Patents

Literature

85results about How to "Smooth removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

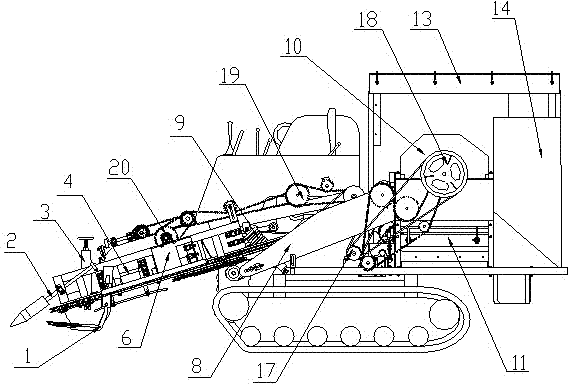

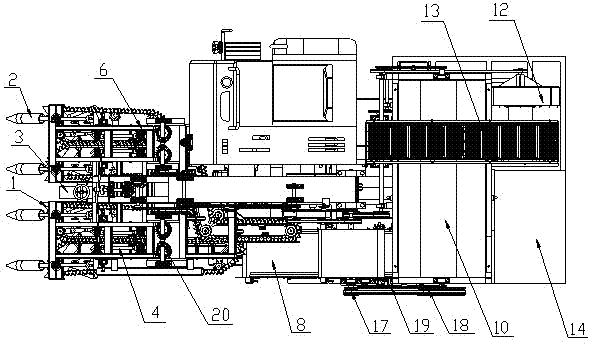

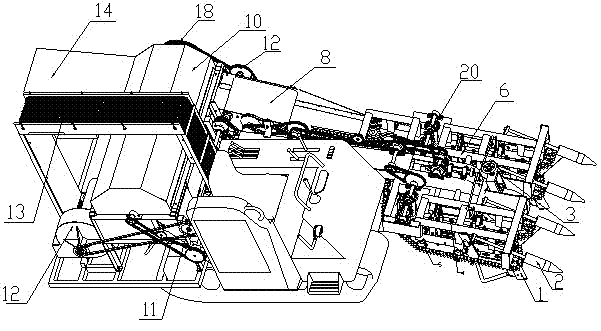

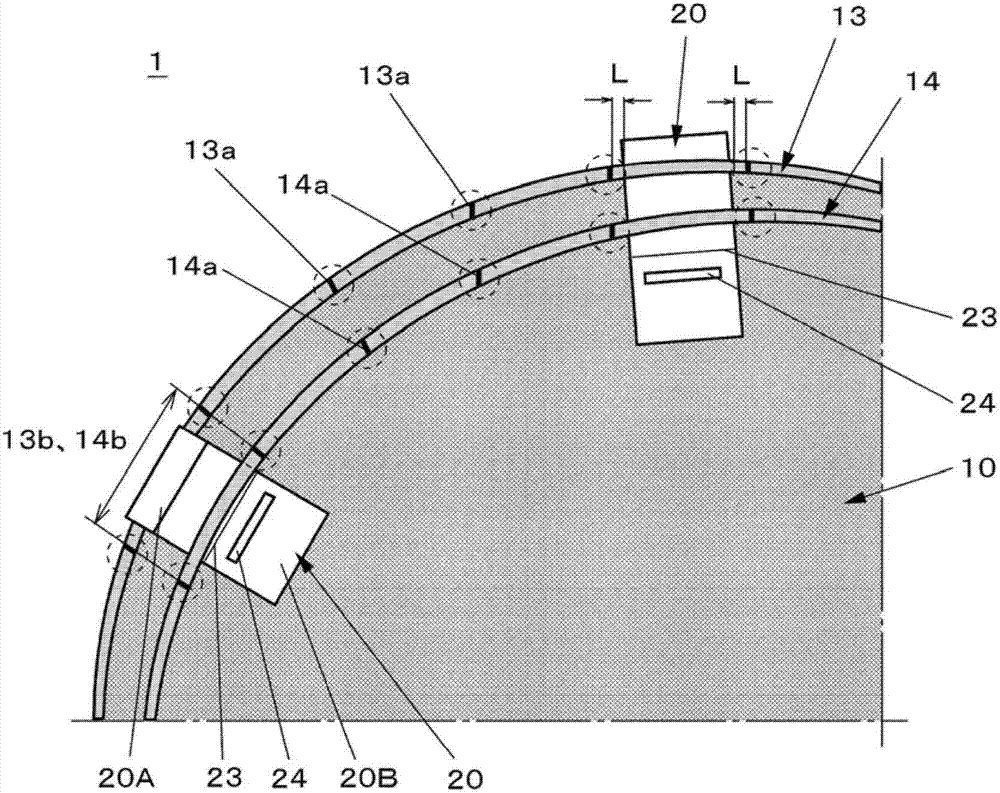

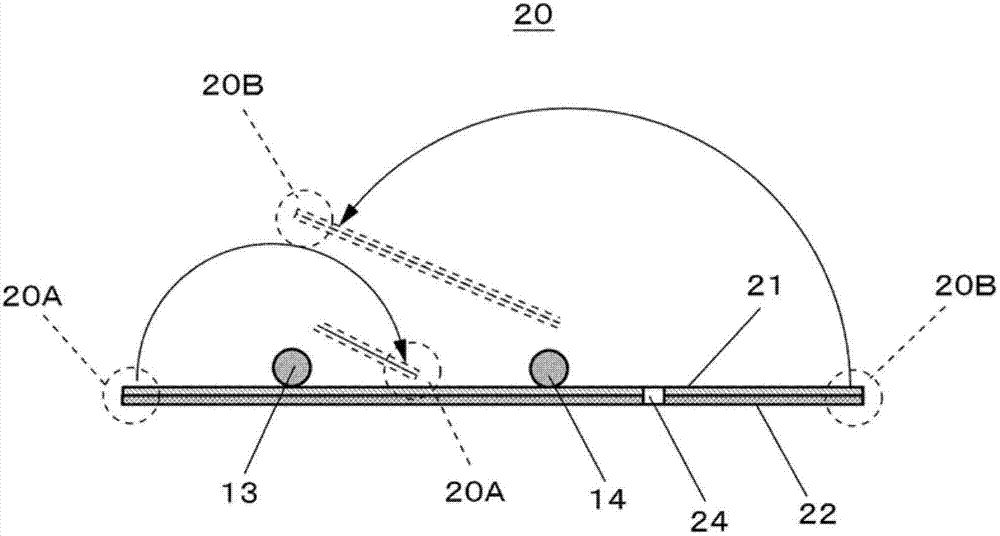

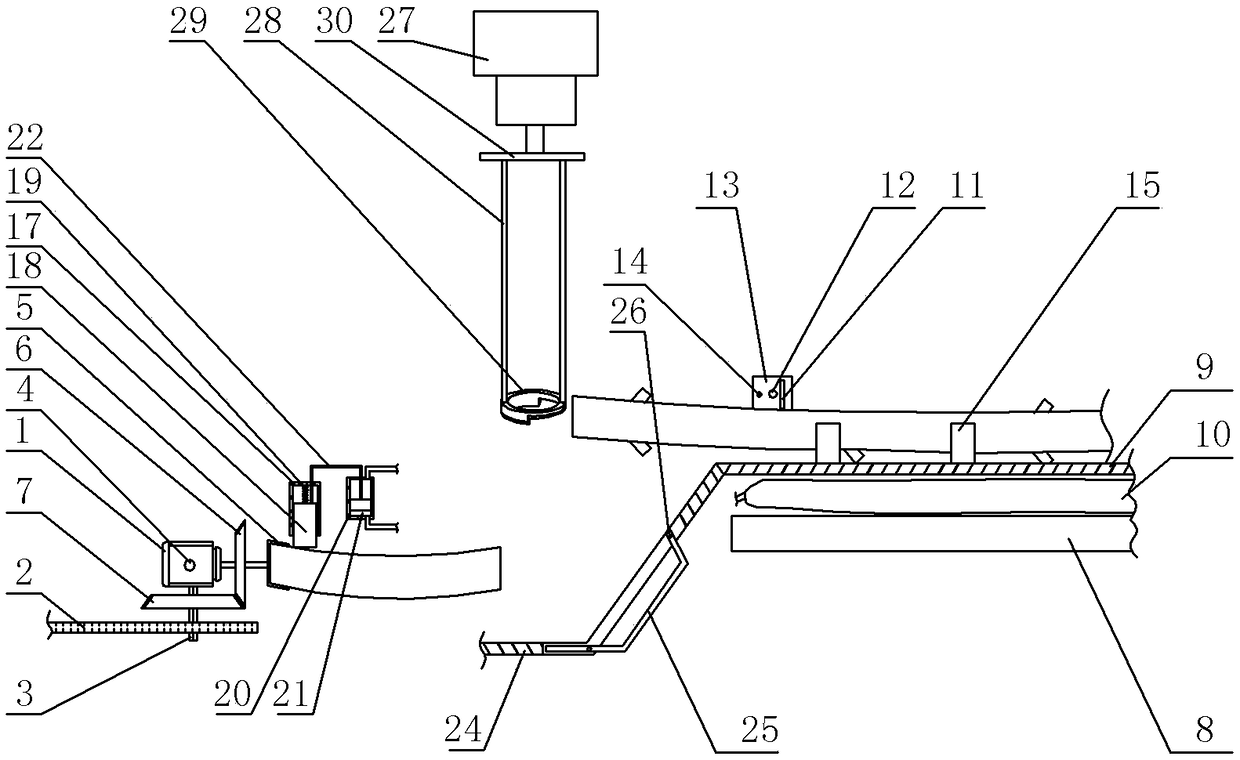

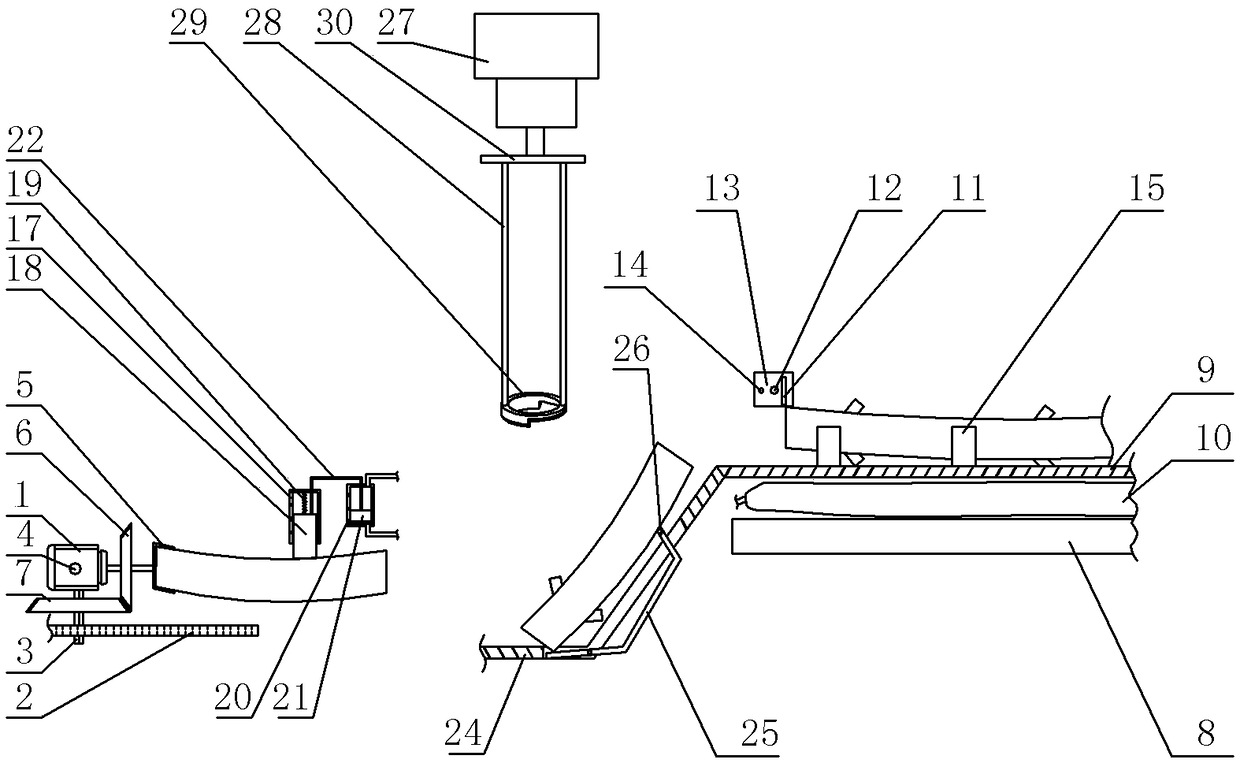

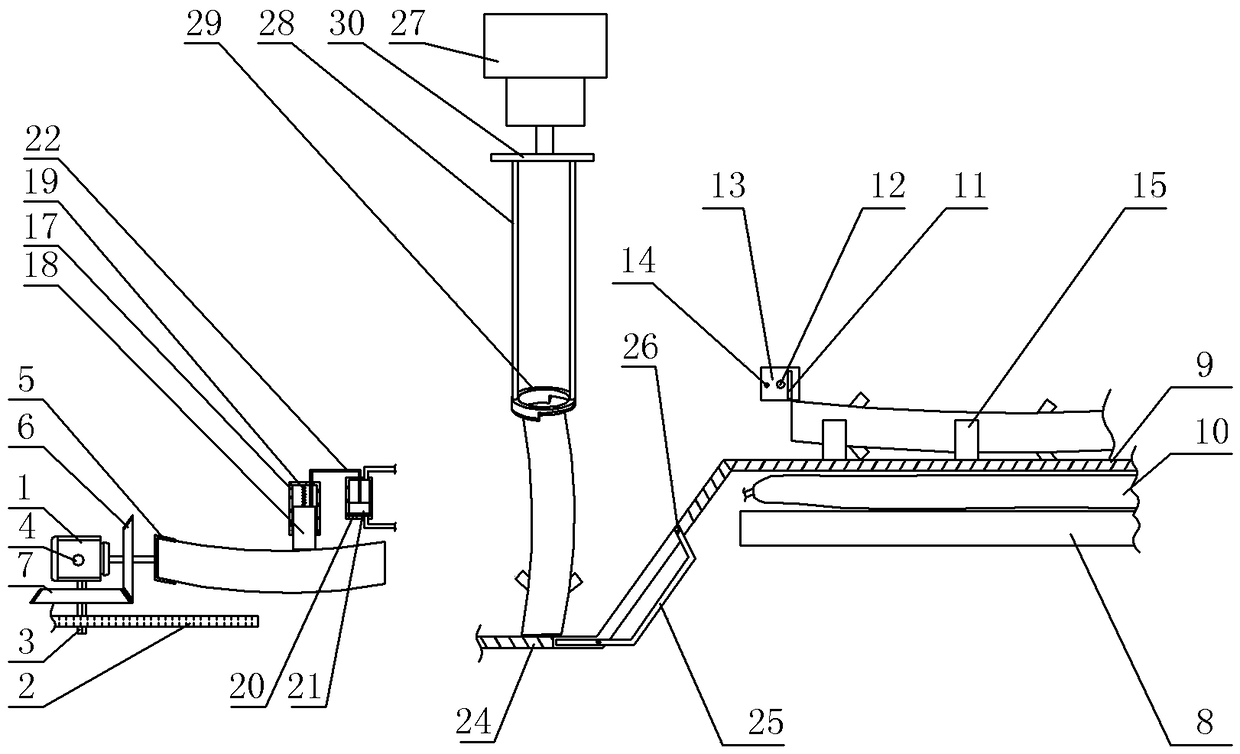

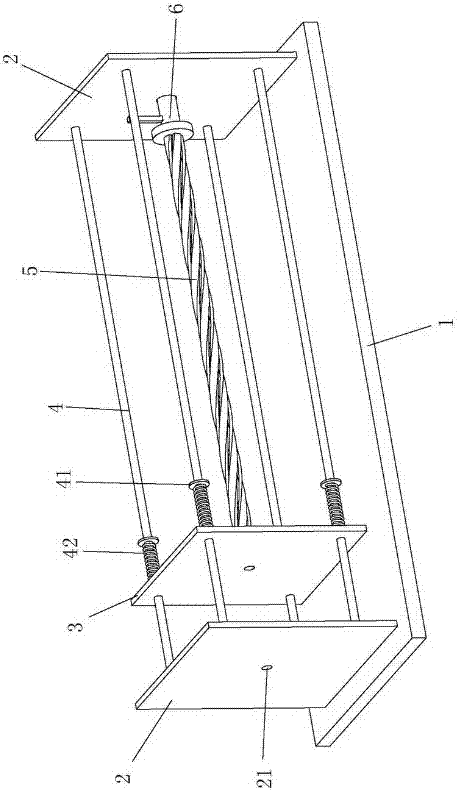

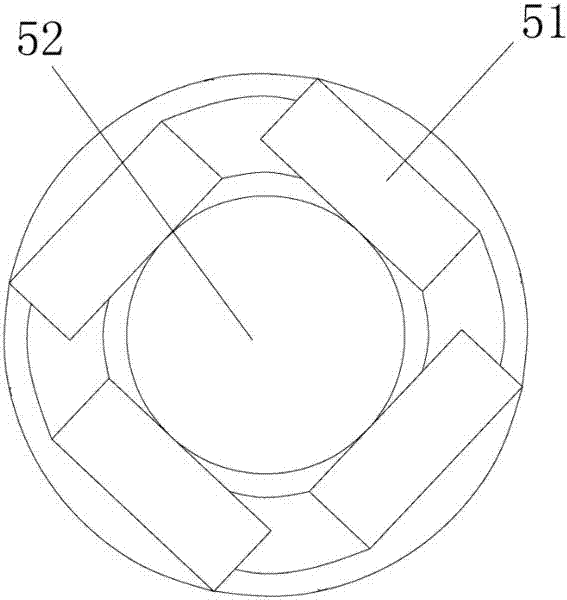

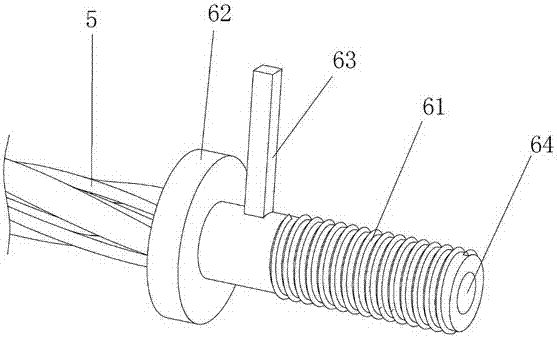

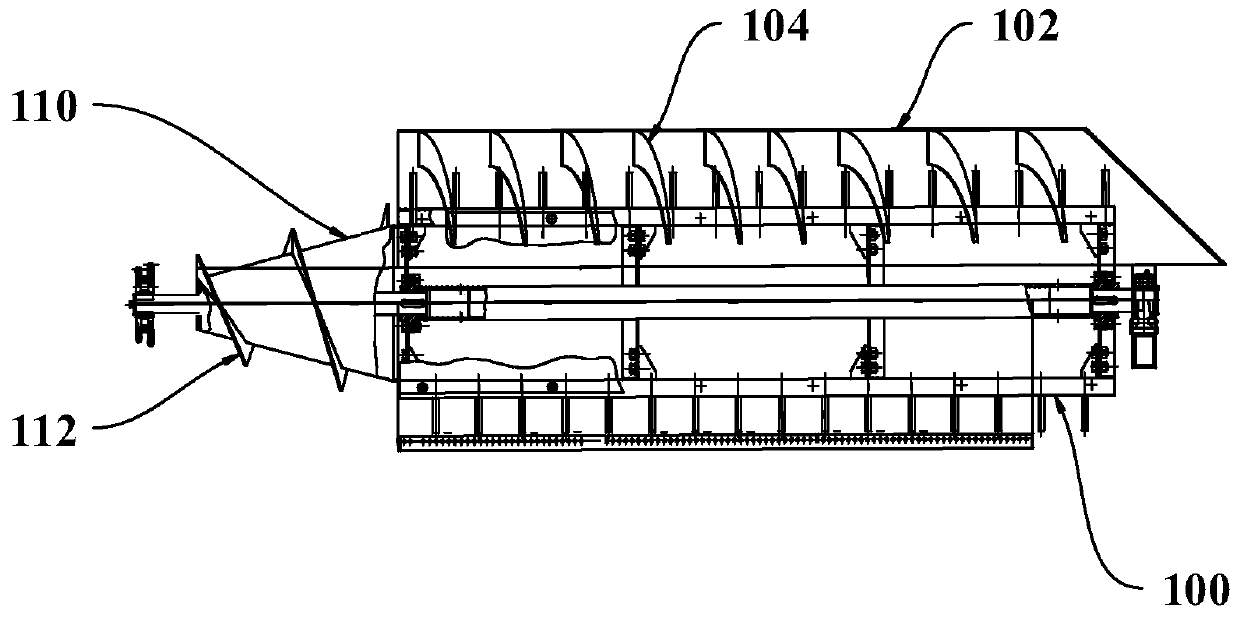

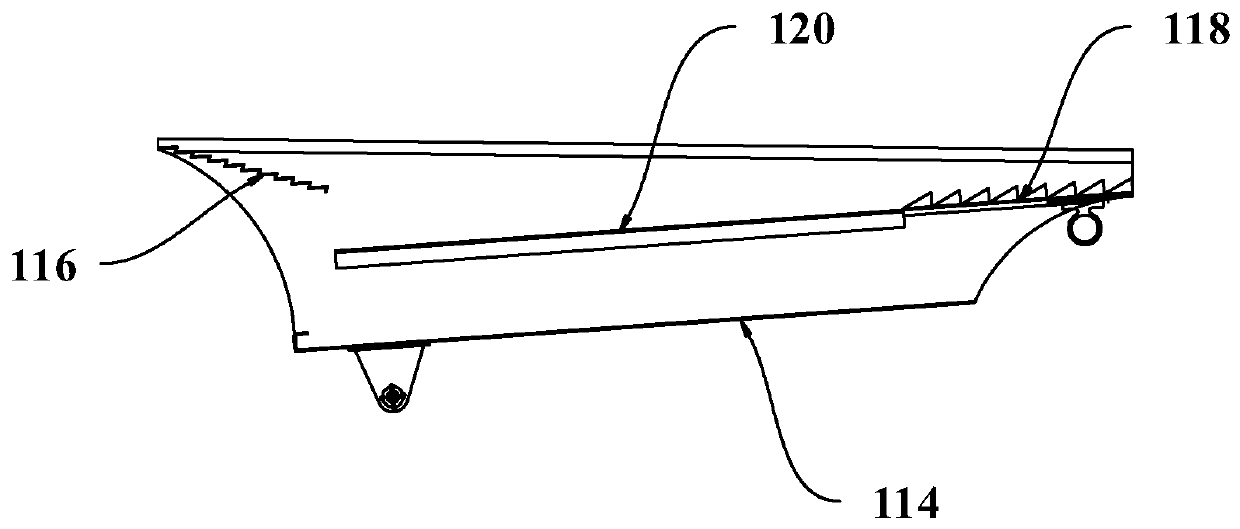

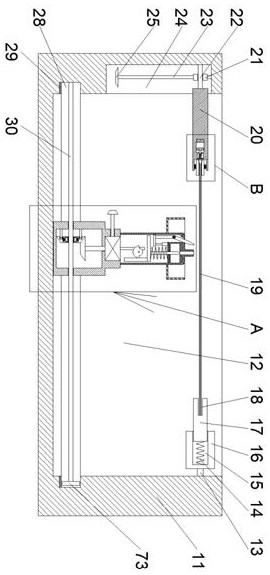

Two-ridge four-row whole-feeding peanut combine harvester

InactiveCN103039175AAchieve harvestRealize the clamping effectDigger harvestersThreshersEngineeringCombine harvester

