Patents

Literature

34results about How to "Achieve satisfaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

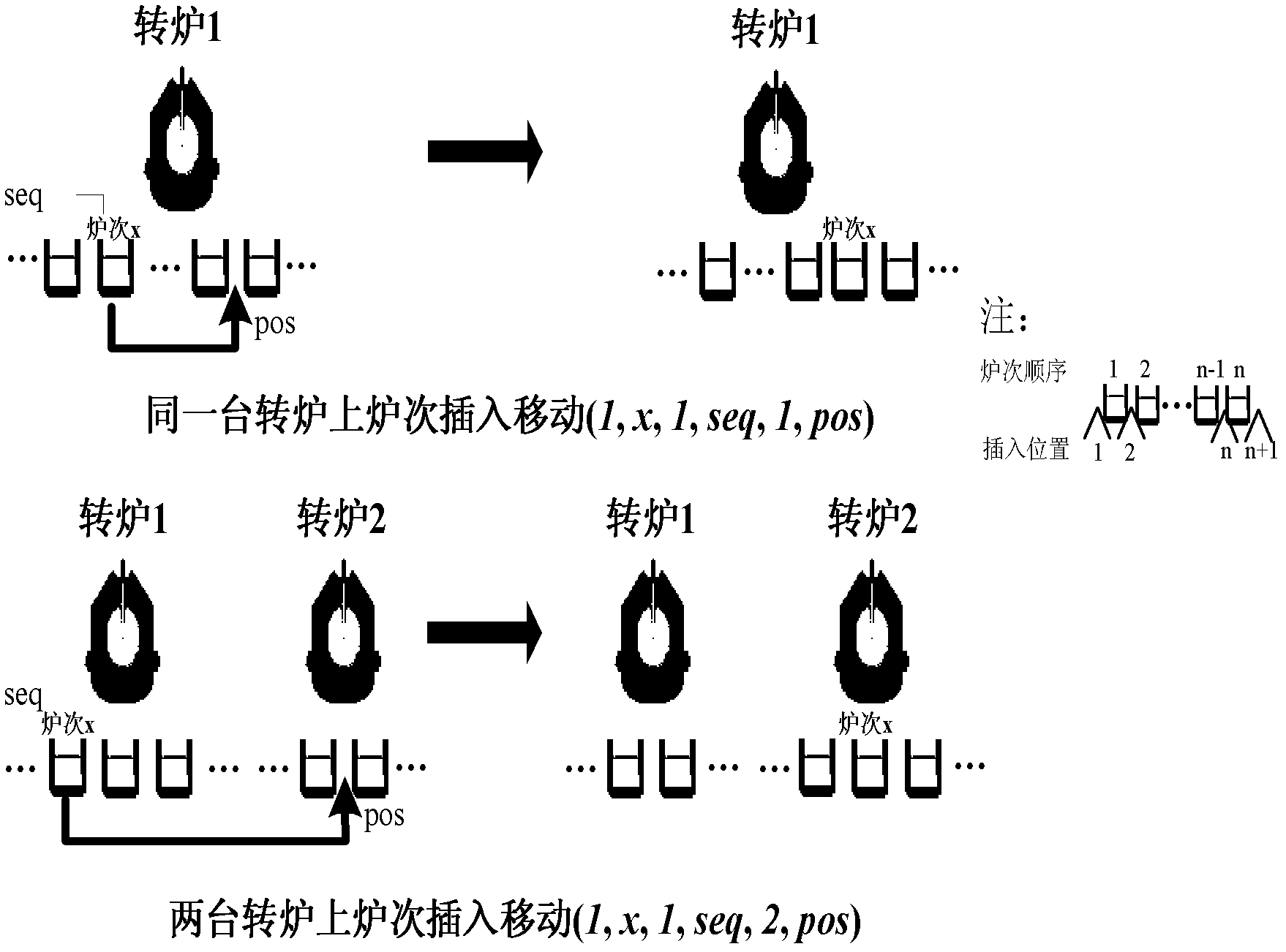

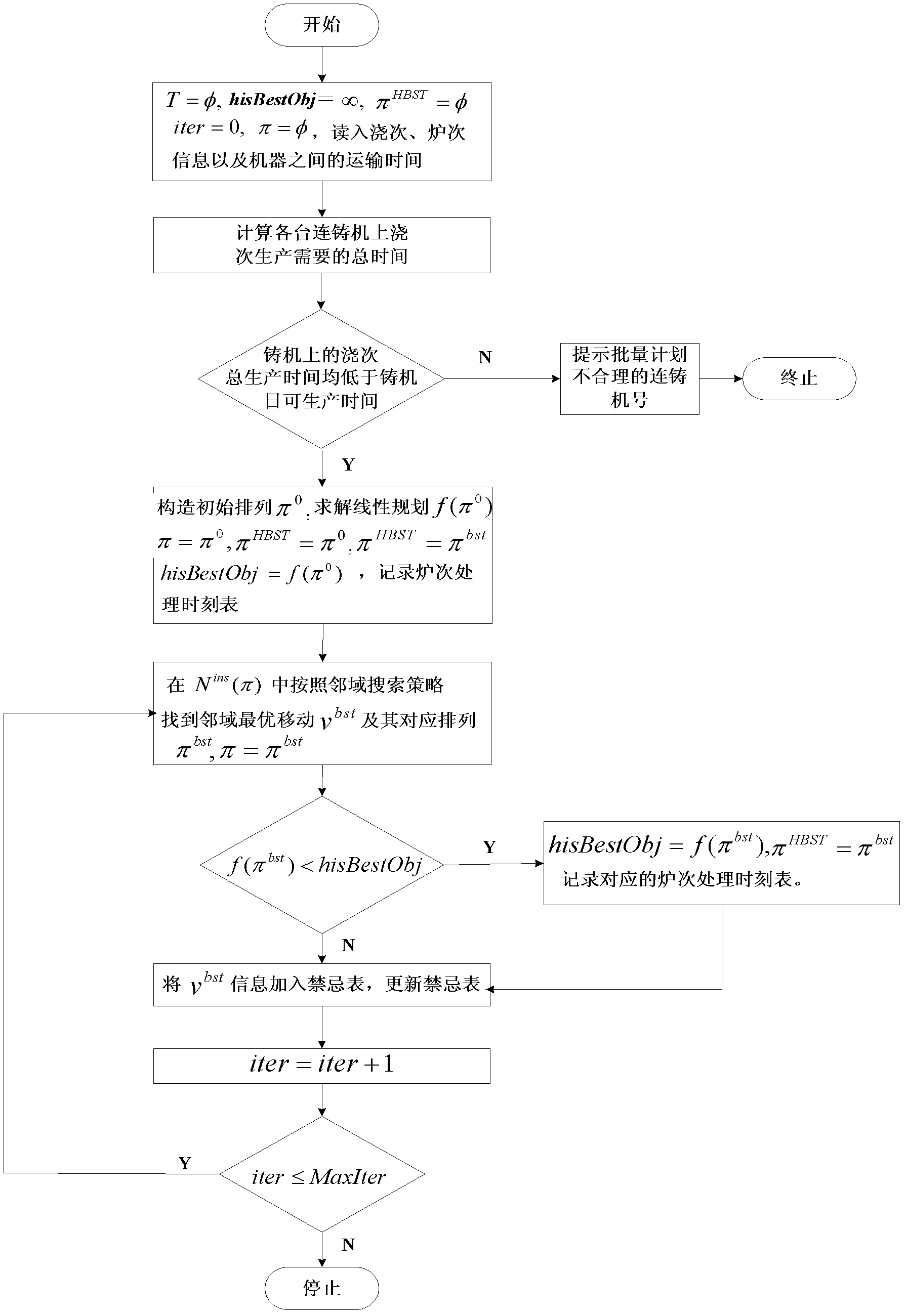

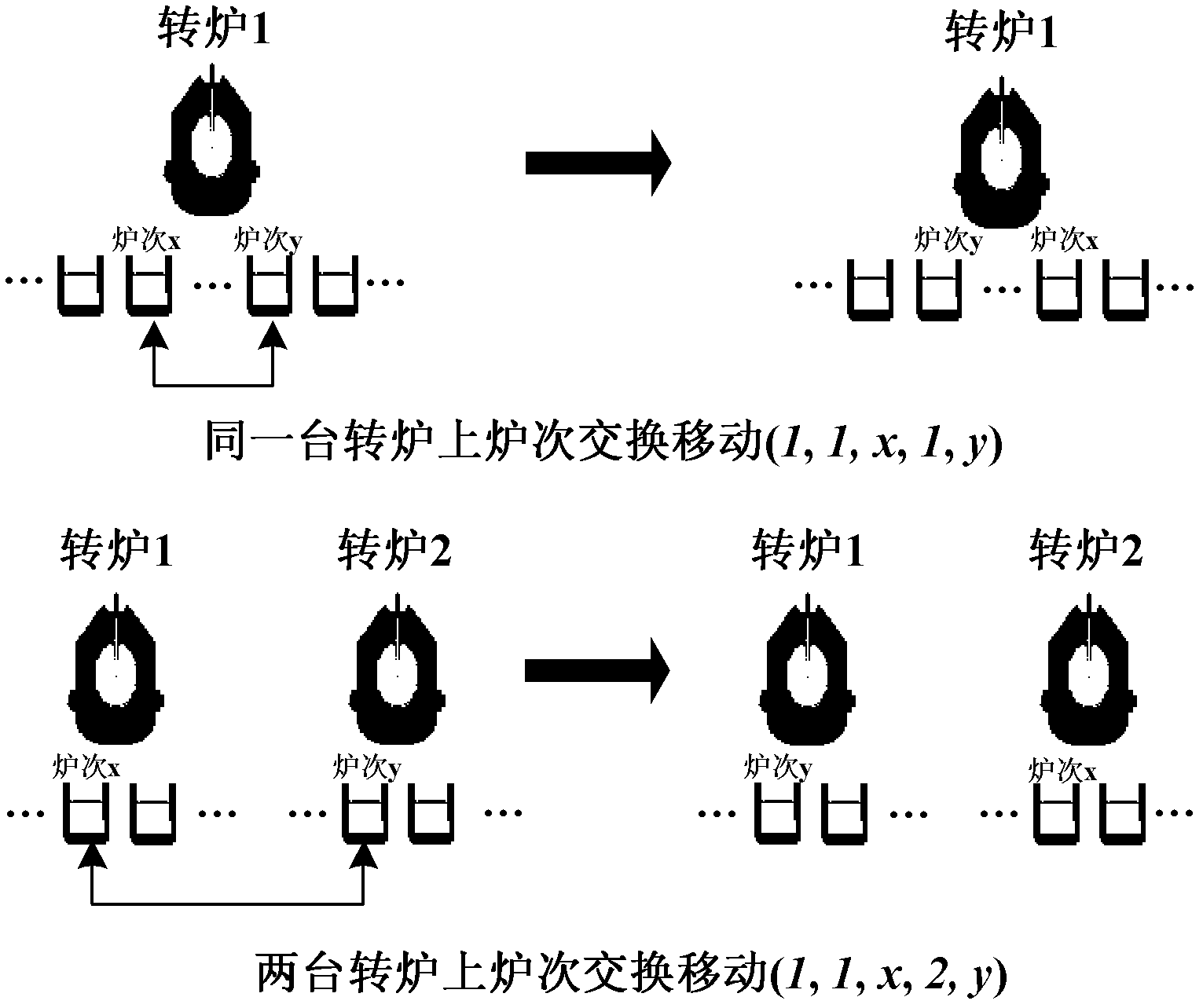

Method for controlling molten steel processing of steelmaking workshop

The invention relates to a method for controlling molten steel processing of a steelmaking workshop. Process constraints in actual production are taken into account to reduce heat losses of molten steel and obtain a process for controlling the molten steel processing of the steelmaking workshop. By adopting the method, prompt production can be achieved, the times of interruption to casting can bereduced, the rate of utilization of production equipment can be increased, the production of a steelmaking plant can be carried out according to the processing startup time of heat on each machine, and the heat can be promptly delivered to a continuous casting machine to ensure continuous casting. Meanwhile, the load on each refining device is uniform, the failure rate is low, and the productivity of the continuous casting machine and the steelmaking workshop can be improved. By adopting the method, new production schemes can be prepared in a short term according to new production environments so as to deal with unavoidable equipment faults and other unexpected accidents. Due to the reasonable and efficient control of the molten steel processing progress, the heat can be utilized on the reasonable machine, excessive heat delivery can be reduced, energy can be saved, the logistic cost can be decreased, the waiting time of molten steel in different procedures and heat losses of the molten steel can be reduced, and the effects of energy conservation and consumption reduction can be achieved.

