Patents

Literature

33results about How to "Fast dismantling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

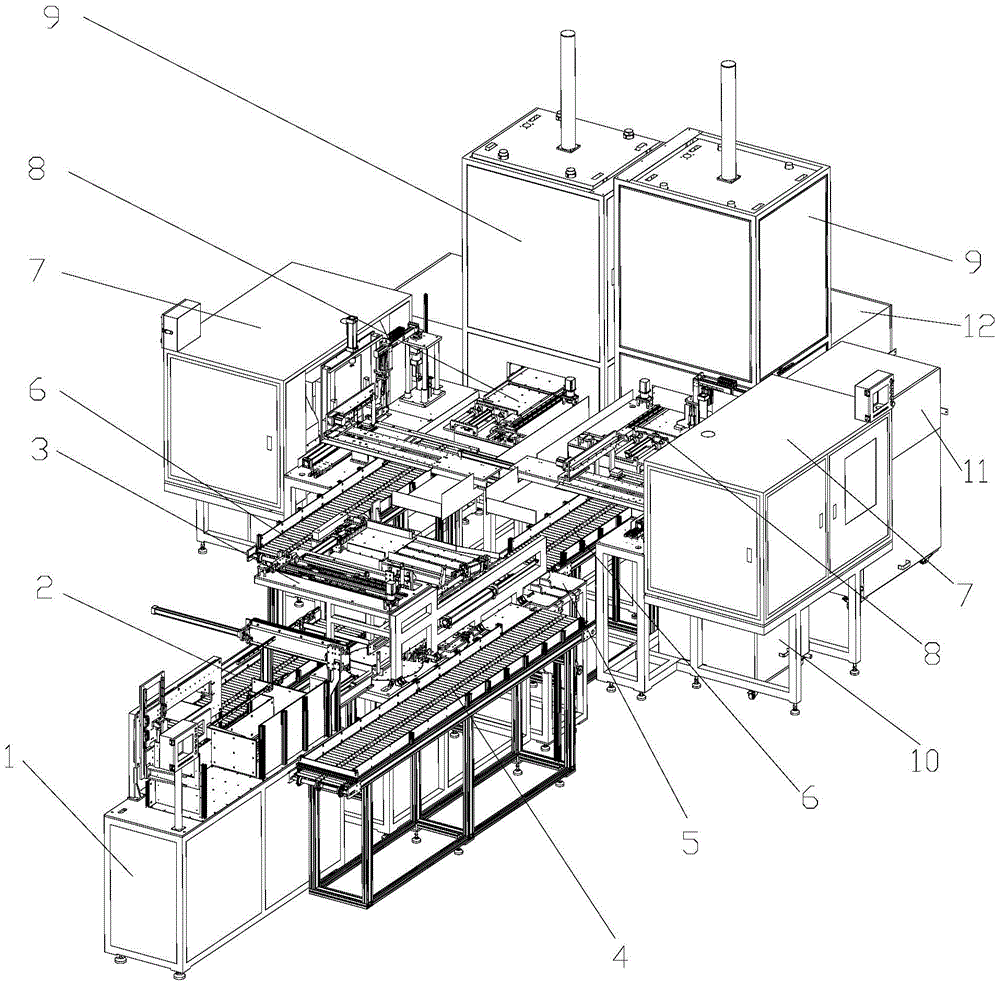

Novel waste power battery full-automatic dismantling device and method

ActiveCN104157927AReduce loss costReduce cooling costsSolid waste disposalWaste accumulators reclaimingPower batteryMaterial distribution

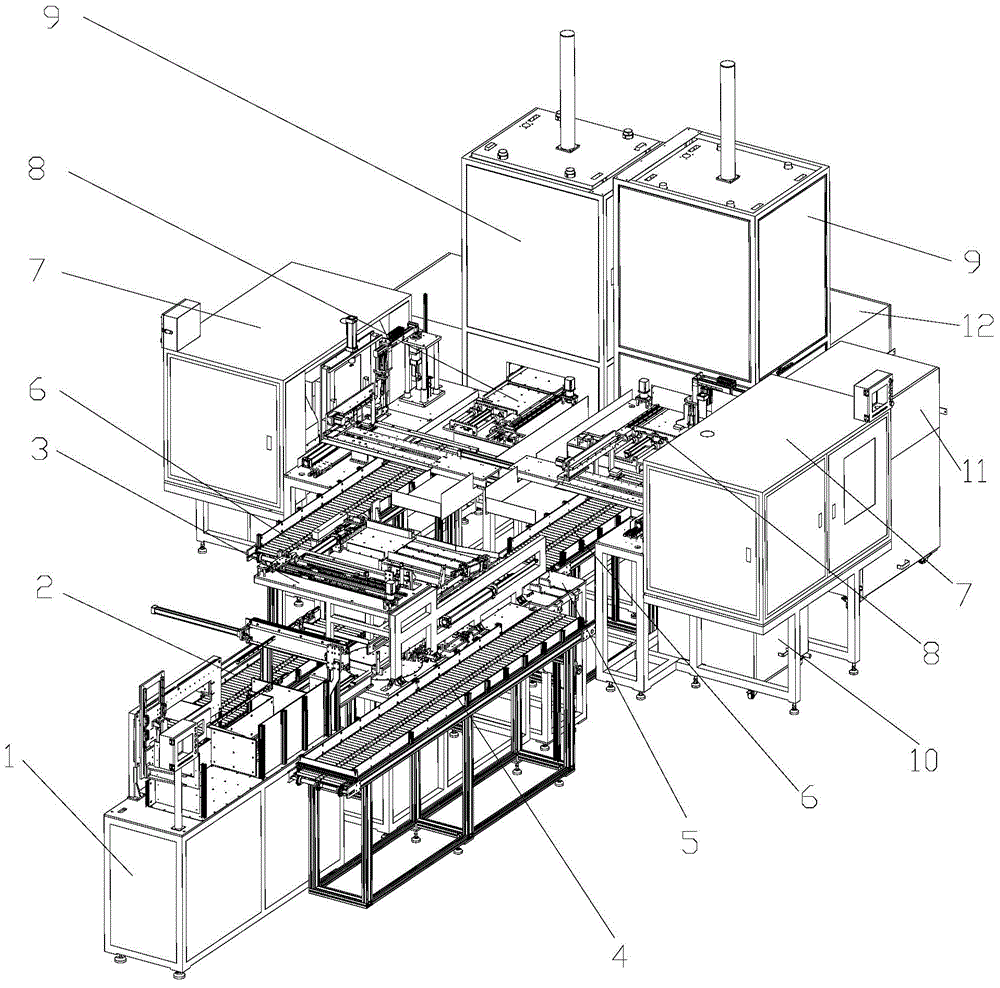

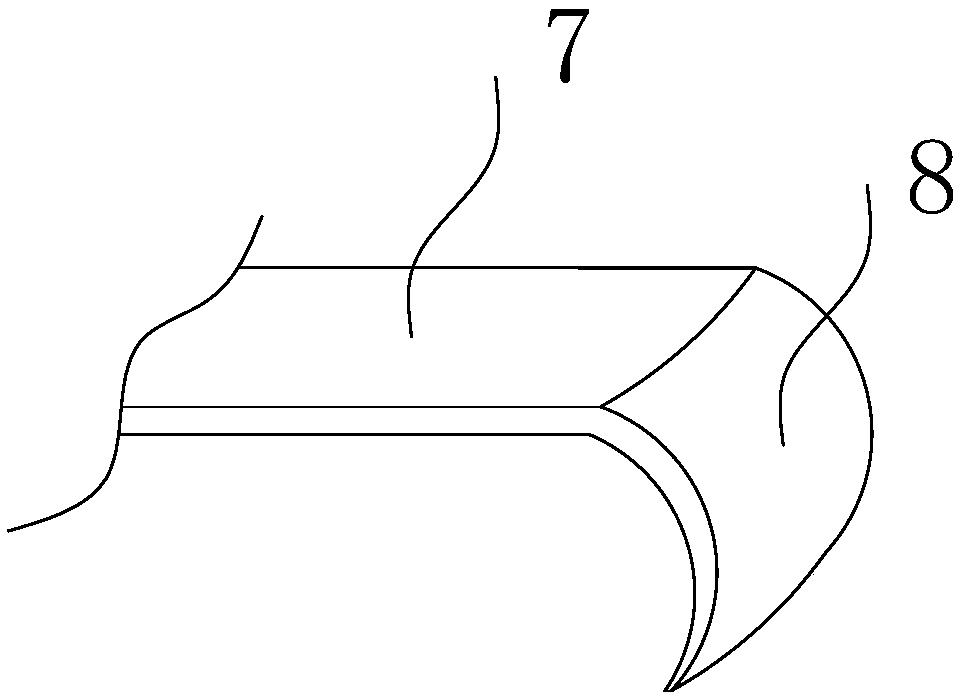

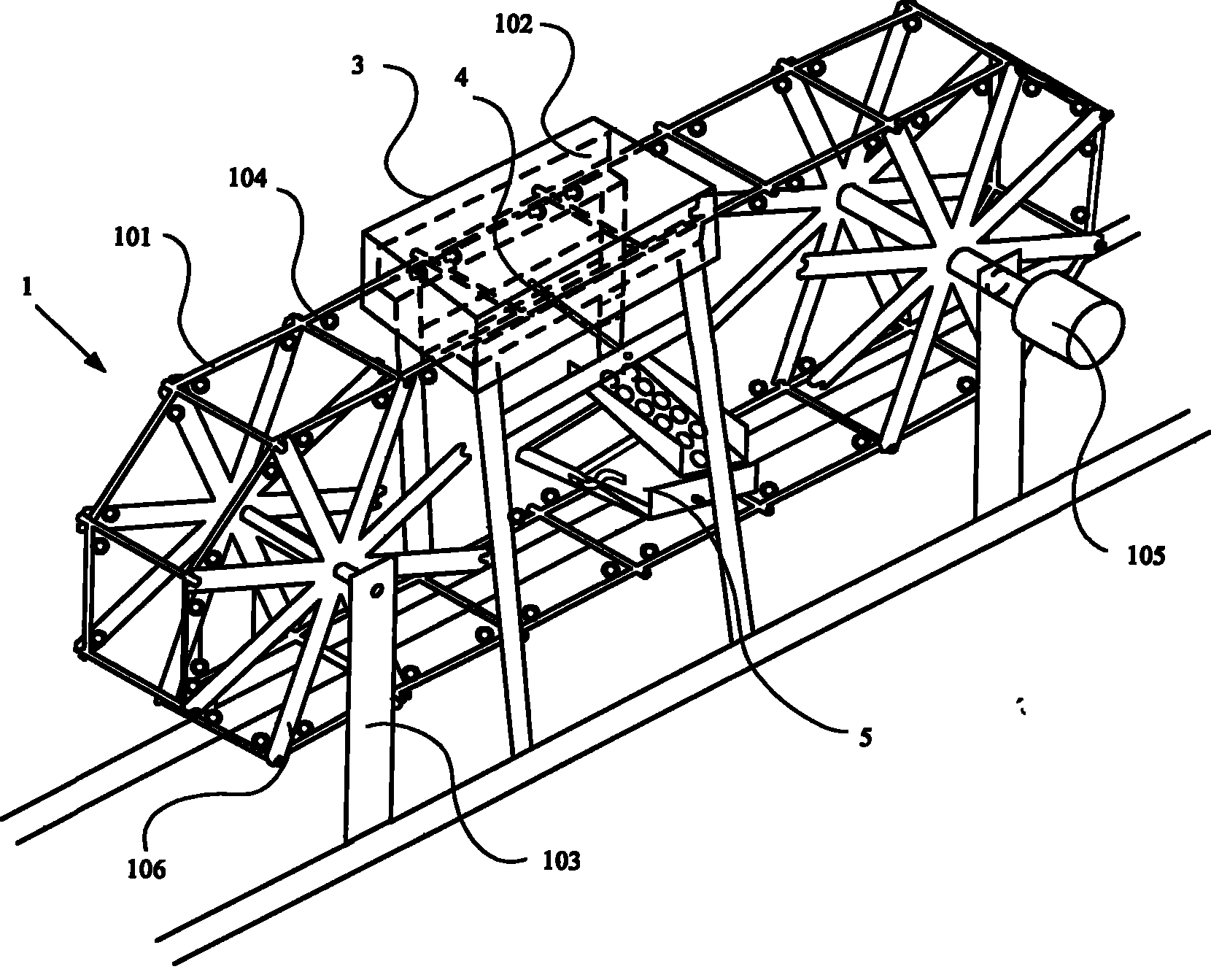

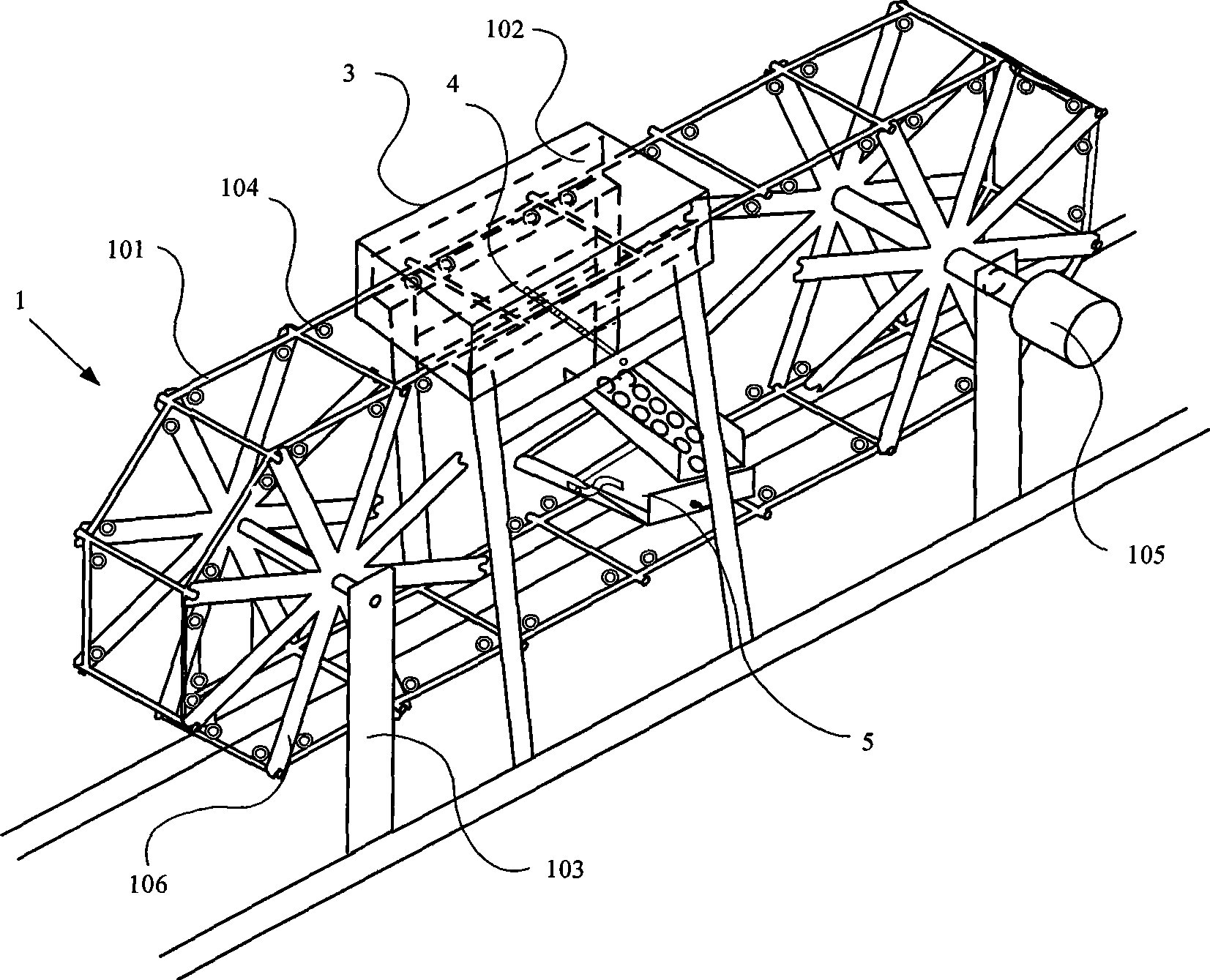

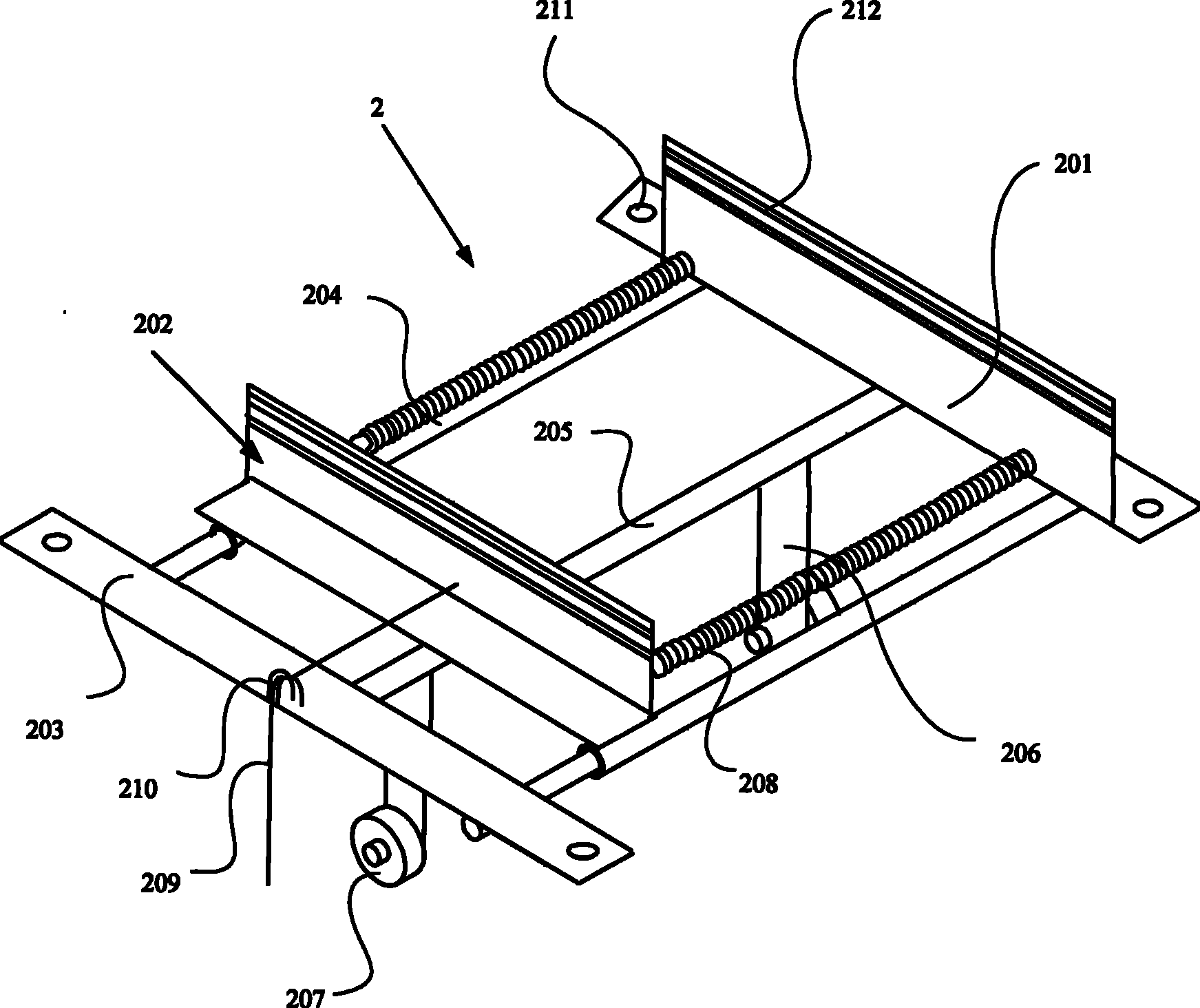

The invention relates to a novel waste power battery full-automatic dismantling device including: 1, a loading mechanism, 2, a loading conveyer, 3, a four-station material poking mechanism, 4, material distribution conveyers, 5, cutting devices, 6, separation feeding mechanisms, 7, separators, 8, outer shell storage boxes, and 9, electric core storage boxes. Along the power battery heading direction, the loading mechanism, the loading conveyer, the four-station material poking mechanism, the material distribution conveyers, the cutting devices, the separation feeding mechanisms and the separators are successively arranged; the outer shell storage boxes and the electric core storage boxes are respectively connected with the separators. The invention also relates to a novel waste power battery full-automatic dismantling method. The device has the advantages of simple structure and high dismantling efficiency, adopts a battery mechanical dismantling way integrating electrode head end one-time cutting and electric core clipping-out, and belongs to the power battery recycling processing field.