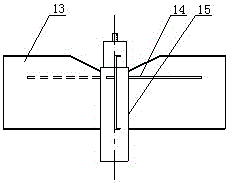

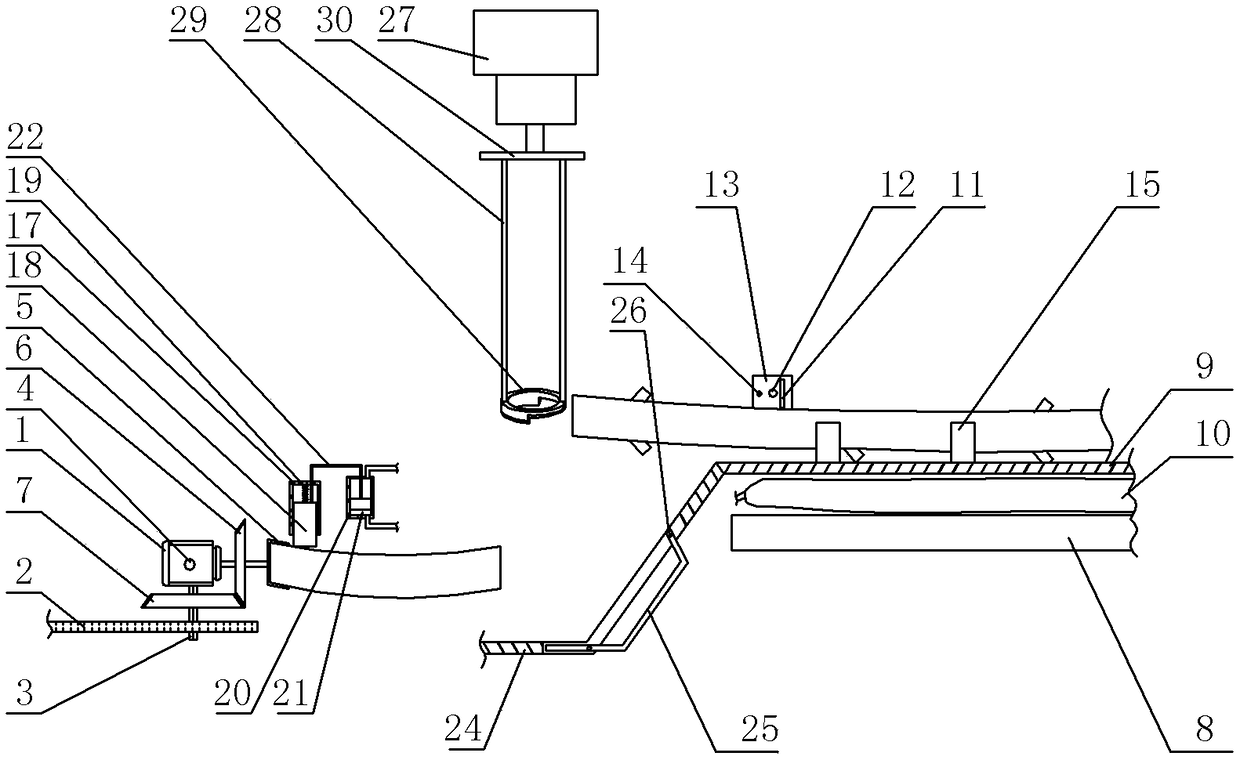

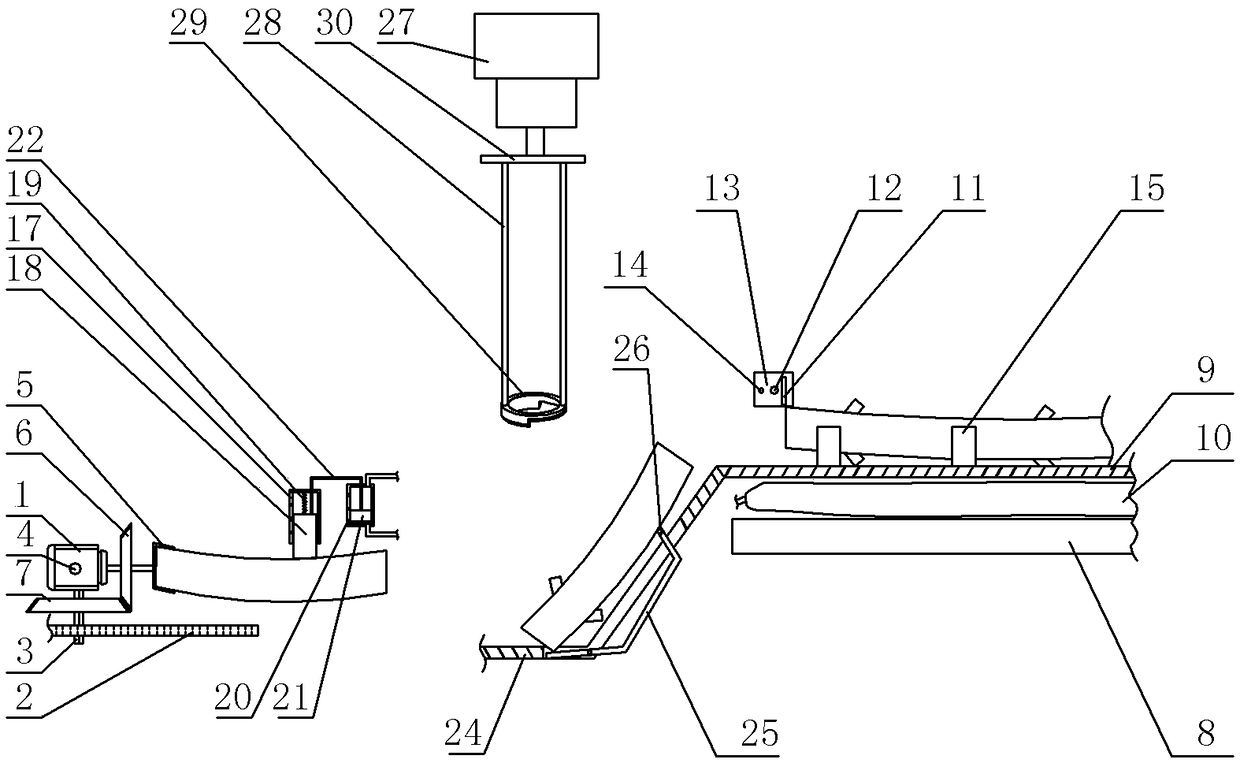

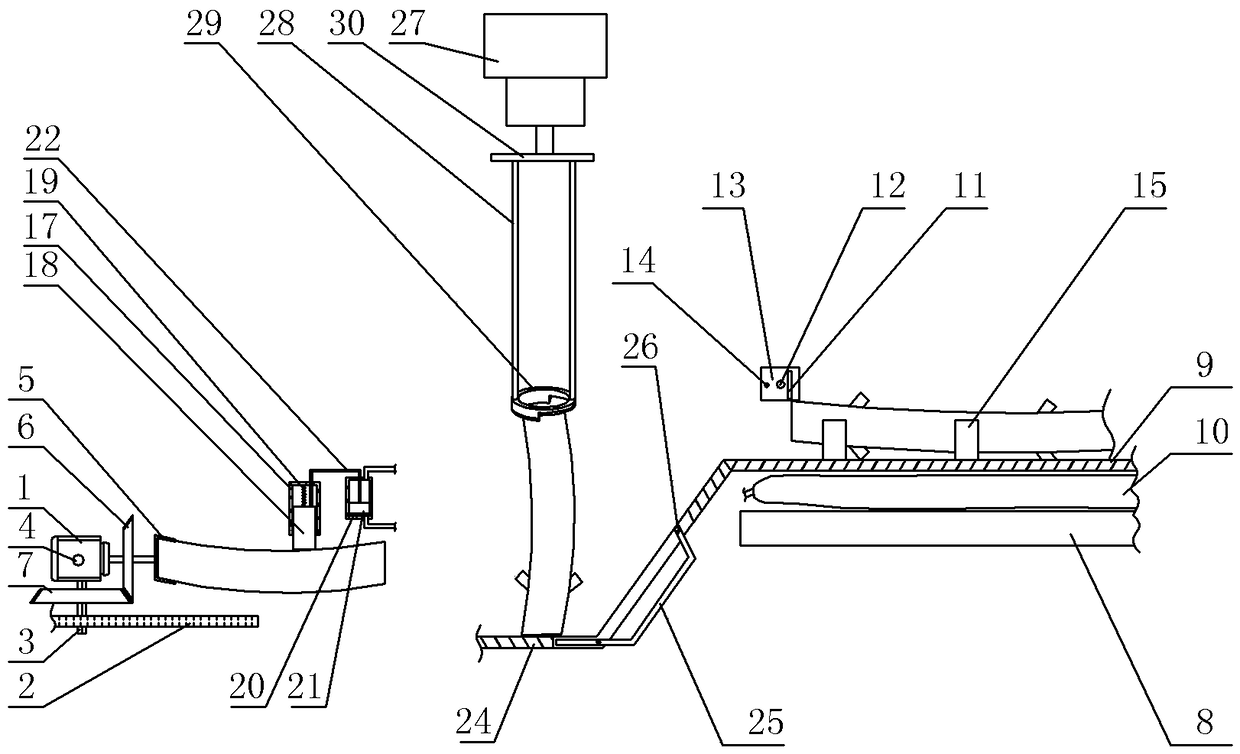

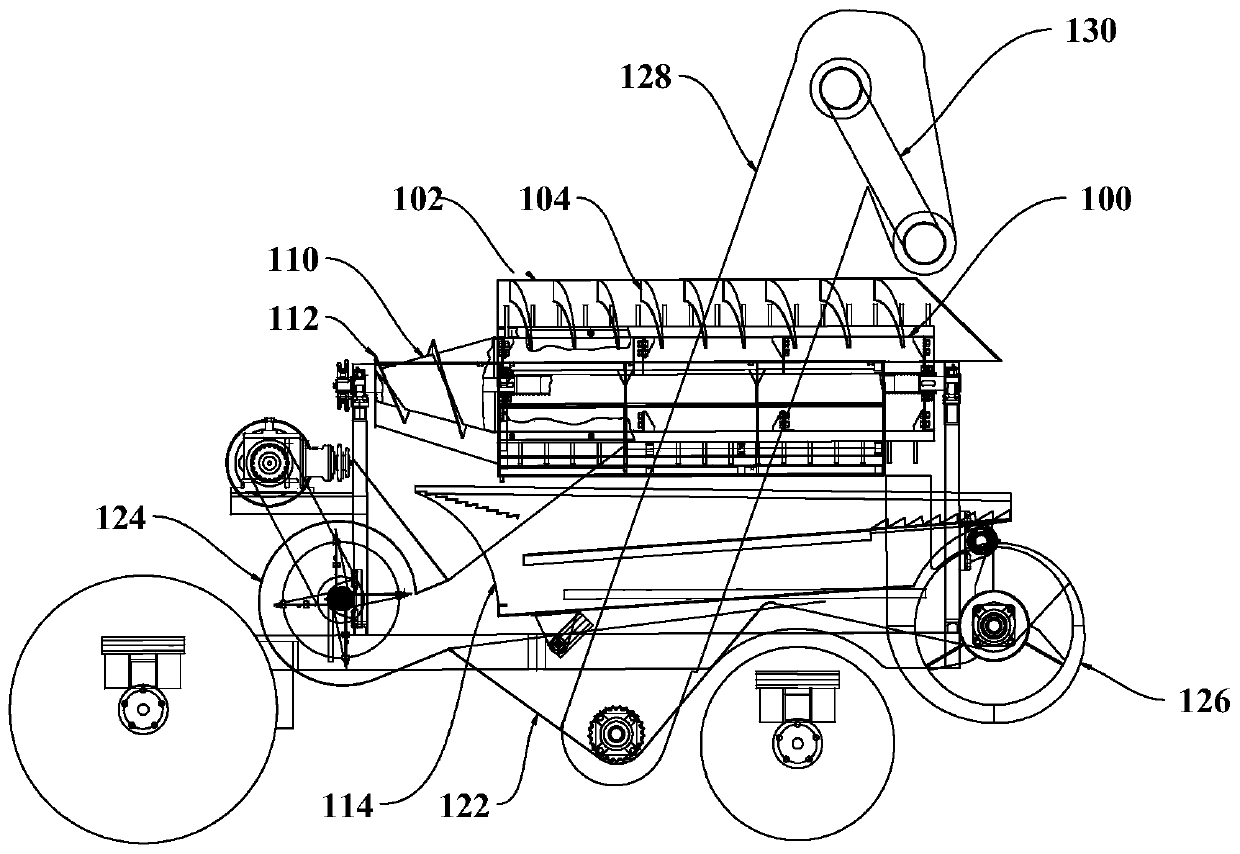

Disclosed is a two-ridge four-row whole-feeding peanut combine harvester. The two-ridge four-row whole-feeding peanut combine harvester comprises a driving device, a clamping conveying device, a peanut picking sorting device and a peanut lifting device, the clamping conveying device comprises a two-ridge four-row clamping conveying collecting device and a conveying device, the two-ridge four-row clamping conveying collecting device comprises a clamping chain rack and clamping chains I, II, III, IV and V, a peanut vine clamping conveying path A is achieved by meshing of the clamping chain I and the clamping chain II, a peanut vine clamping conveying path B is achieved by meshing of the clamping chain III and the clamping chain IV, the clamping conveying collecting device further comprises a clamping collecting device, and the clamping conveying path A, the clamping conveying path B and conveyed peanut vines are gathered at a position of the clamping collecting device. By means of the two-ridge four-row whole-feeding peanut combine harvester, two-ridge four-row peanut vines can be harvested, clamped and conveyed, peanuts can be picked, sorted and collected, the work efficiency of the peanut combine harvester is improved, and time costs are lowered.