Owner:NORTHEASTERN UNIV

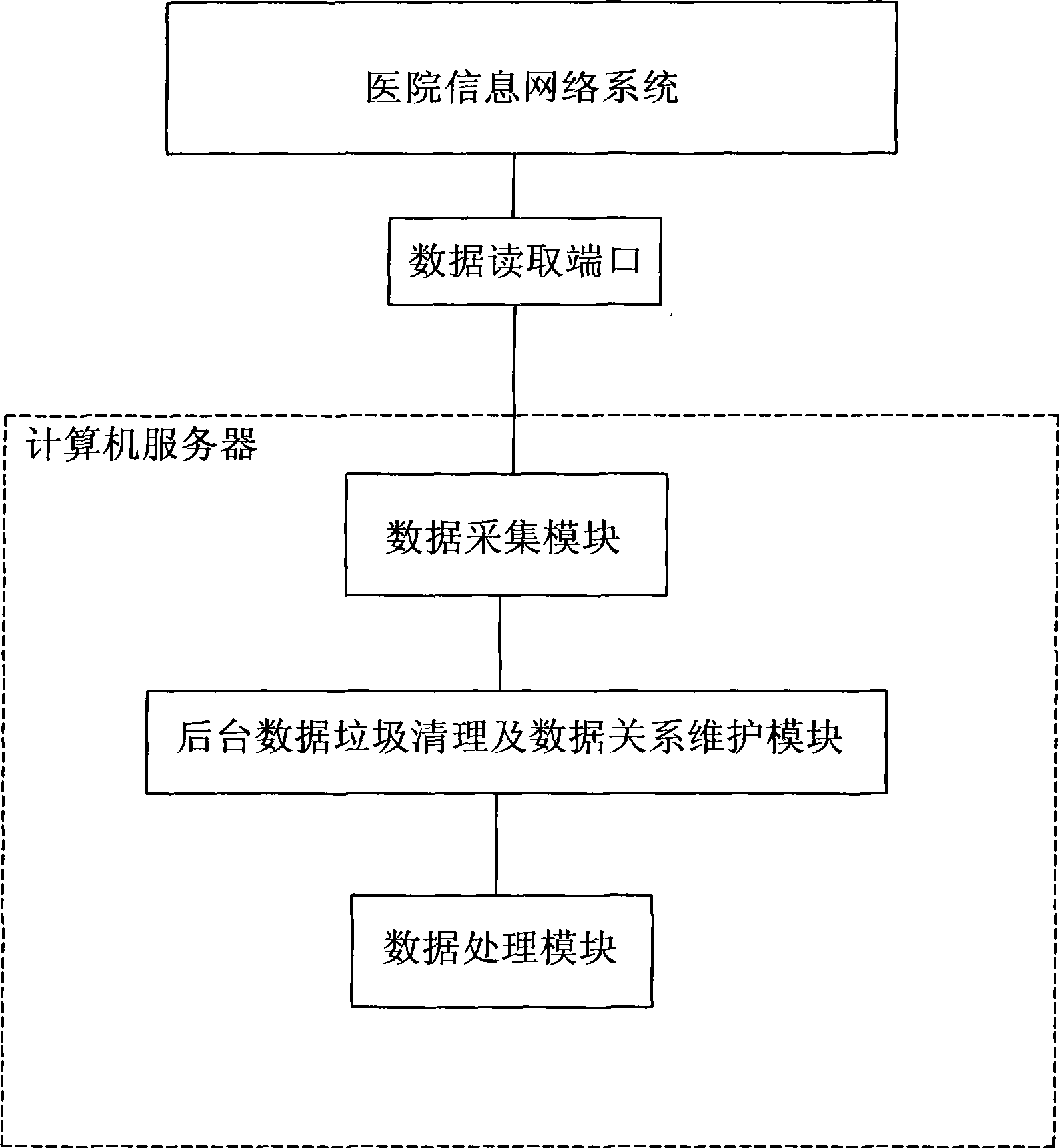

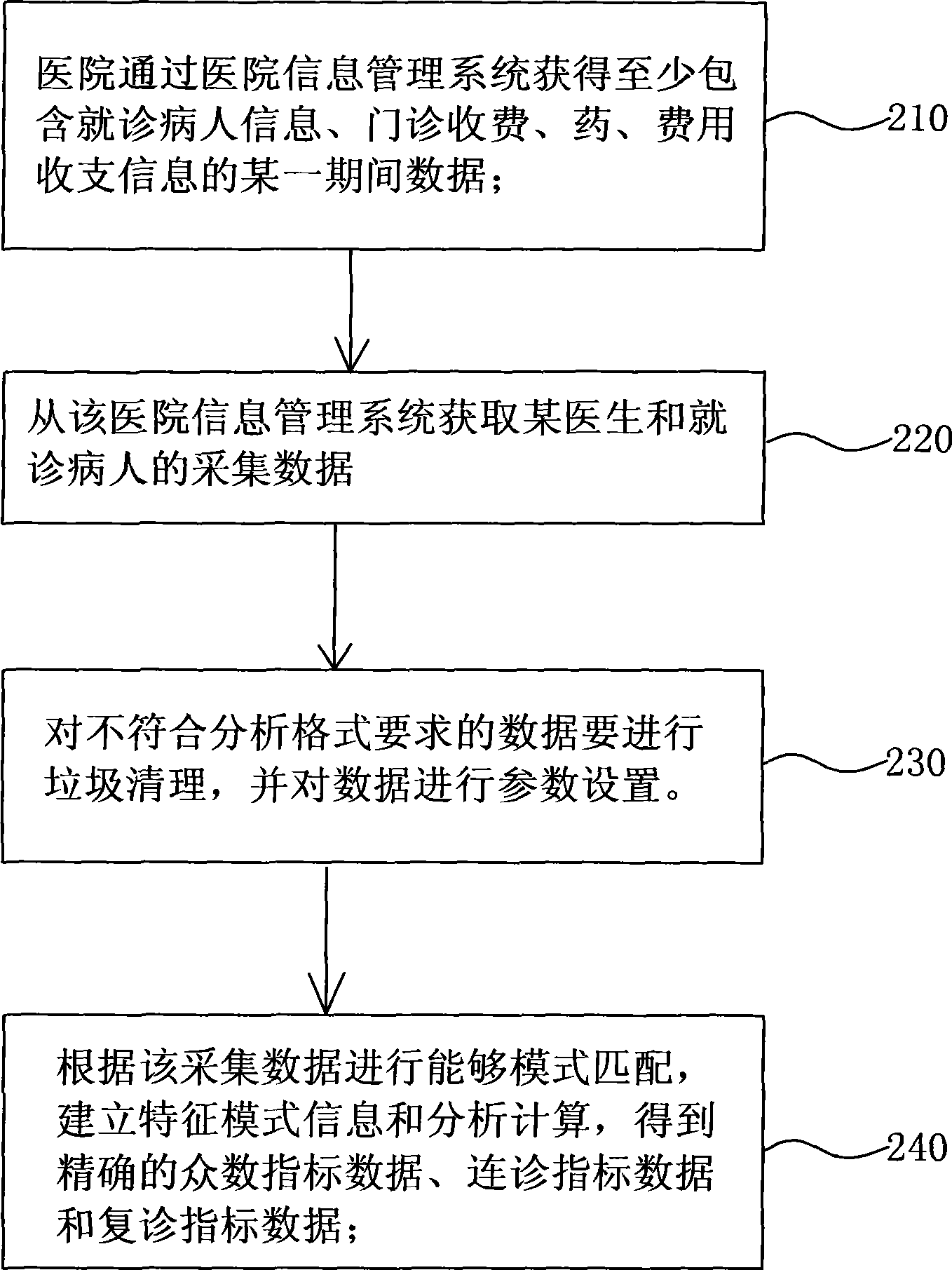

Clinic doctor check evaluating system and evaluating process

InactiveCN101546418AAchieve satisfactionReasonable designData processing applicationsPattern matchingData acquisition

A clinic doctor check evaluating system is used for evaluating the medical service process and result, composed of a hospital information management system arranged at each window of the hospital for collecting the hospital management and out-patient clinic information; a data acquisition module for acquiring the collected information from some doctor and patient from the hospital information management system through a data read port; a data processing module for mode matching to the collected data according to the patient record characteristic and establishing the characteristic pattern information to get the operation check evaluating result for the doctor.

