Alloy casting equipment

A kind of equipment and alloy technology, which is applied in the field of alloy casting equipment, can solve the problems of high labor intensity, low production efficiency, and cooling for a period of time before it can be taken out of the mold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

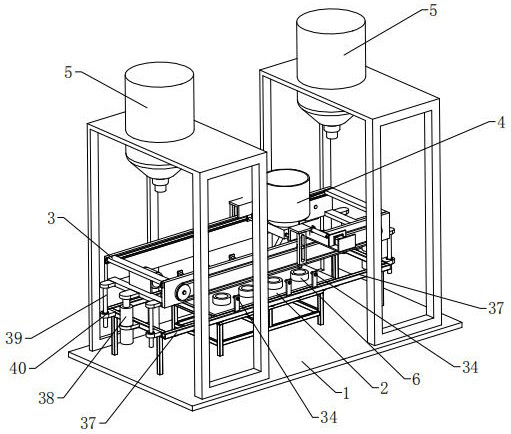

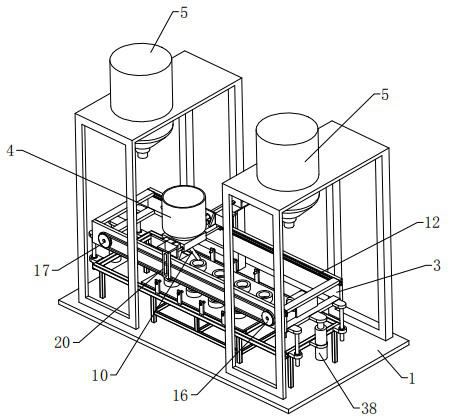

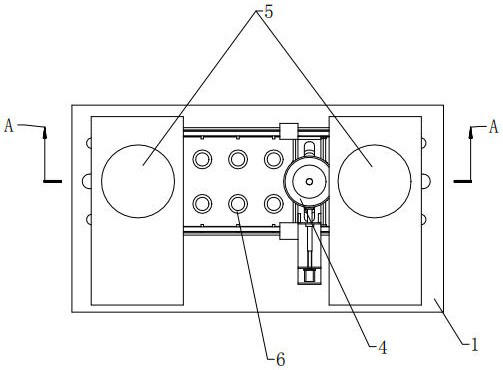

[0030] refer to Figure 1 to Figure 11 As shown, an alloy casting equipment includes a base plate 1, a casting table 2, a rectangular lifting frame 3, a horizontal movement mechanism, a lateral movement mechanism, a casting material bucket 4 and two reserve material tanks 5, and the casting platform 2 is set on the base plate 1 On both sides of the top of the casting table 2, casting molds 6 are arranged at equal intervals along the length direction of the casting table 2. The rectangular lifting frame 3 is horizontal and can be lifted directly above the casting table 2. Two reserve material tanks 5 It is erected symmetrically above the two ends of the rectangular lifting frame 3, and the horizontal moving me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com