Owner:QINGDAO AGRI UNIV +1

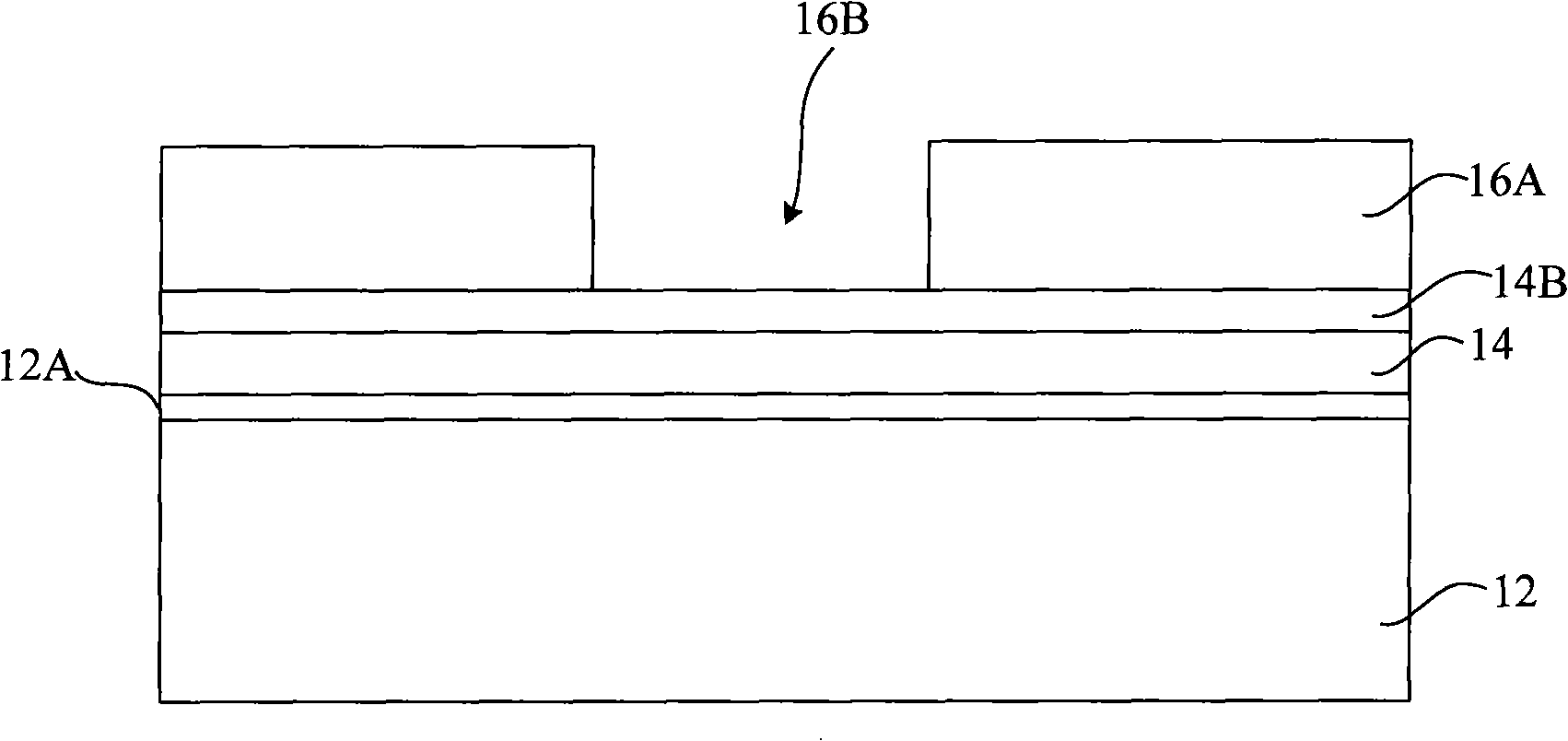

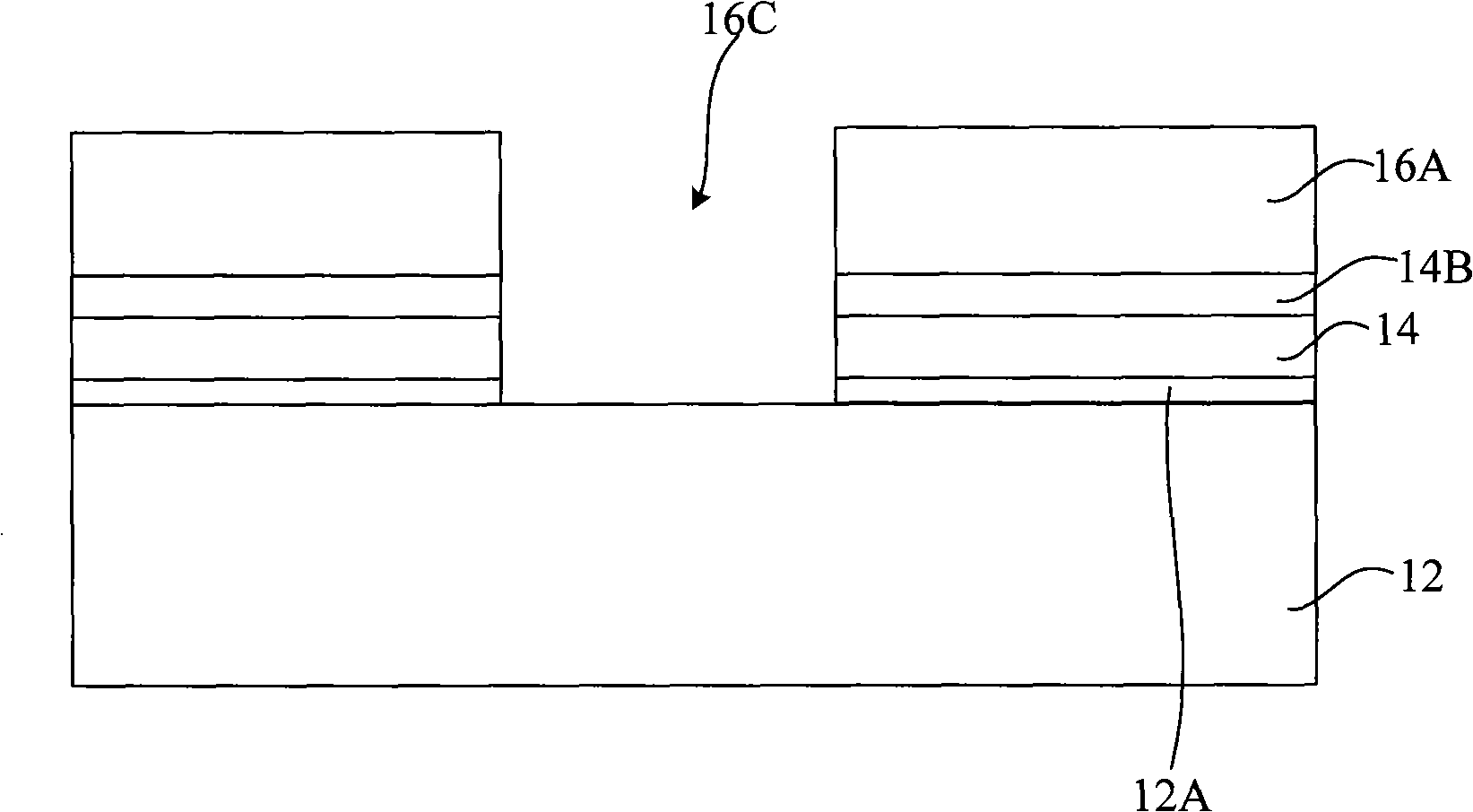

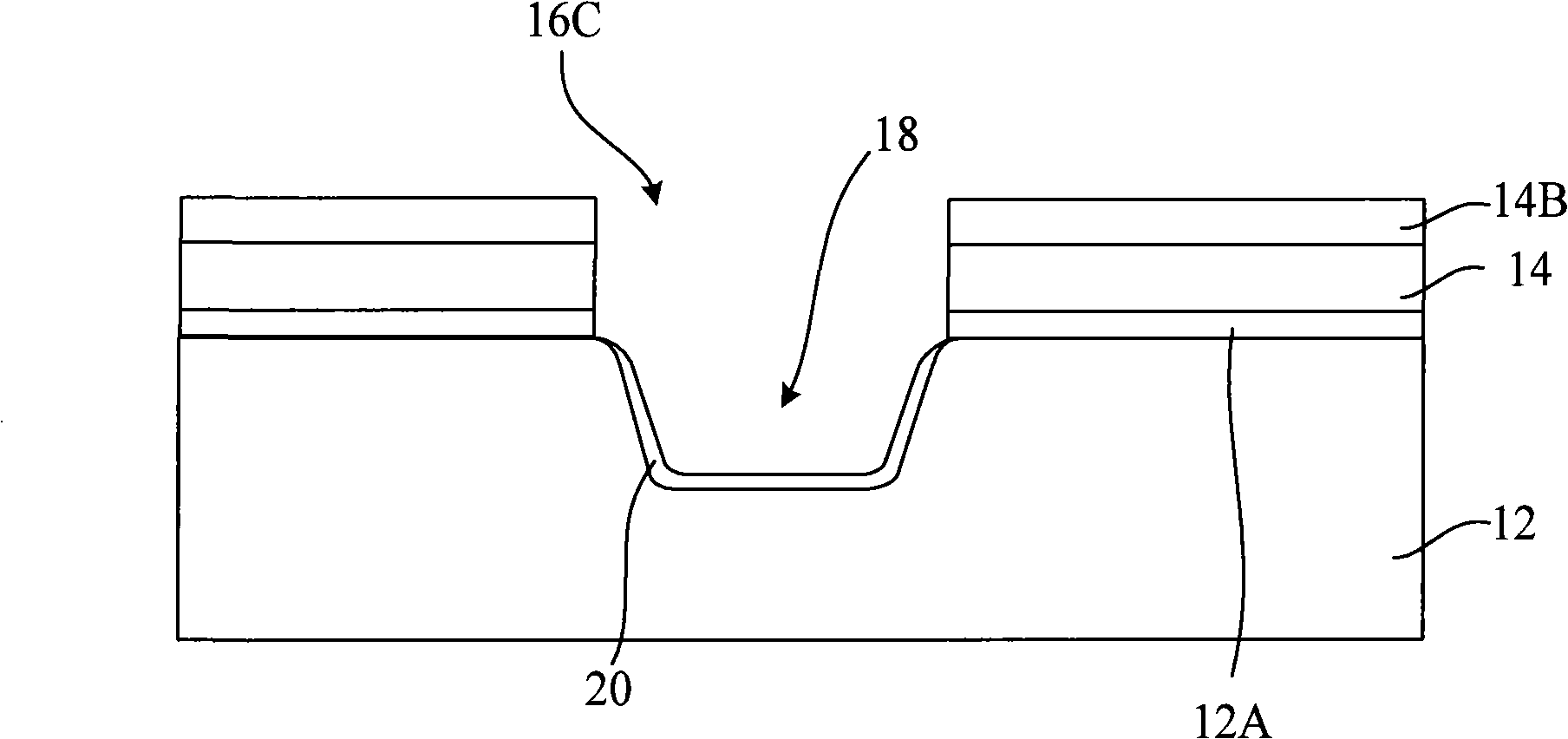

Process for preparing isolation of shallow channel

ActiveCN101312147AReduce leakage currentReduce height differenceSemiconductor/solid-state device manufacturingEngineeringHeight difference

A manufacturing method of shallow groove insulation comprises providing a semiconductor substrate, positioning sequentially formed a pad oxide layer and a hard mask layer, forming a groove in the semiconductor substrate, arranging an opening in a position corresponding to the groove in the pad oxide layer and the hard mask layer, forming a medium layer in the groove and on the hard mask layer, removing the medium material on the hard mask layer by planarization technology, etching the medium layer in the groove to reduce the height difference between the medium layer surface and the semiconductor substrate surface, and lead the edge of the medium layer to form a protuberance. The manufacturing method of shallow groove insulation can reduce the depth of the top edge groove of the shallow groove insulation, and improve the element properties.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

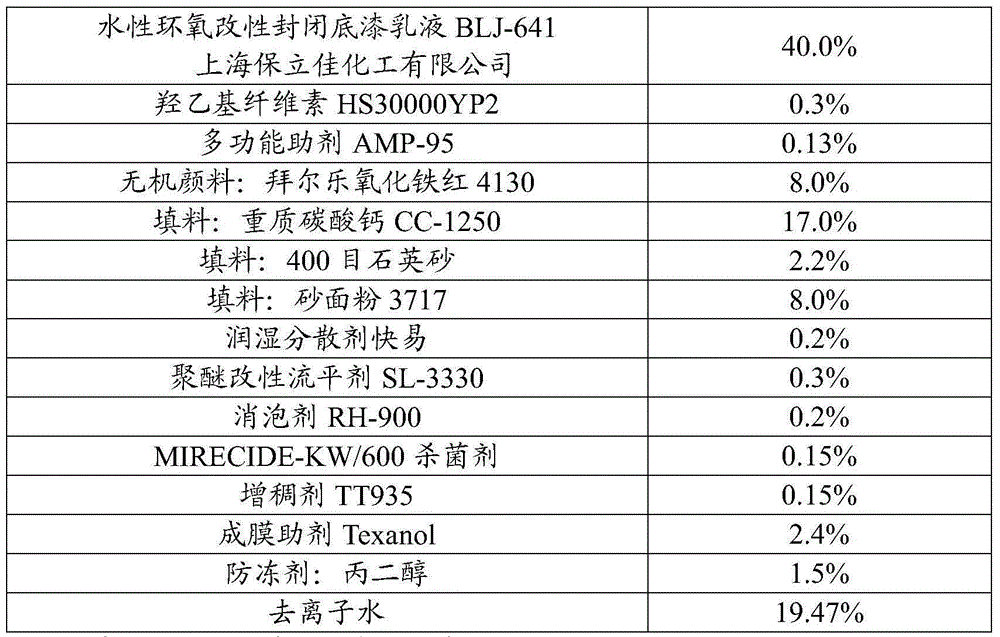

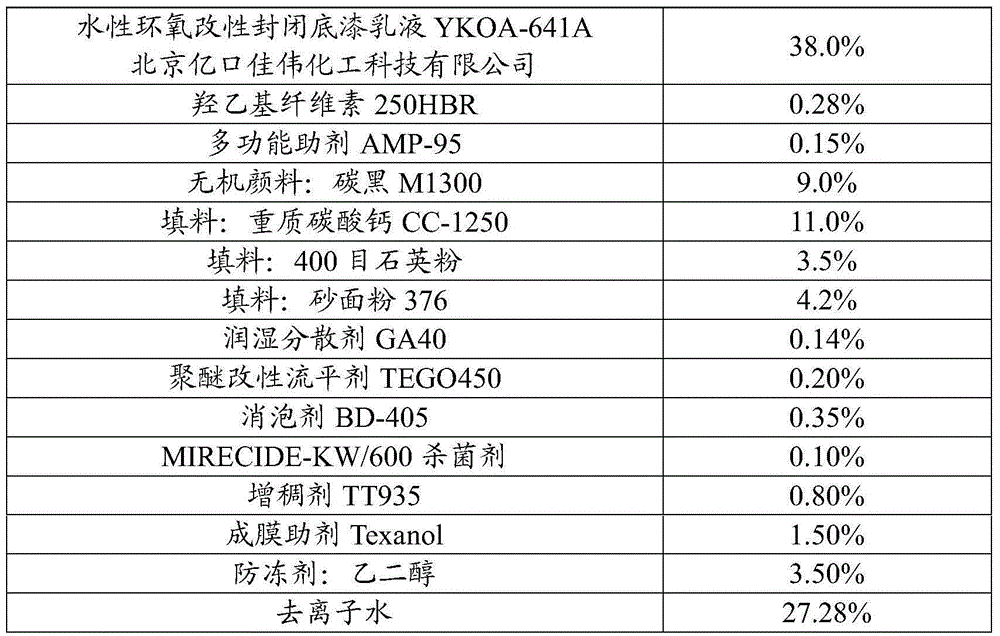

Water-based high-adhesion diving joint priming paint as well as preparation method and application thereof

ActiveCN106700814AImprove permeabilityStrong adhesionEpoxy resin coatingsWater basedInorganic pigments

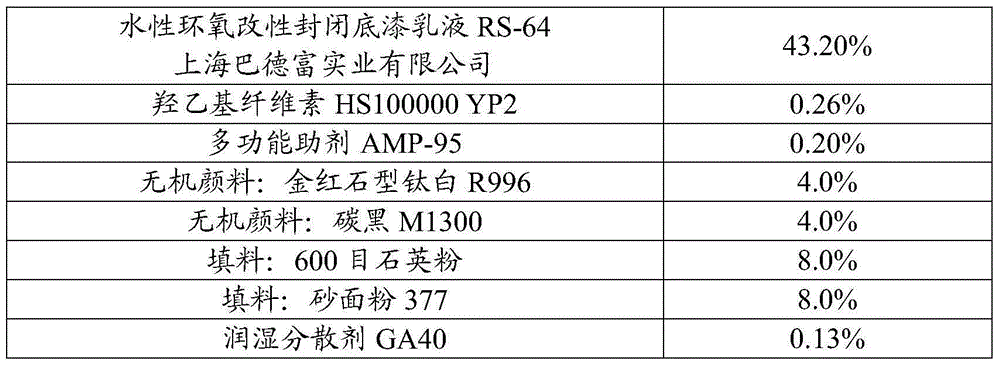

The invention relates to water-based high-adhesion diving joint priming paint, as well as a preparation method and application thereof. The priming paint comprises the following components in percentage by mass: 38.0-43.2% of epoxy-modified sealing emulsion, 0.26-0.3% of hydroxyethyl cellulose, 0.13-0.20% of AMP-95, 8.0-9.0% of an inorganic pigment, 18.7-27.2% of a filler, 0.13-0.20% of a wetting dispersant, 0.1-0.3% of a polyether-modified flatting agent, 0.2-0.4% of an antifoaming agent, 0.1-0.22% of a bactericide, 0.15-0.80% of a thickening agent, 1.5-3.4% of a coalescing agent, 1.5-8.0% of an anti-freezing agent and 15.69-27.28% of water, wherein the pH value of the water-based high-adhesion diving joint priming paint is 8.0-9.5. The water-based high-adhesion diving joint priming paint disclosed by the invention is low in content of VOC (volatile organic compounds), does not contain any substance causing harm to the human body and the environment and has excellent permeability; the priming paint product can be effectively adhered by textured paper, and when the priming paint does not need to be protected after construction completion, the textured paper can be smoothly removed. The water resistance, alkali resistance, alkali burnout resistance and salting-out resistance of the water-based high-adhesion diving joint priming paint products disclosed by the invention can meet standard technical requirements in the industry of priming paint for building external walls.

Owner:上海三银涂料科技股份有限公司

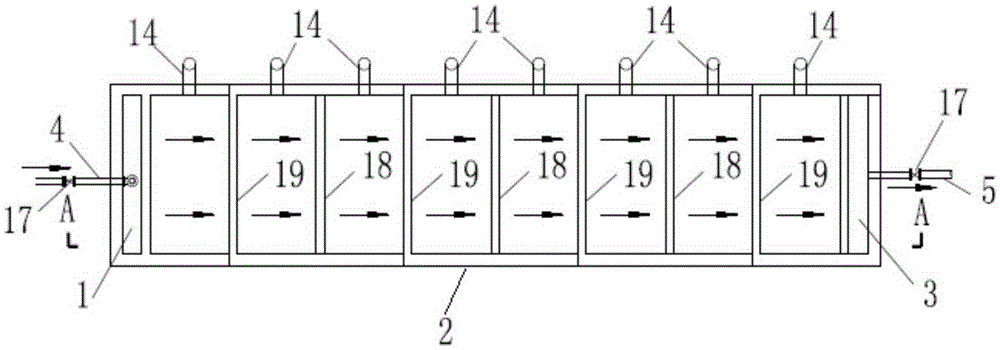

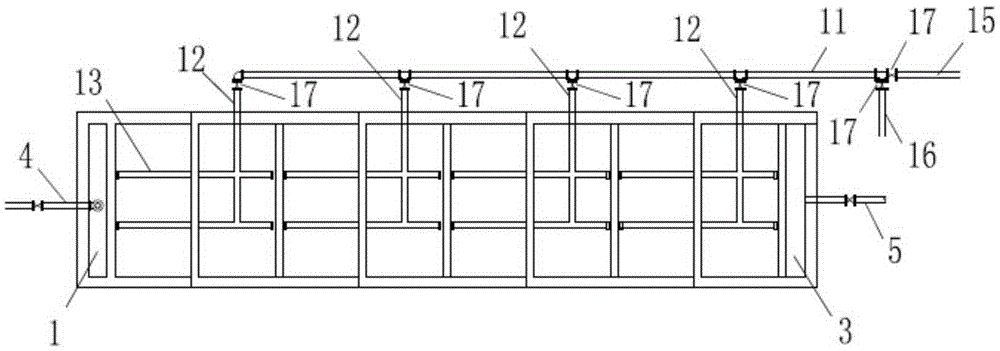

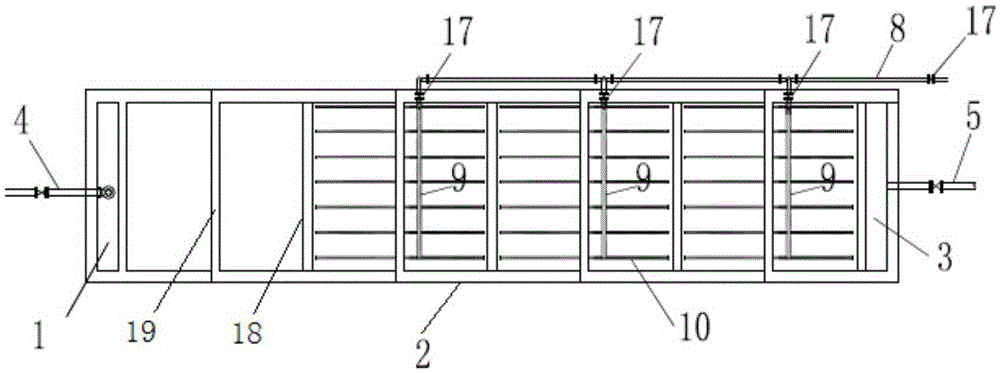

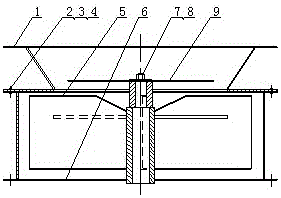

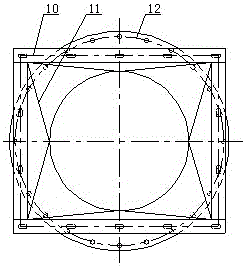

Sewage treatment device and method for self-cleaning type micro-aeration vertical baffled wetland

ActiveCN105236687AImprove fluidityIncrease contact areaMultistage water/sewage treatmentConstructed wetlandWater flow

The invention belongs to the technical field of sewage treatment, and particularly relates to a sewage treatment device and a sewage treatment method for a self-cleaning type micro-aeration vertical baffled wetland. The invention discloses the sewage treatment device for the self-cleaning type micro-aeration vertical baffled wetland. The sewage treatment device consists of a water distribution region, a tank body and a water collecting region; to-be-treated sewage flows into the water distribution region through a water inlet tube, and then flows from the distribution region into the tank body by taking an overflow; outlet water treated by the tank body flows into the water collecting region by taking an overflow; and the tank body is formed by connecting a plurality of stages of vertical baffled wetlands with different treatment functions in series, in a water flow direction, namely an anaerobic wetland, a carbon oxidization wetland and a short-cut nitrification-denitrification wetland. The invention further provides a sewage treatment method by adopting the device. According to the device provided by the invention, the tank body is divided into an anaerobic section, an aerobic section and a micro-aerobic section in the water flow direction, and efficient removal of carbon pollutants and nitrogen pollutants can be realized; and the problems that a conventional constructed wetland is too low in dissolved oxygen, relatively great in land area, easy to block by stuffing and difficult to clean after being blocked are solved.

Owner:CHONGQING UNIV

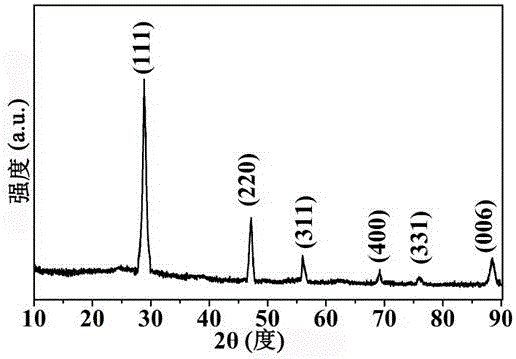

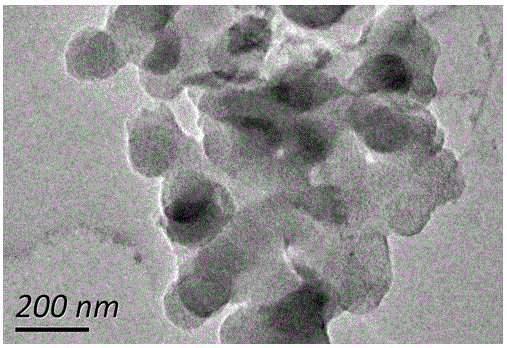

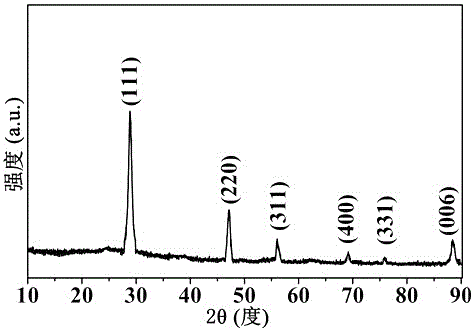

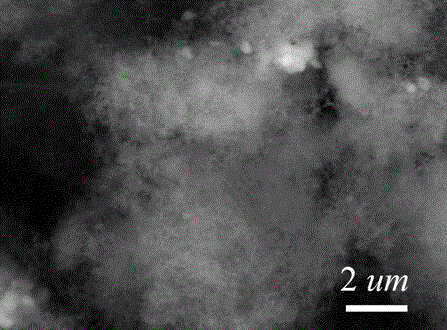

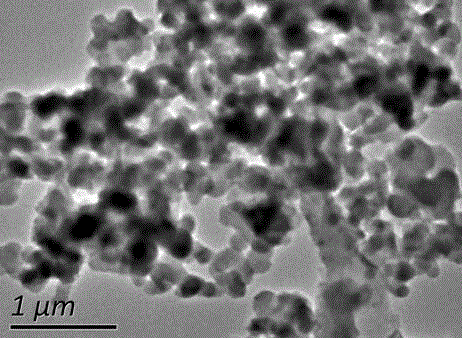

Low-temperature preparation method of rice-hull-based porous silicon material

InactiveCN106430213ASimple processLow priceMaterial nanotechnologyCell electrodesPorous siliconMaterials science

The invention discloses a low-temperature preparation method of a rice-hull-based porous silicon material and belongs to the technical field of nanoelectrode material preparation. The method comprises the steps that first, washed and dried rice hulls are heated and oxidized in air to obtain rice hull ash, then the rich hull ash is soaked with diluted hydrochloric acid, washed with distilled water and dried, and the dried rich hull ash is obtained; the dried rich hull ash, aluminum powder or a mixture of aluminum powder and magnesium powder and a chloride mixture are mixed and then subjected to a sealed heating reaction, the temperature is kept till the reaction is over, then the mixture is cooled to room temperature, the product obtained after the reaction is collected, soaked with diluted hydrochloric acid and washed with distilled water, and the rice-hull-based porous silicon material is obtained. The method has the advantages that the process is simple, the raw materials are low in price, the reaction process has a low requirement for temperature, and the yield is high; the prepared rice-hull-based porous silicon material has excellent electrochemical performance and can be used as a lithium ion battery cathode material, thereby providing a new way for high-value-added utilization of the rice hulls.

