Test pipe segment device for developing internal-flow two-phase-flow Flow-induced Vibration (FIV) experiment

A test tube and tester technology, applied in vibration test, measuring device, machine/structural component test, etc., can solve the problem of limited structural form, difficult to control the flow pattern in the simulated tube, and difficult to control the internal flow in the dynamic response state of the pipeline Type and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0020] The source of medium in the test pipe section is dyed water and air; the equipment provided is centrifugal pump, air compressor and gas-liquid mixer. The specific implementation method is:

[0021] (1) Experiments on the influence of internal two-phase flow flow state changes on pipeline dynamic response

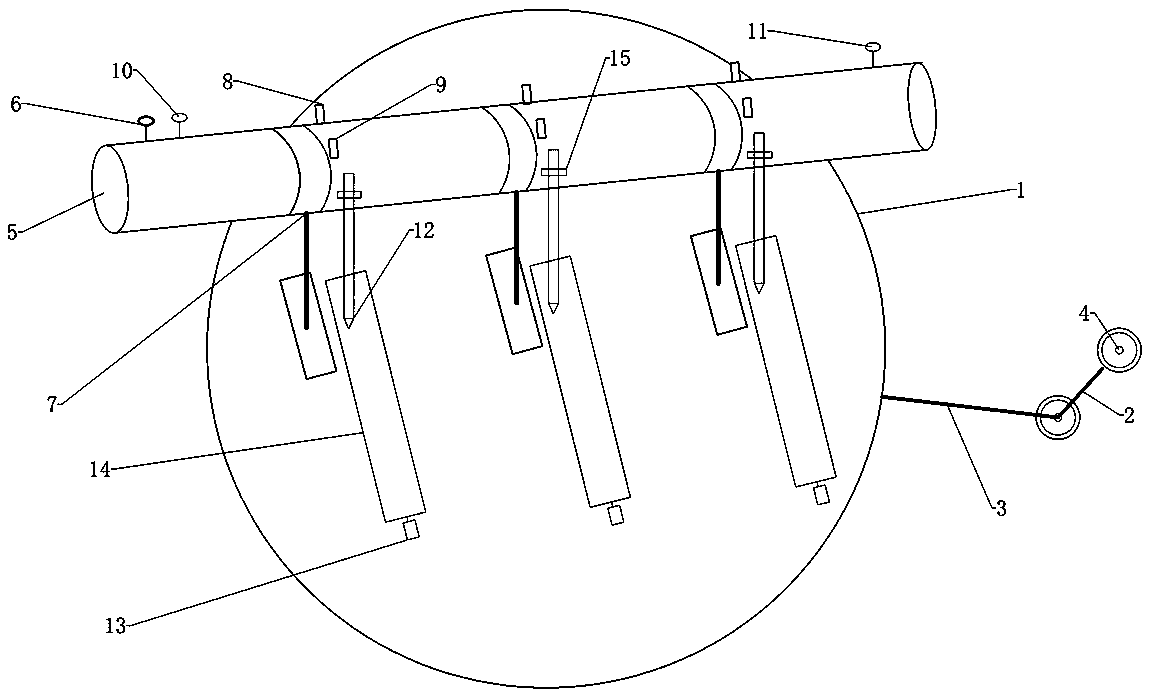

