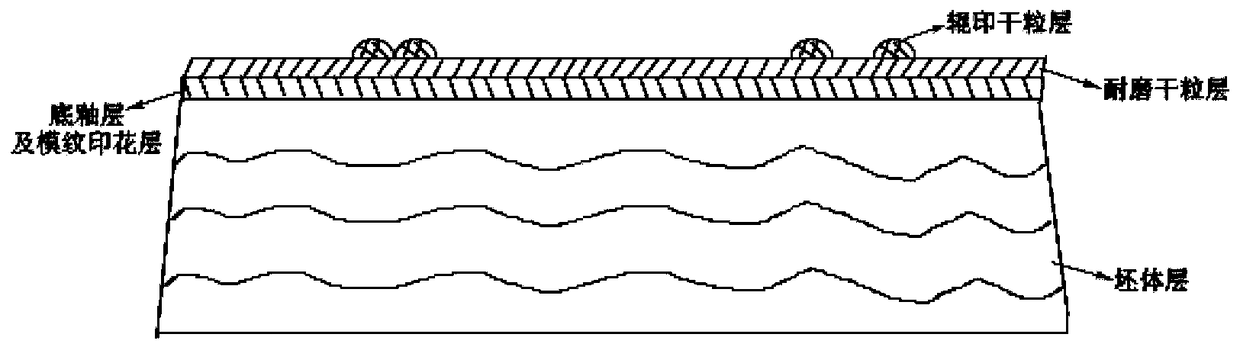

A composite roller printing dry grain three-dimensional ceramic tile and its production technology

A compound roller and dry granulation technology, which is applied in the field of ceramic tile production and manufacturing, can solve the problems of single dry granule layer, difficulty in achieving three-dimensional effect, wear resistance and anti-slip performance, and no open process, etc., to achieve simple and easy process, rich patterns and layers sex, enhance the three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In this embodiment, the formula of roller printing dry particles and friction glaze dry particles are as follows (where L.O.I refers to loss on ignition):

[0056] ingredient

SiO 2

Al 2 O 3

MgO

CaO

K 2 O

NaO 2

A

B

C

L.O.I

total

Dry glaze formula

48.82

24.63

3.5

6.2

4.5

3.0

3.2

3.6

0.7

1.2

99.35

Roll printing dry granular formula

46.79

28.90

3.81

5.24

3.7

3.22

2.12

3.5

0.65

1.47

99.51

[0057] Specific steps are as follows:

[0058] 1. Spray colored base glaze on the dry blank;

[0059] 2. Inkjet printing pattern pattern: After the glaze is applied, the pattern color design of the pattern is printed on the surface by inkjet;

[0060] 3. Then use a thicker screen to evenly print the processed friction glaze on the brick surface. The particle size of the friction glaze dry particles is 200 mesh, the non-slip corundum factor 850 mesh is added 4%, and the glaze thickness is 0.3mm;