Owner:GUANGDONG BRUNP RECYCLING TECH +3

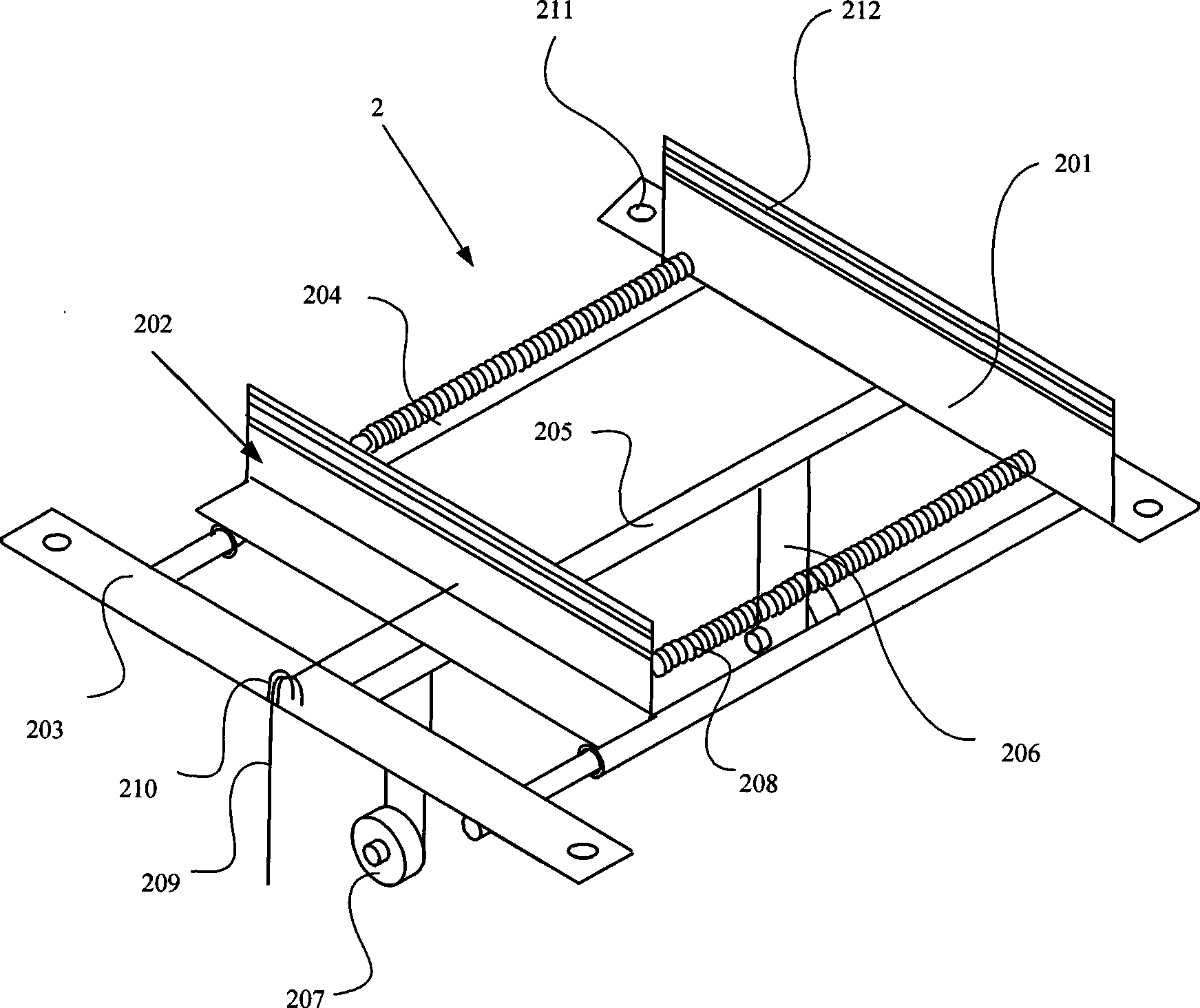

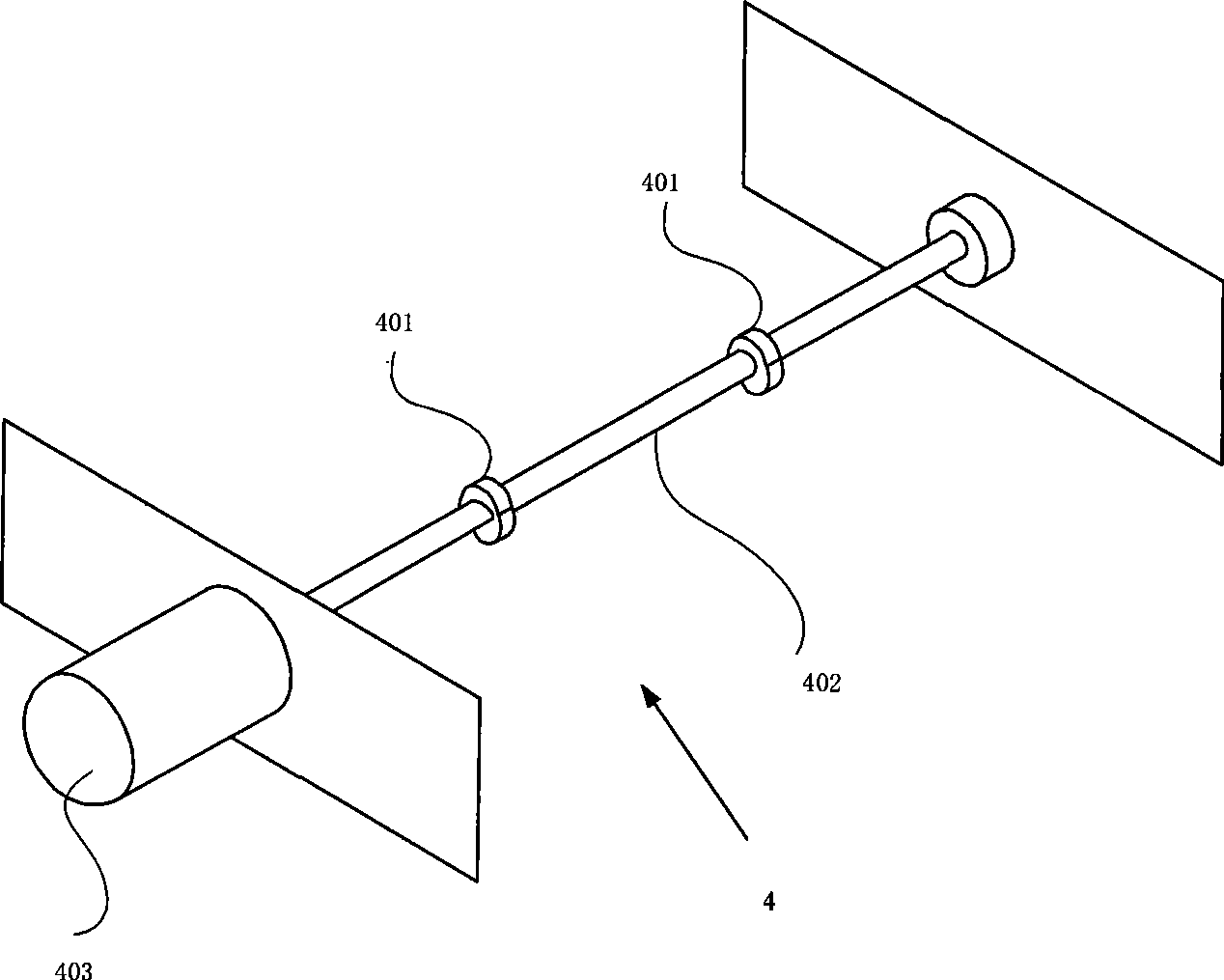

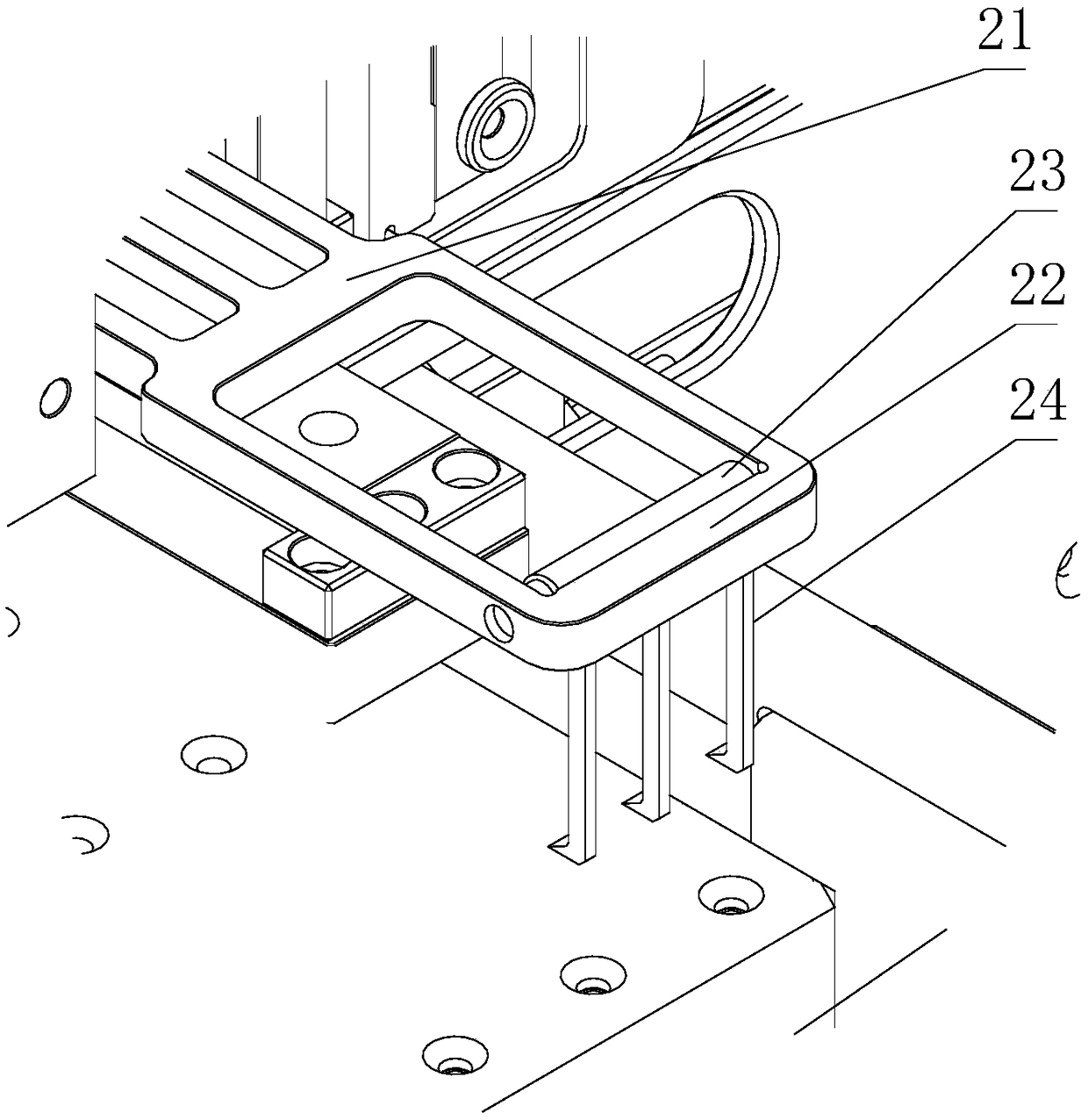

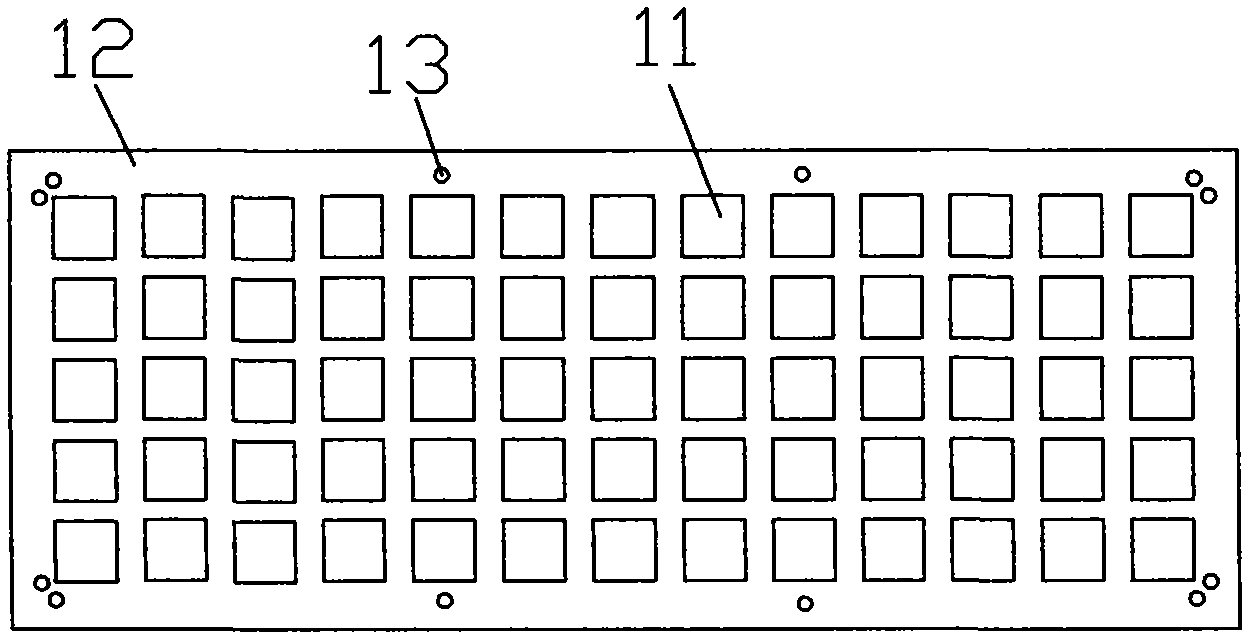

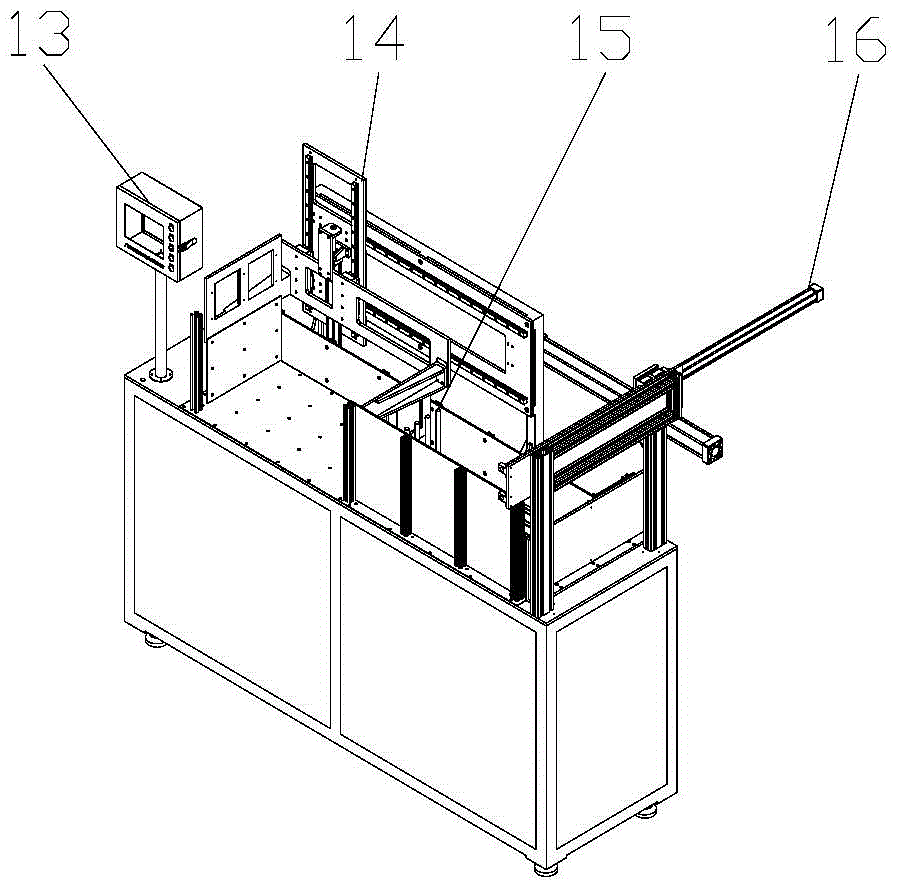

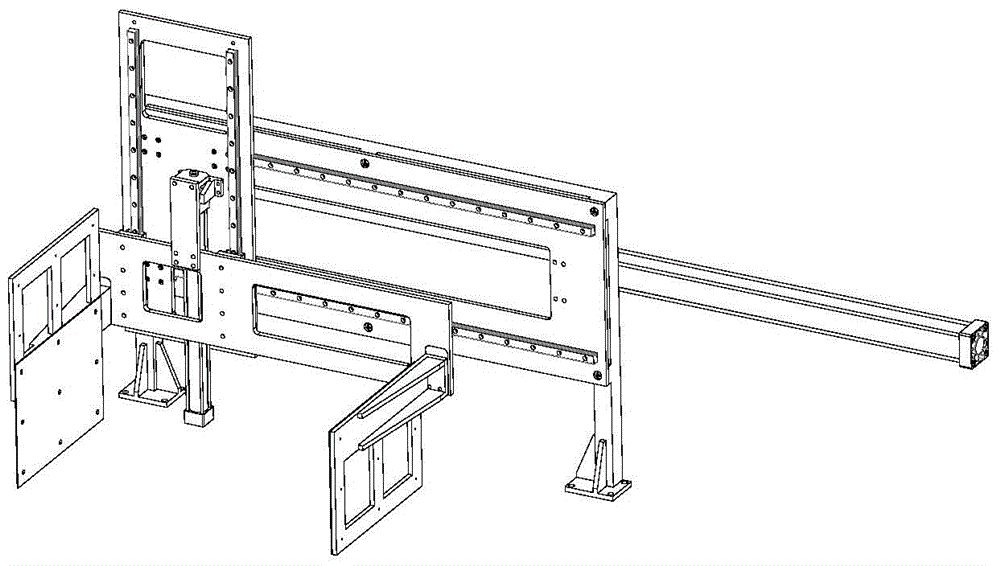

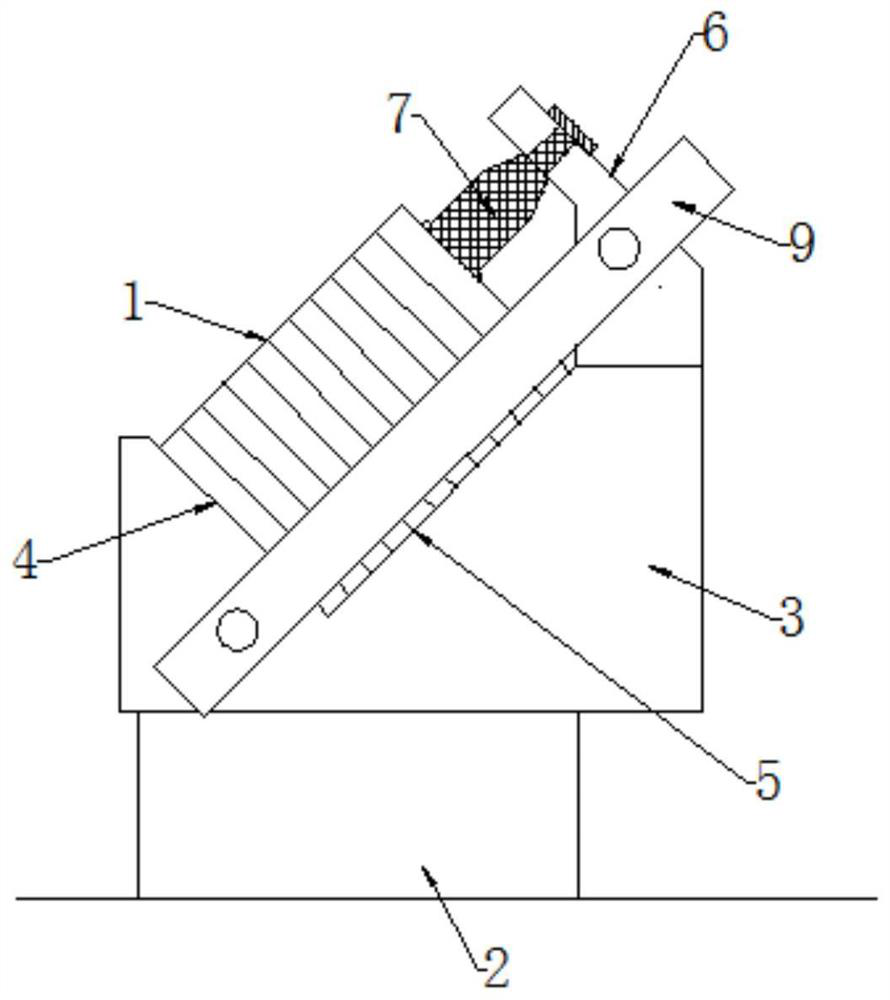

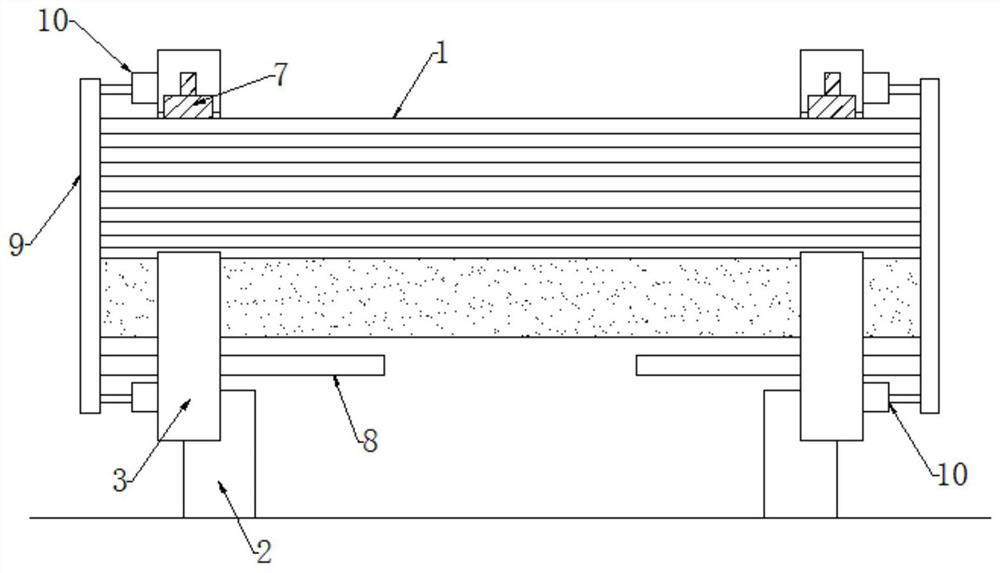

Treatment device and method for non-destructive disassembling the waste circuit board

InactiveCN101386016AFast dismantlingImprove dismantling efficiencySolid waste disposalSoldering apparatusNon destructiveFlue gas

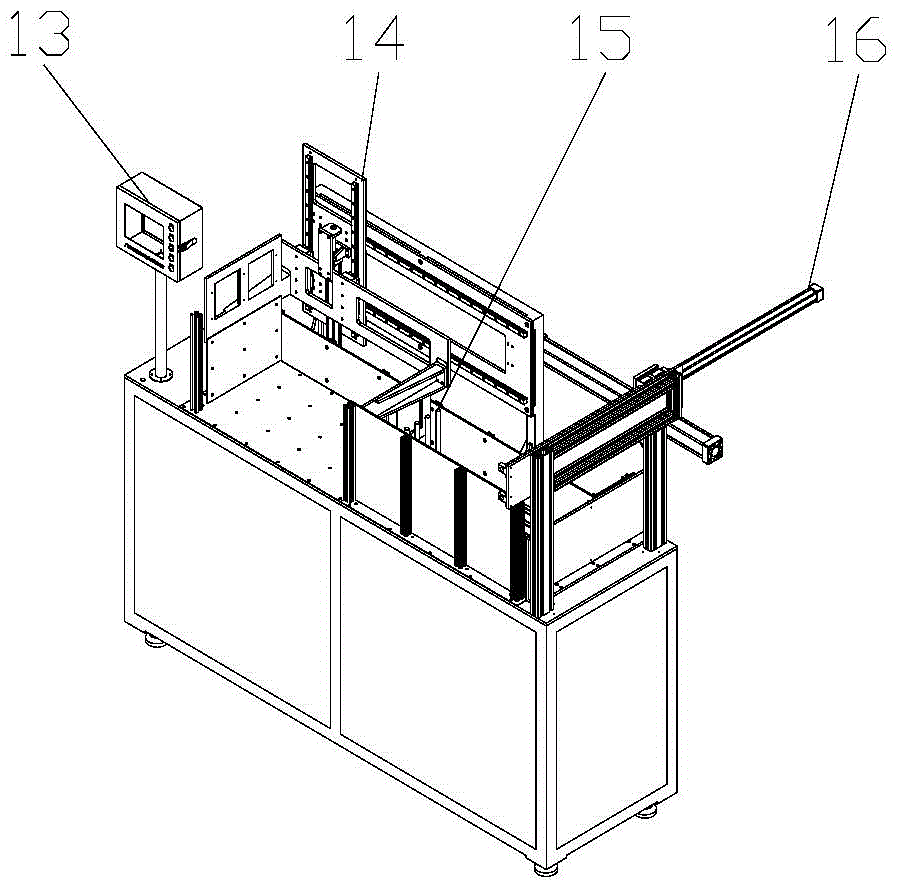

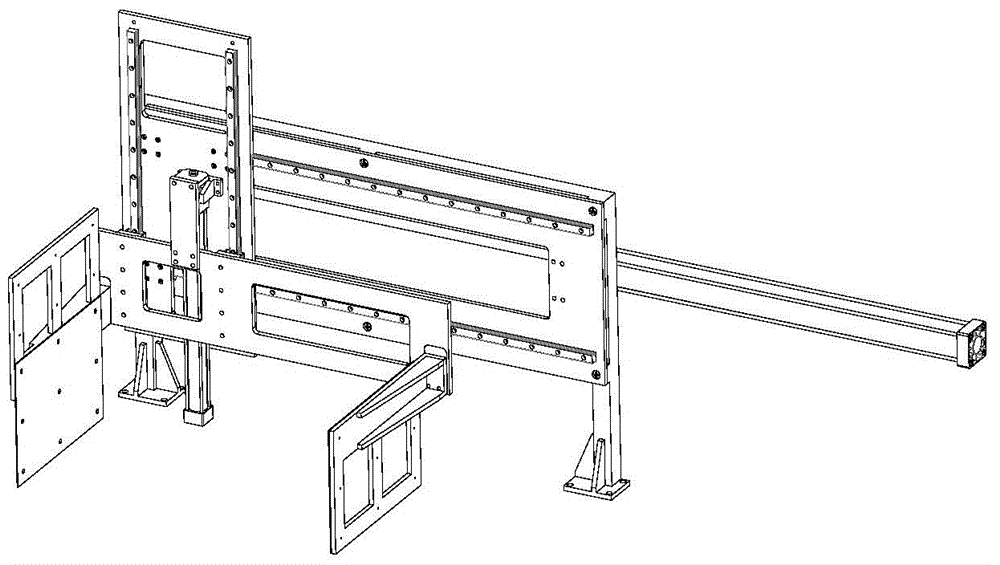

The invention discloses a device for nondestructively disassembling and treating waste circuit boards and a method thereof. The device comprises six parts of a conveying unit, a heating and heat insulation unit, a loading and unloading unit, a vibration unit, a recovery unit and a smoke removing unit. The conveying unit conveys the circuit boards; the heating and heat insulation unit melts soldering tin on the circuit boards; the loading and unloading unit realizes rapid loading and automatic unloading of the circuit boards; the vibration unit is used for separating the soldering tin and components from the circuit boards; the recovery unit is used for realizing separation and recovery of the soldering tin and the components; and the smoke removing unit is used for filtering flue gas dust in waste gas and odor produced in the operation of the device. The device and the method thereof have the advantages of continuous operation, high disassembling efficiency, high heating speed, controllable temperature, energy saving, high nondestructive disassembling rate of the components, small volume, light weight, simple installation, low power, high automation degree and simple processing operation.

