged in the linear direction of the cleaning table and the three roller shafts canbe rotatably arranged on the cleaning table; the flushing assembly comprises three cleaning punches and a horizontal moving plate, and the three cleaning punches are arranged on the horizontal movingplate respectively; the drying mechanism comprises a drying bin and a hot gas fan, the drying bin is fixedly arranged at the top of the drying table, and the hot gas fan is arranged above the drying bin; one end, away from the cleaning table, of the drying table is provided with a storage rack; and one end of the storage rack is in butt joint with one end of the drying table. With the cleaning equipment, automobile parts can be automatically cleaned and dried, and the cleaning and drying efficiency is improved.

Owner:佘娟

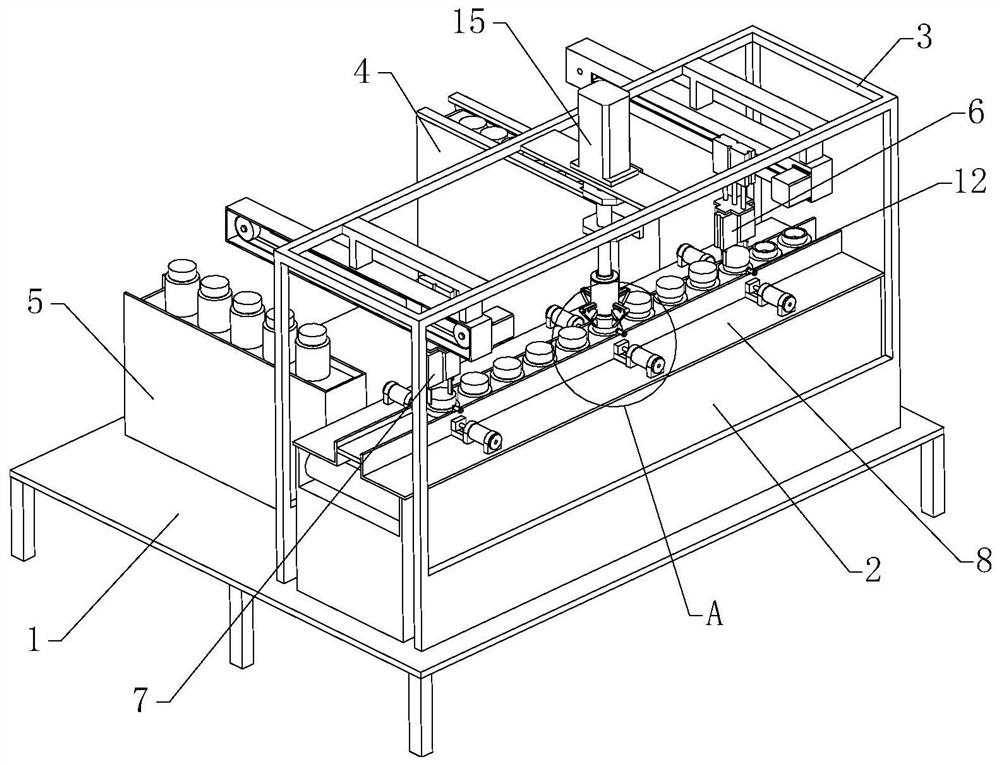

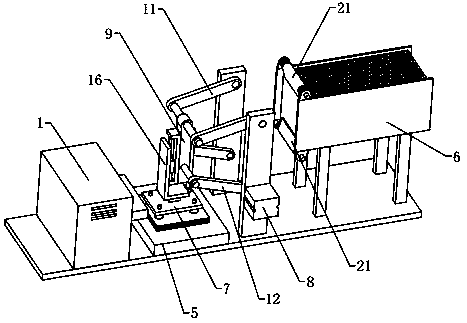

Automatic pressing mechanism for syringe needle assembly

InactiveCN110919326AAct as a guide to movePlay the role of limit movementMetal working apparatusPhysicsSyringe

The invention relates to the technical field of syringe needle processing, in particular to an automatic pressing mechanism for syringe needle assembly. The automatic pressing mechanism comprises an accommodating jig for placing workpieces and a bidirectional pressing and riveting mechanism, the bidirectional pressing and riveting mechanism comprises a horizontal moving assembly, a rotary drivingassembly and two end pressing and riveting assemblies, the two end pressing and riveting assemblies are arranged on the two sides of the accommodating jig correspondingly, the two end pressing and riveting assemblies are symmetrically arranged, each end pressing and riveting assembly is respectively provided with a pressing and riveting block, the rotary driving assembly is located on one side between the two end pressing and riveting assemblies, the output end of the rotary driving assembly is in transmission connection with the interior of each end pressing and riveting assembly, the horizontal moving assembly is horizontal and is located below the rotary driving assembly, the horizontal moving assembly comprises a moving plate, and the interior of the rotary driving assembly is fixedlyconnected with the top of the moving plate. By means of the equipment, the two pressing and riveting blocks can be pressed at the same time in a connecting rod way, pressing quality is improved, and the cost is reduced.