Owner:BEIJING LANGFUTIANJIAN PHARMA TECH CORP

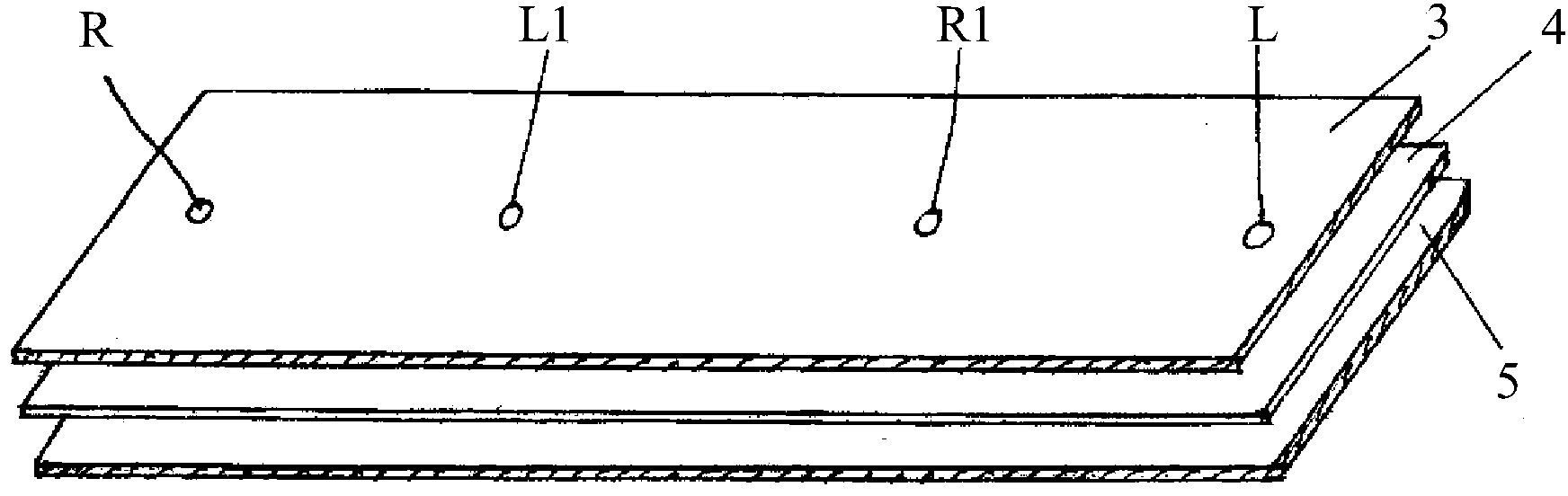

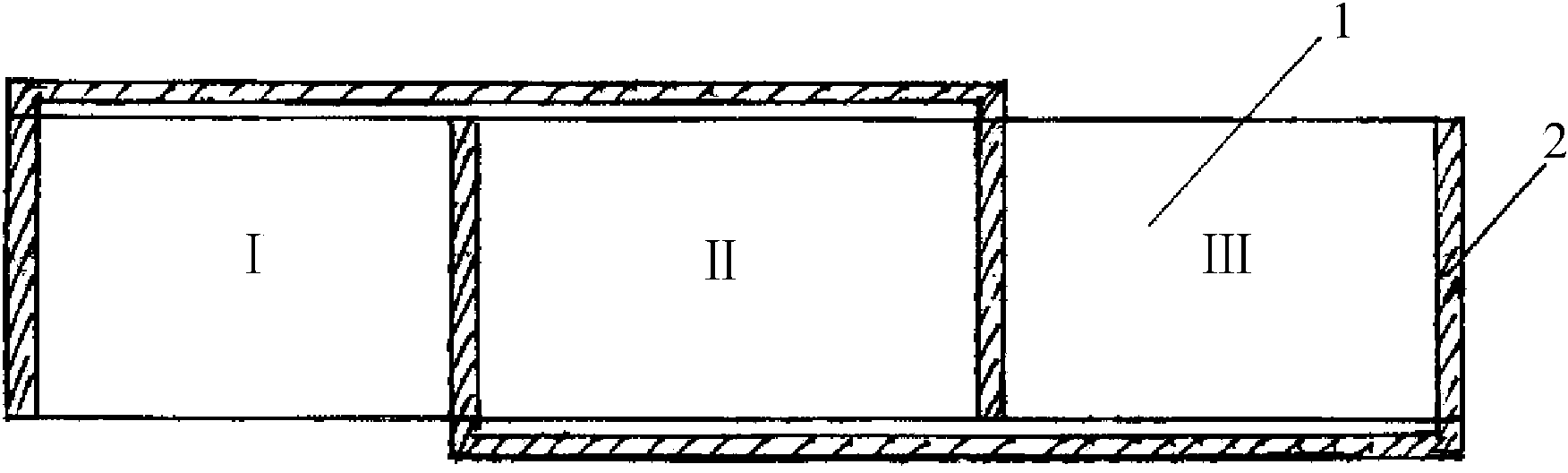

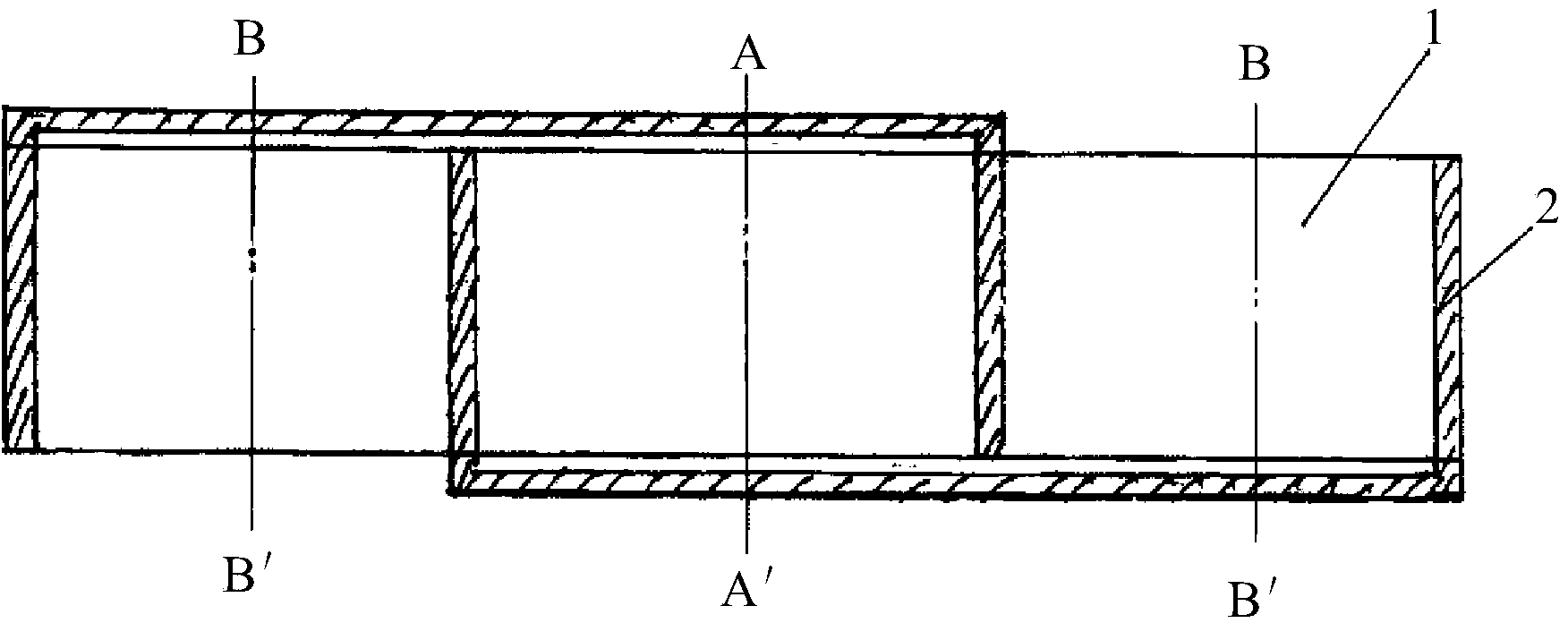

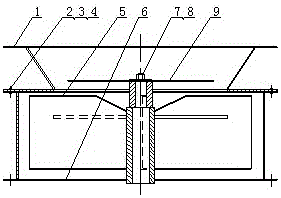

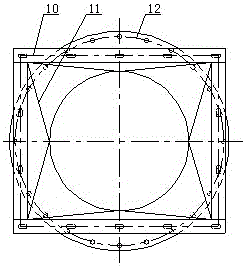

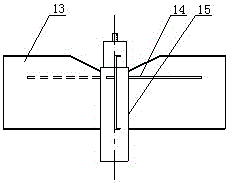

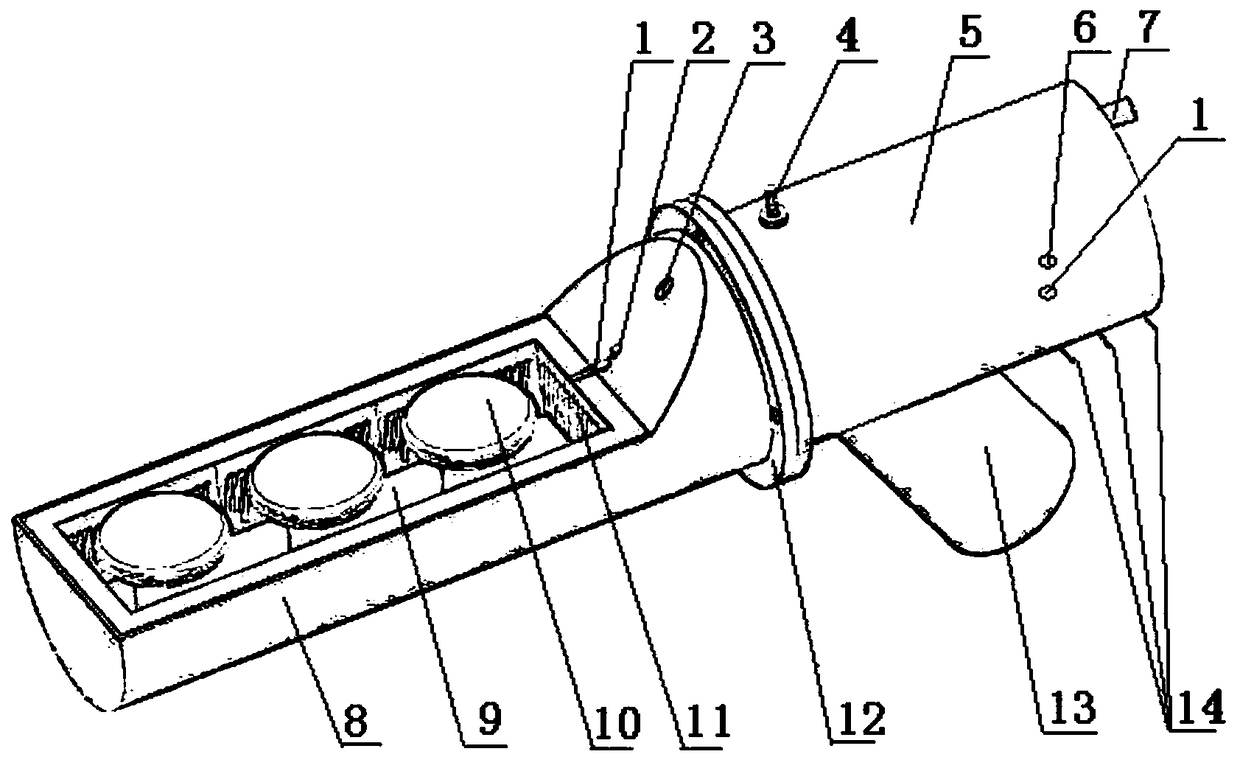

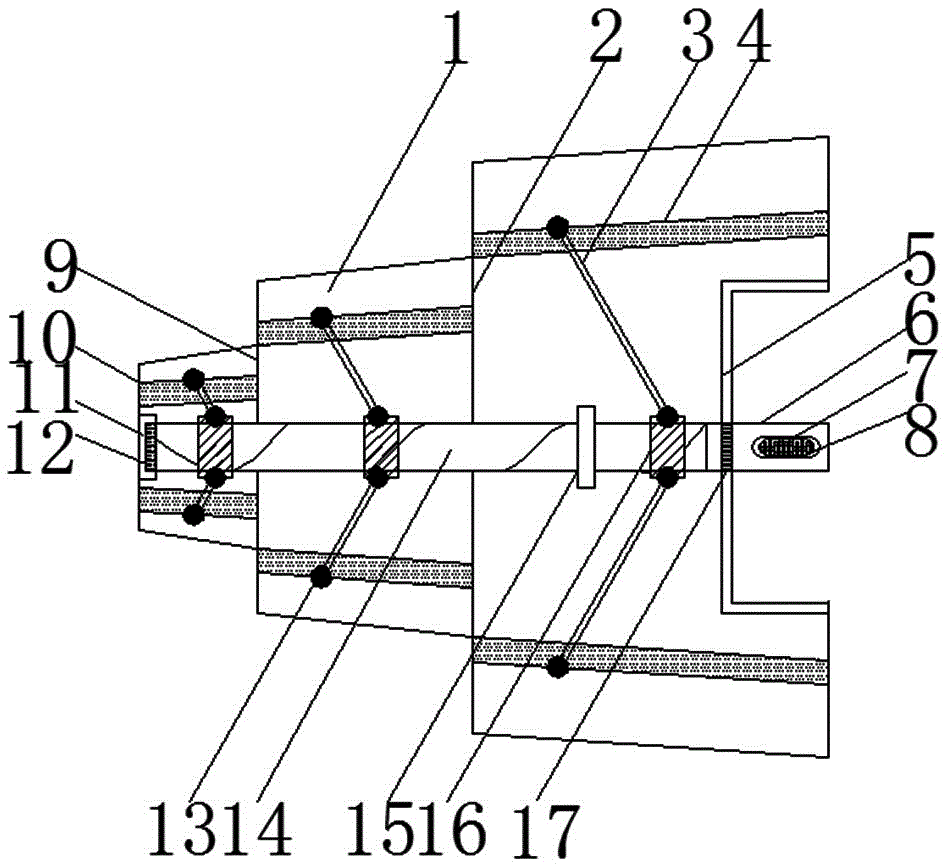

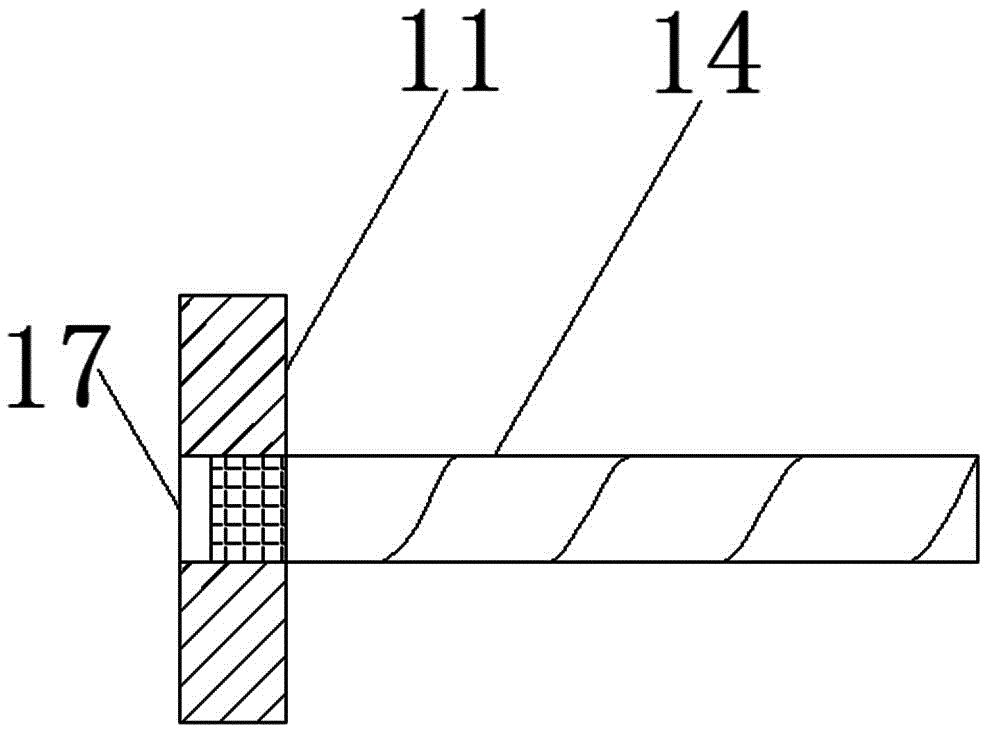

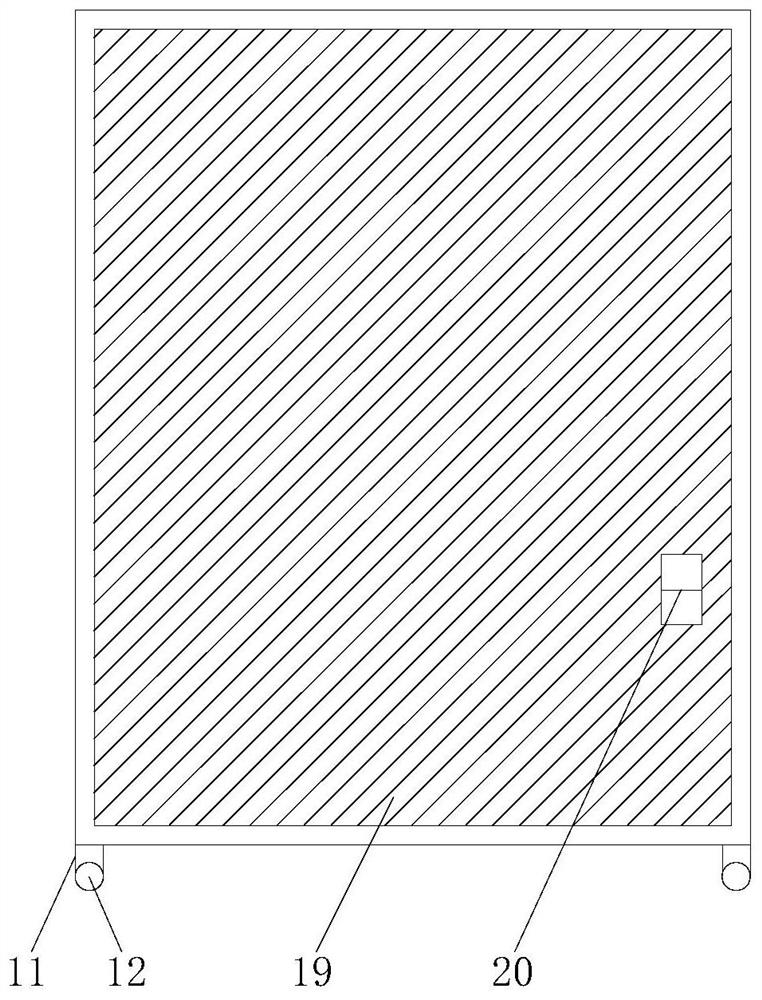

Carbon fiber or carbon crystal electric heating floor capable of being cut at random and mounted conveniently, and use method

ActiveCN103742970AEasy constructionAchieve satisfactionLighting and heating apparatusElectric heating systemFiberCarbon fibers

The invention relates to the field of electric heating floors, in particular to a carbon fiber or carbon crystal electric heating floor capable of being cut at random and mounted conveniently, and a use method. The carbon fiber or carbon crystal electric heating floor solves the problems that the existing electric heating floor cannot be cut at random, and has a larger cold edge and the like. A carbon fiber electric heating core or a carbon crystal electric heating core is located between a composite floor backboard and a composite floor panel; wiring holes are formed in the composite floor backboard; power supply anode connecting lines and power supply cathode connecting lines penetrate through the wiring holes respectively and are connected to an electrode in the carbon fiber electric heating core or the carbon crystal electric heating core; independent heating areas of the carbon fiber electric heating core or the carbon crystal electric heating core are heated respectively or simultaneously; the carbon fiber electric heating core or the carbon crystal electric heating core is carbon fiber heating paper or in a carbon crystal heating paper and electrode composite structure; the carbon fiber heating paper or the carbon crystal heating paper is divided into two or more independent heating areas; and the independent heating areas are connected into a whole by the electrode. Therefore, the floor can be cut transversely and vertically, and the scope within the cold edge meeting the specification is the heating area.

Owner:SHENYANG BEIME WOOD IND

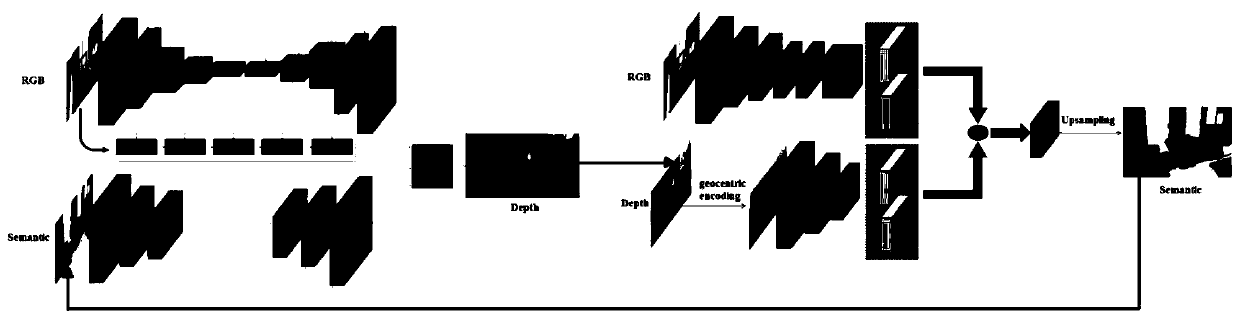

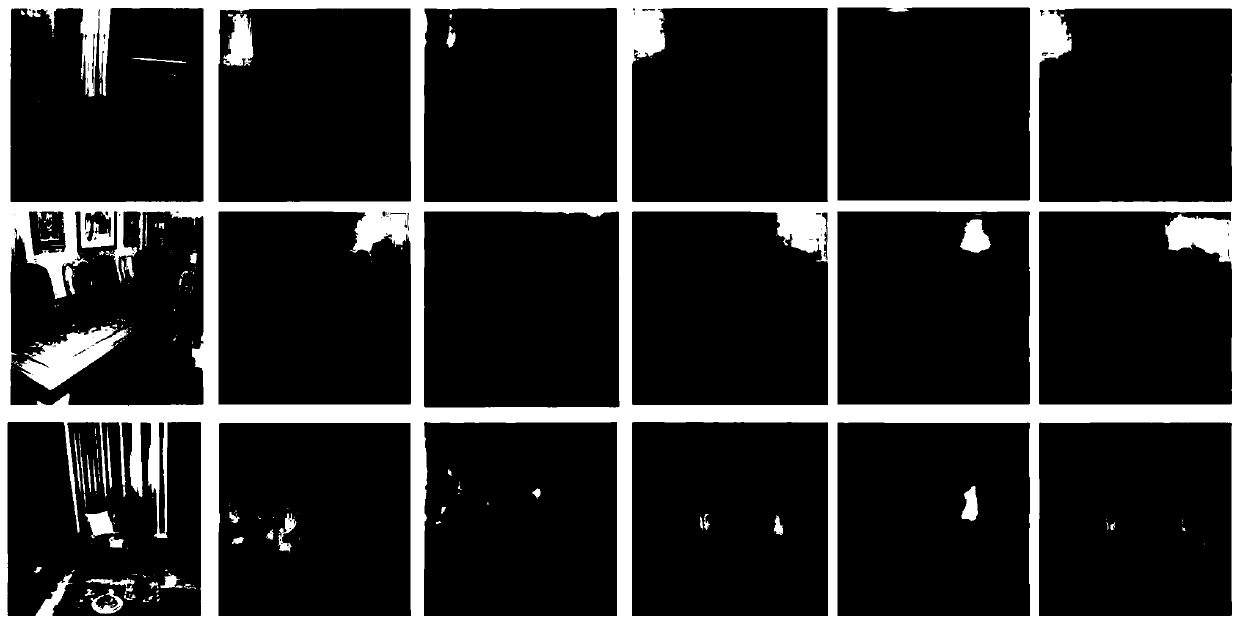

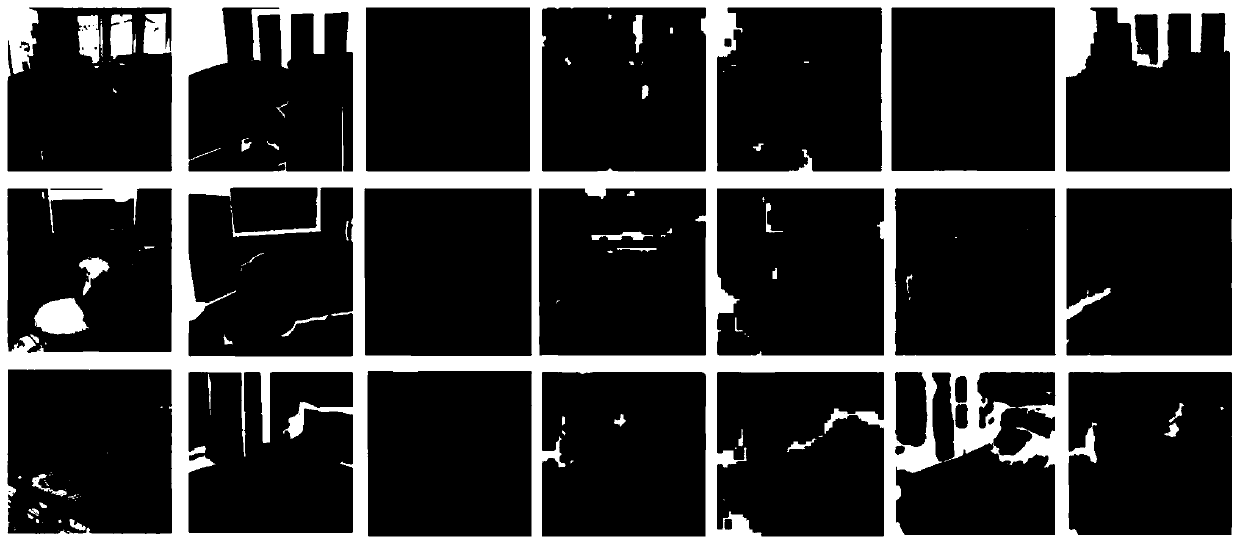

Method for joint estimation of scene depth and semantics by single image

ActiveCN110120049AEasy to implementAchieve satisfactionImage enhancementImage analysisColor imageImaging processing

The invention belongs to the field of computer vision and computer graphics. An iterative network is designed to jointly estimate depth information and semantic information, and mutual prediction results are improved by utilizing complementary characteristics between the depth information and semantic information. According to the technical scheme, the method for jointly estimating the scene depthand the semantics through the single image comprises the following steps: performing photographing through any device with a monocular camera, and using an obtained color image as input of a network;and 2) iteration network: inputting a color image into a framework formed by a multi-task depth convolution network and used for depth estimation and semantic segmentation iteration combined optimization, estimating depth and semantic information of the color image, using the depth information to reconstruct a three-dimensional scene, and using the semantic information to realize understanding ofthe scene. The method is mainly applied to an image processing occasion.

Owner:TIANJIN UNIV

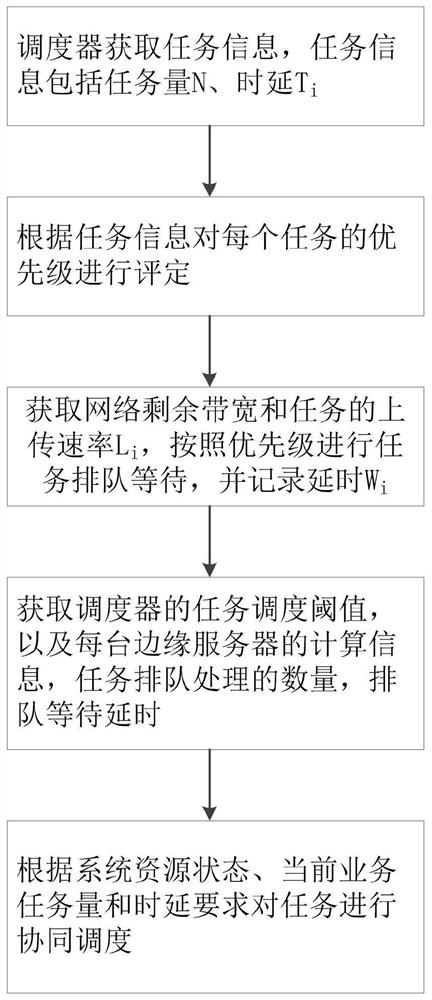

Industrial field big data task coordination degree method based on edge calculation

ActiveCN113032120AAchieve satisfactionRealize reasonable schedulingProgram initiation/switchingResource allocationEdge serverEdge computing

The invention discloses an industrial field big data task coordination degree method based on edge calculation. The method comprises the steps: S1, enabling a scheduler to obtain a task amount Ni and a time delay Ti; S2, evaluating the priority of each task; S3, obtaining the network residual bandwidth R and the uploading rate Li of the tasks, wherein Li represents the uploading rate of the ith task, task queuing waiting is carried out according to the priority, and delay Wi is recorded; S4, obtaining a task scheduling threshold alpha of the scheduler, calculation information of each edge server, the number l of task queuing processing and queuing waiting delay; and S5, carrying out cooperative scheduling on the tasks according to a system resource state, a current business task amount and a delay requirement. According to the invention, resource scheduling of the task between the terminal and the edge server is realized through edge computing, reasonable scheduling of the industrial field task between the terminal equipment and the edge server is achieved, computing resources of the system are fully considered, the task processing capability of the system is improved, the resource consumption of the system can be minimized, and the real-time performance of task scheduling is improved.