Owner:BEIHANG UNIV

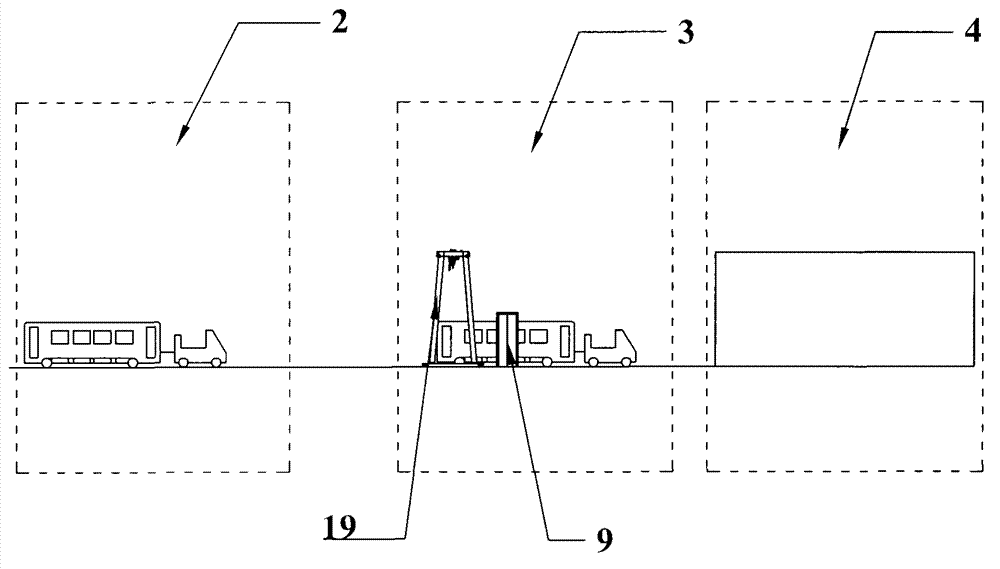

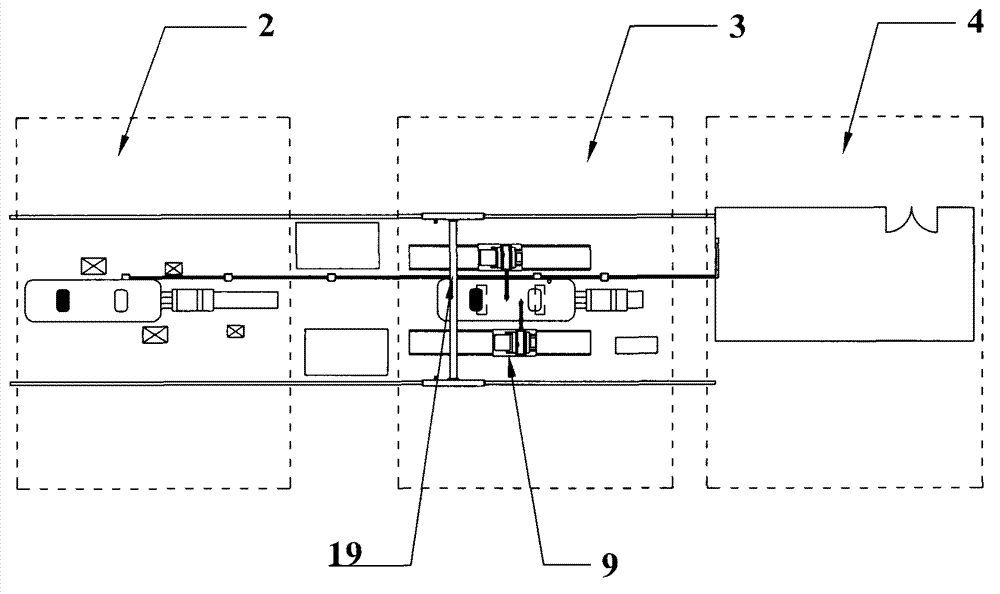

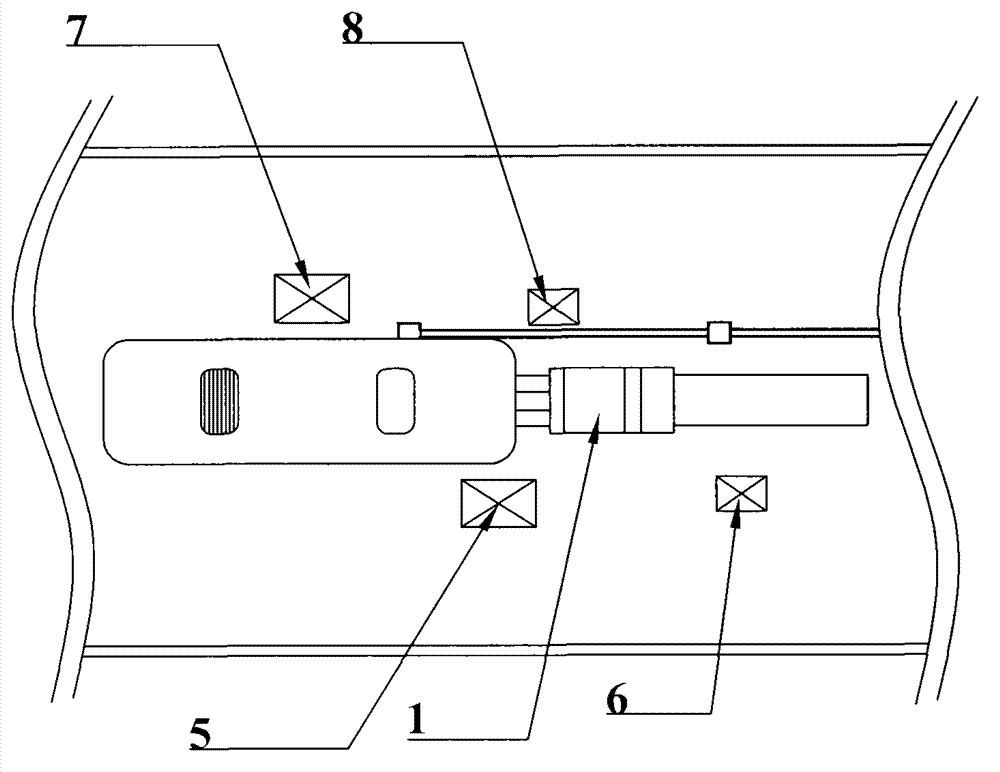

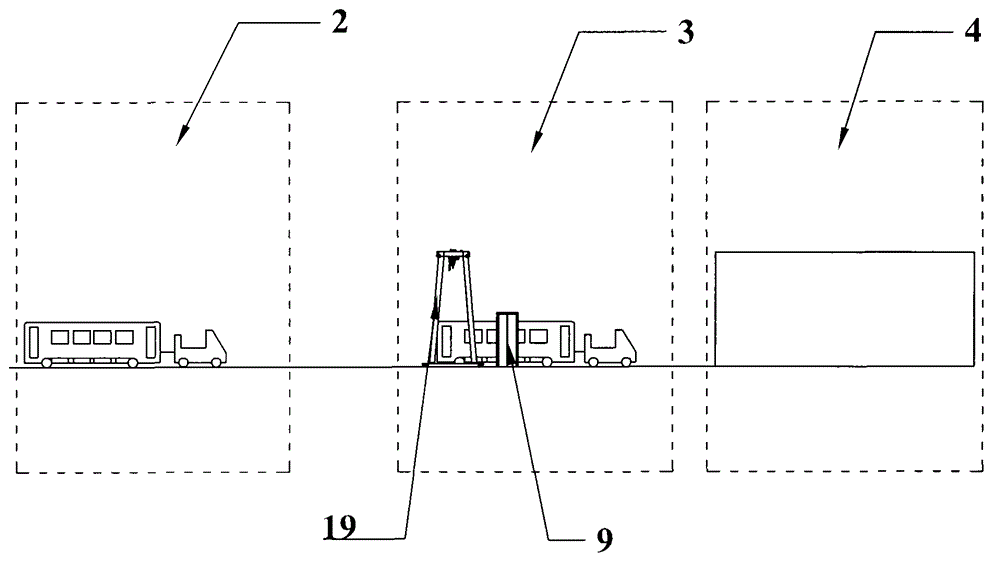

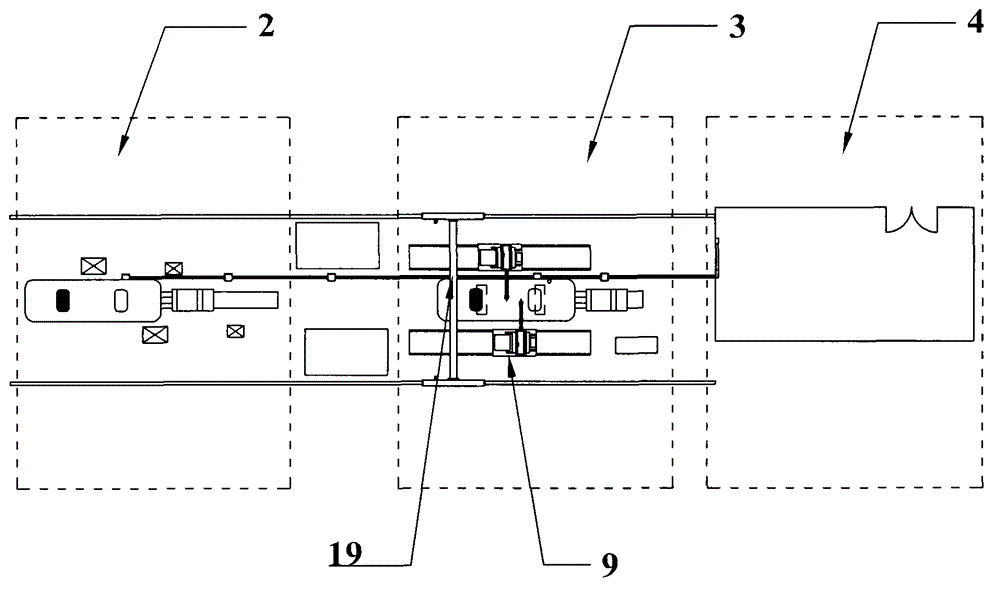

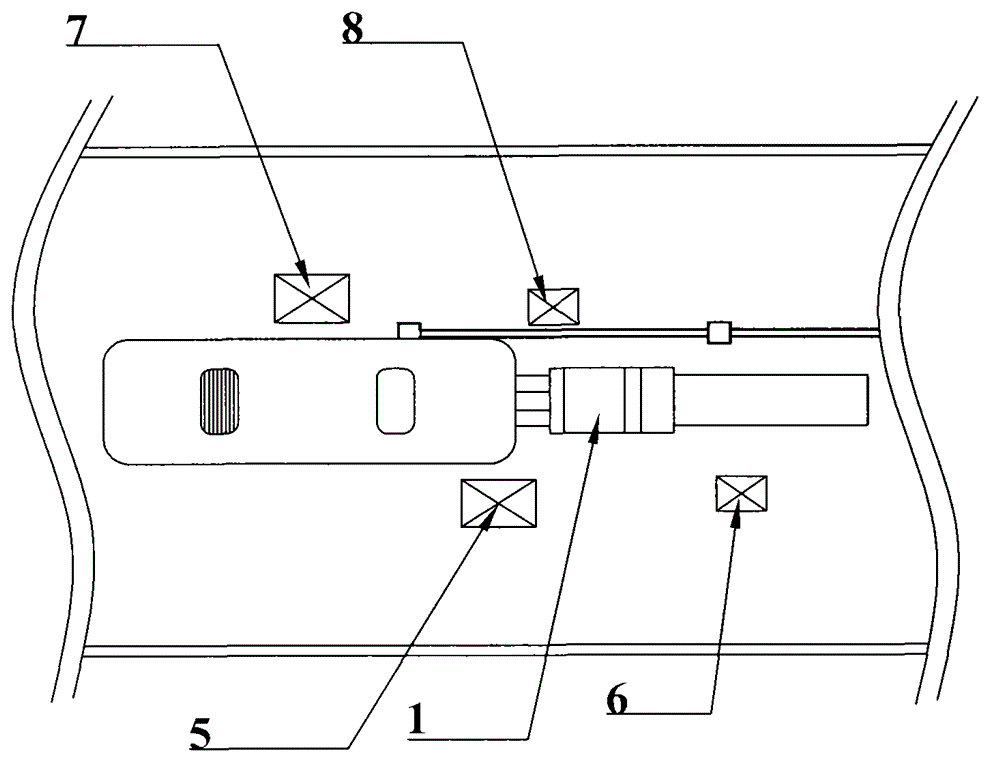

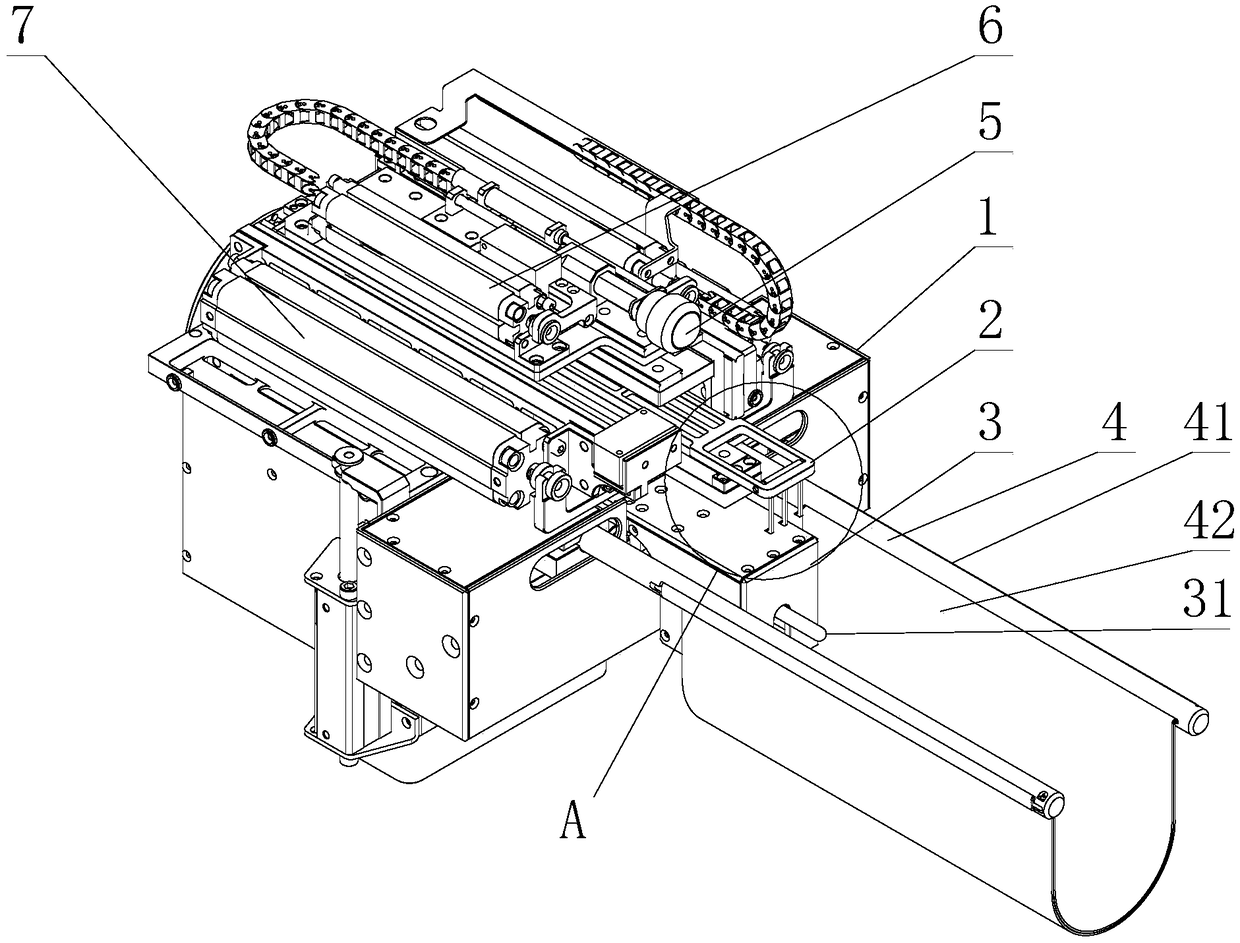

Waste vehicle disassembly production line and corresponding process

InactiveCN103112519AReduce labor intensityLess investmentVehicle dissasembly recoverySolid waste disposalProduction lineRefrigerant reclamation

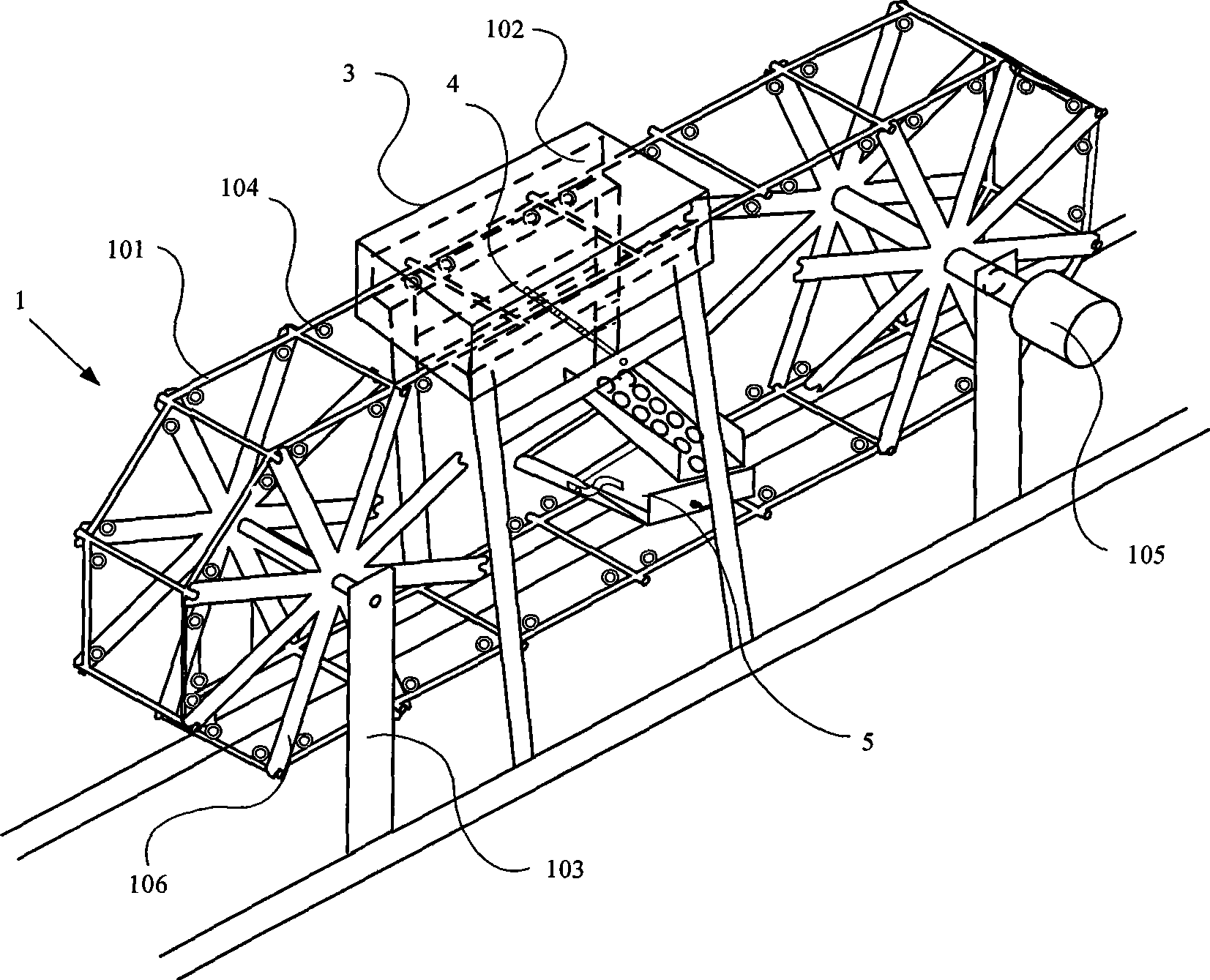

The invention relates to a waste vehicle disassembly production line and corresponding process. Nowadays, a relatively complete disassembly method for waste vehicles does not exist at both home and abroad. The waste vehicle disassembly production line comprises a pretreatment area and a semi-automatic disassembly area, the pretreatment area comprises a waste oil fluid extracting work station, a refrigerant recycling work station, a windshield, an electrical equipment circuit disassembly work station and an inner trim and tyre disassembly work station, wherein a waste oil fluid extracting device is arranged in the waste oil fluid extracting work station, a refrigerant extracting device is arranged in the refrigerant recycling work station, and an air gun sleeve and an air gun unit are arranged on the inner trim and tyre disassembly work station. The semi-automatic disassembly area is arranged on a downstream position of the pretreatment area, and a semi-automatic disassembly device and a material taking and carrying device are arranged in the semi-automatic disassembly area. Not only do the waste vehicle disassembly production line and the corresponding process achieve transformation from manual disassembly to mechanical disassembly, but also the size of cut material can be adjusted according to requirements, and the waste vehicle disassembly production line and the corresponding process are widely used for disassembly of various vehicles and particularly suitable for disassembling of oversize vehicles.

Owner:QINGDAO NEW WORLD ENVIRONMENT PROTECTION CO LTD

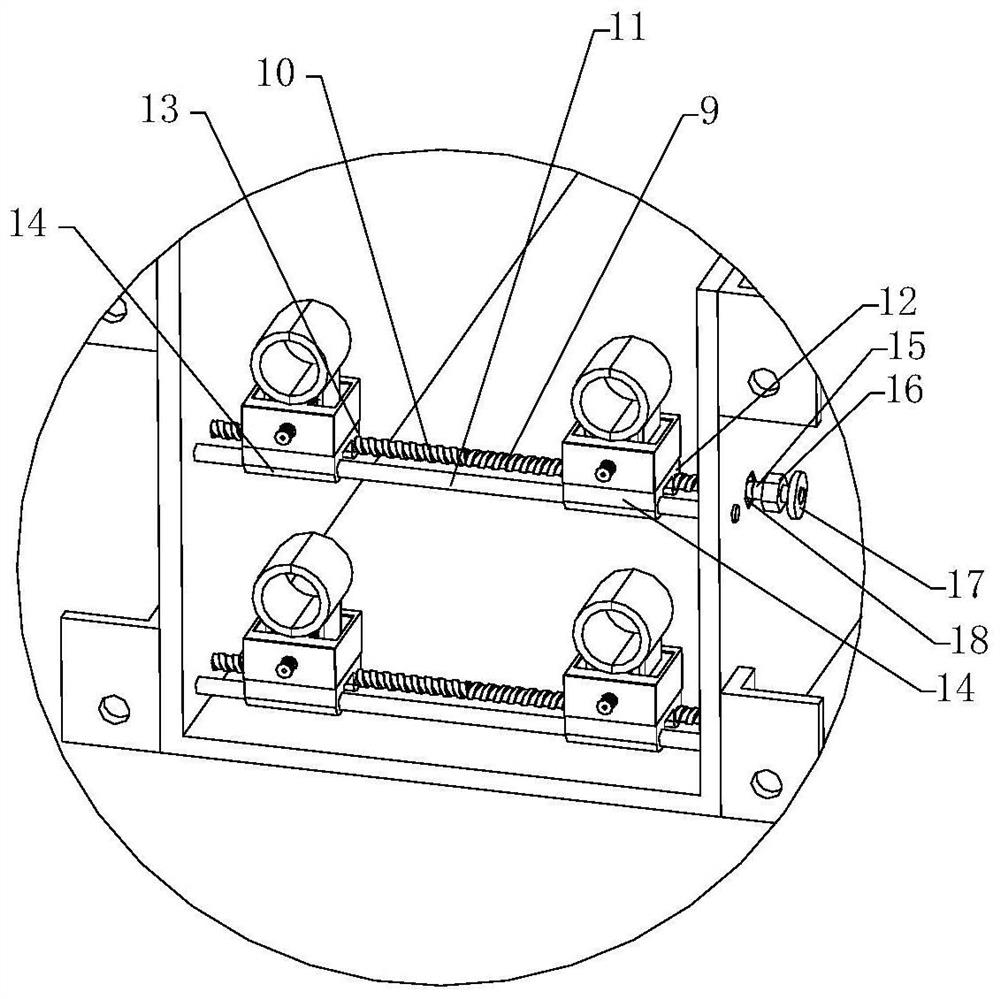

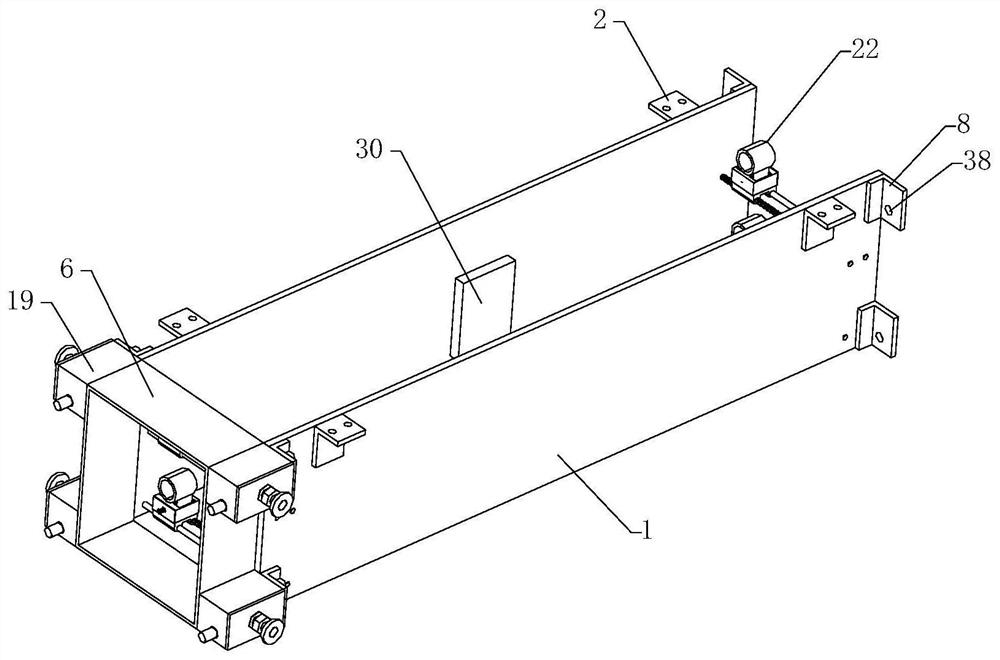

Cable bridge

ActiveCN111817223APlay the role of limit movementFast dismantlingElectrical apparatusAlarmsCable trayElectric cables

The invention relates to the technical field of cable bridges, in particular to a cable bridge. The cable bridge comprises a main bridge frame, mounting plates are respectively arranged at the upper ends of two sides of the main bridge frame; an alarm mechanism is arranged at the middle end in the main bridge frame; distance adjusting mechanisms are arranged at the two ends of the interior of themain bridge frame respectively; each distance adjusting mechanism comprises an adjusting assembly; each adjusting assembly comprises two moving plates capable of moving horizontally and oppositely. Each moving plate is provided with a cable clamping head. A detachable connecting mechanism is arranged at each tail end of the main bridge frame; each connecting mechanism comprises a connecting framecapable of being in butt joint with the corresponding tail end of the main bridge frame and locking assemblies installed at the upper end and the lower end of the two sides of the corresponding connecting frame respectively. The two sides of the main bridge frame are each provided with a connecting plate capable of being detachably connected with the corresponding locking assembly, the cable bridge can adjust a fixed cable, the installation practicability is improved, each hinge frame can be efficiently and independently disassembled, and the later-period maintenance efficiency is improved.