Owner:利辛县众善医药科技有限公司

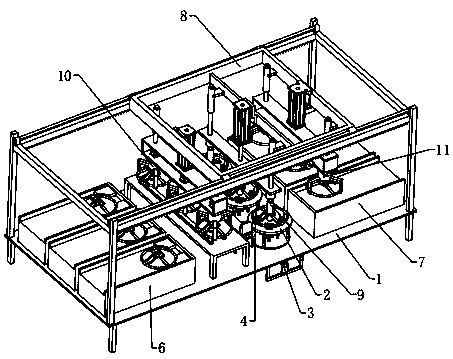

Automatic assembling equipment for automobile shock absorber

InactiveCN110961916APlay the role of limit movementAvoid shakingAssembly machinesEngineeringShock absorber

The invention relates to the technical field of automobile shock absorber machining and relates to automatic assembling equipment for an automobile shock absorber. The automatic assembling equipment comprises a main conveyor, a lower base assembling section, a spring assembling section, a clamping sleeve assembling section, a bearing assembling section, an upper base assembling section, a tightening section and a discharging section. A plurality of positioning jigs are arranged on the main conveyor. A lower base feeding conveyor, a spring feeding conveyor, a clamping sleeve feeding conveyor, abearing feeding conveyor and an upper base feeding conveyor are arranged on one side of the lower base assembling section, one side of the spring assembling section, one side of the clamping sleeve assembling section, one side of the bearing assembling section and one side of the upper base assembling section respectively. Each one of the lower base assembling section, the spring assembling section, the clamping sleeve assembling section, the bearing assembling section and the upper base assembling section comprises a material moving tool mechanism, each material moving tool mechanism comprises a lifting clamping jaw assembly, the equipment can achieve automatic tool assembling on the automobile shock absorber, and the production efficiency is improved.

