Clutch type disassembling mechanism, device and method, and conveying system

A clutch type, clutch technology, applied in the direction of object destacking, transportation and packaging, etc., can solve the problems of energy consumption, cargo layering, stacking together, difficult operation, etc., and achieve the effect of high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

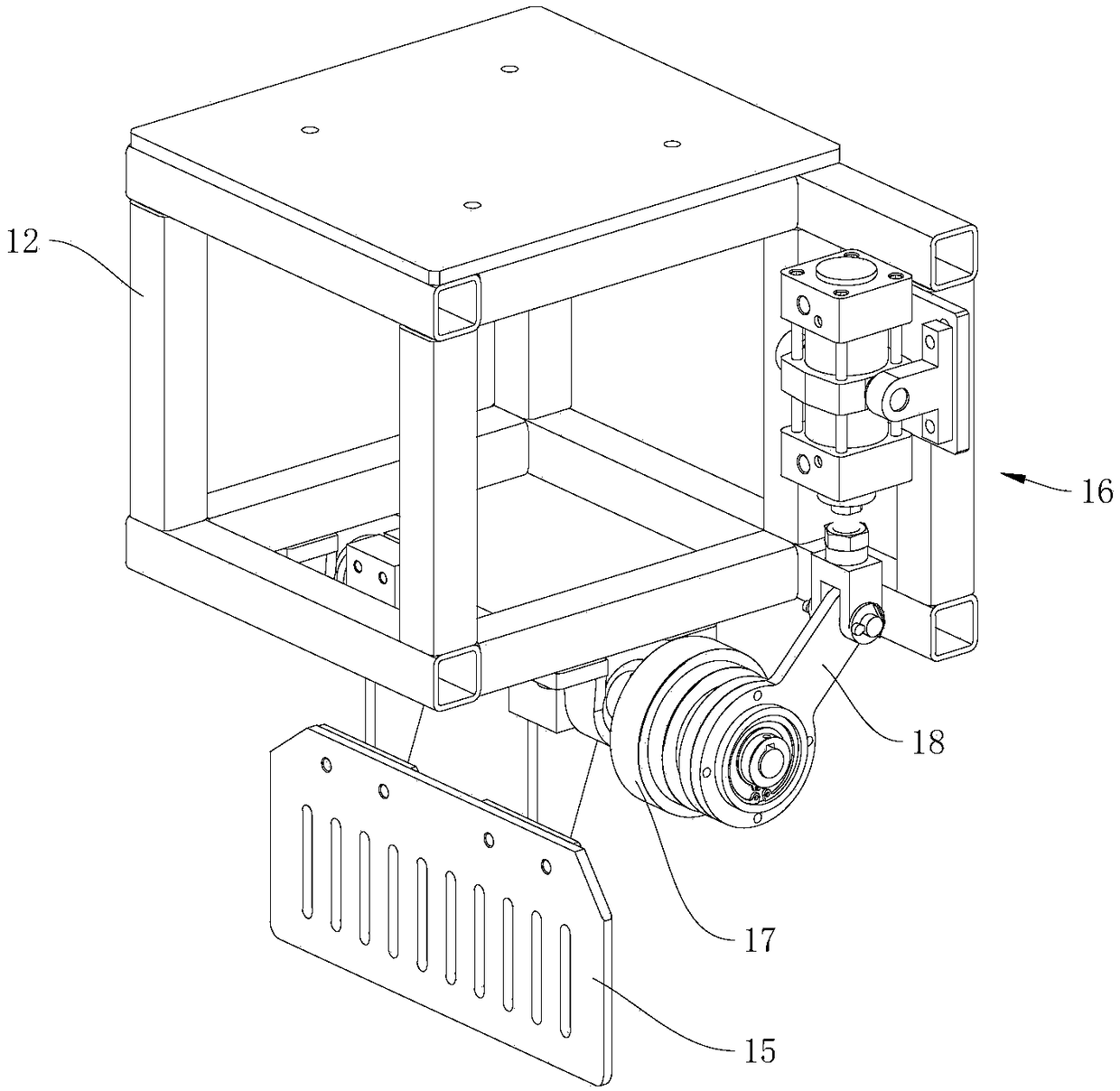

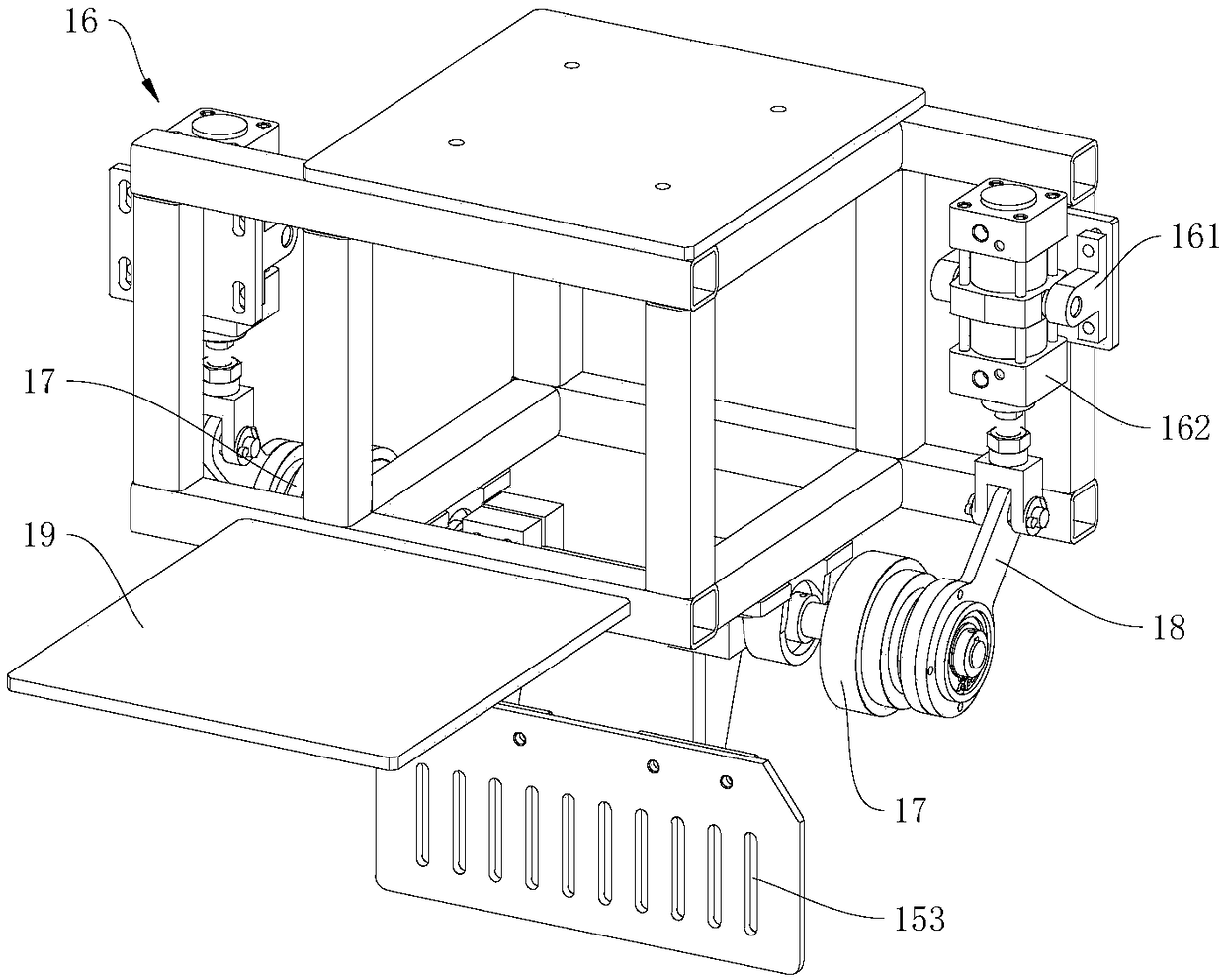

[0050] See figure 1 with figure 2 , figure 1 It is a schematic structural diagram of the clutch-type detachment mechanism 10 provided by the first embodiment of the present invention. figure 2 It is a schematic diagram of the disassembly action of the clutch-type disassembly mechanism 10 provided by the first embodiment of the present invention.

[0051] The first embodiment of the present invention provides a clutch-type detachment mechanism 10, which is applied to the clutch-type detachment device 100 and cooperates with the detachment movement mechanism 20 of the clutch-type detachment device 100 to complete The disassembly and removal operation of the goods 910 from the stack 900. The clutch-type disassembly mechanism 10 has a high disassembly efficiency. The deformation of the goods 910 is small during the disassembly and removal process, and it is suitable for a variety of goods 910 Disassembly and retrieval operations. The clutch type disassembly mechanism 10 can be appl...