Owner:YANGZHOU UNIV

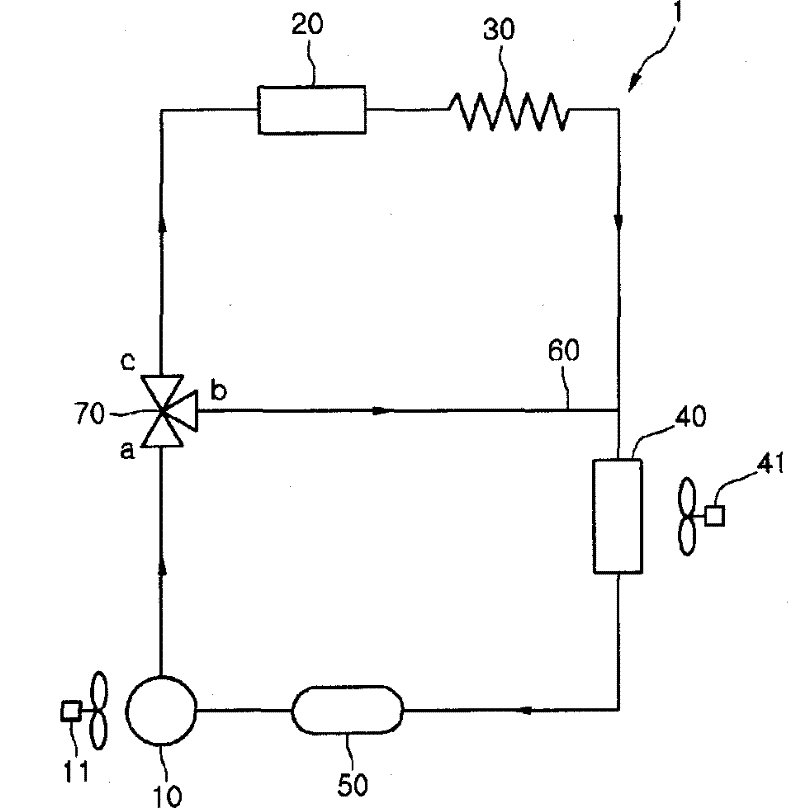

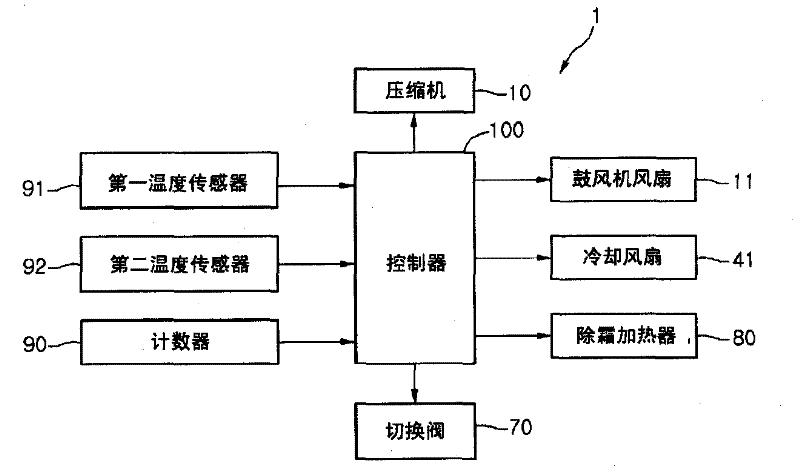

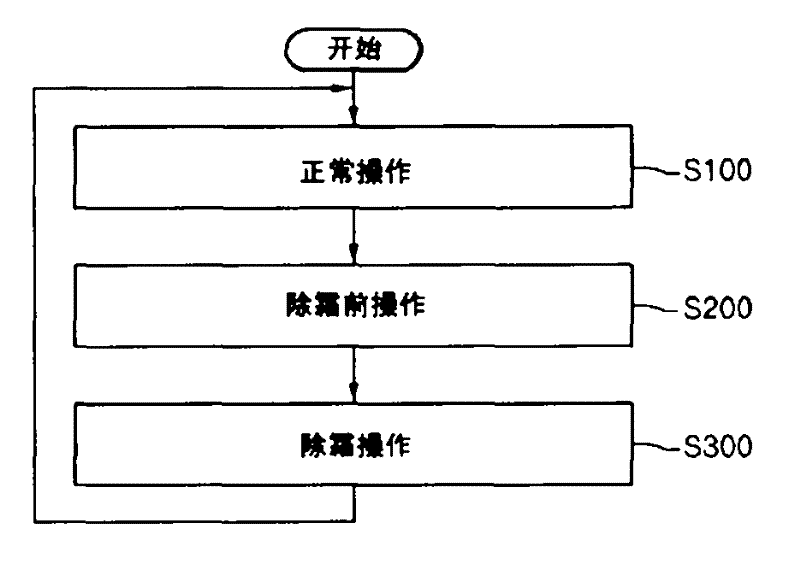

A control method of a refrigerator

InactiveCN102317724AImprove defrosting efficiencyIncrease temperatureLighting and heating apparatusCooling fluid circulationHot TemperatureAutomotive engineering

An embodiment according to the present invention is to provide a control method of a refrigerator that can operate a compressor before a start of a defrost operation and during a predetermined time to supply a high-temperature hot gas to an evaporator. With the control method of the refrigerator according to the embodiments of the refrigerator, the compressor is driven immediately before the defrost operation and the blower fan cooling the compressor stops, such that the high-temperature hot gas can be supplied to the evaporator, thereby increasing the defrost efficiency.

Owner:LG ELECTRONICS INC

Ball milling preparation method of rice hull-based porous silicon nanomaterial

The present invention provides a ball milling preparation method of a rice hull-based porous silicon nanomaterial, belonging to the technical field of preparation of nano-electrode materials. The method comprises the steps of heating to oxidize or incompletely oxidize water-washed and dried rice hull in air, so as to obtain rice hull ash, then soaking by using dilute hydrochloric acid, washing with distilled water and then drying, and obtaining the dried rice hull ash; and mixing the dried rice hull ash with aluminum powder, or aluminum powder, magnesium powder and a corresponding chloride so as to obtain a mixed material, then putting the mixed material in a ball milling machine to grind and cool to room temperature, collecting the product, soaking with dilute hydrochloric acid, then washing with distilled water so as to obtain the rice hull-based porous silicon nanomaterial. The preparation method is simple, the cost of the raw material is low, the yield is high, solid phase reaction is good for industrial production, and the prepared rice hull-based porous silicon nanomaterial has excellent electrochemical performance.

Owner:YANGZHOU UNIV

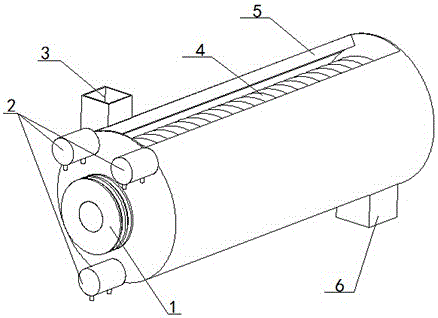

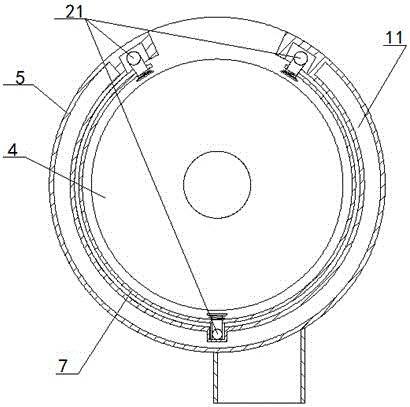

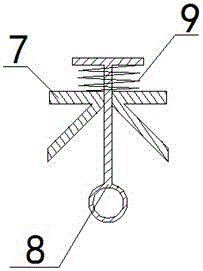

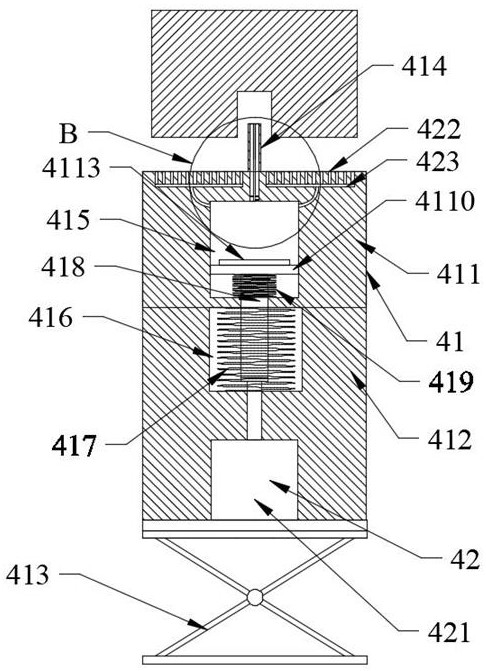

Novel fish meal dryer

InactiveCN105953565AEfficient removalAffect qualityDrying solid materialsHeating arrangementLinear motionHydraulic motor

The invention discloses a novel fish meal dryer and belongs to the field of machines. The novel fish meal dryer comprises a barrel, hydraulic motors, lead screws, loop bars and a scraper. According to the operating principle, steam is introduced into a barrel interlayer and a blade interlayer to dry fish meal. The scraper is in a circular arc shape in the positive direction and is closely attached to the inner wall of the barrel. The loop bars are used for connecting the scraper with the lead screws. The lead screws are driven by the hydraulic motors to rotate. The scraper does back and forth linear motion on the lead screws to achieve the function of automatically removing fish meal adhering to an inner barrel body. The novel fish meal dryer has the beneficial effects that the scraper can effectively remove fish meal adhering to the inner barrel body to prevent the fish meal left on the barrel from going smelly or moldy and affecting the quality and drying effect of subsequent products; and meanwhile, the novel fish meal dryer can play a role in assisting in stirring fish meal to increase the drying speed.

Owner:NANNING FUJIU INFORMATION TECH

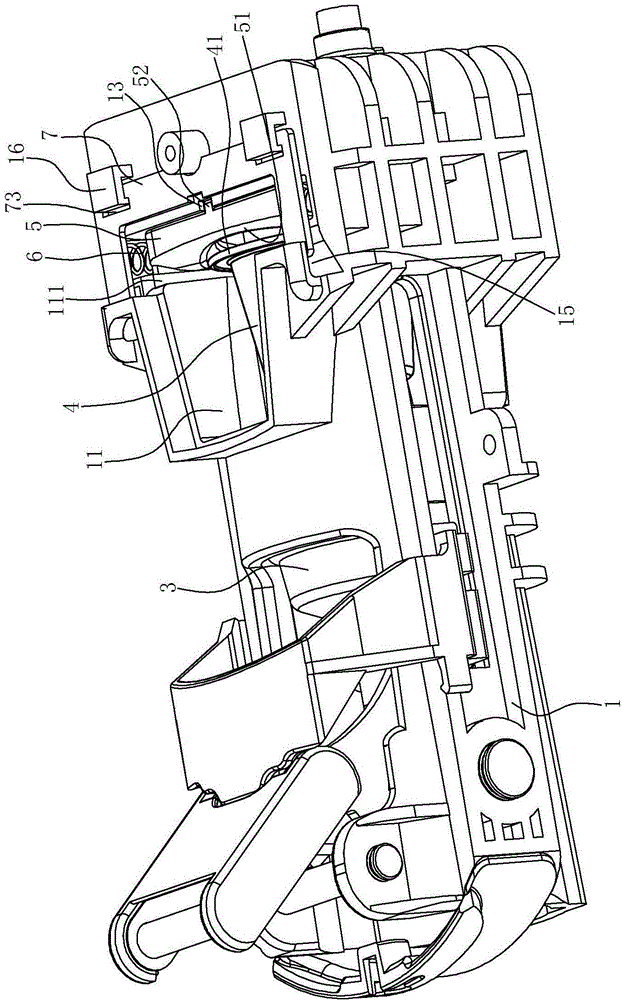

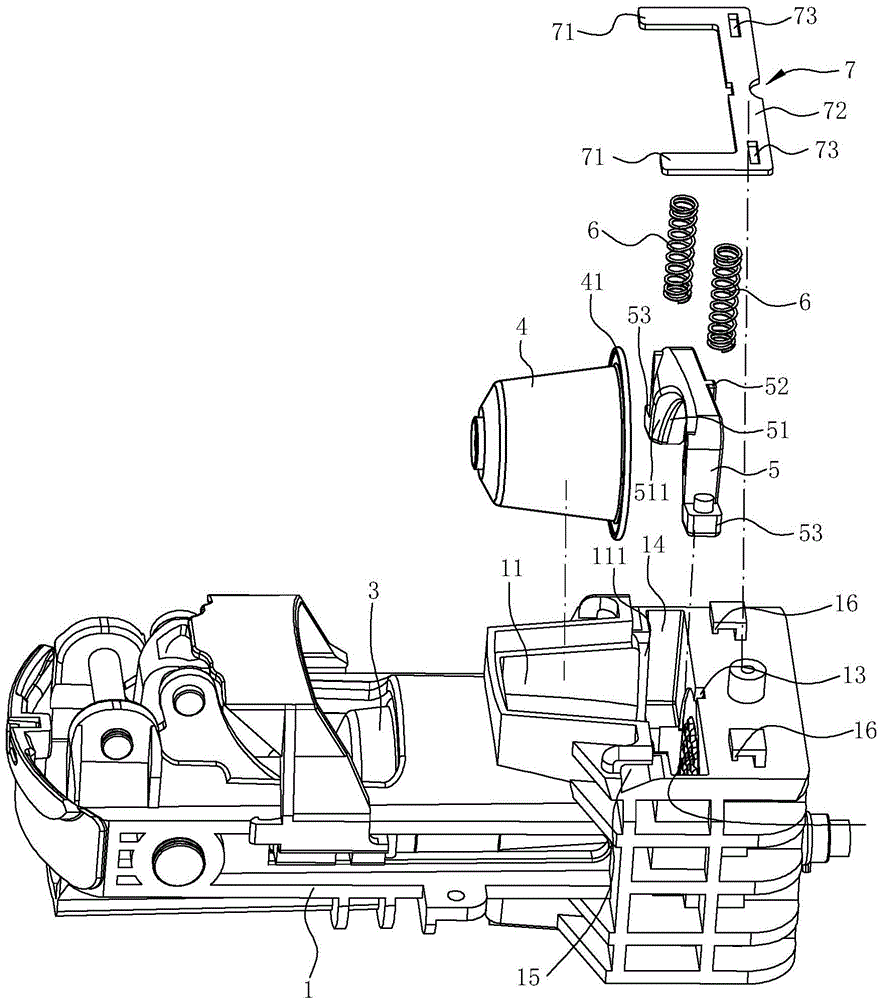

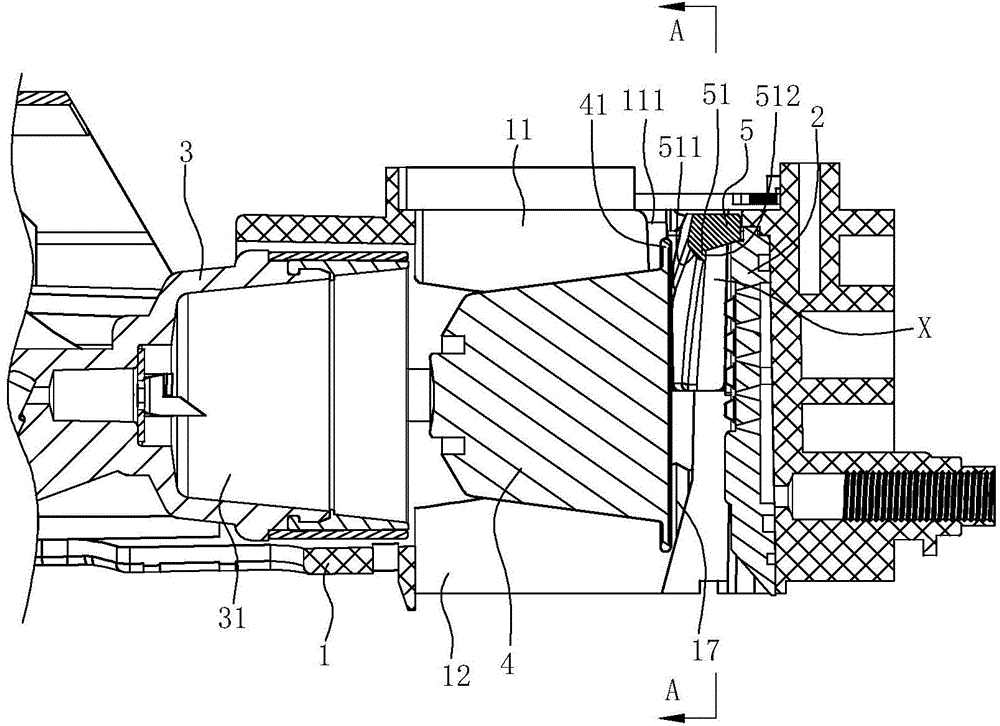

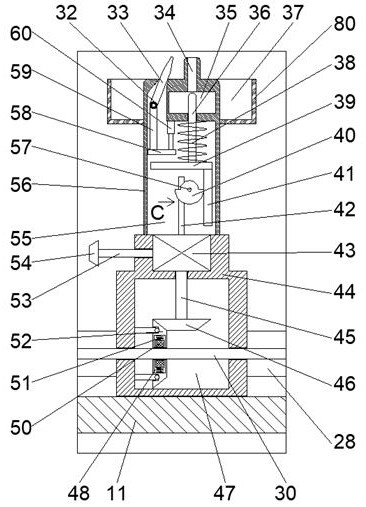

Beverage brewing equipment allowing beverage bag to be removed easily

The invention relates to beverage brewing equipment allowing a beverage bag to be removed easily. The beverage brewing equipment comprises a machine base, a first machine part, a second machine part and a holding mechanism used for receiving and holding the beverage bag after the beverage bag is inserted between the first machine part and the second machine part. The beverage brewing equipment is characterized by further comprising a bag scraping plate and an elastic structure; the bag scraping plate can be constrained inside the machine base and can slide in the vertical direction, the bag scraping plate is provided with a blocking part which extends backwards to the upper portion of the rear of the rear end face of the first machine part, and spacing allowing the annular edge of the beverage bag to be placed is formed between the blocking part and the rear end face of the first machine part; the elastic structure acts on the bag scraping plate so that the bag scraping plate can maintain a downward moving trend. According to the beverage brewing equipment, the beverage bag is removed mainly through the action of the bag scraping plate, the number of related components is small, and the structure is simple; in the process of removing the beverage bag, the bag scraping plate moves downwards and will push the annular edge, so that downward pushing force is produced on the beverage bag; in other words, the falling force of the beverage bag not only comprises the gravity of the beverage bag but also comprises the elasticity of the elastic structure, and therefore it is further ensured that the beverage bag is removed smoothly.

Owner:NINGBO AAA GROUP ELECTRIC APPLIANCE

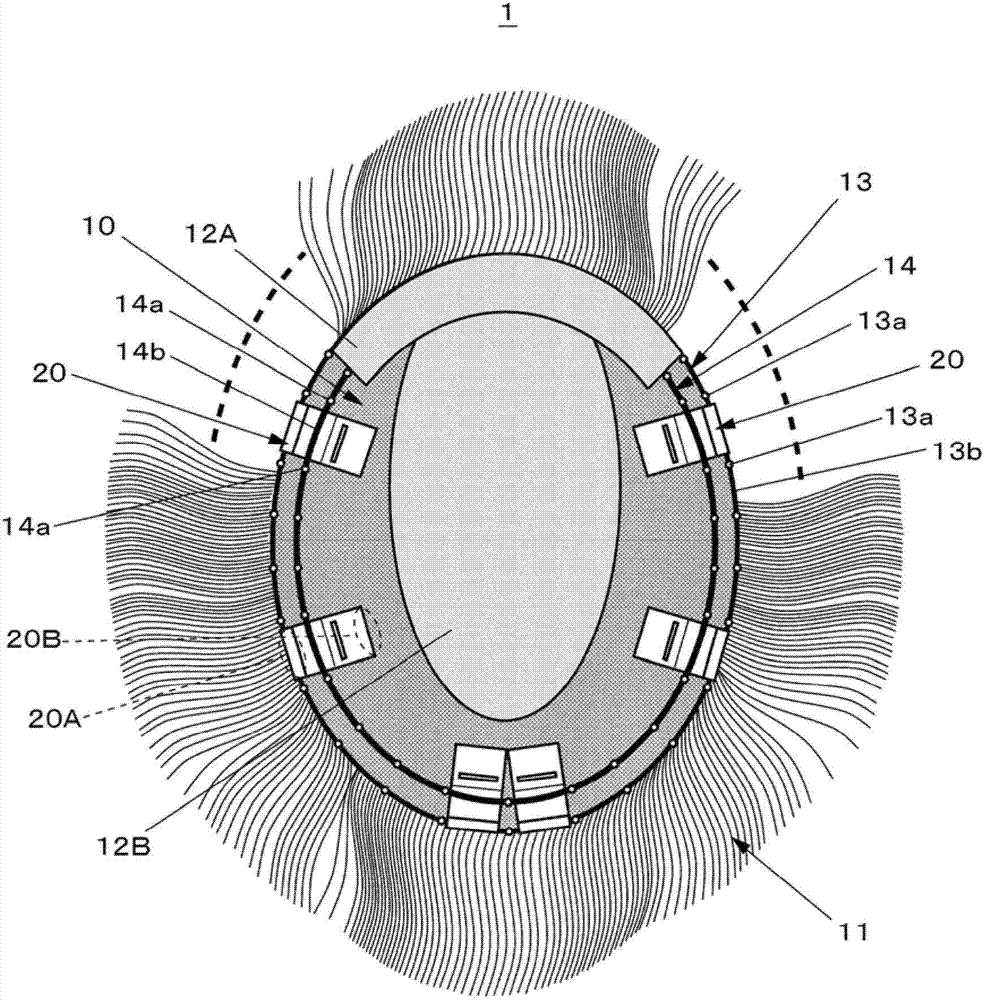

Wig

Owner:ARTNATURE

Multi-purpose slightly-ground oat kernels and production method thereof

InactiveCN108029968AEasy to cleanLow ashFood thermal treatmentFood mechanical treatmentDigestionMoisture

The invention provides multi-purpose slightly-ground oat kernels and a production method thereof. The production method comprises the following steps of removing lignified outer coats of oat kernels,passivating the activity of lipase and the activity of peroxidase through performing oat steaming twice and performing oat baking treatment once, performing high-temperature heat-moisture treatment sothat starch is 100% gelatinized, and then performing slight grinding so as to obtain granules of which the thickness is 1.0-1.8mm. According to the processing method of the multi-purpose slightly-ground oat kernels, the lignified outer coats of oat are removed through brushing the oat, so that digestion by intestinal tracts is facilitated; the activity of the lipase and the activity of the peroxidase are passivated through performing oat steaming twice and performing oat baking treatment once, so that the storage stability of products is strengthened, and the quality guarantee period is prolonged; besides, the starch can be gelatinized through the high-temperature heat-moisture treatment, so that the steaming time of the products is greatly shortened; and the ageing properties of the products can be improved through the slight grinding, so that the steaming time is further shortened, and besides, the situation that the products have slightly glutinous mouth feel, and chewiness and elasticity is guaranteed. The multi-purpose oat kernels disclosed by the invention not only are suitable for being applied to processing of foods of cooked rice, porridge and soup, or coarse cereal porridge and the like, but also can be matched with foods of milk, beverages and the like.

