Shredding device for maize harvesting machine impurity removal draught fan

A technology of corn harvester and chopping device, which is applied in the direction of harvesters, agricultural machinery and implements, cutters, etc., which can solve the problems of large impurity particles discharged, increased load of peeling machines, and blockage of impurity exhaust fans, etc., and achieve fine particle size , Improve the efficiency and reliability of use, and facilitate the use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

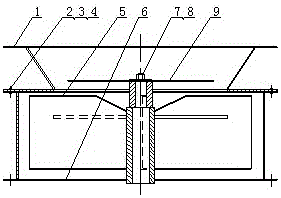

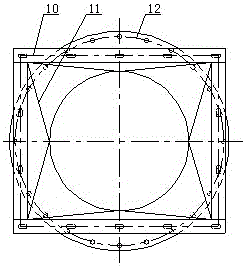

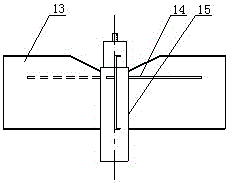

[0023] The corn harvester fan chopping device includes a feeding port 1, a bolt 2, a nut 3, a gasket 4, a fan blade welding 5, a fan casing welding 6, a shaft nut 7, and a shaft pad slice 8 and shredding blade 9; the feeding port 1 is connected with the fan housing welding 6 through bolts 2, nuts 3 and washers 4, the fan blade welding 5 is installed inside the fan housing welding 6, and the fan blade welding Combined 5 is made up of 4 rotating blades 13, 4 rotating blades 14 and a rotating shaft 15. The 4 rotating blades 13 are evenly arranged on the rotating shaft 15 along the circumference, and the 4 rotating blades 14 are installed on the 4 rotating blades 13 respectively. One end of the rotating shaft 15 passes through the lower flange 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com