no. 2 example

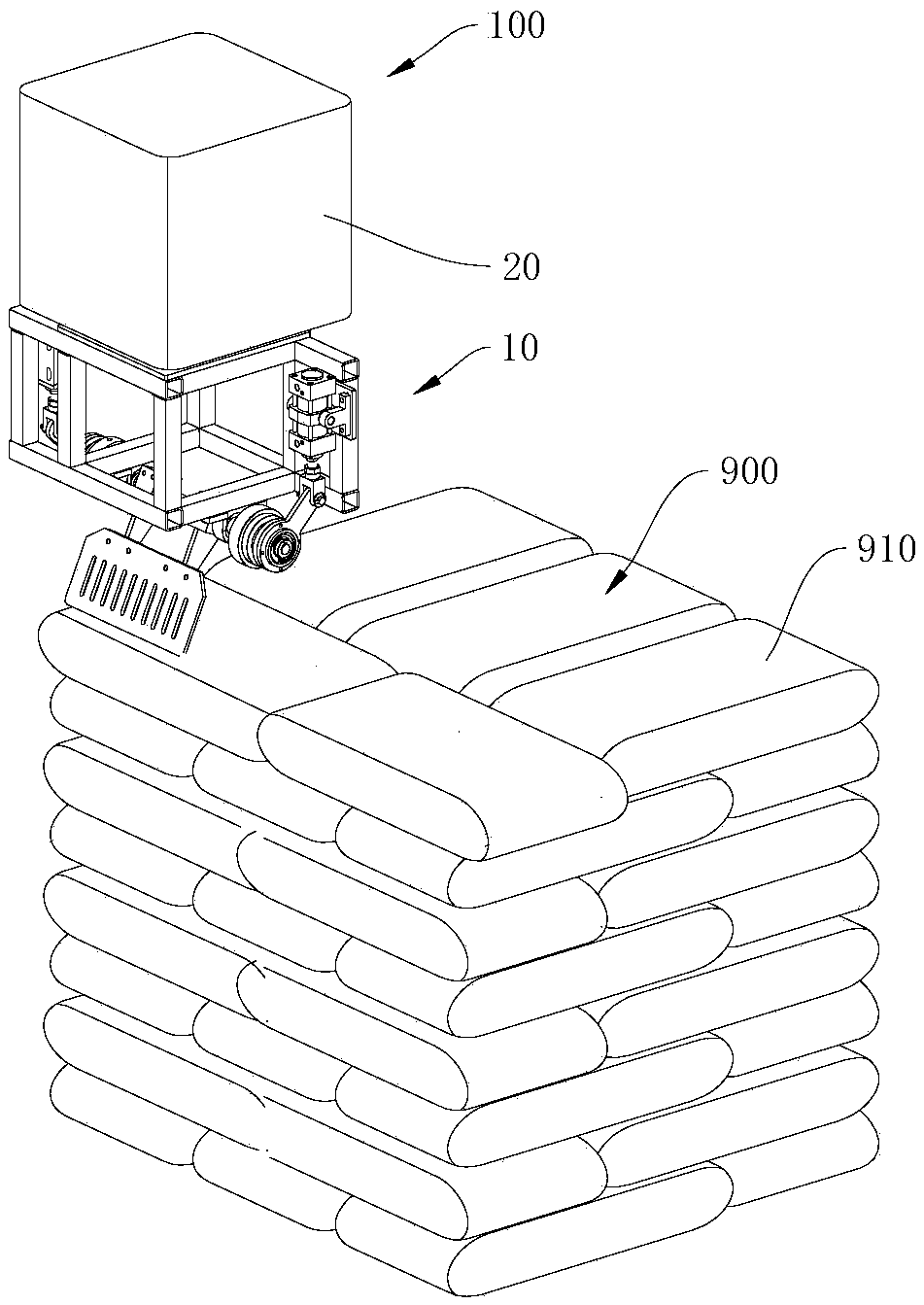

[0084] See Figure 5 , Figure 5 This is a schematic structural diagram of the clutch-type detachable device 100 provided in the second embodiment of the present invention applied to the transmission system 1.

[0085] This embodiment provides a clutch-type detachment device 100. The clutch-type device uses the clutch-type detachment mechanism 10 described in the first embodiment, which also has high detachment efficiency, which causes damage to the goods 910 during the detachment process. The deformation is small, and it is suitable for the characteristics of the dismantling operation of a variety of goods 910. The clutch type disassembly device 100 can be applied to a palletizing system, a transmission system 1, a production line, an automated warehouse, a logistics system, or an automated factory, etc. Of course, the clutch type disassembly device 100 can also be used independently.

[0086] Among them, take the clutch-type disassembly device 100 applied to the transmission syst...

no. 3 example

[0114] See Picture 10 , Picture 10 It is a schematic flowchart of the clutch-type disassembly method provided by the third embodiment of the present invention.

[0115] This embodiment provides a clutch-type detachment method, which is applied to the clutch-type detachment mechanism 10 of the foregoing first embodiment and the clutch-type detachment device 100 of the foregoing second embodiment.

[0116] The clutch disassembly method includes:

[0117] S101: Switch to the disengaged state through the clutch 17, so that the toggle member 15 can freely rotate to the vertical state under the action of gravity.

[0118] S102: Drive the toggle member 15 to move on the top of the cargo 910 on the top of the stack 900 by removing the movement mechanism 20, and make the toggle member 15 fall to one side of the cargo 910 under the action of gravity.

[0119] Among them, since the clutch 17 is in the disengaged state, the toggle member 15 can freely rotate up and down, it can rotate under the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com