Patents

Literature

39results about How to "Manual labor intensity is high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

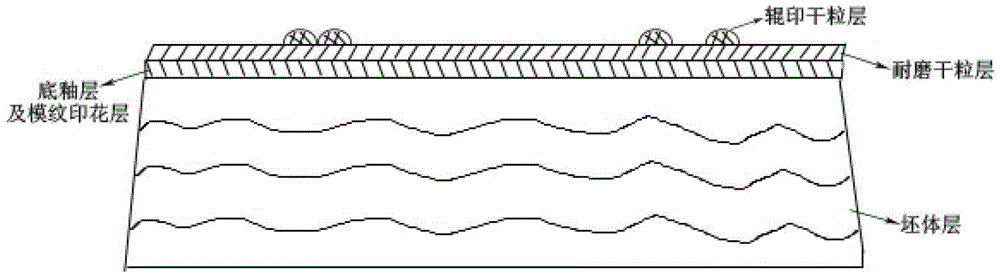

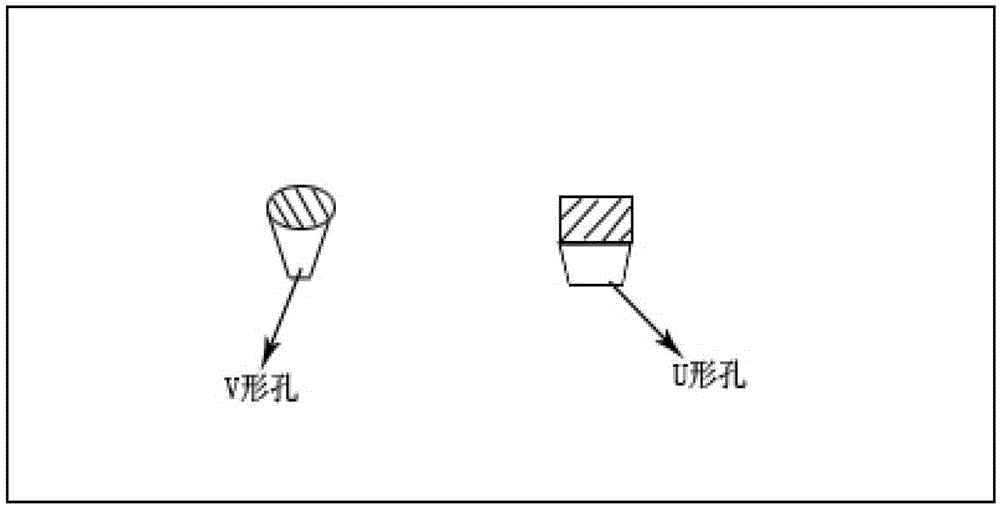

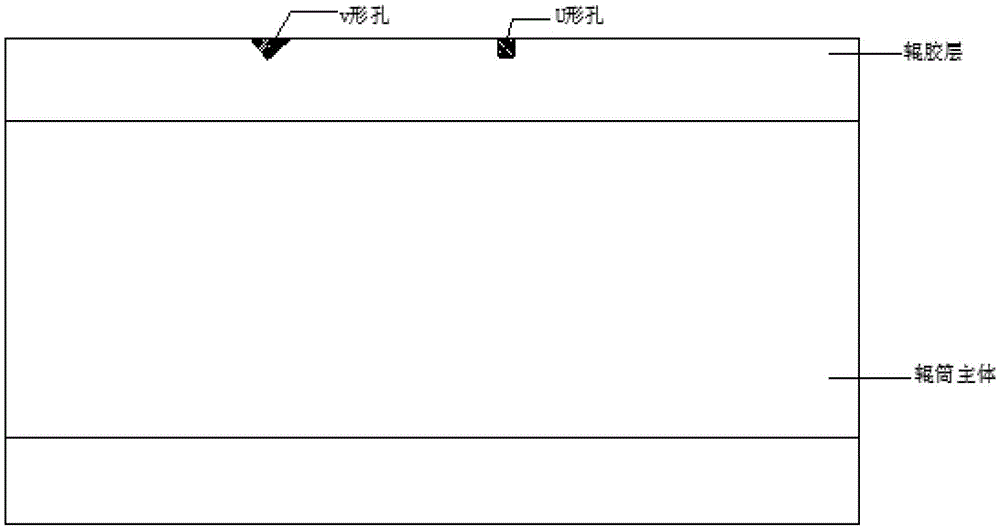

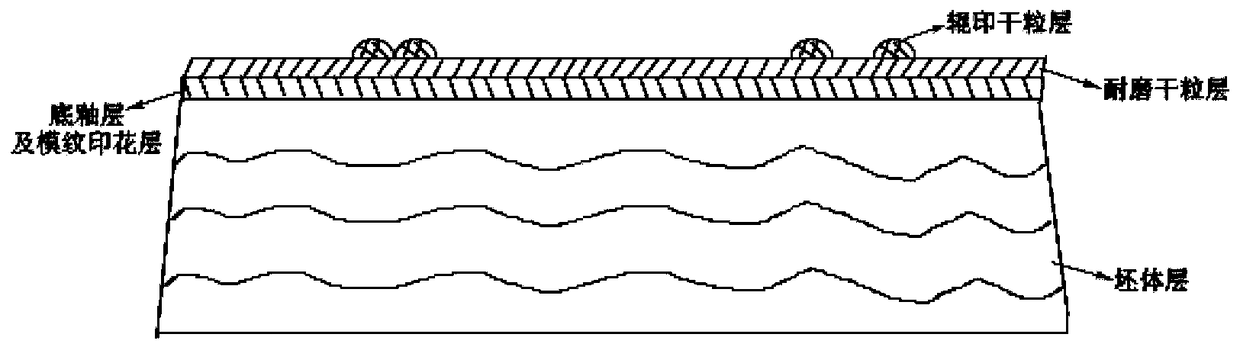

Composite roller printing dry grain three-dimensional ceramic tile and production technology thereof

The present invention relates to a composite roller printing dry grain three-dimensional ceramic tile and a production technology thereof, the composite roller printing dry grain three-dimensional ceramic tile comprises, in order from bottom to top, a blank layer, a bottom glaze layer, a mold pattern layer, an anti-wear dry grain layer and a colored embossed dry grain layer, wherein the anti-wear dry grain layer comprises anti-wear dry grains, the particle size of the anti-wear dry grains is 200 to 250 mesh, the colored embossed dry grain layer comprises colored dry grains, and the particle size of the colored dry grains is 120 to 140 mesh. The mold pattern layer and the colored embossed dry grain layer are matched with each other, so that the composite roller printing dry grain three-dimensional ceramic tile has rich patterns and hierarchy; the anti-wear dry grain layer and the colored embossed dry grain layer can increase skid and wear resistance of the ceramic tile, and enhance stereoscopic impression, the anti-wear dry grain layer with the smaller the particle size is closely linked, increases the contact area with a contact substance, increases friction area, and enhances product skid resistance; and the colored embossed dry grain layer with the larger particle size increases embossing thickness and enhances the stereoscopic impression and anti-wear ability of the product.