Owner:JIANGSU UNIV

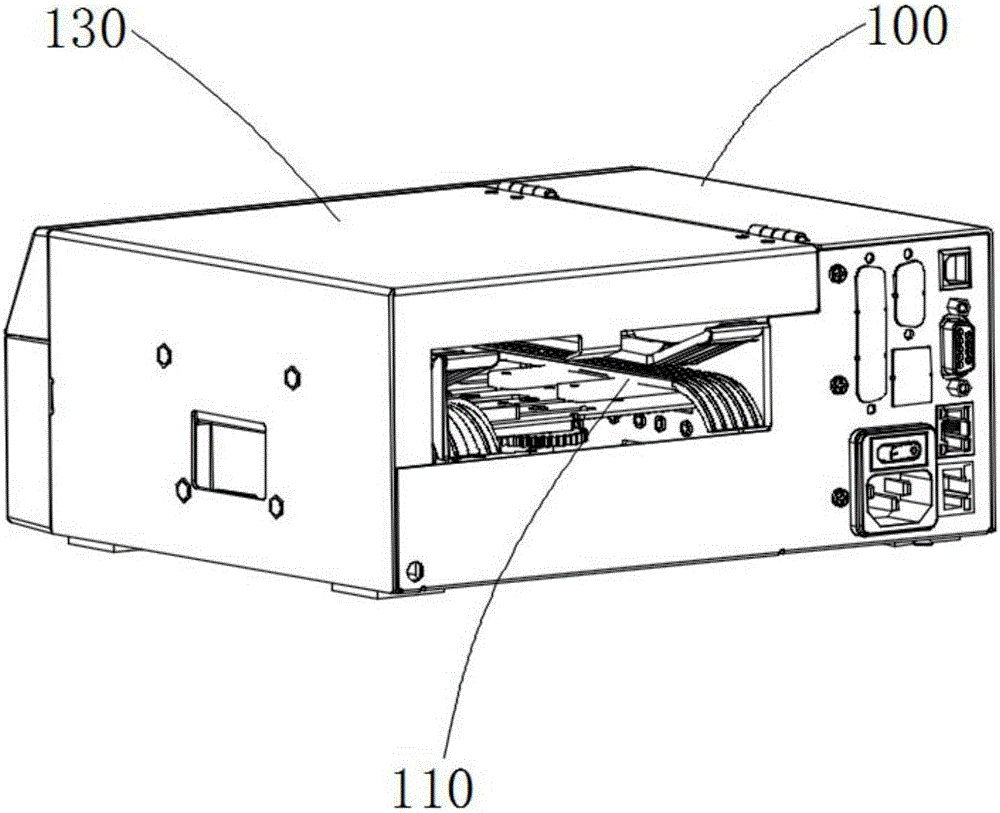

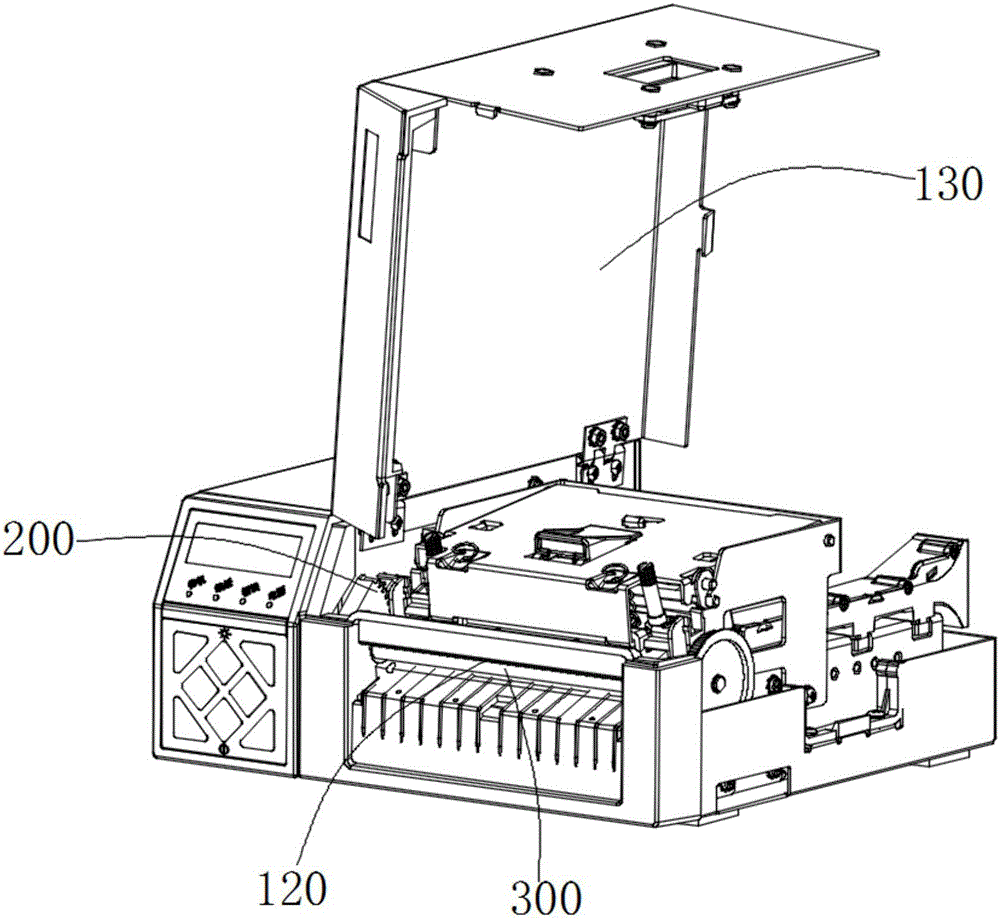

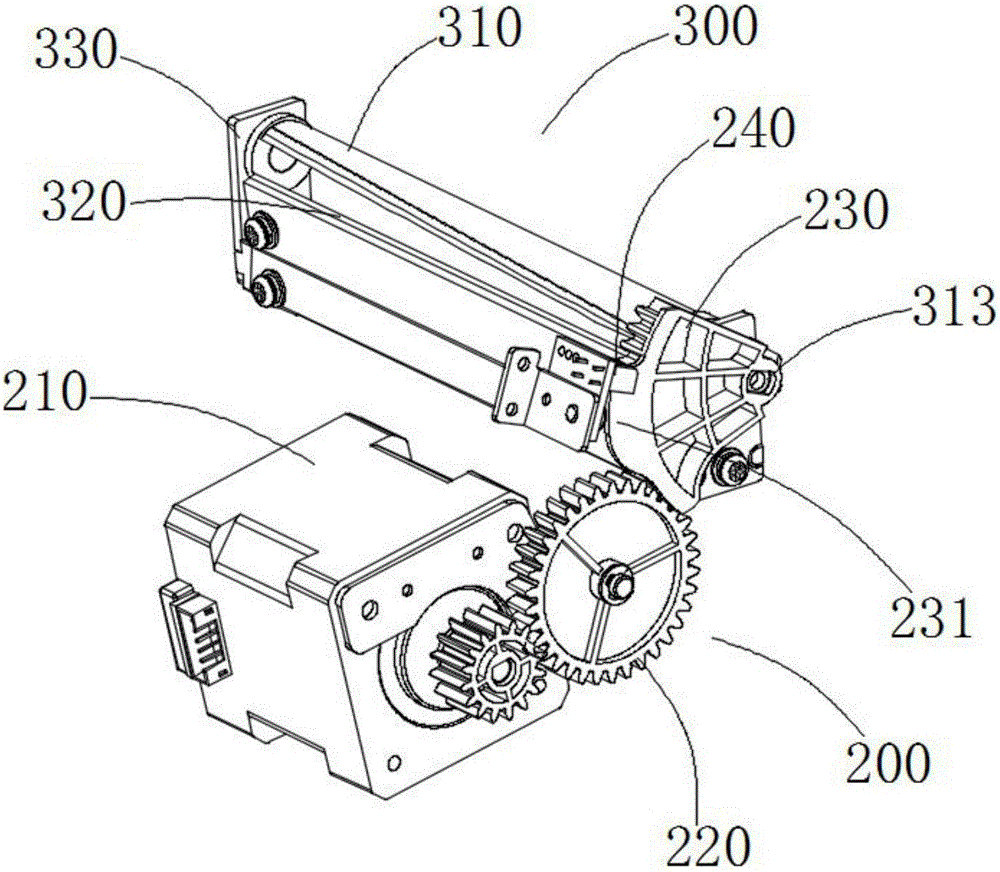

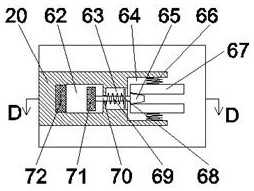

Efficient cutter device used for printer and printer

The invention provides an efficient cutter device used for a printer and the printer. The cutter device comprises a fixing frame, a fixed cutter and a movable cutter. The fixed cutter is arranged on the fixing frame and provided with a fixed blade, and a cutting edge of the fixed blade is formed by two intersecting planes. The movable cutter is located above the fixed cutter and rotatably arranged on the fixing frame. The movable cutter comprises a movable blade and a support, wherein the movable blade is arranged in the support, and a cutting edge of the movable blade is formed by intersecting a curved surface and a plane and arranged obliquely relative to the cutting edge of the fixed blade, and protrudes outwards relative to the support. A scrap discharging space is formed between the top surface of the movable blade and the support. According to the cutter device, the cutting edge of the movable blade protrudes outwards relative to the support, and the scrap discharging space is formed between the top surface of the movable blade and the support. Paper scraps generated in the cutting process are removed out smoothly along the scrap discharging space, so that smooth cutting is ensured.

Owner:XIAMEN HANIN ELECTRONICS TECH CO LTD

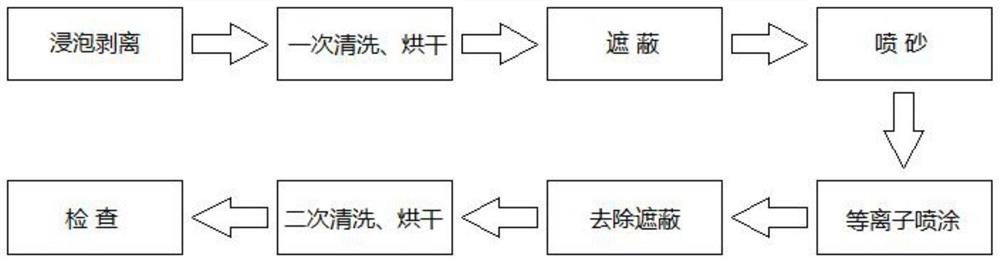

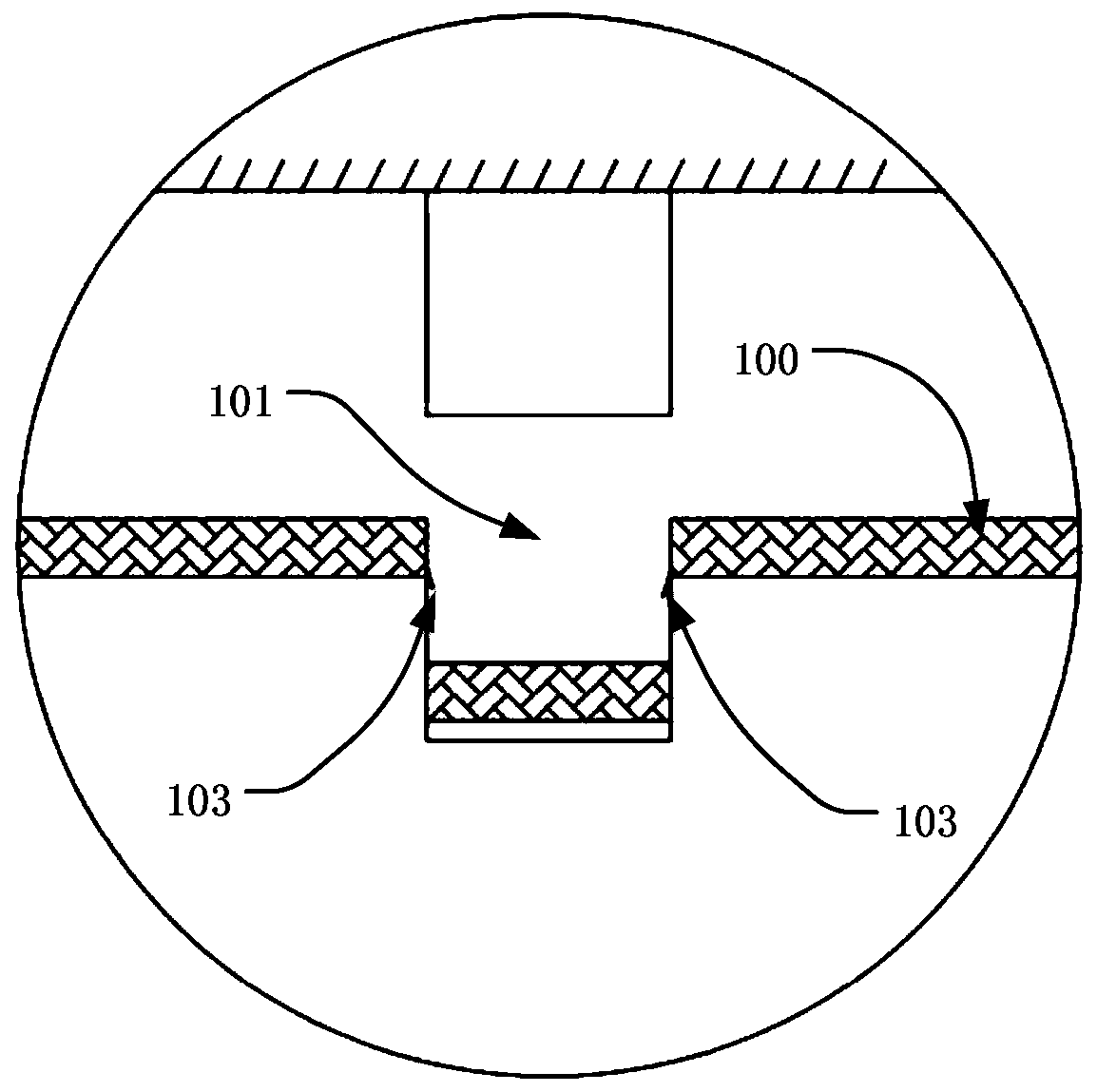

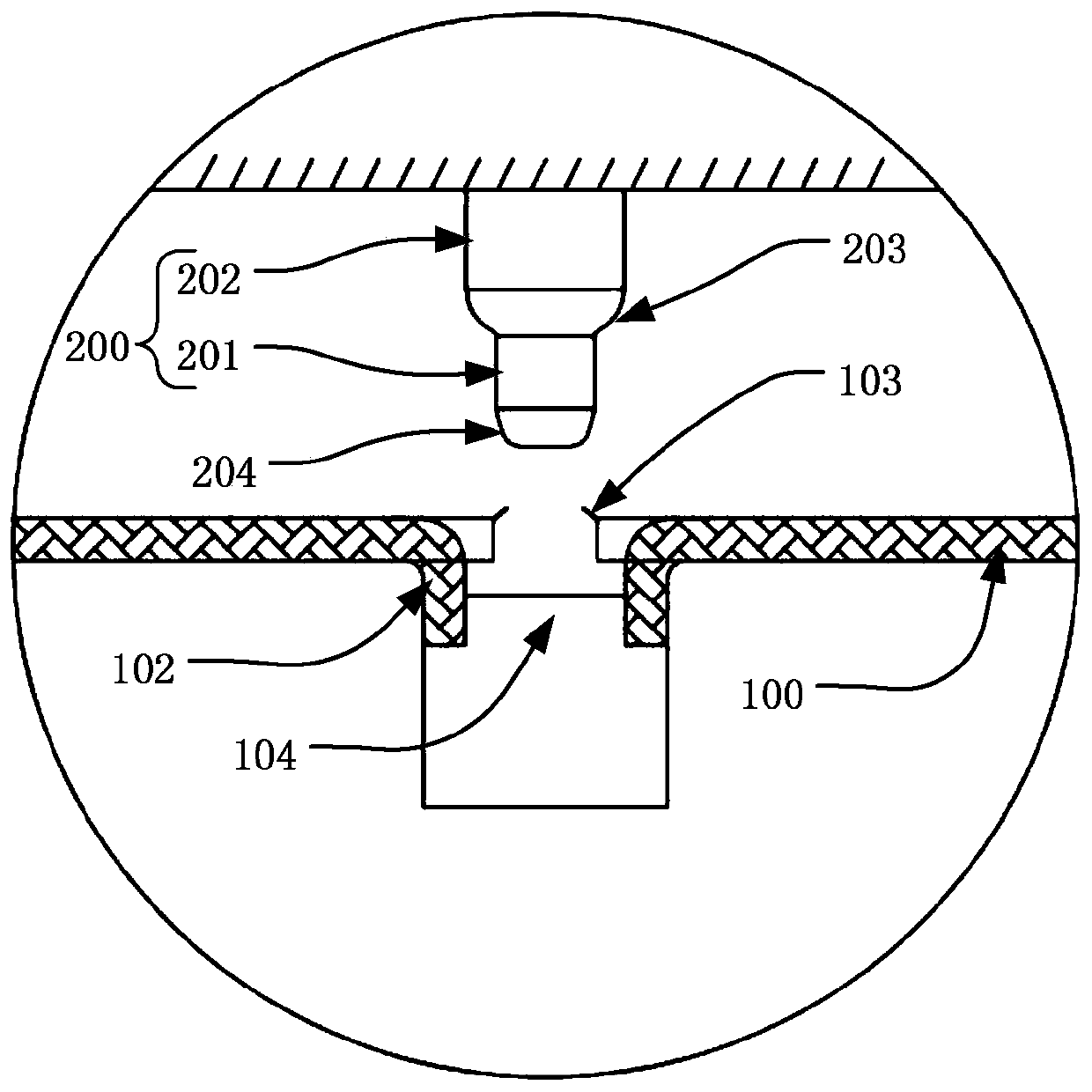

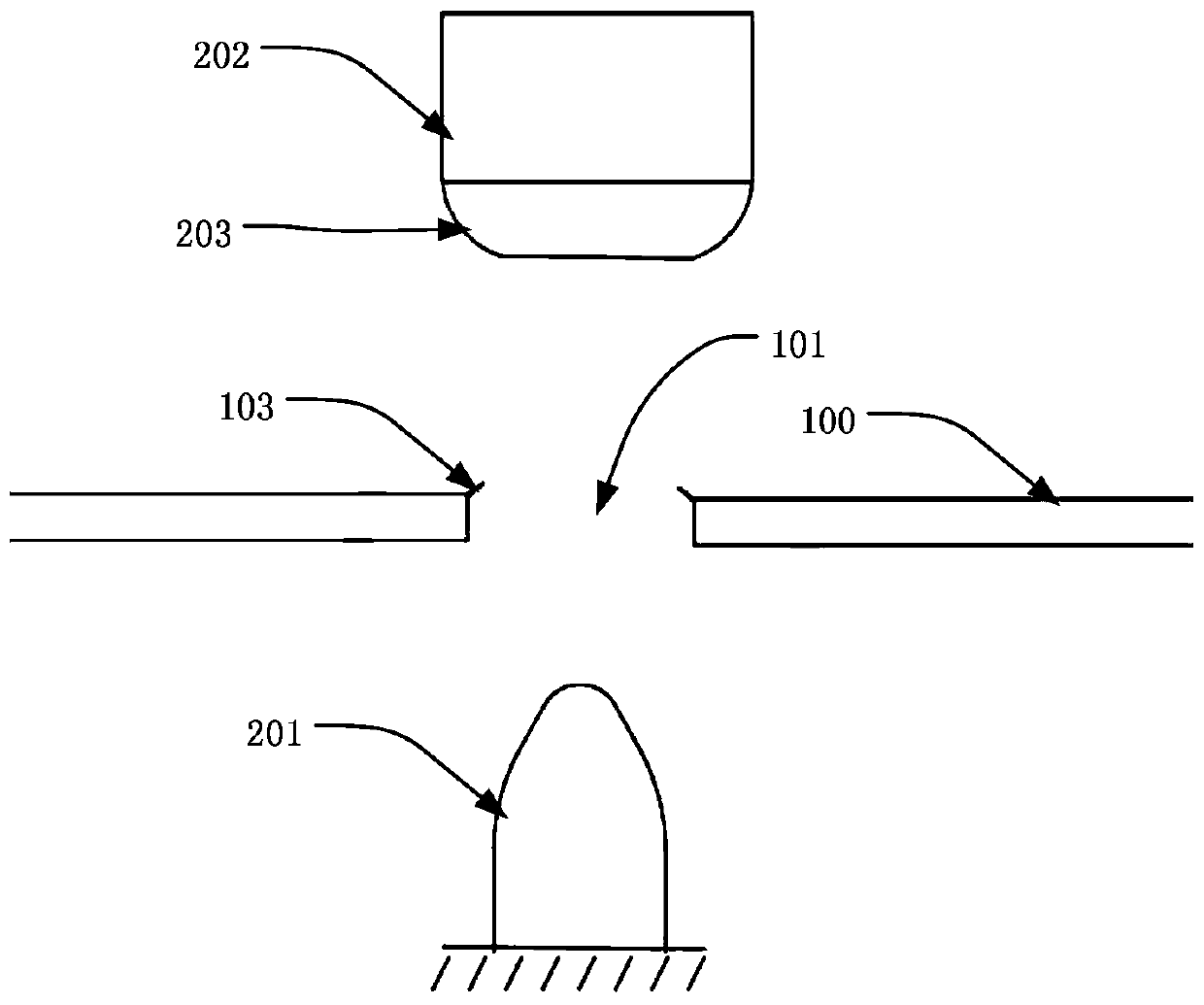

Meltallizing method of ceramic part for dry etching process

The invention discloses a meltallizing method of a ceramic part for a dry etching process. The meltallizing method comprises the steps of firstly, putting the ceramic part to be meltallized into a soaking solution for soaking; cleaning the ceramic part with pure water and drying; shielding the ceramic part by adopting a high-temperature-resistant shielding adhesive tape and a Teflon cap, shieldinga non-meltallizing surface, and exposing the meltallizing surface; carrying out sand blasting treatment on the meltallizing surface, and then carrying out plasma spraying on the meltallizing surface;then removing the high-temperature-resistant shielding adhesive tape and the Teflon cap which shield the ceramic part, and then carrying out secondary cleaning and drying; and finally, checking the appearance and the size of the meltallizing coating. According to the method, the meltallizing coating with the required thickness can be obtained, the corrosion resistance of the ceramic part is improved, and the service life of the ceramic part is prolonged.

Owner:合肥微睿科技股份有限公司

Punch structure and stamping method

ActiveCN110732591ASmooth removalSave processing and manufacturing spaceShaping toolsIndustrial engineeringManufacturing engineering

The invention provides a punch structure and a stamping method, and belongs to the technical field of stamping. The punch structure is used for stamping a plate-shaped piece, the plate-shaped piece isprovided with a first through hole, burrs are generated at the edge of the first through hole located on one side plate face of the plate-shaped piece, the punch structure comprises a second punch head part, the second punch head part is used for stamping and flanging from one side plate face of the plate-shaped piece to the other side plate face of the plate-shaped piece, the edge of the stamping end of the second punch head part is a second fillet transition, and the second fillet transition is used for removing the burrs. According to the punch structure, a mode of removing burrs manuallyis canceled, and the manufacturing process is saved, so that the manufacturing efficiency of flanging is improved.