Owner:天津龙鼎熙石化新能源科技有限公司

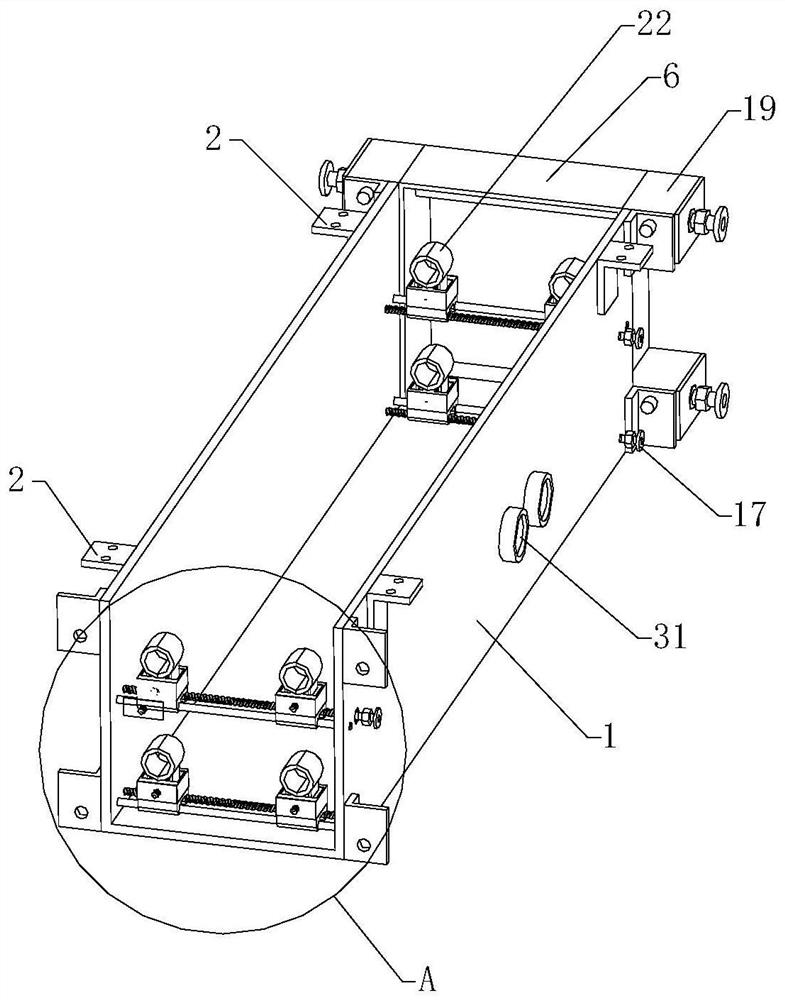

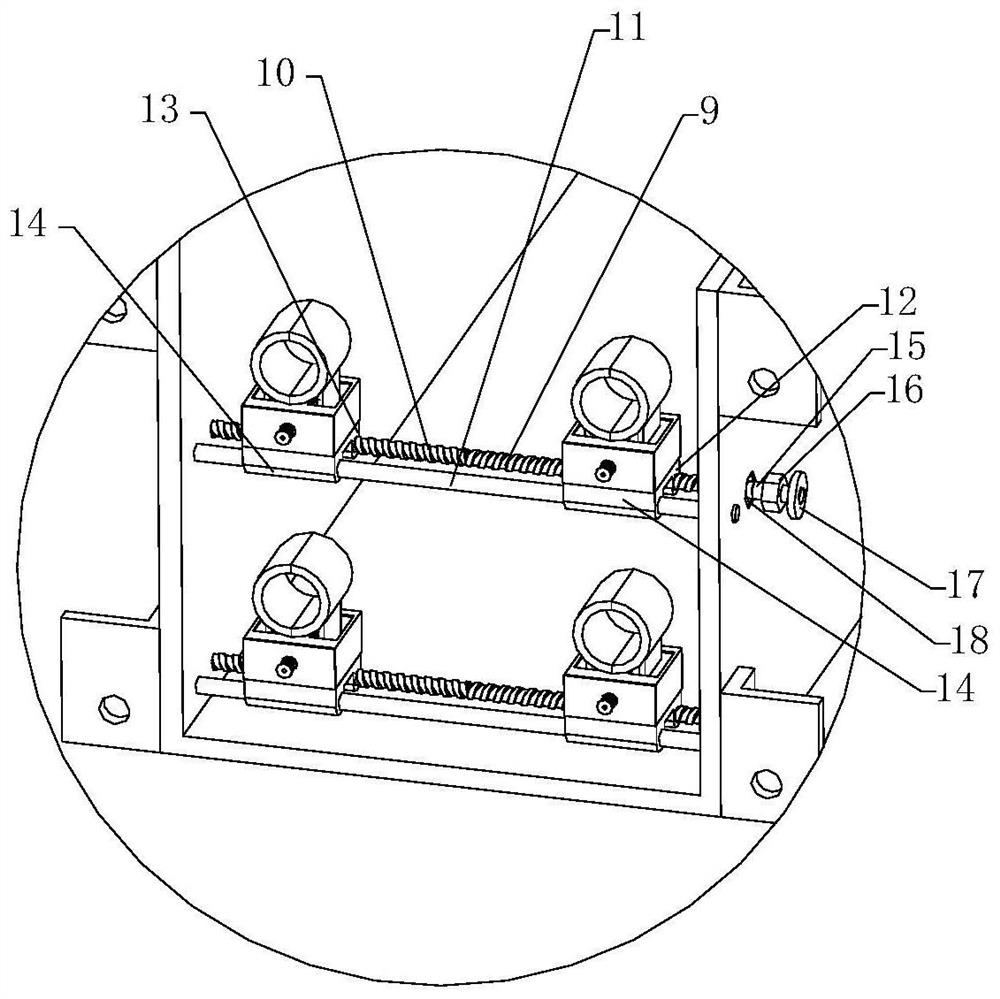

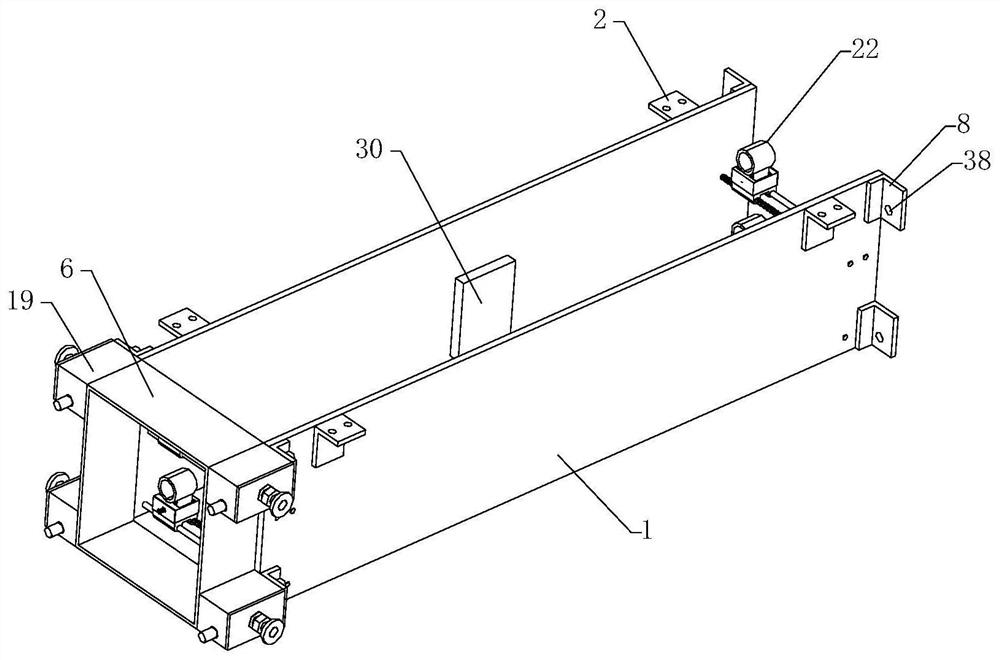

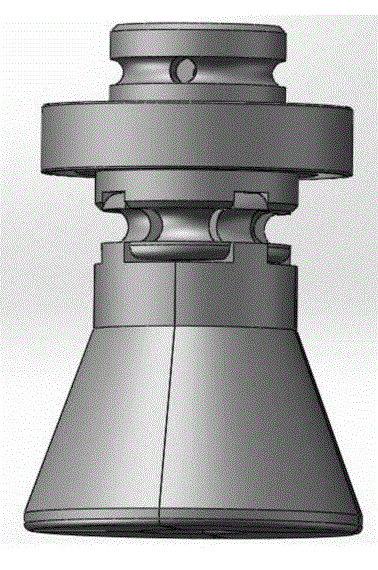

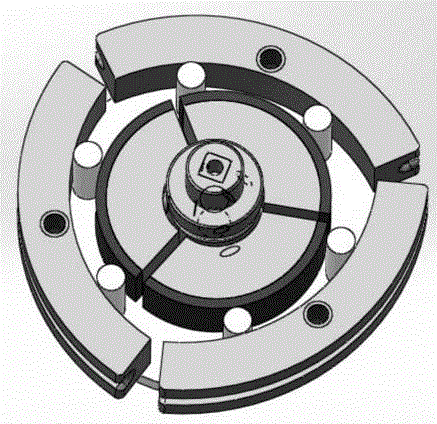

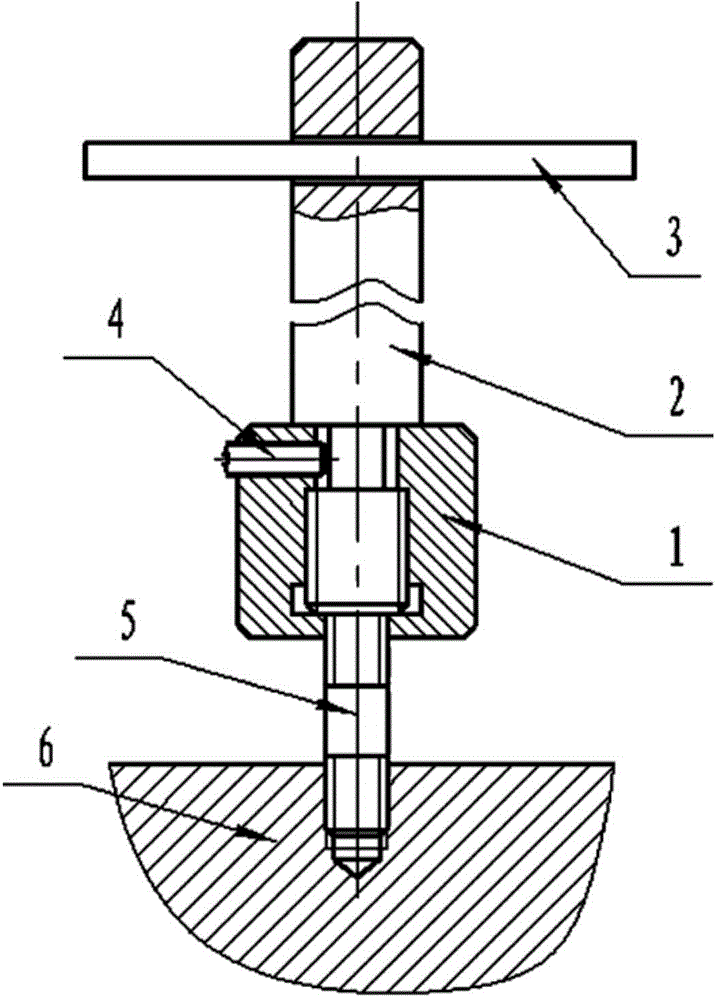

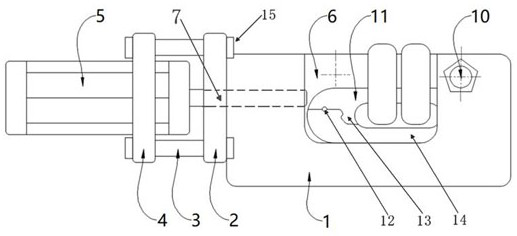

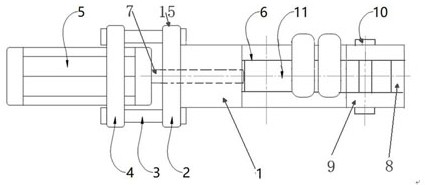

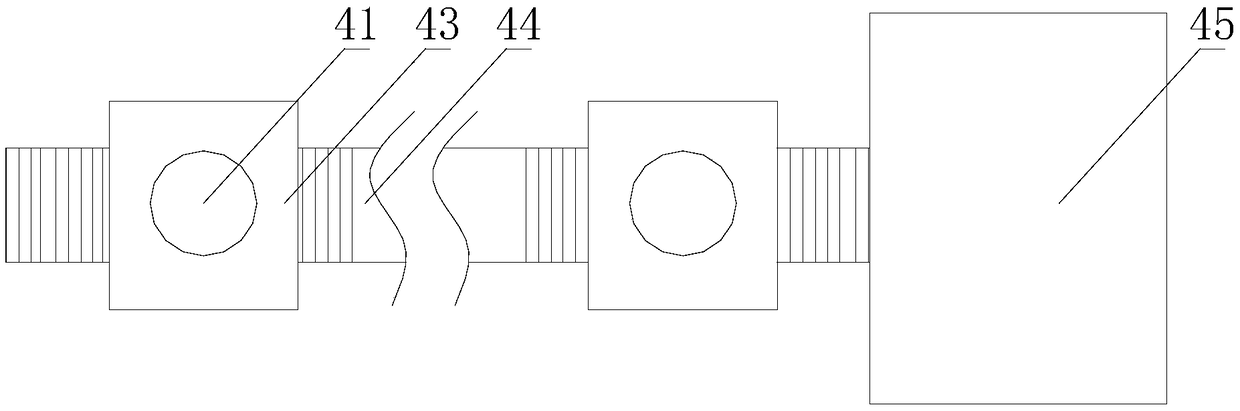

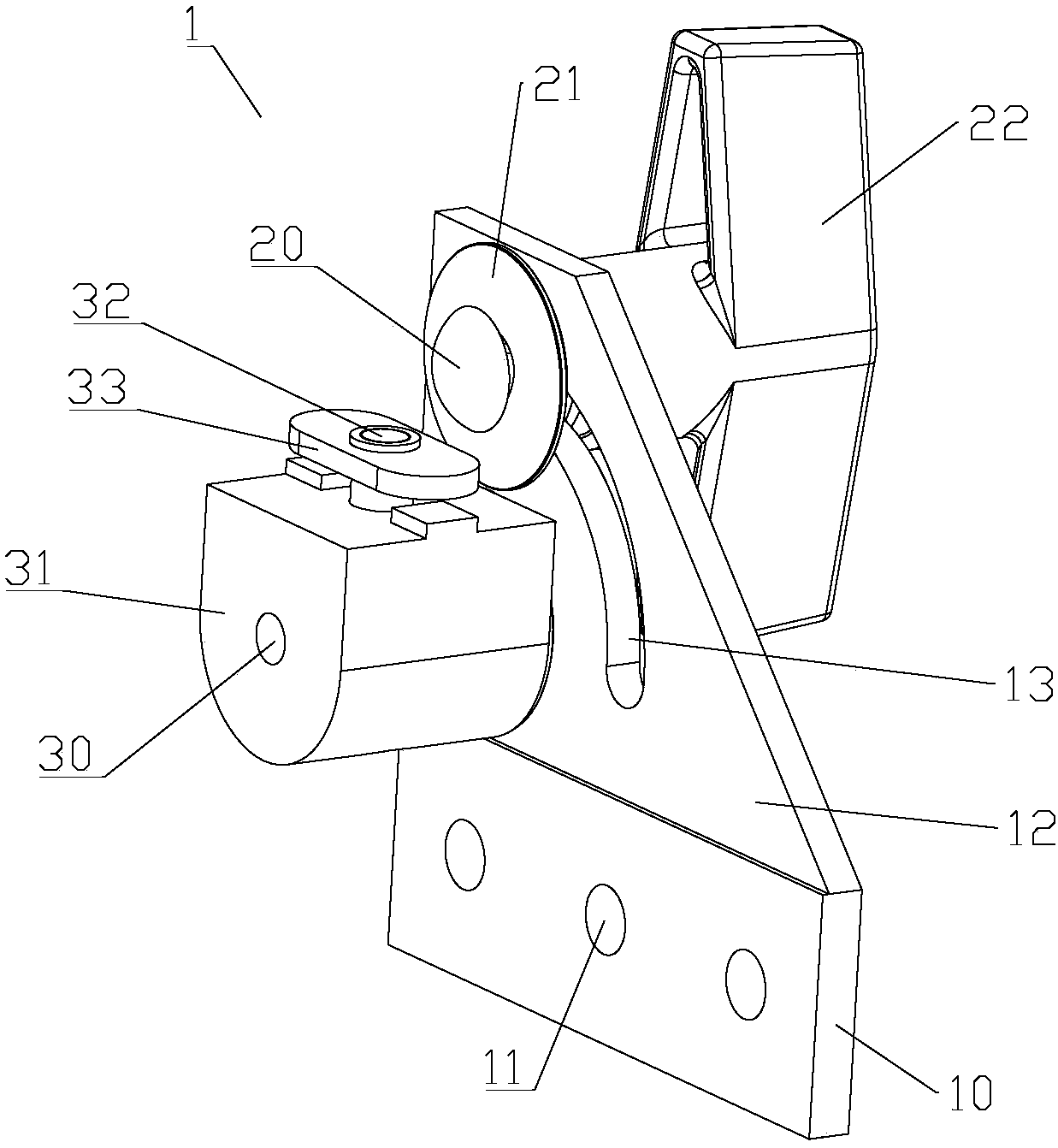

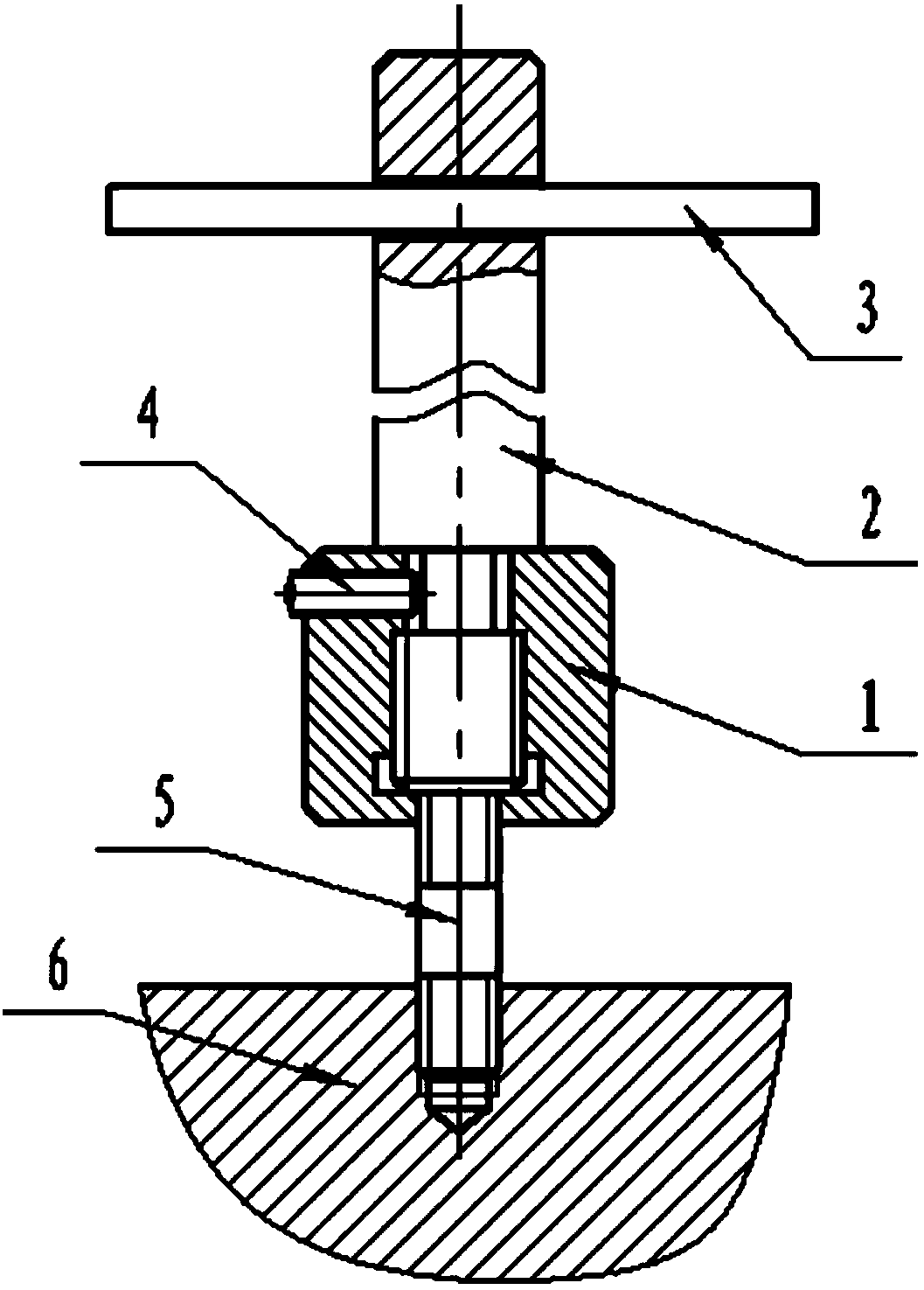

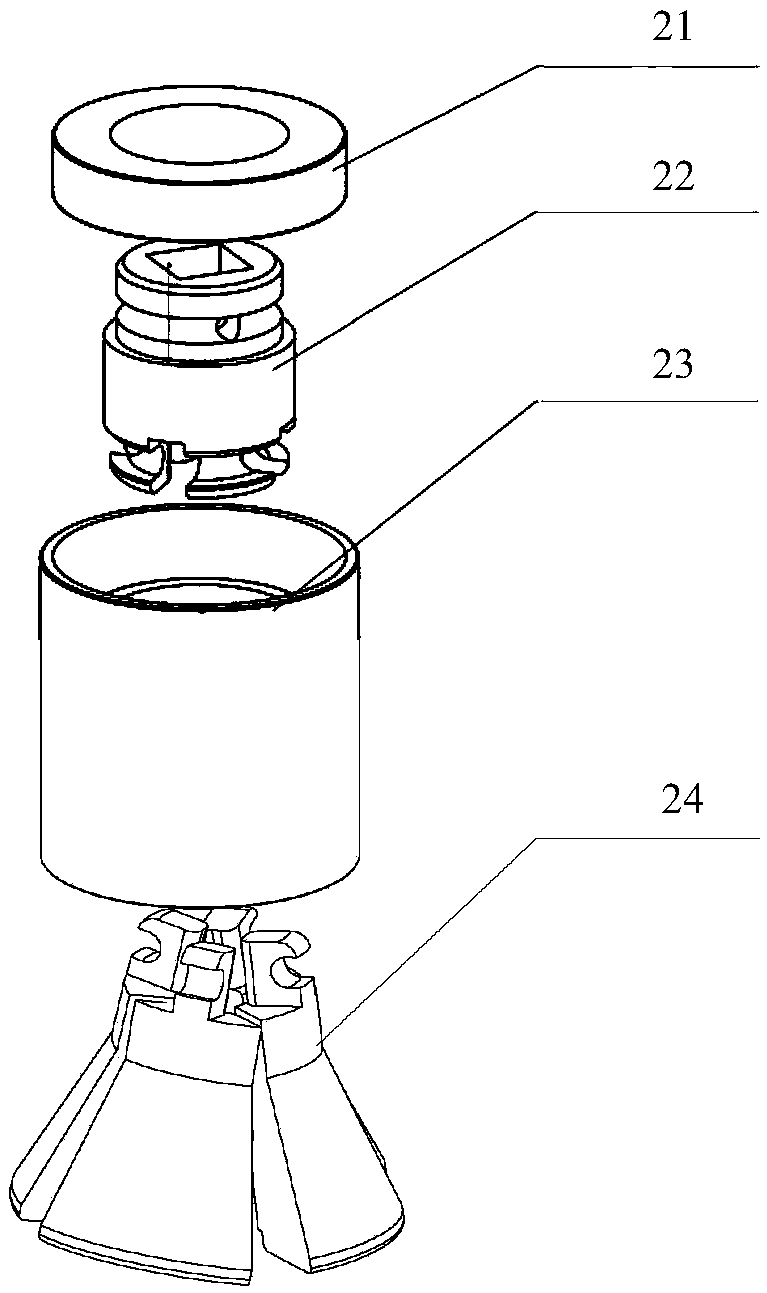

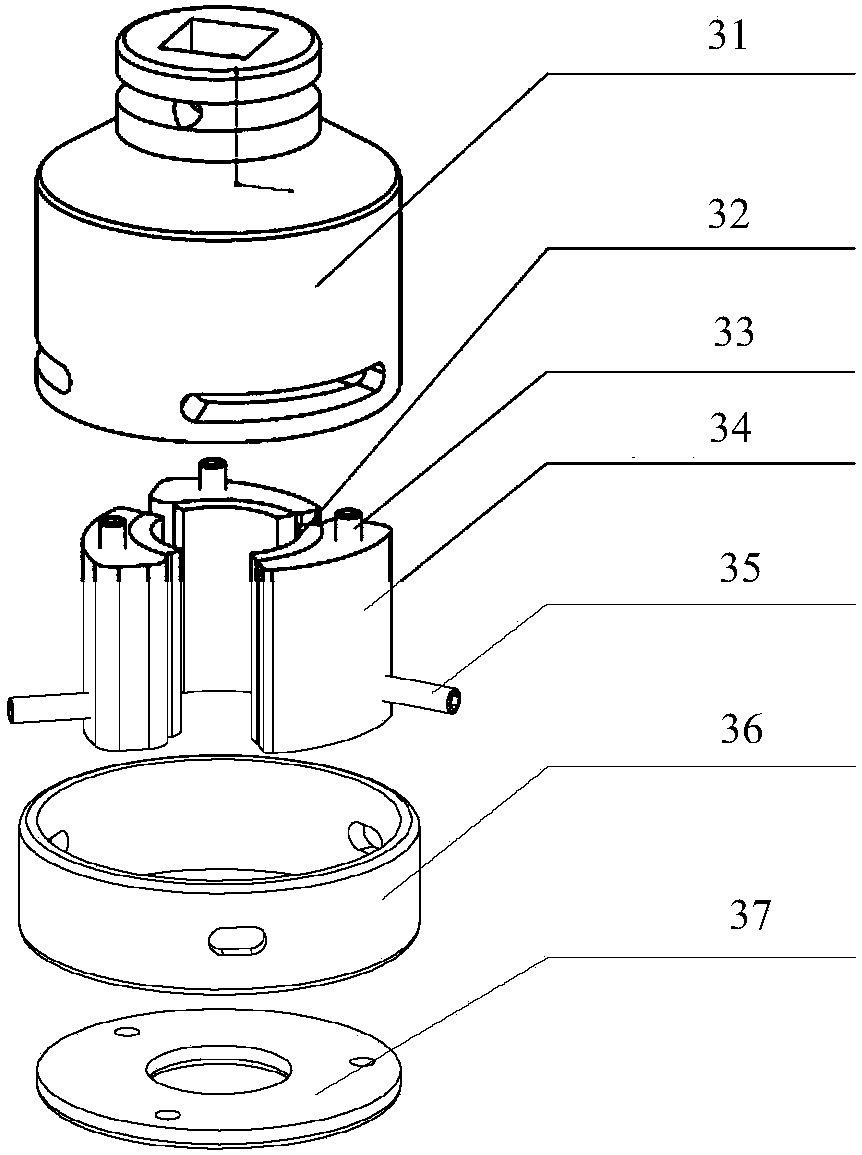

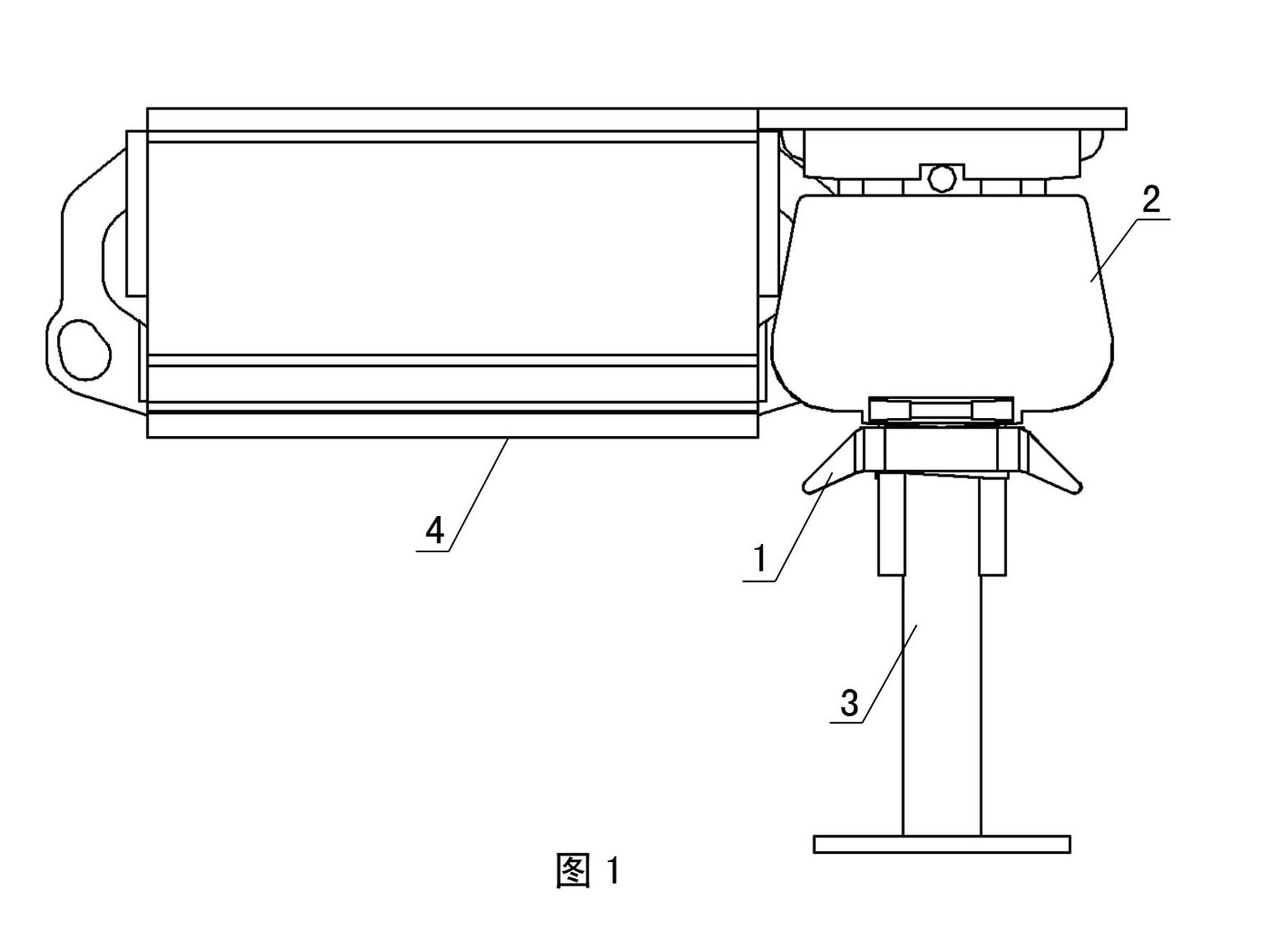

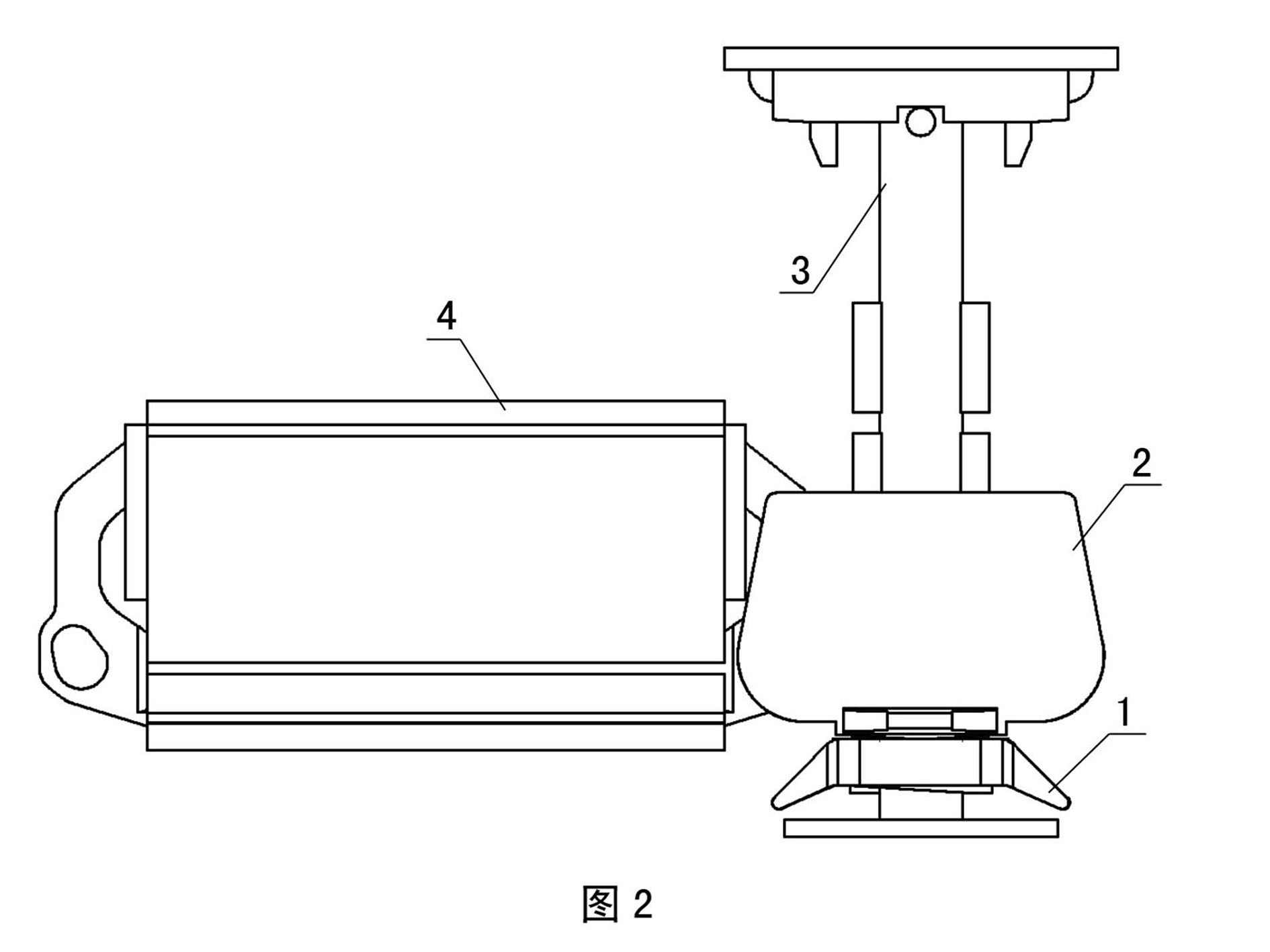

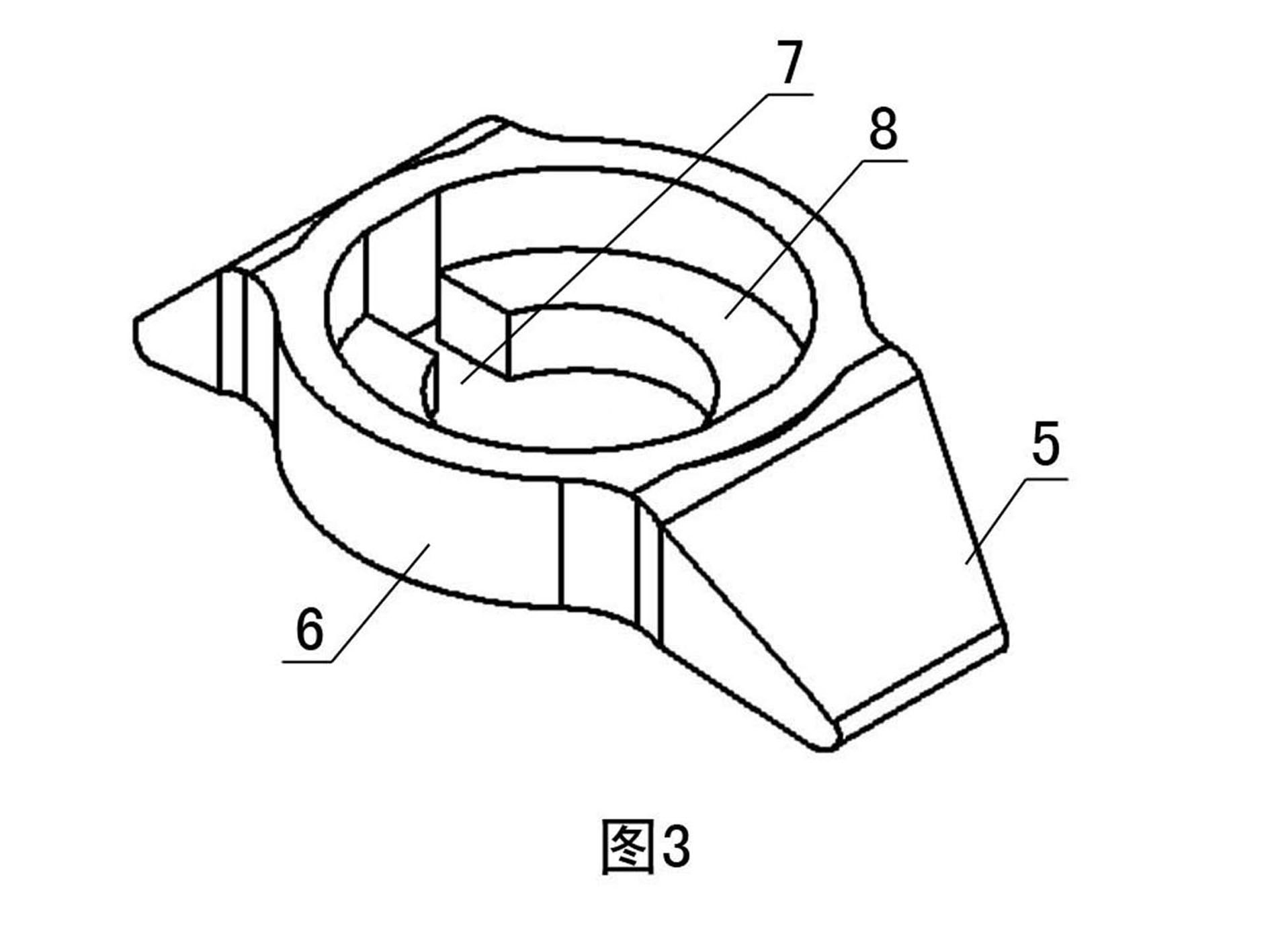

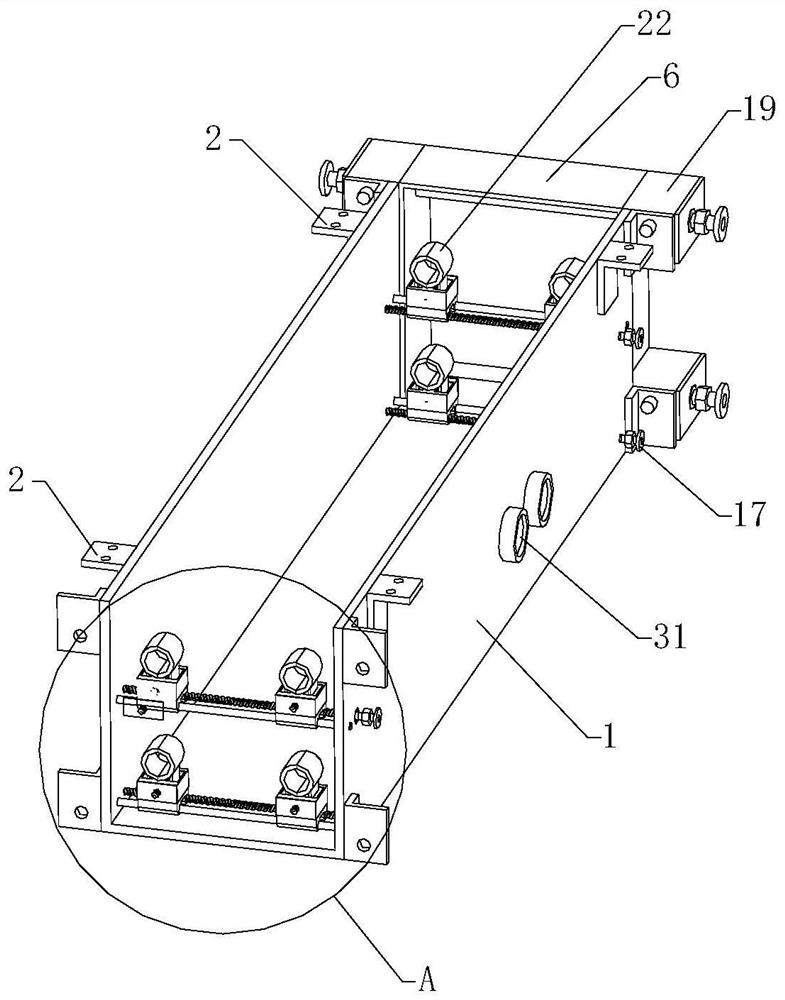

Bolt tightening device, bolt loosening device and multi-bolt tightening and loosening device

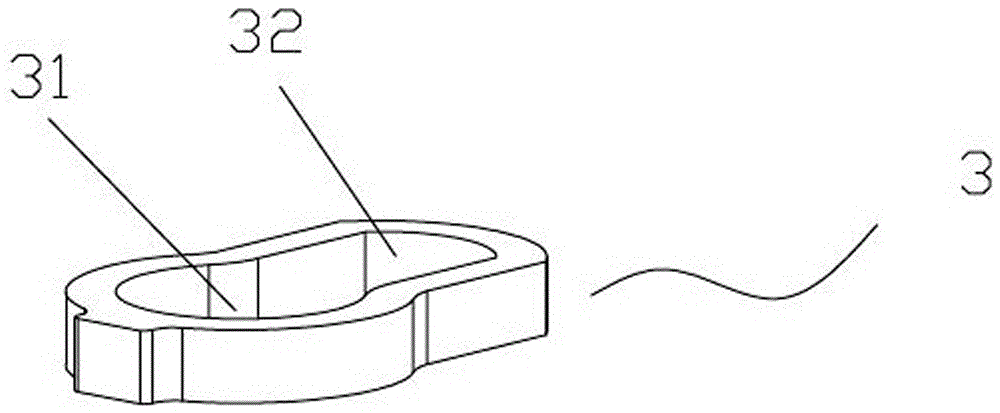

The invention relates to the technical field of bolt tightening, in particular to a bolt tightening device, a bolt loosening device and a multi-bolt tightening and loosening device and aims at solving the problems that tightening and loosening of studs or total-thread bolts in the prior art are large in labor intensity, low in working efficiency and low in technical content due to the fact that no special tool exists for clamping threads of the bolts or sleeves cannot be rapidly taken down after the bolts are clamped through the thread sleeves. According to the rapid stud tightening device, the principles of coaxial decentration, blocking conical surface clamping, centrifugal force, friction force and the like are applied, the threads of the studs can be accurately and rapidly clamped for tightening or loosening, the equipment can be rapidly taken down after the studs are tightened or loosened, and the working efficiency can be greatly improved when the device is used inn cooperation with a high-speed electric or pneumatic impact wrench.

Owner:SHANGHAI CHENGJIE ELECTROMECHANICAL CO LTD

Disassembly and recovery method of square power battery cover plate

ActiveCN108539316AReduce material purityFast dismantlingWaste accumulators reclaimingBattery recyclingRecovery methodPower battery

