Tool bit conveying and clamping system for diamond thin-walled drill laser welding machine

A laser welding and thin-wall drilling technology, applied in laser welding equipment, welding equipment, metal processing and other directions, can solve the problems of implementation and promotion of laser welding technology, and achieve great market prospects and market value, great labor intensity, accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

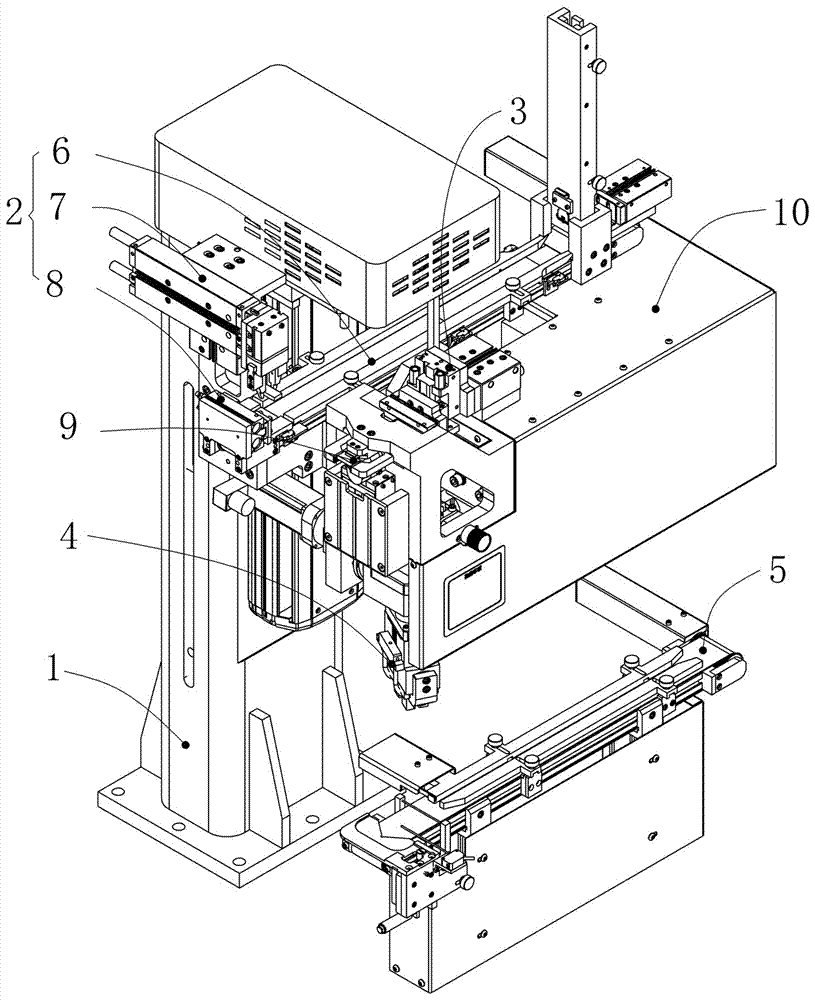

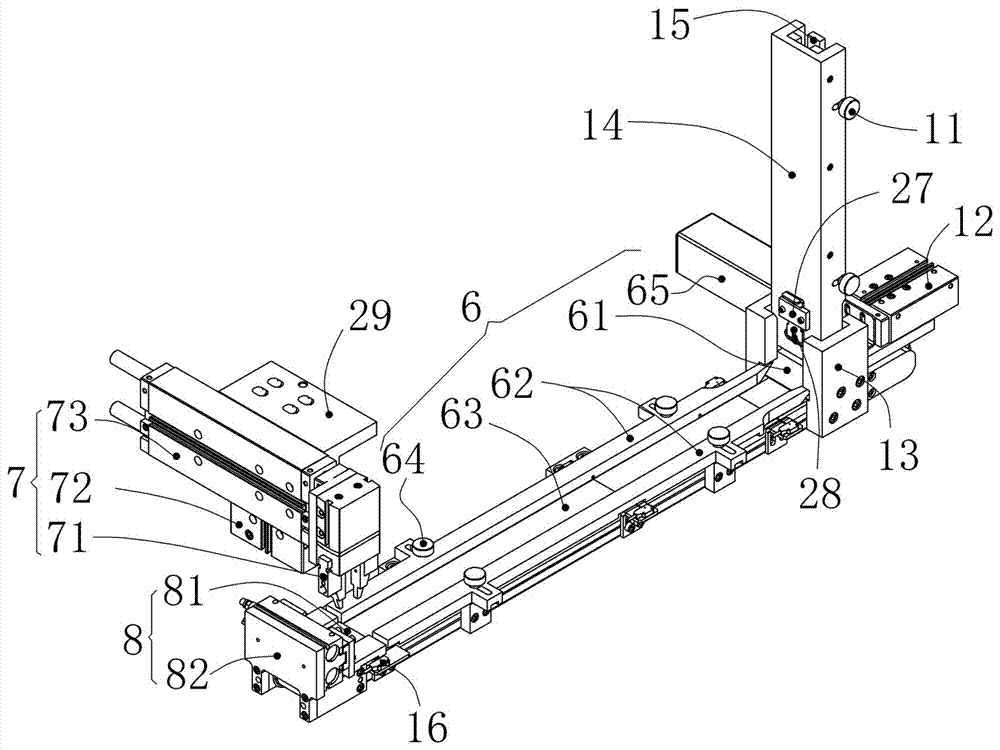

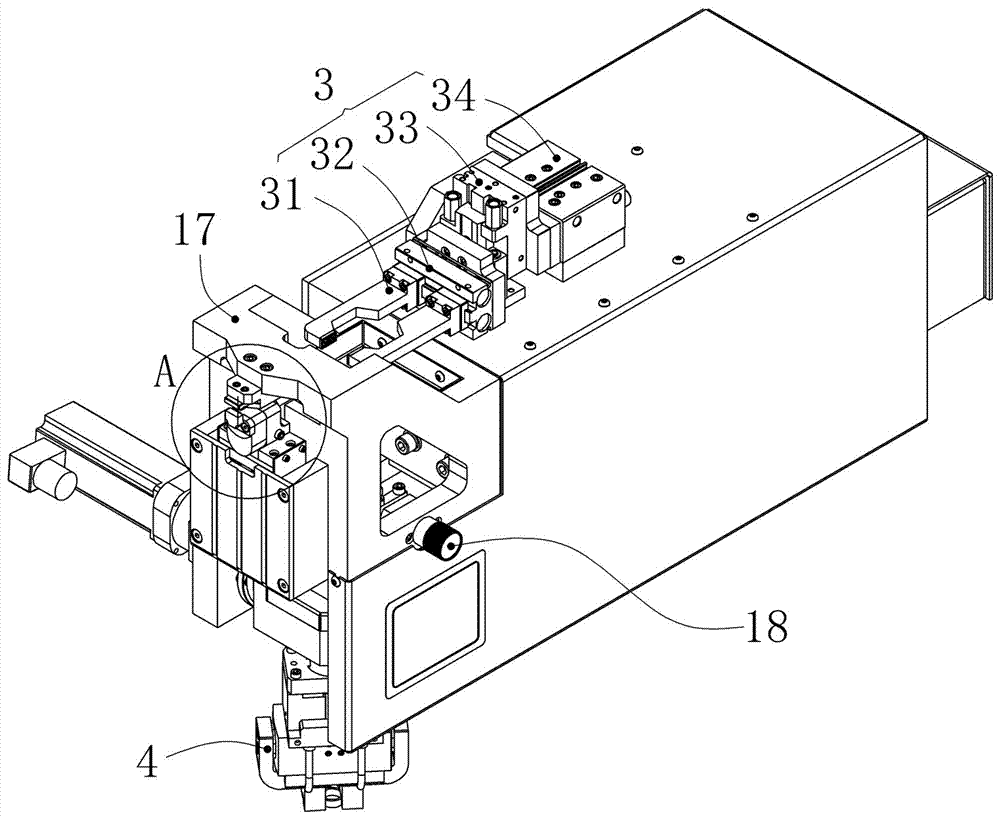

[0026] Embodiment 1: see Figure 1 to Figure 6 , a diamond thin-wall drill laser welding machine cutter head transmission and clamping system, including a support frame 1, a single-tooth cutter head transmission device 2 fixed on the support frame 1, a single-tooth cutter head buffer device 3, and a horizontal slide table 10 , the front end of the horizontal slide table 10 is provided with a single-toothed cutter head clamping device 9 and a ring-toothed cutter head clamping device 4, and a ring-toothed cutter head conveying device 5 is provided below it; the single-toothed cutter head conveying device 2 will The single-tooth cutter head is conveyed and transferred to the single-tooth cutter head buffer station, and the single-tooth cutter head clamping device 9 clamps and sends the single-tooth cutter head buffered on the buffer device 3 to the welding station; The ring-toothed cutter head conveying device 5 conveys the ring-toothed cutter head 20 to the ring-toothed cutter h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com