Owner:宁波奥克斯厨电制造有限公司 +1

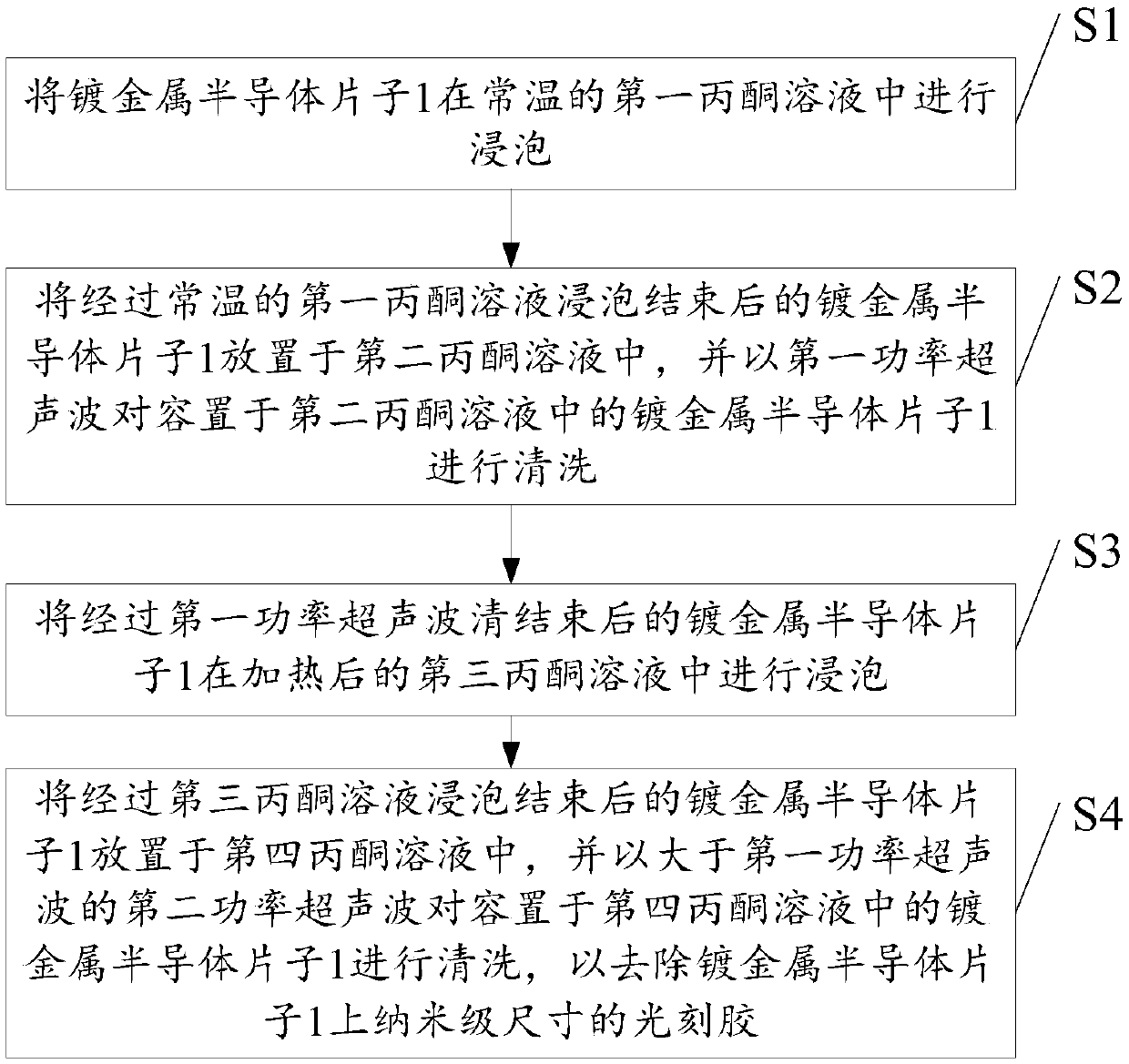

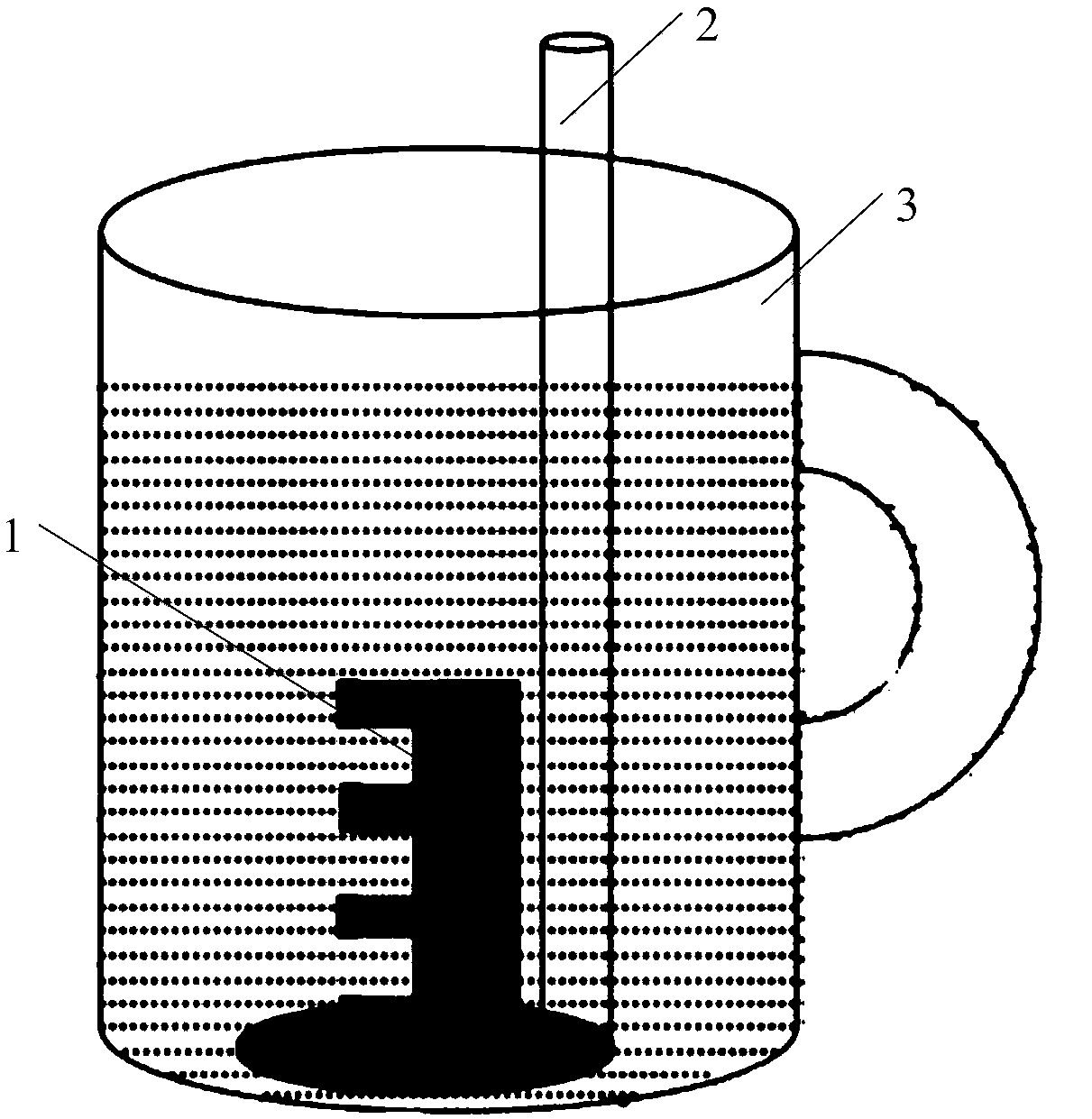

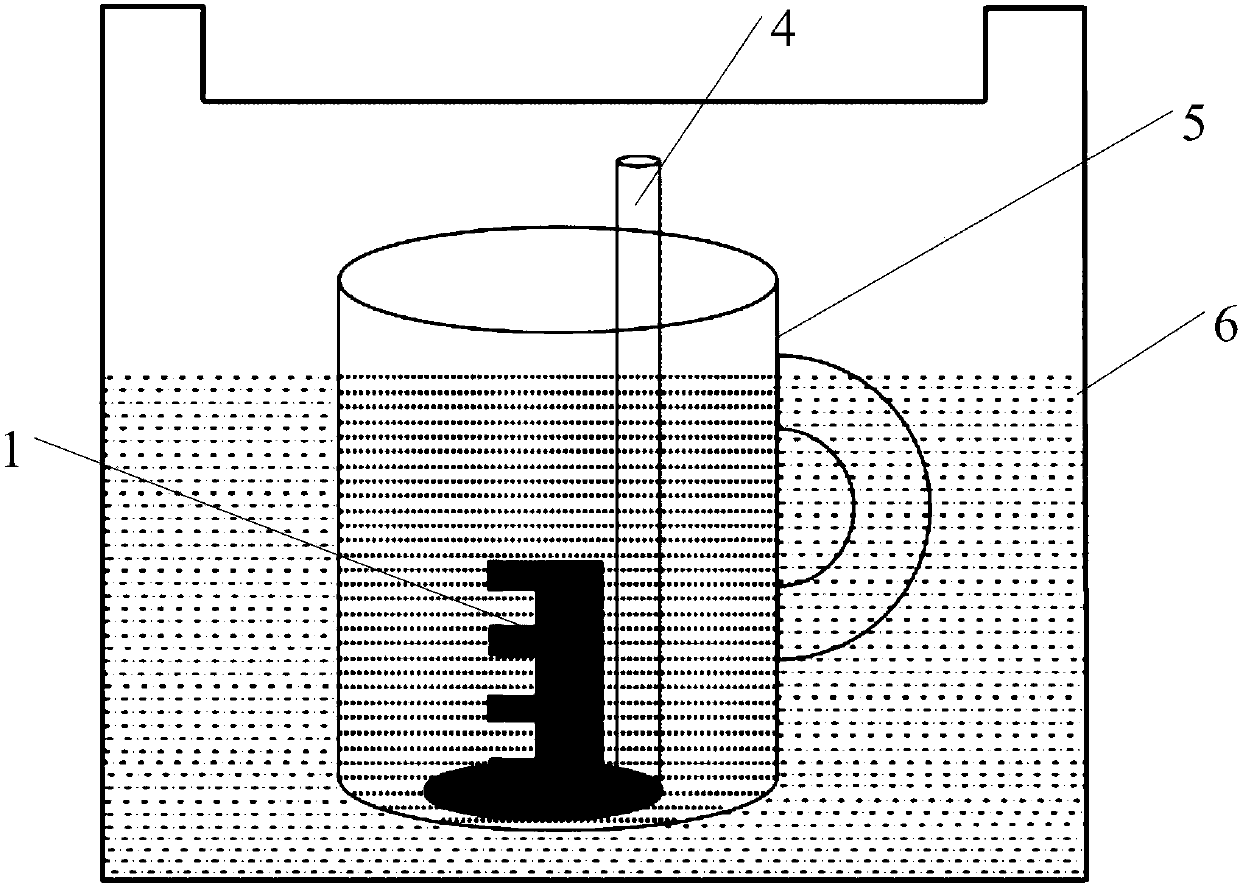

Nano-level dimension semiconductor photoresist peeling method

ActiveCN107665810AEasy accessDissolve smoothlySemiconductor/solid-state device manufacturingSupersonic wavesEngineering

The invention discloses a nano-level dimension semiconductor photoresist peeling method. The method comprises steps that a metalized semiconductor plate is immersed in first acetone solution under normal temperature; the metalized semiconductor plate after being immersed in the first acetone solution under the normal temperature is disposed in second acetone solution, and the metalized semiconductor plate disposed in the second acetone solution is cleaned through first power supersonic waves; the metalized semiconductor plate after being cleaned through the first power supersonic waves is immersed in heated third acetone solution; the metalized semiconductor plate after being immersed in the third acetone solution is disposed in fourth acetone solution, and the metalized semiconductor plate disposed in the fourth acetone solution is cleaned through second power supersonic waves greater than the power supersonic waves to remove nano-level dimension photoresist from the metalized semiconductor plate. The method is advantaged in that a technical problem of unexposed photoresist residues in the nano-level dimension structure is solved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

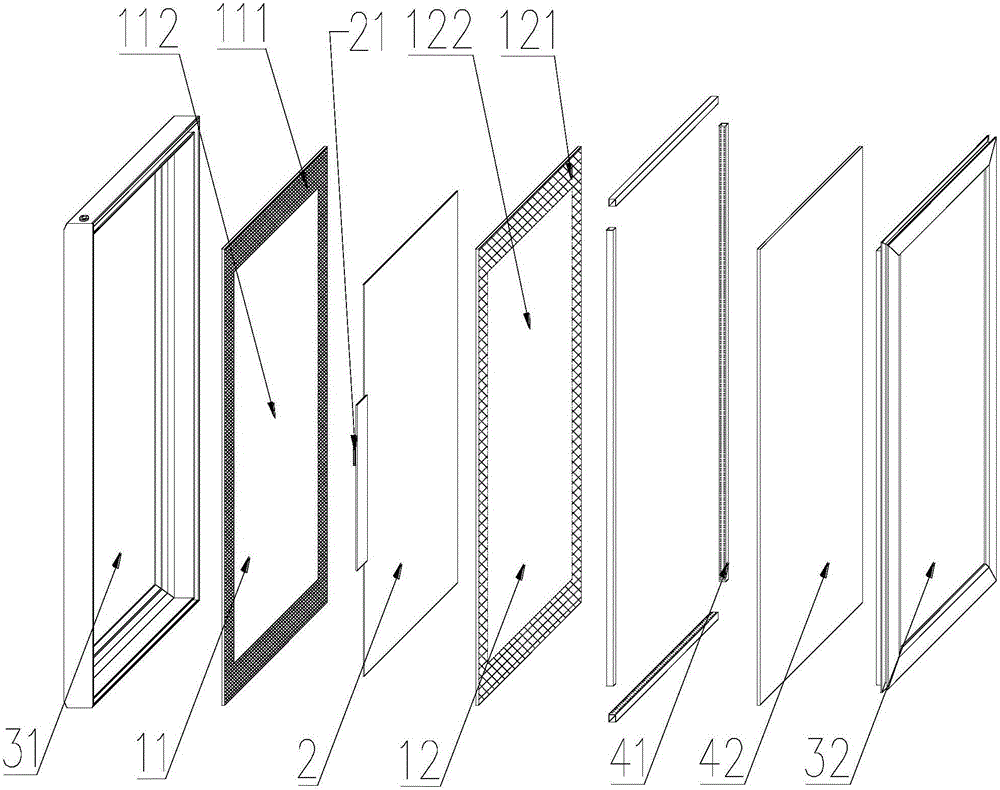

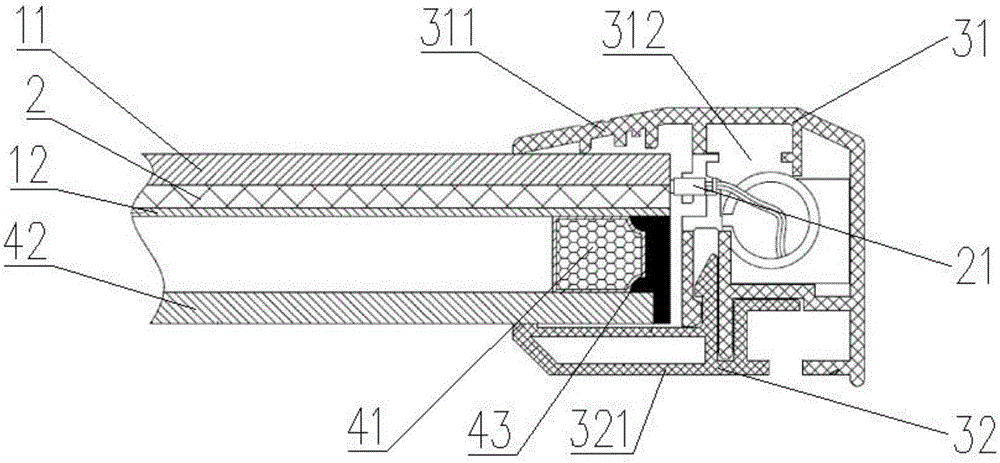

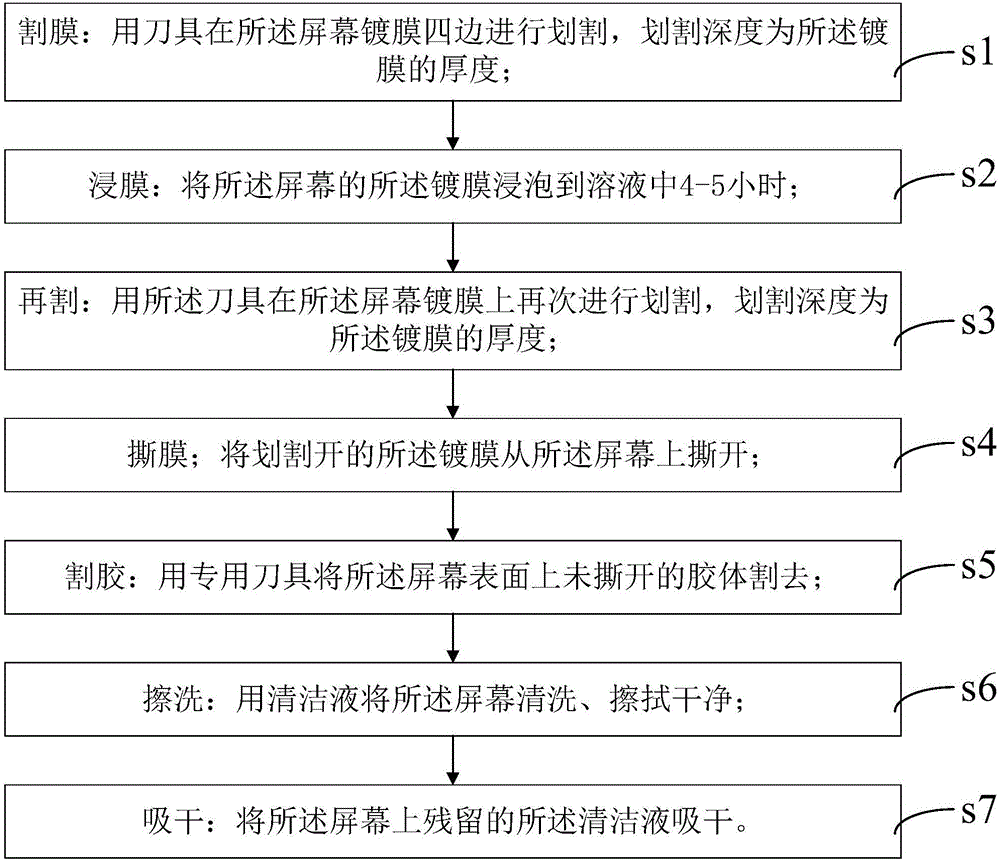

Method for removing film coated on screen

InactiveCN105825774AEasy to tearSmooth removalLighting and heating apparatusLayered productsChemistryCoating

The invention discloses a method for removing a film coated on a screen. The method comprises the following steps: cutting the film, namely (s1) cutting the four edges of the film coated on the screen by using a cutter, wherein the cutting depth is equal to the thickness of the film coated; (s2) soaking the film, namely soaking the film coated on the screen into a solution for 4-5 hours; (s3) recutting, namely recutting the film coated on the screen by using the cutter, wherein the cutting depth is equal to the thickness of the film coated; (s4) tearing the film, namely tearing the cut film coated from the screen; (s5) cutting glue, namely cutting off the glue without being torn from the screen by using a special cutter; (s6) scrubbing, namely washing the screen by using cleaning liquid and scrubbing cleanly; and (s7) sucking to be dry, namely sucking the residual cleaning liquid to be dry on the screen. The method disclosed by the invention has the advantages that the film coated can be smoothly removed from the screen, the process is simple and the operation is convenient.

Owner:NINGBO JINGEAO ELECTRONICS CO LTD

Shredding device for maize harvesting machine impurity removal draught fan

InactiveCN106688455AImprove reliability and efficiencyEasy to useMowersThreshersFlangeEconomic benefits

The invention relates to a shredding device for a maize harvesting machine impurity removal draught fan. The shredding device comprises a discharging opening, a bolt, a nut, a gasket, a fan blade seam, a draught fan shell seam, an axle nut, an axle gasket and a shredding blade. The discharging opening and the fan shell seam are connected through the bolt, the nut and the gasket. The fan blade seam is installed inside the fan shell seam. The fan blade seam is composed of four rotating vanes, four rotating blades and a rotating shaft, the four rotating vanes are uniformly arranged on the rotating shaft in the circumferential direction, the four rotating blades are installed on the four rotating vanes respectively, one end of the rotating shaft penetrates through a lower flange in the fan shell seam to be connected with a motor, the other end of the rotating shaft is provided with the shredding blade, and the shredding blade is fixed through the axle nut and the axle gasket. Due to the fact that maize straw and other impurities are cut through the shredding blade and the rotating blades two times, particles become finer and smaller, the field returning effect is better, the impurity removal draught fan is not likely to be blocked, the number of impurities entering a peeling machine is small, the service life of the peeling machine is prolonged, and economic benefits are created.

Owner:YONGMENG MACHINERY CO LTD

Wood machining device

InactiveCN108638264AAvoid the inconvenience of adjusting the direction of the delimbing knifeSmooth removalTree debarkingBand sawsWood machiningPulp and paper industry

The invention relates to field of wood machining, in particular to a wood machining device which comprises a cutting mechanism, a branch removing mechanism, a peeling mechanism and a transferring mechanism. The cutting mechanism comprises a supporting unit and a cutting unit. The supporting unit comprises a supporting table, a supporting plate and an airbag. The cutting unit comprises a screw rod,a nut base and a cutting saw. The peeling mechanism comprises a peeling unit and a gas generating unit. The peeling unit comprises a sliding rail, a peeling cutter and a spring. The gas generating unit comprises a connecting rod, a piston and a pipe body. The two ends of the pipe body communicate with the airbag. The branch removing mechanism comprises a receiving plate, a vertical rotating rod and a branch removing unit. The branch removing unit comprises a stamping rod, a branch removing cutter and an air cylinder. One end of the stamping rod is fixedly connected with an output shaft of theair cylinder, and the other end of the stamping rod is hinged to the branch removing cutter. By the adoption of the technical scheme, bent wood can be peeled conveniently.