Owner:MONALISA GRP CO LTD

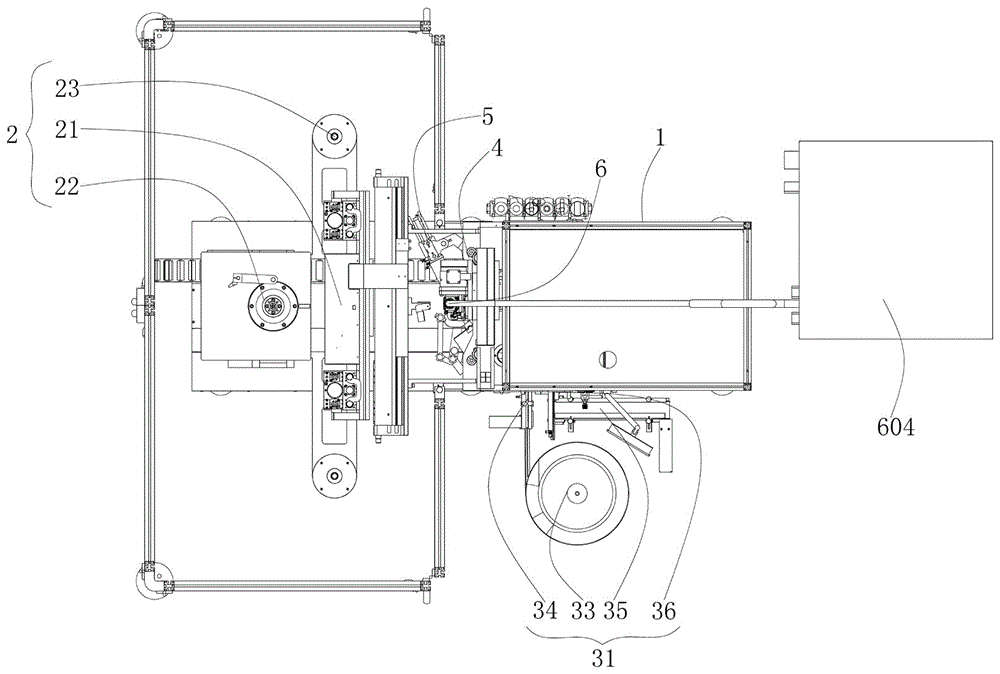

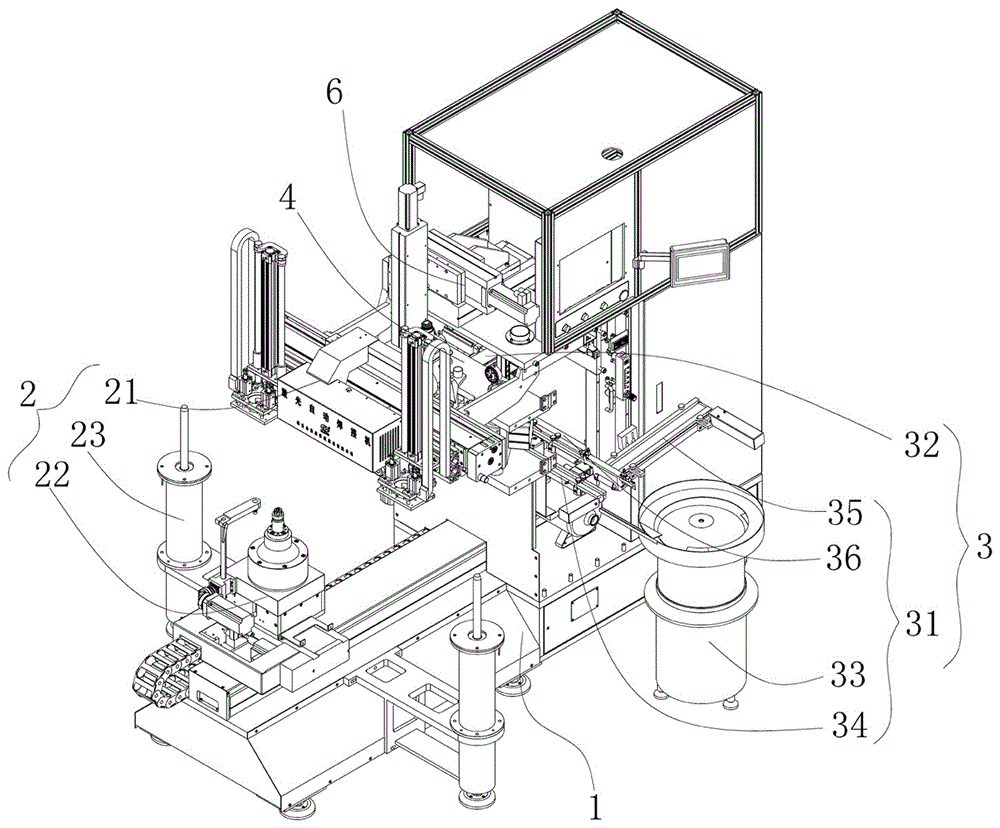

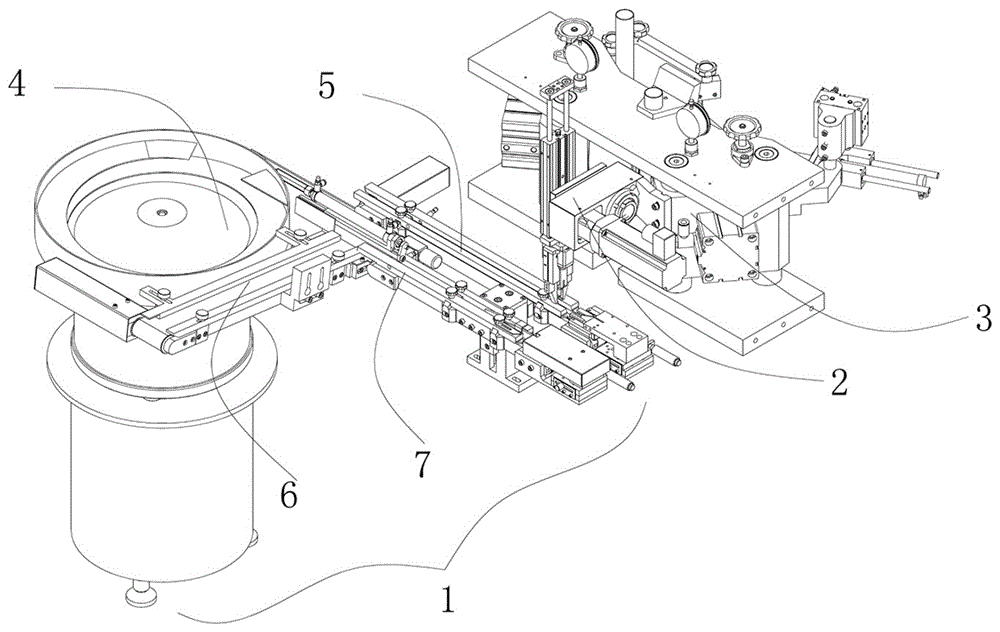

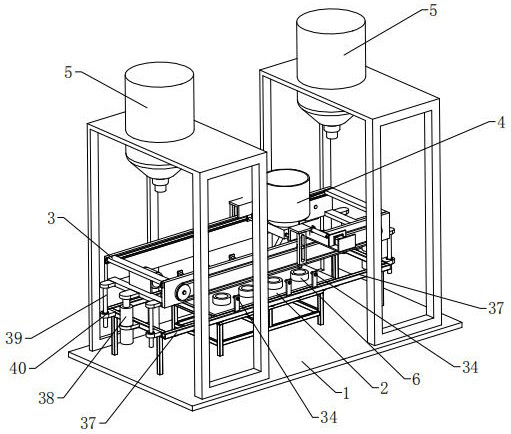

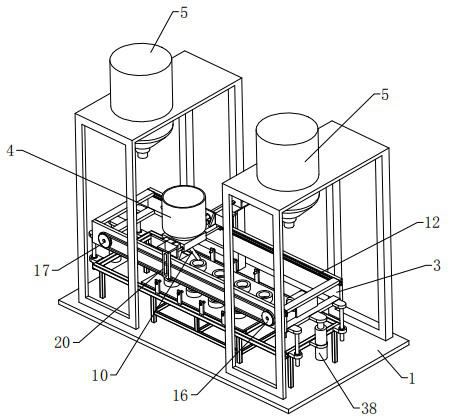

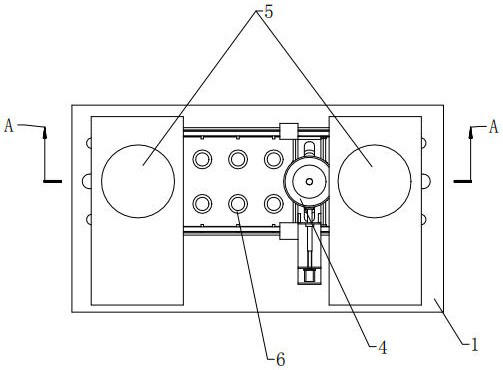

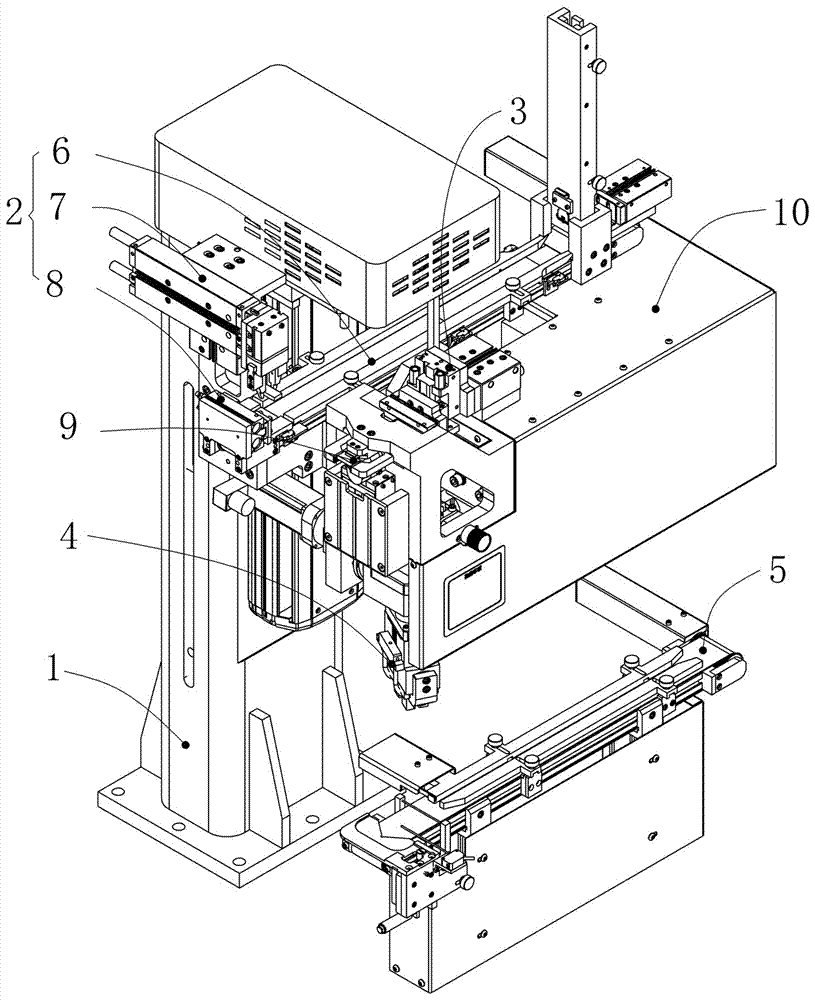

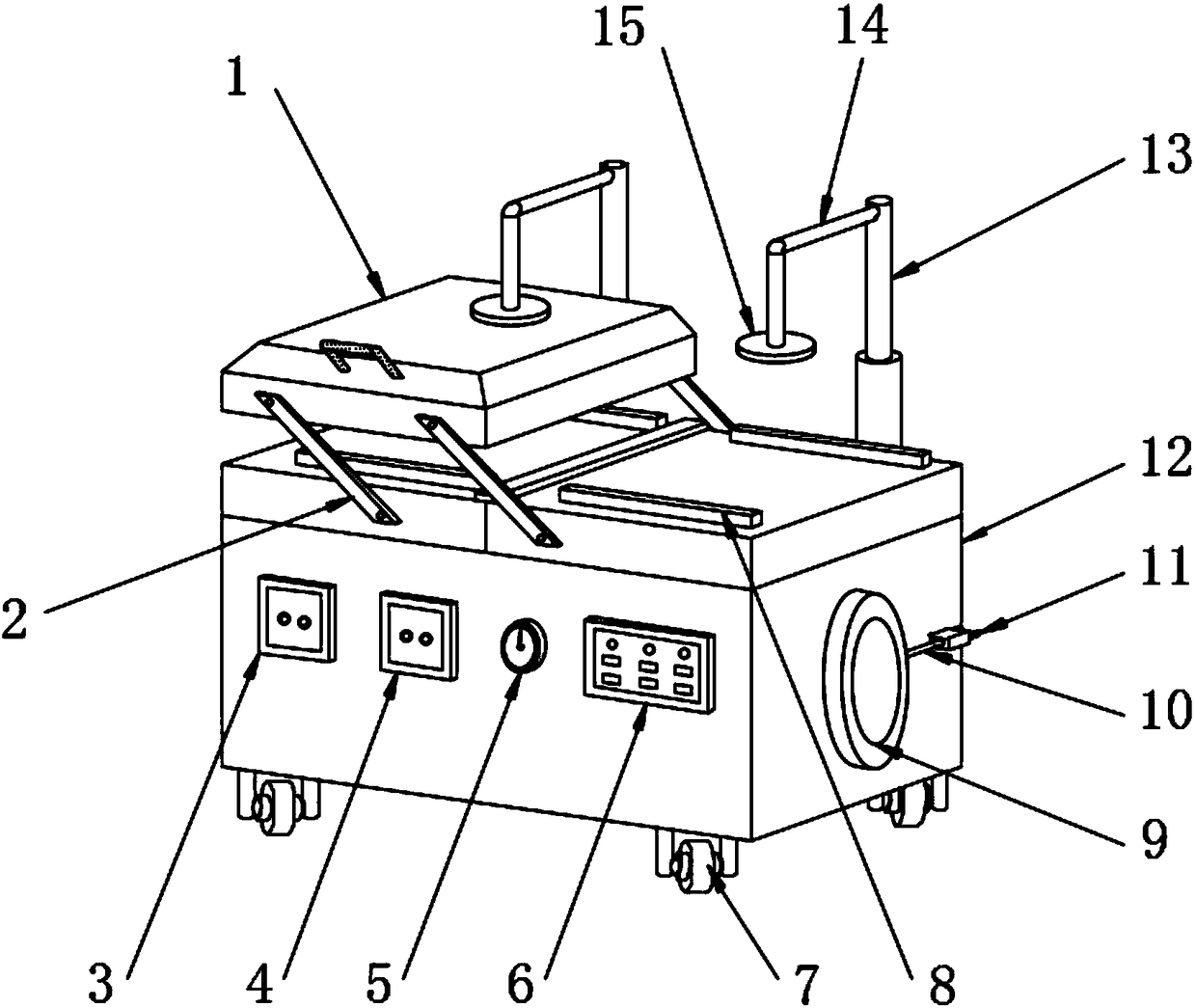

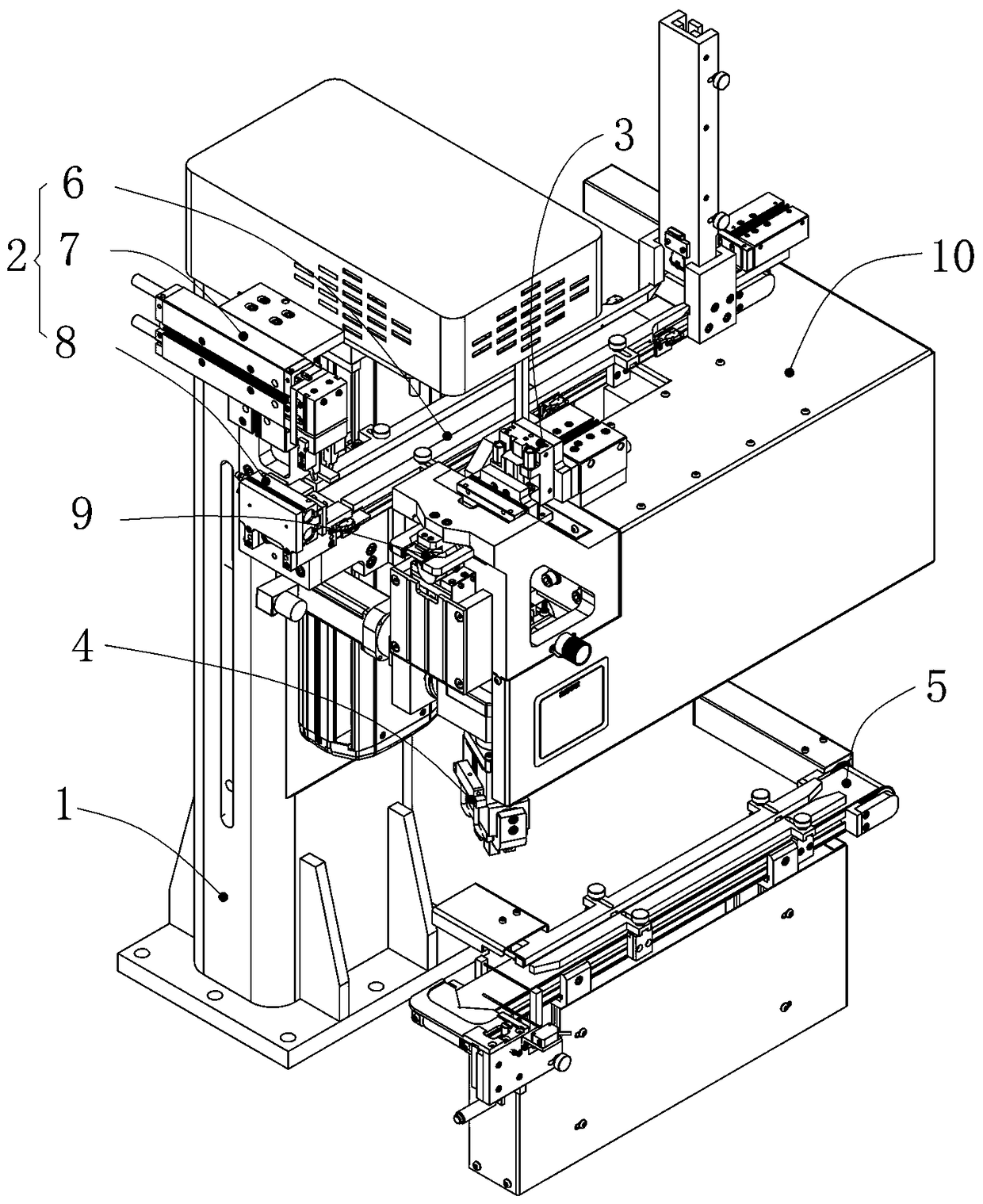

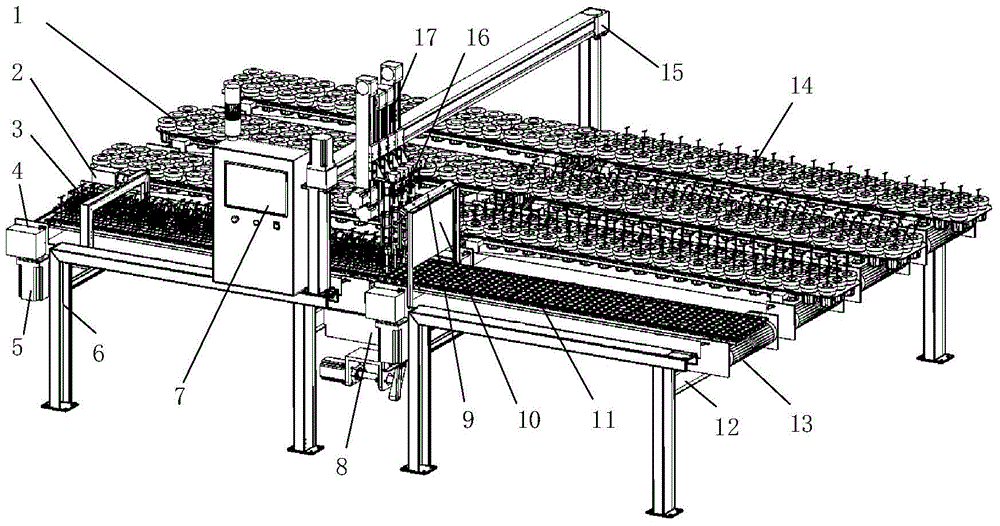

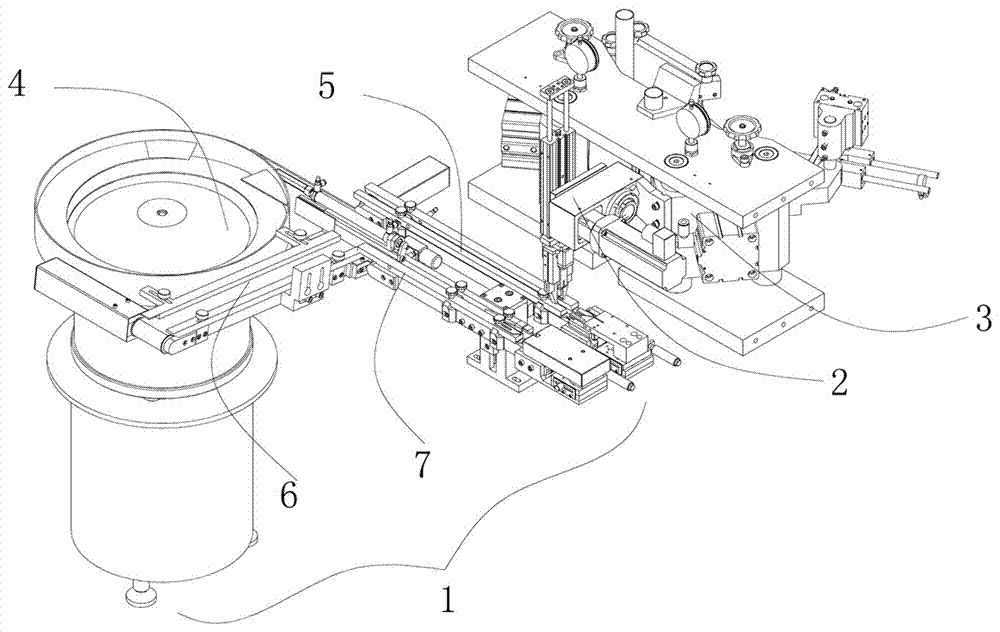

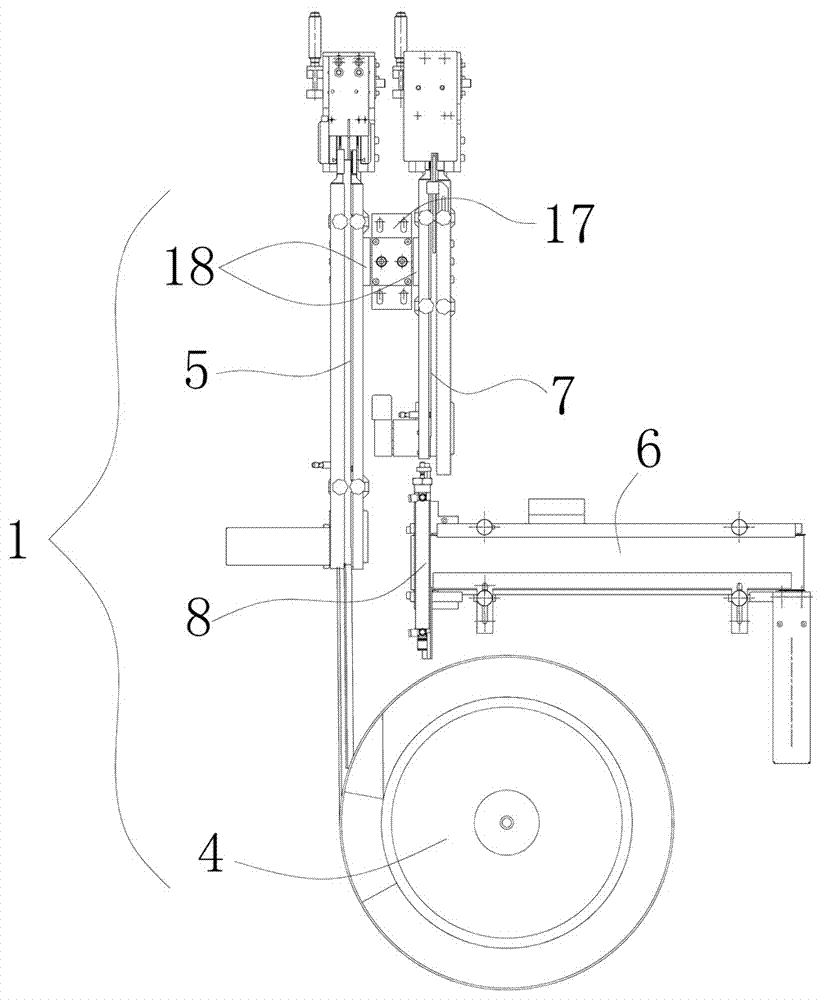

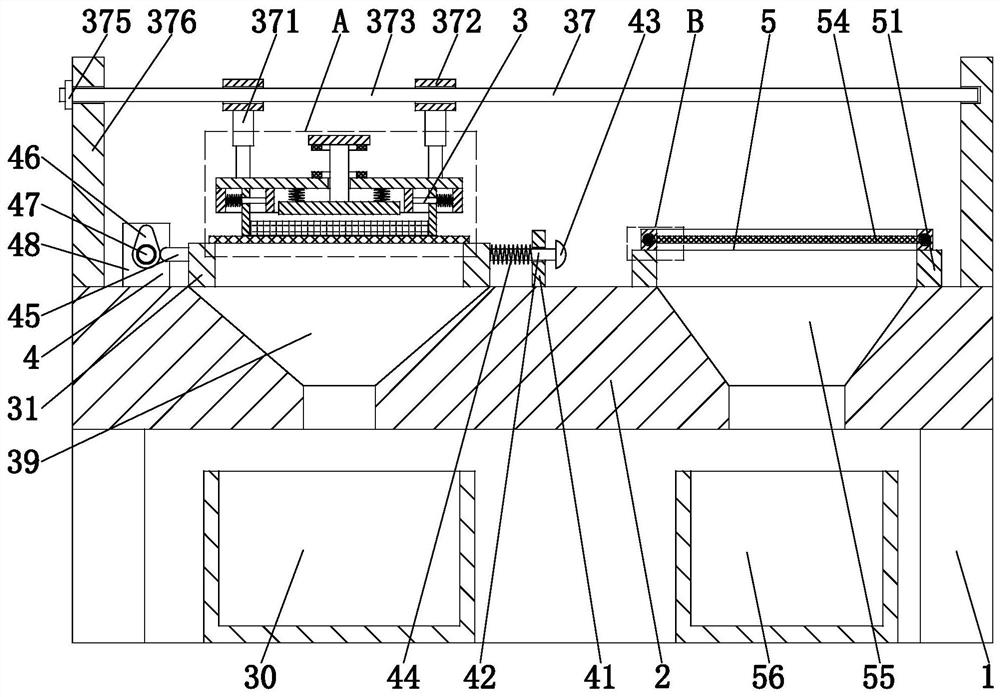

Laser automatic welding machine for diamond saw blades

ActiveCN106425095AHigh degree of mechanizationReduce manufacturing costLaser beam welding apparatusHigh volume manufacturingEngineering

The invention belongs to the technical field of diamond saw blade welding, and particularly relates to a laser automatic welding machine for diamond saw blades. The machine comprises a machine body, a saw blade absorbing grabbing system, a base body rotary indexing system, a tool bit conveying grabbing system, a welding clamping assembling system and a laser welding light path system; saw blade base bodies and tool bits are grabbed and subject to alignment pairing through the saw blade absorbing grabbing system and the tool bit conveying grabbing system, clamping positioning is completed through the welding clamping assembling system, and welding is carried out through the laser welding light path system; after the tool bits are welded, the saw blade base bodies are rotated to the next welding station through the base body rotating indexing system until the tool bits on the saw blade base bodies are welded, and the finished product saw blades are conveyed and discharged to the storing position through the saw blade absorbing grabbing system. The machine is a producing machining device which is high in speed, free of contact and small in deformation, large-batch production can be achieved, the welding strength is high, in the cutting and using process, the tooth disengaging phenomenon is avoided, and use safety of the machine is greatly improved.