Owner:CHONGQING UNIV

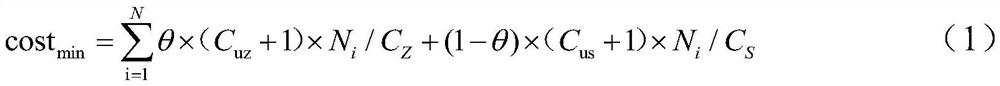

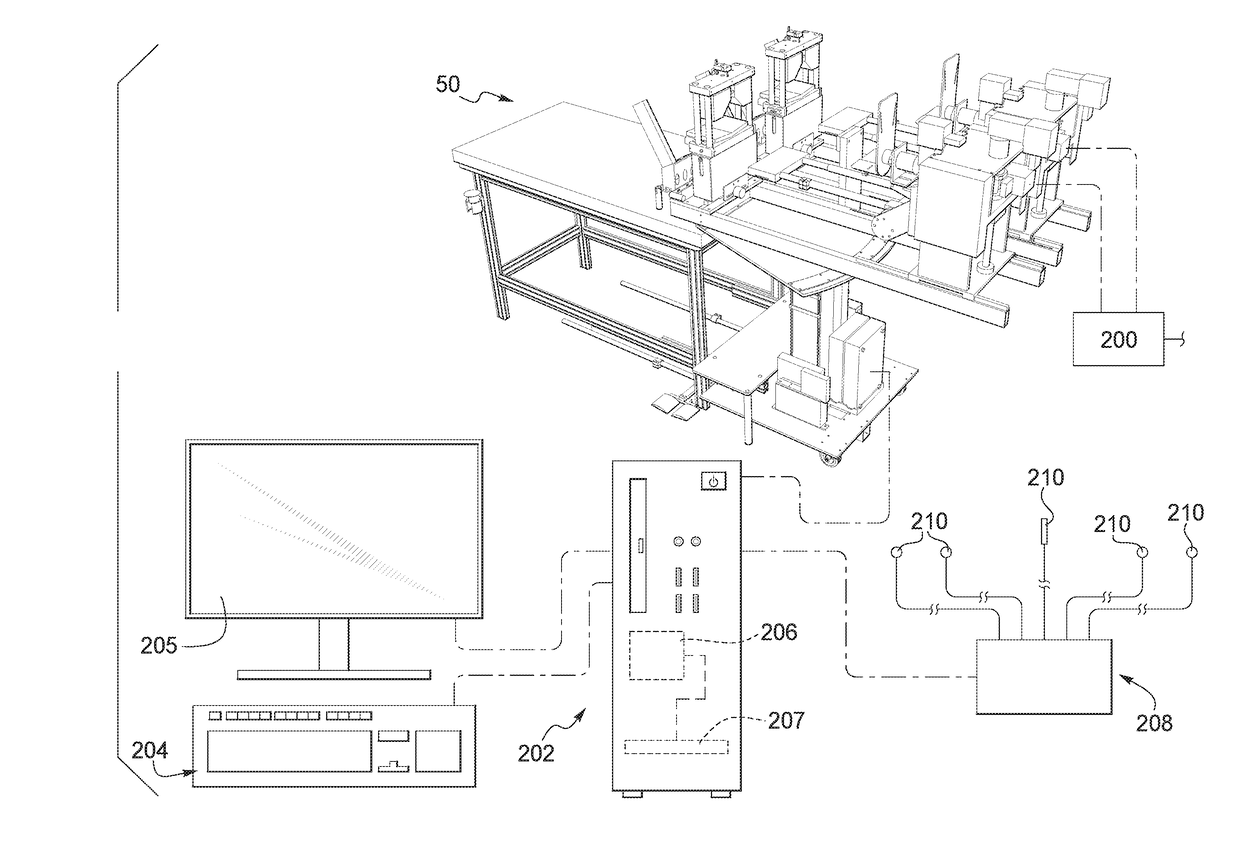

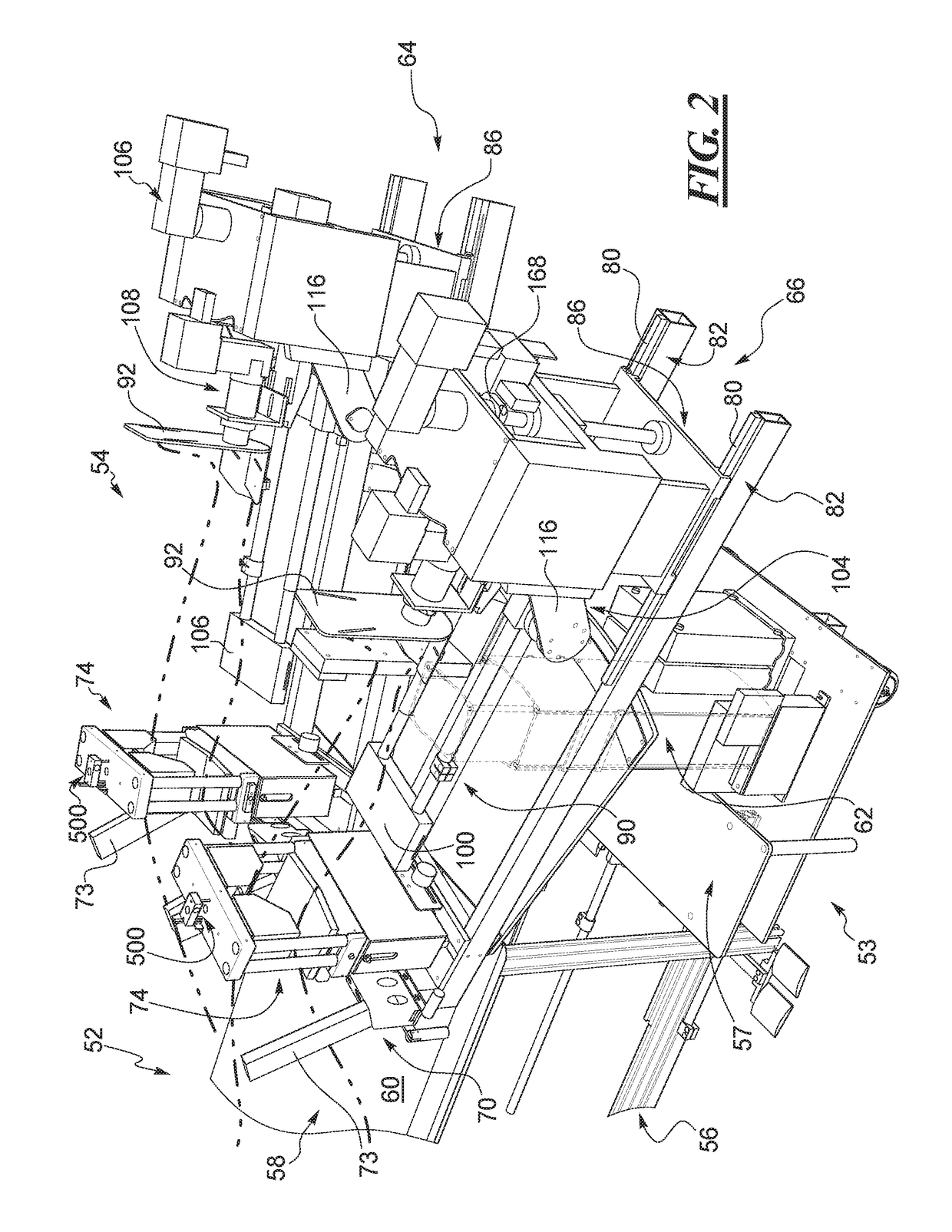

Floating patella sensor, knee stabilizer with same and robotic knee testing apparatus with same

ActiveUS20170143250A1Accurate objective reliable reproducible measureEasy to measureDiagnostic recording/measuringSensorsJoint manipulationKnee Joint

Owner:ERMI

Color scraped cloth scraping and preparation method thereof

The invention relates to a fabric. The fabric does not need printing or dyeing, dyes can be directly scraped on the fabric to dye the fabric, and then the fabric is moulded. The invention also discloses a pollution-free color scraped cloth scraping and a preparation method thereof. The scraping is prepared from the following components in percentage by weight: 56 to 65% of acrylic emulsion, 27 to 33% of titanium dioxide, 1.8 to 2.2% of thickening agent, 0.8 to 1.2% of ammonia water, 1.8 to 2.2% of antifoaming agent, and 3.5 to 5.5% of dye. The fabric does not need printing and dyeing, a foaming coating is added on the fabric, the color of the front surface can be obtained through adjusting the formula of color paste, and the requirements of customers can be met.

Owner:浙江华辰新材股份有限公司

Shredding device for maize harvesting machine impurity removal draught fan

InactiveCN106688455AImprove reliability and efficiencyEasy to useMowersThreshersFlangeEconomic benefits

The invention relates to a shredding device for a maize harvesting machine impurity removal draught fan. The shredding device comprises a discharging opening, a bolt, a nut, a gasket, a fan blade seam, a draught fan shell seam, an axle nut, an axle gasket and a shredding blade. The discharging opening and the fan shell seam are connected through the bolt, the nut and the gasket. The fan blade seam is installed inside the fan shell seam. The fan blade seam is composed of four rotating vanes, four rotating blades and a rotating shaft, the four rotating vanes are uniformly arranged on the rotating shaft in the circumferential direction, the four rotating blades are installed on the four rotating vanes respectively, one end of the rotating shaft penetrates through a lower flange in the fan shell seam to be connected with a motor, the other end of the rotating shaft is provided with the shredding blade, and the shredding blade is fixed through the axle nut and the axle gasket. Due to the fact that maize straw and other impurities are cut through the shredding blade and the rotating blades two times, particles become finer and smaller, the field returning effect is better, the impurity removal draught fan is not likely to be blocked, the number of impurities entering a peeling machine is small, the service life of the peeling machine is prolonged, and economic benefits are created.

Owner:YONGMENG MACHINERY CO LTD

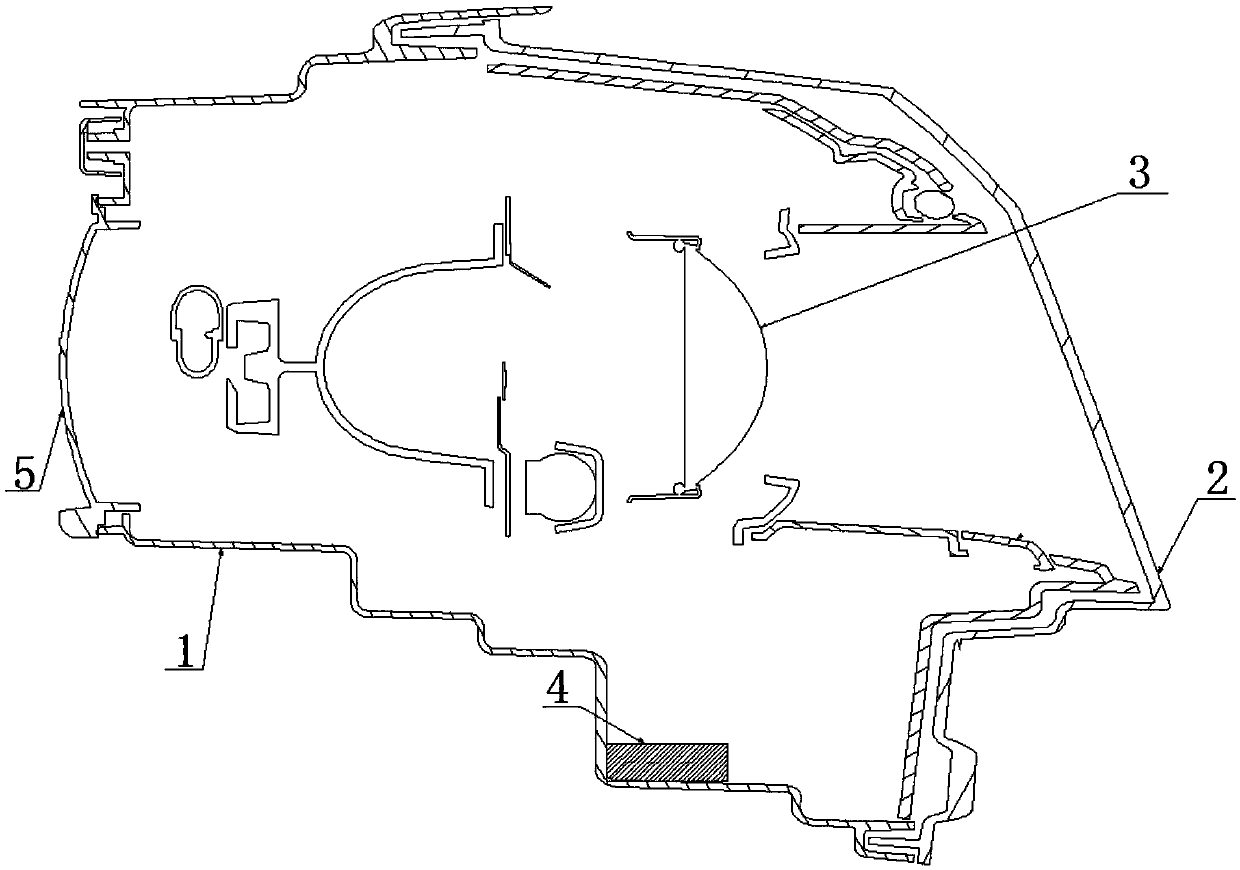

Fogging prevention automotive lamp and automobile

PendingCN109519878AReduce humidityAvoid easy to produce flow marksLighting and heating apparatusSignalling/lighting devicesIrradiationDrying Agents

The invention relates to the technical field of automobile parts, and discloses a fogging prevention automotive lamp. The fogging prevention automotive lamp comprises a lamp body (1) and a lens (2). The lamp body (1) and the lens (2) cooperate to form a sealed cavity. A projection unit (3) is arranged in the sealed cavity, and a drying agent (4), keeping away from the irradiation direction of theprojection unit (3), in the sealed cavity. By means of the fogging prevention automotive lamp, the cost can be greatly reduced, unnecessary parts and surface treatment are eliminated, and the foggingprevention automotive lamp is suitable for a large-scale batched production mode; and the interior of the automotive lamp can be prevented from fogging. The invention further discloses an automobile.

Owner:HASCO VISION TECHNOLOGY CO LTD

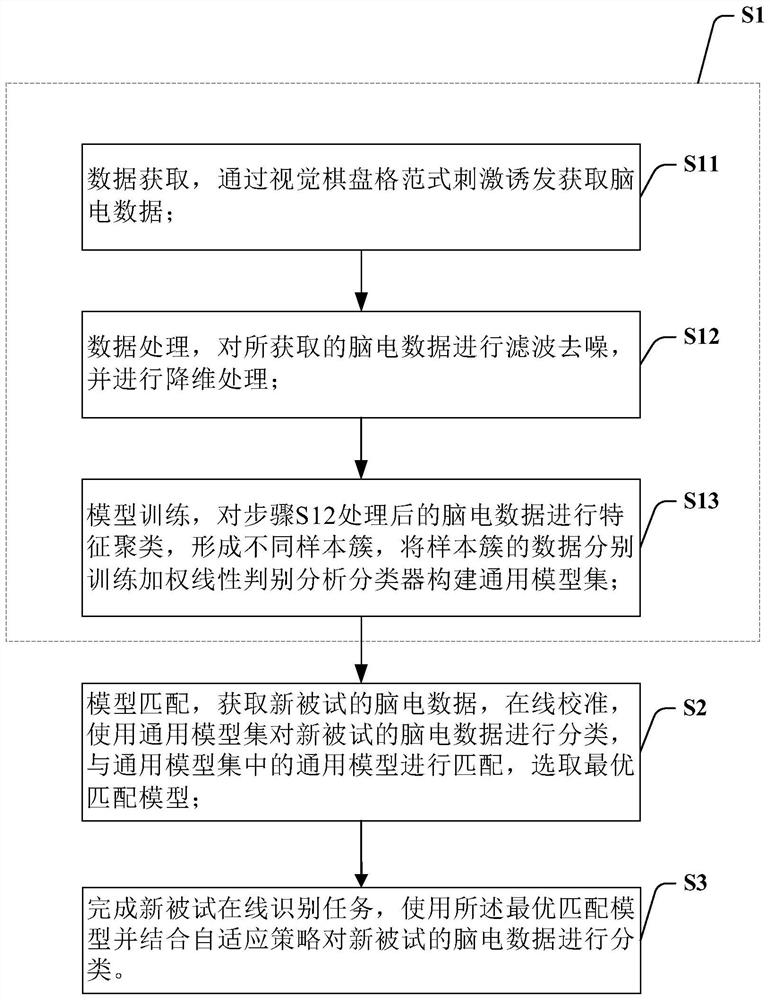

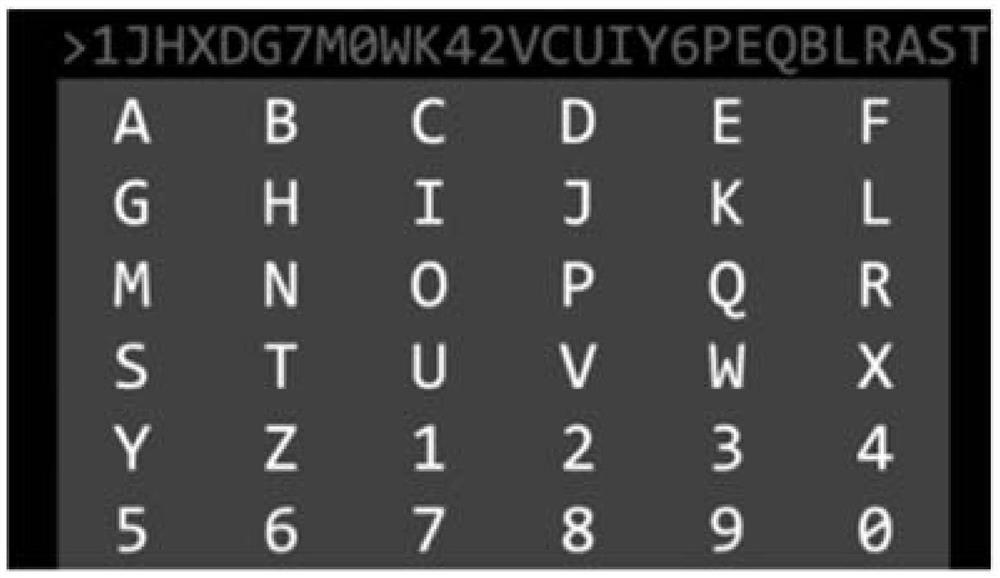

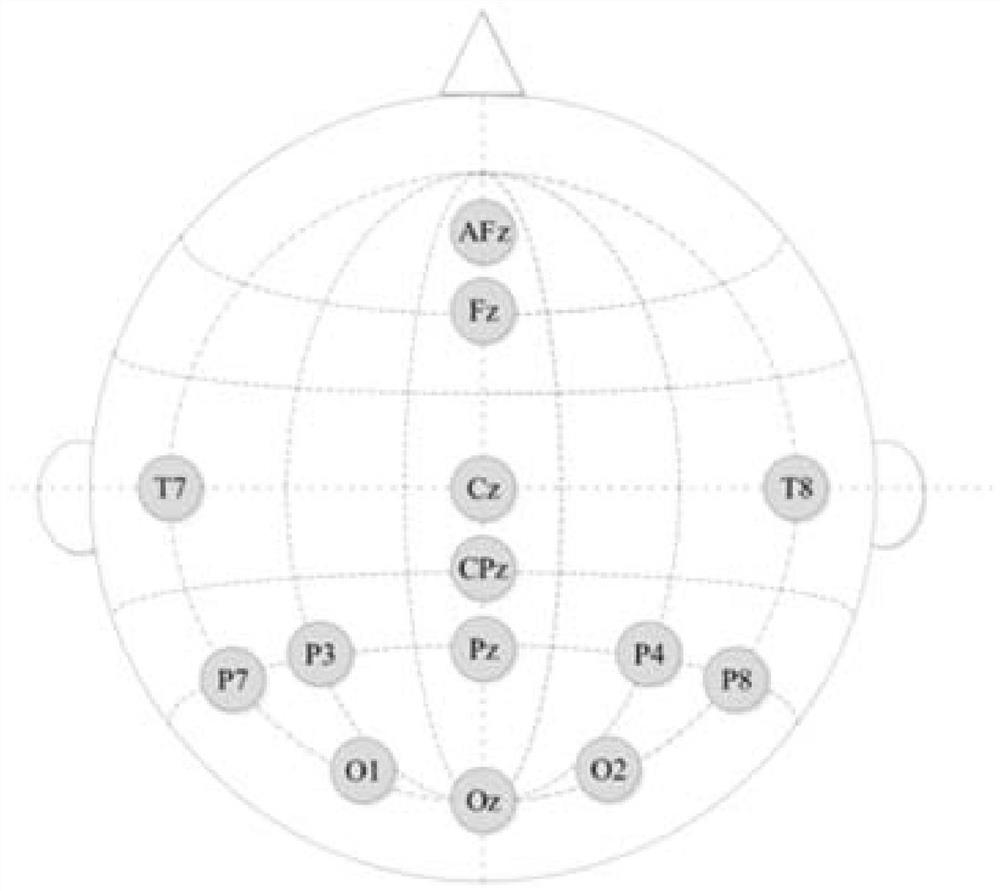

Method and device for reducing P300 training time based on general model

PendingCN113705732AAchieve satisfactionImprove satisfactionCharacter and pattern recognitionDiagnostic recording/measuringEngineeringData mining