Owner:YUQING COUNTY XINGDA FURNITURE MFG

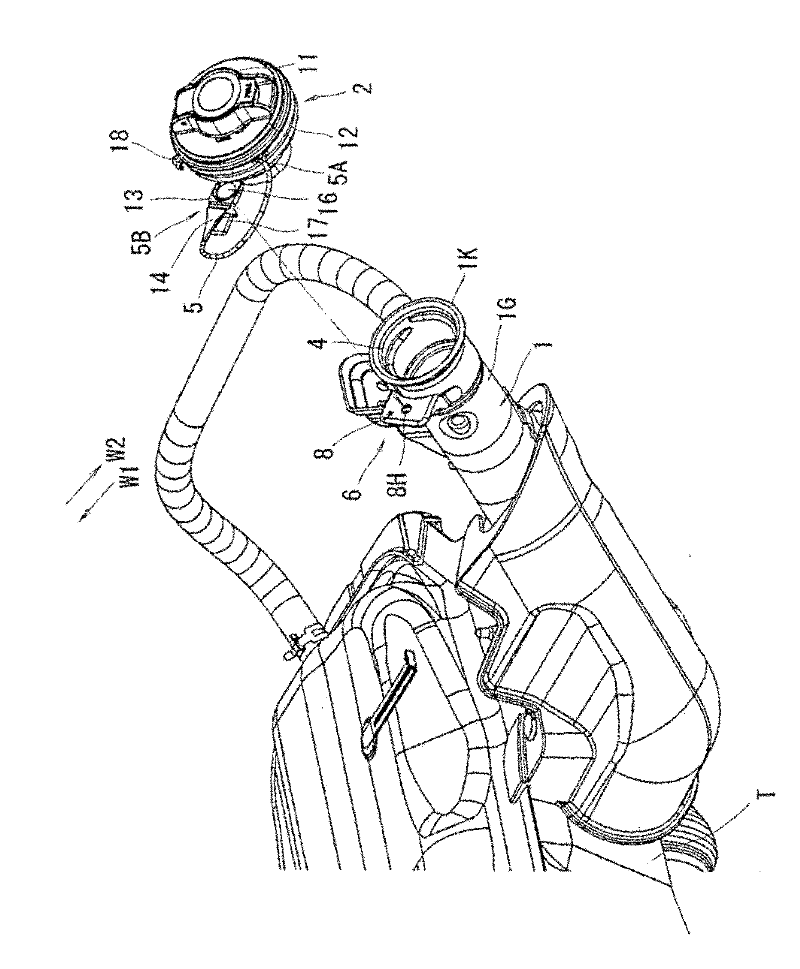

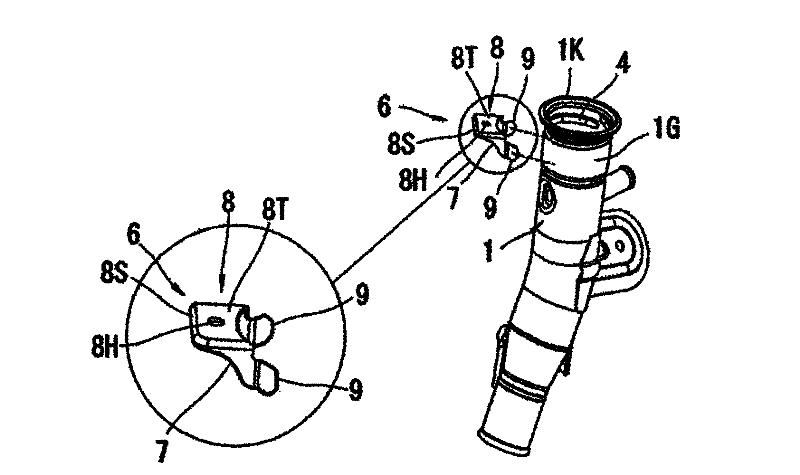

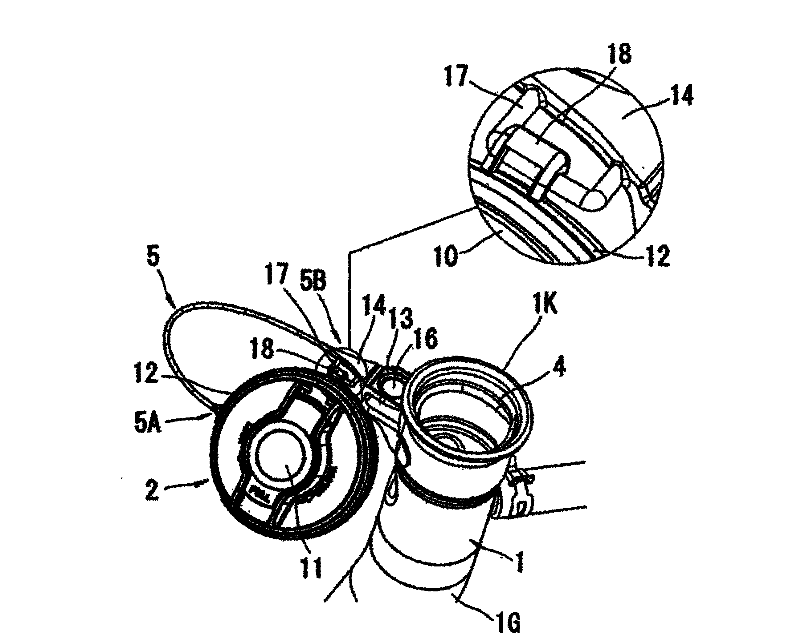

Fuel supply part structure of vehicle

Provided is a fuel supply part structure of a vehicle. The fuel supply part structure comprises a fuel charging port (1) connected with a fuel tank (T) and connected with a vehicle body when a part near a charging opening (1K) is exposed to the outside; and a fuel discharging port cover (2) installed on the charging opening (1K) of the fuel charging port (1) and connected with one end (5A) of a tightening rope (5). A support (6) is connected to the external surface (1G) of the fuel charging port (1) at a place near the charging opening (1K), and the other end (5B) of the tightening rope (5) is attached to the support (6).

Owner:SUZUKI MOTOR CORP

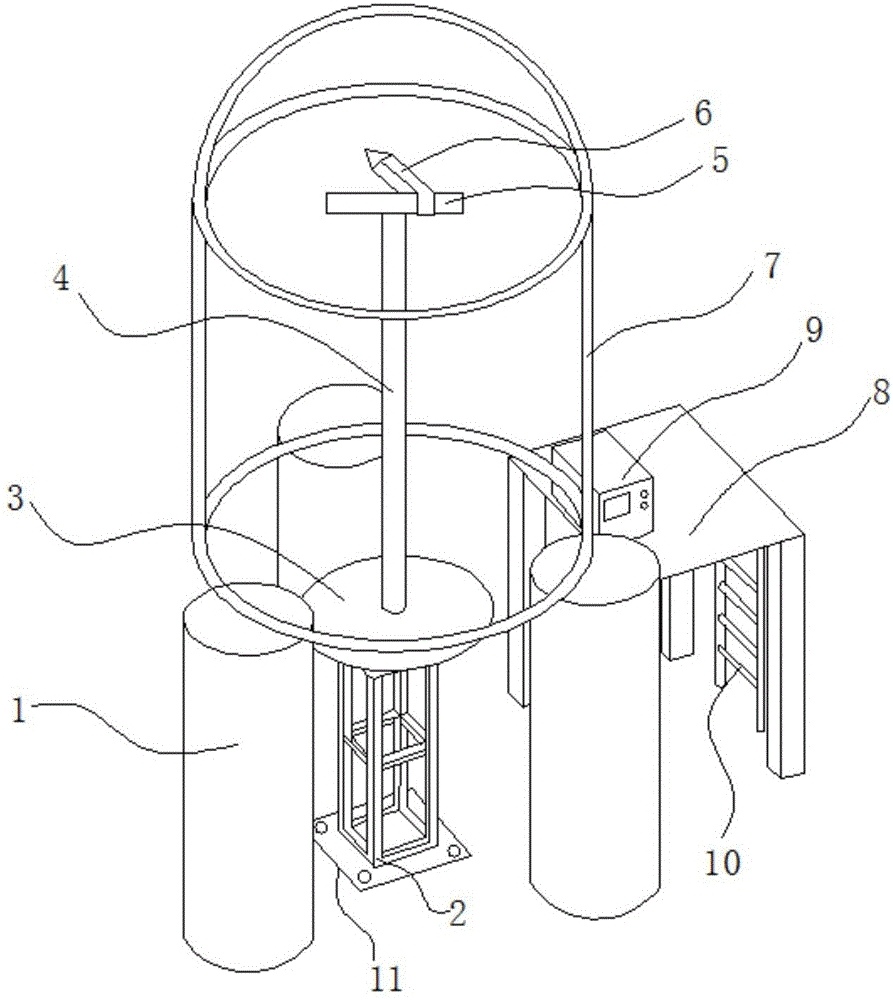

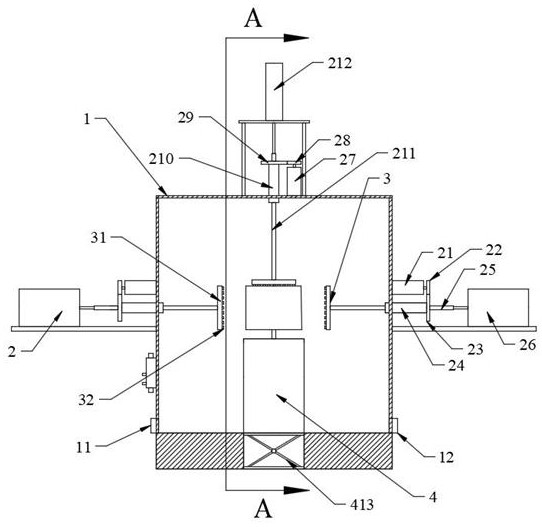

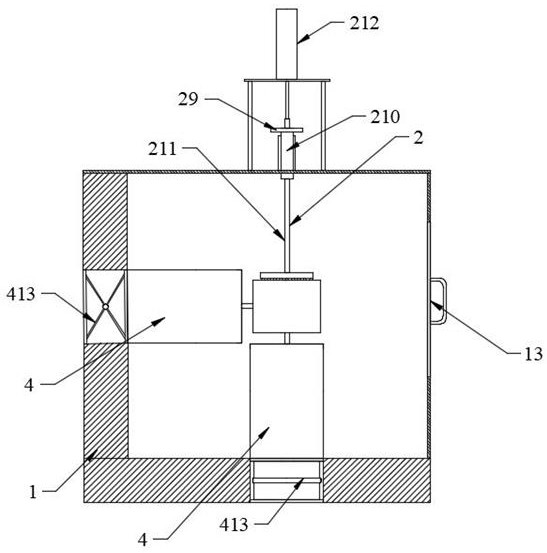

Method and device for removing oxide skin of polycrystalline silicon reduction furnace bell jar through laser

InactiveCN106112269AFast return on investmentLow costLaser beam welding apparatusPolycrystalline siliconOxide

The invention discloses a method and device for removing oxide skin of a polycrystalline silicon reduction furnace bell jar through laser. The method comprises the following steps that S1, the polycrystalline silicon reduction furnace bell jar is hoisted on supporting stand pillars; S2, a laser generator is started, a rotary working disk drives a Z-direction sliding rail to rotate, an X-direction sliding rail slides on the Z-direction sliding rail from bottom to top, and the polycrystalline silicon reduction furnace bell jar is automatically and rotationally scanned from bottom to top through the Z-direction sliding rail, the X-direction sliding rail and the rotary working disk; and S3, laser emitted by a laser emitting head is used for irradiating the inner wall of the polycrystalline silicon reduction furnace bell jar, the oxide skin adhering to the inner wall of the polycrystalline silicon reduction furnace bell jar is removed rapidly and conveniently, and the metal color of the polycrystalline silicon reduction furnace bell jar is restored. The oxide skin of the polycrystalline silicon reduction furnace bell jar can be rapidly and thoroughly removed, and the polycrystalline silicon reduction furnace bell jar is not damaged; the investment recovery is rapid, the cost is low, and no noise is generated; and no chemical agent or decontamination liquid is needed, the removed oxide skin is solid powder and can be recycled, and the environment is not polluted.

Owner:吴起正 +1

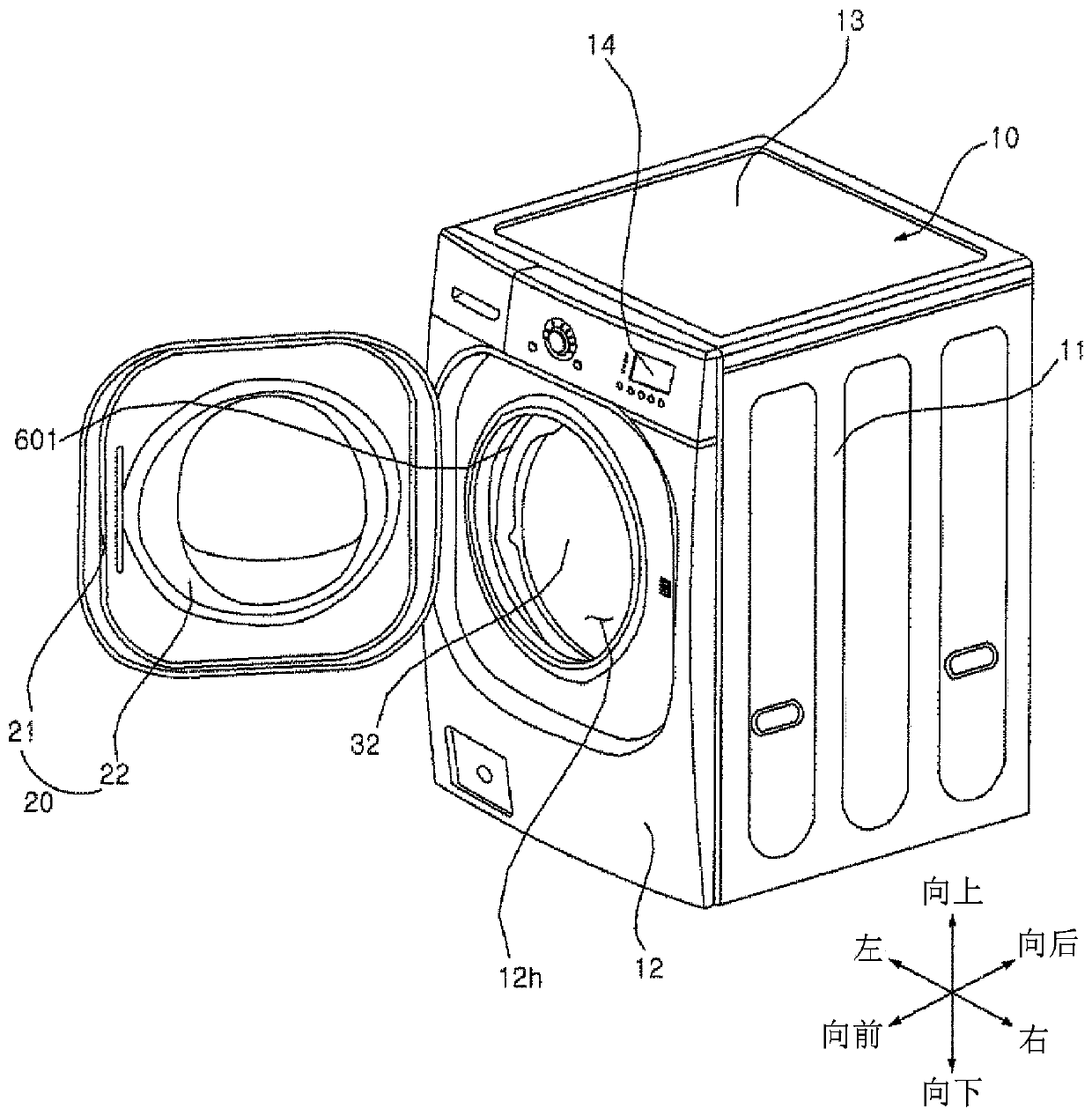

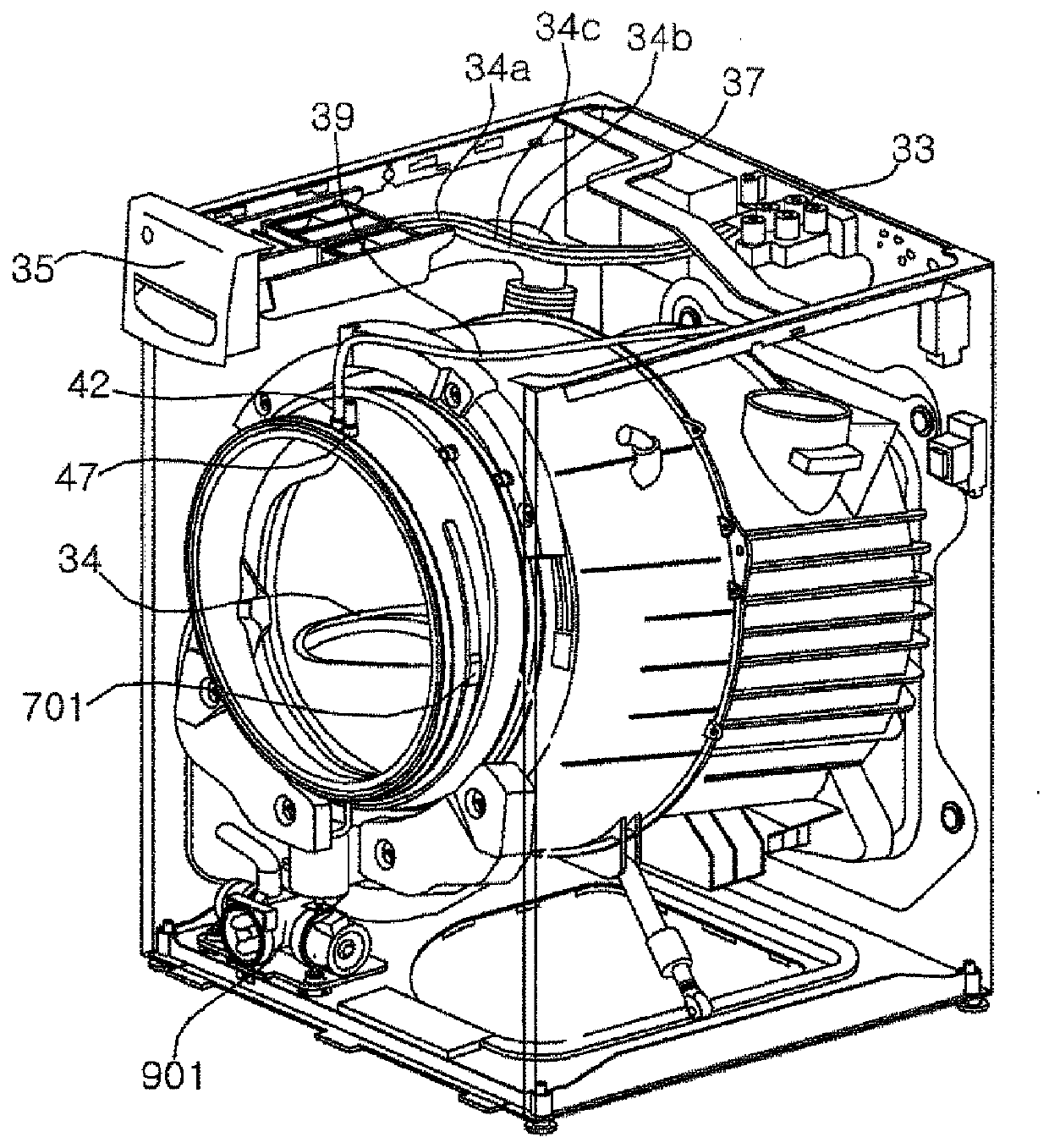

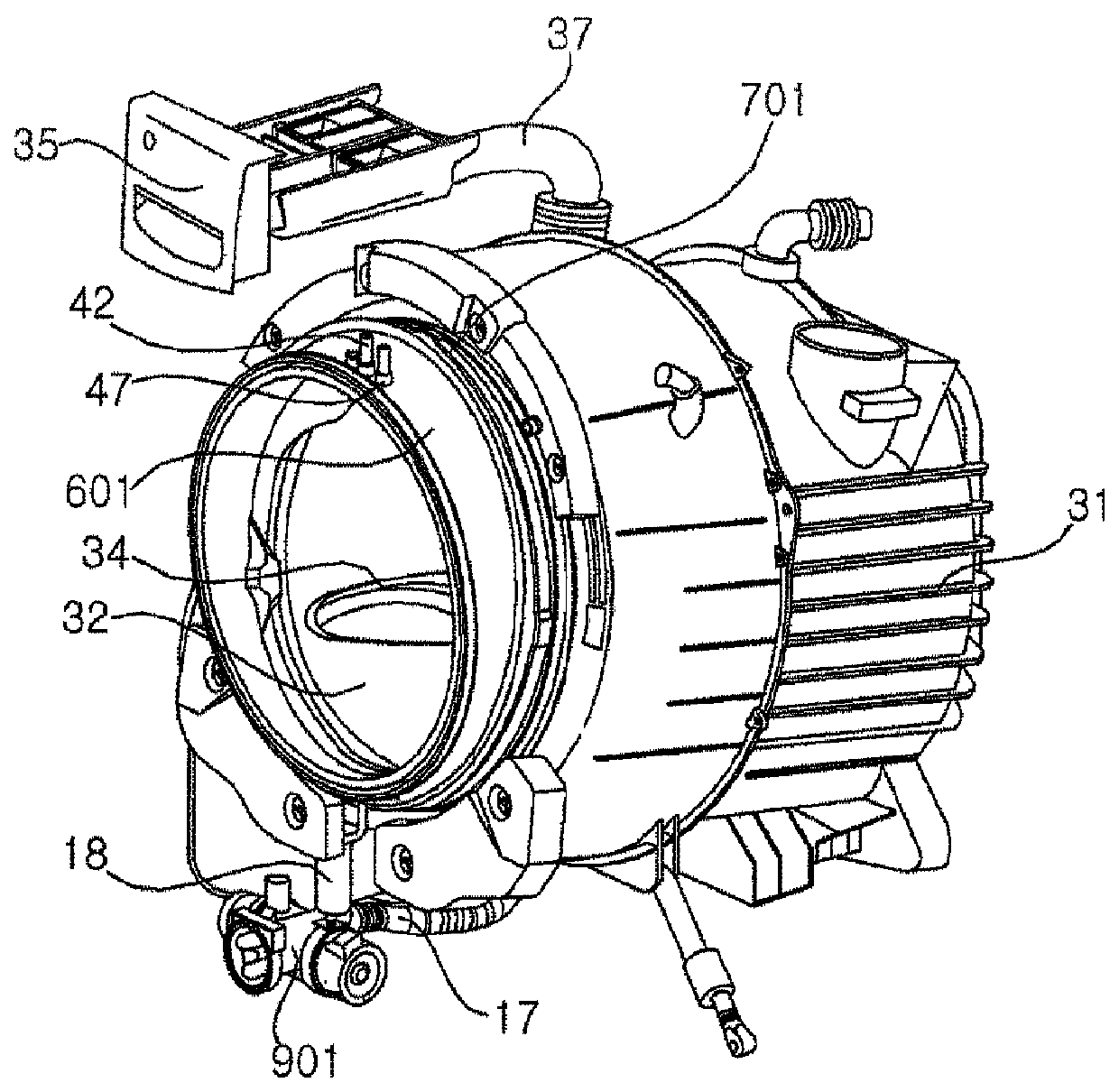

Washing machine

PendingCN110352274ASmooth releaseEasy to dryOther washing machinesControl devices for washing apparatusLaundry washing machineWasher

The present invention relates to a washing machine comprising: a casing having a insertion hole for inserting laundry thereinto on the front surface thereof; a tub disposed in the casing and containing laundry water and having an inlet communicating with the insertion hole; a drum, rotatably disposed within the tub, for accommodating laundry; a pump for pumping water discharged from the tub; a gasket for making the insertion hole communicate with the inlet of the tub and having a plurality of nozzles for spraying water into the drum; and a nozzle water supply pipe, fixed to the gasket and having an inlet through which water pumped by the pump flows, for dividing and guiding water that has flowed through the inlet into a first sub flow and a second sub flow, the nozzle water supply pipe including a plurality of first nozzle water supply ports, formed on a first flow passage to which the first sub flow is guided, for supplying the first sub flow individually to any two or more nozzles among the plurality of nozzles, and a plurality of second nozzle water supply ports, formed on a second flow passage to which the second sub flow is guided, for supplying the second sub flow individually to other two or more nozzles among the plurality of nozzles.