Owner:郑州金海威科技实业有限公司

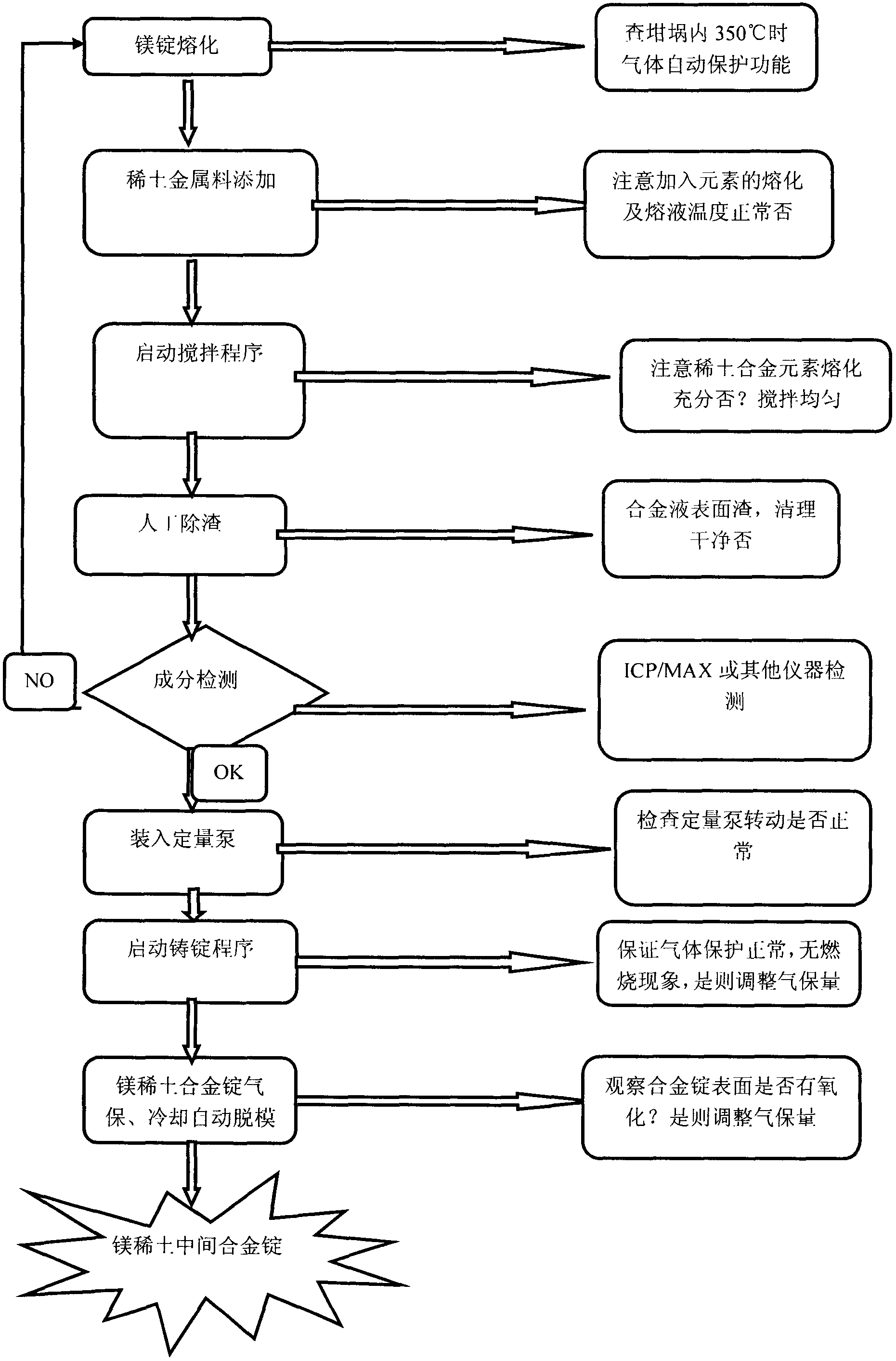

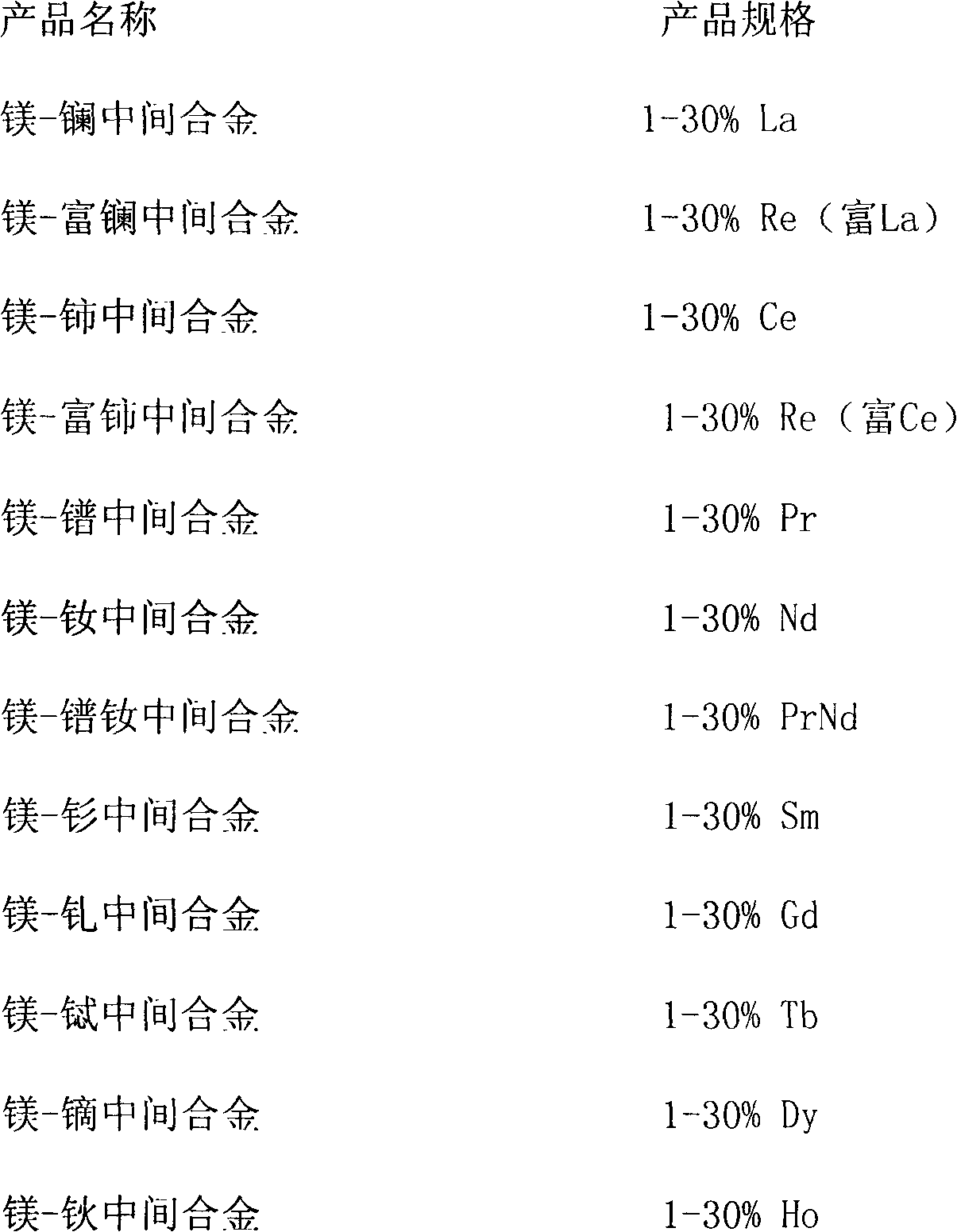

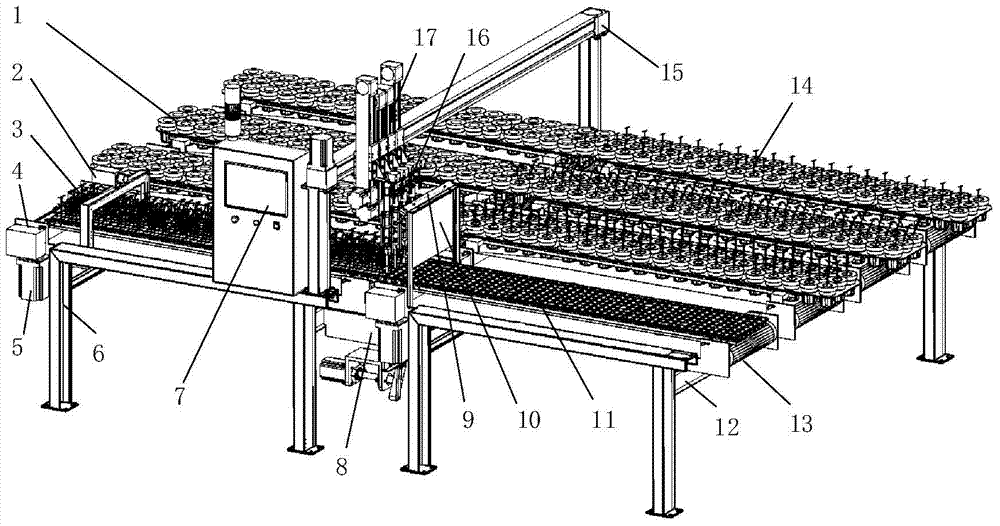

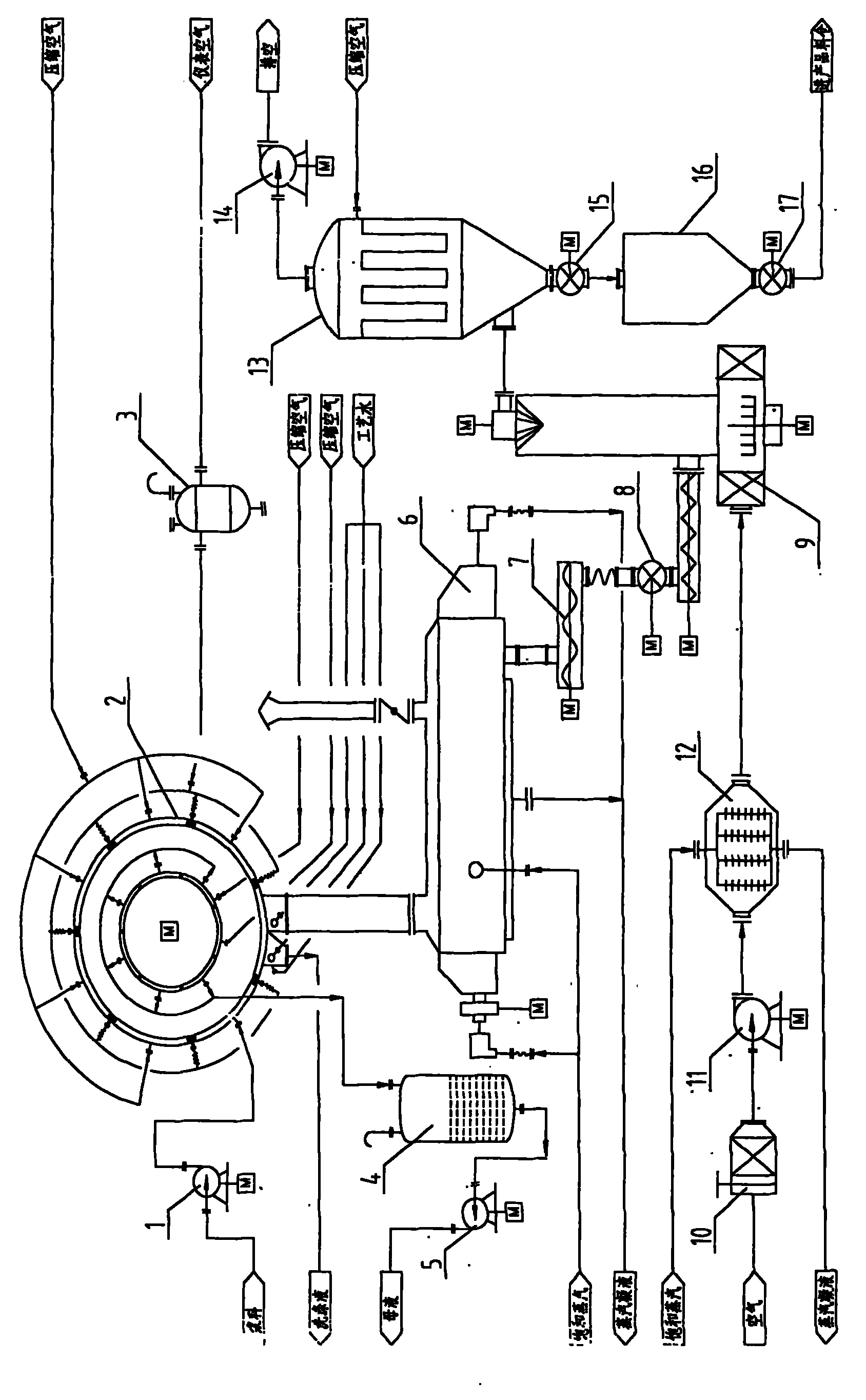

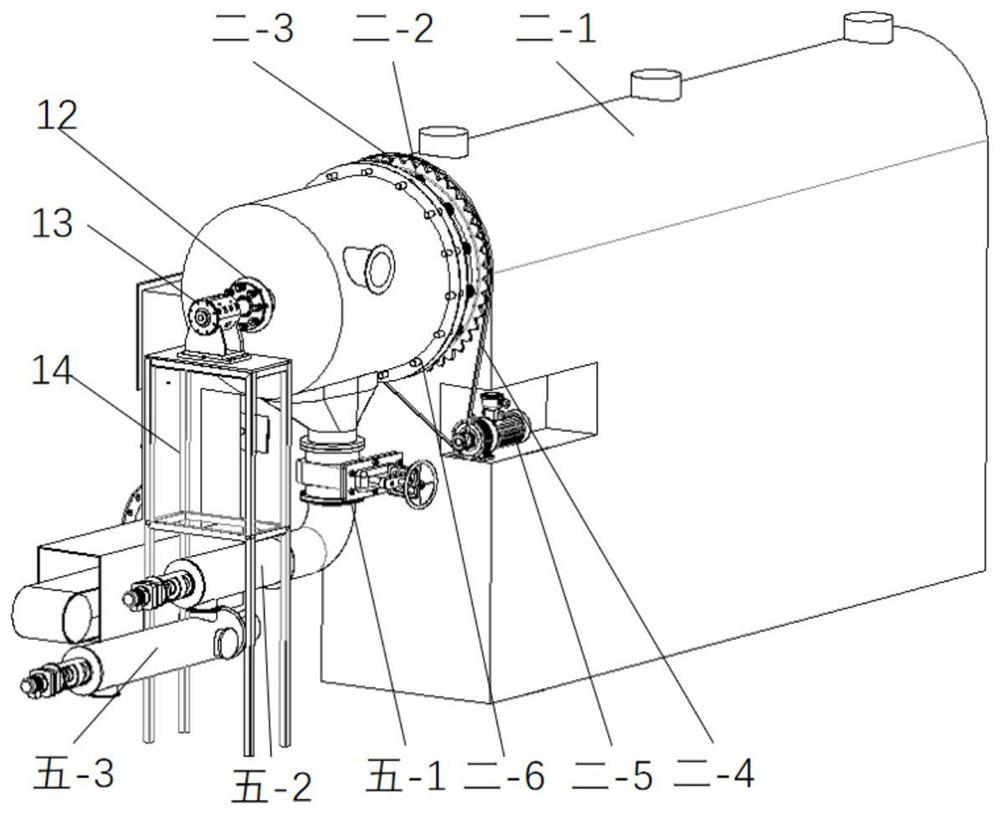

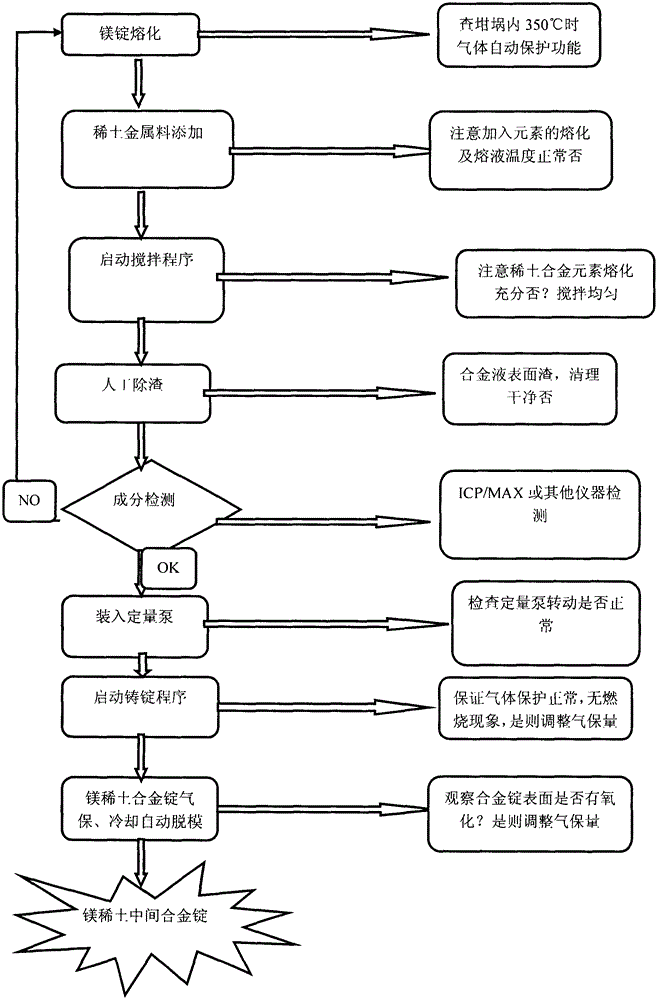

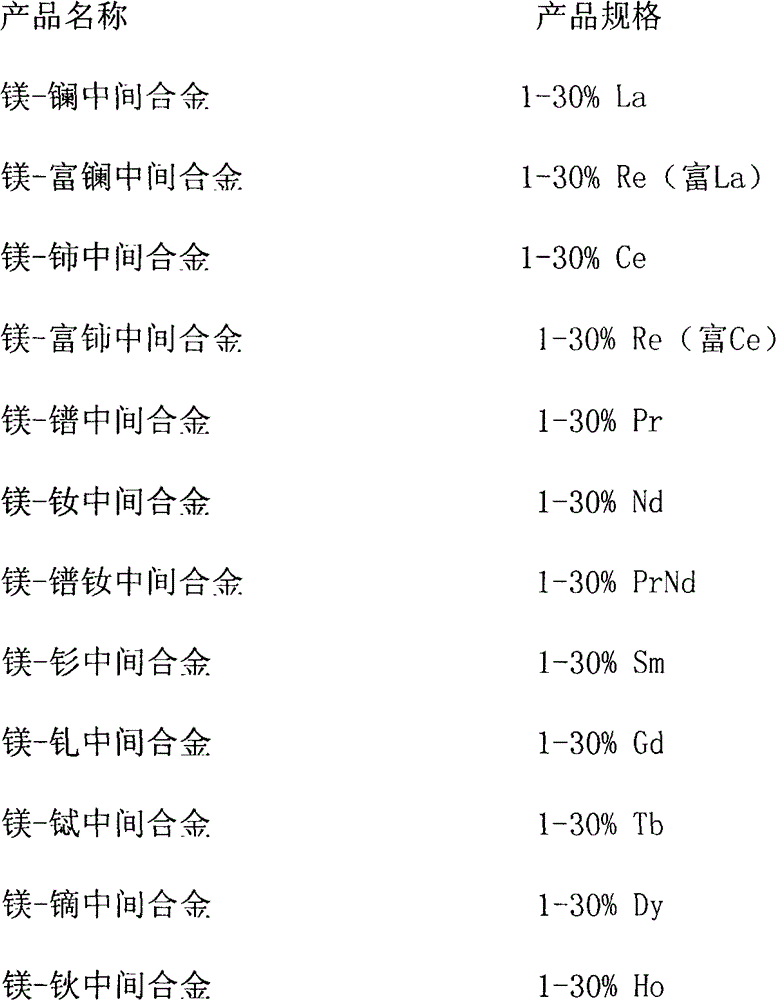

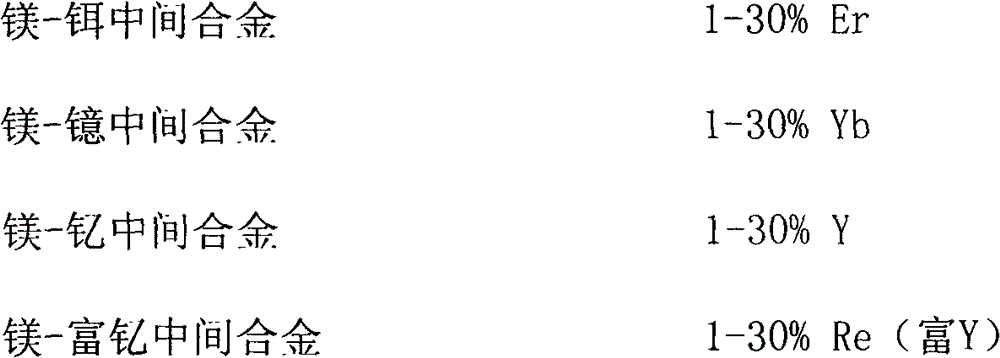

Method for continuously and automatically producing magnesium-rare earth intermediate alloys

ActiveCN103540777ASafe and efficient productionNo pollution in the processMolten metal pouring equipmentsRare earthNickel free

The invention discloses a method of continuously and automatically producing 16 magnesium-rare earth intermediate alloys such as a magnesium-neodymium intermediate alloy. The method comprises the following steps: after melting a magnesium ingot raw material by a finery, adding a rare earth metal material, manually deslagging, and automatically stirring and homogenizing by a system, and sampling and testing alloy components which are qualified; then pouring an alloy liquid to an ingot case of a pig moulding machine through a metering pump to form a continuous and automatic ingot casting; and cooling the alloy liquid to form standard magnesium-rare earth intermediate alloys. The key point of the invention is as follows: the method is applicable to continuous and automatic ingot casting production of 16 magnesium-rare earth intermediate alloys such as the magnesium-neodymium intermediate alloy, so that the labor intensity of production is reduced, and the production safety is greatly improved in anhydrous environment production. The produced product is consistent and high in yield. According to a crucible manufactured by a nickel-free high temperature alloy steel plate, carbon content is not introduced in the production process, the production efficiency is high, and the method is applicable to continuous production on a large scale, free from environmental pollution. Waste residues can be recycled, thereby truly realizing safe and efficient production of the magnesium-rare earth intermediate alloys on a large scale.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

