Packaging device for textile fabrics

A technology of textile fabrics and packaging machines, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of prolonging production and processing time, increasing labor intensity, and single function, so as to prolong production and processing time and increase Great artificial labor intensity, scientific and reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

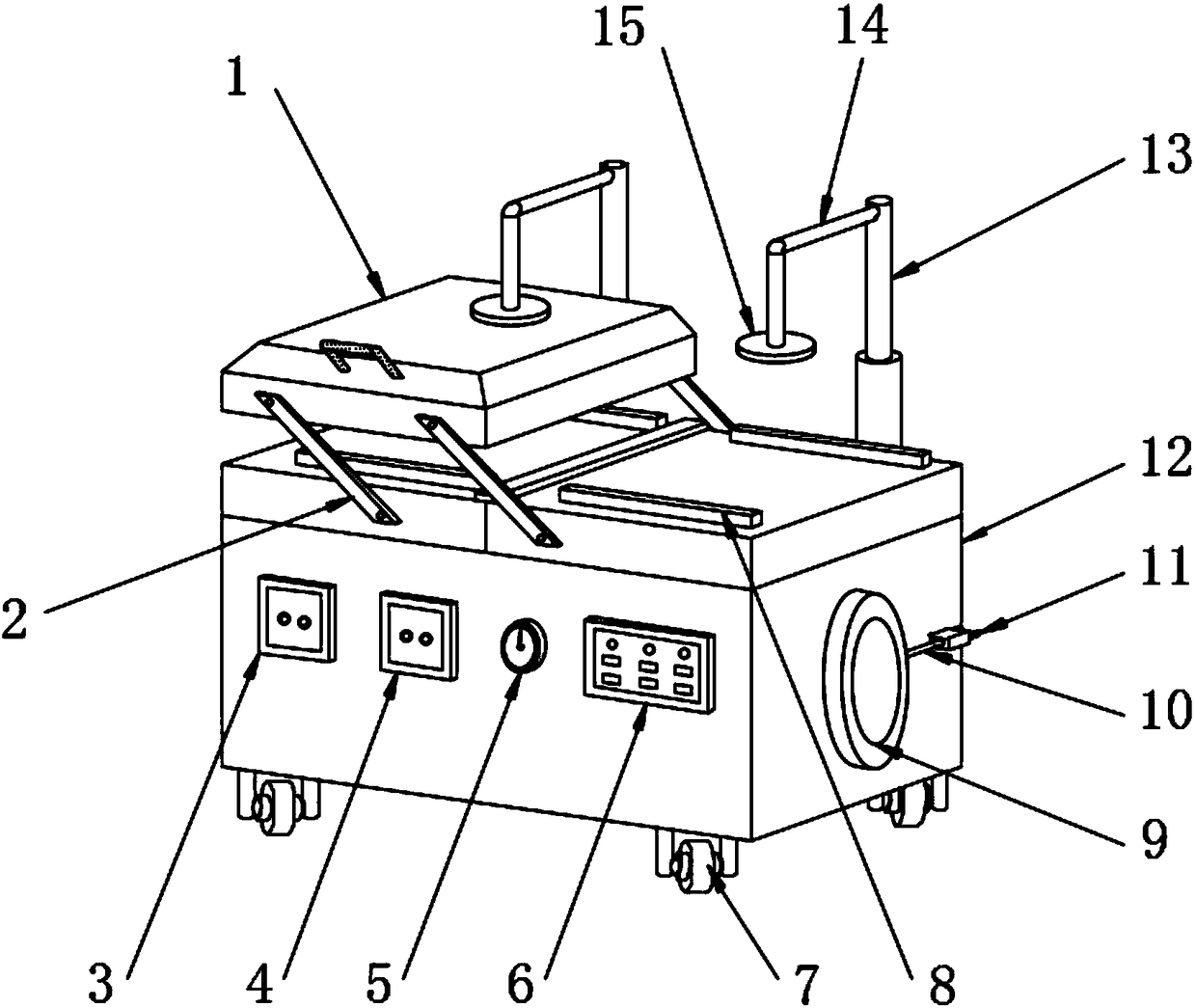

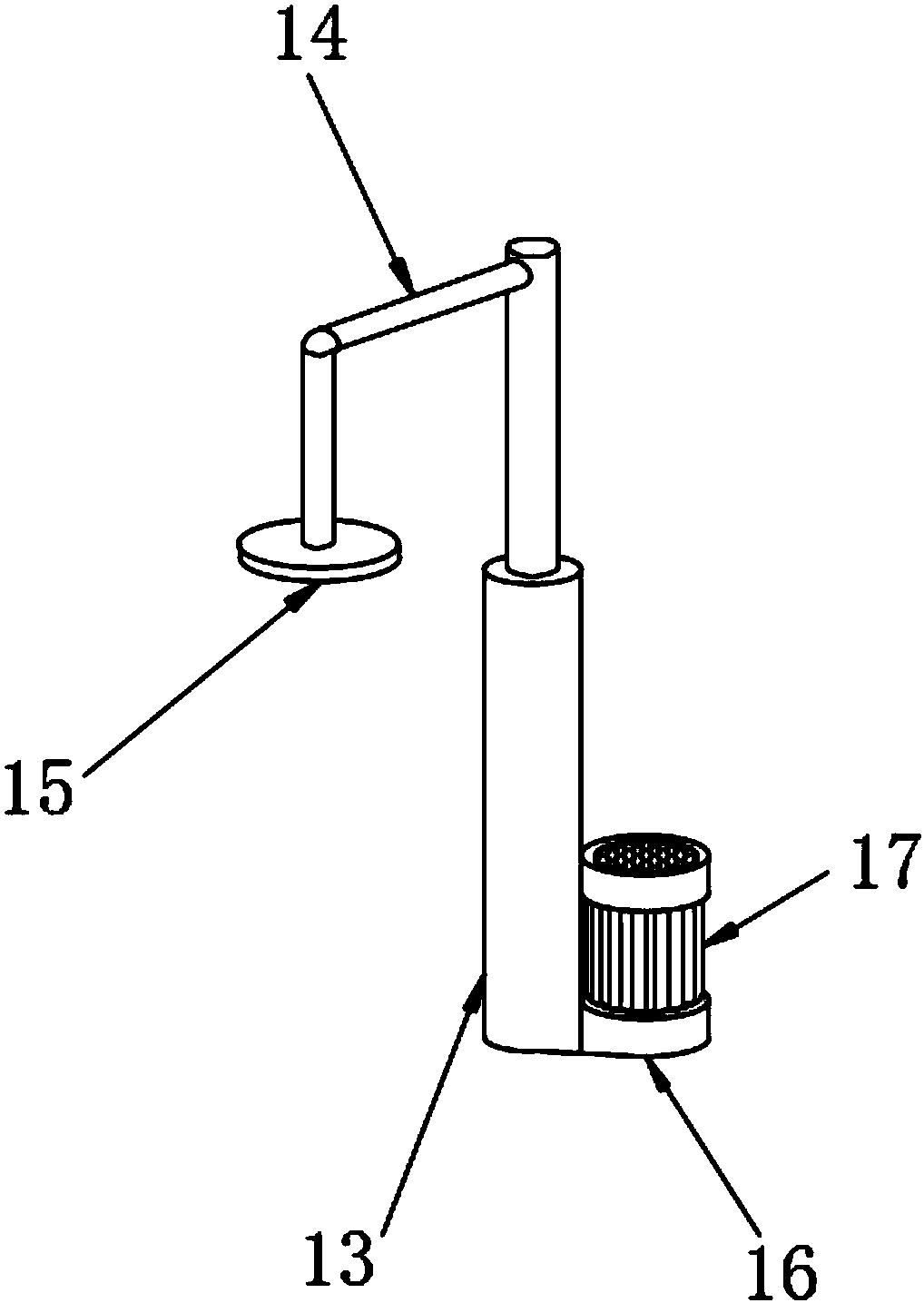

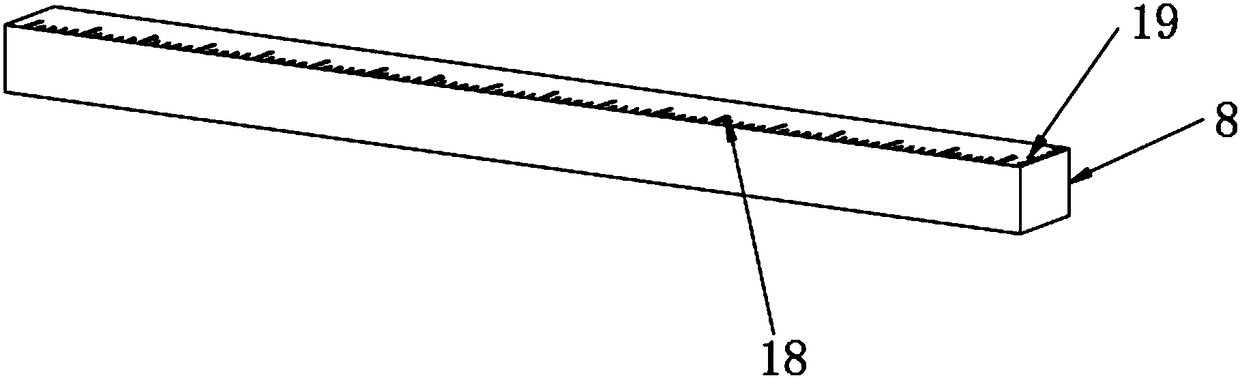

[0018] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a packaging device for textile fabrics, comprising a packaging machine main body 12, the bottom of the packaging machine main body 12 is provided with four universal self-locking wheels 7 distributed in a rectangular shape, and the packaging machine A wire take-up device 9 is embedded on one side wall of the main body 12, a control panel 6 is fixedly connected to one side of the front surface of the main body 12 of the packaging machine, and a Barometer 5, cable 10 is embedded in the outside of wire take-up 9, plug 11 is installed on one end of cable 10, a second control switch 4 is arranged on one side of barometer 5, and second control switch 4 is arranged on one side There is a first control switch 3, the upper surface of the main body 12 of the packaging machine is fixedly connected with a sealing placement plate 8, and the rear side of the main body 12 of the packaging machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com