Combined type plastic board formwork

A combined, plastic technology, applied in the fields of formwork/template components, on-site preparation of building components, construction, etc., can solve problems such as obstacles to the popularization and application of plastic templates, large coefficient of thermal expansion and contraction, and large influence of temperature changes. Achieve the effect of improving rigidity, large overall rigidity and more turnover times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

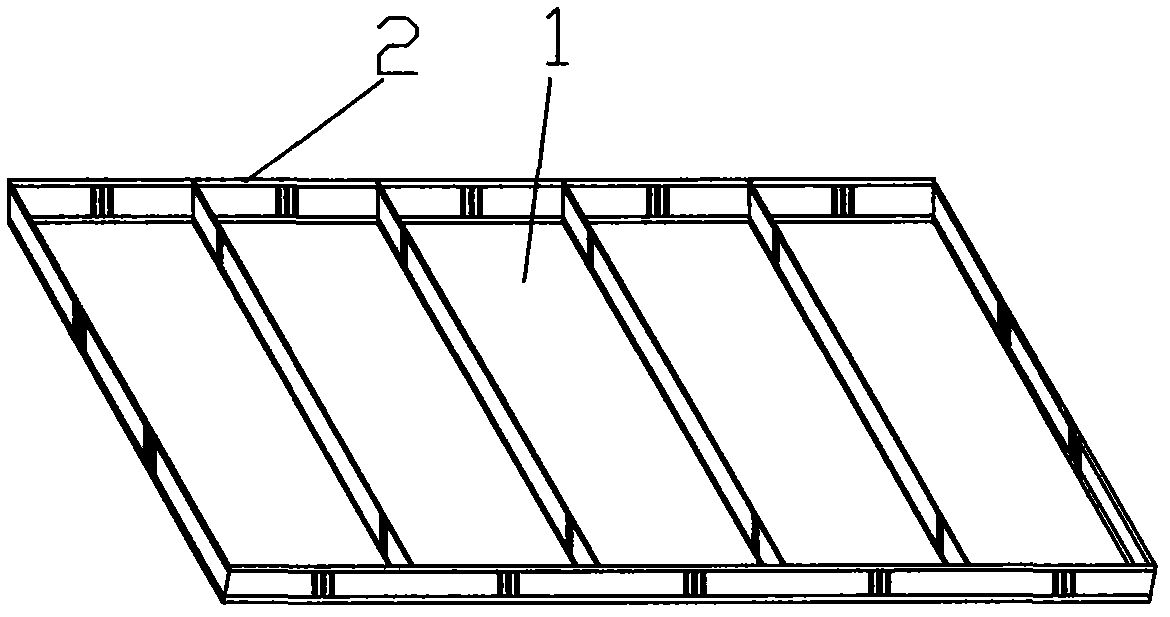

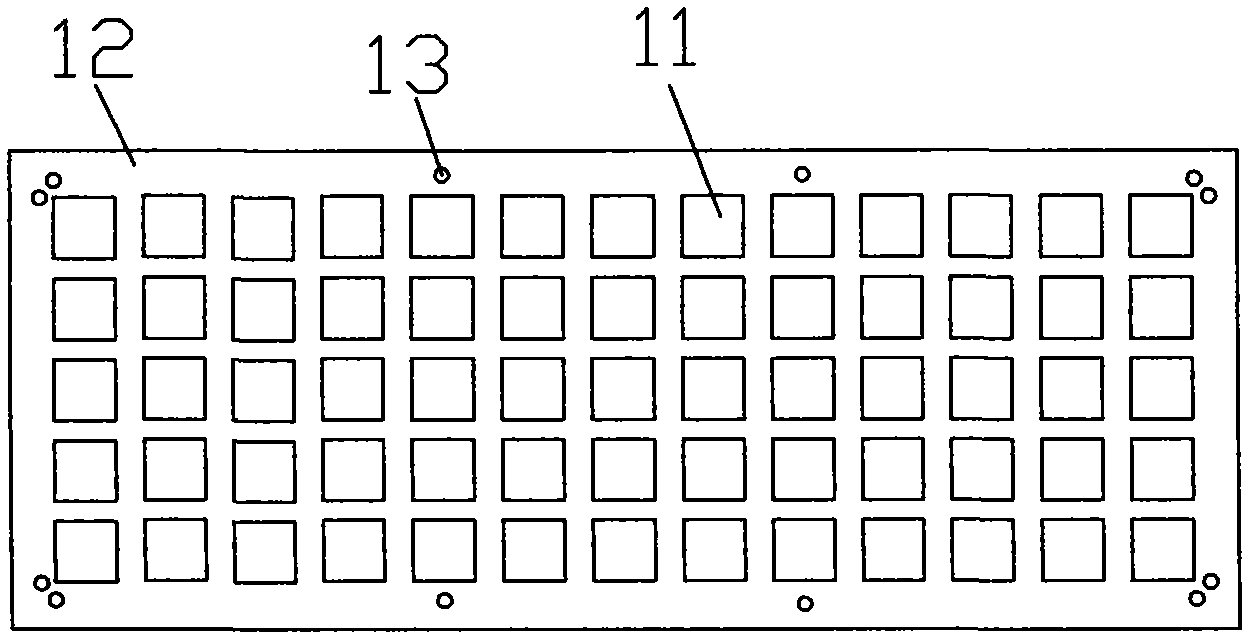

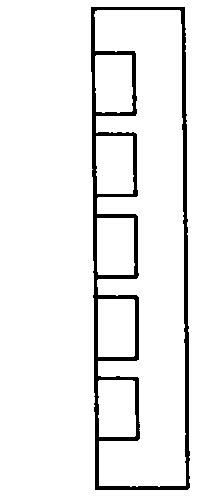

[0012] Such as figure 2 and image 3 As shown, the present invention is a combined plastic panel formwork, which includes several plastic panel surfaces 1, plastic panel concave-convex grids 11 are evenly distributed on the top of the plastic panel surface 1, and side ribs are provided on the four sides of the plastic panel surface 1. 12; if figure 1 As shown, the steel frame 2 is connected to the side rib 12 of the plastic panel 1; the steel frame 2 includes a horizontal steel frame 21 and a longitudinal steel frame 22, and two long sides of the plastic panel Horizontal steel frames 21, several vertical steel frames 22 are arranged between the two horizontal steel frames 21, the vertical steel frames 22 are all perpendicular to the horizontal steel frames 21, and are uniformly arranged; the plastic panels 1 are connected by U-shaped pins. The four sides of the plastic plate surface 1 are provided with connecting holes 13, and the steel frame 2 and the plastic plate surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com