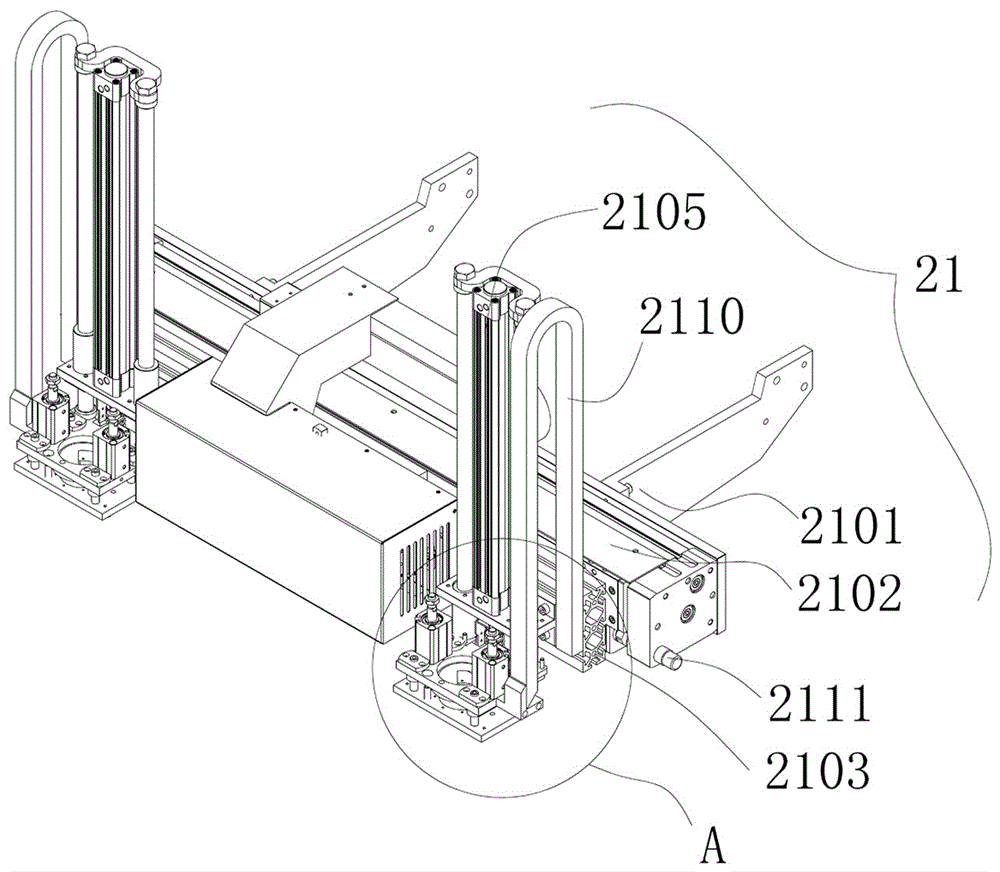

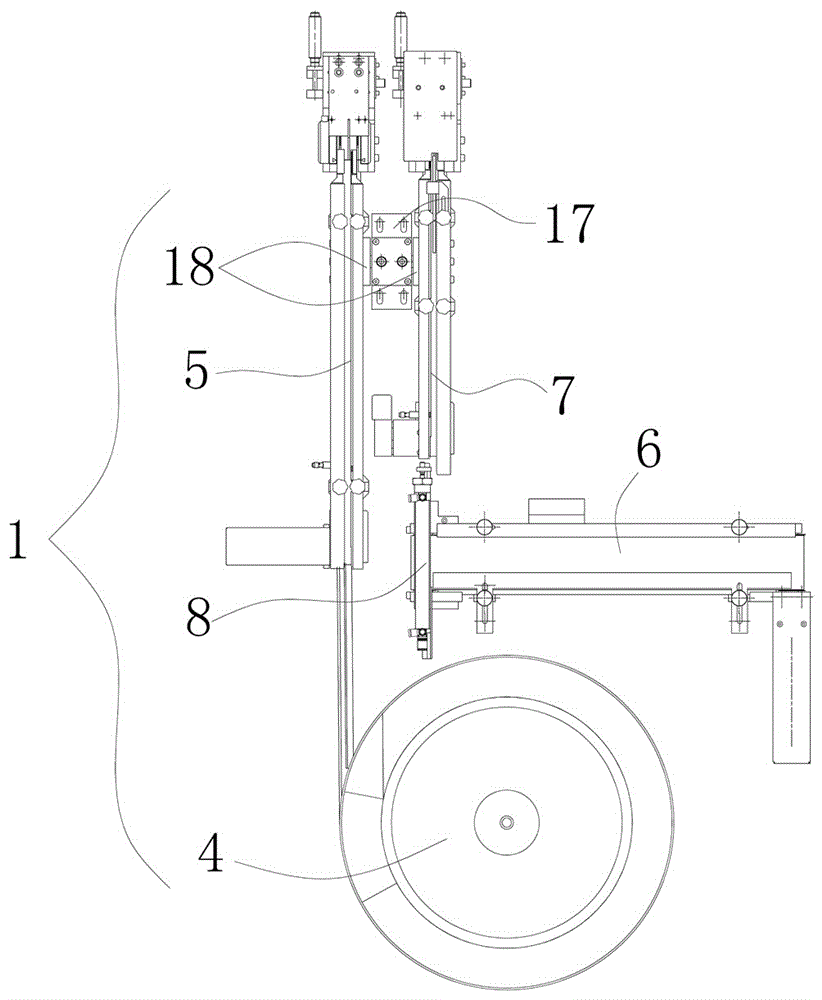

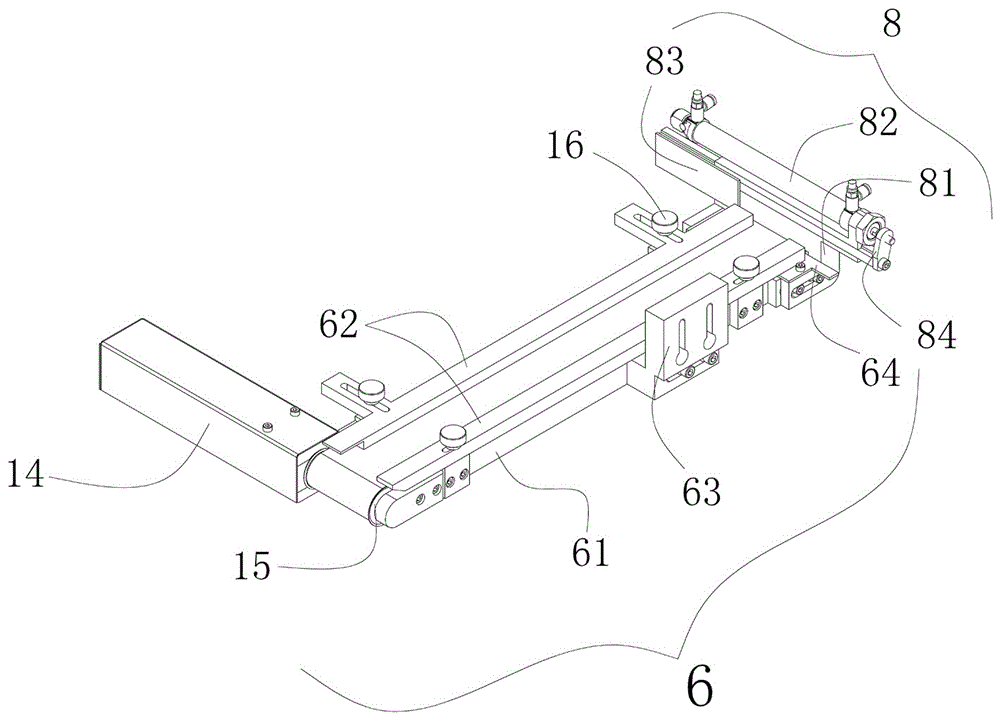

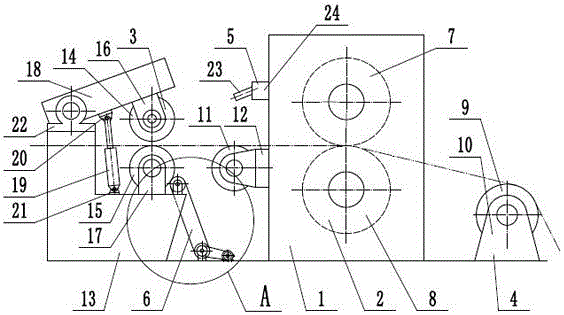

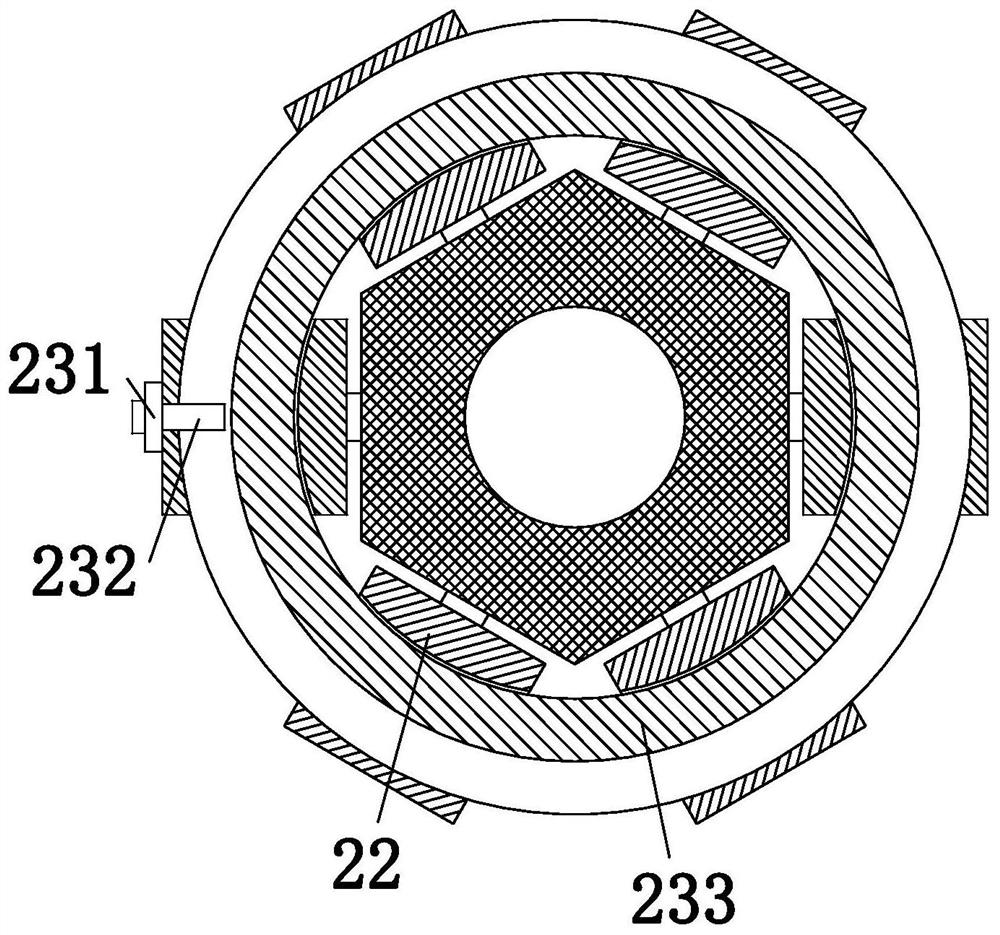

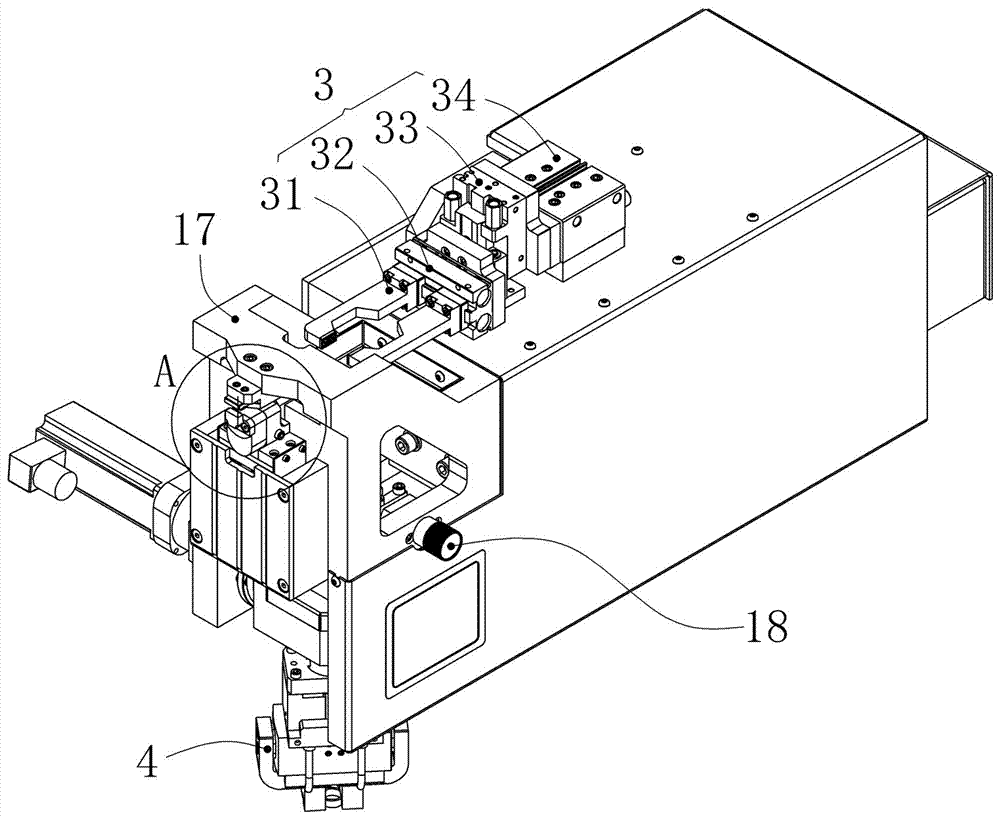

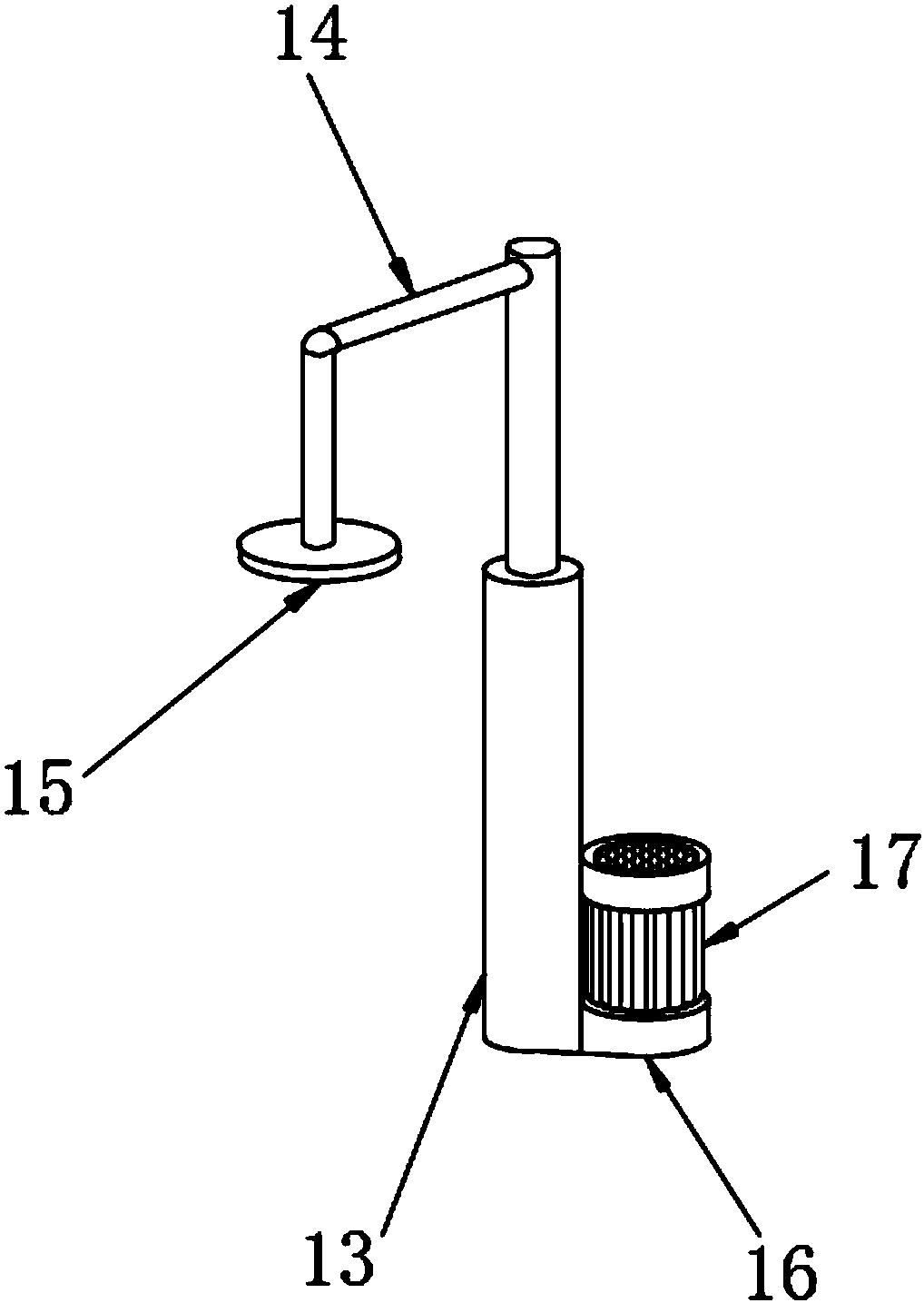

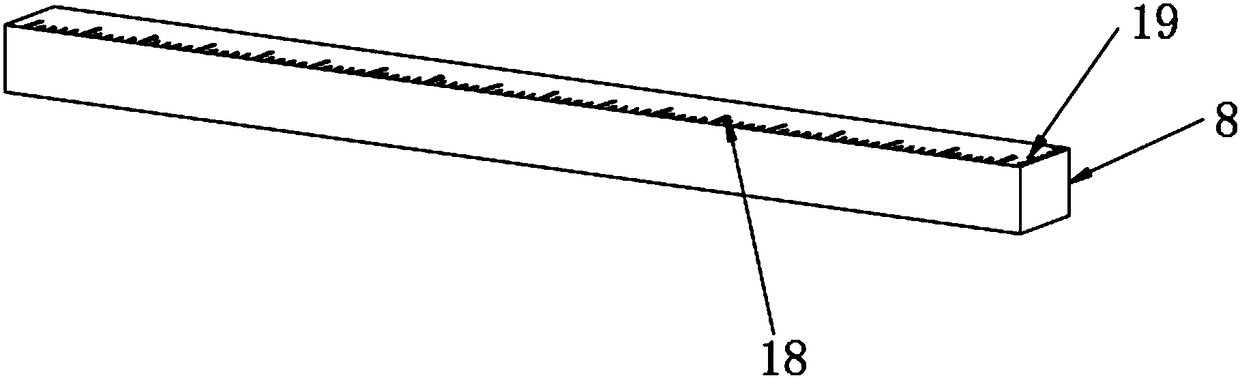

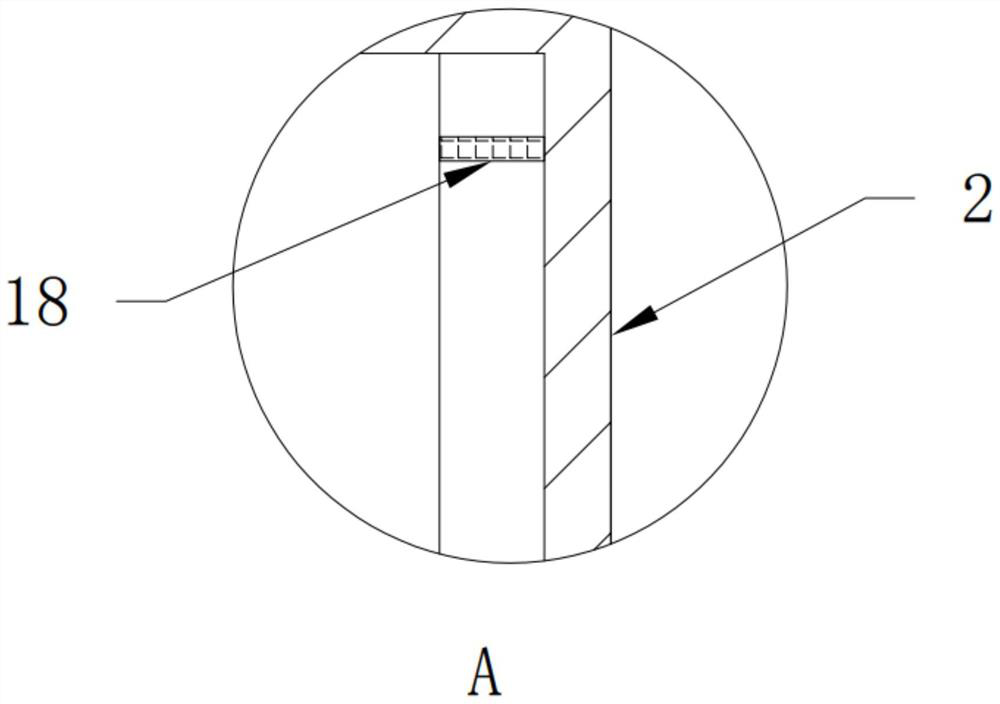

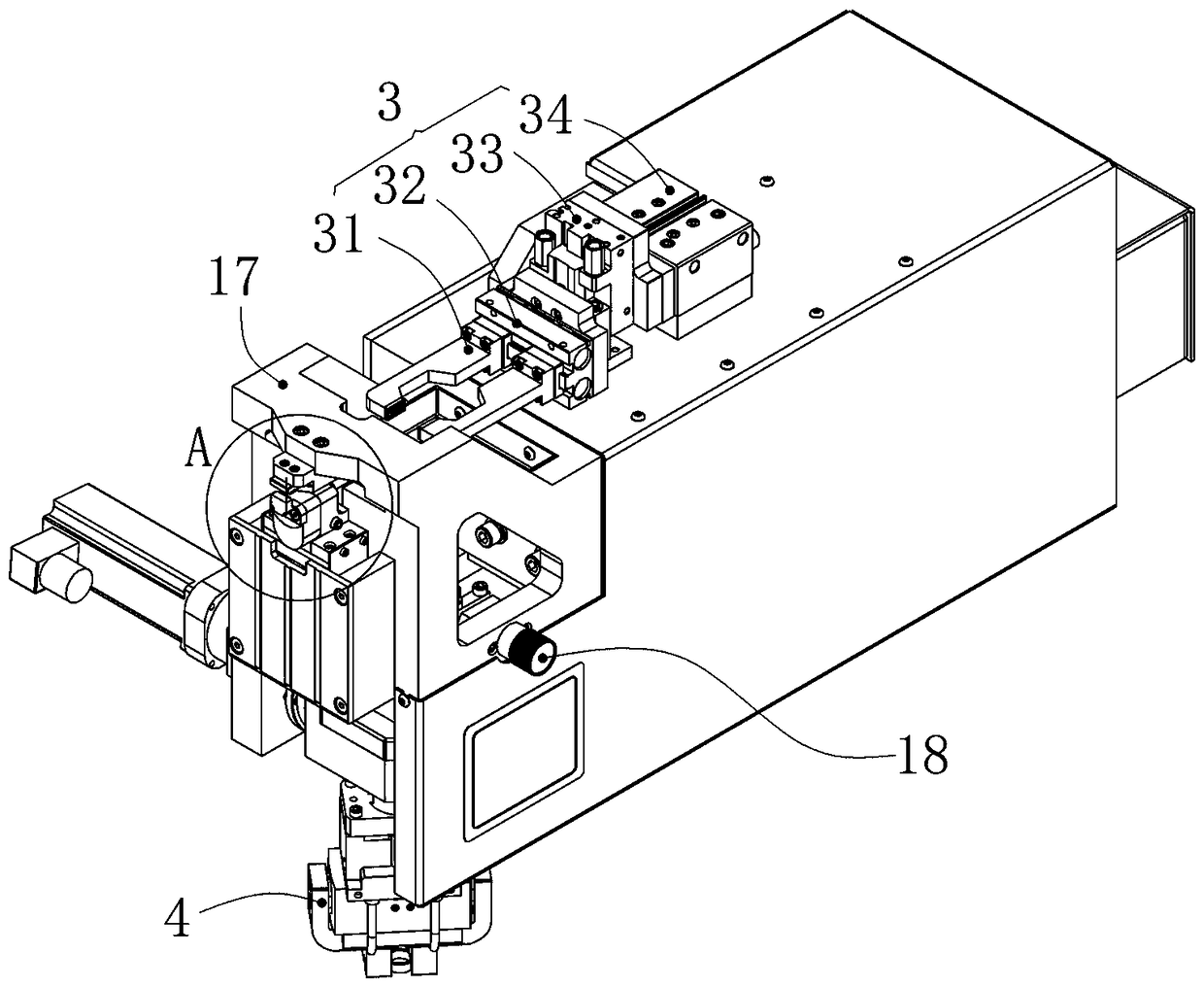

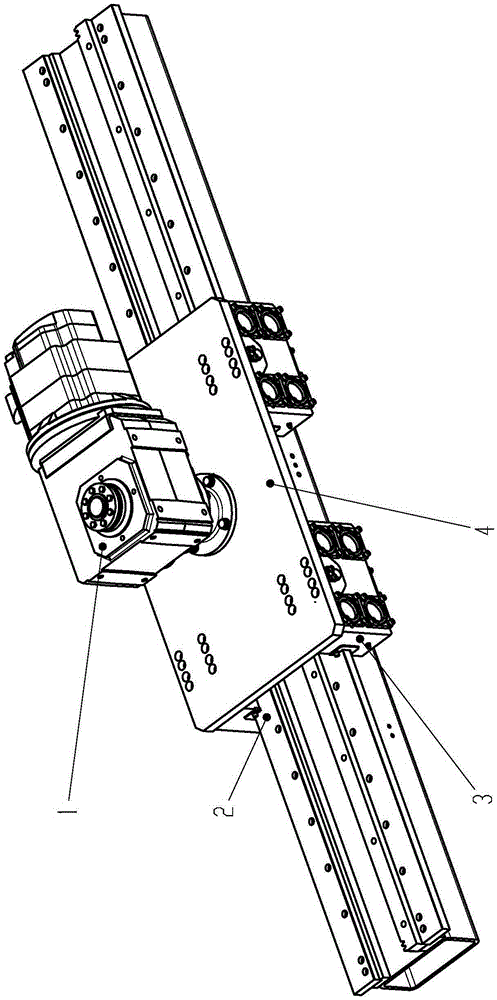

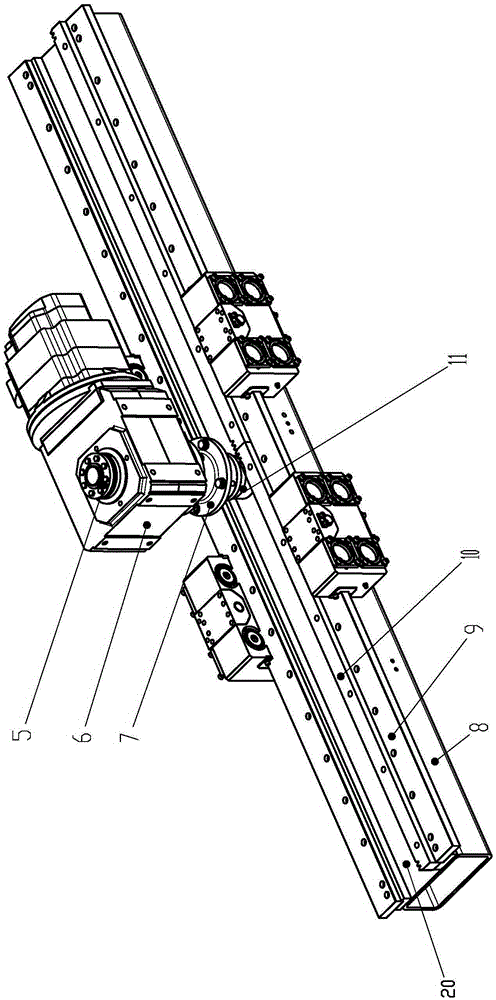

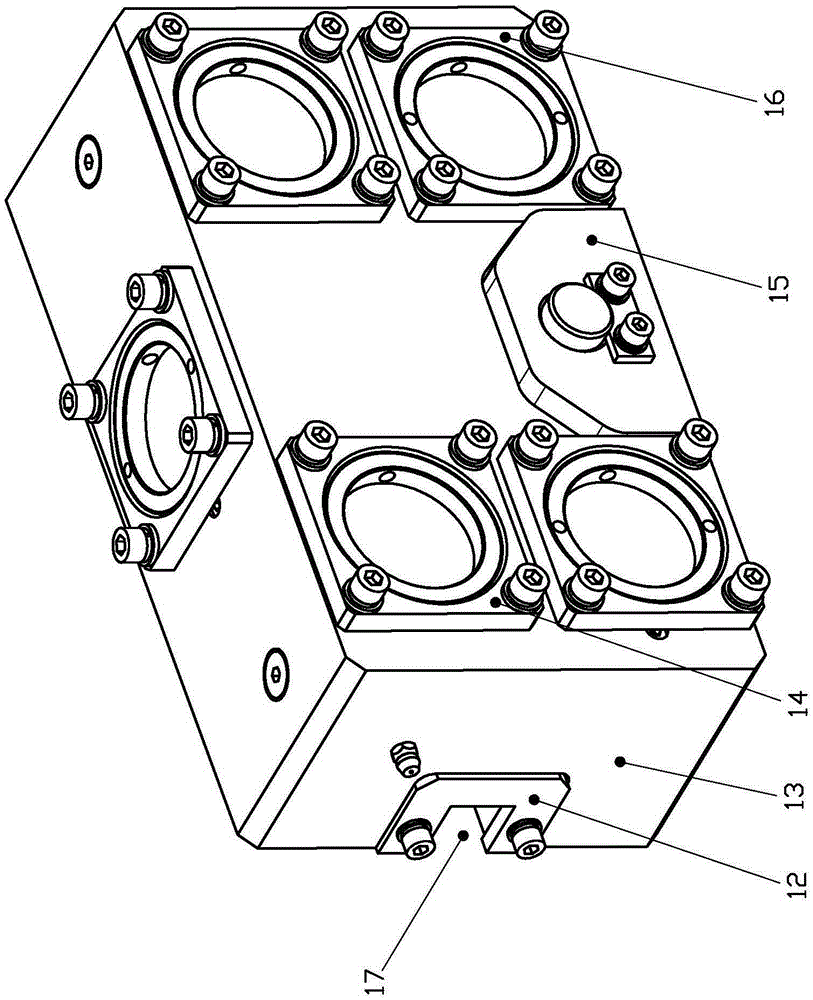

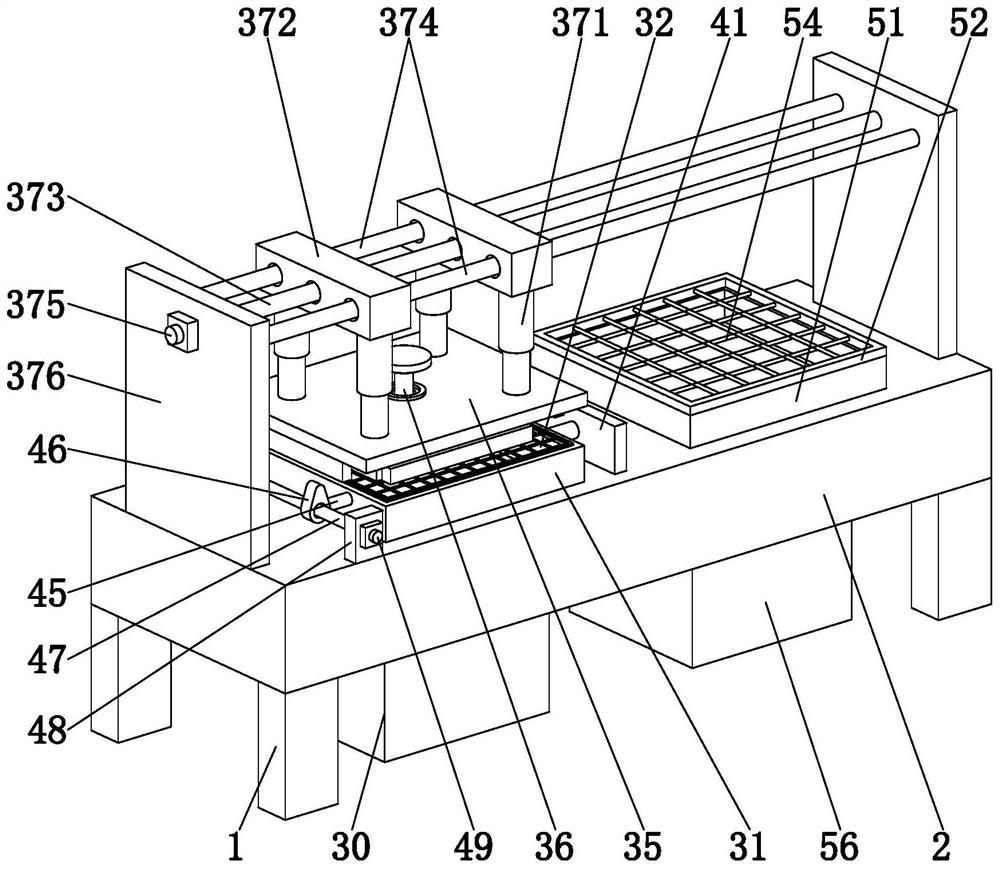

Tool bit conveying, catching and clamping system of saw web laser welding machine

ActiveCN106271137AReasonable structural designCompact designLaser beam welding apparatusTool bitNormal teeth

The invention belongs to the technical field of diamond saw web welding. A tool bit conveying, catching and clamping system of a saw web laser welding machine comprises a rack, a tool bit conveying device, a tool bit catching device and a tool bit clamping device, wherein the tool bit conveying device comprises a supporting vertical column and a normal tooth conveying unit and a protection tooth conveying unit which are arranged on the supporting vertical column; the normal tooth conveying unit and the protection tooth conveying unit respectively array normal tooth tool bits and protection tooth tool bits in a fixed direction, and convey the tool bits to a tool bit catching station; the tool bit catching device catches the normal tooth tool bits or the protection tooth tool bits according to a welding working procedure, and conveys the normal tooth tool bits or the protection tooth tool bits which are caught to a clamping station of the tool bit clamping device, and the tool bits are located and clamped by the tool bit clamping device. The tool bit conveying, catching and clamping system of the saw web laser welding machine is integrated and high in mechanical degree, can automatically realize tool bit conveying and clamping, is accurate in location, can greatly reduce the labor intensity of a worker, and is relatively low in labor cost; and the production cost of an enterprise is reduced.

Owner:郑州金海威科技实业有限公司

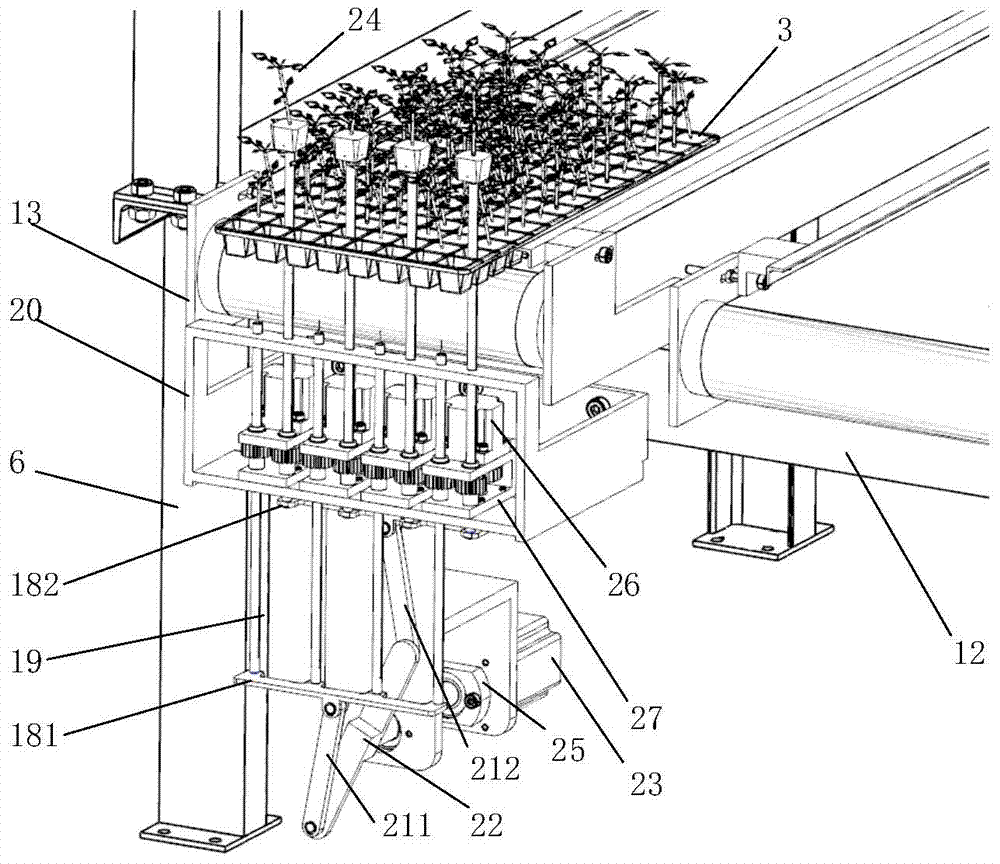

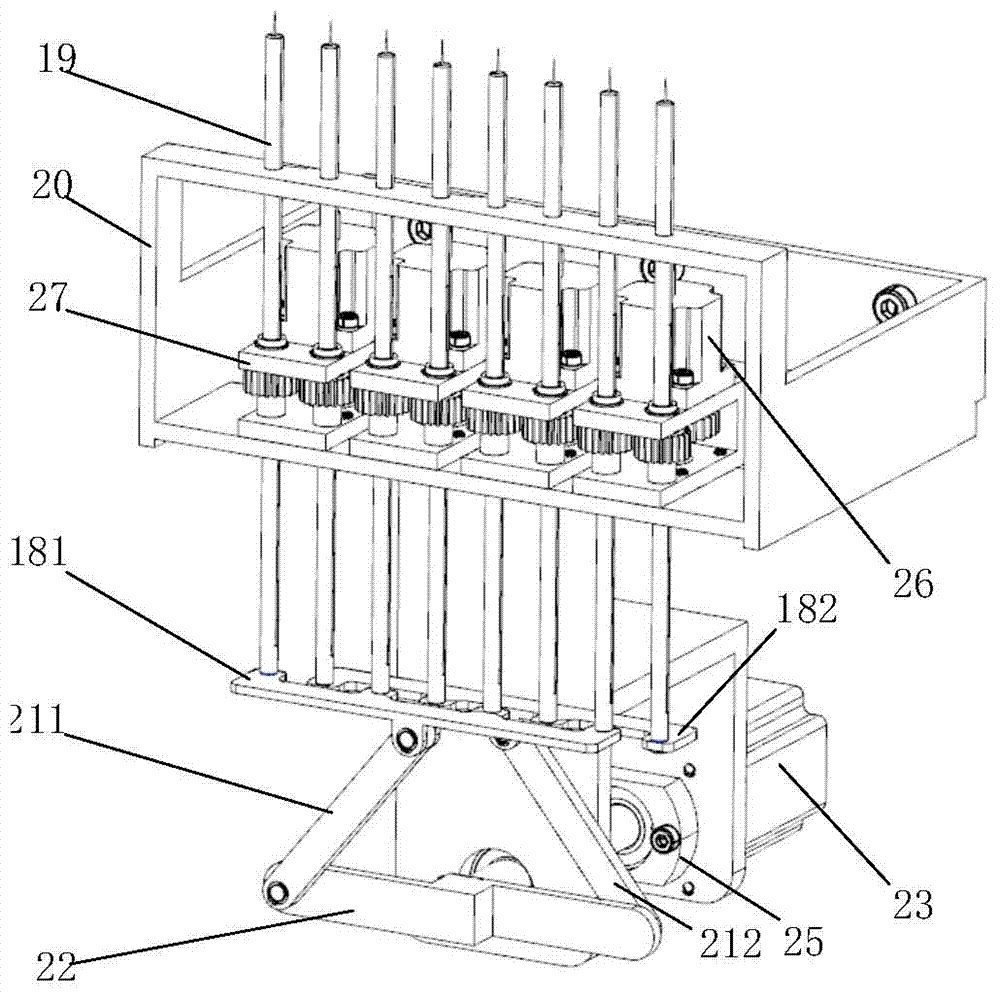

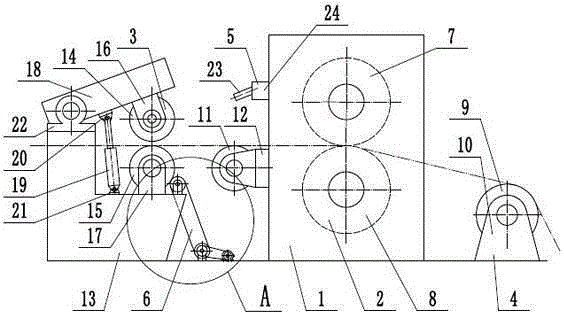

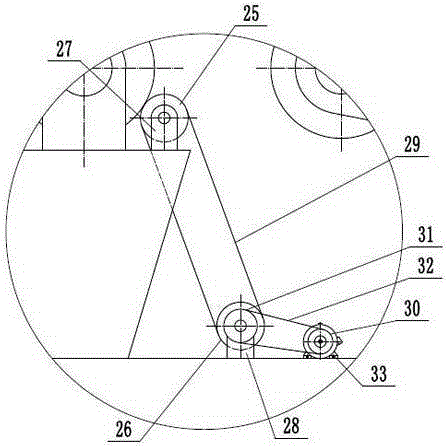

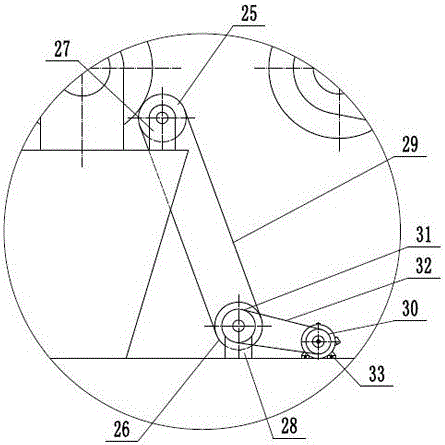

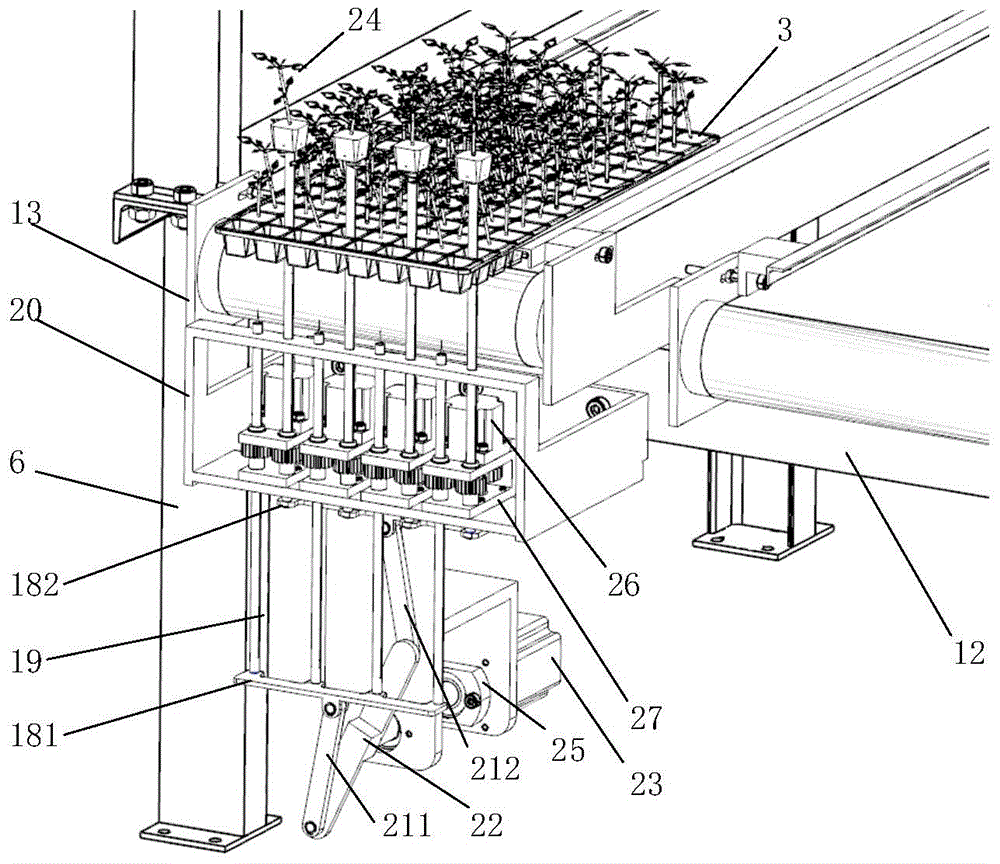

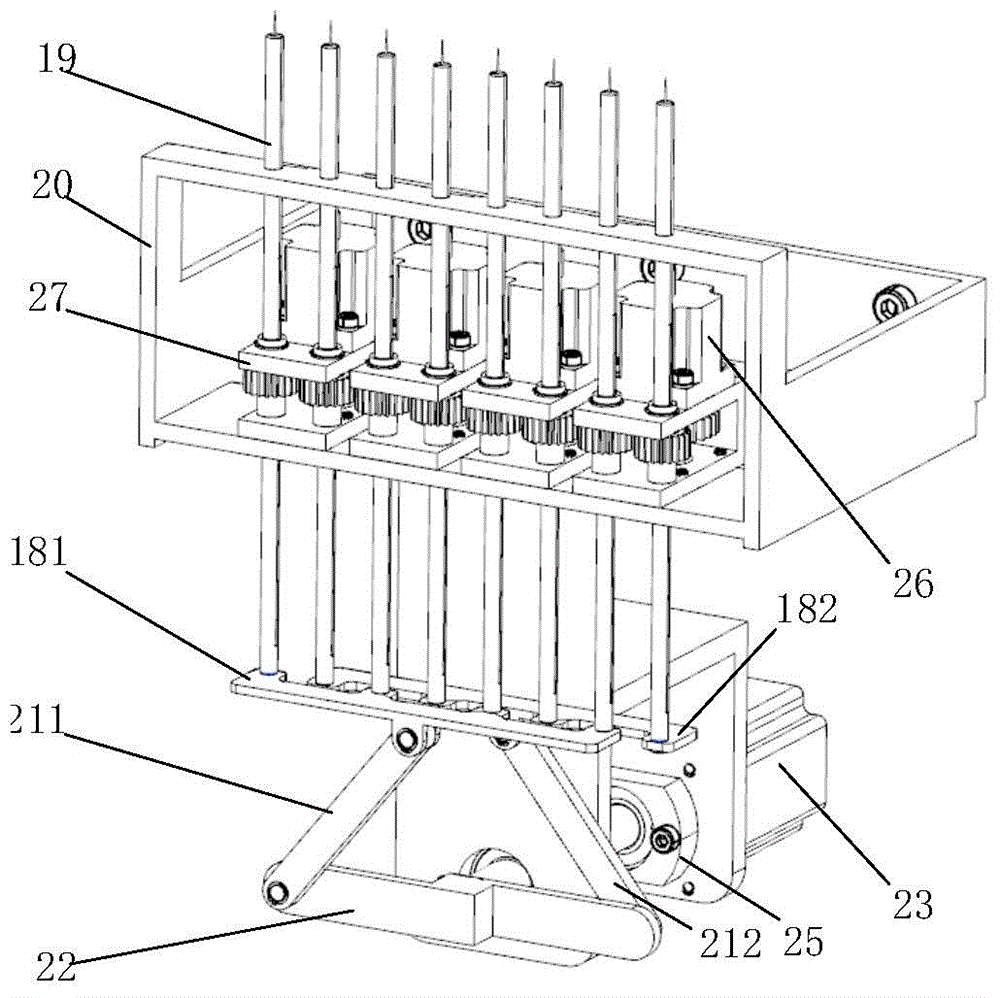

Potted seedling lifting and rotating device

The invention belongs to the technical field of modern agricultural equipment, and discloses a potted seedling lifting and rotating device. The potted seedling lifting and rotating device comprises a seedling lifting and rotating device bracket (20), a seedling lifting driving motor (23), a seedling lifting driving crank (22), a first seedling lifting driving connecting rod (211), a second seedling lifting driving connecting rod (212), a first lifting rod supporting plate (181), a second lifting rod supporting plate (182), a lifting rod (19), a lifting rod rotating driving motor (26), a big gear (28), a small gear (31), a lifting rod rotating driving supporting base (27), a lifting rod sleeve (30) and a lifting rod driving pin (29). The device disclosed by the invention has the characteristics of simple and compact structure and high working efficiency, and is capable of realizing four actions: lifting towards left side, not lifting, lifting towards right side and rotating seedlings, in a process of selecting and transplanting the seedlings, so as to meet a demand of continuous selecting and transplanting operation. Components of the device are in modular design, so as to guarantee high maintenance and good reliability of entire machine. The device is low in manufacturing cost and is economically applicable.