Owner:嘉兴嘉嘉汽车零部件制造有限公司

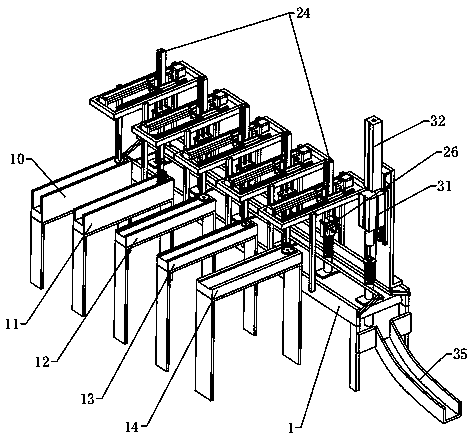

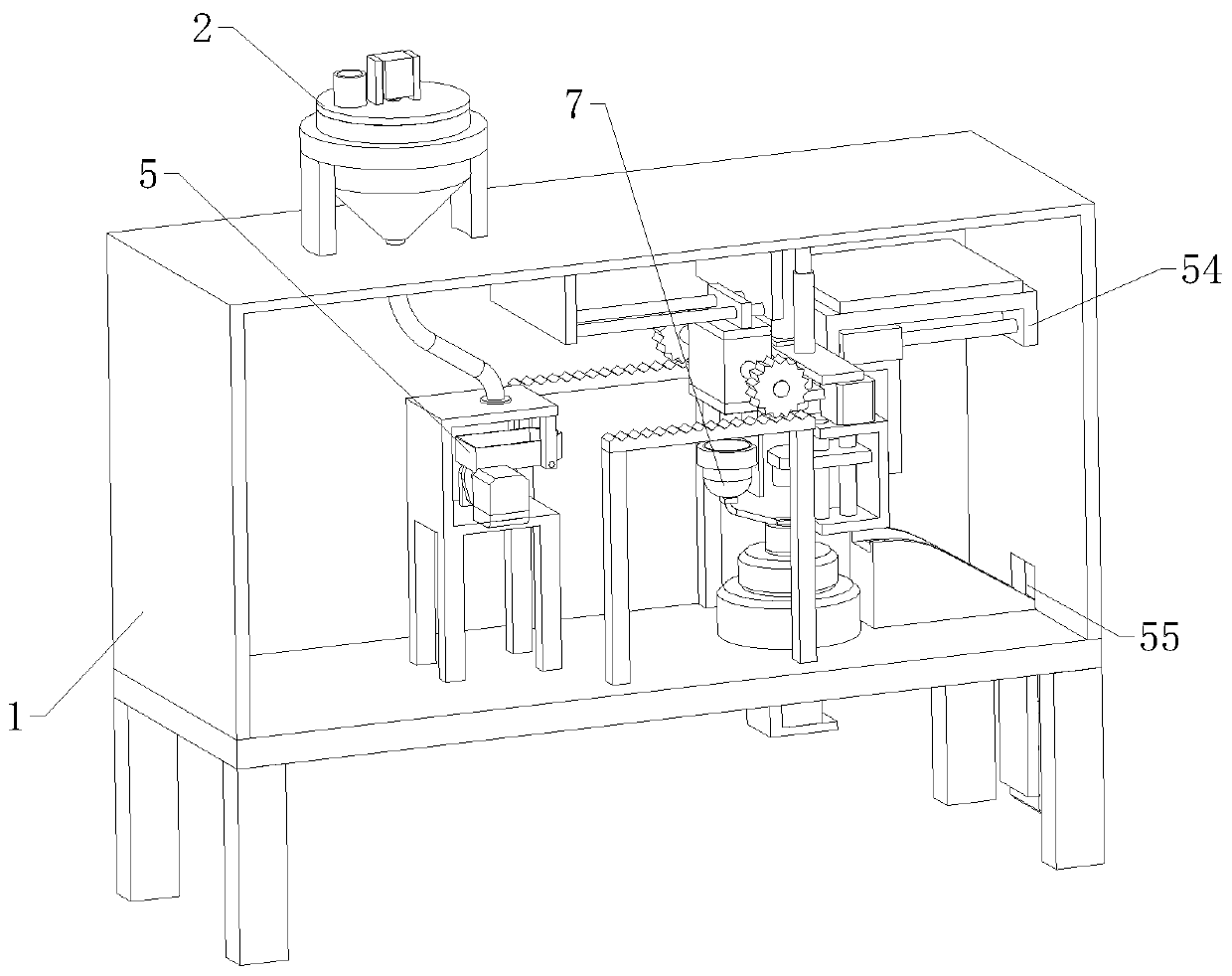

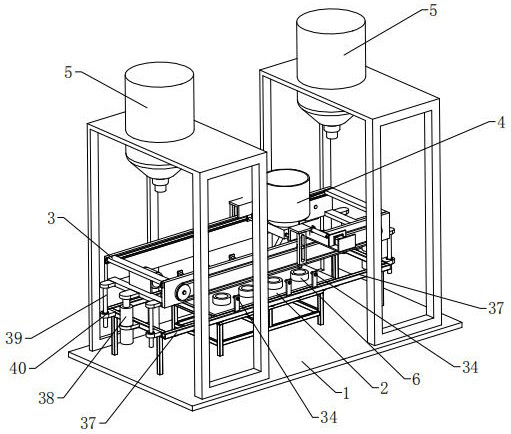

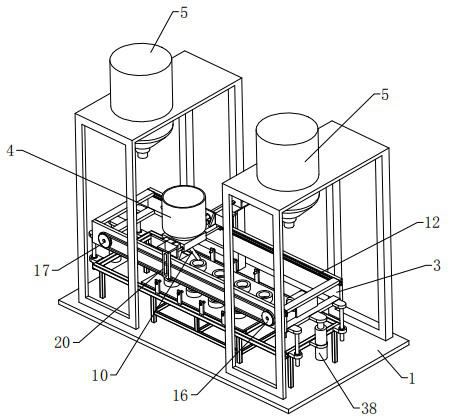

Automatic ring forming equipment of neodymium iron boron

ActiveCN110323057AAvoid stickingPlay the role of limit movementInductances/transformers/magnets manufactureNeodymium iron boronEngineering