The invention discloses a disassembly and recovery method of a square power battery cover plate and relates to the technical field of battery material recovery. The method comprises the following steps: firstly, cutting a notch in a cover plate at the periphery of a pole along the radial direction of the pole by utilizing a cutting tool, extending the outer end of the notch to the outer edge of the cover plate, and extending the inner end of the notch to the inner edge of the cover plate in contact with the pole; then, clamping the cover plate by utilizing a clamp, and enabling the cover plateto rotate along the direction away from the notch so as to open the notch; and after the cover plate rotates for a certain angle, enabling the pole to automatically fall off from the cover plate, andsimultaneously, separating a plastic bracket below the cover plate, thereby realizing disassembly and recovery of the pole, the cover plate and the plastic bracket. Disassembly of the cover plate andseparation and recovery of all parts can be quickly realized by utilizing the cutting tool and the clamp, so that the pole is automatically separated from the cover plate.

Owner:安徽南都华铂新材料科技有限公司

Vertical chain connector dismounting device

PendingCN112570642AReasonable structural designEasy to operateMetal chainsMetal chainmaking toolsHydraulic cylinderMortise and tenon

The invention discloses a vertical chain connector dismounting device. Two ends of an upper ring body and two ends of a lower ring body of a chain connector are connected through a mortise and tenon structure and fixed through an expansion pin; the chain connector is placed in a limiting groove in the middle of a base; the limiting groove is formed in the longitudinal direction of the base, and the limiting groove limits longitudinal movement of the lower ring body of the chain connector; the upper ring body of the chain connector can longitudinally move towards one end of the base, and a fixing device is arranged at the other end of the base; a hydraulic cylinder is connected with the fixing device; and a piston rod of the hydraulic cylinder is parallel to the longitudinal axis of the limiting groove, the piston rod is higher than the lower ring body of the chain connector, the piston rod penetrates through a longitudinal through groove of the base to act on the end part of the upperring body, and the piston rod pushes the upper ring body to move longitudinally to shear off the expansion pin of connecting the upper ring body and the lower ring body. The dismounting device has theadvantages of being reasonable in structural design, convenient to operate, high in dismounting speed, safe, reliable, and low in labor intensity and and is capable of effectively reducing non-productive operation time and reducing the cost.