The invention relates to a method and device for reducing P300 training time based on a general model. The method for reducing the P300 training time comprises the following steps of S1, establishing a general model set, including the following steps of S11, acquiring data; S12, processing data; and S13, carrying out model training; S2, matching the models, acquiring the new tested electroencephalogram data, performing online calibration, classifying the new tested electroencephalogram data by using the general model set, matching the new tested electroencephalogram data with the general models in the general model set, and selecting an optimal matching model; and S3, completing a new tested online recognition task, and classifying the new tested electroencephalogram data by using the optimal matching model in combination with an adaptive strategy. According to the scheme provided by the invention, the online identification task can be completed only by calibrating a small amount of individual data when a new user joins in.

Owner:EAST CHINA UNIV OF SCI & TECH

Non-adhesive technology of gold plating finger OSP process

ActiveCN104582314ALow costEasy to operatePrinted element electric connection formationTest analysisNickel sulfide

The invention discloses a non-adhesive technology of a gold plating finger OSP process. The non-adhesive technology comprises the following steps: firstly, increasing the purity of nickel bath liquid medicine, and shortening the cleaning maintenance period of the nickel bath liquid medicine so that the cleaning maintenance frequency of the nickel bath liquid medicine is adjusted to be 5-10 days at a time from 30 days at a time; secondly, reducing impurities of the nickel bath liquid medicine, and shortening the Hartz piece test analysis period of flexible and moisture additives in a nickel bath so that the Hartz piece test analysis frequency is adjusted to be 5-10 days at a time from one month at a time; thirdly, eliminating copper ions, taking 3-5 hours as a time period, and conducting cleanup operation on the copper ions adsorbed by nickel sulfide residuals on the surface of an anode nickel film; fourthly, adopting a microetching mode of sulfuric acid matched with hydrogen peroxide by an OSP, and controlling the microetching rate of the OSP to be 30-60 microinches per second. The invention provides the non-adhesive technology of the gold plating finger OSP process.

Owner:SHENGHUA ELECTRONICS HUIYANG +1

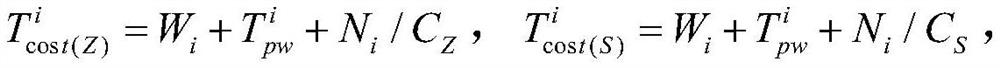

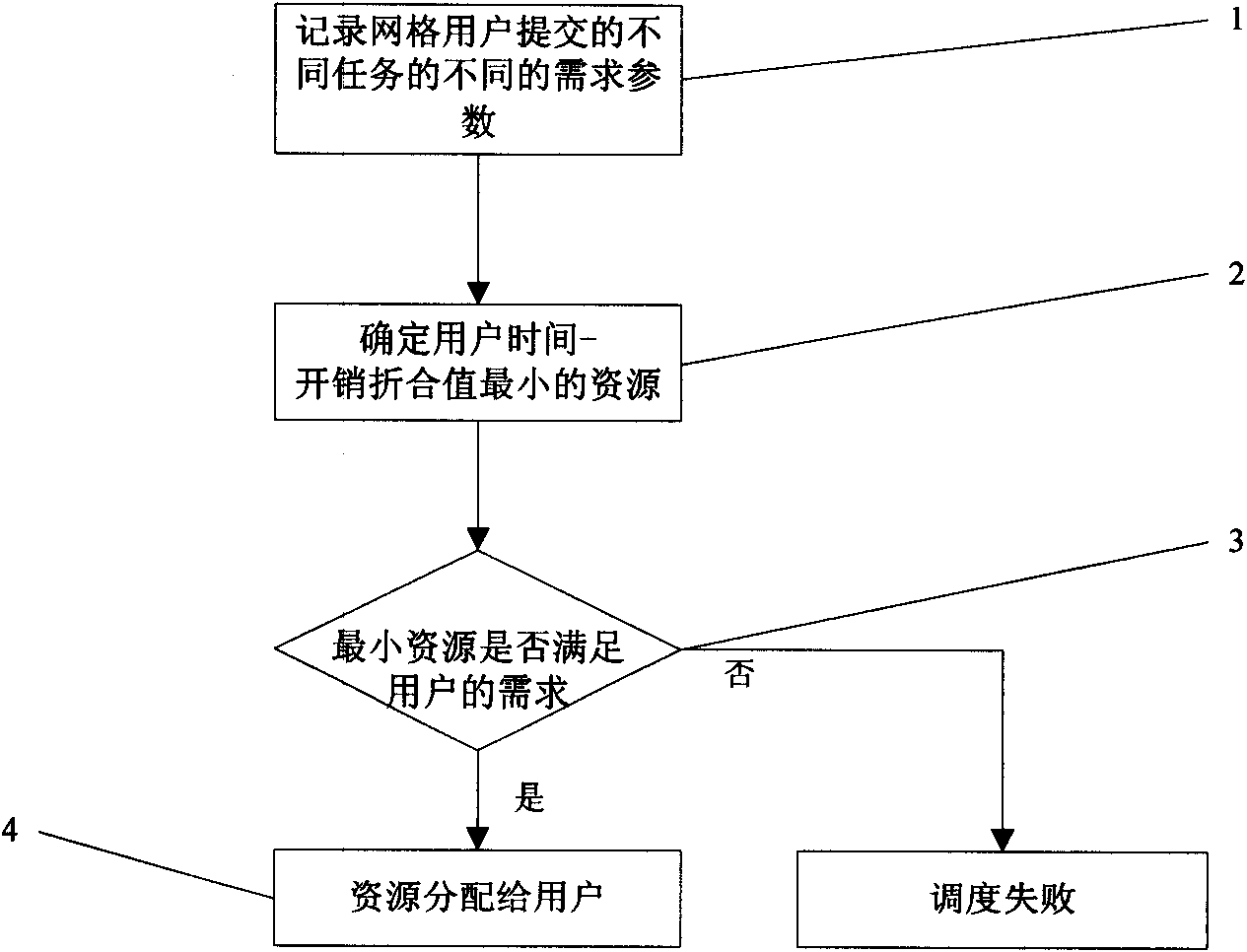

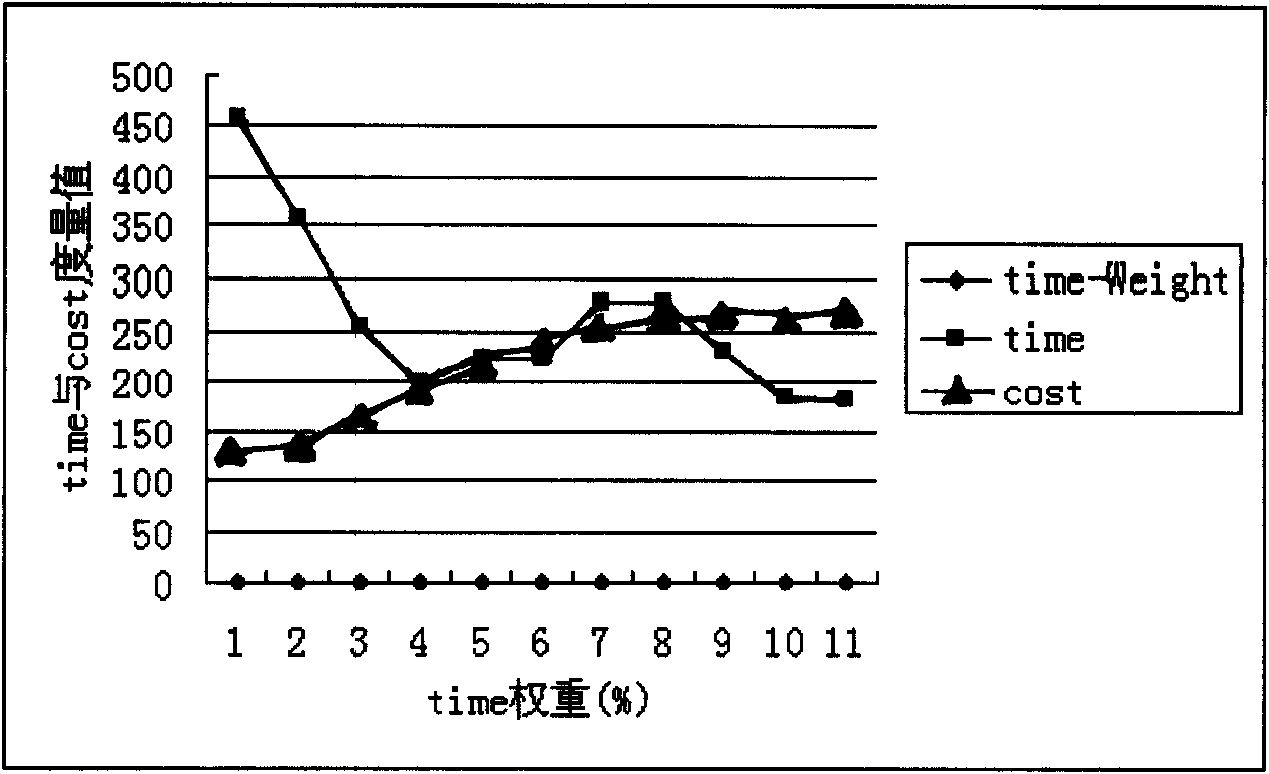

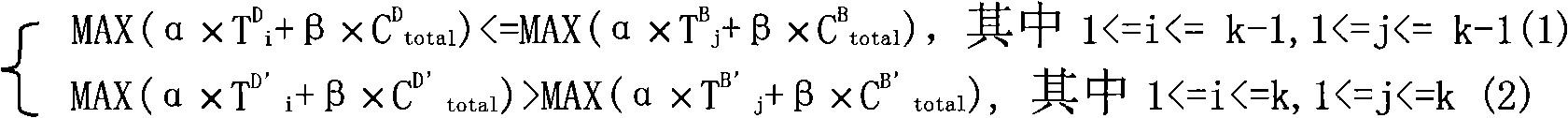

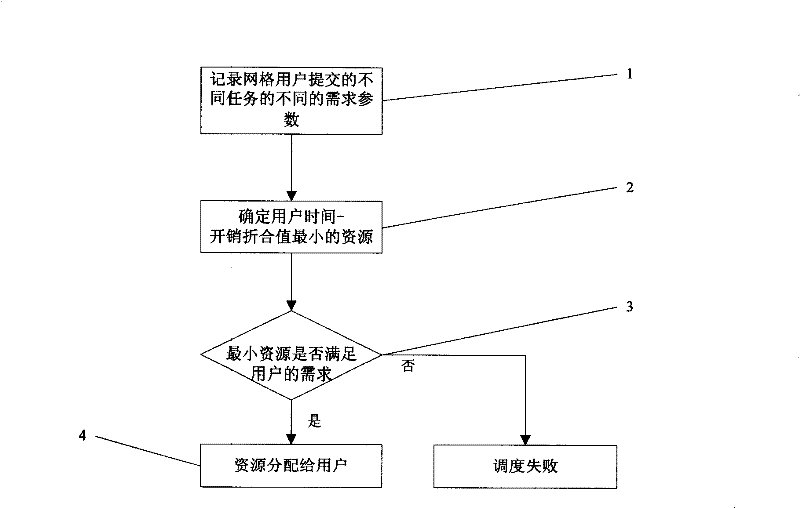

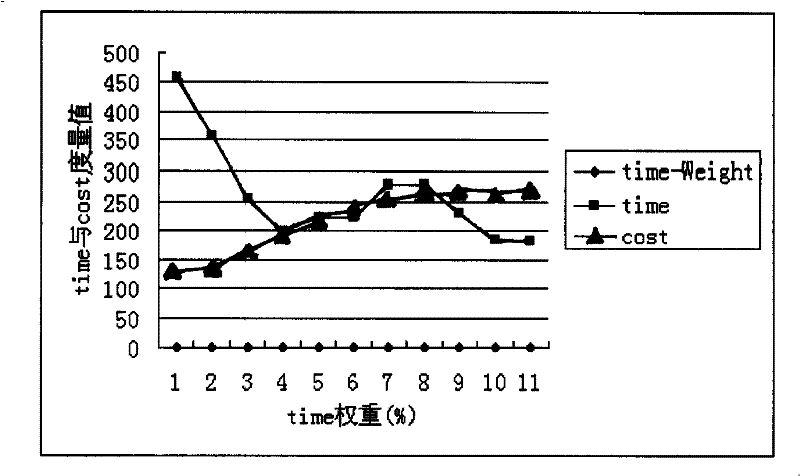

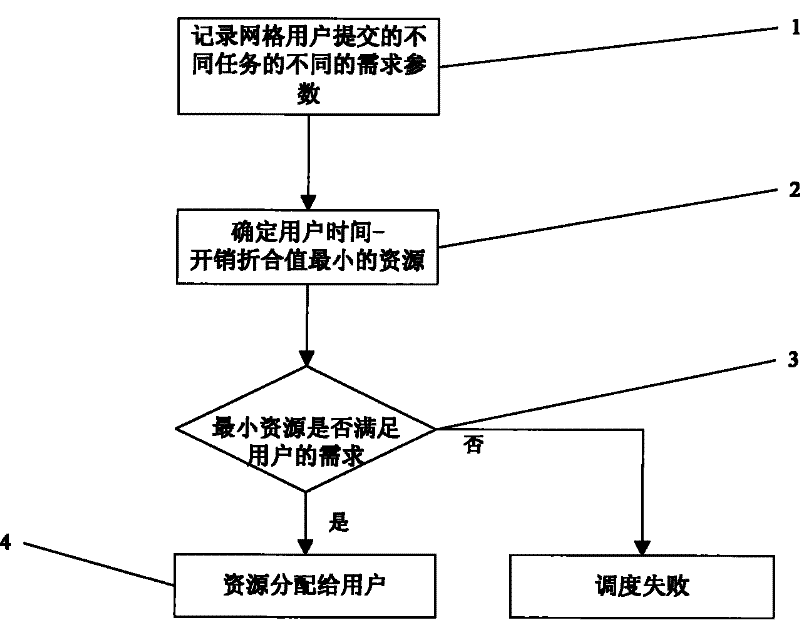

Scheduling method of grid resources of multi-Qos

Aiming at the problem of scheduling resources in the grid computing, the invention provides a scheduling method of grid resources of multi-Qos, which selects the most economic resource to schedule when in each scheduling. Compared with the prior art, the invention can complete the task at the least scheduling driving function value while meeting the user QoS, and realizes the satisfaction of a user to the max.

