Digital intelligent balance weight device for electrified railway compensation balance weight factory

A technology of electrified railways and counterweight devices, which is applied in the direction of measuring devices, detailed information of weighing equipment, instruments, etc., can solve the problem that the pre-allocation of catenary compensation weights cannot meet the pre-allocation requirements, and achieve convenient weighing and high efficiency. Low, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

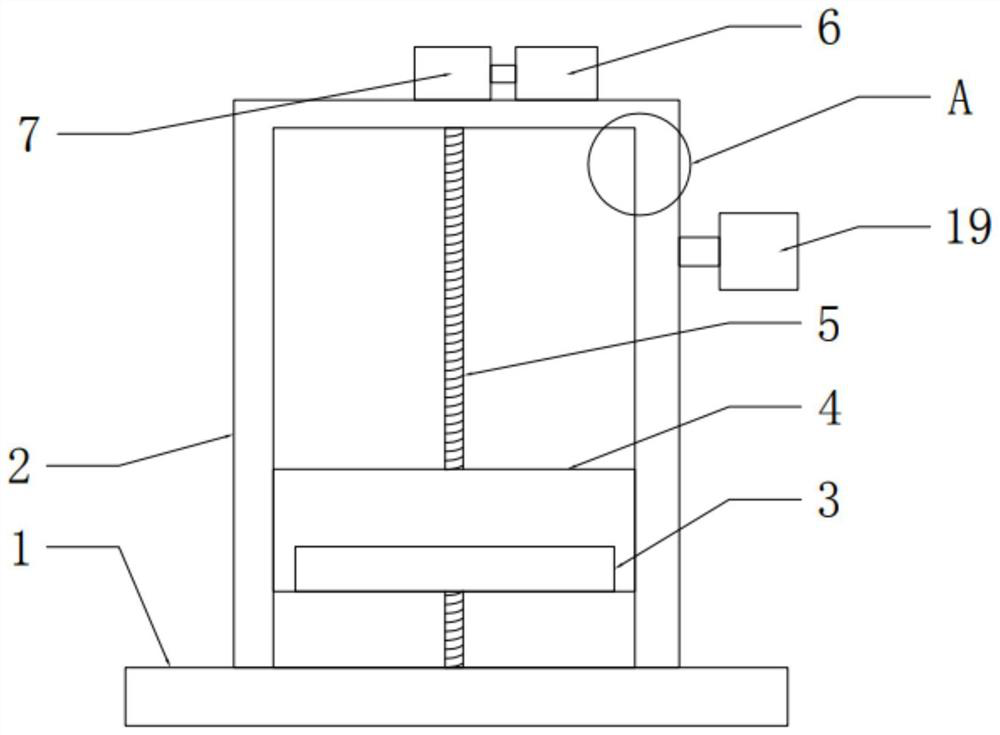

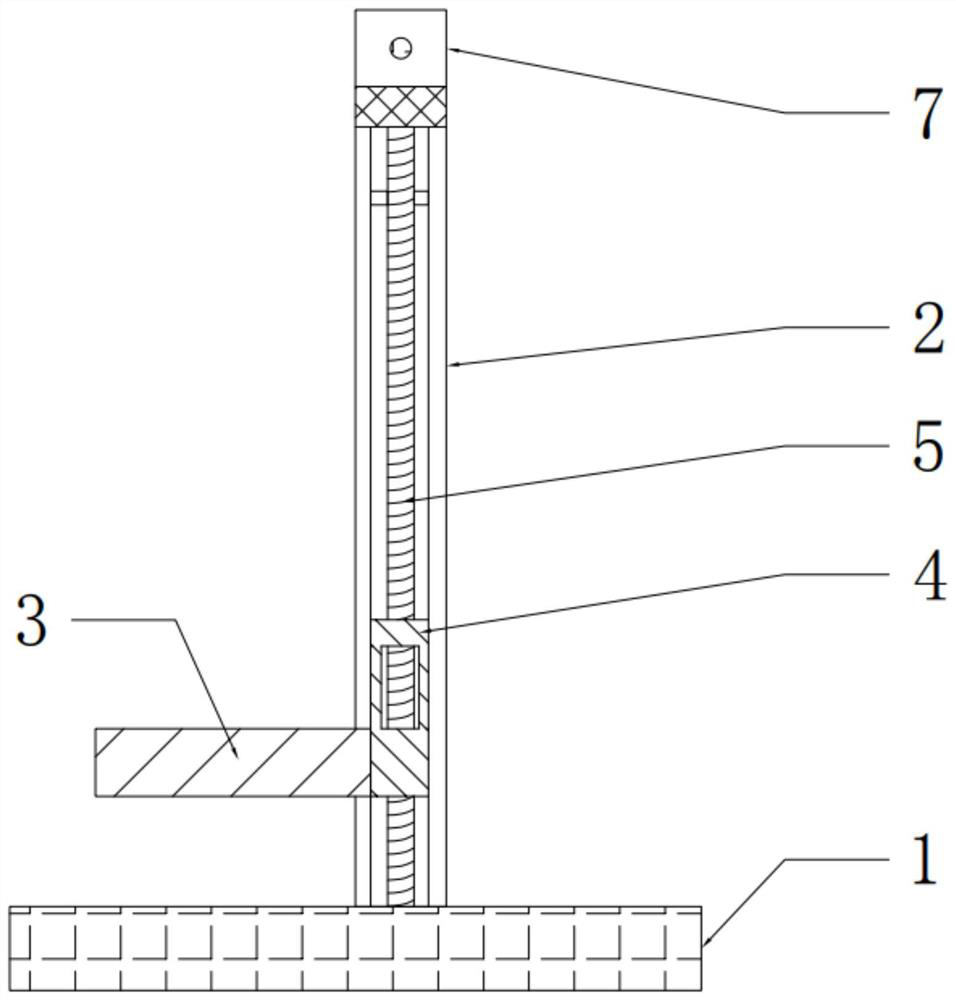

[0038] like figure 1 , figure 2 and image 3 As shown in the figure, the digital-intelligent counterweight device of the electrified railway compensating weight factory includes a load-bearing base 1, a vertical slide 2 and a lifting platform 3. The vertical slide 2 is vertically arranged on the upper end of the load-bearing base 1, and the vertical slide 2 is in the shape of a gate. A sliding frame 4 is slidably connected in the vertical slideway 2, and a screw rod 5 is arranged in the vertical slideway 2. The screw rod 5 is perpendicular to the load-bearing base 1, and the sliding frame 4 is provided with a threaded hole matching the screw rod 5. The rod 5 is connected with the sliding frame 4 through threaded holes, and the upper end of the vertical slideway 2 is provided with a low-speed motor 6 rotatably connected with the screw rod 5. The sliding frame 4 is fixedly connected, the lifting platform 3 is provided with a weight sensor, the side of the vertical slide 2 awa...

Embodiment 2