Owner:BEIJING TIANDI HUATAI MINING MANAGEMENT CO LTD +1

A production line for dismantling used vehicles and corresponding technology

InactiveCN103112519BReduce labor intensityLess investmentVehicle dissasembly recoverySolid waste disposalProduction lineRefrigerant reclamation

Owner:QINGDAO NEW WORLD ENVIRONMENT PROTECTION CO LTD

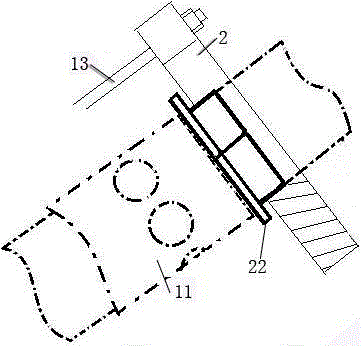

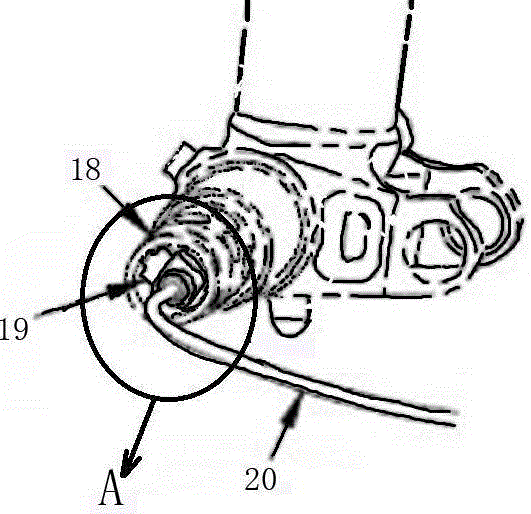

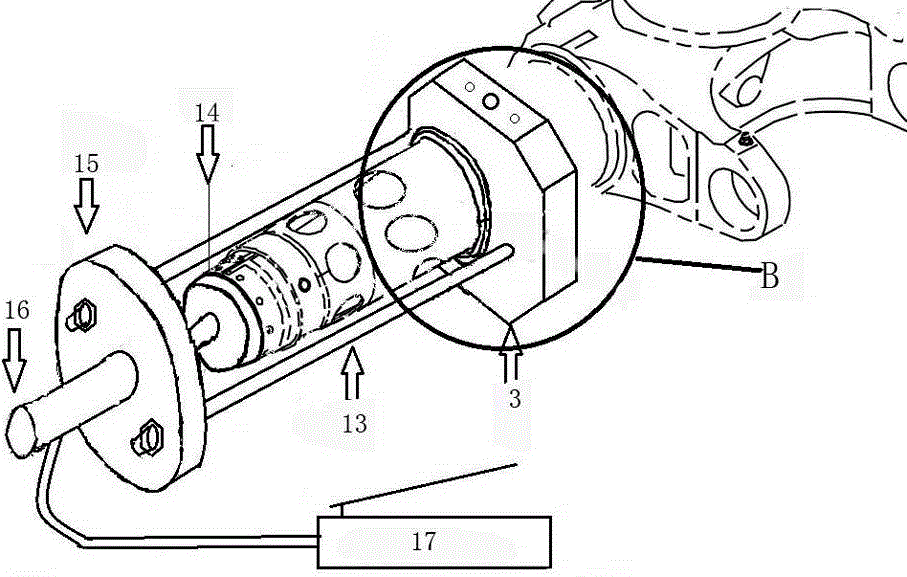

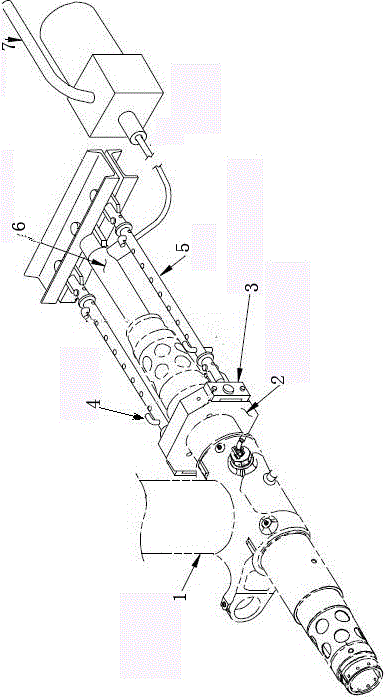

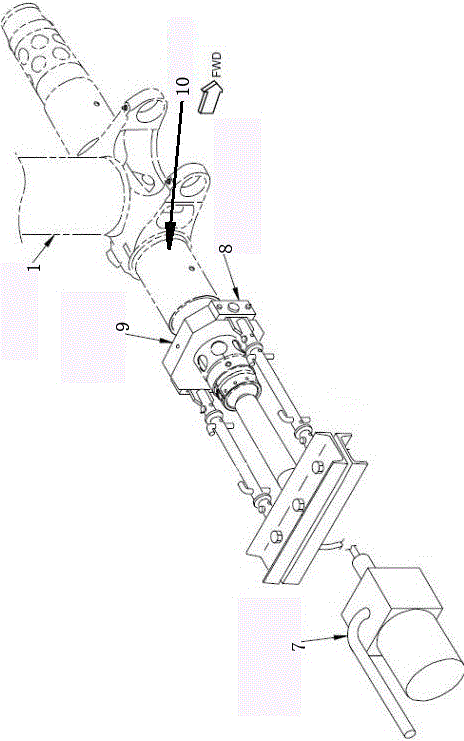

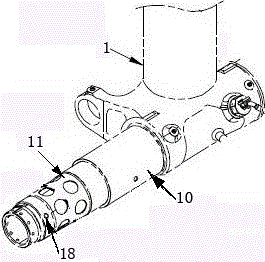

Tool for steering disassembly and bogie disassembling method

InactiveCN109465624ALow failure rateReduce the difficulty of motion controlMetal working apparatusBogieEngineering

The invention discloses a tool for steering disassembly and a bogie disassembling method. The tool comprises a tool frame and a clamping device. The clamping device comprises a pulling rod assembly and a supporting part. The pulling rod assembly comprises a pulling rod body. A grabbing mechanism is further installed on the pulling rod body. The pulling rod body is a telescopic rod. The grabbing mechanism comprises a rotating shaft and a stop rod. The rotating shaft is hinged to the pulling rod body. A folding edge is further arranged at the free end of the pulling rod body. The stop rod can rotate to be parallel to the pulling rod body. The supporting part is located under the pulling rod body. The method is the using method of the tool. By the adoption of the tool and the disassembling method in the scheme, the fault rate in the disassembling process of a bogie can be effectively reduced, and meanwhile, the tool and the method have the characteristics that the speed of completing matching with parts on the bogie and removing matching is high.

Owner:成都岁生科技有限责任公司

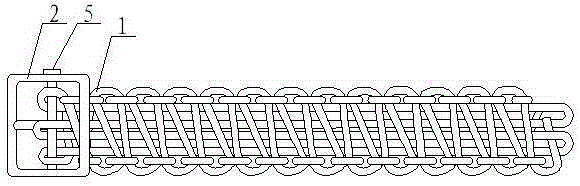

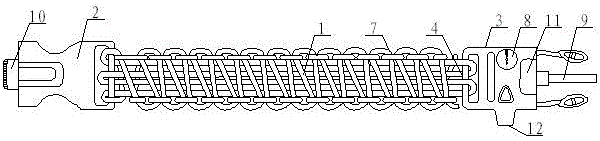

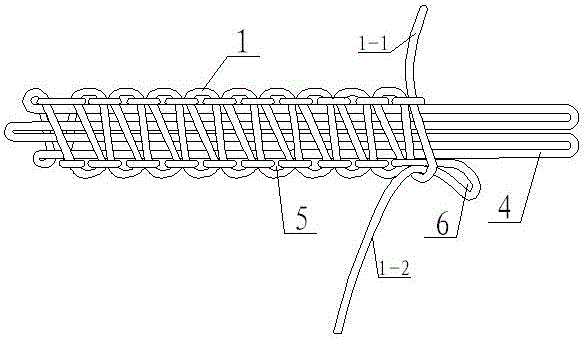

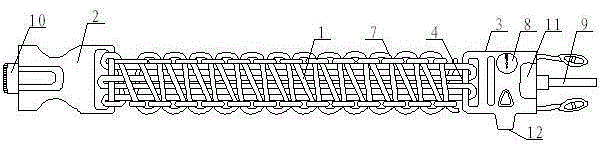

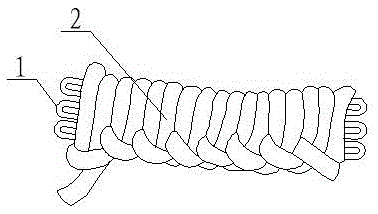

Fast disassembly type emergency lifesaving reflective waistband

InactiveCN105329424AQuick disassemblyPlay the role of emergency lifesavingVessel signalling devicesLife-savingEngineering

A fast disassembly type emergency lifesaving reflective waistband comprises a waistband body and a metal buckle. The waistband body is formed by detachably arranging a high-strength parachute cord. One end of the parachute cord is fixed to the metal buckle. A reflective strip is arranged on the parachute cord. Due to the adoption of the technical scheme, the fast disassembly type emergency lifesaving reflective waistband has the advantages of being simple in structure and convenient to weave, the effect of the waistband can be achieved, the waistband body can be rapidly disassembled into a long lifesaving parachute cord, the disassembling speed is high, disassembling is convenient, the effect of emergency lifesaving can be achieved in time, and the effect of striking help calling is achieved at night due to the reflective strip.