Owner:EAST CHINA NORMAL UNIV

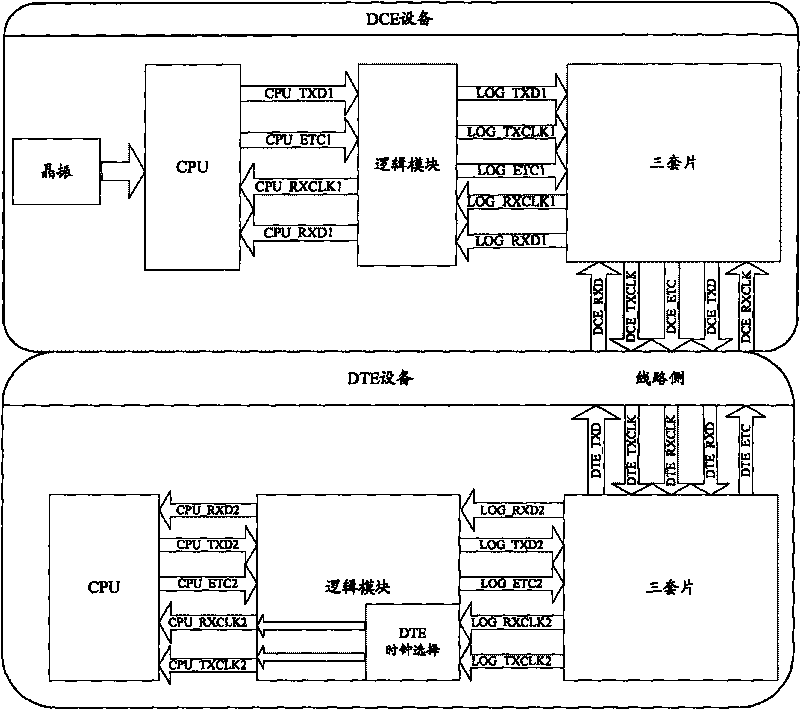

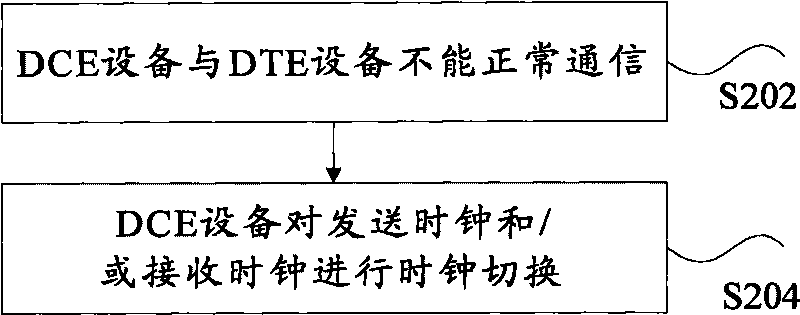

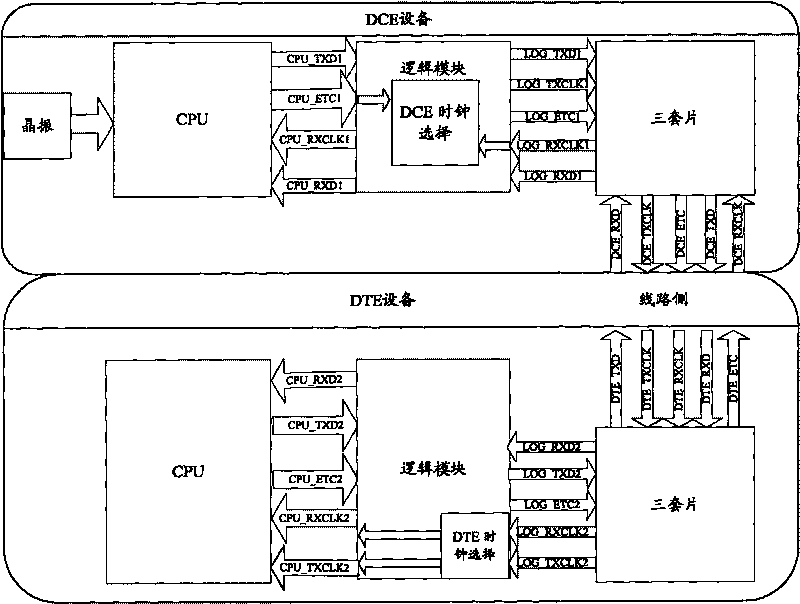

Method for selecting clock source and data communication equipment

InactiveCN101710858ACan't solveSolve the problem of normal communication of some non-standard DTE equipmentSynchronising arrangementData terminalComputer compatibility

The invention discloses a method for selecting clock source and a data communication equipment. The method is applied to communication between the data communication equipment (DCE) and the data terminal equipment (DTE), wherein, when DCE and DTE can not communicate normally, DCE carries out clock switchover on the transmitting clock and / or the receiving clock. The invention can improve reliability and compatibility of DCE.

Owner:ZTE CORP

Scheduling method of grid resources of multi-Qos

Owner:EAST CHINA NORMAL UNIV

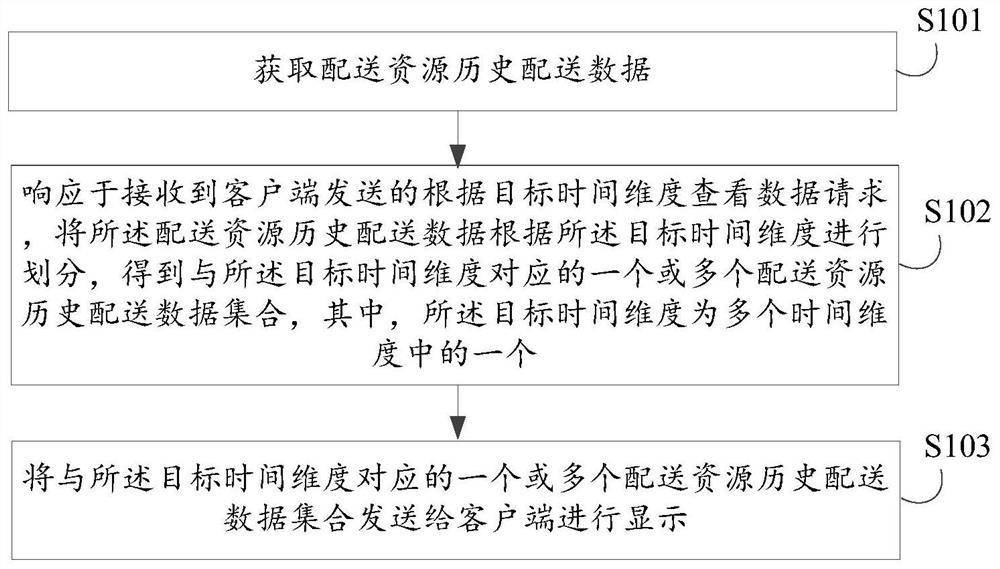

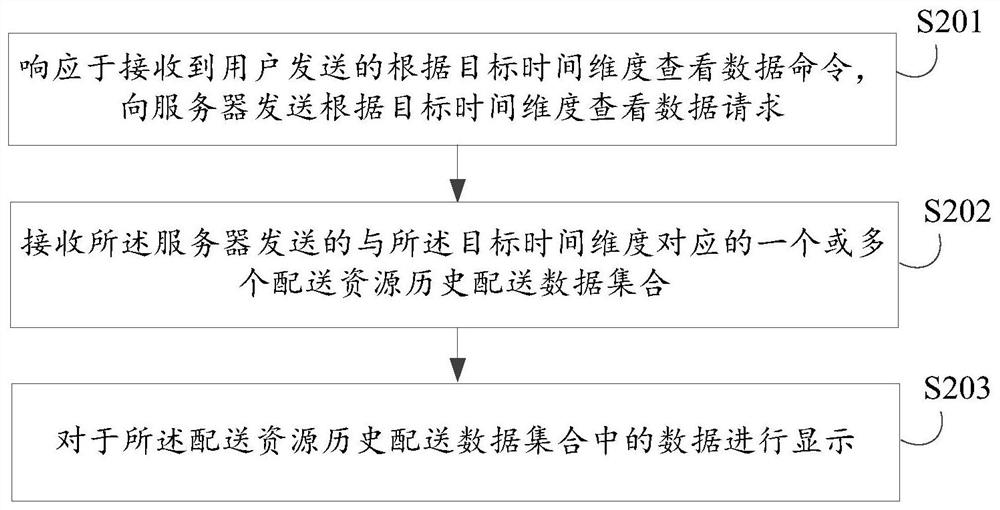

Data processing method and device, electronic equipment, storage medium and program product

PendingCN114881567AAchieve a sense of accomplishmentAchieve satisfactionDigital data information retrievalLogisticsData processingQuality of service

The embodiment of the invention discloses a data processing method and device, electronic equipment, a storage medium and a program product. The data processing method comprises the steps of obtaining historical distribution data of distribution resources; in response to a received request of checking data according to a target time dimension sent by a client, dividing the historical distribution data of the distribution resources according to the target time dimension to obtain one or more historical distribution data sets of the distribution resources corresponding to the target time dimension, the target time dimension is one of a plurality of time dimensions; and sending one or more distribution resource historical distribution data sets corresponding to the target time dimension to a client for display. According to the technical scheme, the achievement sense and satisfaction sense of the logistics deliveryman can be realized, the motivation of the logistics deliveryman can be stimulated, and the use experience of the logistics deliveryman, the logistics delivery quality and the Internet platform service quality can be improved.

Owner:RAJAX NETWORK &TECHNOLOGY (SHANGHAI) CO LTD

Liquid fuel gasification combustor suitable for mixed alcohol oil and capable of achieving complete combustion

Owner:天津清欣热能科技有限公司

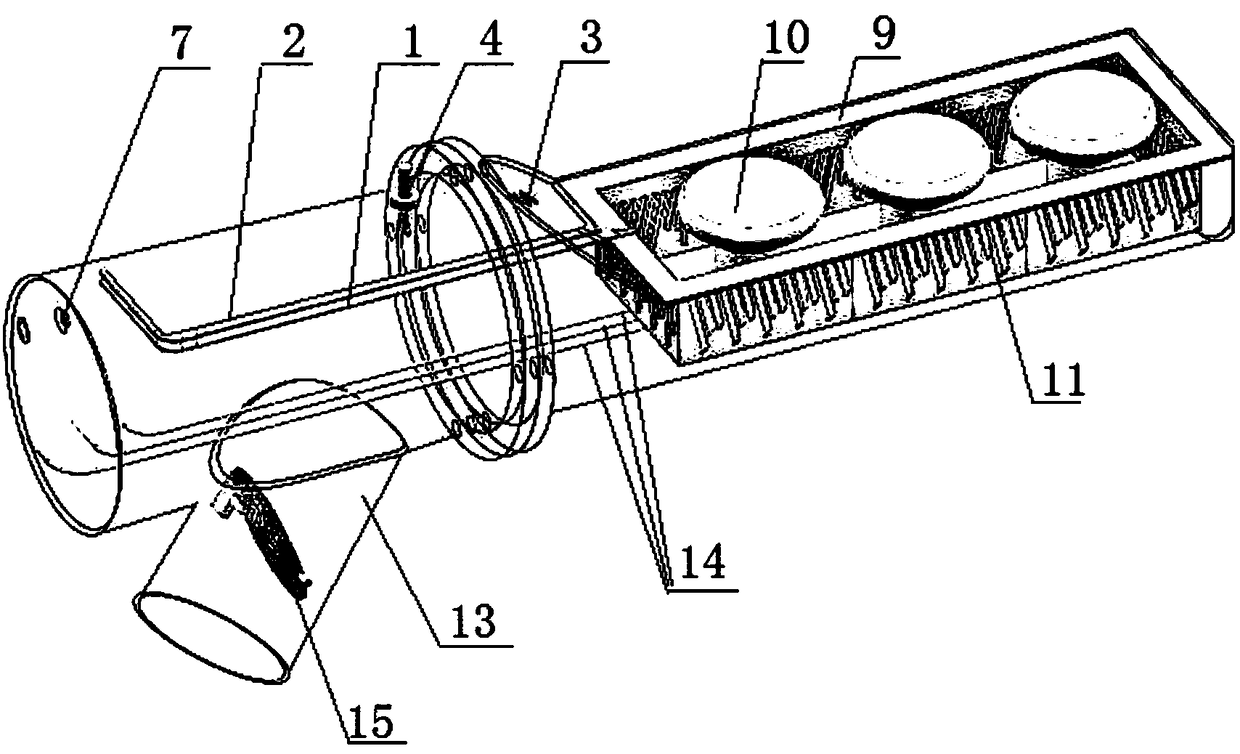

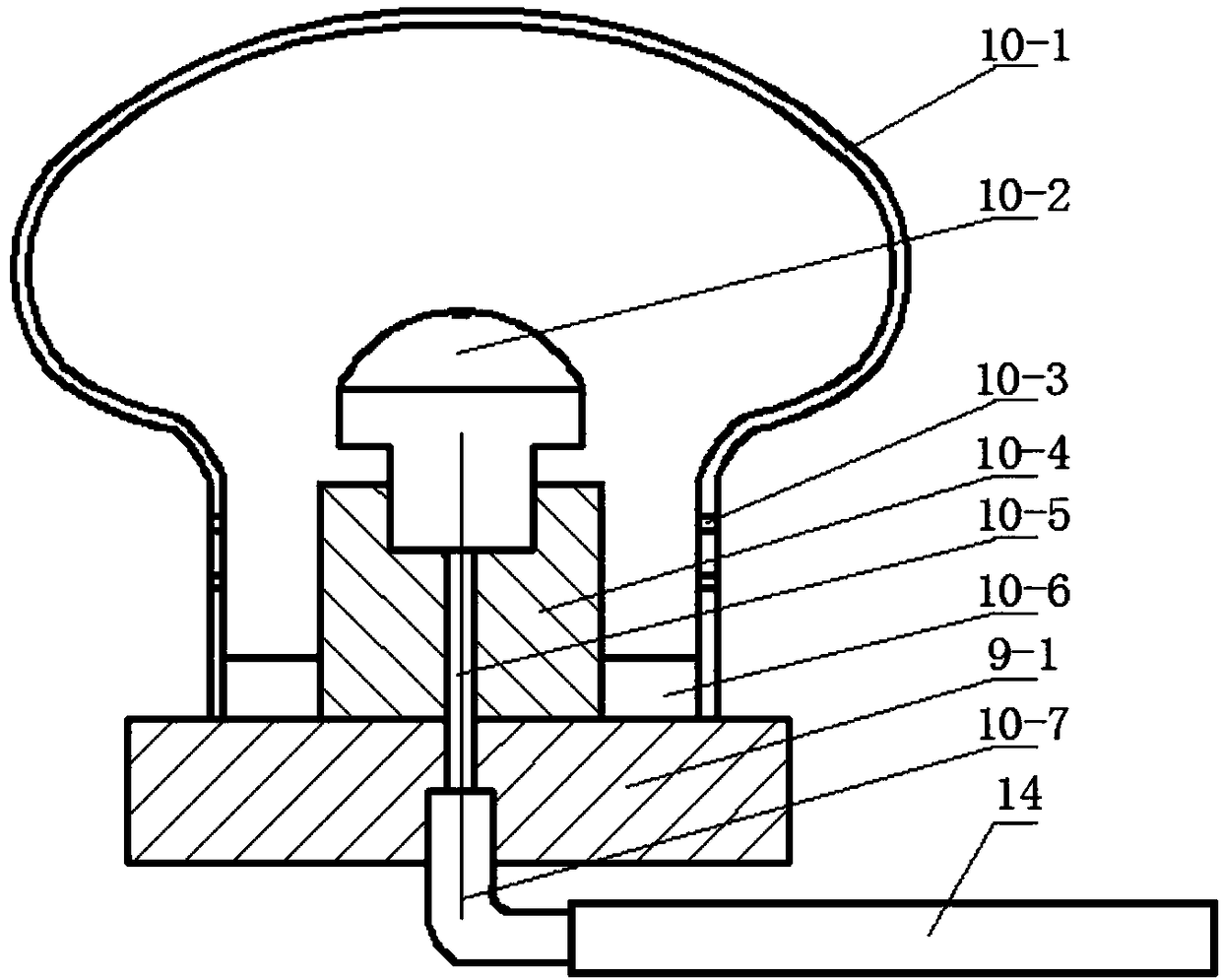

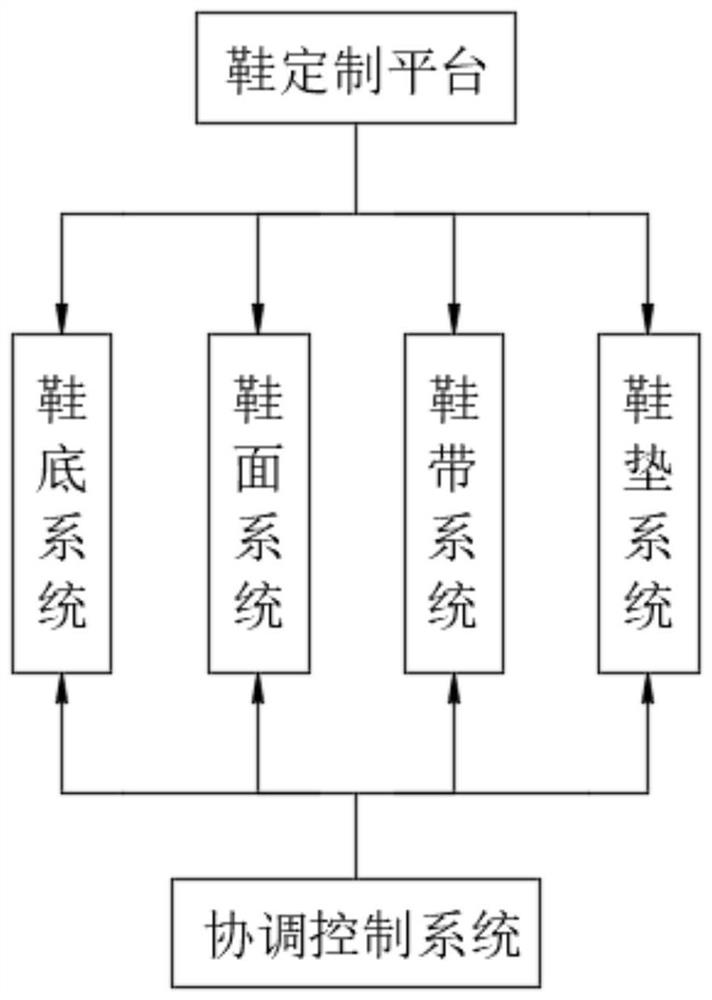

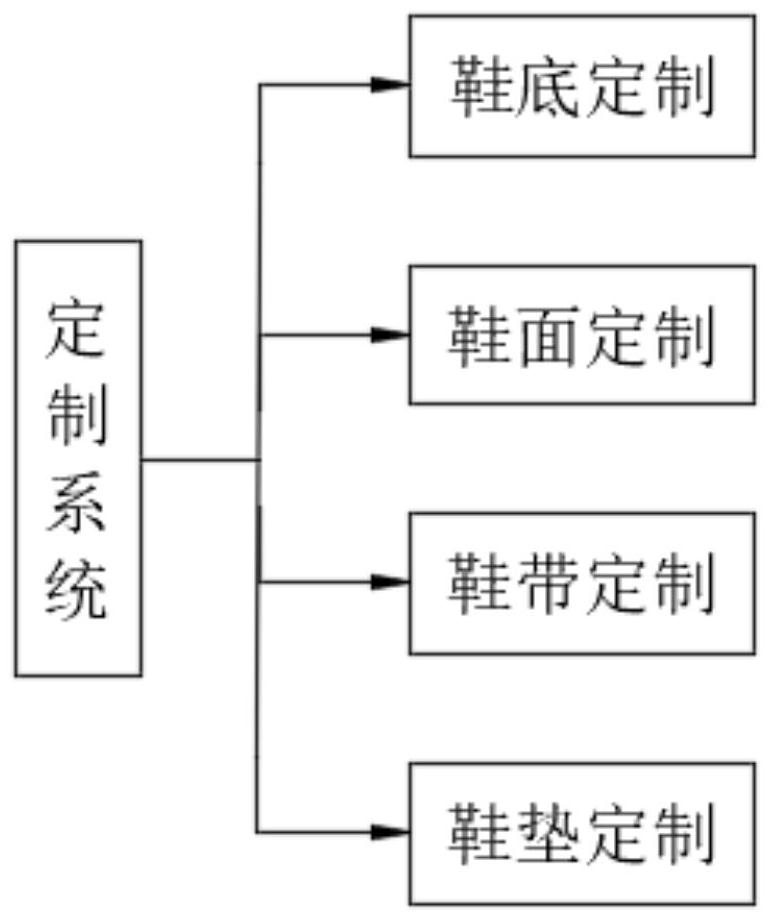

Digital 3D printing shoe customization platform

InactiveCN113103591ARealize requirementsAchieve satisfactionAdditive manufacturing apparatusShoemaking devicesShoe lacesControl system

