Grouting pump and connecting structure of plunger and crosshead

A connecting structure and cross-head technology are applied to the components, pumps, and pump elements of a pumping device for elastic fluids, which can solve problems such as increasing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

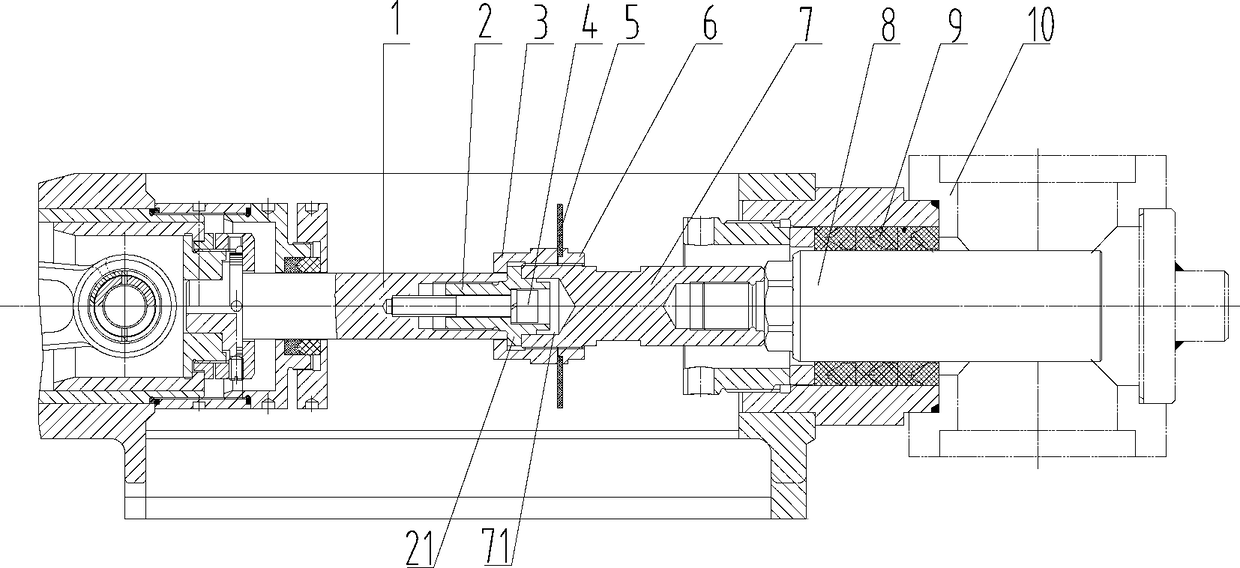

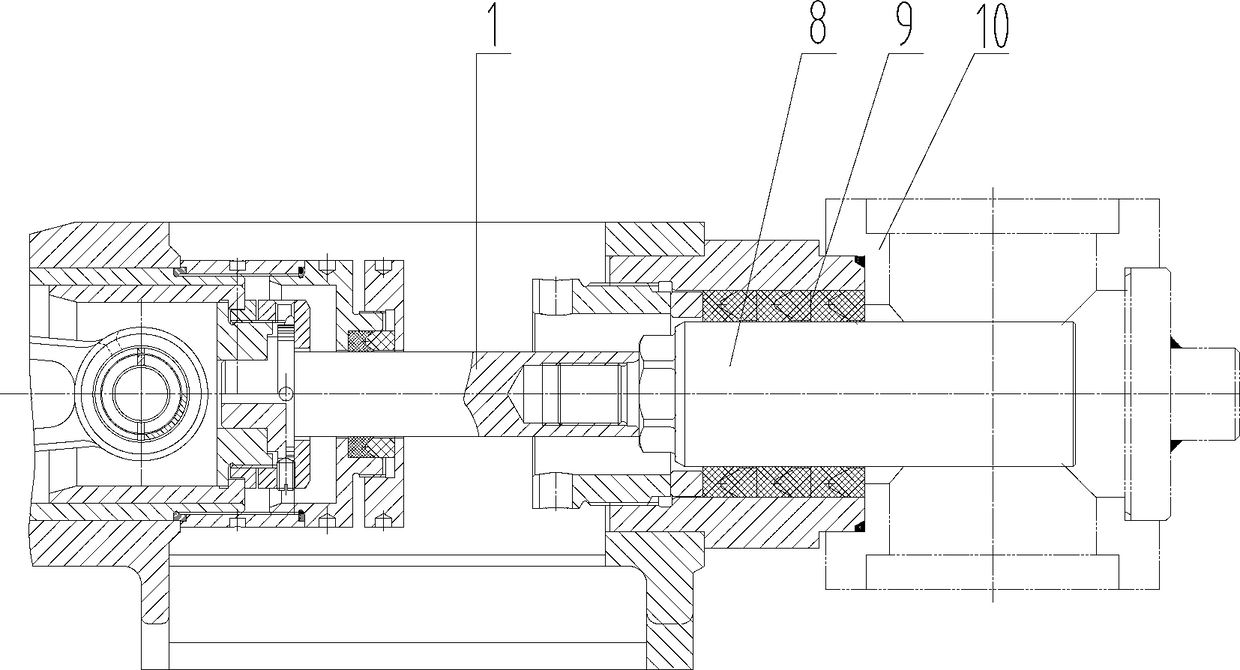

[0026] Such as figure 1 Among them, a connection structure between a plunger and a crosshead of a grouting pump includes a plunger 8 and a crosshead 1, the plunger 8 is connected to the crosshead 1 through a connecting body 7, and the connecting body 7 is a detachable structure. With this structure, it is possible to quickly replace the plunger 8 without disassembling the heavy liquid end, reduce labor intensity, and improve maintenance efficiency.