Owner:CHINA AGRI UNIV

Aluminum plate rolling device

ActiveCN105195513AAchieve orientationAchieve coolingRolling equipment maintainenceGuiding/positioning/aligning arrangementsTransverse beamNozzle

The invention provides an aluminum plate rolling device, which belongs to the technical field of metal processing, and comprises a first rolling component, a second rolling component, a guiding component, a cooling component and a cleaning component, a first upper press roll and a first lower press roll which are arranged on the first rolling component are up and down adjacent but not contacted, a feeding guide roll of the guiding component is rotatably arranged on a feeding guide roll support, a discharge guide roll is rotatably arranged on a discharge guide roll support, the left end of a transverse beam of the second rolling component is hinged on a bearing support seat, the second upper press roll is rotatably arranged on a second upper support, the upper and the lower ends of a driving air cylinder are respectively hinged on an air cylinder upper support seat and an air cylinder lower support seat, an air nozzle of the cleaning component is rotatably arranged on a nozzle support, an upper cleaning roll of the cleaning component and a second lower press roll are adjacent but not contacted, and a cleaning curtain is encircled on the upper cleaning roll and a lower cleaning rolls. The aluminum plate rolling device achieves real-time cleaning of the surface of the second lower press roll, and improves rolling quality of an aluminum plate.

Owner:南通市中京机械有限公司

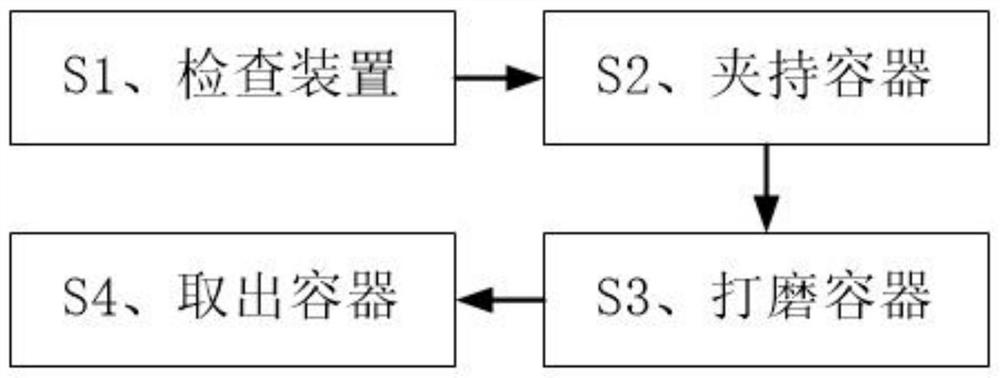

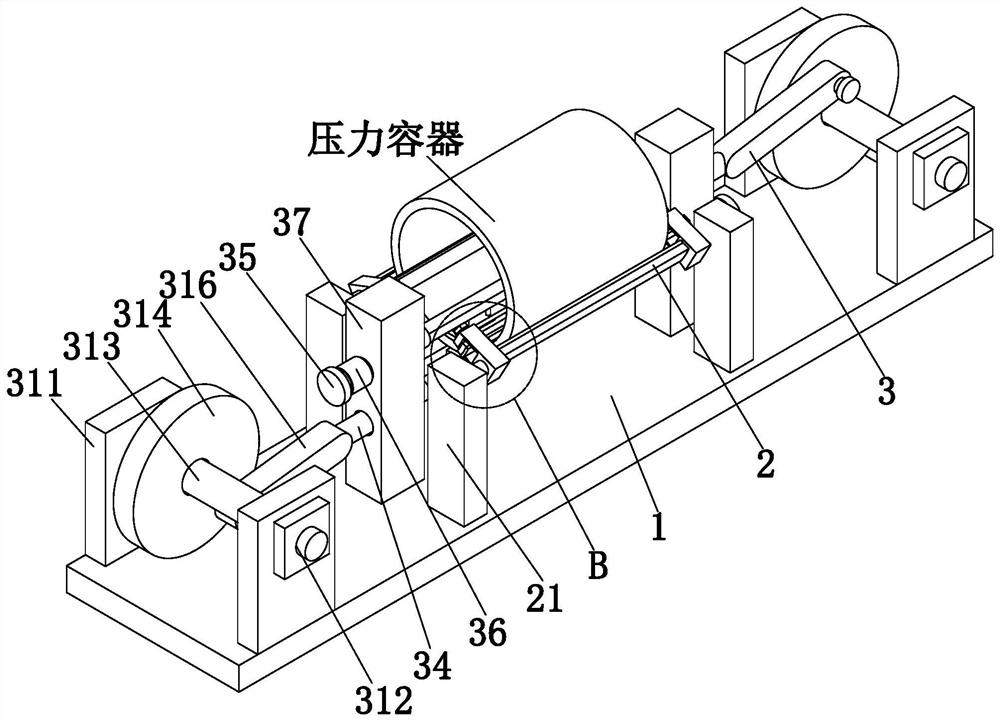

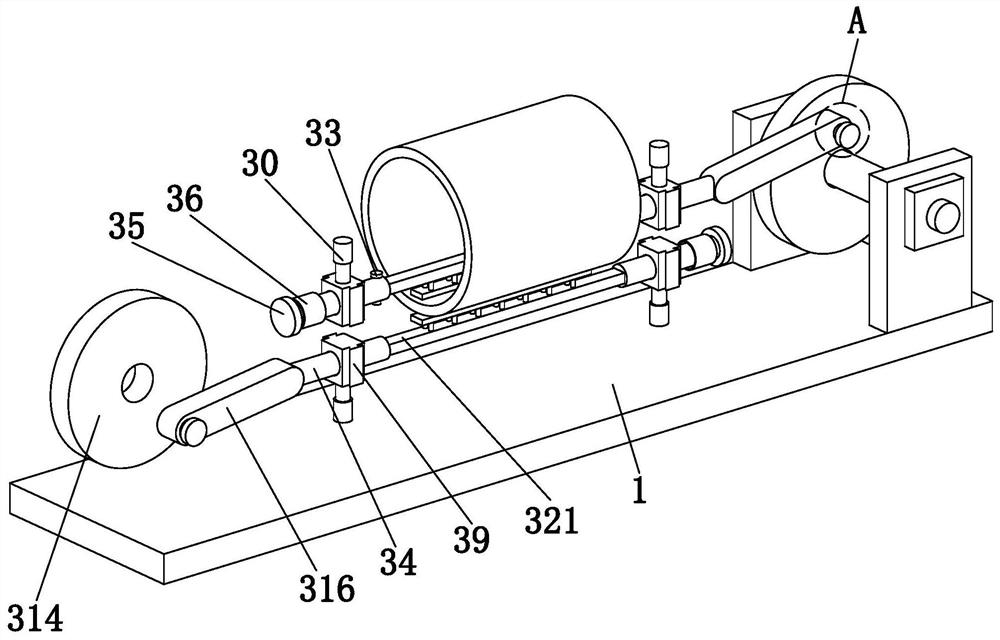

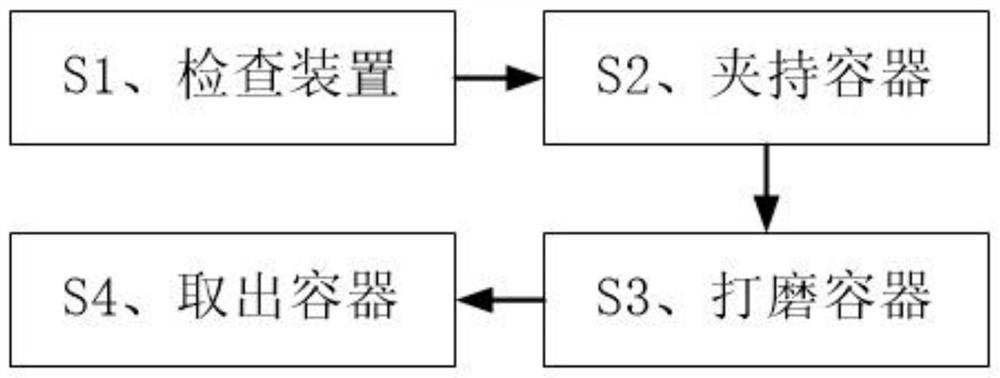

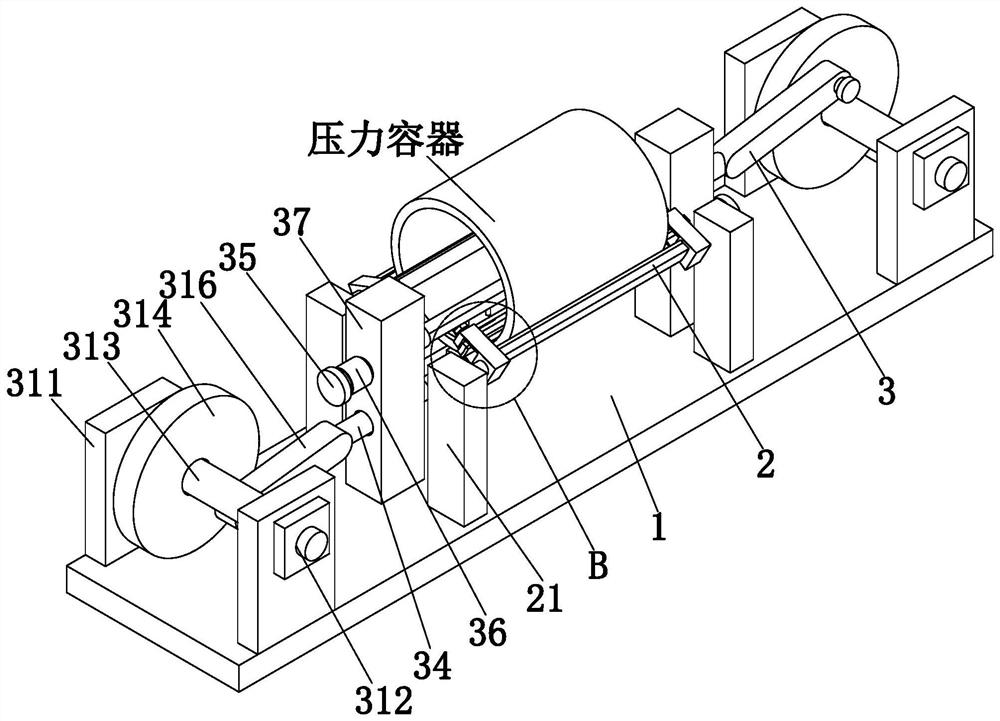

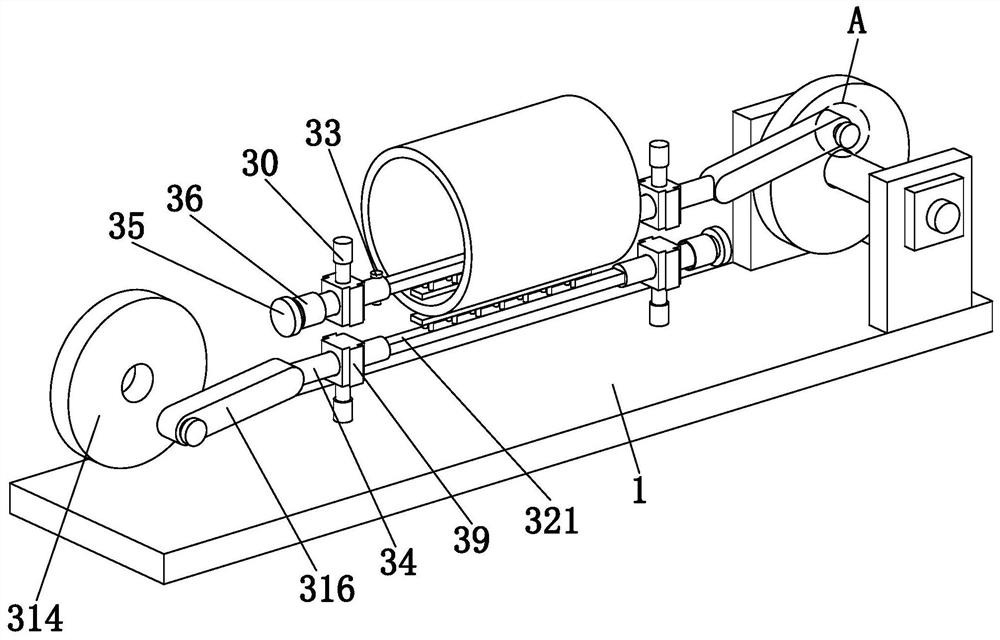

Chemical pressure container processing method

ActiveCN112355769AManual labor intensity is highDecrease productivityEdge grinding machinesGrinding drivesSlag (welding)Process engineering

The invention provides a chemical pressure container processing method. A chemical pressure container processing device is used in the method. The device comprises a base, a clamping and limiting mechanism and a grinding mechanism. The chemical pressure container processing method can solve the following problems existing in the chemical pressure container processing process that a, a chemical pressure container is bent into a cylinder shape in a plate shape, a connector of the chemical pressure container is welded and sealed in a welding manner, welding slag can be generated at the welding position, and in other words, the welding position needs to be ground to remove the welding slag; b, in the current traditional manner, the welding position is mostly ground manually through a grindingmachine, the manual labor intensity is large in the manner, the work efficiency is low, and particularly the welding position of the inner wall of the chemical pressure container is ground; and c, a grinding device in the current market is complex in structure, high in price and single in function effect, and can only aim at a certain specification, and the practical value of the grinding device is not high.

Owner:ANHUI SUDONG PETROCHEM POWER EQUIP MFG GRP

Method for lowering inorganic ultrafine powder slurry moisture content by adding rotary drum pressurizing type filtering machine

InactiveCN102976368AManual labor intensity is highReduce manual labor intensityMagnesium hydroxideFiltrationEngineering

The invention proposes a method for lowering energy consumption for drying inorganic ultrafine powder slurry by adding a rotary drum pressurizing type filtering machine. A pressurizing rotary drum filtering machine system is added in front of a conventional paddle dryer, and the inorganic ultrafine powder slurry moisture content is greatly reduced by pressure filtration. The method is characterized by continuous operation, saved energy, lowered consumption, reduced tail gas discharge quantity, and conformity with the national industrial policy of energy conservation and emission reduction.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +2

Alloy casting equipment

ActiveCN111906287APlay the role of limit movementSimple structureMelt-holding vesselsAlloyMaterial storage

The invention relates to the technical field of alloy casting, in particular to alloy casting equipment which comprises a base plate, a casting table, a rectangular lifting frame, a horizontal movingmechanism, a transverse moving mechanism, a casting material hopper and two material storage tanks. Casting moulds are arranged on two sides of the top part of the casting table along the length direction of the casting table at equal intervals; the horizontal moving mechanism comprises a moving transverse plate capable of oppositely moving between the two material storage tanks along the length direction of the rectangular lifting frame; the transverse moving mechanism comprises a transverse moving frame capable of transversely moving along the moving transverse plate; a discharging pipe is arranged at the lower end of the casting material hopper; an inverted-V-shaped material guiding pipe is arranged at the bottom of the discharging pipe; and two ends of the bottom part of each inverted-V-shaped material guiding pipe can be in butt joint with the casting moulds arranged on two sides of the casting table respectively. According to the technical scheme, the alloy casting equipment is simple in structure, and multiple workpieces can be cast at the same time at a time, so that the production efficiency is obviously improved; and meanwhile, the alloy casting equipment is high in automation degree, large in manual labor intensity and low in cost.

Owner:山西一禾铝业科技新材料有限公司

Method for preparing 2, 4-dinitroaniline by using microreactor

PendingCN111635322AIncrease productivityReduce energy consumptionOrganic compound preparationChemical industryMicroreactorChlorobenzene

The invention relates to the technical field of preparation of 2, 4-dinitroaniline, in particular to a method for preparing 2, 4-dinitroaniline by using a microreactor. The method comprises the following steps: (1) preparing equipment, namely preparing a preheater, the microreactor and two chromatographic pumps; (2) connecting reaction equipment, respectively connecting two chromatographic pumps with the preheater and the micro-reactor, then connecting the preheater with the micro-reactor, and putting the preheater and the microreactor into a constant-temperature oil bath after the connectionis completed; (3) conveying a reaction material, namely conveying ammonia water to the preheater at a preset flow rate, conveying the molten 2, 4-dinitrochlorobenzene to the microreactor at a preset flow rate, and mixing and reacting with the ammonia water to obtain 2, 4-dinitroaniline; and (4) after the reaction of the material in the step (3) is completed, preparing the redundant ammonia gas into ammonia water again for reuse through an ammonia gas recovery device, and continuing to reuse the ammonia generated by the reaction of ammonium chloride generated by the reaction and potassium hydroxide. Tthe method has the characteristics of high production efficiency, low energy consumption, economy, environmental protection, safety and reliability.

Owner:杭州迈科瑞科技有限公司

An aluminum plate rolling device

ActiveCN105195513BAchieve orientationAchieve coolingGuiding/positioning/aligning arrangementsRolling equipment maintainenceEngineeringTransverse beam

Owner:南通市中京机械有限公司

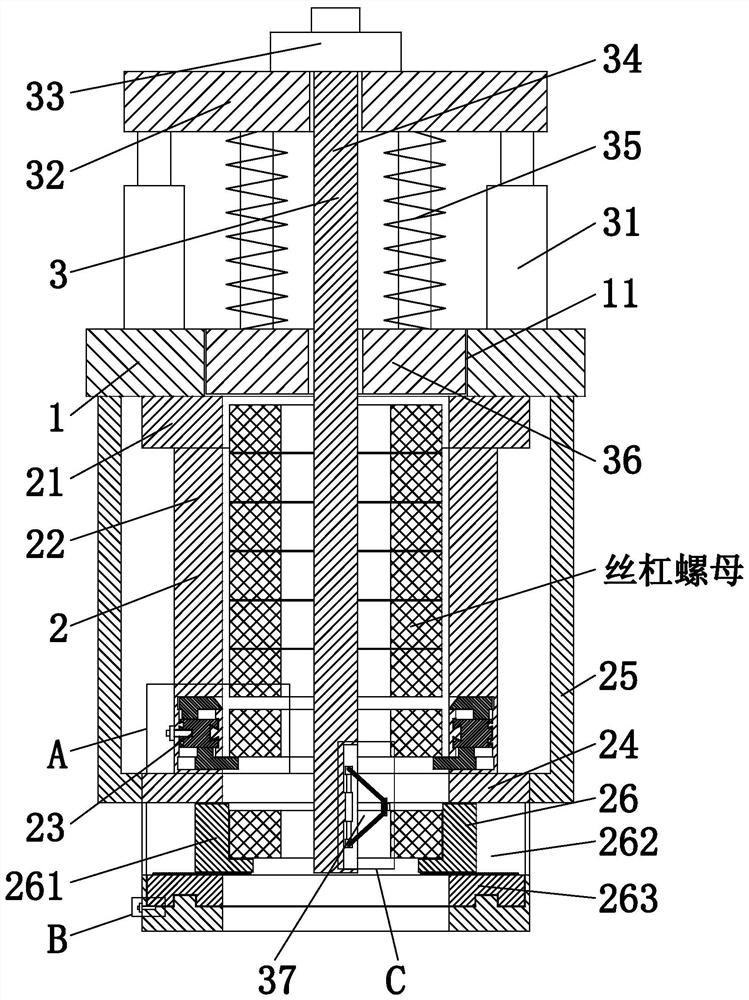

Lead screw nut batch tapping device and tapping method

InactiveCN112091334AManual labor intensity is highDecrease productivityThread cutting machinesProcess engineeringScrew thread