The invention relates to the field of processing of neodymium iron boron magnets, and in particular relates to automatic ring forming equipment of neodymium iron boron. The automatic ring forming equipment of neodymium iron boron comprises a chassis and further comprises a feeding mechanism, a weighing mechanism, a horizontal material moving mechanism, a hydraulic mechanism and a blanking mechanism; the feeding mechanism comprises a stirring tank; the stirring tank is vertically arranged at one end of the top of the chassis; a feeding hole is formed on the top of the stirring tank; a materialguide pipe is arranged at the bottom of the stirring tank; the weighing mechanism comprises a weighing guide component; the weighing guide component comprises a weighing temporary storage box; a material guide hole is arranged at one end of the weighing temporary storage box; the hydraulic mechanism comprises an upper mould component and a lower mould component; the horizontal material moving mechanism comprises a horizontal moving component and a feeding tank; the blanking mechanism comprises a material fetching component, a horizontal blanking mobile component and a blanking track; the horizontal blanking component is arranged at one side of the upper mould component; the material fetching component is positioned below the horizontal blanking component; and the blanking track is positioned below the material fetching component. By means of the automatic ring forming equipment of neodymium iron boron in the invention, automatic pressing and forming can be realized; furthermore, automatic feeding and blanking can be realized; and the production efficiency is increased.

Owner:COLLEGE OF APPLIED SCI JIANGXI UNIV OF SCI & TECH

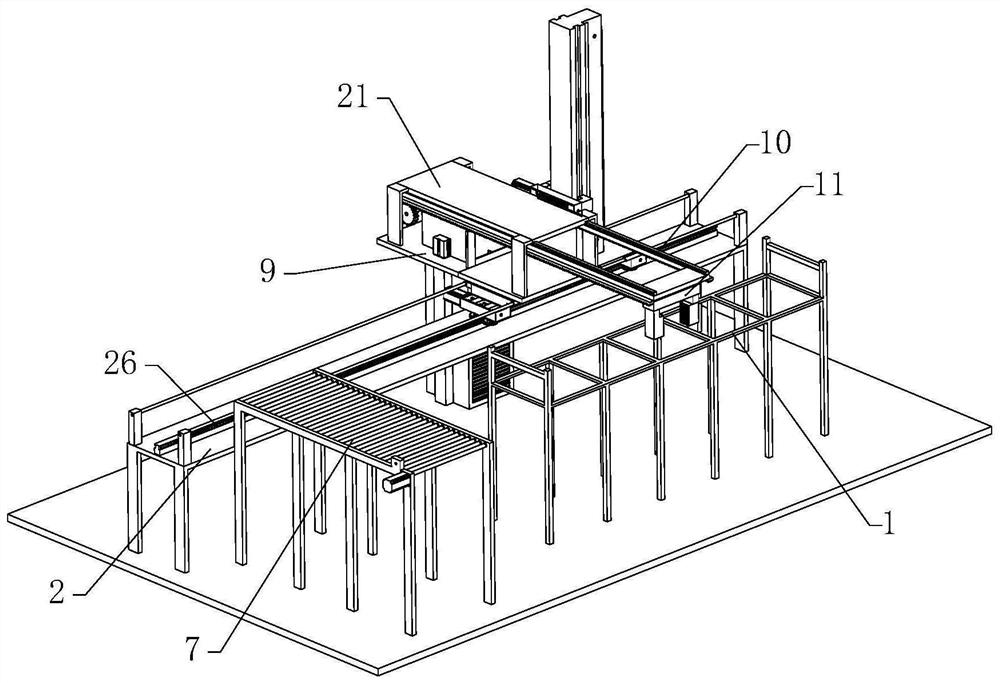

Low-temperature refrigeration house automatic cargo truck for large-batch shipment

ActiveCN112794055APlay the role of limit movementPrevent self-slipConveyor partsStructural engineeringReclaimer

The invention relates to the technical field of refrigeration houses, in particular to a low-temperature refrigeration house automatic cargo truck for large-batch shipment. The low-temperature refrigeration house automatic cargo truck comprises a goods shelf, a conveying sliding table, a moving mechanism, a lifting mechanism, a horizontal material taking mechanism, a material storage mechanism and a blanking conveyor; the moving mechanism comprises a moving plate capable of linearly moving along the conveying sliding table; the lifting mechanism is arranged at the top of the moving plate and comprises a lifting plate capable of ascending and descending; the horizontal material taking mechanism is arranged at the top of the lifting plate and comprises a telescopic frame capable of horizontally and telescopically moving, and a clamping jaw used for grabbing goods is arranged at the bottom of the tail end of the telescopic frame; and the material storage mechanism is arranged at the bottom of the lifting plate, the material storage mechanism comprises a material storage box for temporarily storing the goods and a lifting goods bearing plate, wherein the lifting goods bearing plate is used for bearing the goods in the material storage box and moves in a lifting mode. Through the arrangement, the goods can be loaded on a large scale and automatically conveyed and discharged in a sliding rail mode, and the goods discharging efficiency is improved.