Owner:CHONGQING LYUYANG ENVIRONMENTAL PROTECTION TECH CO LTD

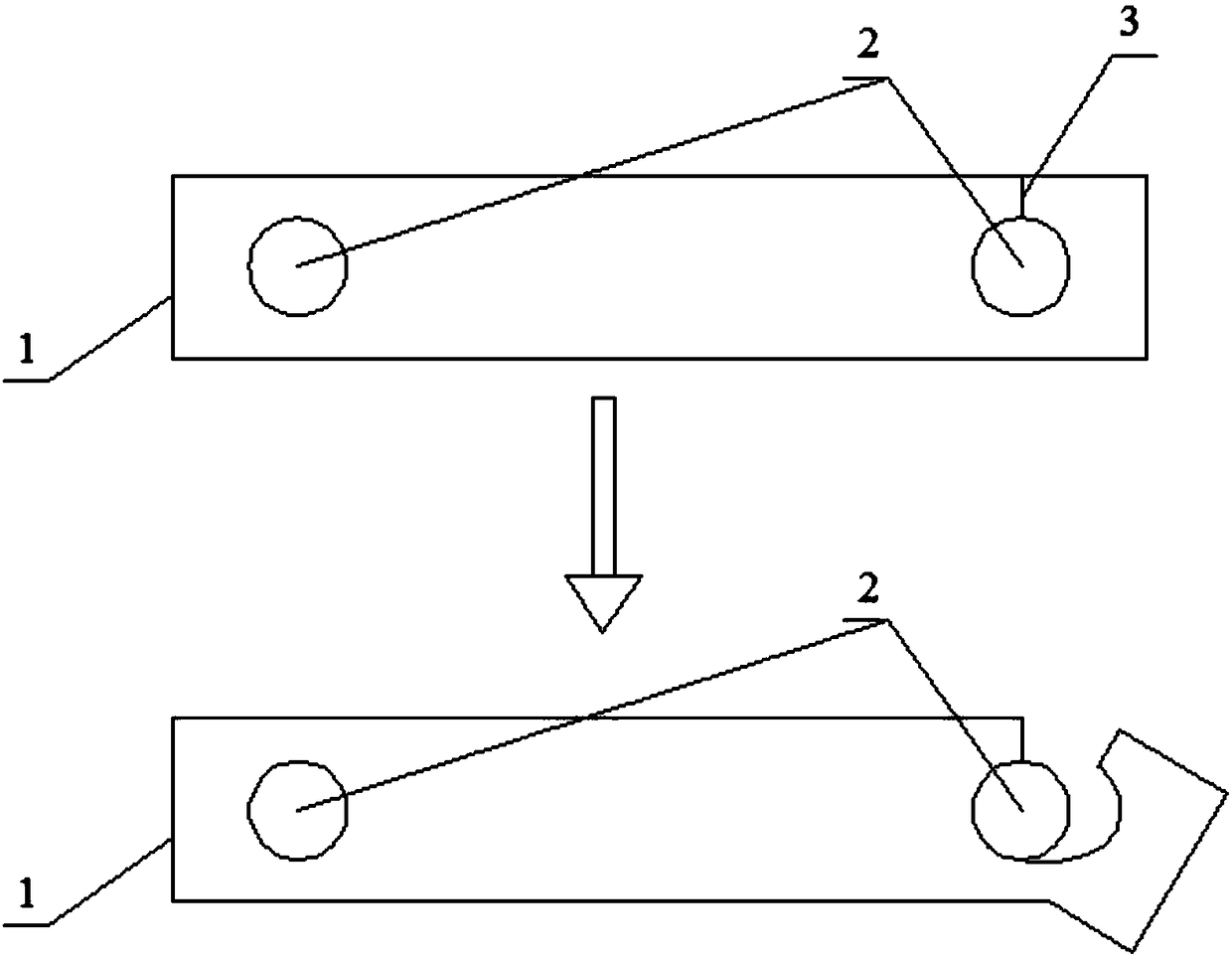

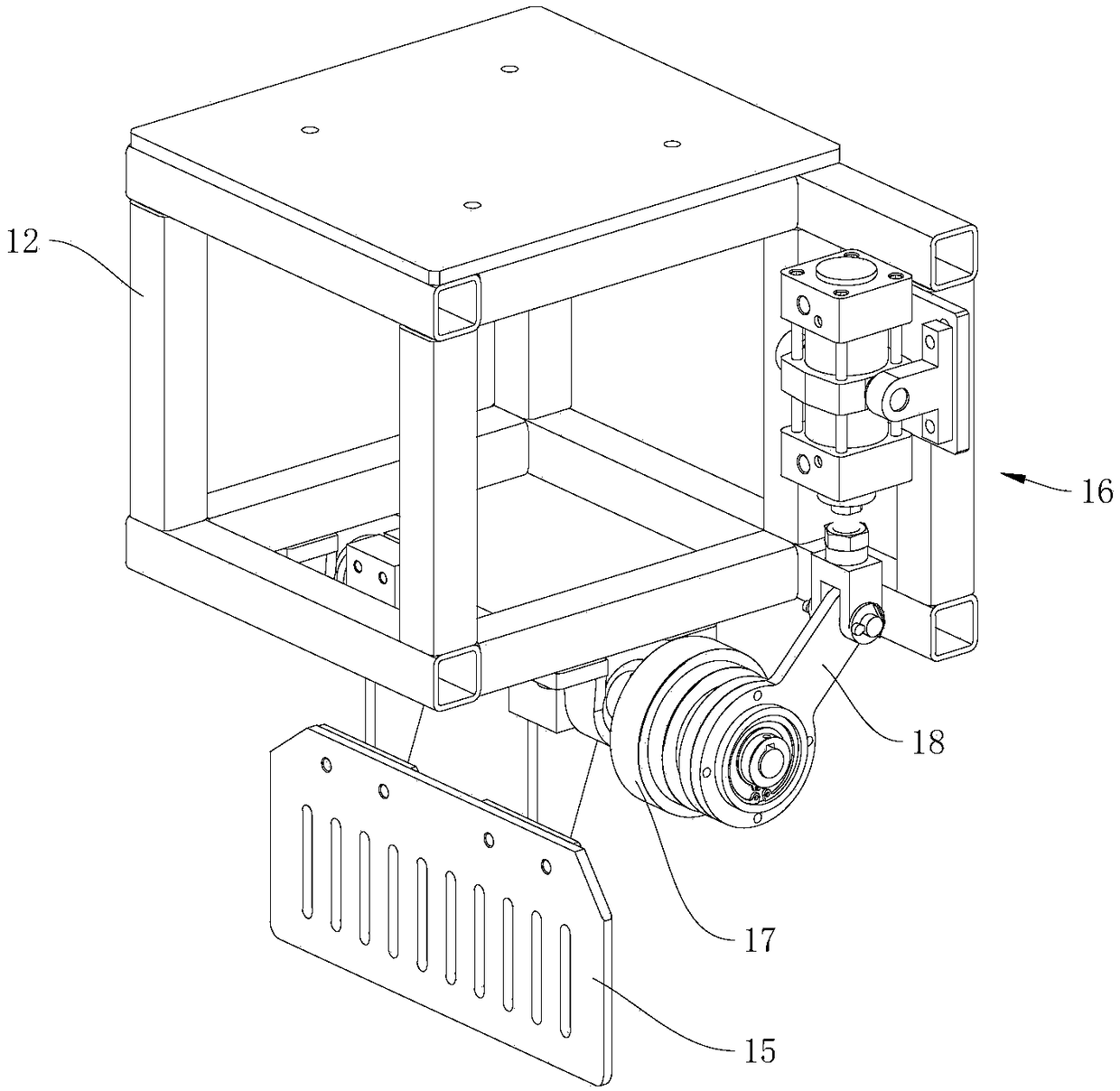

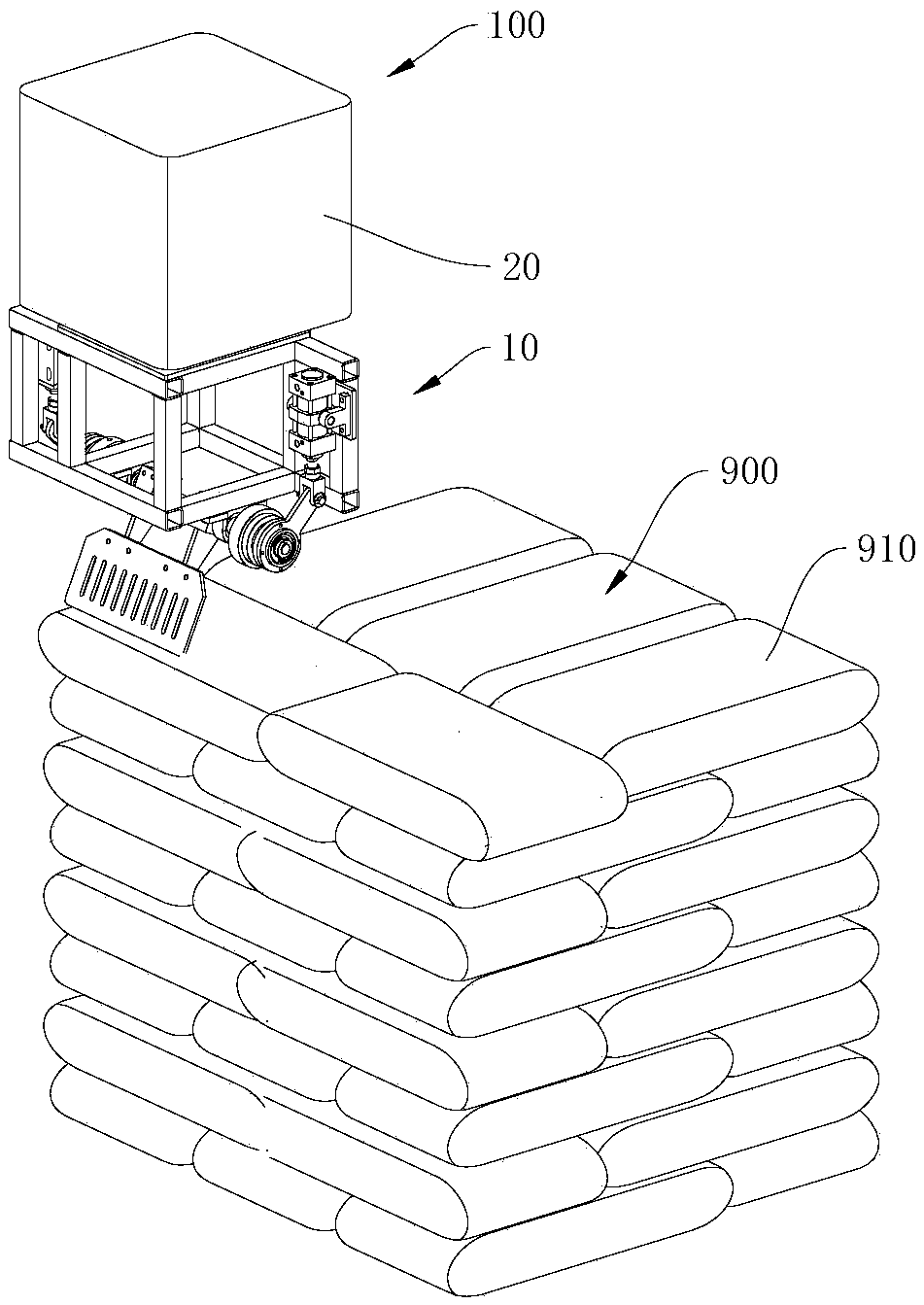

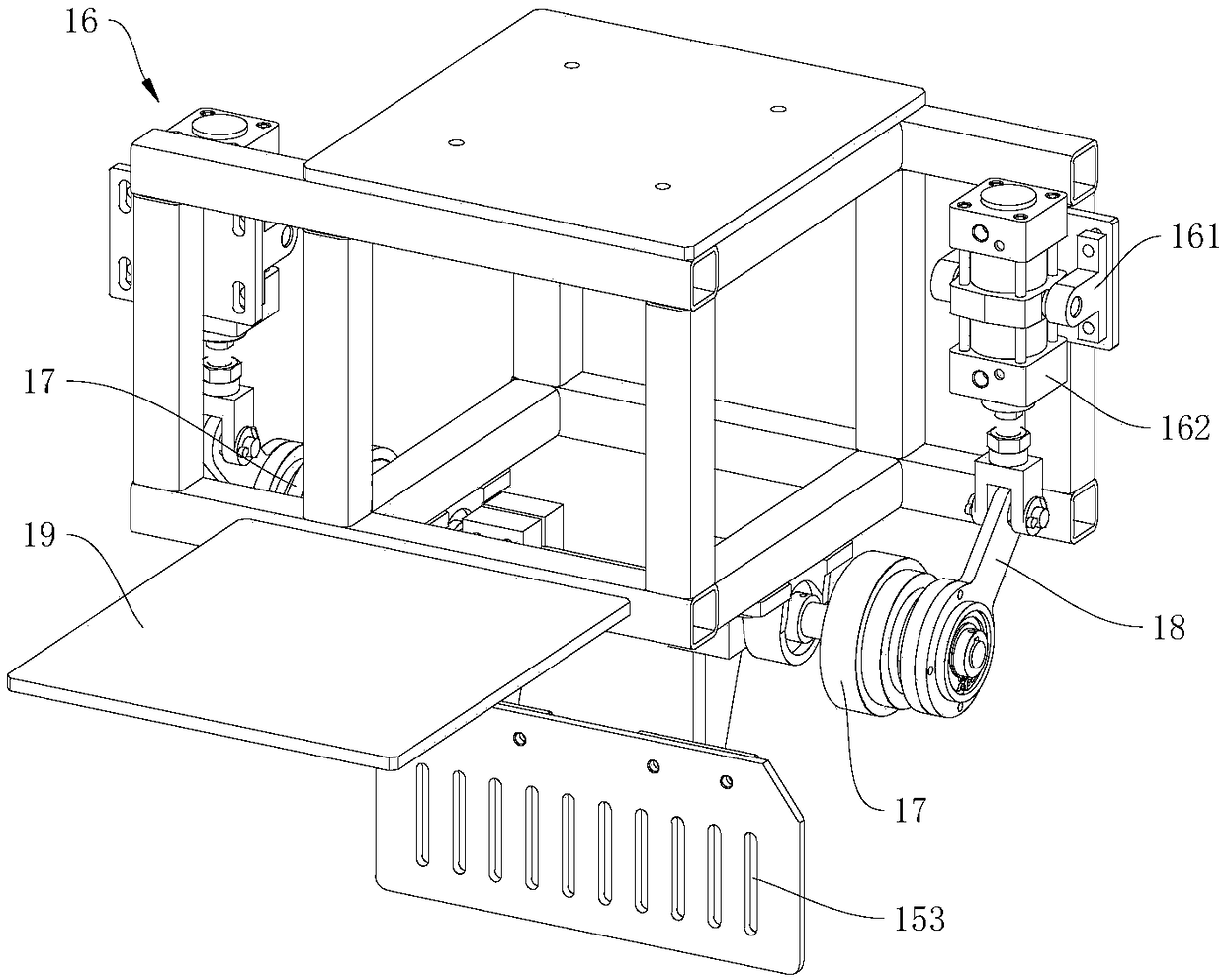

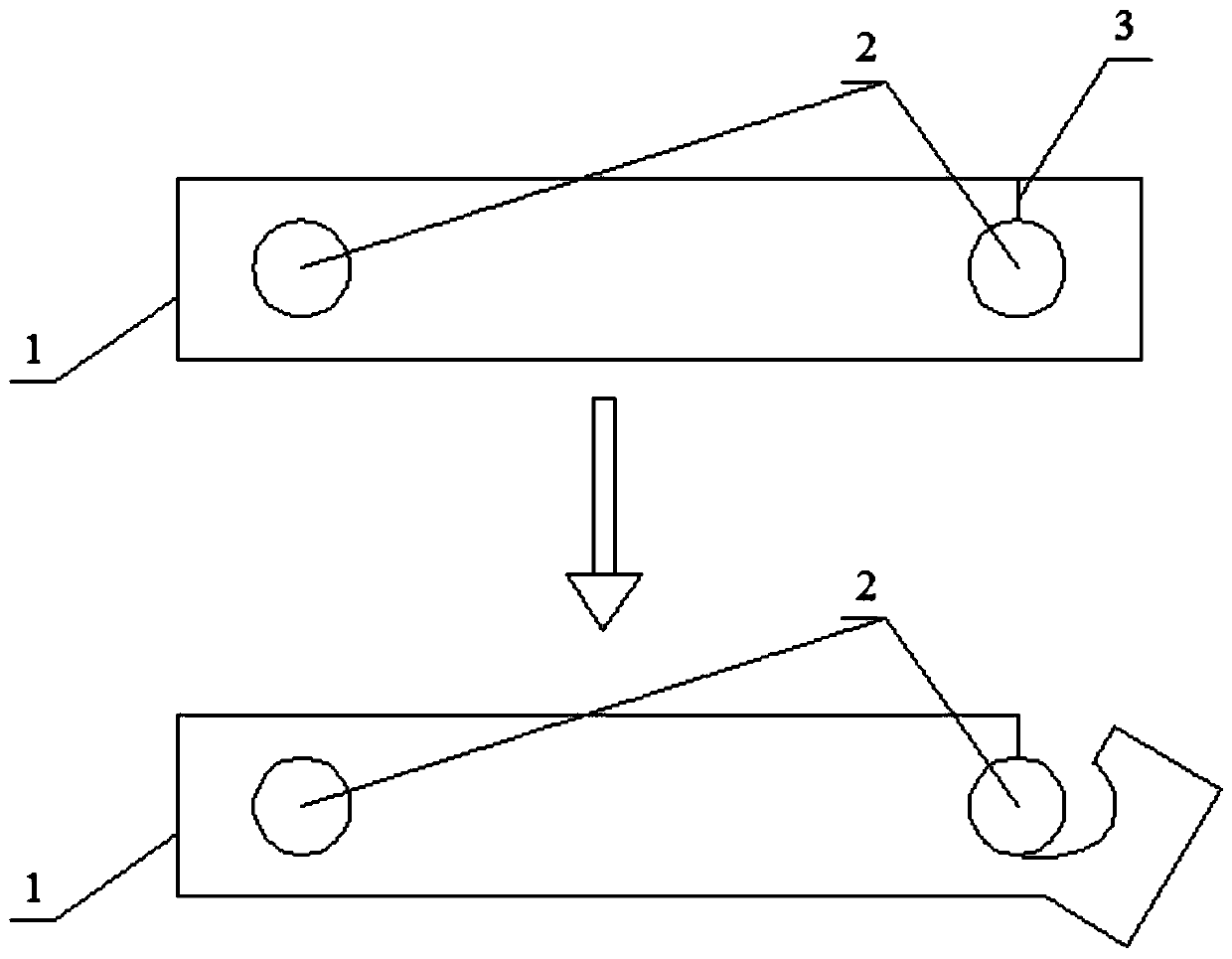

Clutch type disassembling mechanism, device and method, and conveying system

The invention discloses clutch type disassembling mechanism, device and method, and a conveying system, and relates to the technical field of logistics equipment. The clutch type disassembling mechanism comprises a support piece, a moving piece and a clutch, wherein the support piece is connected with a disassembling movement mechanism of the clutch type disassembling device and is connected withthe moving piece and the clutch; the moving piece is used for moving cargoes on a goods stack to get far away from the goods stack, is rotatably connected with the support piece, and is connected withthe clutch; when the clutch is at the disengaged state, the moving piece can rotate up and down relative to the support piece; and when the clutch is at the locked state, the moving piece cannot rotate up and down relative to the support piece, and an acute angle is formed between one side of the lower part of the moving piece and a horizontal plane. The clutch type disassembling mechanism, device and method, and the conveying system have high disassembling efficiency, causes less deformation of the cargoes during the disassembling process, and are suitable for disassembling the multiple cargoes.

Owner:CHINA HEFEI TAIHE OPTOELECTRONICS TECH

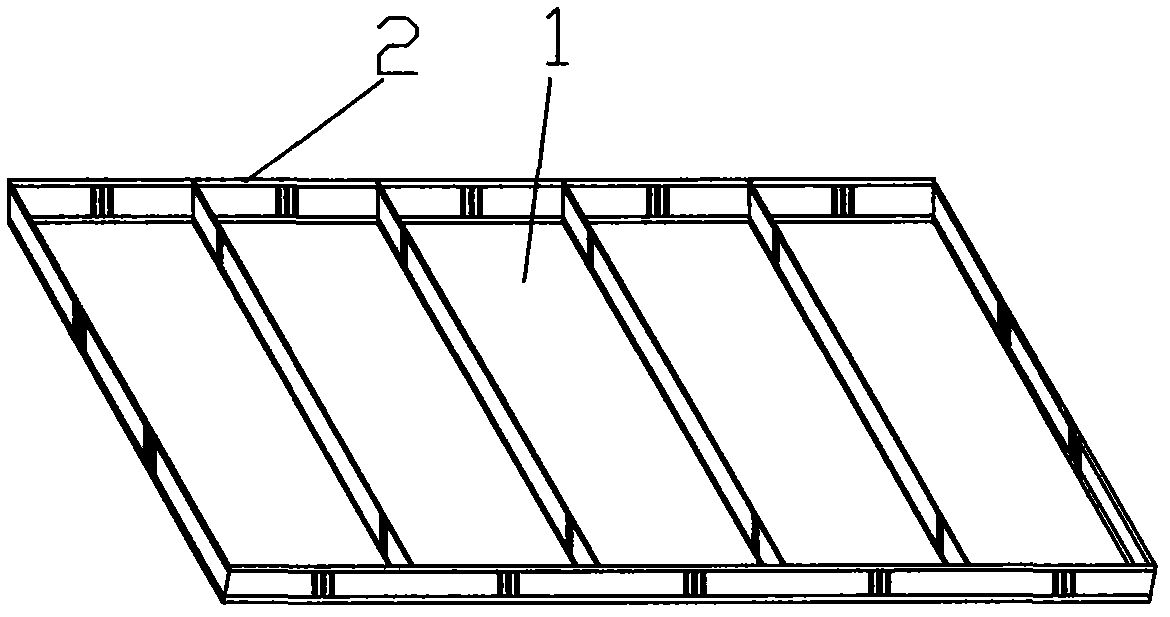

Combined type plastic board formwork

InactiveCN102561676AReduce usageReduce weightForming/stuttering elementsEconomic benefitsReusability

The invention discloses a combined type plastic board formwork, which comprises a plurality of plastic boards. Plastic board concave and convex cases are uniformly distributed on the plastic boards, and side ribs are disposed on four sides of each plastic board; the side ribs of the plastic boards are connected with steel frames; the steel frames comprise transverse steel frames and longitudinal steel frames; and the plastic boards are connected via U-shaped pins. The combined type plastic board formwork has the advantages of high integral rigidity and bearing ability, simple structure, convenience in operation, reusability and the like; shortcomings of all-metal or all-plastic formworks are overcome, and the large-width combined type formwork is manufactured by means of respective advantages of an all-metal formwork and an all-plastic formwork; the combined type plastic board formwork can be used for various concrete structures, and is particularly used for horizontal form erecting of floors, erecting and disassembling are fast, labor is saved, concrete surfaces are smooth, and turnover frequency is high; the turnover frequency of the combined type plastic board formwork is higher than the turnover frequencies of a steel mold and a combined board, the combined type plastic board formwork has the advantages of zero pollution, corrosion resistance, durability, easiness in demolding and the like, the boards can be replaced and recycled, and comprehensive economic benefits including energy conservation, environmental protection and the like are realized.

Owner:青建集团股份公司

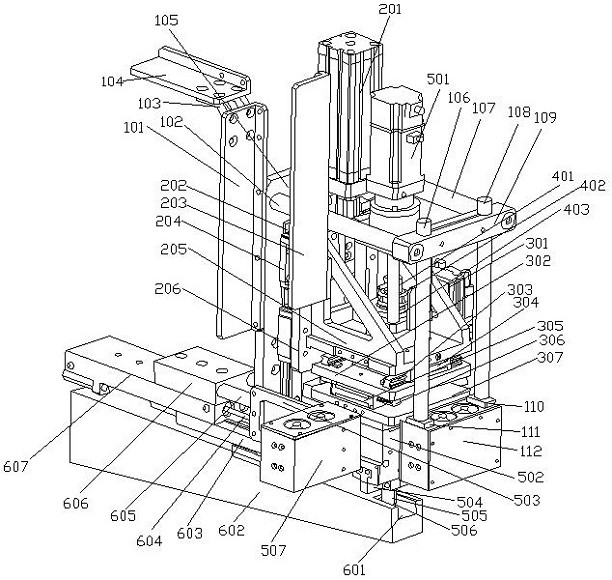

Disassembly technological equipment of main undercarriage axle sleeves and brake sleeves of 737NG series aircrafts

ActiveCN104858638AShorten the shutdown maintenance cycleReduce in quantityAircraft componentsMetal working apparatusHydraulic cylinderBrake

The invention provides disassembly technological equipment of main undercarriage axle sleeves and brake sleeves of 737NG series aircrafts. The disassembly technological equipment comprises a brake sleeve positioning plate, a brake sleeve-disassembling broaching module, a driving hydraulic cylinder, a hydraulic cylinder mounting base, an aluminous heel block, at least two pull rods and a sleeve body, wherein a broaching is matched with a brake sleeve disassembling hole; the brake sleeve positioning plate and the hydraulic cylinder mounting base are all provided with through holes; each pull rod all penetrates through two through holes; the brake sleeve positioning plate and the hydraulic cylinder mounting base are limited on the pull rods through nuts; the sleeve body comprises a cylinder part and a flange and two half bodies connected face to face. When the equipment is used, the sleeve body sleeves an axle, the flange end of the sleeve body is in contact with the inner end surface of an axle sleeve, the brake sleeve positioning plate sleeves the cylinder part, and the inner diameter of the center hole of the brake sleeve positioning plate is smaller than the outer diameter of the flange; when in disassembly, the hydraulic cylinder mounting base is positioned on the outer side of the outer end of the main undercarriage axle, a position rod presses the aluminous heel block on the outer end of the main undercarriage axle to convey the acting force to the main undercarriage axle through the aluminous heel block.

Owner:SHANDONG TAIKOO AIRCRAFT ENG

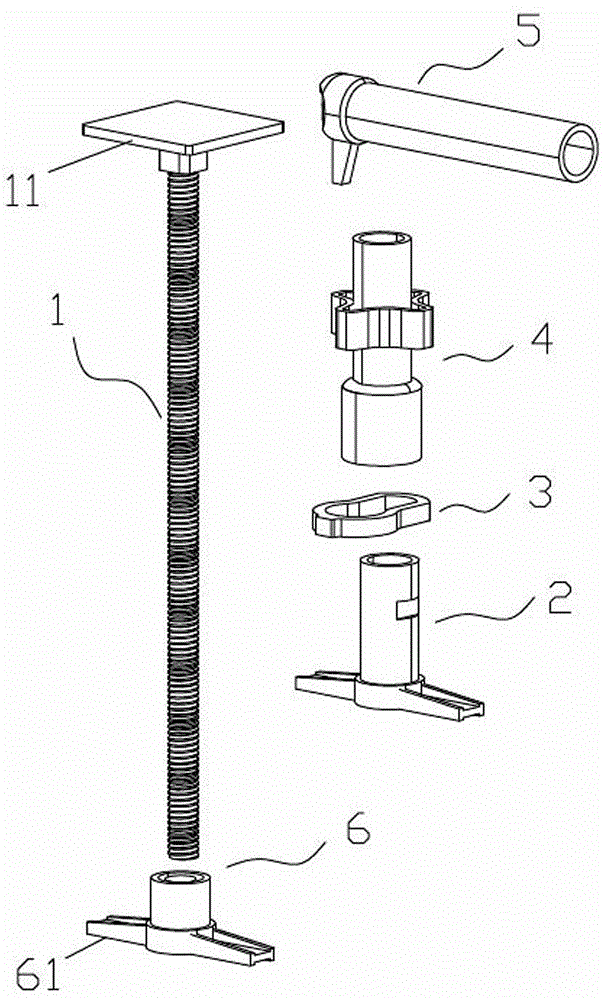

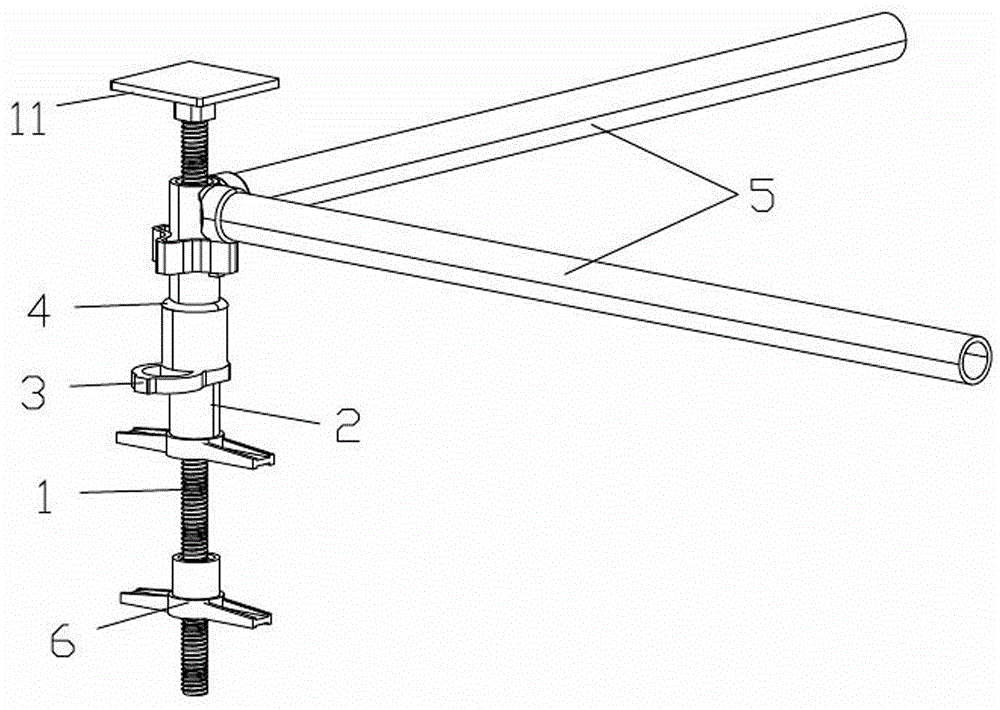

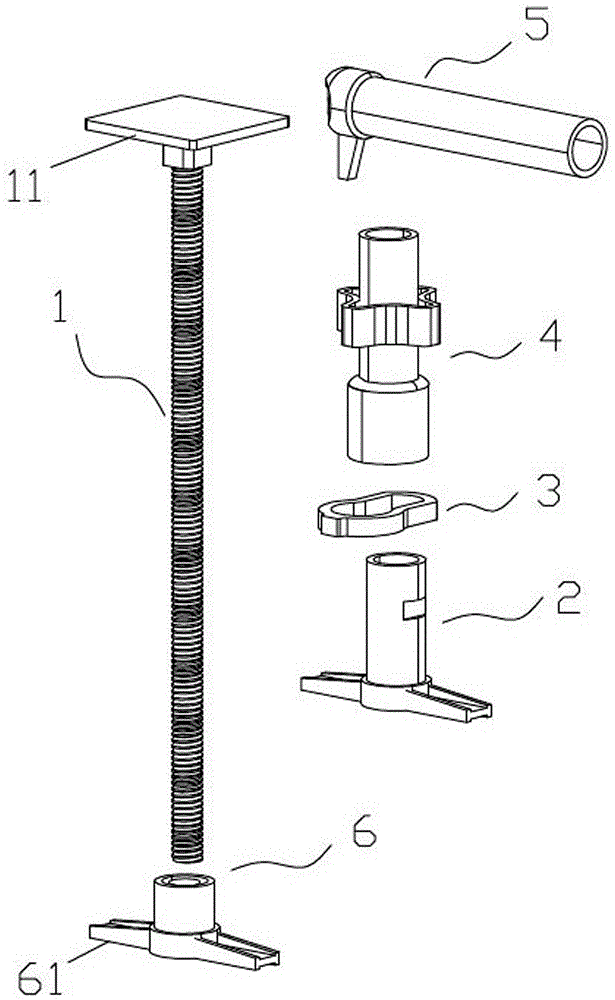

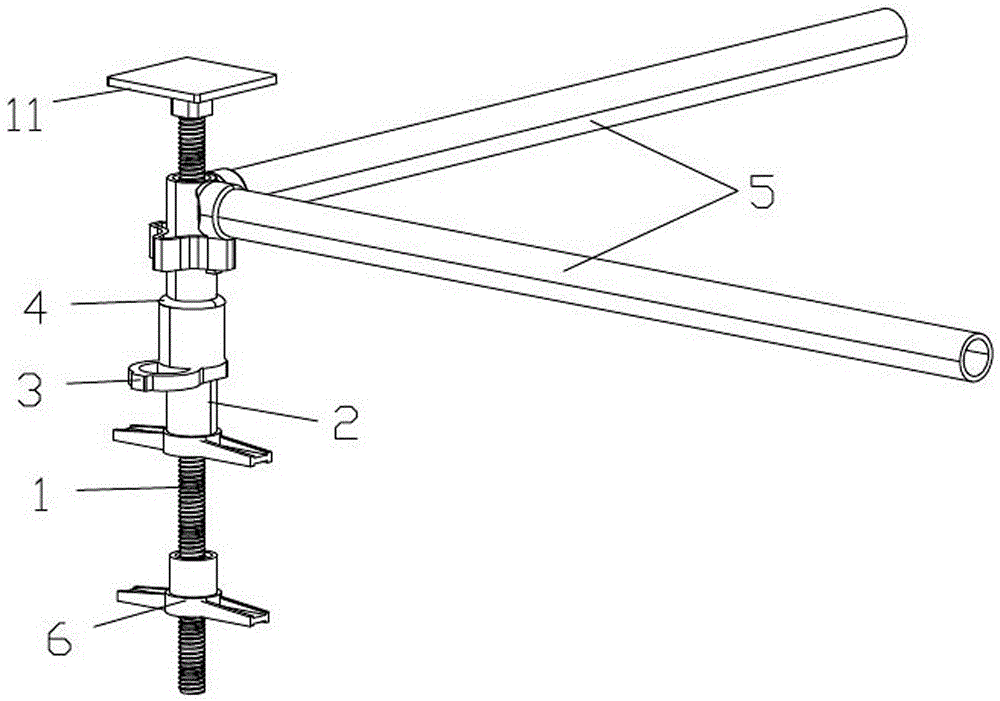

Device for early removal and quick removal of building formwork

ActiveCN104358411ARealize early demolitionRealize quick releaseForms/shuttering/falseworksScaffold accessoriesStructure propertyEngineering

The invention provides a device for early removal and quick removal of a building formwork, and relates to the technical field of building concrete forming. The device comprises a vertical column, a support cylinder body, a long ring and a transverse rod connecting matching device, wherein the long ring is used for realizing the supporting and slipping functions. The device is characterized in that transverse rods can be detached without the detachment of the vertical rod, so the early removal and quick removal of the building formwork are realized; when the formwork is removed, the force is applied to the long ring to move out of a positioning groove, the support cylinder body enters a slip hole, then the long ring loses the support and falls down, the transverse rod connecting matching device, the transverse rods and the formwork will automatically fall down, and the vertical rod still vertically stands; in the installation process, the positioning groove of the support cylinder body is clamped and embedded in a positioning hole, the long ring is supported by the support cylinder body, the transverse rod connecting matching device is also supported, the support cylinder body is rotated, the height of the transverse rod connecting matching device is adjusted, convex nails at the two ends of the transverse rods are inserted into connecting buckles of the transverse rod connecting matching device, and then the support frame body is built. The device has the advantages that the structure is simple, the structure property is good, and the material turnover is quick.

Owner:中国建筑第五工程局有限公司广州分公司 +1

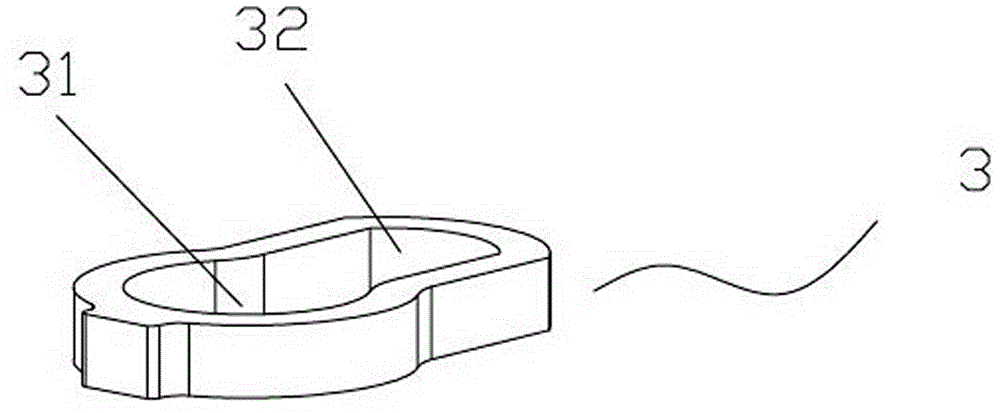

Snap spring disassembling equipment

InactiveCN111791036AFast dismantlingStore in timeMetal working apparatusElectric machinerySemi automatic

The invention discloses snap spring disassembling equipment which comprises a supporting device, a lifting device, a positioning device, a centering device, a disassembling device and a material device. The operation of the whole equipment is supported by the supporting device, and the positioning device is upwards supported by a triangular support of the lifting device; the positioning device isused for achieving downward moving positioning of the snap spring, the centering device is used for achieving displacement fine adjustment in the disassembling process of the snap spring, and the snapspring is kept in the center of the positioning device all the time. The disassembling device is used for disassembling the snap spring; temporary storage and transportation of the disassembled snapsprings are achieved through the material device, and materials can be conveniently stored in the waste box in time. The whole process is achieved through operation of the air cylinder and the motor and is basically completed in a semi-automatic mode, only one person needs to conduct corresponding operation beside according to signals of the detector, the disassembling speed of the snap spring isgreatly increased, the working efficiency is improved, and then the production yield of brake linings is increased.

Owner:上海冉本智能科技有限公司

Fast unweaving device for packaging ropes of fertilizer packaging bag

InactiveCN108284991AEasy to sort outFast dismantlingArticle unpackingBiochemical engineeringFertilizer

The invention discloses a fast unweaving device for packaging ropes of a fertilizer packaging bag. The fast unweaving device comprises a fixing plate. A plurality of fixing screw holes are formed in the fixing plate. The fixing plate is connected with a supporting plate, and the supporting plate is provided with an arc-shaped groove. A rotating shaft is movably arranged in the arc-shaped groove. Apressing piece is arranged at one end of the rotating shaft, and a fastening knob is arranged at the other end of the rotating shaft. The supporting plate is provided with a fixing shaft, and the fixing shaft is provided with a block body in a rotatable mode. The top face of the block body is fixedly connected with a vertical rod, and an elastic sheet is arranged at the top end of the vertical rod. According to the fast unweaving device for the packaging ropes of the fertilizer packaging bag, the rotating shaft capable of moving along the arc-shaped groove is arranged on the body, and the pressing piece at one end of the rotating shaft can be used for fixing one branch of the packaging ropes; and the unweaving device is further provided with the rotatable block body, the elastic sheet arranged on the block body can be used for fixing the branches of the packaging ropes, and therefore the packaging ropes can be arranged conveniently, and the unweaving speed of the packaging ropes is increased.