Owner:合肥禾松信息科技有限公司

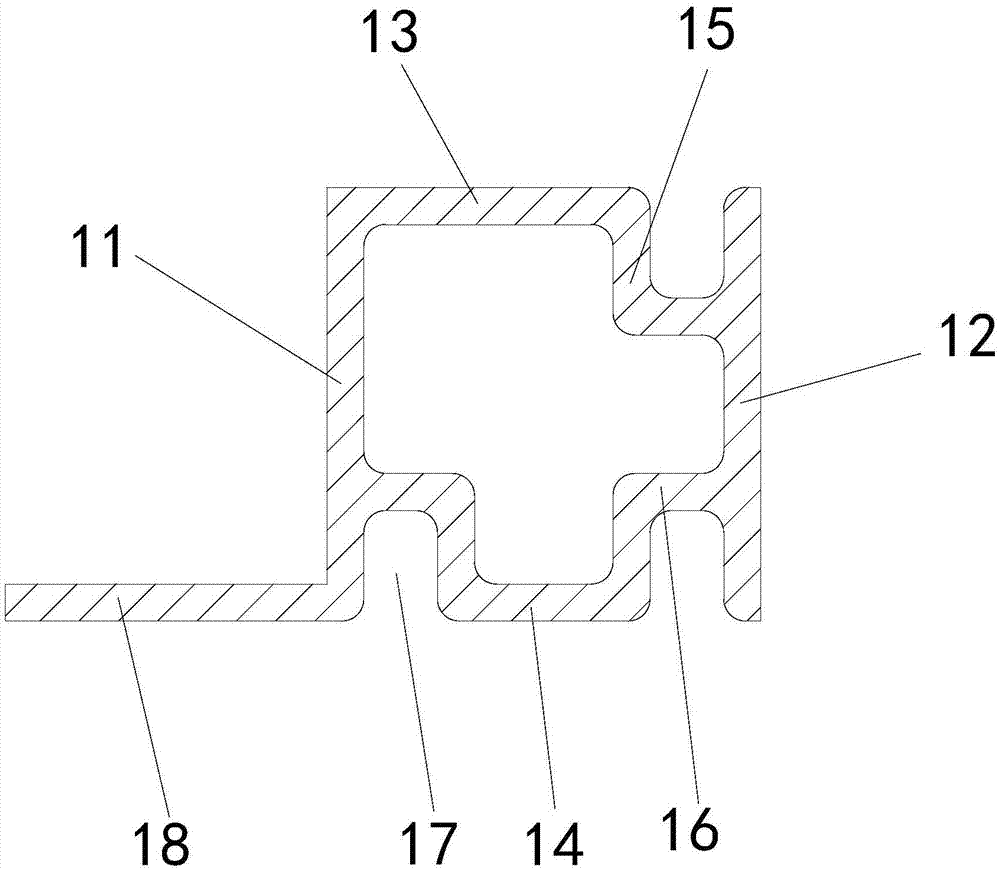

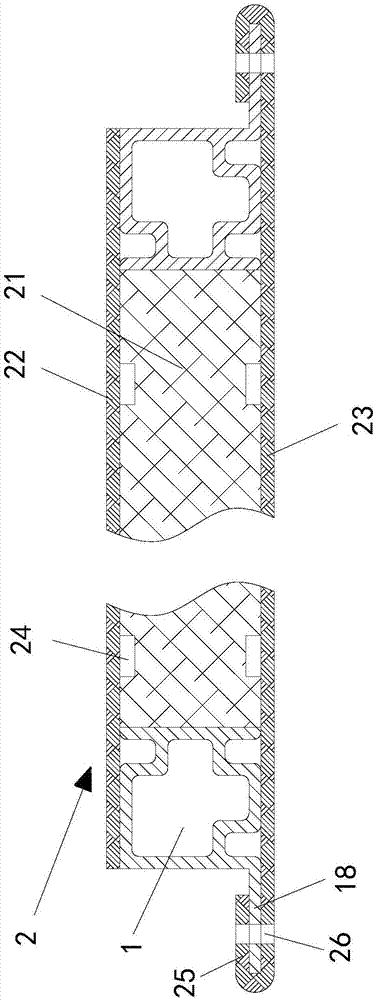

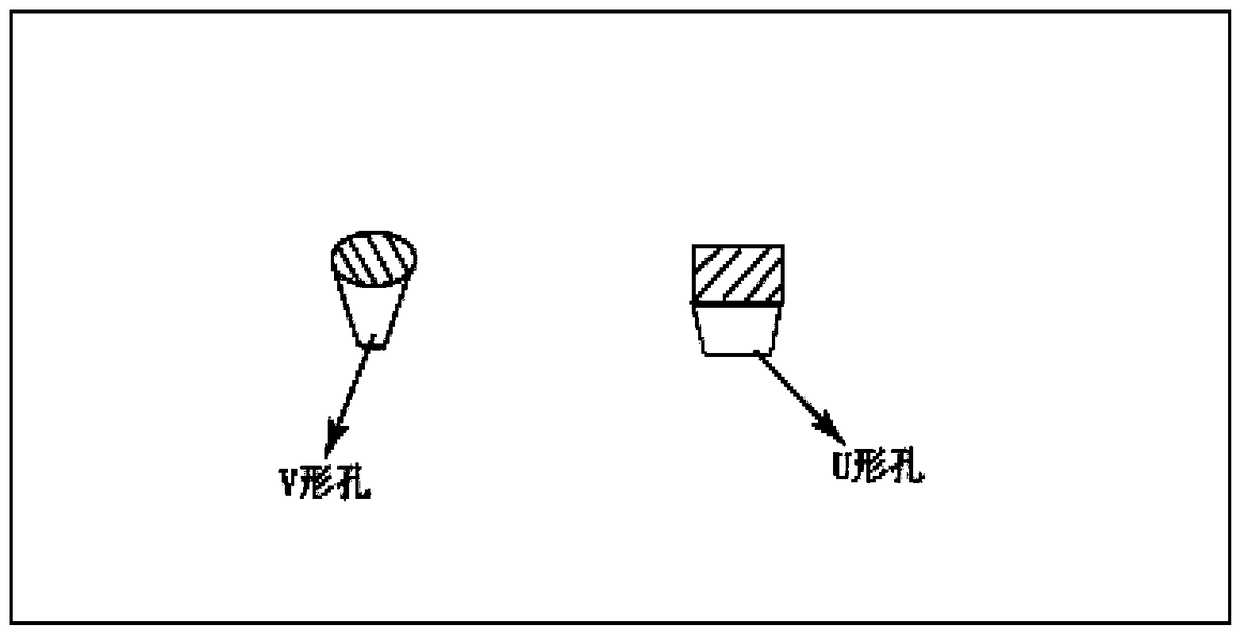

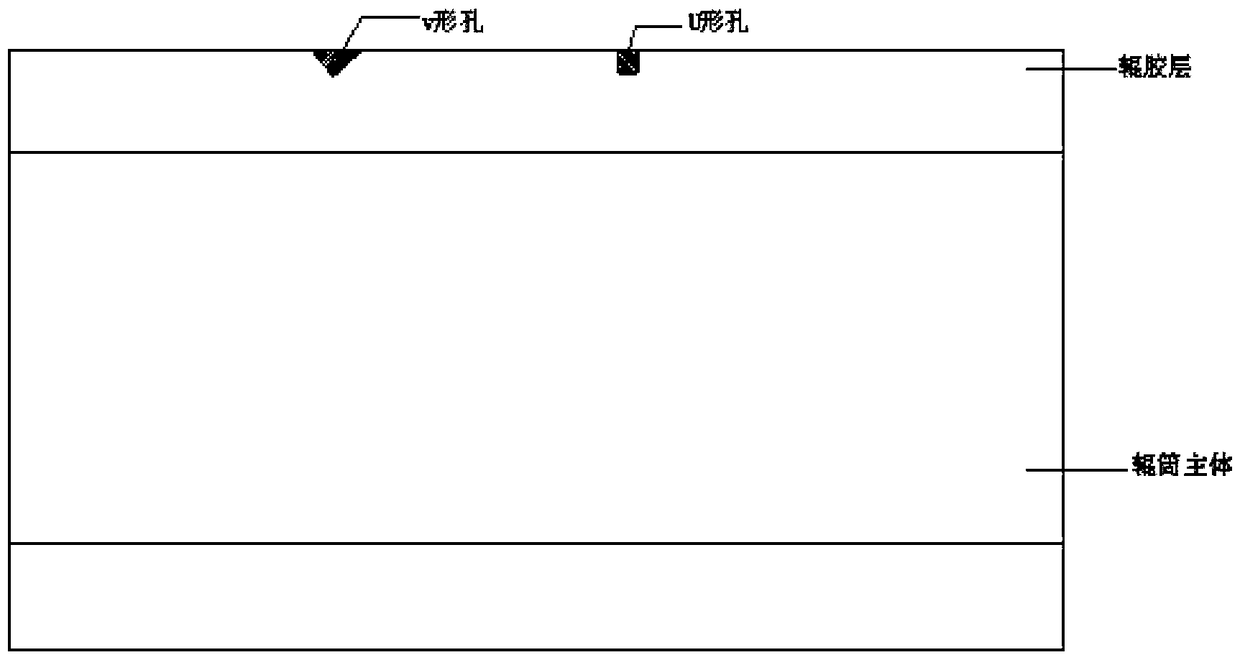

Composites profile, composite board and manufacturing method of composite board

PendingCN107344558AImprove pasting effectManual labor intensity is highAxle-box lubricationFlat articlesSurface bondingAdhesive

The invention discloses a composites profile. Upper and lower sides of an outer frame and an inner frame are fixedly connected through an upper frame and a lower frame; and the end parts of the upper frame and the lower frame are bent to form bending parts. An adhesive is stored in an adhesive storage tank of the composite profile, and a gap in the surface of the profile is supplemented, so that the adhesive effect of the composite board is improved. According to the composite board, two end parts of a sandwich panel are bonded to the inner frame of the composite profile; the upper surfaces of the sandwich panel and the upper frame are bonded with an upper cover board of the sandwich panel and the lower surfaces are bonded with a lower cover board of the sandwich panel. According to the composite board, the adhesive effect of the composite board is improved. A manufacturing method of the composite board comprises the steps of bonding the sandwich panel and the side surface of the inner frame; bonding the upper cover board of the sandwich panel on the upper surfaces of the composite profile and the sandwich panel; and bonding the lower cover board of the sandwich panel on the lower surfaces of the sandwich panel, the composite profile and an auxiliary connection plate. According to the manufacturing method of the composite board, the requirements of the operation process of a worker are reduced, thereby reducing the labor intensity of the worker.

Owner:徐卫国

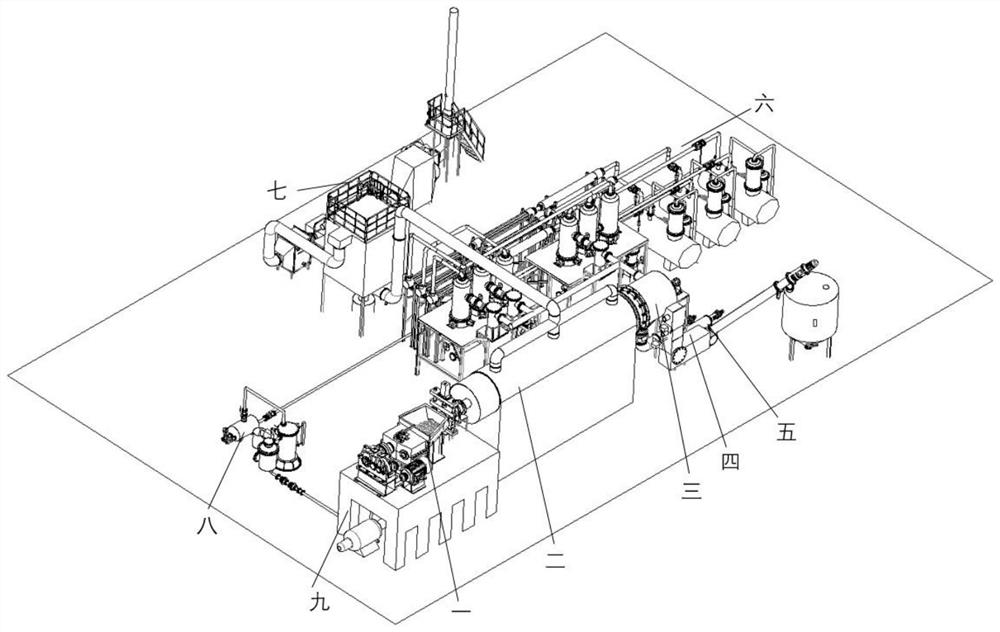

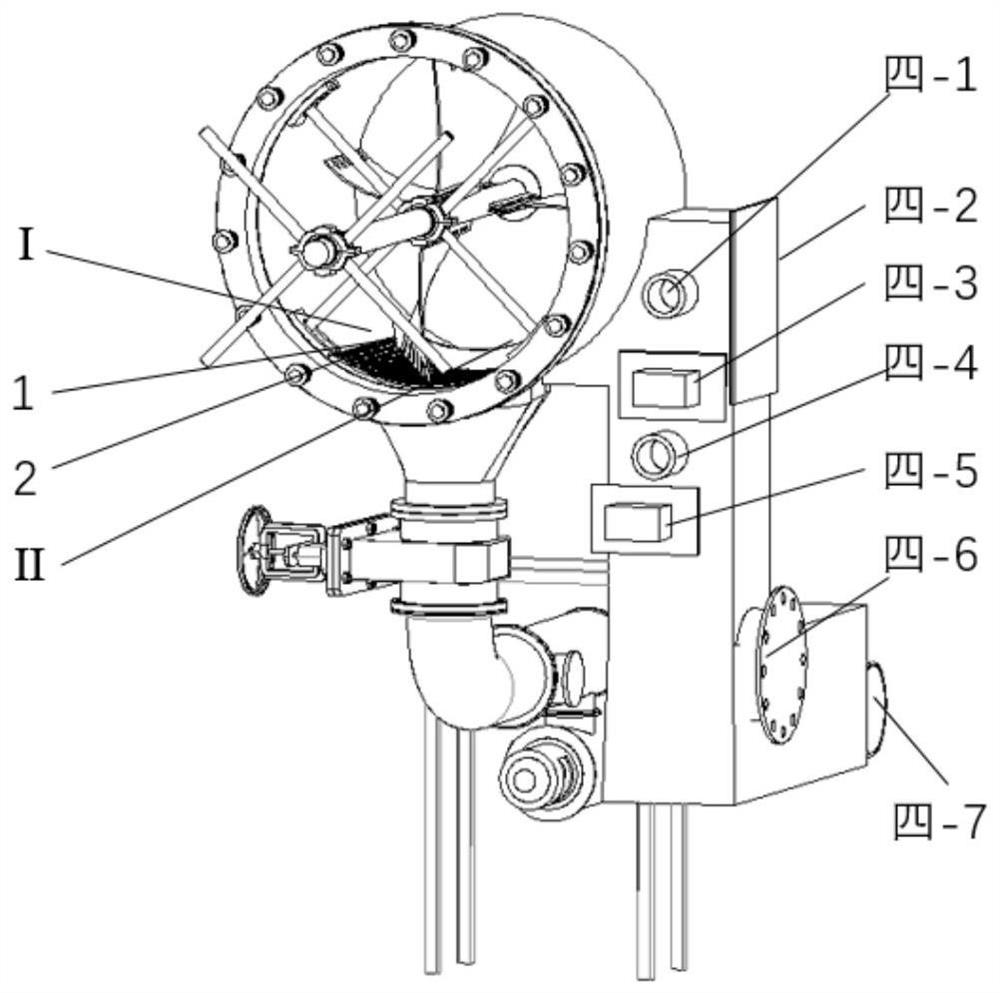

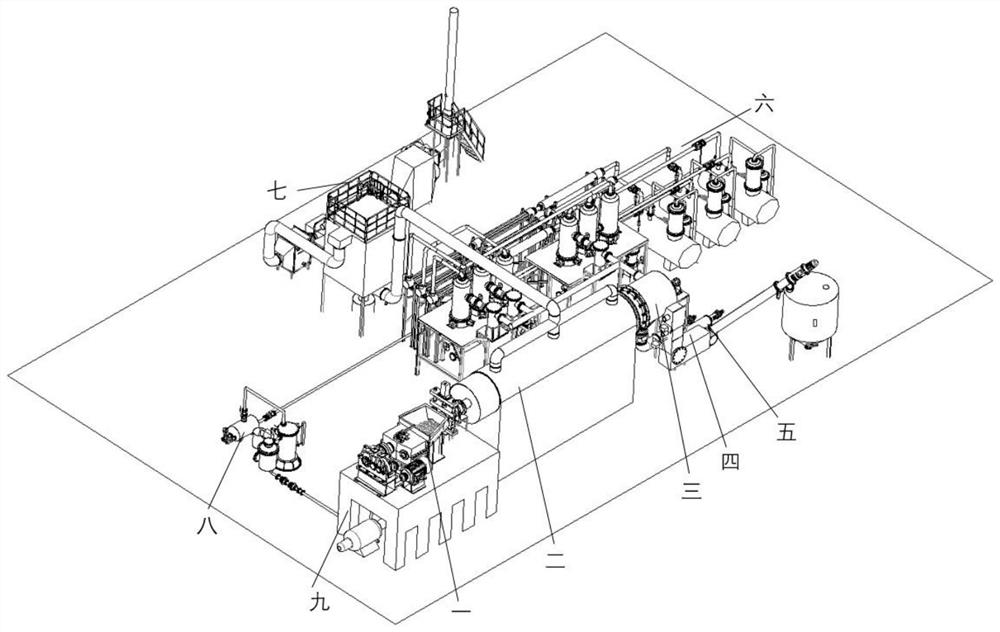

Method and equipment for automatically separating solid-phase products of whole waste tire industrial continuous cracking

ActiveCN113072968AContinuous crackingEfficient crackingProductsReagentsCollection systemDelivery system

The invention discloses a method and equipment for automatically separating solid-phase products of whole waste tire industrial continuous cracking. The equipment comprises a special-shaped double-cone continuous feeding system, a cracking reactor main body system, a cracking solid-phase product separation system, a steel wire conveying system, a cracking carbon black continuous output system, a cracking oil product grade automatic collection system, a modular distributed intelligent tail gas comprehensive treatment system, a cracking non-condensable combustible gas recycling system, a combustion heat supply system and a catalytic cracking intelligent control system which are connected through connecting parts; the cracking solid-phase product separation system comprises a solid-phase product separation blade and a steel wire conveying blade structure, and a baffle is arranged between the solid-phase product separation blade and the steel wire conveying blade, so that a cracking steel wire must cross the middle baffle in the conveying process; and in the conveying process of the solid-phase product separation blades, cracked steel wire balls are always in the rolling process, AND carbon black mixed in the cracked steel wires is gradually leaked out. The problem that in the prior art, efficiency is low is solved, and reliability is high.

Owner:QINGDAO UNIV OF SCI & TECH

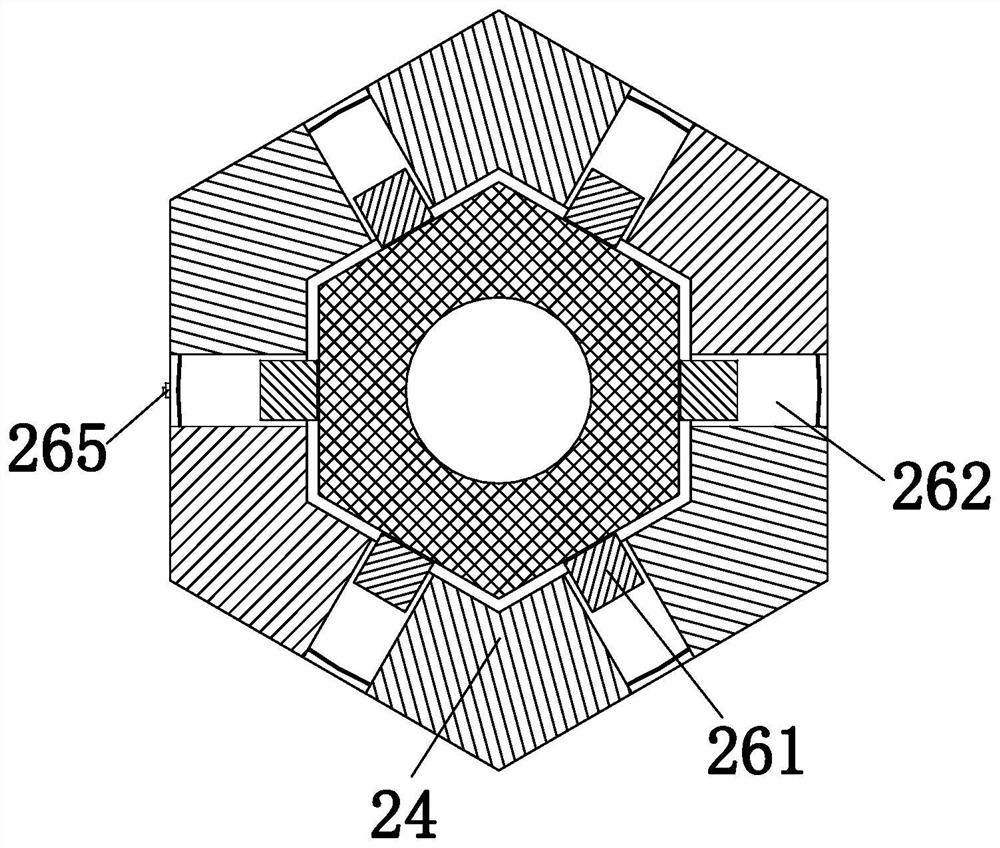

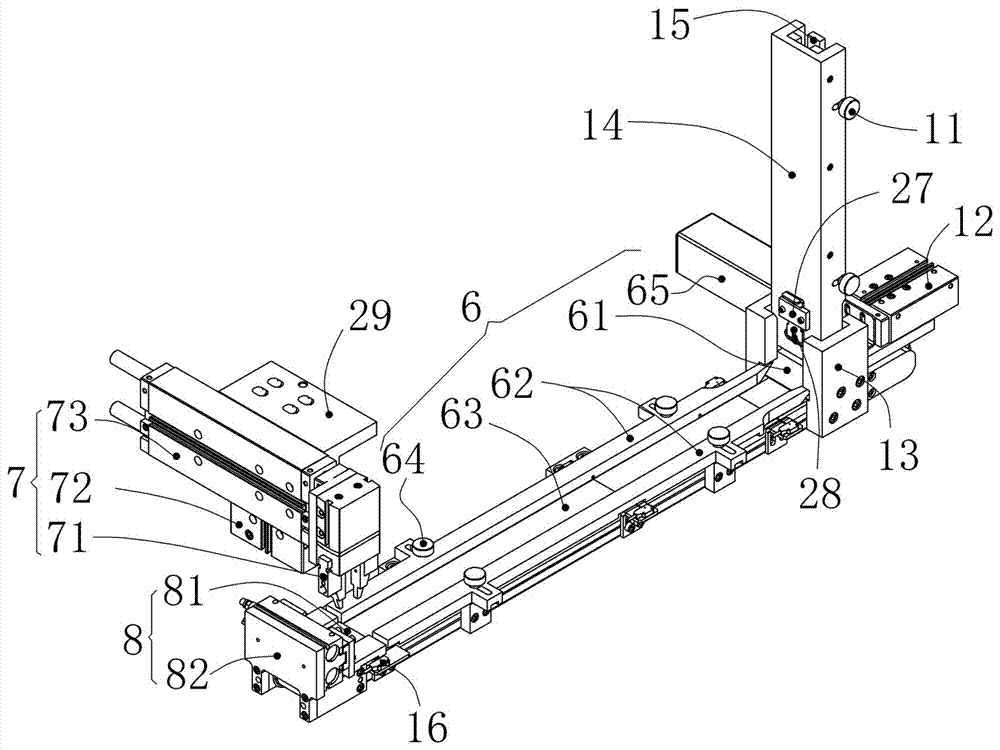

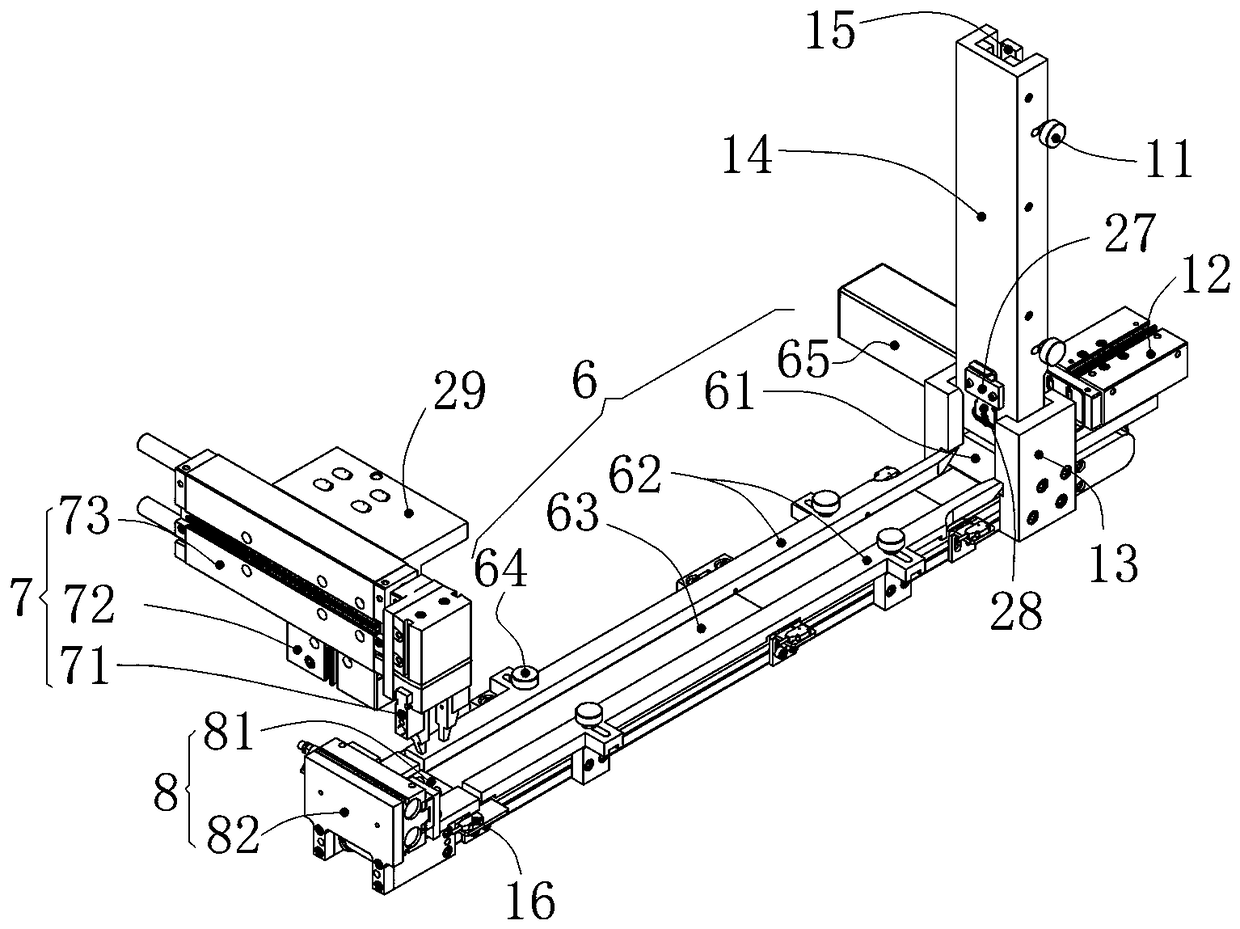

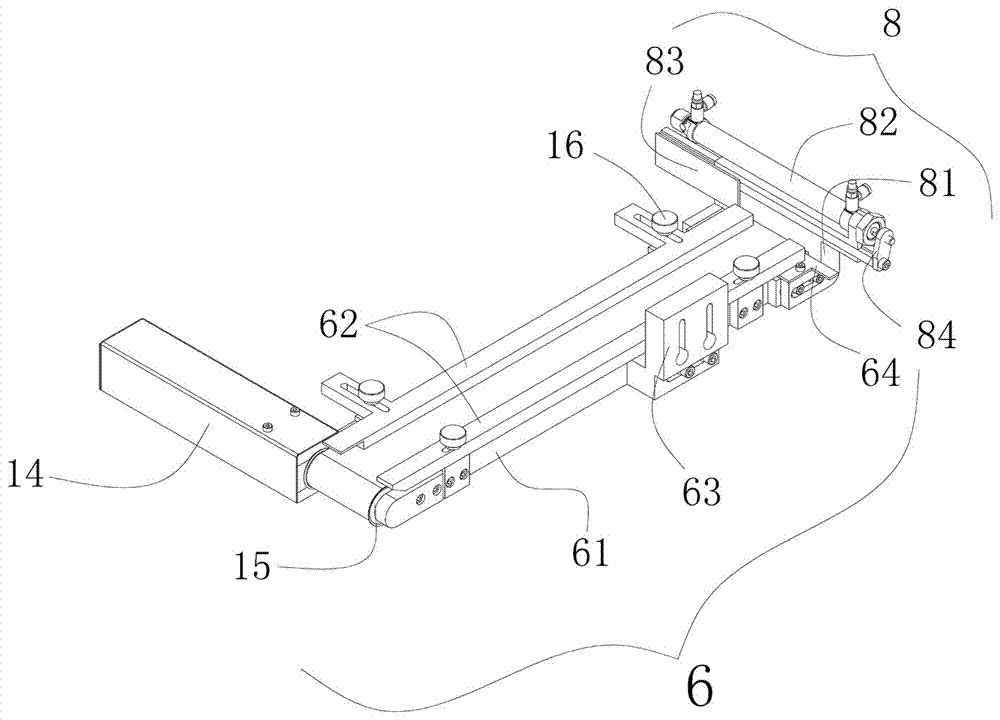

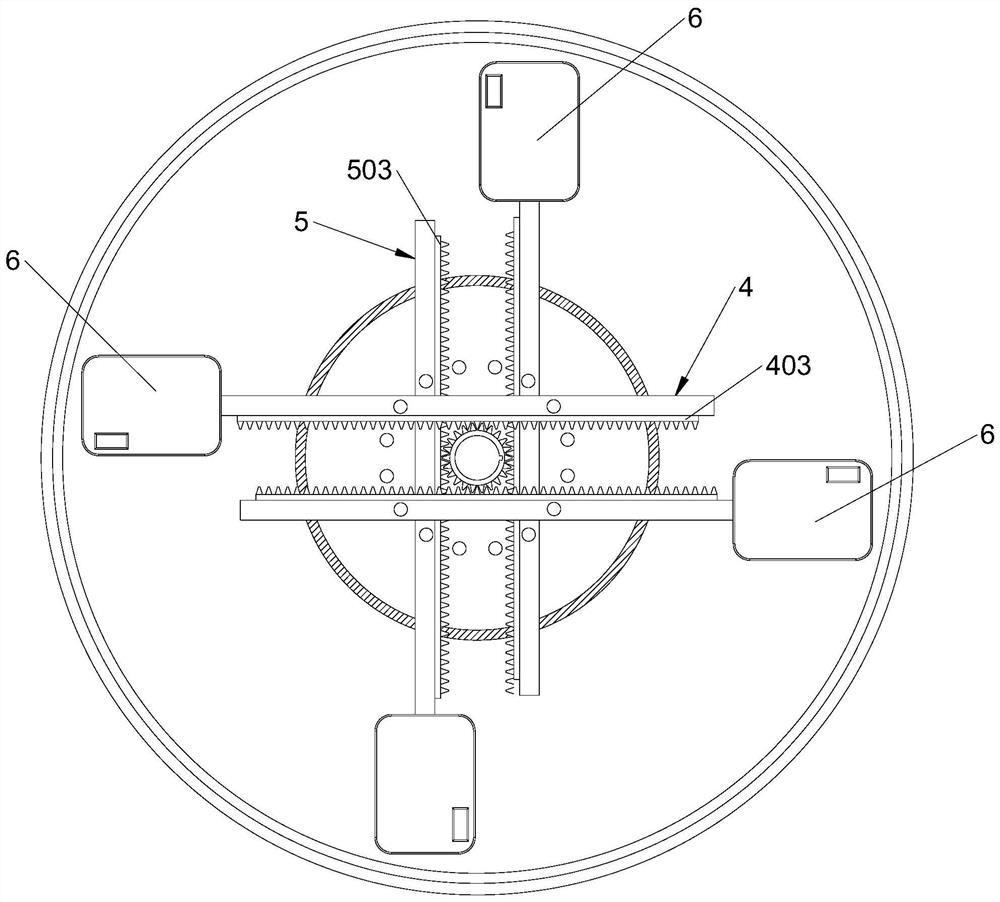

Tool bit conveying and clamping system for diamond thin-walled drill laser welding machine