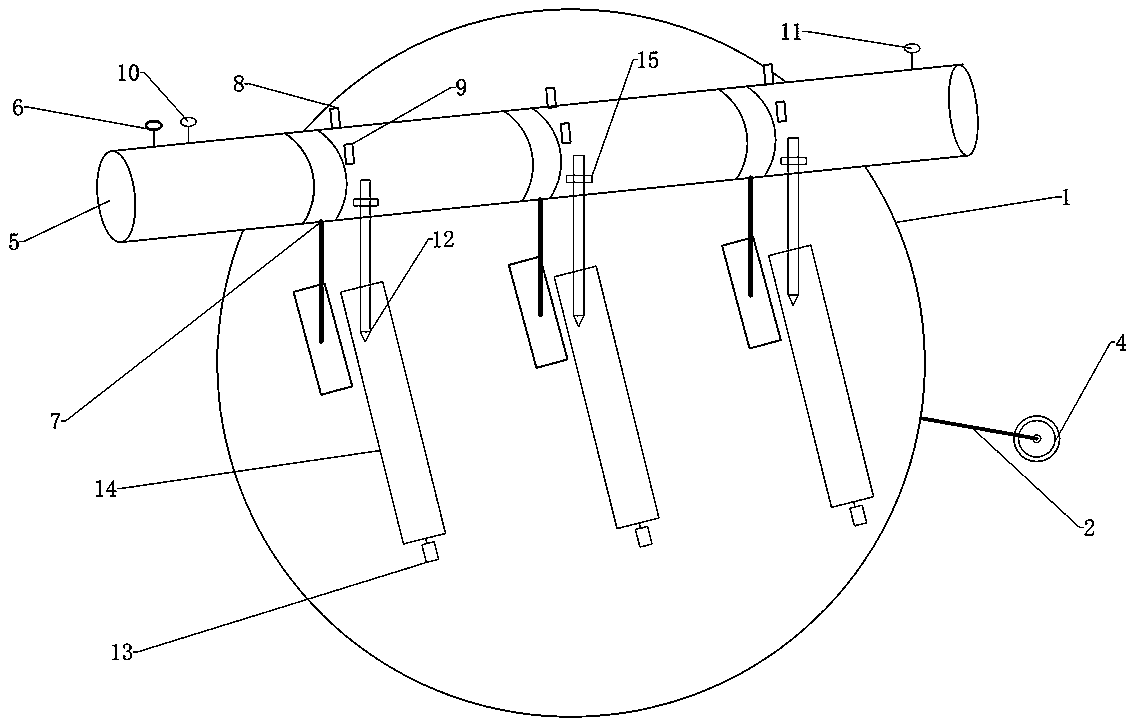

[0022] The first step is to place three 7 movable supports on the 1 / 4, 1 / 2, 3 / 4 lengths of the 5 transparent tempered glass tubes, and fix the main body of the test tube section. Arrange the high-speed camera so that it is parallel to the main body of the test pipe section. At 1 / 4, 1 / 2, and 3 / 4 of the pipeline, arrange 8 gamma ray testers, 9 acceleration sensors, 12 pencils, 13 uniform moving cars and 14 paper tapes;

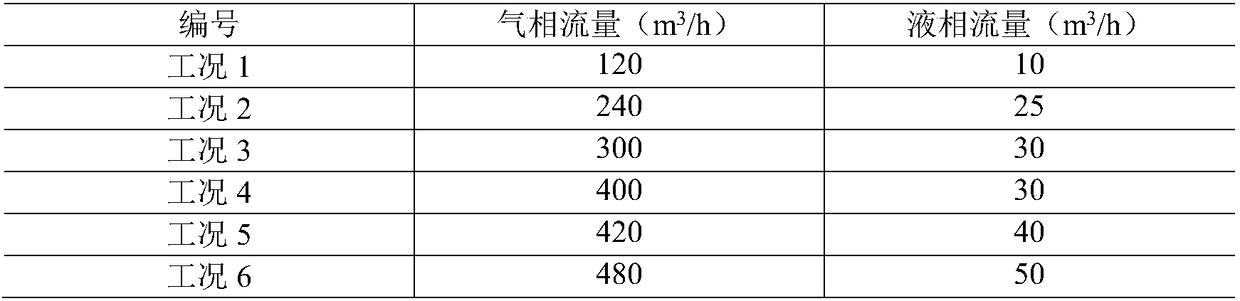

[0023] The second step is to set 6 groups of different working conditions, as shown in Table 1, in which the gas flow range is 0-480m 3 / h, the liquid flow range is 0-50m 3 / h;

[0024] Table 1 Experimental working conditions table

[0025]

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com