Owner:福建易太食品发展有限公司

Heavy truck rim tumbling and polishing equipment

InactiveCN111409013APlay the role of limit movementFast deliveryEdge grinding machinesPolishing machinesGear wheelPolishing

The invention relates to the technical field of heavy truck machining, in particular to heavy truck rim tumbling and polishing equipment. The heavy truck rim tumbling and polishing equipment comprisesa rack, a hollow cylindrical material box capable of ascending and descending is arranged below one end of the rack, a lifting conveying table is arranged below the other end of the rack, a horizontal moving mechanism is arranged at the top of the rack, the horizontal moving mechanism comprises a moving frame capable of horizontally moving between the material box and the lifting conveying table,a gear rotating mechanism is arranged at the bottom of the moving frame, the gear rotating mechanism comprises a shifting column capable of rotating in the axis direction of the material box, a material taking mechanism is arranged at the bottom of the shifting column, and the material taking mechanism comprises a plurality of extrusion blocks which are circularly distributed and can abut againstthe inner wall of a rim. The heavy truck rim tumbling and polishing equipment can achieve automatic feeding and discharging, fully polishing the rim of a heavy truck can be carried out, and the polishing efficiency is improved.

Owner:陈壮

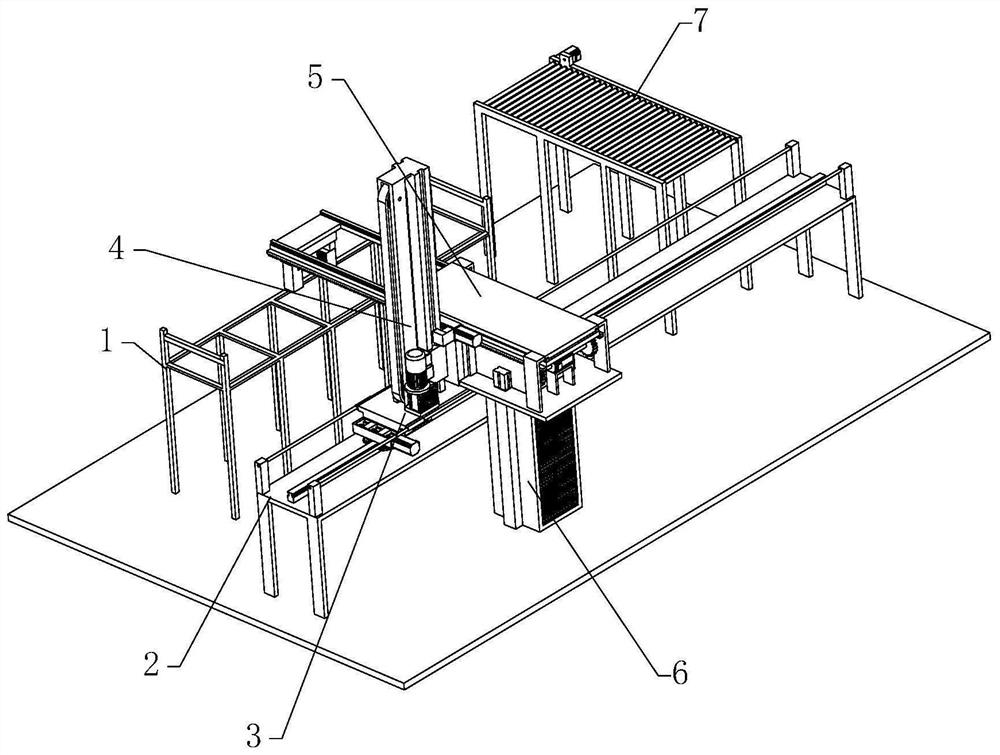

Sheet shearing device capable of synchronizing shearing and arranging

ActiveCN110695430AEasy to moveIncrease productivityMetal-working feeding devicesShearing machinesPunchingStructural engineering

The invention relates to the sheet material processing technology field, in particular to a sheet shearing device capable of synchronizing shearing and arranging. The sheet shearing device capable ofsynchronizing the shearing and the arranging comprises a processing table, wherein conveying assemblies are respectively arranged on two sides of the processing table, a through opening is formed in the processing table, a punching assembly is arranged above the through opening, a clamping assembly is arranged between the punching assembly and the through opening, the clamping assembly comprises two clamping positioning blocks, a punching sheet which can move into the through hole is arranged above the two clamping positioning blocks, a workpiece guiding rail is arranged below the processing table, one end of the top of the workpiece guiding rail and the through opening are set in a butting mode, the other end of the workpiece guiding rail extends towards one side of the processing table,a horizontal moving assembly is arranged above the workpiece guiding rail, the horizontal moving assembly comprises a moving plate, a workpiece fetching and material placing assembly is arranged on the moving plate, a workpiece arranging rail is arranged at one end of the workpiece guiding rail, and a plurality of storage boxes are arranged on the workpiece arranging rail. The sheet shearing device capable of synchronizing the shearing and the arranging precisely punches sheet materials, can automatically performs the arranging, and improves production efficiency of the sheet materials.