ActiveCN106984908AReasonable structural designCompact designOther manufacturing equipments/toolsMetal working apparatusTool bitEngineering

The invention discloses a tool bit conveying and clamping system for a diamond thin-walled drill laser welding machine. The tool bit conveying and clamping system comprises a supporting frame, a single-tooth tool bit conveying device, a single-tooth tool bit temporarily-storing device and a horizontal sliding table, wherein the single-tooth tool bit conveying device and the single-tooth tool bit temporarily-storing device are fixed to the supporting frame correspondingly. A single-tooth tool bit clamping device and a ring-tooth tool bit clamping device are arranged at the front end of the horizontal sliding table, and a ring-tooth tool bit conveying device is arranged below the horizontal sliding table. The single-tooth tool bit conveying device is used for conveying a single-tooth tool bit and transferring the single-tooth tool bit to a single-tooth tool bit temporarily-storing station. The single-tooth tool bit clamping device is used for clamping and conveying the single-tooth tool bit temporarily stored on the temporarily-storing device to a welding station. The ring-tooth conveying device is used for conveying a ring-tooth tool bit to a ring-tooth tool bit clamping station, and the ring-tooth clamping device is used for clamping and conveying the ring-tooth tool bit to the welding station. According to the tool bit conveying and clamping system for the diamond thin-walled drill laser welding machine, due to the structural design of the single-tooth tool bit conveying device and the ring-tooth tool bit conveying device, automatic conveying, grabbing and clamping of two kinds of different tool bits are achieved, and a good foundation is provided for the subsequent welding process.

Owner:郑州金海威科技实业有限公司

A kind of processing method of chemical pressure vessel

ActiveCN112355769BManual labor intensity is highDecrease productivityEdge grinding machinesGrinding drivesSlag (welding)Engineering

The invention provides a chemical pressure vessel processing method, which uses a chemical pressure vessel processing device, which includes a base, a clamping and limiting mechanism, and a grinding mechanism. The invention provides a method for processing chemical pressure vessels, which can solve the following problems in the process of processing chemical pressure vessels: a. The chemical pressure vessel has a plate-shaped bending to form a cylinder, and its interface is welded and sealed by welding , so that welding slag will be produced at the welding place, that is, the welding place needs to be polished to remove the welding slag; b. In the current traditional method, most of the welding places are manually sanded and polished by a grinder, which is labor-intensive. The work efficiency is low, especially for grinding the welding part of the inner wall of the chemical pressure vessel; c. The grinding devices currently in the market have complex structures, are expensive, and have single functions and effects, and can only be aimed at a certain specification, making their practical value not high.

Owner:ANHUI SUDONG PETROCHEM POWER EQUIP MFG GRP

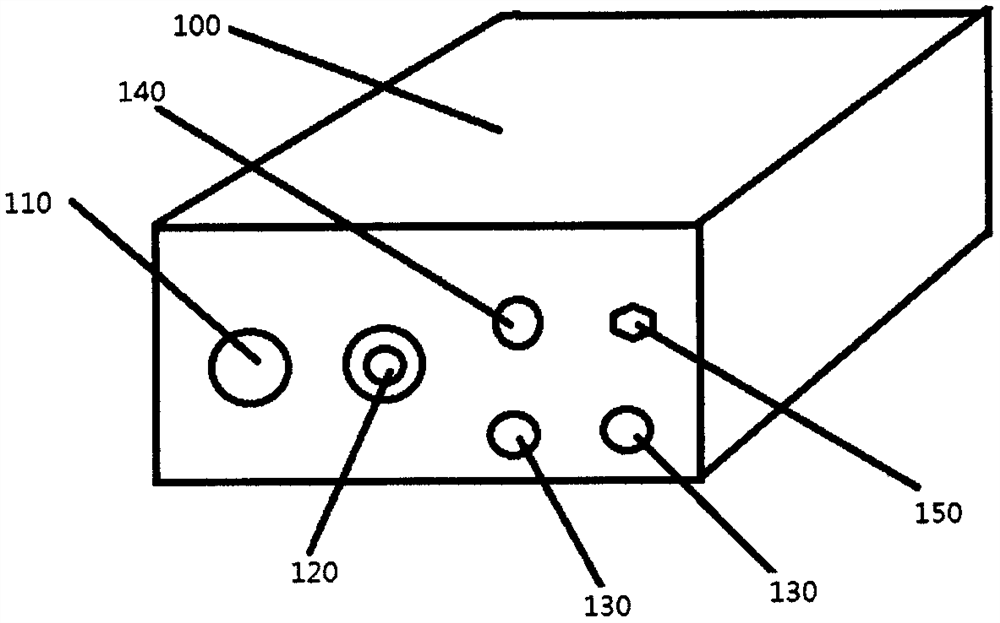

Device and method for detecting lead sealing state of large-thickness nonmetal coating accessory

PendingCN112345630APlace stableManual labor intensity is highMaterial magnetic variablesReference testEngineering

The invention discloses a device and a method for detecting the lead sealing state of a large-thickness nonmetal coating accessory. The device comprises a cuboid, a sensor and a remote signal transmission module, and a plurality of ports are formed in one side of the cuboid. The device is characterized in that a probe connecting port is arranged on the adjacent left side of one side of the cuboid,a communication port is arranged on the right side of the probe connecting port, and on the right side of the communication port, ports are arranged in an up-down manner, two ports are arranged on the upper side, and two ports are arranged on the lower side. According to the device for detecting the lead sealing state of a large-thickness nonmetal coating accessory, it is guaranteed that the detection sensor is perpendicular to the detection face, a reference test block and an eddy current sensor cannot generate inclination angles in the adjustment process, and the potential fault hazard caused by the fact that the reference test block and the eddy current detection sensor are held and stabilized by people is avoided.

Owner:INNER MONGOLIA POWER GRP

Packaging device for textile fabrics

InactiveCN108584018AScientific and reasonable structureEasy to useWrapper twisting/gatheringFixed frameSelf locking

The invention discloses a packing device for textile fabrics. The packing device for the textile fabrics comprises a packing machine main body, wherein four universal self-locking wheels which are distributed in a rectangular mode are arranged at the bottom end of the packaging machine main body, and a wire winder is embedded in one side wall of the packaging machine main body; a control panel isfixedly connected to one side of the front surface of the packaging machine main body, a pressure gauge is embedded in the position, close to the inner side of the control panel, of the front surfaceof the packaging machine main body; and a cable wire is embedded in the outer side of the wire winder. According to the packaging device for the textile fabrics, the structure is scientific and reasonable, the use is safe and convenient, a fixing frame can be driven to move downwards through an electric hydraulic rod, so that manpower is replaced for pressing a sealing cover, the labor intensity of workers is reduced, the cable wire can be stored through the wire winder, the practicability is improved, the carrying is convenient, the operation is simple, and the position of a bag to be packaged can be adjusted through a transverse scale line and a longitudinal scale line on the upper surface of a sealing placement plate.

Owner:响水县嘉亿纺织有限公司

A composite roller printing dry grain three-dimensional ceramic tile and its production technology

The present invention relates to a composite roller printing dry grain three-dimensional ceramic tile and a production technology thereof, the composite roller printing dry grain three-dimensional ceramic tile comprises, in order from bottom to top, a blank layer, a bottom glaze layer, a mold pattern layer, an anti-wear dry grain layer and a colored embossed dry grain layer, wherein the anti-wear dry grain layer comprises anti-wear dry grains, the particle size of the anti-wear dry grains is 200 to 250 mesh, the colored embossed dry grain layer comprises colored dry grains, and the particle size of the colored dry grains is 120 to 140 mesh. The mold pattern layer and the colored embossed dry grain layer are matched with each other, so that the composite roller printing dry grain three-dimensional ceramic tile has rich patterns and hierarchy; the anti-wear dry grain layer and the colored embossed dry grain layer can increase skid and wear resistance of the ceramic tile, and enhance stereoscopic impression, the anti-wear dry grain layer with the smaller the particle size is closely linked, increases the contact area with a contact substance, increases friction area, and enhances product skid resistance; and the colored embossed dry grain layer with the larger particle size increases embossing thickness and enhances the stereoscopic impression and anti-wear ability of the product.

Owner:MONALISA GRP CO LTD

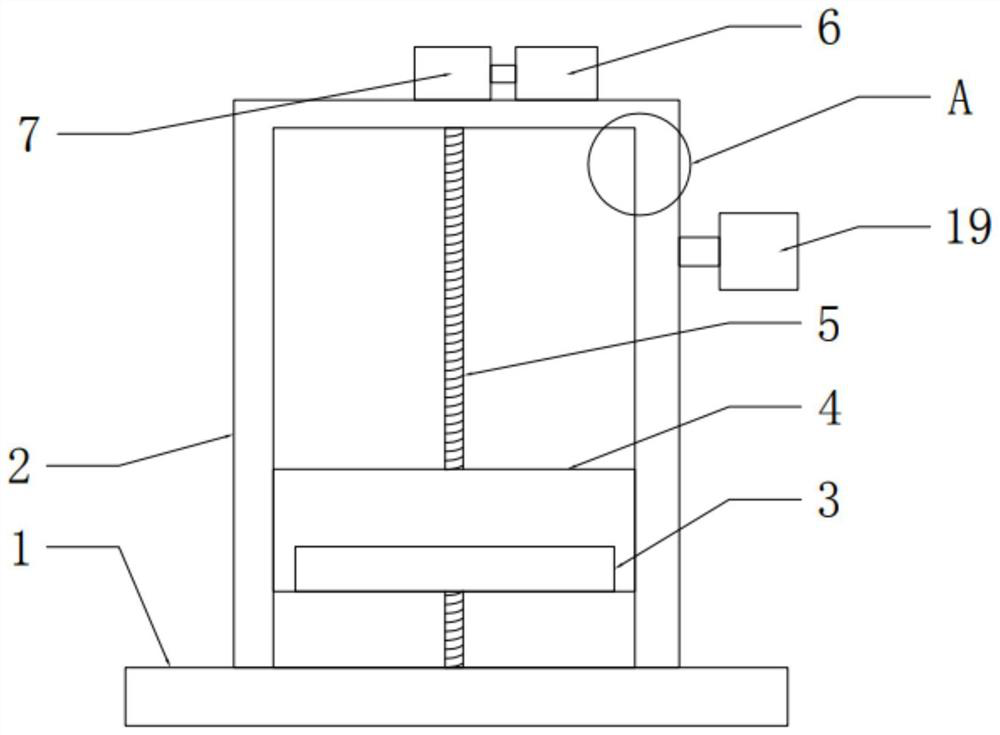

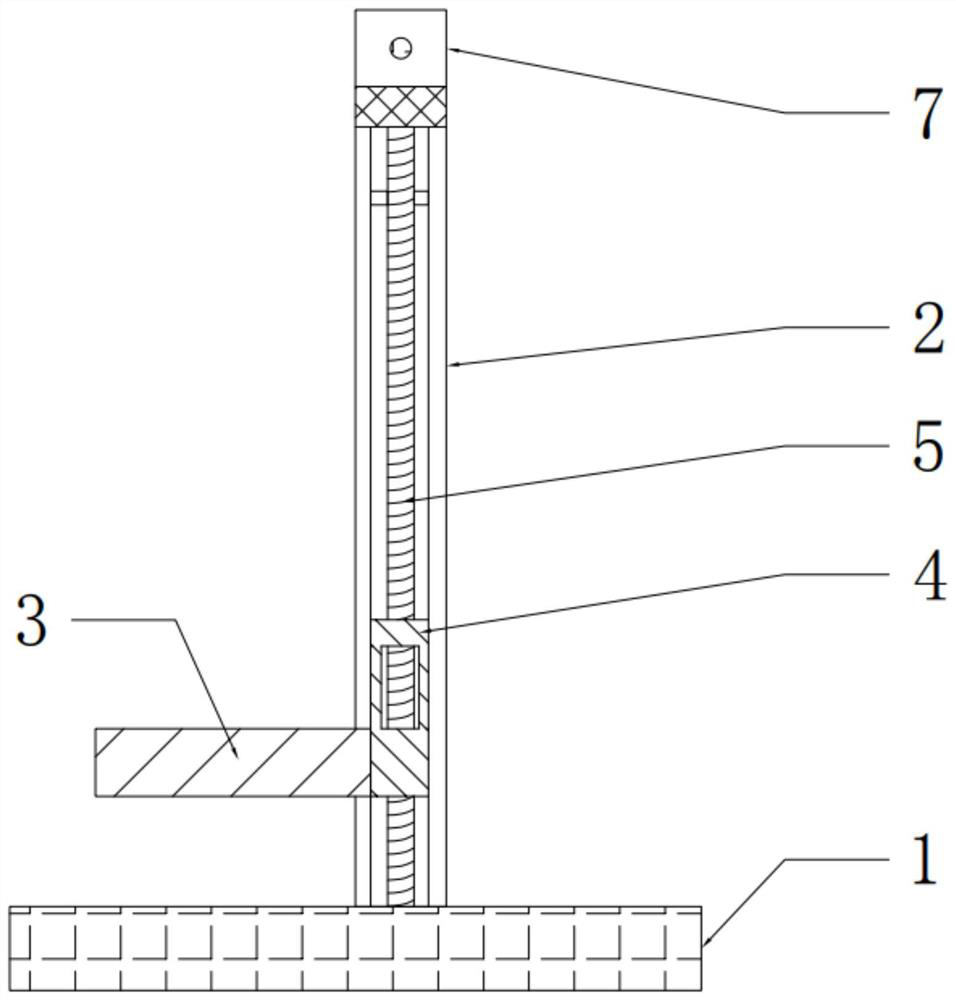

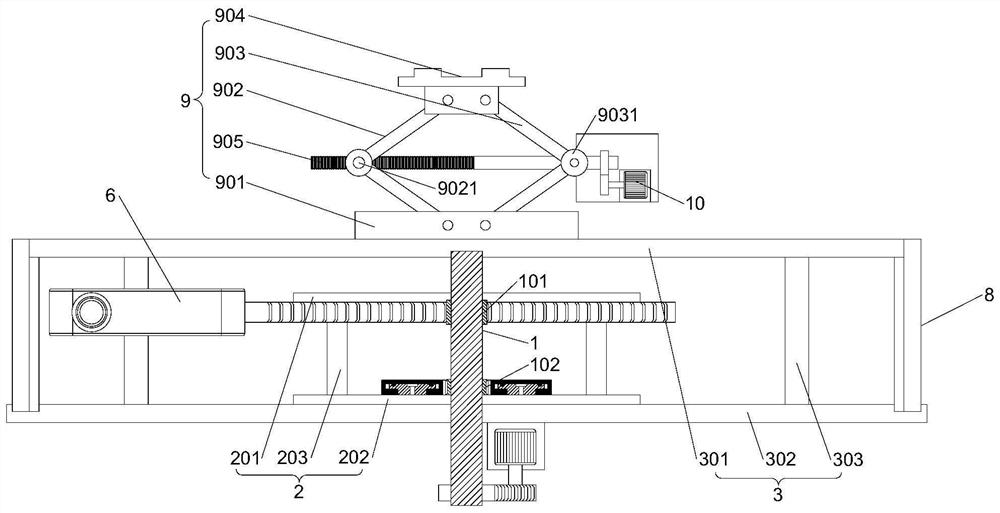

Digital intelligent balance weight device for electrified railway compensation balance weight factory

PendingCN114674406AManual labor intensity is highReduce efficiencyWeighing apparatus detailsTrolley linesElectrical connectionRailway electrification system

The electrified railway compensation balance weight factory digital intelligent counterweight device comprises a bearing base, a vertical slide way and a lifting table, the vertical slide way is vertically arranged at the upper end of the bearing base, a sliding frame is slidably connected in the vertical slide way, and a lead screw is arranged in the vertical slide way and is perpendicular to the bearing base; a threaded hole matched with the lead screw is formed in the sliding frame, the lead screw is in threaded connection with the sliding frame through the threaded hole, a low-speed motor rotationally connected with the lead screw is arranged at the upper end of the vertical sliding way, one side of the lifting table is fixedly connected with the sliding frame, a weight sensor is arranged on the lifting table, and a controller is arranged on the side, away from the lifting table, of the vertical sliding way. The controller is electrically connected with the weight sensor and the low-speed motor. Weight can be monitored in real time when the balance weights are bunched, a worker can directly carry the bunched balance weights, the problem that pre-assembling of an existing overhead line system compensation balance weight cannot meet the pre-assembling requirement is effectively solved, and working efficiency is improved.

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP +1

Diamond thin-wall drill laser welding machine cutter head transmission and clamping system

ActiveCN106984908BReasonable structural designCompact designOther manufacturing equipments/toolsMetal working apparatusTool bitEngineering

The invention discloses a tool bit conveying and clamping system for a diamond thin-walled drill laser welding machine. The tool bit conveying and clamping system comprises a supporting frame, a single-tooth tool bit conveying device, a single-tooth tool bit temporarily-storing device and a horizontal sliding table, wherein the single-tooth tool bit conveying device and the single-tooth tool bit temporarily-storing device are fixed to the supporting frame correspondingly. A single-tooth tool bit clamping device and a ring-tooth tool bit clamping device are arranged at the front end of the horizontal sliding table, and a ring-tooth tool bit conveying device is arranged below the horizontal sliding table. The single-tooth tool bit conveying device is used for conveying a single-tooth tool bit and transferring the single-tooth tool bit to a single-tooth tool bit temporarily-storing station. The single-tooth tool bit clamping device is used for clamping and conveying the single-tooth tool bit temporarily stored on the temporarily-storing device to a welding station. The ring-tooth conveying device is used for conveying a ring-tooth tool bit to a ring-tooth tool bit clamping station, and the ring-tooth clamping device is used for clamping and conveying the ring-tooth tool bit to the welding station. According to the tool bit conveying and clamping system for the diamond thin-walled drill laser welding machine, due to the structural design of the single-tooth tool bit conveying device and the ring-tooth tool bit conveying device, automatic conveying, grabbing and clamping of two kinds of different tool bits are achieved, and a good foundation is provided for the subsequent welding process.

Owner:郑州金海威科技实业有限公司

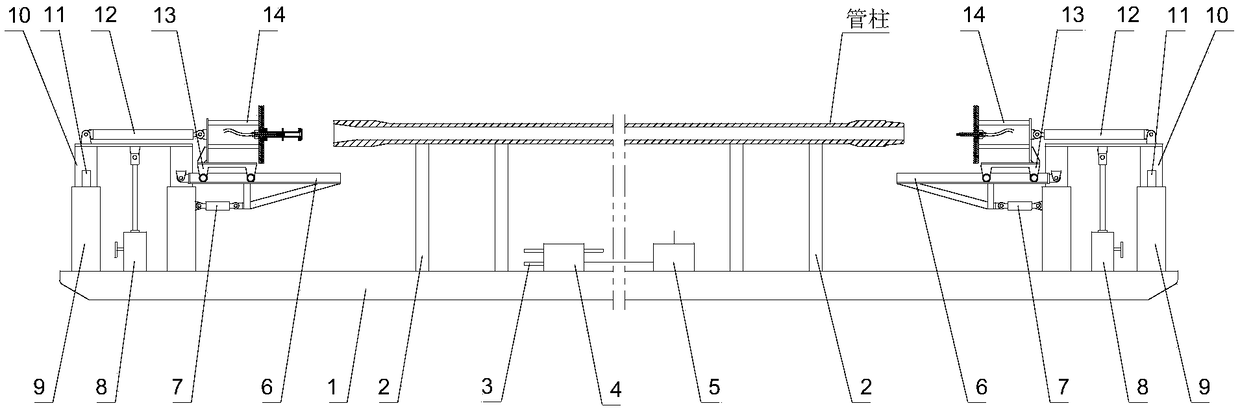

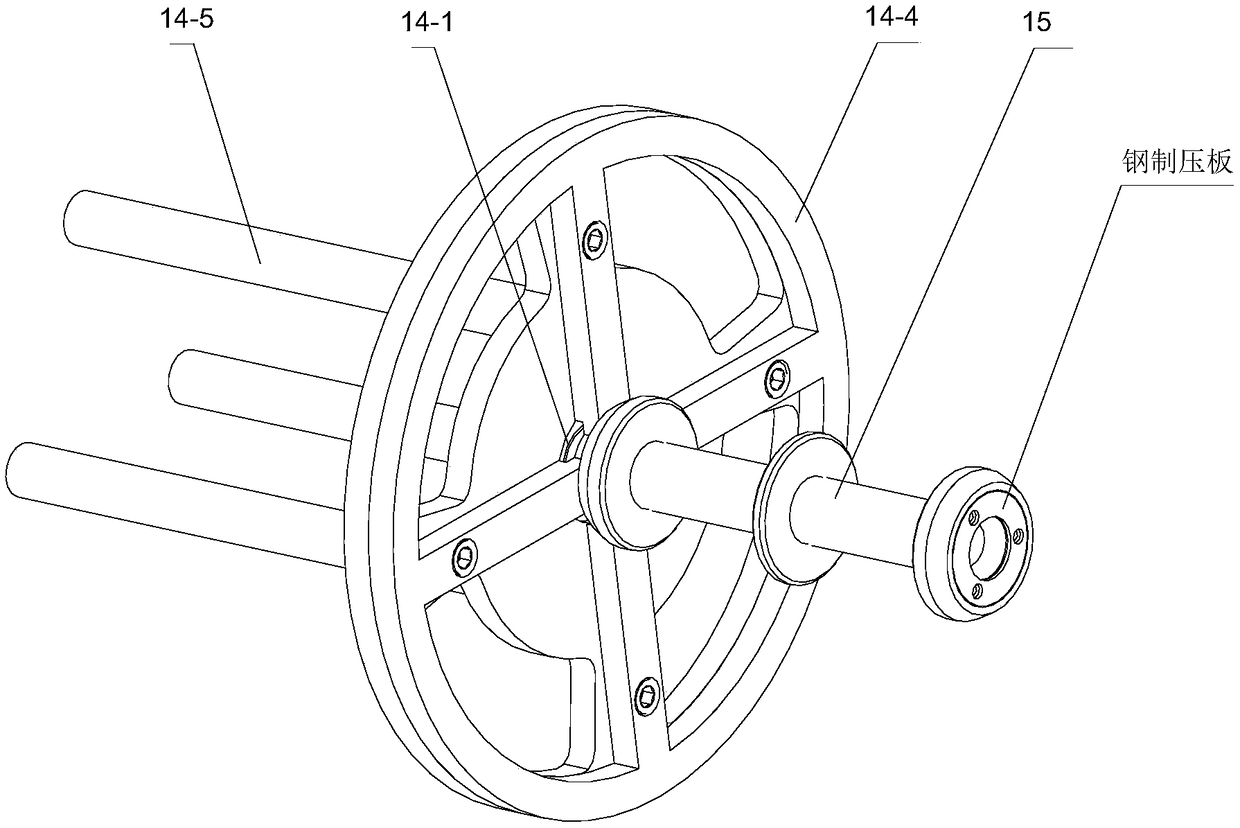

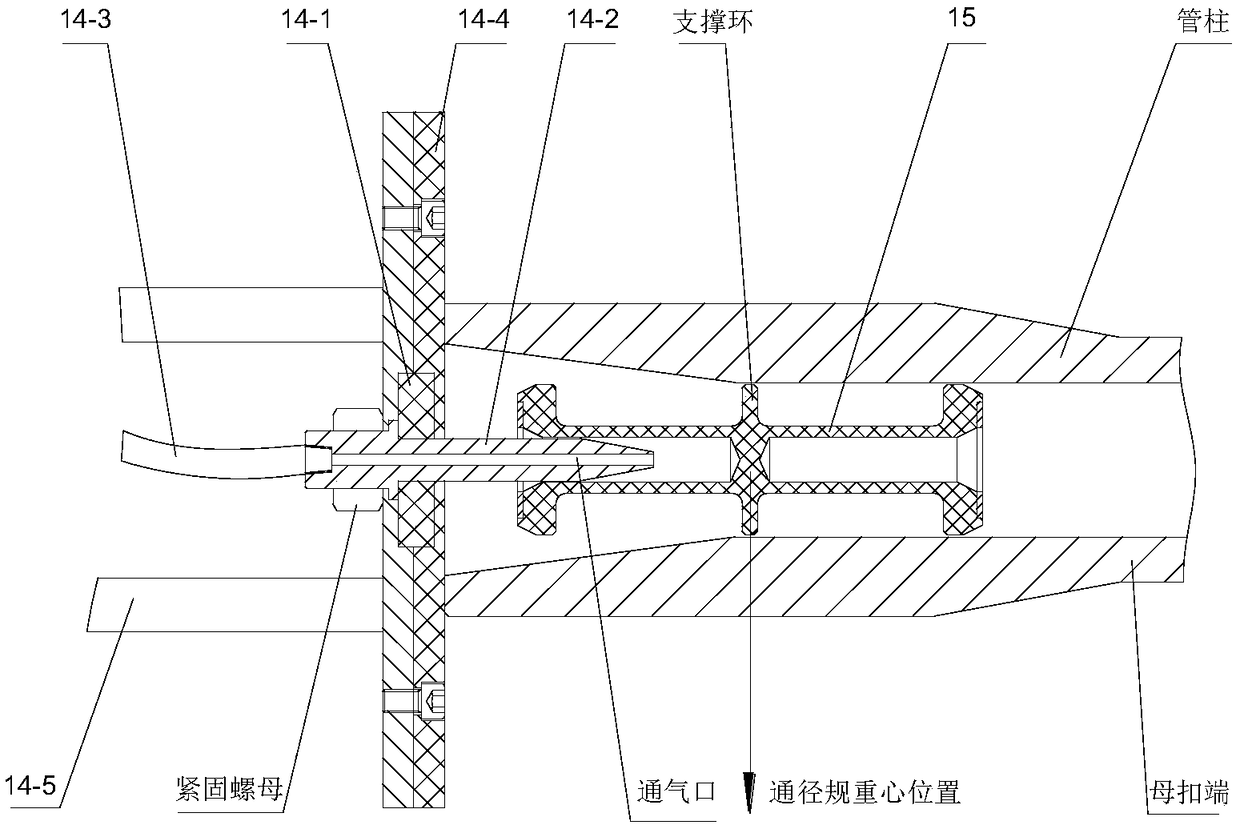

Pneumatic circulating type pipe drift diameter detecting device and pipe drift diameter detecting method