[0027] The preferred solution is as figure 1 Among them, the crosshead 1 is socketed with the positioning body 2, the outer nut 3 is socketed with the crosshead 1, and is axially limited by the boss 21 of the positioning body 2, the outer nut 3 is threaded with the connecting body 7, and the connecting body 7 is connected with the Plunger 8 threaded connection. With this structure, it is easy to disassemble and improve the coaxial precision between the crosshead 1 and the plunger 8 .

[0028] In a preferred solution, the crossh...

Embodiment 2

[0034] Such as figure 1 Among them, a grouting pump, including a plunger 8, a crosshead 1 for connecting the driving device, the plunger 8 is installed in the cylinder body, the cylinder body is provided with a hydraulic end for liquid inlet and discharge, the plunger 8 is connected to the crosshead 1 through the connecting body 7, and the connecting body 7 is a detachable structure;

[0035] The crosshead 1 is socketed with the positioning body 2, the outer nut 3 is socketed with the crosshead 1, and is axially limited by the boss 21 of the positioning body 2, the outer nut 3 is threaded with the connecting body 7, and the connecting body 7 is connected with the plunger 8 threaded connections.

[0036] In a preferred solution, the crosshead 1 is provided with an internal thread, the positioning body 2 is provided with an external thread, and the crosshead 1 is threadedly connected with the positioning body 2;

[0037] One end of the positioning body 2 is provided with a pos...

Embodiment 3

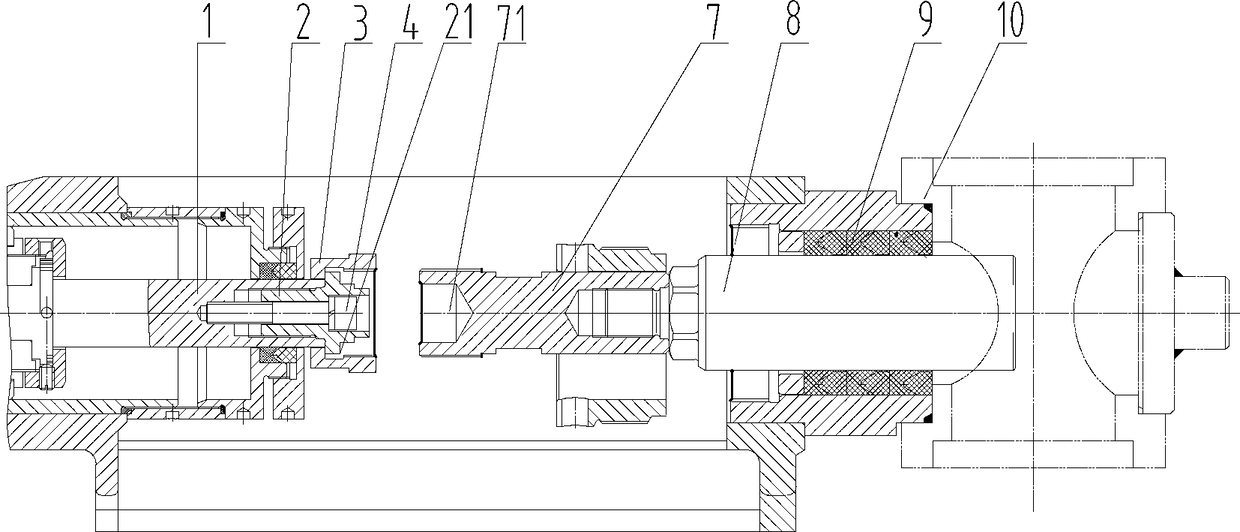

[0043] Plunger removal method attached image 3 , Figure 4 , Turn the crank linkage mechanism of the grouting pump with a tool, the connecting rod drives the crosshead 1 to rotate to the slurry suction position, and loosen the plunger 8 sealing group. Loosen the threaded connection between the locking nut 6 and the outer nut 3 and the connecting body 7, and continue to rotate the crank linkage mechanism so that the connecting rod drives the crosshead 1 to reach the slurry suction limit position. At this time, there is a gap between the connecting body 7 and the positioning body 2 distance. Use a tool to separate the threaded connection between the connecting body 7 and the plunger 8 . Take out the connecting body 7, and finally take out the plunger 8. Putting back the new plunger 8 is a reverse process of disassembly. After the plunger 8 is installed, compress the plunger 8 sealing group.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com