Owner:泰州市梦之谷科技发展有限公司

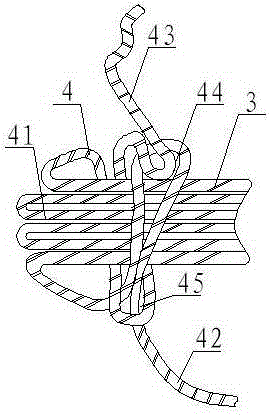

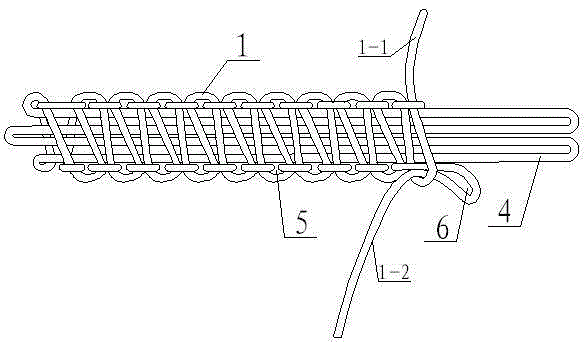

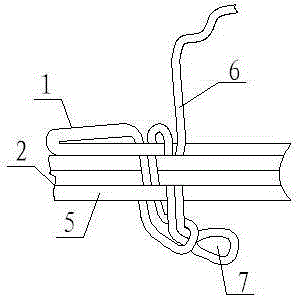

A double-head quick-release emergency rescue bracelet

ActiveCN105326167BFast dismantlingPlay the role of emergency lifesavingWatch chainsOrnamental chainsEmergency rescueEngineering

A double-head quick-release type emergency lift-saving bracelet comprises a parachute cord, a plastic clamping head and a plastic plug. The middle of the parachute cord is wound between the plastic clamping head and the plastic plug to form a supporting core wire, the section, from one end to the supporting core wire, of the parachute cord is an A end wire, and the section, from the other end to the supporting core wire, of the parachute cord is a B end wire. The initial end of the A end wire is bent to form a main tied ring, the initial end of the B end wire is bent to form an auxiliary tied ring which penetrates through the main tied ring from top to bottom and is located below the supporting core wire, a next main tied ring of the A end wire penetrates through the auxiliary tied ring from bottom to top and is located above the supporting core wire, and a next auxiliary tied ring of the B end wire then penetrates through the corresponding main tied ring from top to bottom and is located below the supporting core wire; the A end wire and the B end wire are arranged in the mode from the corresponding ends of the supporting core wire to the corresponding other ends of the supporting core wire in sequence to form a bracelet body, and the ends of the A end wire and the B end wire are tied and inserted into the bracelet body. The double-head quick-release type emergency lift-saving bracelet has the advantages of being simple in structure and convenient to braided, a long life-saving rope can be quickly formed when the two ends of the bracelet are pulled in the opposite directions, the release speed is high, release is convenient, and the emergency lift-saving effect can be achieved in time.

Owner:重庆恒壁科技有限公司

Bolt tighteners, bolt looseners and multi-bolt tighteners

ActiveCN106312918BQuick tightenFast dismantlingMetal-working hand toolsImpact wrenchCentrifugal force

Owner:SHANGHAI CHENGJIE ELECTROMECHANICAL CO LTD

Early-dismantling support of aluminum alloy top plate

InactiveCN101864835BConstruction safety is not affectedFaster turnaroundForms/shuttering/falseworksSheet steelHigh stress

The invention provides an early-dismantling support of an aluminum alloy top plate which comprises a support main body and a template support connected on the support main body, wherein the support main body consists of a vertical steel pipe, a lower connecting plate welded on the lower end of the vertical steel pipe, an upper support plate welded on the upper end of the vertical steel pipe and limit sheets welded at the middle part of the vertical steel pipe; the vertical steel pipe is sheathed with a jacking which is formed by casting cast steel; and the vertical steel pipe between the jacking and the upper support plate is also sheathed with a slide support which is formed by welding steel plates. The early-dismantling support has the advantages of fast and convenient dismantling, highworking efficiency, simple structure, high stress intensity, convenient and flexible operation, easily mastered construction process, accelerated construction progress and shortened construction period.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Double-head quick-release type emergency lift-saving bracelet

ActiveCN105326167AFast dismantlingPlay the role of emergency lifesavingWatch chainsOrnamental chainsLine segmentEngineering

A double-head quick-release type emergency lift-saving bracelet comprises a parachute cord, a plastic clamping head and a plastic plug. The middle of the parachute cord is wound between the plastic clamping head and the plastic plug to form a supporting core wire, the section, from one end to the supporting core wire, of the parachute cord is an A end wire, and the section, from the other end to the supporting core wire, of the parachute cord is a B end wire. The initial end of the A end wire is bent to form a main tied ring, the initial end of the B end wire is bent to form an auxiliary tied ring which penetrates through the main tied ring from top to bottom and is located below the supporting core wire, a next main tied ring of the A end wire penetrates through the auxiliary tied ring from bottom to top and is located above the supporting core wire, and a next auxiliary tied ring of the B end wire then penetrates through the corresponding main tied ring from top to bottom and is located below the supporting core wire; the A end wire and the B end wire are arranged in the mode from the corresponding ends of the supporting core wire to the corresponding other ends of the supporting core wire in sequence to form a bracelet body, and the ends of the A end wire and the B end wire are tied and inserted into the bracelet body. The double-head quick-release type emergency lift-saving bracelet has the advantages of being simple in structure and convenient to braided, a long life-saving rope can be quickly formed when the two ends of the bracelet are pulled in the opposite directions, the release speed is high, release is convenient, and the emergency lift-saving effect can be achieved in time.

Owner:重庆恒壁科技有限公司

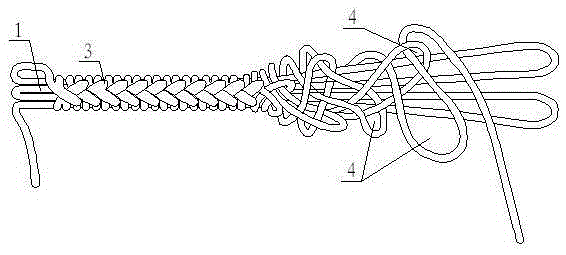

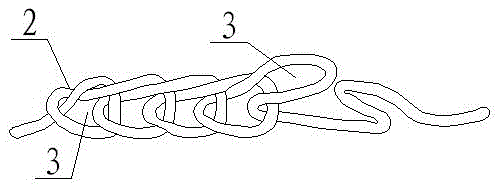

Decorative life-saving handle strap

ActiveCN105361397AImprove comfortImprove the decorative effectOther accessoriesHigh intensityLife saving

A decorative life-saving handle strap comprises a handle strap body, wherein the handle strap body is a strap-shaped body which is made of a high-strength life-saving rope which is disassembled conveniently; a protective strap which is convenient to disassemble is wound on the surface of the strap-shaped body and wraps the surface of the strap-shaped body to form an arc surface; a tip of the life-saving rope forming the strap-shaped body is continuously bent on the front surface and the back surface of the strap-shaped body to form a plurality of easily disassembled rings; one of the easily disassembled rings on the back surface of the strap-shaped body penetrates in one of the easily disassembled rings on the front surface of the strap-shaped body and sleeves the next adjacent easily disassembled ring on the front surface of the strap-shaped body; and after being tensioned, the easily disassembled rings on the back surface and the front surface of the strap-shaped body are heart-shaped on the front surface of the strap-shaped body. The decorative life-saving handle strap is simple in structure, convenient to knit and good in decoration effect, not only has the effect of a handle, but also can be disassembled into a quite long life-saving rope, and is high in disassembling speed and convenient to disassemble; the emergency life-saving effect can be achieved in time; and the surface of the handle strap is the arc surface, and the carrying comfort level is improved.

Owner:大化瑶族自治县计量检定测试所

737ng series aircraft main landing gear axle sleeve and brake sleeve removal tooling

ActiveCN104858638BShorten the shutdown maintenance cycleReduce in quantityAircraft componentsMetal working apparatusHydraulic cylinderControl engineering

The invention provides disassembly technological equipment of main undercarriage axle sleeves and brake sleeves of 737NG series aircrafts. The disassembly technological equipment comprises a brake sleeve positioning plate, a brake sleeve-disassembling broaching module, a driving hydraulic cylinder, a hydraulic cylinder mounting base, an aluminous heel block, at least two pull rods and a sleeve body, wherein a broaching is matched with a brake sleeve disassembling hole; the brake sleeve positioning plate and the hydraulic cylinder mounting base are all provided with through holes; each pull rod all penetrates through two through holes; the brake sleeve positioning plate and the hydraulic cylinder mounting base are limited on the pull rods through nuts; the sleeve body comprises a cylinder part and a flange and two half bodies connected face to face. When the equipment is used, the sleeve body sleeves an axle, the flange end of the sleeve body is in contact with the inner end surface of an axle sleeve, the brake sleeve positioning plate sleeves the cylinder part, and the inner diameter of the center hole of the brake sleeve positioning plate is smaller than the outer diameter of the flange; when in disassembly, the hydraulic cylinder mounting base is positioned on the outer side of the outer end of the main undercarriage axle, a position rod presses the aluminous heel block on the outer end of the main undercarriage axle to convey the acting force to the main undercarriage axle through the aluminous heel block.

Owner:SHANDONG TAIKOO AIRCRAFT ENG

A fully automatic dismantling device and method for waste power batteries

ActiveCN104157927BReduce loss costReduce cooling costsSolid waste disposalWaste accumulators reclaimingPower batteryEngineering

Owner:GUANGDONG BRUNP RECYCLING TECH +3

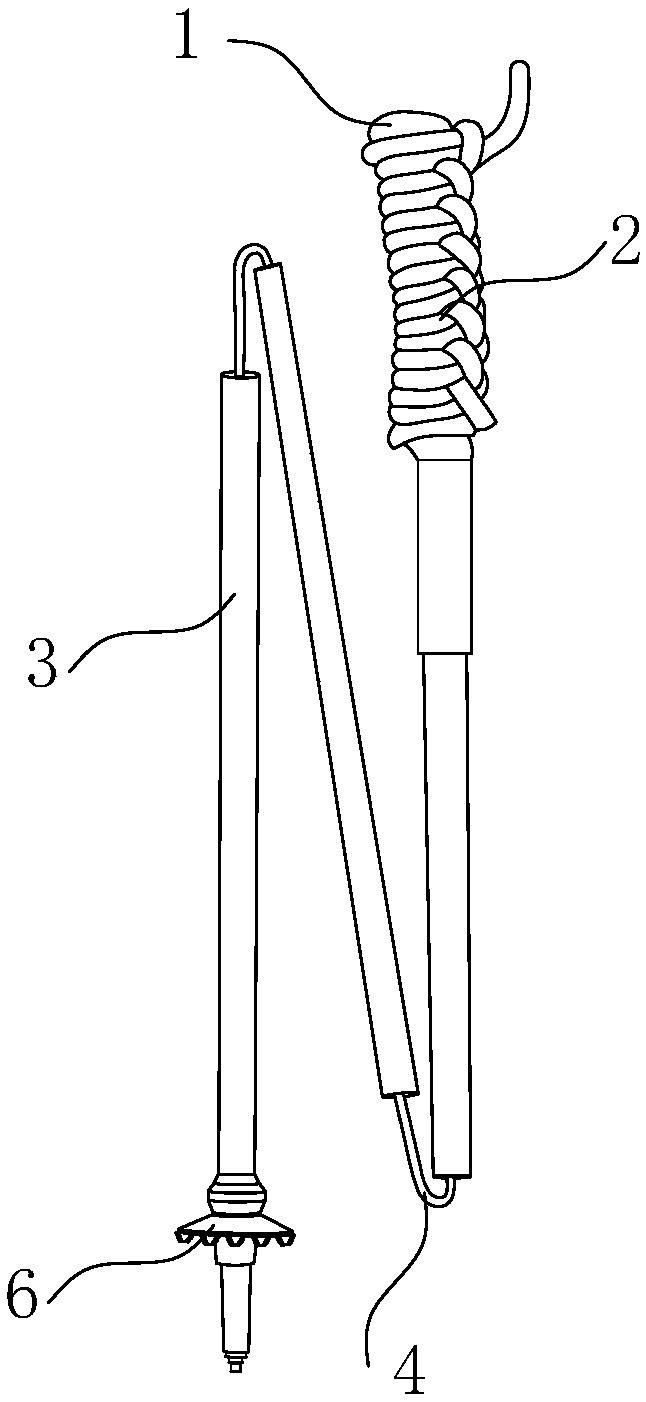

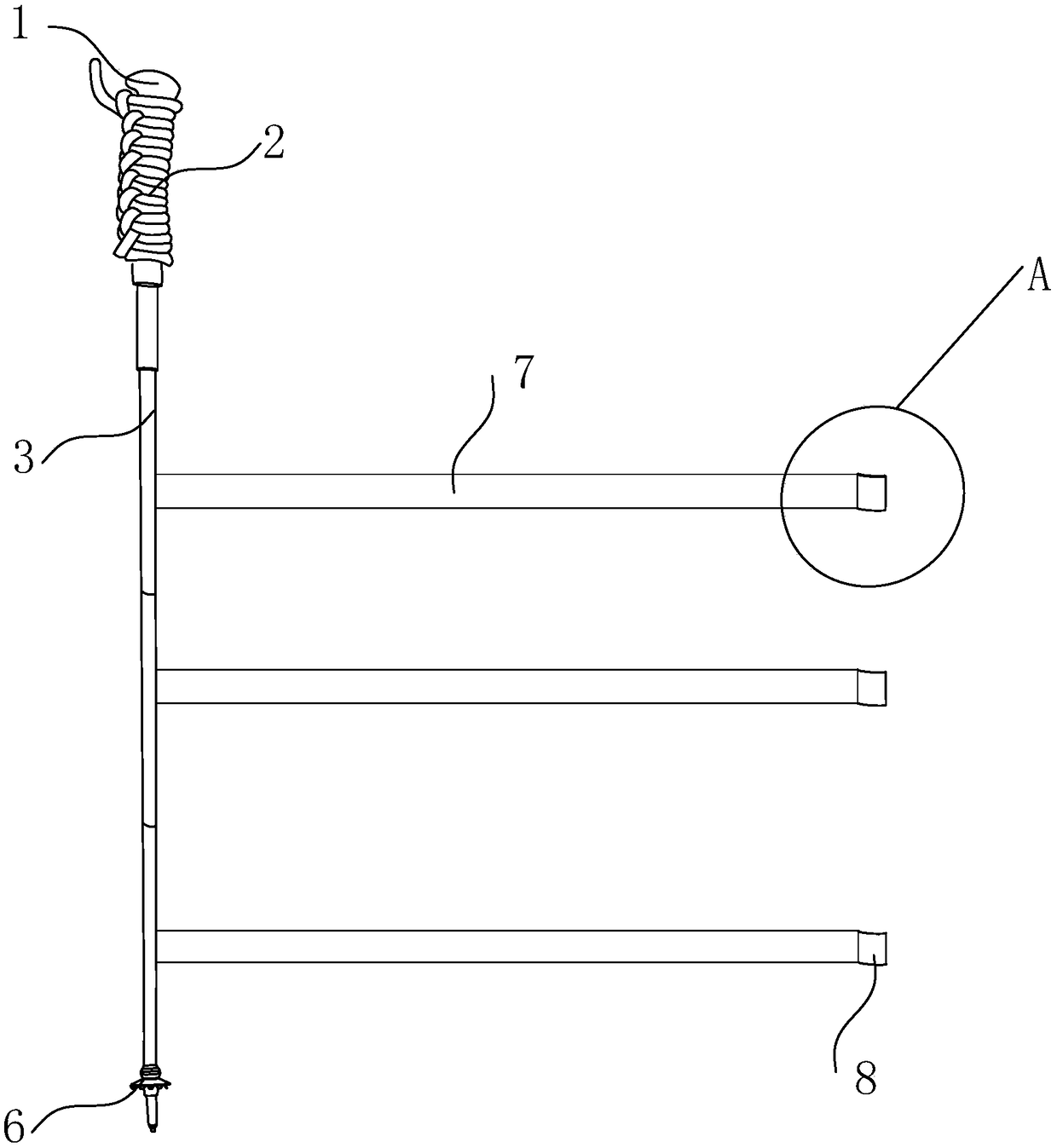

An outdoor mountaineering auxiliary walking stick

ActiveCN106388161BFast dismantlingEasy to disassembleWalking sticksMountaineeringMechanical engineeringOpen cavity

The invention provides an outdoor mountaineering assisting walking stick, comprising a handle and a supporting rod, wherein the handle is configured with a life-saving rope, the life-saving rope is configured on the outer surface of the handle by a detachable set, wherein, the detachable set is that: fixing one end of the life-saving rope on the handle, the other end containing a plurality of locking rings formed by continuous bends, fixing each locking ring on the handle, and a behind locking ring passing in sequence through an adjacent former locking ring and locking a former locking ring to a protective belt; the supporting rod comprises a plurality of single pull quick casing tubes and a sleeve rope for connecting the casing of each tube, one end of rope connects the inner sleeve of the cased tube, the other end connects a stringing mechanism; and the wall of each section of the cased tube opens cavity on the same side, the cavity inside is arranged with a drumming wheel, the drumming wheel inside contains an elastic strip, the outer end of the elastic strip contains a stop part matching with the outer wall of the cased tube; when the utility model is used, the elastic strip pulls out and the stop part connects with another rod and forms a stretcher.

Owner:YICHANG HONGJIAN ALUMINUM IND

Treatment device and method for non-destructive disassembling the waste circuit board

InactiveCN101386016BFast dismantlingImprove dismantling efficiencySolid waste disposalSoldering apparatusNon destructiveFlue gas

The invention discloses a device for nondestructively disassembling and treating waste circuit boards and a method thereof. The device comprises six parts of a conveying unit, a heating and heat insulation unit, a loading and unloading unit, a vibration unit, a recovery unit and a smoke removing unit. The conveying unit conveys the circuit boards; the heating and heat insulation unit melts soldering tin on the circuit boards; the loading and unloading unit realizes rapid loading and automatic unloading of the circuit boards; the vibration unit is used for separating the soldering tin and components from the circuit boards; the recovery unit is used for realizing separation and recovery of the soldering tin and the components; and the smoke removing unit is used for filtering flue gas dustin waste gas and odor produced in the operation of the device. The device and the method thereof have the advantages of continuous operation, high disassembling efficiency, high heating speed, controllable temperature, energy saving, high nondestructive disassembling rate of the components, small volume, light weight, simple installation, low power, high automation degree and simple processing operation.

Owner:BEIHANG UNIV

A method for dismantling and recycling a square power battery cover plate

ActiveCN108539316BReduce material purityFast dismantlingWaste accumulators reclaimingBattery recyclingPower batteryStructural engineering

The invention discloses a disassembly and recovery method of a square power battery cover plate and relates to the technical field of battery material recovery. The method comprises the following steps: firstly, cutting a notch in a cover plate at the periphery of a pole along the radial direction of the pole by utilizing a cutting tool, extending the outer end of the notch to the outer edge of the cover plate, and extending the inner end of the notch to the inner edge of the cover plate in contact with the pole; then, clamping the cover plate by utilizing a clamp, and enabling the cover plateto rotate along the direction away from the notch so as to open the notch; and after the cover plate rotates for a certain angle, enabling the pole to automatically fall off from the cover plate, andsimultaneously, separating a plastic bracket below the cover plate, thereby realizing disassembly and recovery of the pole, the cover plate and the plastic bracket. Disassembly of the cover plate andseparation and recovery of all parts can be quickly realized by utilizing the cutting tool and the clamp, so that the pole is automatically separated from the cover plate.

Owner:安徽南都华铂新材料科技有限公司

Emergency life-saving handle used on knapsack

An emergency life-saving handle used on a knapsack is disclosed. The emergency life-saving handle comprises a handle belt body, wherein the handle belt body is a belt-shaped body formed by a high-strength life-saving rope in a conveniently-detached manner; a conveniently-detached protective belt is arranged on the surface of the belt-shaped body; and the belt-shaped body is packaged by the protective belt into a cambered surface. By adoption of the technical scheme, the emergency life-saving handle has the advantages of simple structure and convenience in weaving; two ends of the handle rope are pulled towards the opposite directions to form the quite long life-saving rope rapidly; the emergency life-saving handle is rapid in detaching, convenient to detach, and capable of performing an emergency life-saving function; and in addition, the surface of the handle belt is the cambered surface, so that the comfortable feeling in taking the handle belt is improved.

Owner:CHONGQING LYUYANG ENVIRONMENTAL PROTECTION TECH CO LTD

A cable tray

ActiveCN111817223BPlay the role of limit movementFast dismantlingElectrical apparatusAlarmsCable trayElectric cables

The present invention relates to the technical field of cable bridges, in particular to a cable bridge, comprising a main bridge, mounting plates are respectively arranged at the upper ends of both sides of the main bridge, an alarm mechanism is provided at the inner middle end of the main bridge, and the inner two ends of the main bridge are respectively A spacing adjustment mechanism is provided, and each spacing adjustment mechanism includes an adjustment assembly, and each adjustment assembly includes two moving plates that can move horizontally in opposite directions, and each moving plate is respectively provided with a cable clamping head, each of the main bridge The two ends are respectively provided with detachable connecting mechanisms, and each connecting mechanism includes a connecting frame that can be docked with the end of the main bridge frame and locking assemblies installed on the upper and lower ends of the two sides of the connecting frame respectively, and the two sides of the main bridge frame are respectively provided with The connection plate that can be detachably connected with each locking component can adjust the fixed cables to improve the practicality of installation, and can efficiently separate each hinge frame separately to improve the efficiency of later maintenance.

Owner:天津龙鼎熙石化新能源科技有限公司

A device for realizing early dismantling and quick dismantling of building formwork

ActiveCN104358411BFast dismantlingImprove work efficiencyForms/shuttering/falseworksScaffold accessoriesStructure propertyEngineering

Owner:中国建筑第五工程局有限公司广州分公司 +1

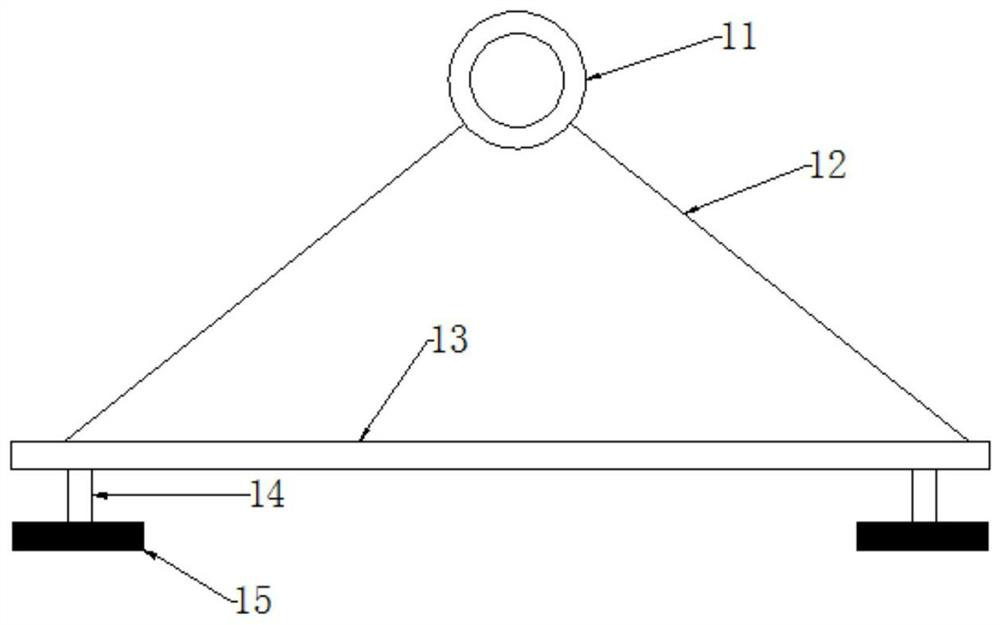

Forming method of balancing weight of solid ballast

PendingCN113334024AQuick assemblyQuick releaseWelding/cutting auxillary devicesCounterweightsMaterials preparationBatten

The invention discloses a forming method of a balancing weight of a solid ballast. The forming method comprises the steps of material preparation, batten hoisting and welding. A forming tool in the hoisting and welding steps comprises at least two vertical supporting rods arranged at intervals, and a supporting plate is vertically arranged above each supporting rod; and L-shaped containing notches are formed in the upper ends of the supporting plates in an inwards-sunken manner, the short arm end points of the containing notches are lower than the long arm end points of the containing notches, the short arm end points of the containing notches are collinear, and the connecting line of the short arm end points is parallel to the connecting line of the long arm end points. According to the forming method, the L-shaped containing notches are formed in the supporting plates, and when battens fall into the L-shaped containing notches due to the self-gravity of the battens, alignment of the side faces of the stacked battens and the opposite side edges of the battens is automatically achieved; and in the welding process, the balancing weight does not need to be turned over, so that the labor intensity of workers for aligning the side edges of the battens one by one and turning over the balancing weight is reduced, and the working efficiency is improved.

Owner:CHENGXI SHIPYARD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com