The invention discloses a digital 3D printing shoe customization platform which comprises a shoe system, a coordination control system and a data acquisition system. The shoe system comprises a sole system, a vamp system, a shoelace system and an insole system, and the coordination control system is used for coordination control over soles, vamps, shoelaces and insoles; and the sole system includes an outsole, an insole and a surrounding structure, the insole includes a cushioning base and a stabilizing base plate, the size and shape of the stabilizing base plate are tailored according to the scenario of use. According to the digital 3D printing shoe customization platform, a data acquisition system is used for acquiring a use scene, used sport basic data and personal preferences, modeling is carried out through a computer according to the data acquired by the data acquisition system, a three-dimensional structure of a sport shoe is generated and previewed, secondary modification can be carried out according to a previewed sample, and the individual requirements and satisfaction of shoes can be better realized.

Owner:苏州斯克莱特数字科技有限公司

Method for preparing gingkgo health care cigarette

InactiveCN101268862BSober mindFree from physical and mental harmTobacco treatmentDrug compositionsHazardous substancePhysical well being

The invention discloses a preparation method of a gingko health cigarette, which includes the following steps that: (1) liquorice is added into a container, clean water is added to marinate for 30 minutes, the weight ratio of the liquorice and the water is 1:8 to 10, liquorice water solution is obtained by filter through boiling and cooling after being marinated; (2) folium ginkgo is added in thecontainer, and the liquorice water solution is added to marinate for 3 to 5 hours, the weight ratio of the folium ginkgo and the liquorice water solution is 1:3 to 5, after being marinated, the folium ginkgo is fished out for airing or drying and is cut into folium ginkgo shred; (3) the folium ginkgo shred is used as a measuring unit, and is evenly sprayed with menthence of 0.1 to 0.5 percent andevenly sprayed with cigarette spicery of 0.5 to 1.0 percent to be made into a semi finished tobacco shred; (4) the semi finished tobacco shred is made according to the existing cigarette manufacturing method to obtain the gingko health cigarette. The gingko health cigarette of the invention contains no hazardous substance, such as alkaloid of tobacco, nicotine, etc., thereby ensuring that the smoker feels satisfied by eliminating the fatigue, and favoring being good for the health.

Owner:林光和

Multifunctional chuck

InactiveCN105855581AImprove quality and efficiencyImprove work efficiencyChucksInterference fitEngineering

The invention discloses a multifunctional chuck. The multifunctional chuck comprises a rhombus clamping key, a supporting rod, a groove opening, a supporting face, a bolt and a rotary shaft. The rotary shaft is arranged below the rhombus clamping key. The rotary shaft is connected with the supporting rod. The supporting rod is connected with a nut through the rotary shaft. The groove opening is formed in the outer portion of the rhombus clamping key. The groove opening is in gap junction with the rhombus clamping key. The supporting face is fixed to the right end face of a fixing end. A through hole is formed in the supporting face. A fixing neck portion is connected to the right side of the fixing end. A fixing tail is connected to the right side of the fixing neck portion. A bearing is mounted in the through hole. The through hole is connected with the bearing in an interference fit manner. The bolt is fixed to the bearing. The left side of a rotary rod and the bolt are fixed. A key groove is formed in the rotary rod. According to the multifunctional chuck, the three-in-one taper type design manner is adopted, product quality and working efficiency are improved greatly, frequent replacement due to the difference of the size is not needed, and sliding caused by untight swelling is avoided.

Owner:SHANGHAI HERO CHAMPION COATING TECH

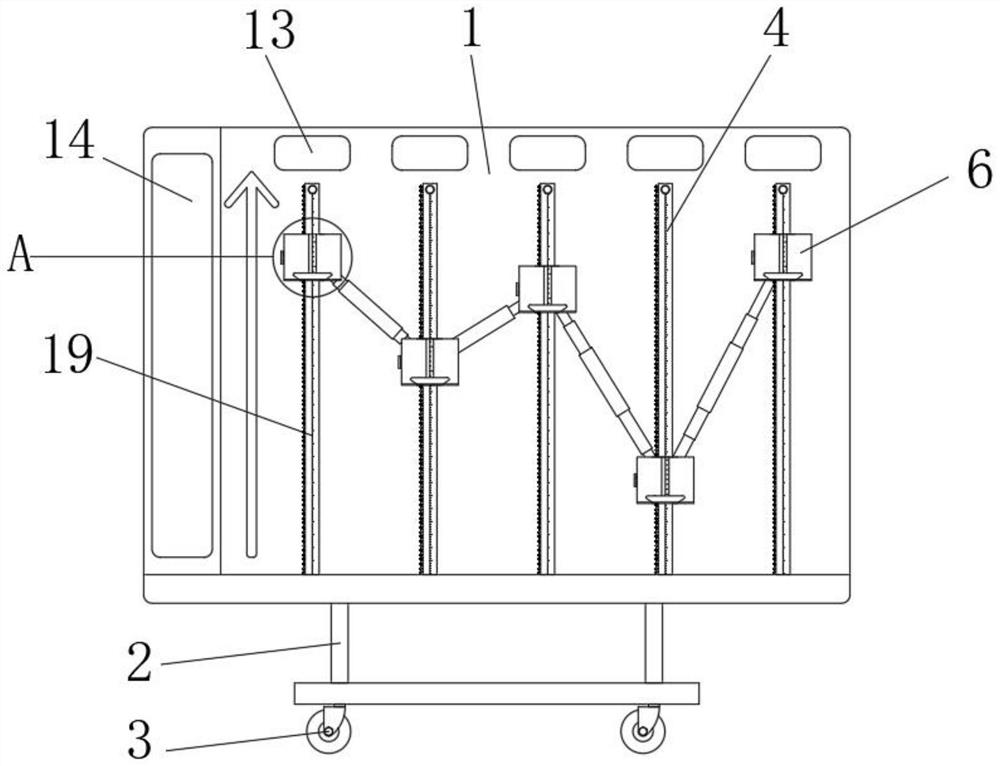

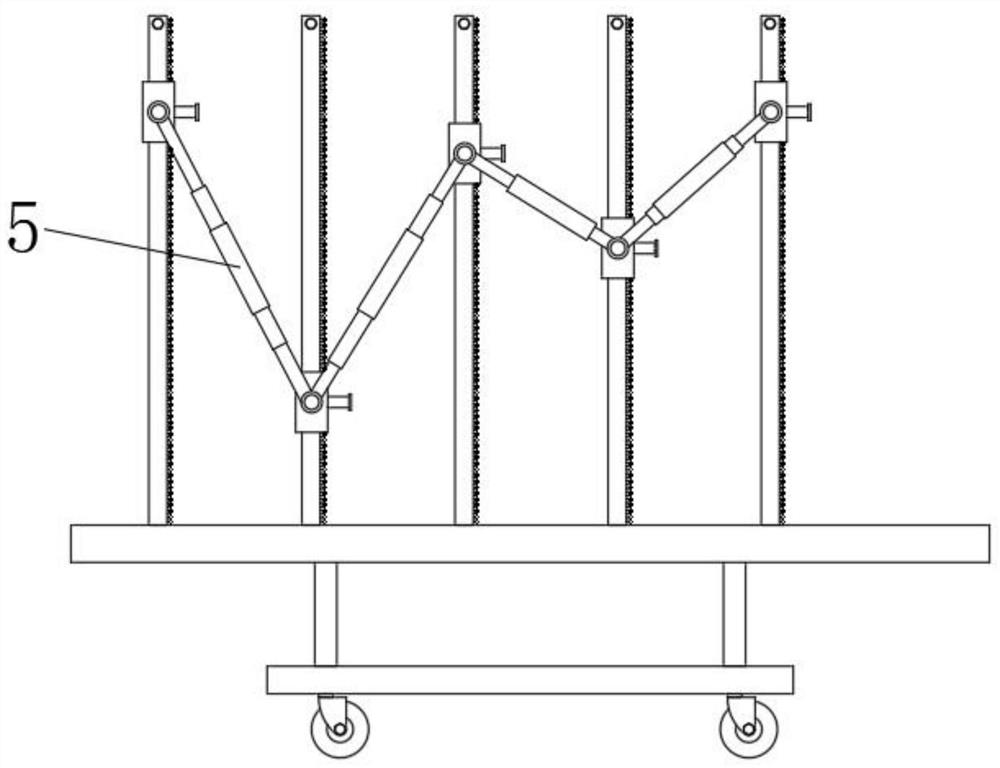

Sales display board for environmental protection equipment parts

InactiveCN112493777AEasy to judgeAchieve satisfactionShow shelvesShow hangersDisplay boardDisplay device

The invention discloses a sales display board for environmental protection equipment parts. The sales display board comprises a back plate and a support, the back plate is vertically and fixedly connected to the support, universal wheels are fixedly connected to the bottom of the support, lifting devices are fixedly connected to the support, a telescopic rod is arranged between the lifting devices, and the two ends of the telescopic rod are movably connected with the lifting devices. And the lifting devices are movably connected with a display device. For traditional sales numbers, the sales display board can enable merchants to judge sales information of products more conveniently through the height of the movable block, then business adjustment is carried out, environment-friendly equipment parts satisfying the market are produced and sold in a targeted mode, customers can know which products are optimal products more visually and clearly, and the satisfaction degree is achieved to the greatest extent.

Owner:湖南联企科创环保有限公司

A kind of gel filter stick for heating and fuming and its preparation method

ActiveCN108576910BImprove the suction experienceGood suction experienceTobacco preparationTobacco treatmentBiotechnologyNicotiana tabacum

The invention discloses a heating-mode smoking gel filter rod and a preparation method thereof, and relates to the technical field of cigarette smoking materials. The heating-mode smoking gel filter rod is prepared from a variety of raw materials, including a support material, a flavoring module, a mouthfeel module, an energy module, a smoking module and a gel module; the flavoring module is tobacco extraction The taste module includes one or more homologous plants of medicine and food, the Jintou module is a plant alkaloid or a derivative of the plant alkaloid, the smoking module is a sugar alcohol, and the gel module is a phase change gel. The preparation method for a heating-mode smoking gel filter rod is simple and easy to implement, and the obtained smoking material has a good smoking experience. The smoke enters the consumer's mouth at the same time, achieving physical and psychological satisfaction.

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD

Garlic-flavored seafood-taste seasonings

InactiveCN110547432ANot easy to overcomeOvercome the defect of full fusion of meat foodFood scienceZanthoxylum bungeanumShrimp

The invention relates to garlic-flavored seafood-taste seasonings, and belongs to the technical field of seasonings. The garlic-flavored seafood-taste seasonings are prepared from the following components in parts by weight of 50-100 parts of garlic cloves, 30-60 parts of shrimp heads, 30-50 parts of shrimp roes, 40-80 parts of onions, 20-40 parts of abalone paste, 30-60 parts of dried squids, 10-20 parts of ginger, 5-15 parts of sesame oil, 5-10 parts of zanthoxylum oil, 10-20 parts of pepper powder, 10-20 parts of chicken essence, 10-25 parts of oyster oil, 5-15 parts of citronella and 5-20parts of Chinese cinnamon. The seasonings disclosed by the invention bring new feeling and more convenience for food life of people.

Owner:秦在珍

A kind of smoking film material for heating mode and preparation method thereof

ActiveCN108523205BImprove the suction experienceSimple methodTobacco preparationTobacco treatmentNicotiana tabacumAlcohol sugars

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD

Fuming gel filter stick for heating way and preparation method of fuming gel filter stick

ActiveCN108576910AImprove the suction experienceGood suction experienceTobacco preparationTobacco treatmentFlavorAlcohol sugars

The invention discloses a fuming gel filter stick for a heating way and a preparation method of the fuming gel filter stick, which relates to the technical field of cigarette fuming materials. The fuming gel filter stick for the heating way is prepared from various raw materials, wherein the raw materials are prepared from a supporting material, a blending module, a taste module, a vigor module, afuming module and a gel module; the blending module is tobacco extract, the taste module is prepared from one or more edible and medicinal plants, the vigor module is plant alkaloid or a derivative of the plant alkaloid, the fuming module is sugar alcohol, and the gel module is phase-changing gel. The preparation method of the fuming gel filter stick for the heating way is simple and easy, an obtained fuming material is good in smoking experience, in the heating state, the gel has the phase changing, and flavor components enter the mouth of a consumer together with the plant alkaloid and smoke, so that the physical and spiritual satisfactory can be achieved.