ActiveCN109238098ALow manual work efficiencyManual labor intensity is highMechanical diameter measurementsEngineeringControl valves

The invention discloses a pneumatic circulating type pipe drift diameter detecting device, which comprises a base. A detecting unit is respectively fixedly connected at the two ends of the base; eachdetecting unit comprises a drift diameter detecting mechanism assembly; each of the drift diameter detecting mechanism assemblies is connected with a drift diameter gauge; at least two pipe string positioning frames are arranged on the base between the two detecting units; the base is also provided with a pneumatic control valve group and a controller, which are interconnected with each other; thedetecting unit is respectively connected with the pneumatic control valve group and the controller; and the pneumatic control valve group is also connected with an air source port. The device in theinvention realizes automatic circulating drift diameter operation of the two ends of the pipe string; an unfreezing method when the drift diameter is unqualified is also increased; the controller canbe also used for operation; the automatic degree is high; the labor intensity is greatly reduced; the device is simple and practical; and the equipment investment cost is low.

Owner:BAOJI PETROLEUM MASCH CO LTD +2

Potted seedling lifting and rotating device

InactiveCN103688632BIncrease labor costManual labor intensity is highTransplantingGear wheelModular design

The invention belongs to the technical field of modern agricultural equipment, and discloses a potted seedling lifting and rotating device. The potted seedling lifting and rotating device comprises a seedling lifting and rotating device bracket (20), a seedling lifting driving motor (23), a seedling lifting driving crank (22), a first seedling lifting driving connecting rod (211), a second seedling lifting driving connecting rod (212), a first lifting rod supporting plate (181), a second lifting rod supporting plate (182), a lifting rod (19), a lifting rod rotating driving motor (26), a big gear (28), a small gear (31), a lifting rod rotating driving supporting base (27), a lifting rod sleeve (30) and a lifting rod driving pin (29). The device disclosed by the invention has the characteristics of simple and compact structure and high working efficiency, and is capable of realizing four actions: lifting towards left side, not lifting, lifting towards right side and rotating seedlings, in a process of selecting and transplanting the seedlings, so as to meet a demand of continuous selecting and transplanting operation. Components of the device are in modular design, so as to guarantee high maintenance and good reliability of entire machine. The device is low in manufacturing cost and is economically applicable.

Owner:CHINA AGRI UNIV

A linear drive roller conveyor system

ActiveCN104003128BIncrease swingReduce in quantityCleaningMechanical conveyorsEngineeringDelivery system

The invention discloses a linear driving roller conveying system which comprises a fixing support, a driving mechanism and a conveying system installation plate arranged between the fixing support and the driving mechanism. A sliding groove is formed in the upper end face of the fixing support, one side or two sides of the sliding groove is / are provided with a rack / racks, a gear is arranged at the lower end of the driving mechanism and penetrates through the conveying system installation plate to be meshed with the rack / racks, the two sides of the conveying system installation plate are provided with two roller modules respectively, and the roller modules can horizontally move along a lateral rail after being buckled to a lateral rail of the fixing support. By means of the linear driving roller conveying system, gaps between the lateral rails and the roller modules can be adjusted according to different working conditions through the roller modules, the requirements for accuracy of lateral plate installation blocks and the lateral rails are accordingly reduced, the conveying system is easy to swing under the high-speed working condition, and the roller modules can conduct pre-pressing on the lateral rails to solve the problems.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD +1

Saw blade laser welding machine's cutter head conveying grabbing and clamping system

ActiveCN106271137BReasonable structural designCompact designLaser beam welding apparatusTool bitEngineering

The invention belongs to the technical field of diamond saw web welding. A tool bit conveying, catching and clamping system of a saw web laser welding machine comprises a rack, a tool bit conveying device, a tool bit catching device and a tool bit clamping device, wherein the tool bit conveying device comprises a supporting vertical column and a normal tooth conveying unit and a protection tooth conveying unit which are arranged on the supporting vertical column; the normal tooth conveying unit and the protection tooth conveying unit respectively array normal tooth tool bits and protection tooth tool bits in a fixed direction, and convey the tool bits to a tool bit catching station; the tool bit catching device catches the normal tooth tool bits or the protection tooth tool bits according to a welding working procedure, and conveys the normal tooth tool bits or the protection tooth tool bits which are caught to a clamping station of the tool bit clamping device, and the tool bits are located and clamped by the tool bit clamping device. The tool bit conveying, catching and clamping system of the saw web laser welding machine is integrated and high in mechanical degree, can automatically realize tool bit conveying and clamping, is accurate in location, can greatly reduce the labor intensity of a worker, and is relatively low in labor cost; and the production cost of an enterprise is reduced.

Owner:郑州金海威科技实业有限公司

Automatic separation method and equipment for solid phase products of continuous pyrolysis of waste tire whole tire industry

ActiveCN113072968BContinuous crackingEfficient crackingProductsReagentsCollection systemIndustrial engineering

The invention discloses a method and equipment for automatic separation of solid phase products of continuous cracking of waste tire industry, including a special-shaped double-cone continuous feeding system connected by connecting parts, a cracking reactor main system, a separation system of cracking solid phase products, and steel wires. Conveying system, pyrolysis carbon black continuous output system, pyrolysis oil level automatic collection system, modular distributed intelligent tail gas comprehensive treatment system, pyrolysis non-condensable combustible gas recycling system, combustion heating system and catalytic cracking intelligent control system; cracking solid The phase product separation system includes a solid phase product separation blade and a steel wire conveying blade structure. There is a baffle between the solid phase product separation blade and the steel wire conveying blade, so that the cracked steel wire must cross the middle baffle during the conveying process; the solid phase product separation During the conveying process of the blades, the cracked steel wire clusters are always in the rolling process, so that the carbon black mixed in the cracked steel wires gradually leaks out. The invention solves the problem of low efficiency in the prior art and has high reliability.

Owner:QINGDAO UNIV OF SCI & TECH

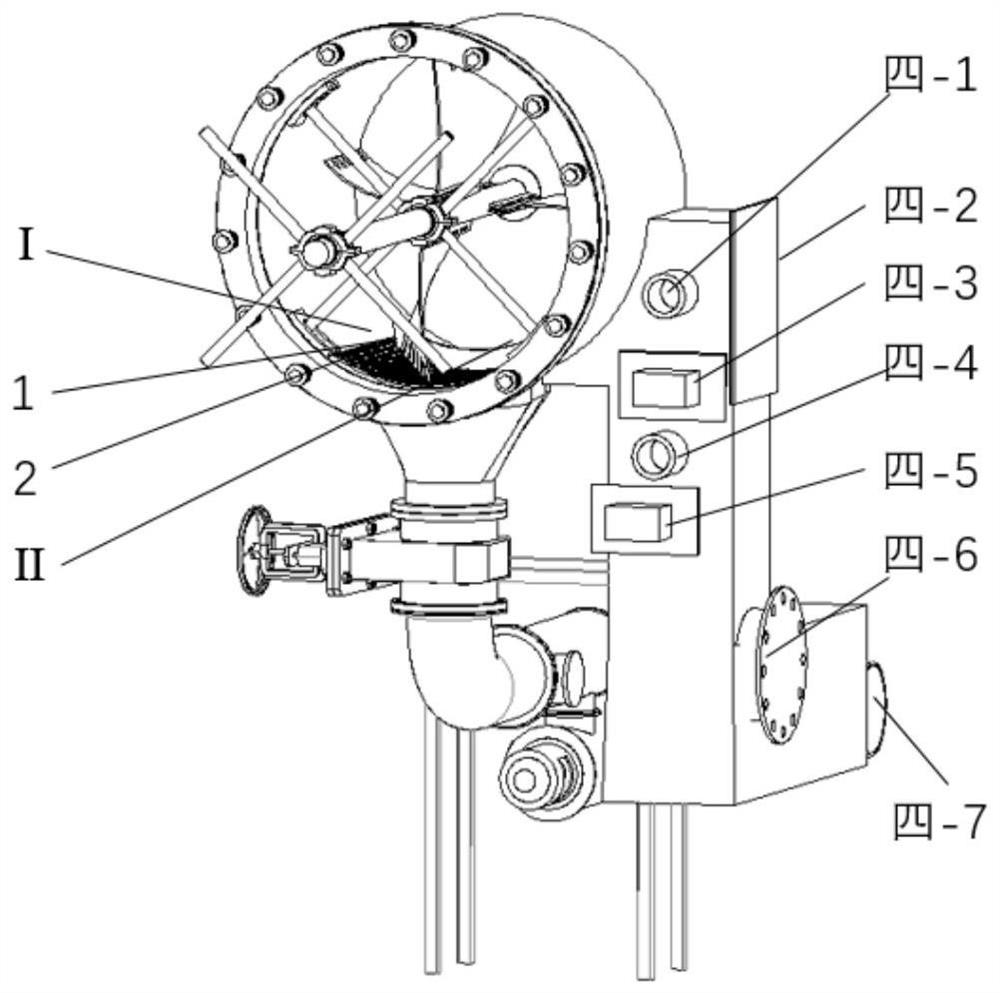

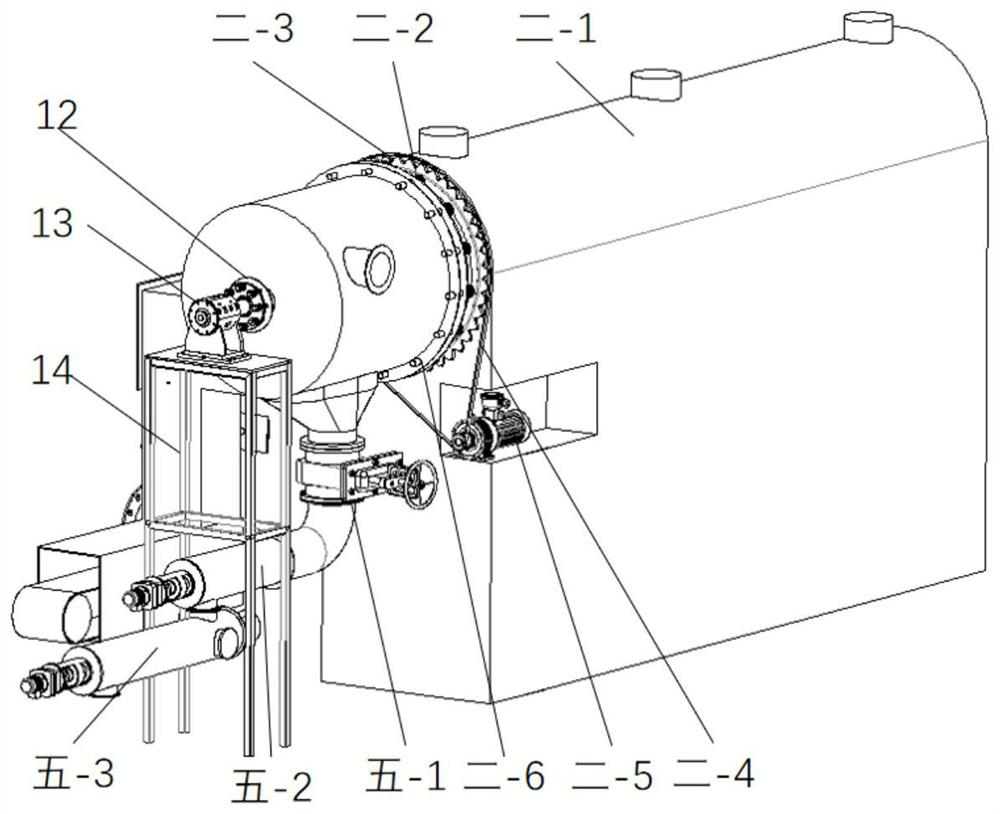

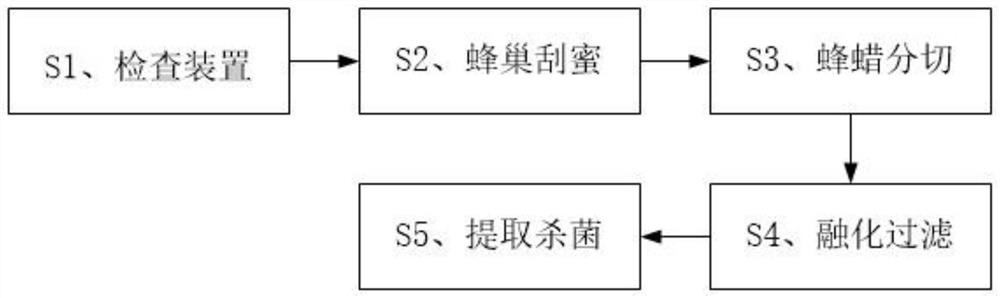

Cosmetic matrix raw material preparation treatment process

InactiveCN112716880ALow efficiencyLow degree of automationCosmetic preparationsToilet preparationsProcess engineeringHoney extraction

The invention provides a cosmetic matrix raw material preparation and treatment process, which uses a cosmetic matrix raw material preparation and treatment device, and the device comprises a support frame, a base, a honey scraping mechanism, a reciprocating motion mechanism and a slitting mechanism. The invention provides a cosmetic matrix raw material preparation and treatment process, which can solve the following problems in the cosmetic matrix raw material preparation and treatment process: a, during beewax extraction, honey in honeycombs needs to be scraped firstly, then beewax is cut into small pieces, and then centrifugal filtration and sterilization are performed to obtain pure beewax; according to traditional honey scraping, honey in honeycombs is shaken out by manually shaking a honey extractor, the extraction mode is low in efficiency, and the manual work intensity is relatively high; b, the honey extractor extracts the honey in the honeycombs to obtain beeswax, and the beeswax is manually cut into small pieces by means of tools in a traditional mode, so that the working efficiency is low, the automation degree of the device is low, and a large amount of manpower is needed.

Owner:南京楠凡钰商贸有限公司

A self-adjusting immersive panoramic projection device

ActiveCN111998192BRealize automatic adjustmentSmall footprintFouling preventionMachine framesPanoramaEngineering

Owner:深圳魔秀文化科技有限公司

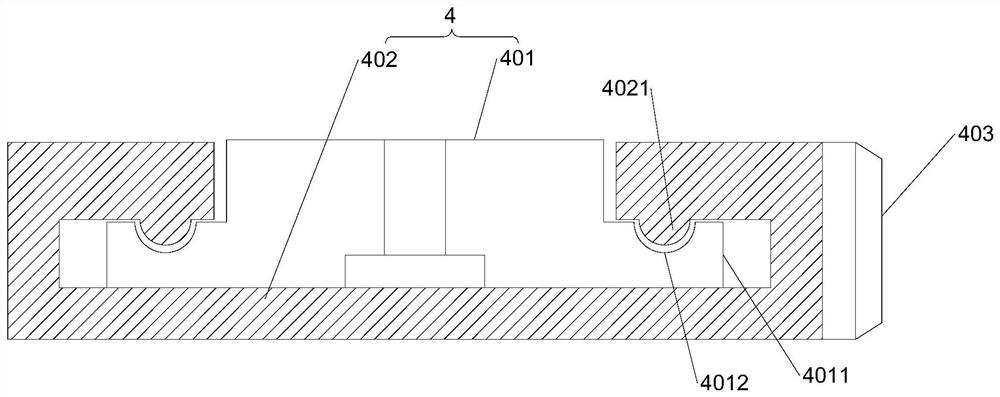

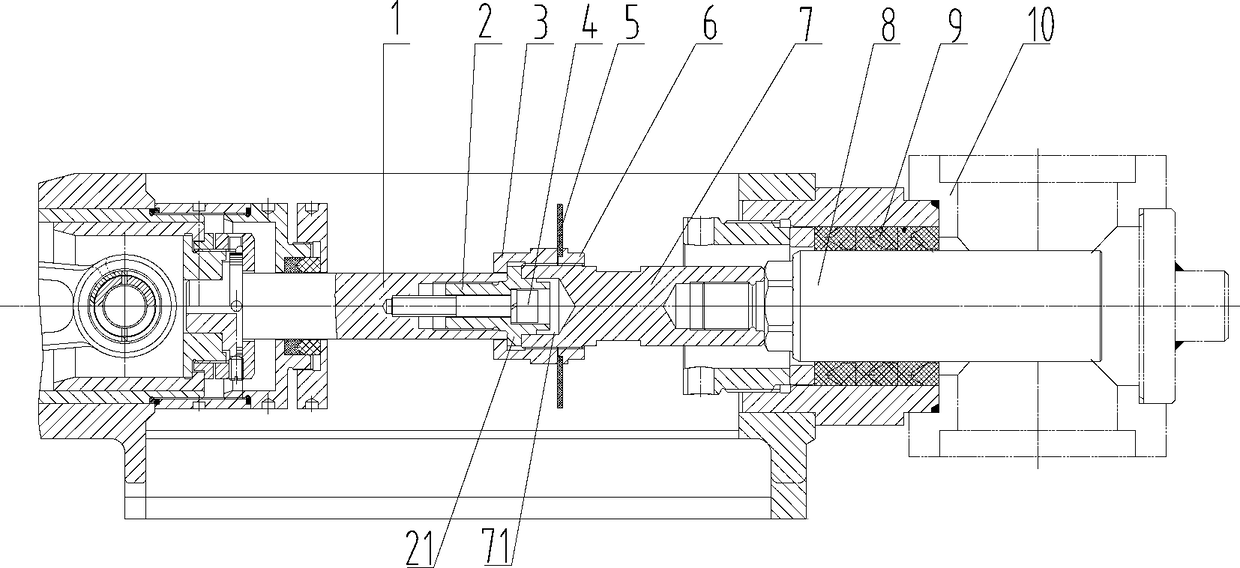

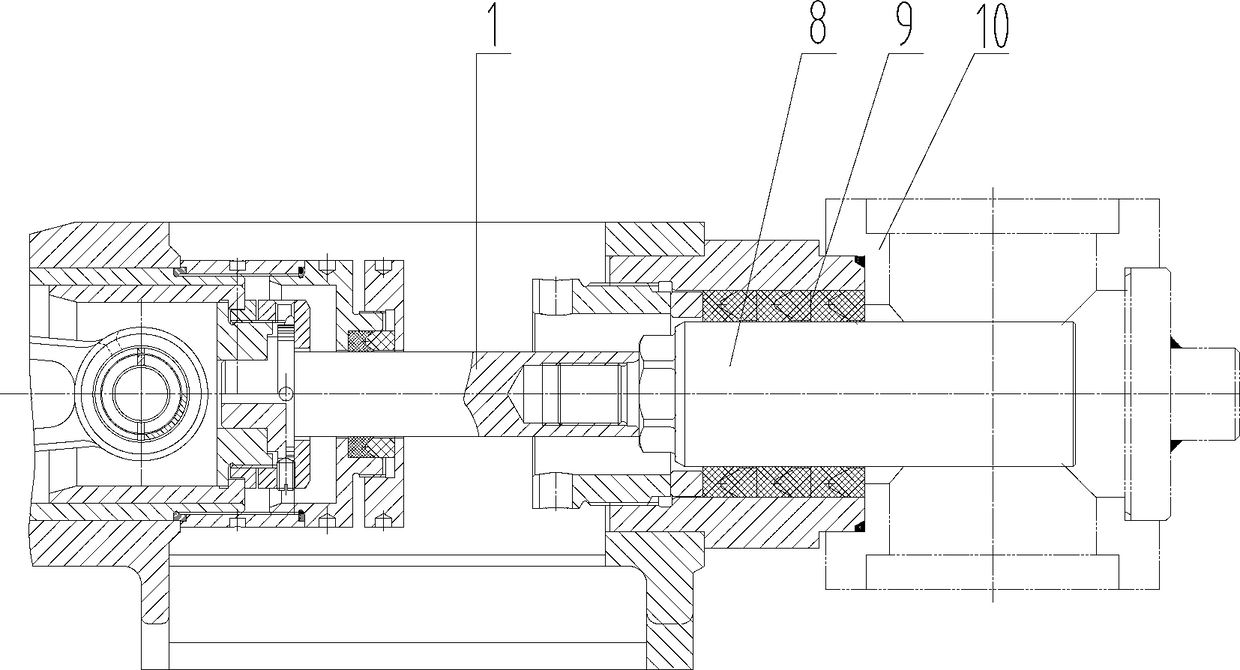

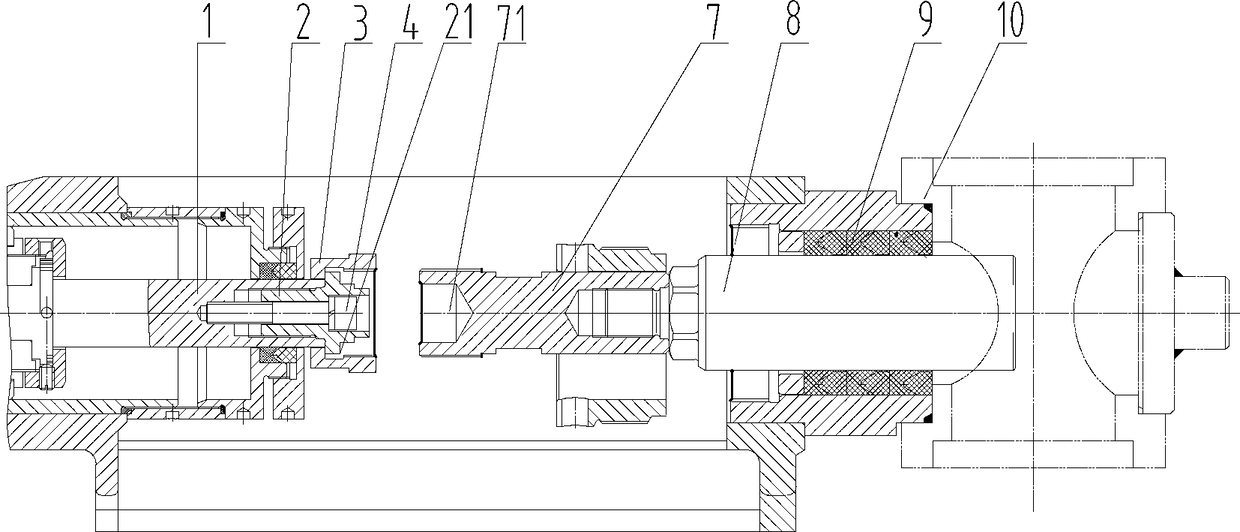

Grouting pump and connecting structure of plunger and crosshead

ActiveCN109058062ARealize detachableManual labor intensity is highPositive displacement pump componentsPumpsEngineeringPlunger

The invention provides a connecting structure of a plunger and a crosshead of a grouting pump. The connecting structure comprises the plunger and the crosshead, the plunger is connected with the crosshead through a connecting body, and the connecting body is of a detachable structure. In the construction site, a three-cylinder grouting pump is generally used, when one plunger is replaced every time, the heavy hydraulic end needs to be disassembled, so that the labor intensity of workers is additionally increased; and in order to better accelerate the efficiency, the plunger and the crosshead are designed into a detachable mechanism, so that the effects that the heavy hydraulic end is not disassembled, the plunger is rapidly replaced, the labor intensity of the workers is reduced, and the construction efficiency is improved are achieved.

Owner:三川德青工程机械有限公司

A method for continuous automatic production of magnesium-rare earth master alloy

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com