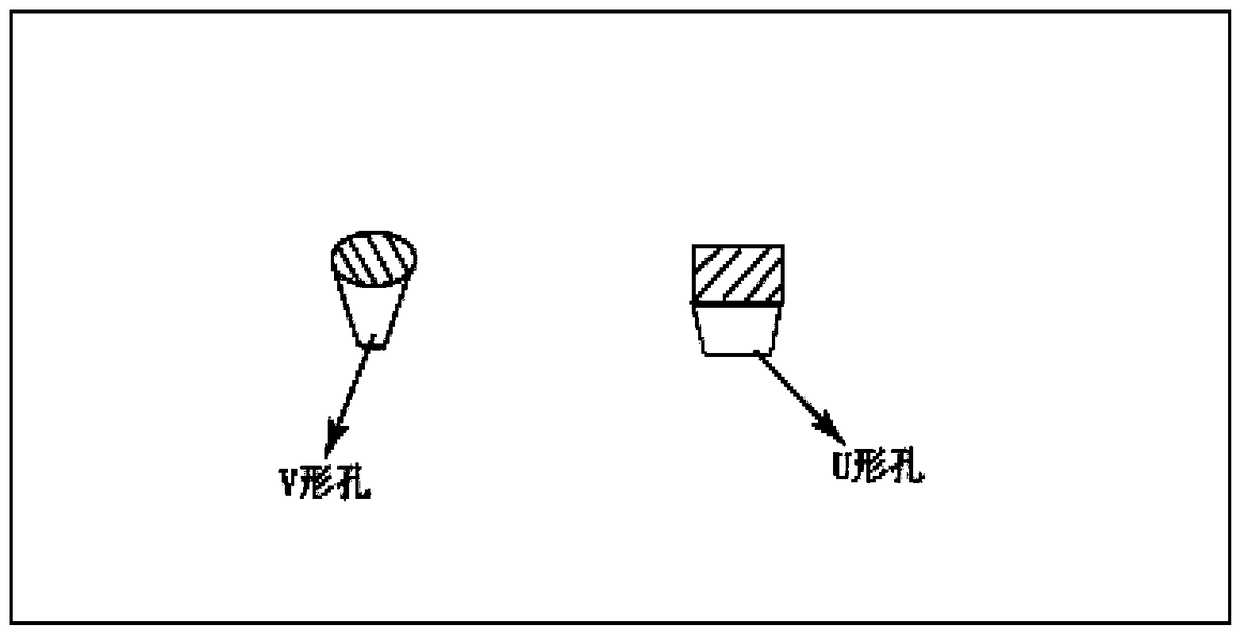

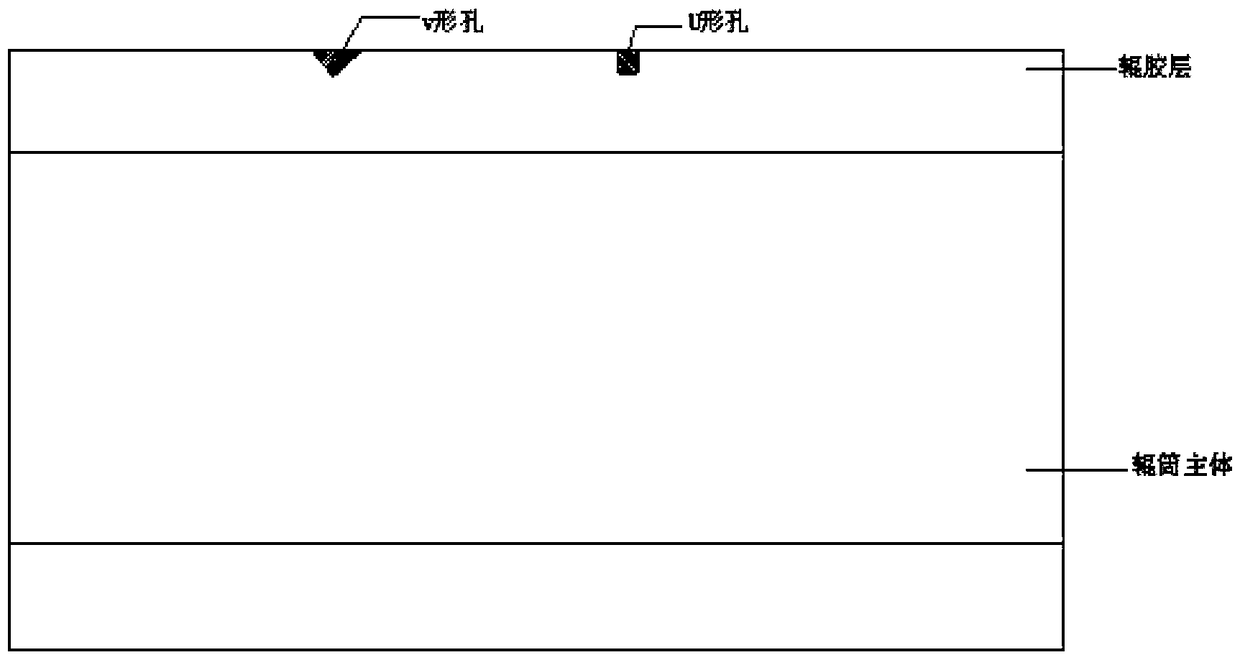

[0061] 4. Roll-printed colored embossed dry particles: The diameter of the roller-printed dry particles is 120...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com