Owner:南通海拓机械有限公司

Alloy casting equipment

ActiveCN111906287APlay the role of limit movementSimple structureMelt-holding vesselsAlloyMaterial storage

The invention relates to the technical field of alloy casting, in particular to alloy casting equipment which comprises a base plate, a casting table, a rectangular lifting frame, a horizontal movingmechanism, a transverse moving mechanism, a casting material hopper and two material storage tanks. Casting moulds are arranged on two sides of the top part of the casting table along the length direction of the casting table at equal intervals; the horizontal moving mechanism comprises a moving transverse plate capable of oppositely moving between the two material storage tanks along the length direction of the rectangular lifting frame; the transverse moving mechanism comprises a transverse moving frame capable of transversely moving along the moving transverse plate; a discharging pipe is arranged at the lower end of the casting material hopper; an inverted-V-shaped material guiding pipe is arranged at the bottom of the discharging pipe; and two ends of the bottom part of each inverted-V-shaped material guiding pipe can be in butt joint with the casting moulds arranged on two sides of the casting table respectively. According to the technical scheme, the alloy casting equipment is simple in structure, and multiple workpieces can be cast at the same time at a time, so that the production efficiency is obviously improved; and meanwhile, the alloy casting equipment is high in automation degree, large in manual labor intensity and low in cost.

Owner:山西一禾铝业科技新材料有限公司

Automatic assembling equipment for medical mask breathing sheet

InactiveCN111227344APrevent slidingPlay the role of limit movementDomestic articlesProtective garmentUltrasonic weldingEngineering

The invention relates to the technical field of medical mask processing, in particular to automatic assembling equipment for medical mask breathing sheets. The equipment comprises a rack and a turntable, the equipment further comprises a positioning containing mechanism, a base feeding mechanism, a breathing sheet feeding mechanism, a clamping ring feeding mechanism, an ultrasonic welding mechanism and a discharging mechanism. The turntable is horizontally arranged above the rack; an index plate is arranged at the bottom of the rack; and the positioning containing mechanism, the base feeding mechanism, the breathing sheet feeding mechanism, the clamping ring feeding mechanism, the ultrasonic welding mechanism and the discharging mechanism are arranged at the top of the rack. The positioning containing mechanism comprises positioning assemblies corresponding to the output ends of the base feeding mechanism, the breathing sheet feeding mechanism, the clamping ring feeding mechanism, theultrasonic welding mechanism and the discharging mechanism in a one-to-one mode. Each positioning assembly is arranged on the turntable and comprises four clamps used for clamping workpieces, the breathing pieces and the breathing valves can be automatically and sequentially assembled in batches through the equipment, and the production efficiency is improved.

Owner:孟晓辉

Agricultural ecological analysis water and soil sampling device based on Internet

InactiveCN114791370AAbsorb smoothlyEasy dischargeWithdrawing sample devicesGrain treatmentsThe InternetEcological analysis

The invention discloses an agricultural ecological analysis water and soil sampling device based on the Internet, the agricultural ecological analysis water and soil sampling device comprises a frame, bottom wheels, an Internet control main body, a sampling mechanism, a storage battery and a charging interface, the bottom wheels are connected to four ends of the bottom of the frame, and the optimally arranged sampling mechanism is fixed to one side of the top of the frame; the sampling mechanism integrally performs remote operation on a terminal through an internet control main body, and after a sampling position is selected, the sampling mechanism is inserted into soil through a positioning support structure to increase the integral support strength during sampling, so that the problem of tipping in the sampling process is avoided; the soil sampling structure is matched with the inner cylinder sleeve, the outer cylinder sleeve and the telescopic rod, so that the soil can be conveniently discharged after being sampled; furthermore, the water sampling structure can be prevented from being blocked by sundries when absorbing a water sample under the action of a chopping assembly at the water absorbing end of the pipe fitting, so that the water sample can be smoothly collected, and the working efficiency of water and soil sampling is improved to a certain extent.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS +1