[0042] like Figure 4 , Figure 5 and Image 6 As shown, the structure of this embodiment is roughly the same as that of Embodiment 2, and this embodiment is further optimized on the basis of Embodiment 1: the lifting platform 3 is provided with a vertically downward through hole 8, and a vertical downward through hole 8 is provided with a pendant. In the mass rod fixing platform 9, the cross-sectional area of the through hole 8 is larger than the bottom end area of the drop mass rod, and the cross sectional area of the through hole 8 is smaller than the bottom end area of the drop mass rod.

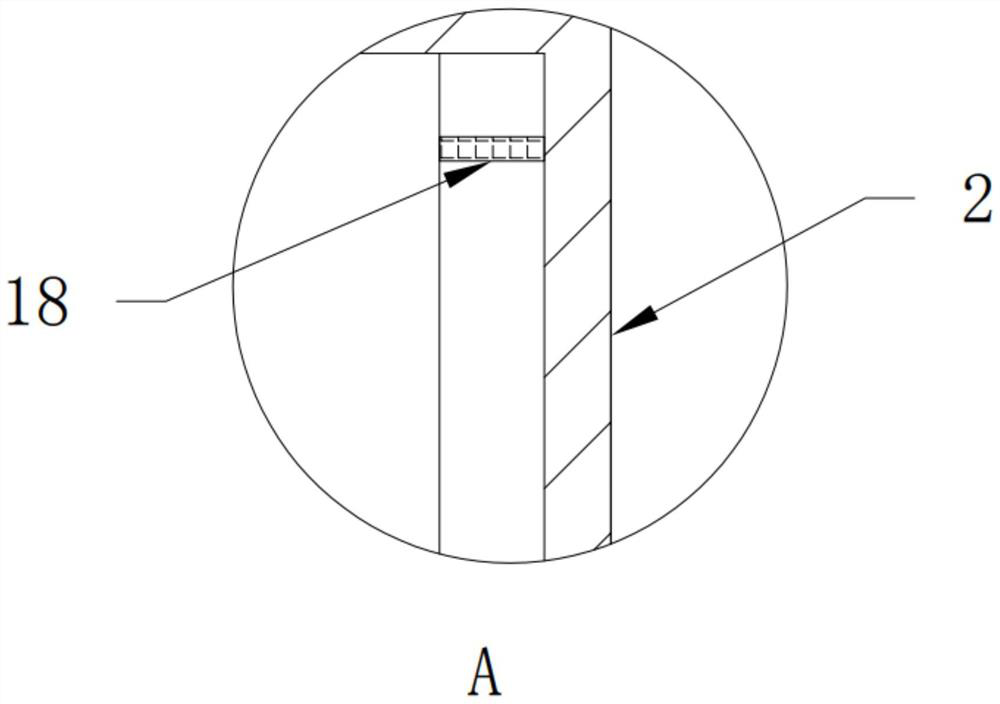

[0043] Further, a limit block 18 is arranged in the upper part of the vertical slideway 2 .

[0044] Further, an organ cover 10 is slidably connected to the side of the vertical slide 2 close to the lifting platform 3 and the side symmetrical to the lifting platform 3 .

[0045] Further, there are buffer pads 11 vertically below the lift table 3 , the number of buffer pads 11 ...

Embodiment 3

[0048] like Figure 7 As shown, the structure of this embodiment is roughly the same as that of Embodiment 2, and this embodiment is further optimized on the basis of Embodiment 2: the two sides of the portal vertical slideway 2 are fixedly connected with a load-bearing main frame 12, and the load-bearing main frame 12 The bottom end is fixedly connected with the load-bearing base 1 .

[0049] Further, the upper end cover of the vertical slideway 2 is provided with a dust cover 13, and the dust cover 13 covers the low-speed motor 6 and the gearbox 7 inside.

[0050] Further, a balance crane 15 is provided on one side of the lifting platform 3, a chassis is provided at the bottom end of the balance crane 15, a leveling leg 16 is provided on the chassis, a pulley is provided at the bottom end of the chassis, and a permanent magnet is provided on the hoisting part of the balance crane 15. Suction cup 17.

[0051] Specifically, the two sides of the frame of the portal vertical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com