Owner:LG ELECTRONICS INC

Method for processing school desk

InactiveCN108687908AAvoid the inconvenience of adjusting the direction of the delimbing knifeSmooth removalTree debarkingBand sawsWood shavingsMotor drive

The invention relates to the field of wood processing, in particular to a method for processing a school desk. The method comprises the following steps that 1, wood processing equipment is prepared; 2, wood is driven to rotate and move through a moving and rotating mechanism; 3, the wood is peeled by a peeling knife, wood chips are generated in the peeling process, a piston is driven to move in areciprocating mode by the peeling knife while peeling is conducted, generated airflow promotes an airbag to swell, thus the whole wood is pushed to move, meanwhile, a first servo motor drives a screwto rotate, thus a nut seat and a cutting saw are driven to move, and the whole wood is cut into sectioned wood; 4, tree branches are cut; 5, the wood chips, wood slag and shavings are mixed to be crushed so as to obtain a mixture, rolling is conducted after glue is added into the mixture, and a mother plate is prepared; and 6, paint is applied to the mother plate, after the paint is dry, the edgeof the mother plate is sealed to prepare a compression plate, and then the compression plate is assembled into the school desk. When the method is adopted, the bent wood is conveniently processed intothe school desk after being peeled.

Owner:YUQING COUNTY XINGDA FURNITURE MFG

A device for removing burrs from the metal braiding layer of cables

ActiveCN105139971BAdjust the tightnessAdjustable sizeCable/conductor manufactureUltimate tensile strengthElectric cables

The invention relates to a production equipment for cables with braided shielding layers, in particular to a device for removing burrs from the metal braiding layer of cables, which includes a cleaning assembly and tension plates arranged at both ends of the cleaning assembly to tension it, and the cleaning assembly consists of Composed of several friction strips, the combination of the friction strips forms channels distributed along the length direction to remove burrs on the metal braided layer of the cable passing through the channel, and the tension plate is provided with a the through hole of the channel. The invention is simple in structure and easy to use. Only need to pass the cable braided wire core through the channel formed by the combination of friction strips to remove the burrs on the cable braided wire core, which is simple, convenient and fast, and greatly reduces the labor of workers. Strength, at the same time, by rotating the connection end, the size of the channel can be adjusted to adapt to cables of different specifications, so that the friction strip can smoothly remove burrs without wrinkling the cable braid.

Owner:ZHEJIANG ZHENGDAO CABLE CO LTD

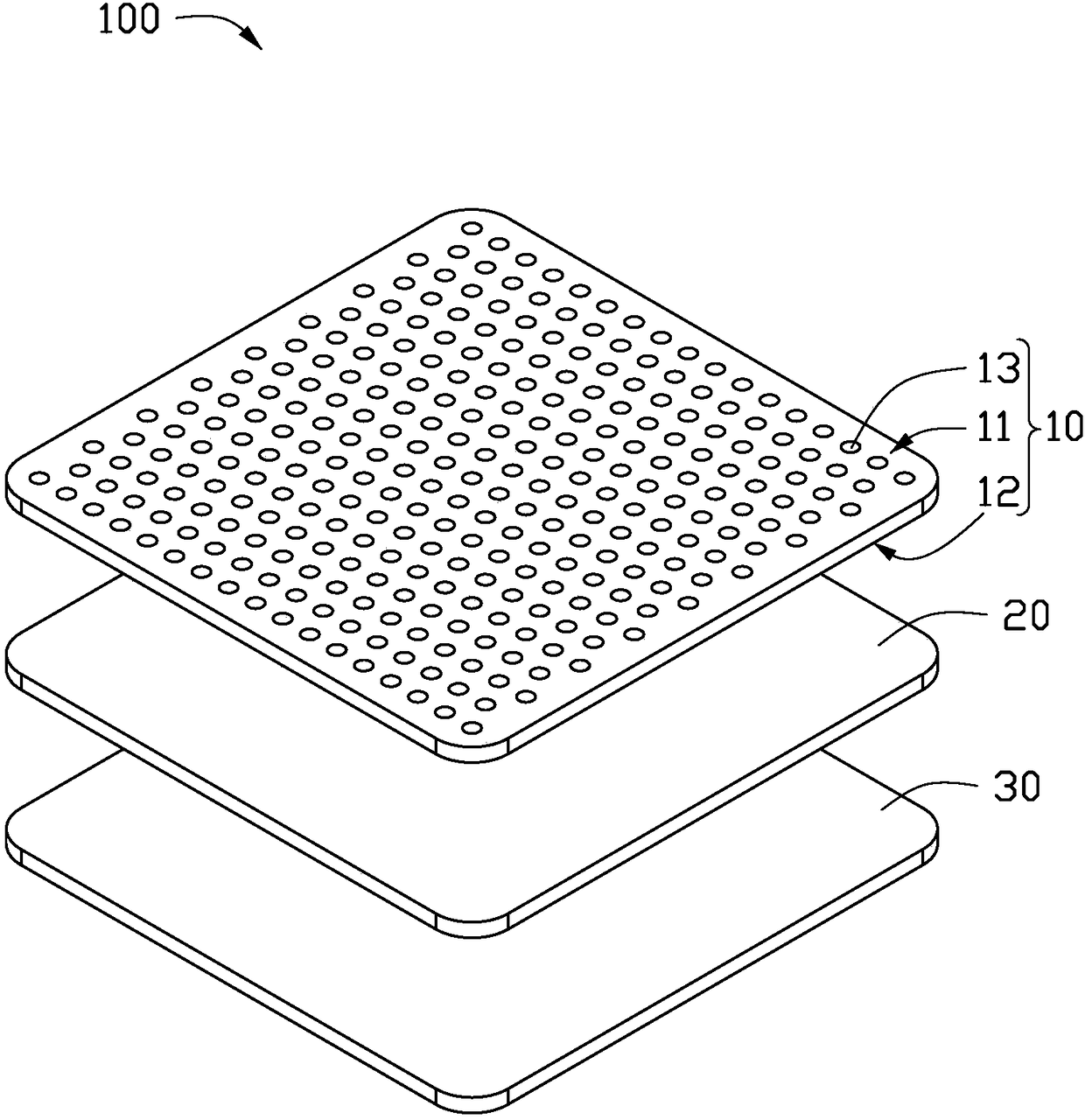

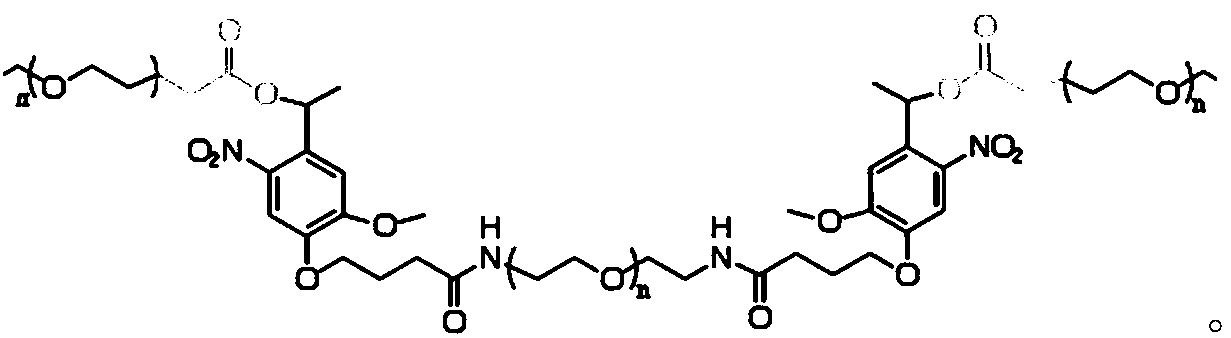

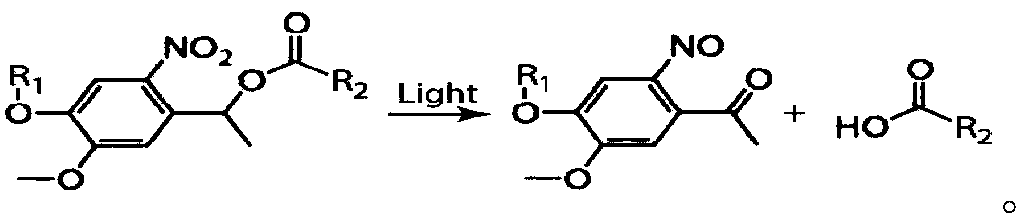

Wound dressing and removal method thereof

InactiveCN109420196ASmooth removalPromote degradationAbsorbent padsBandagesBiomedical engineeringAnti adhesion

A wound dressing comprises a wound contact layer. At least one photodegradable molecule and at least one anti-adhesion molecule react to form the wound contact layer, wherein the photodegradable molecule contains at least one o-nitrobenzyl group. The invention further relates to a removal method of the wound dressing.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

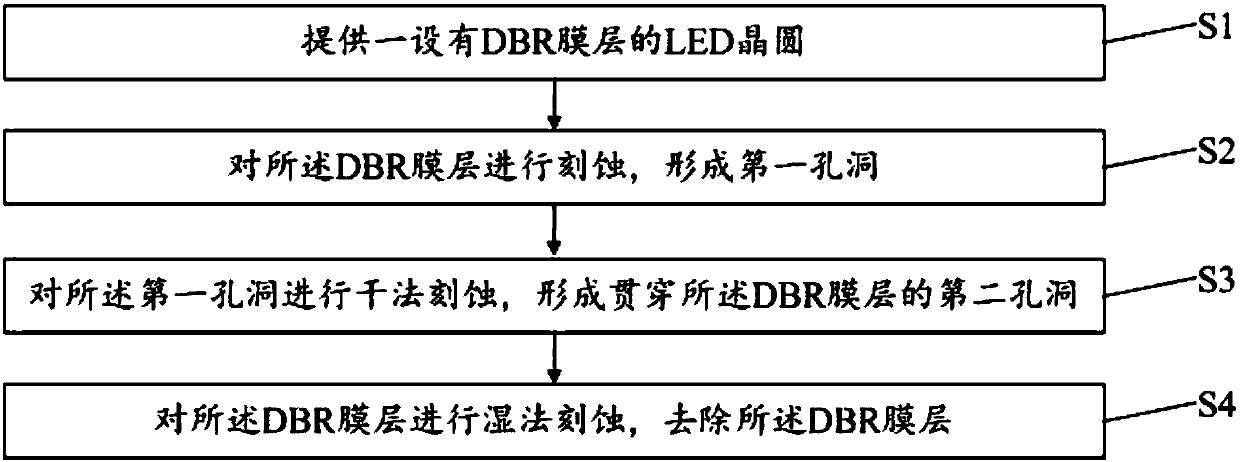

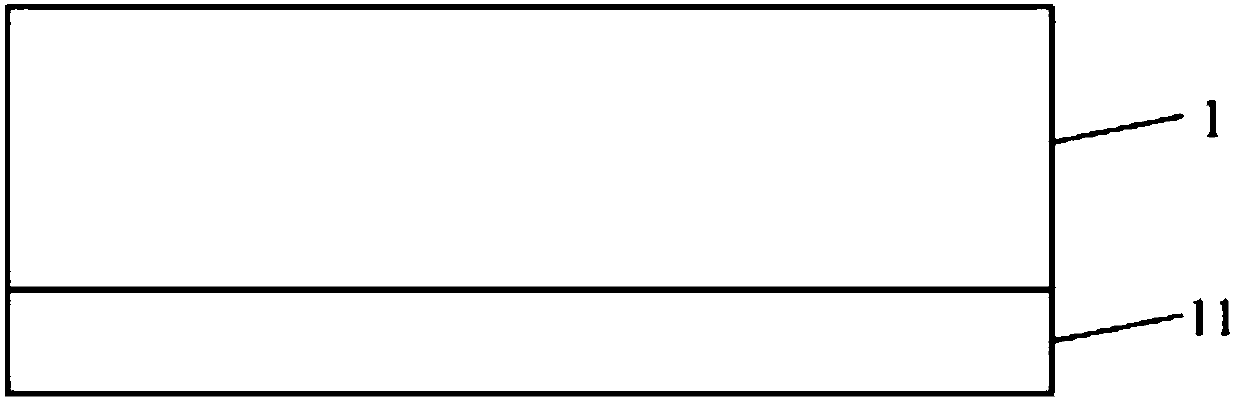

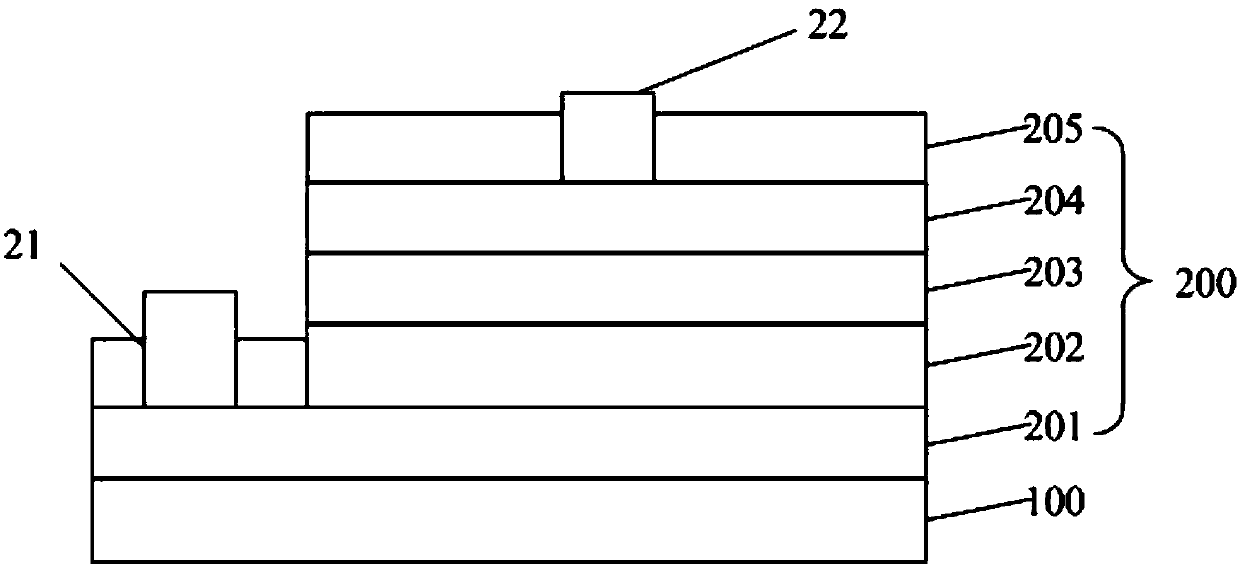

Manufacturing method for removing DBR film

The invention provides a manufacturing method for removing a DBR film. The method comprises steps: an LED wafer is provided, wherein the bottom part of the LED wafer is provided with the DBR film; theDBR film is etched to form first holes; dry etching is carried out on the first hole to form second holes passing through the DBR film; and wet drying is carried out on the DBR film, and the DBR filmis removed. Photoetching is firstly carried out on the DBR film to form multiple first holes with the same specification and the same size, subsequent etching is facilitated, and the DBR film is smoothly removed finally; further, through forming the second holes, an etching solution can be permeated between the DBR film and the substrate of the wafer conveniently, the DBR film can be removed conveniently, and the DBR film removal rate is improved.

Owner:FOSHAN NATIONSTAR SEMICON

Silicon dioxide extraction process based on highland barley husks

The invention discloses a silicon dioxide extraction process based on highland barley husks, and belongs to the technical field of material recovery. During extraction, the process includes washing the highland barley husks with water, and drying and smashing the husks to obtain highland barley husk powder; carrying out hydrothermal carbonization reaction on the highland barley husk powder and a sulfuric acid solution, instantly releasing pressure, discharging, performing filtration, collecting a filter cake, and washing the filter cake with deionized water until a washing solution is neutral;freezing the washed filter cake with liquid nitrogen, grinding the filter cake, and unfreezing to obtain an unfrozen material; pouring the unfrozen material into a saturated ammonium nitrate solution, removing surface floaters, collecting lower-layer precipitates, and performing vacuum freeze drying on the lower-layer precipitates to obtain a refined material; putting the refined material into atubular furnace, slowly heating in an oxygen atmosphere, calcining the material, cooling and discharging to obtain a calcined material; and repeatedly washing the obtained calcined material with water, and carrying out vacuum freeze drying to obtain refined silicon dioxide, thereby completing the silicon dioxide extraction process of the highland barley husks. The silicon dioxide extraction rate is high, and the product has high purity.

Owner:崔建中

Threshing device used for long-stem crop

PendingCN110896737ARemoved smoothlySmooth removalMowersCuttersAgricultural scienceAgricultural engineering

The invention relates to the field of agricultural machinery, and provides a threshing device used for a long-stem crop. The threshing device comprises a threshing component, a screening component anda material collection component, wherein the threshing component comprises a roller and a shell; the roller can be rotatably arranged in the shell; the excircle surface of the roller is provided witha first threshing device; the inner wall of the shell is provided with a second threshing device cooperated with the first threshing device; the lower side plate of the shell is provided with a material falling hole; the screening component is arranged on a position which is below the threshing component and corresponds to the material falling hole, and is used for filtering impurities in particles; and the material collection component is arranged below the screening component and is used for collecting the particles. By use of the threshing device provided by the invention, the successful removal, impurity removal and collection of the particles of long-stem crops, including Vicia villosa Roth and the like, can be effectively improved, the particle removal difficulty of the long-stem crops, including Vicia villosa Roth and the like, can be lowered, and removal and collection efficiency is improved. The threshing device is suitable for large agricultural machinery and is favorable for developing to a quick, efficient and mechanical direction.

Owner:SHENYANG AGRI UNIV

Sample collecting method for detecting local roughness of soil surface

InactiveCN108801202AReduce labor intensityEasy to operatePreparing sample for investigationSoil scienceSurface roughness

The invention discloses a sample collecting method for detecting local roughness of a soil surface. On the basis of cooperation of a soft and dry bar-shaped object with a gluing agent, the flexible bar-shaped object is processed into a hard bar-shaped object; and the roughness of the formed hard bar-shaped object is consistent with that of to-be-detected soil. Therefore, the soil surface roughnessof the to-be-detected position can be simulated and depicted well based on combination of the soft and dry bar-shaped object with the gluing agent; the local position of the soil can be sampled; theoperation becomes simple; post-stage detection is carried out conveniently; the high detection precision is ensured; and the labor intensity of the operator is reduced.

Owner:FOSHAN GAOMING XILUO TECH CO LTD

Die casting deburring device with multi-angle rotating mechanism

PendingCN113385757AEffectively fixedFlat surfaceMachining working media supply/regenerationElectrical-based auxillary apparatusDie castingStructural engineering

The invention discloses a die casting deburring device with a multi-angle rotating mechanism. The die casting deburring device comprises a reaction box, a rotating unit, a fixing unit and a surface treatment unit, the rotating unit is installed on the wall face of the reaction box, one end of the rotating unit is located outside the reaction box, the other end of the rotating unit extends into the reaction box, the ends, extending into the reaction box, of the fixing unit and the rotating unit are fixedly connected, the surface treatment unit is located on the inner side of the reaction box, and the surface treatment unit is fixedly connected with the inner side wall of the reaction box. According to the die casting deburring device, through cooperation of a burr treatment assembly and a flattening assembly, burrs on the surface of a workpiece are removed, the surface of the workpiece with the burrs removed is flattened, a hole detection block is designed for a blind hole in the surface of a die casting, and it is guaranteed that the inner surface of the blind hole can be treated.

Owner:江苏中科云控智能工业装备有限公司

Device capable of removing soldering tin of partial components on circuit board

The invention discloses a device capable of removing soldering tin of partial components on a circuit board. The device capable of removing the soldering tin of the partial components on the circuit board comprises a shell; a working cavity with an upward opening is formed in the shell; a slide block is arranged on the lower wall of the working cavity in a mobile manner; an advancing cavity is formed in the slide block; a screw rod is slidingly arranged on the left and right wall of the advancing cavity in a communication manner; an annular cavity with an inward opening is formed in the side wall of the working cavity in a surrounded manner; an annular rack is arranged on the lower wall of the annular cavity; a steering wheel is fixedly connected to the right end of the screw rod; the lower end of the steering wheel is engaged with the annular rack; and a switching wheel is connected to the screw rod through threads. According to the device capable of removing the soldering tin of thepartial components on the circuit board, the soldering tin of the components on the circuit board can be selectively removed, and the components can be taken off; when the circuit board is put into the device, the circuit board can be well fixed by a clamping device so as to smoothly remove the soldering tin; during removing the soldering tin, the removing device can move in all directions so as to remove the soldering tin in each position; and moreover, during removing the soldering tin, the soldering tin is removed through vacuum suction so that the device is convenient and fast.

Owner:方德兰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com