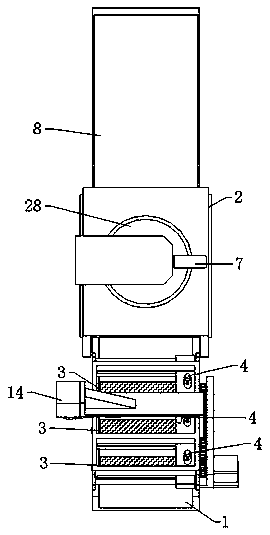

Automatic loading stamping equipment

InactiveCN111745070APlay the role of limit movementStable guided conveyingMetal-working feeding devicesPositioning devicesStructural engineeringMachine

The invention relates to the technical field of stamping equipment, in particular to automatic loading stamping equipment. The automatic loading stamping equipment comprises a rack, a receiving mechanism, a putting mechanism, a stamping mechanism and a guide mechanism, the stamping mechanism comprises a stamping table mounted in the middle end of the top of the rack, the top of the stamping tableis provided with a stamping machine, the putting mechanism comprises a vertical support, a first putting mechanism and a second mechanism, the guide mechanism comprises an extension vertical plate mounted on the side, close to the stamping table, of the vertical support, an upper end guide wheel and a lower end guide wheel, the upper end guide wheel and the lower end guide wheel are arranged on the upper end and the lower end of the vertical face of the extending vertical plate correspondingly, the receiving mechanism is located on the side, away from the guide mechanism, of the stamping table, the receiving mechanism is mounted on the rack and comprises a receiving machine used for receiving, the equipment is provided with multiple putting wheels, when strips on one putting wheel are usedup, the other putting wheel with the strips can be efficiently converted for conveying, and the production efficiency is improved.

Owner:贾涛

Heterogeneous end cover assembling equipment

InactiveCN111390495APlay the role of limit movementReduce the temperatureMetal working apparatusPhysicsHot work

The invention relates to the technical field of heterogeneous end cover assembling, in particular to heterogeneous end cover assembling equipment. The equipment comprises a processing table and further comprises an end cover pushing mechanism, a flexible shaft locating pushing mechanism, a horizontal movement mechanism and a bidirectional heating mechanism, wherein the end cover pushing mechanismcomprises a butt-joint jig, a clamping groove is formed in the end, adjacent to the flexible shaft locating pushing mechanism, of the butt-joint jig, an end cover body is detachably arranged inside the clamping groove, the flexible shaft locating pushing mechanism comprises a flexible shaft sliding rail and two guide components, a locating groove used for containing a workpiece is formed in the flexible shaft sliding rail, a plurality of guide wheels are arranged on each guide component, the bidirectional heating mechanism comprises two arc-shaped heating pipes, a rectangular through opening used for avoiding movement of each arc-shaped heating pipe is formed in the processing table, and the bidirectional heating mechanism comprises a pushing plate which can move horizontally in the lengthdirection of the end cover body. Through the equipment, a heterogeneous end cover can be assembled automatically, the uniformity of the surface of the hot-worked heterogeneous end cover is improved,and processing quality is improved.

Owner:美弗莱克斯控制系统(嘉兴)有限公司

Assembly device for segmental prefabricated assembled bridge joint structure

ActiveCN111501556AAvoid bendingPlay the role of limit movementBridge erection/assemblyClassical mechanicsStructural engineering

The invention relates to the technical field of segmental prefabricated assembled bridges, in particular to an assembly device of a segmental prefabricated assembled bridge joint structure. The devicecomprises a machining table, an opposite moving mechanism is arranged at the top of the machining table; the opposite moving mechanism comprises two moving frames which are horizontally and symmetrically arranged; a lifting abutting mechanism is arranged between the two moving machines. A horizontally arranged placing table is arranged above each moving frame; a sliding groove is formed in the top of each containing table. Positioning grooves are respectively formed in the adjacent ends of two placing tables; a lifting mechanism is arranged below one end, close to the positioning groove, of each placing table; a first positioning mechanism capable of abutting against a workpiece is arranged above each lifting mechanism. A horizontal moving mechanism is further arranged below each placingtable, the working end of each horizontal moving mechanism is provided with a second positioning mechanism capable of abutting against a corresponding workpiece, the equipment can automatically assemble the segmental prefabricated assembled bridge joint, labor force is reduced, and efficiency is improved.

Owner:江苏永捷特种装备有限公司

Flange multi-angle drilling integrated equipment

InactiveCN111203565APlay the role of limit movementLow costFeeding apparatusMetal working apparatusPhysicsScrap

The invention relates to the technical field of flange processing, in particular to flange multi-angle drilling integrated equipment. The flange multi-angle drilling integrated equipment comprises a machining table. A horizontal moving assembly is arranged on the machining table. The horizontal moving assembly comprises a horizontal moving plate capable of horizontally moving on the machining table. A transverse adjusting assembly is arranged on the horizontal moving plate. The transverse adjusting assembly comprises a transverse moving plate. An electric rotary disk is arranged on the top ofthe transverse moving plate. A rotary plate is arranged above the electric rotary disk. The top of the rotary plate is provided with clamping jaws. A scrap collection assembly is arranged at one end of the bottom of the transverse moving plate. A side drilling mechanism and a top drilling mechanism are arranged at the two ends of the machining table correspondingly. The side drilling mechanism comprises a first lifting assembly, a transverse moving assembly and a side drilling machine. The top drilling mechanism comprises a second lifting assembly and a top drilling machine. The two sides of the manufacturing table are provided with a feed conveying table and a discharge conveying table correspondingly. The flange multi-angle drilling integrated equipment can conduct automatic feeding anddischarging and can also conduct multi-angle drilling on a flange, reduce the cost and improve the production efficiency.

Owner:杨浩

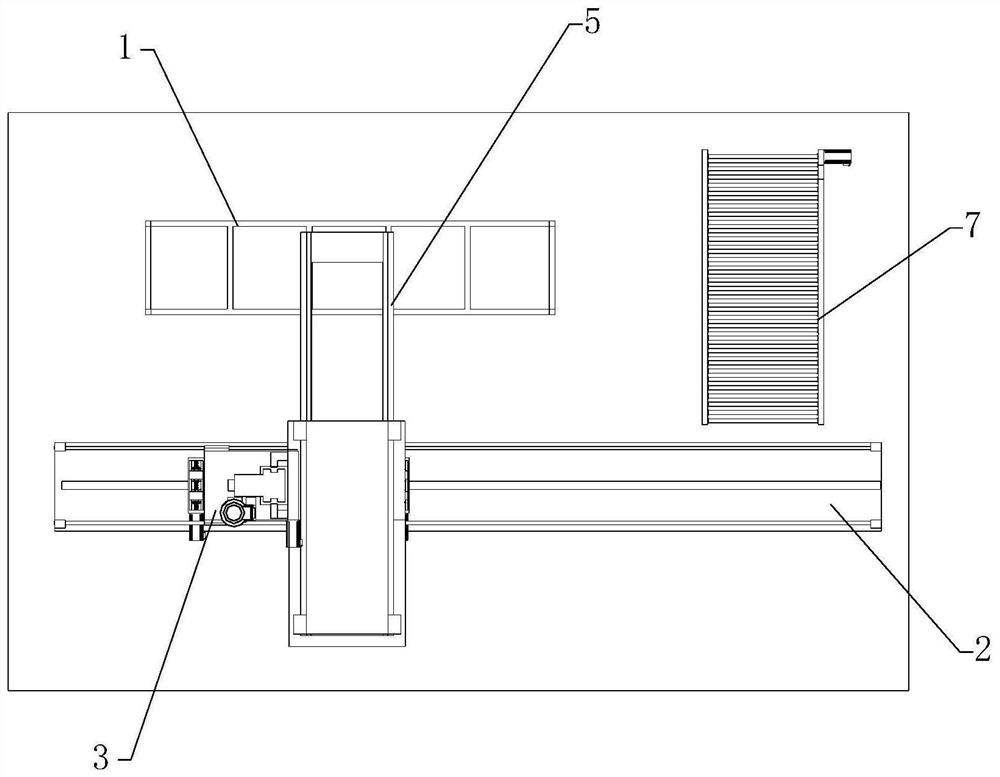

Hollow glass automatic glue mechanism

ActiveCN110817427APlay the role of limit movementAccurate automatic overlayConveyor partsEngineeringMachining

The invention relates to the technical field of glass machining, in particular to a hollow glass automatic glue mechanism. The mechanism comprises a glue machine, and further comprises a machining table, a loading assembly and a taking assembly. The top of the machining table is provided with an operation table used for machining of glass, the glue machine is arranged on one side of the operationtable, the loading assembly is located on the other side, away from the glue machine, of the operation table, the loading assembly comprises a loading rail horizontally arranged, the taking assembly is located between the operation table and the loading rail, and the taking assembly comprises a taking clamping jaw moving between one end of the taking assembly and a table board of the operation table. Through the mechanism, glass required to be glued is precisely automatically stacked, and the machining efficiency is improved.

Owner:王志伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com