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD

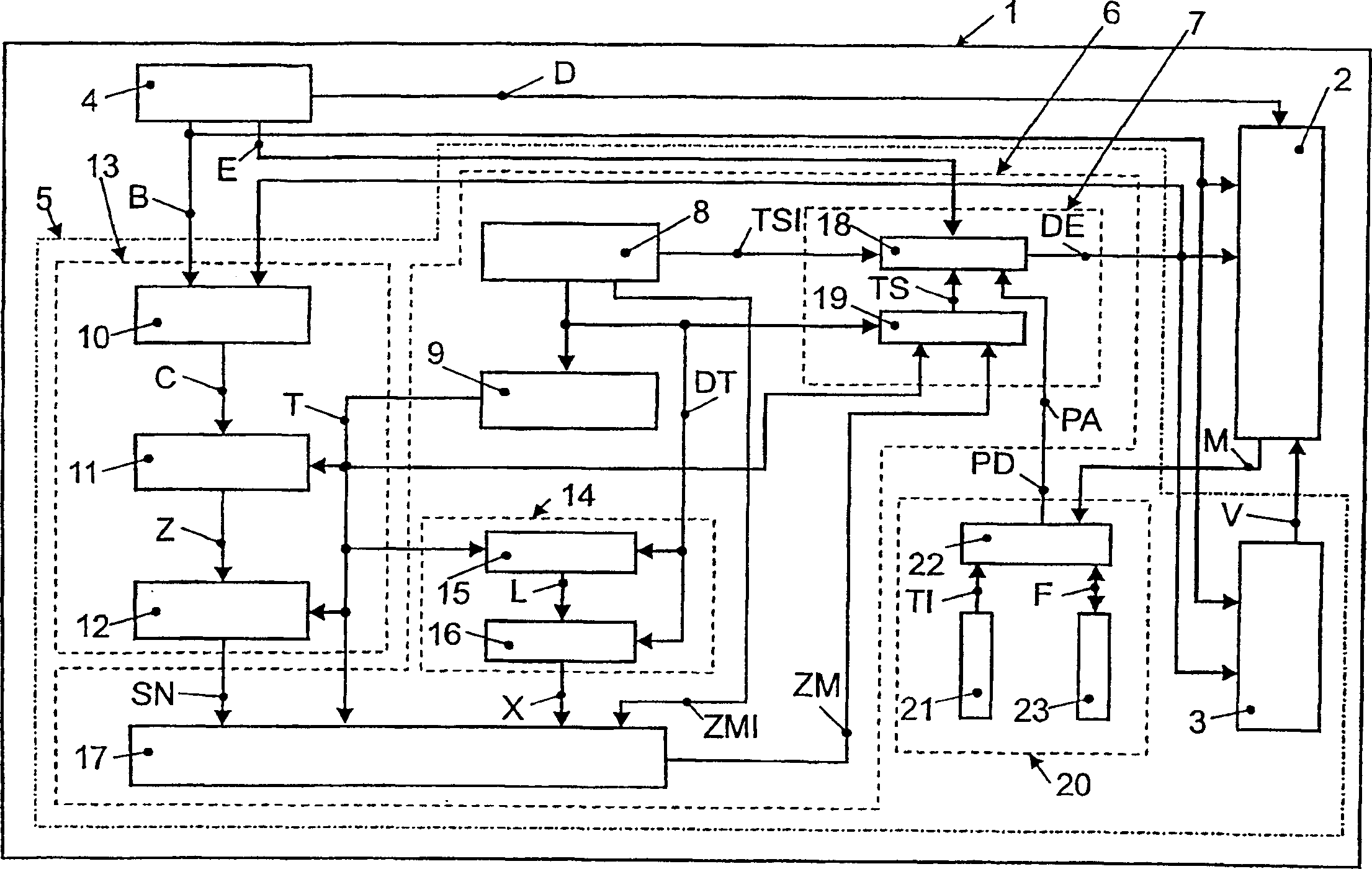

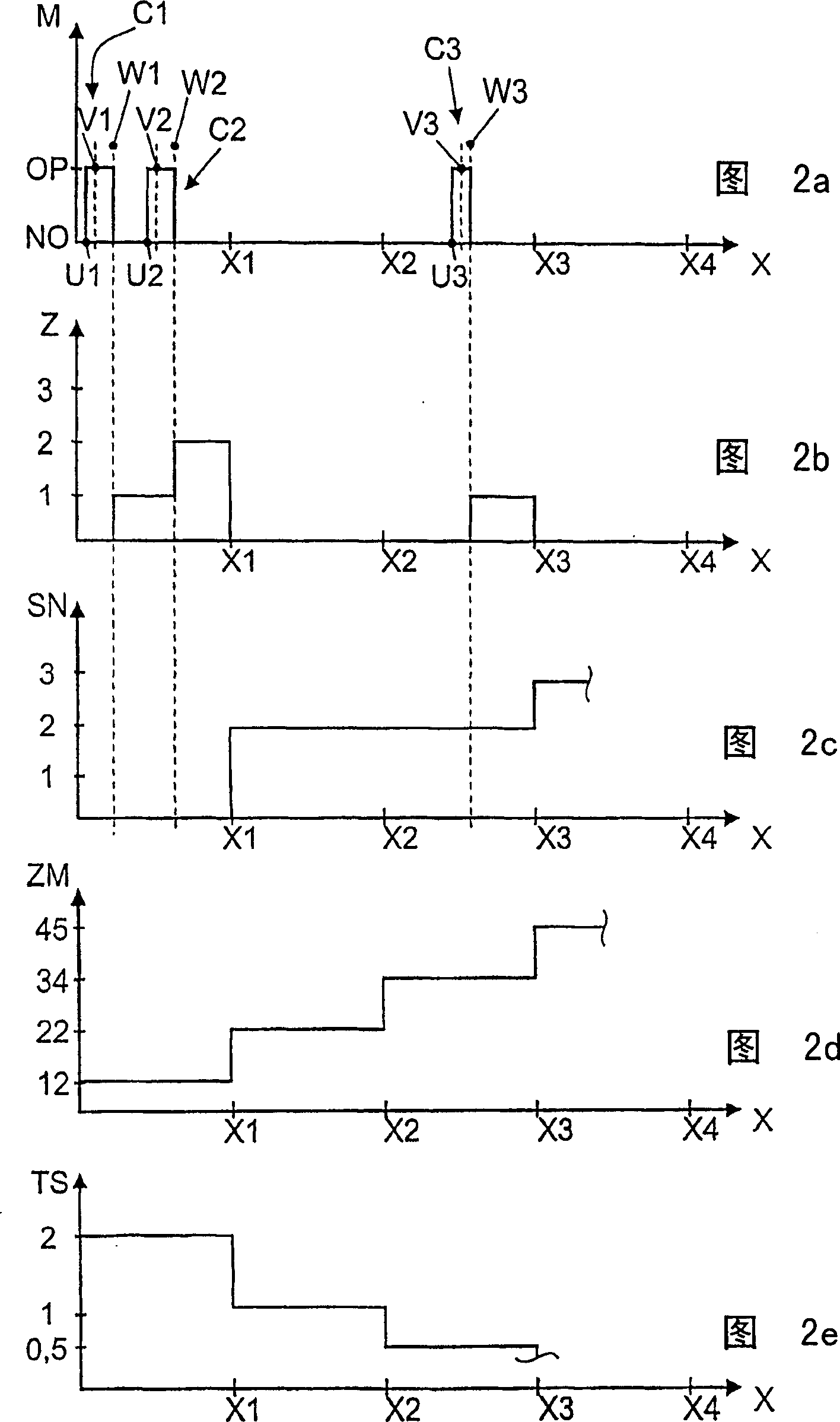

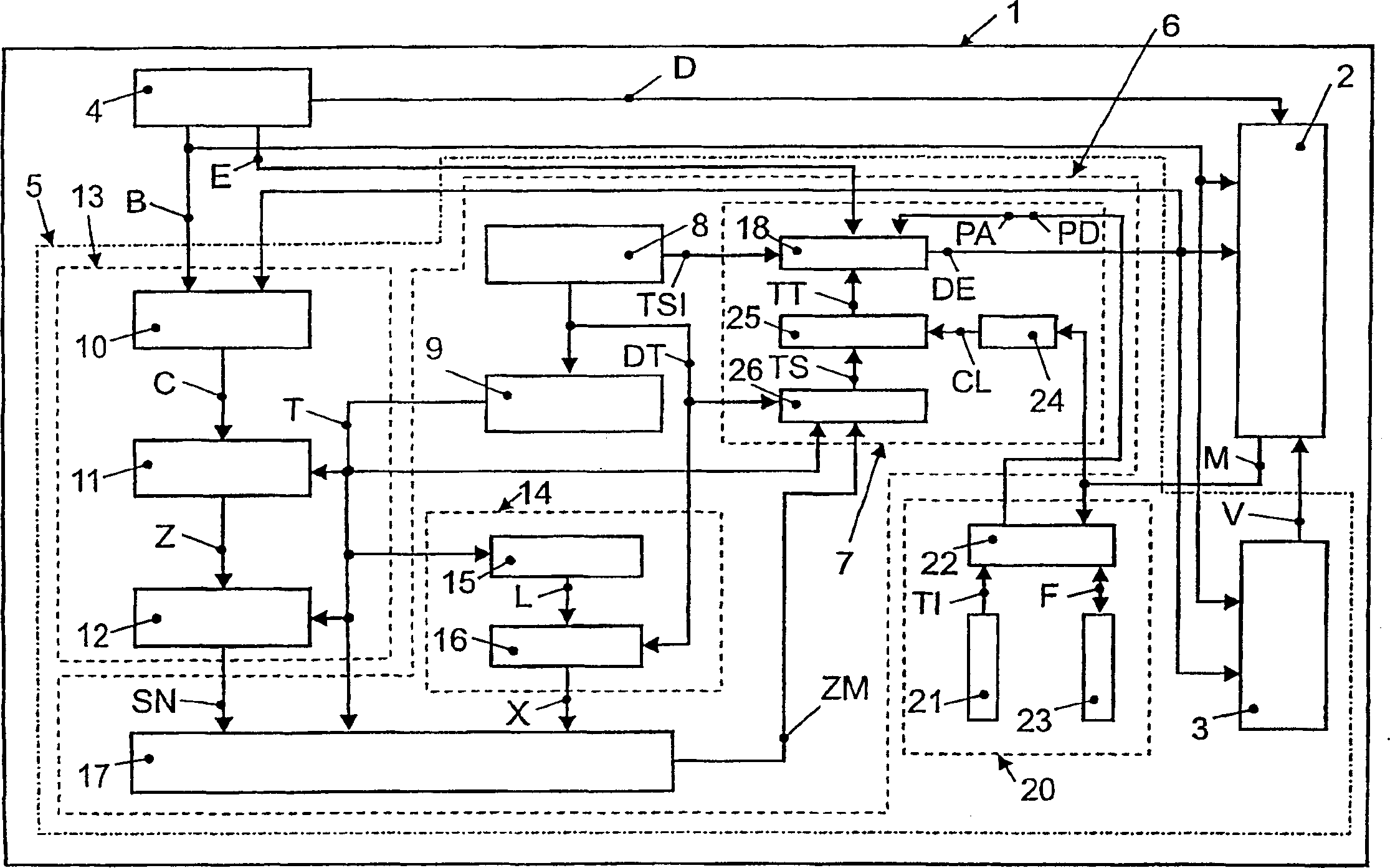

Device with modular unit able to be started and stop

InactiveCN1280811CAvoid delayFlexible adjustmentTelevision system detailsRecord information storageModular unitComputer module

A device (1) which can be activated during runtime, comprising a modular unit (2) which can be activated and stopped, and comprising stopping means (5) designed to stop the activated modular unit (2), The stop means have delay means (6) designed to delay the stop of the modular unit (2) according to the end time during the running time of the plant (1), and also have changing means (7) designed to vary the end time .

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

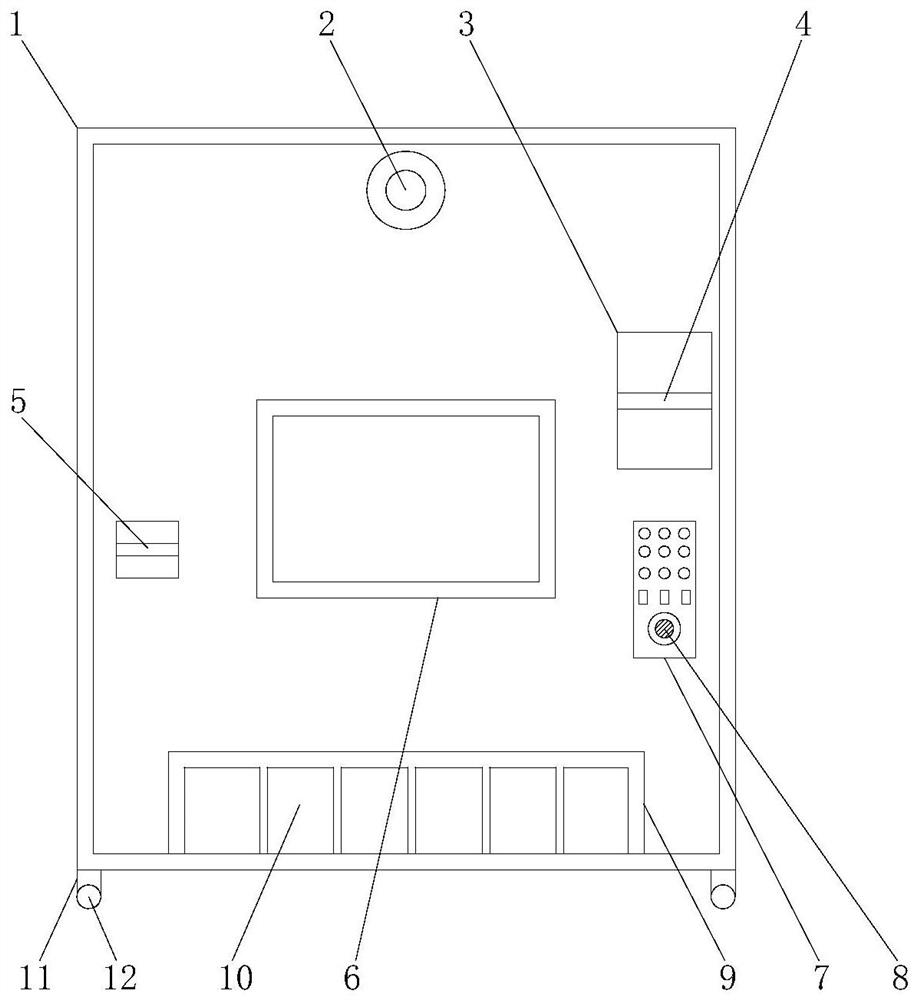

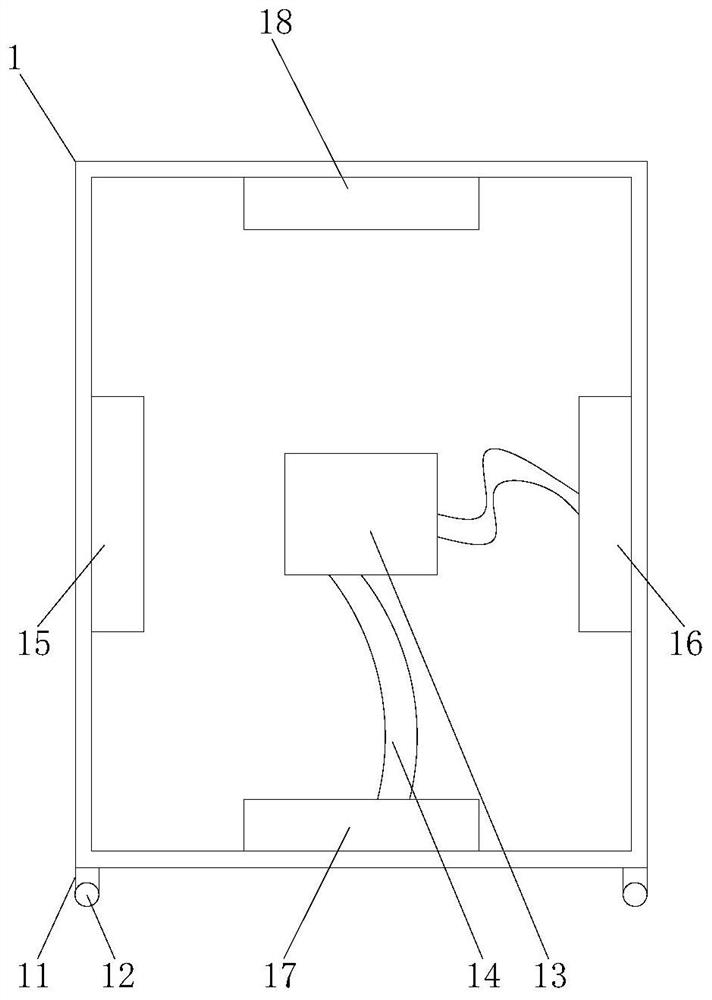

Self-service selling and packaging machine based on Internet of Things

InactiveCN112053496AEasy to useCause loss problemCoin-freed apparatus detailsCasings/cabinets/drawers detailsThe InternetEngineering

The invention discloses a self-service selling and packaging machine based on Internet of Things. The machine comprises a self-service selling and packaging machine body, an infrared camera is arranged in the center of the front face of the top of the self-service selling and packaging machine body, and a central controller is movably installed on the inner side of the front face of the self-service selling and packaging machine body. An anti-theft device and an automatic alarm device are fixedly installed on the back face of the self-service selling and packaging machine body. According to the self-service selling and packaging machine based on the Internet of Things, the infrared camera is arranged in the center of the front face of the top of the self-service selling and packaging machine body, the infrared sensor is movably installed at the top end of the inner side of the front face of the self-service selling and packaging machine body, and the face of a customer is shot throughthe infrared camera; related information is transmitted to the central controller through the infrared sensor, so that a customer can use the machine safely and conveniently, the customer can inquirethe information stored in the central controller when an accident occurs, and the problem of loss of the customer due to loss of the information is solved.

Owner:SHAOXING UNIVERSITY

Travel information coding index handbook and method for realizing same

InactiveCN1359080AAchieve satisfactionSimple structureSpecial data processing applicationsData miningDatabase

The present invention relates to a tourist information code index handbook and its implement method. Said handbook includes tourist spot name and names of its matched service stores and shops, and their correspondent information codes and key words. Said invention adopts a specific unique code for every tourist spot and its matched service store and shop, and adopts the combination of dsurface domainance index handbook and implicit tourist system information coding scheme to implement said invention.

Owner:阮闯

Seasoning material for stewing meat products

The present invention discloses a seasoning material for stewing meat products and belongs to the technical field of seasoning materials. The seasoning material comprises the following components in parts by weight: 50-100 parts of spices, 15-35 parts of dried tangerine peels, 5-15 parts of radix angelicae, 5-20 parts of fructus momordicae, 5-20 parts of nutmeg, 10-30 parts of licorice, 20-30 parts of dried haws, 20-50 parts of fresh ginger, 20-40 parts of garlic cloves, 10-30 parts of dried durian, 2-20 parts of fructus tsaoko, 5-15 parts of edible vinegar, 30-60 parts of crystal sugar, 20-40parts of light soy sauce, 30-50 parts of dark soy sauce, 20-40 parts of onion bulbs and 5-10 parts of lemongrass herb. The seasoning material brings new feeling and more convenience to food life of people.

Owner:秦在珍

Crab-flavored bean product cooking seasonings

The invention relates to crab-flavored bean product cooking seasonings, and belongs to the technical field of seasonings. The crab-flavored bean product cooking seasonings are prepared from the following components in parts by weight of 10-30 parts of crabmeat, 10-20 parts of crab cream, 15-30 parts of yolk, 20-30 parts of dried fingerlings, 20-40 parts of dried small shrimps, 15-35 parts of whitegranulated sugar, 5-20 parts of bruised ginger, 10-15 parts of chopped garlic, 10-30 parts of cooked sesame seeds, 5-15 parts of a soybean sauce, 5-12 parts of a Korean sweet chili sauce, 10-20 partsof oyster oil and 5-15 parts of blend oil. The crab-flavored bean product cooking seasonings disclosed by the invention bring new feeling and more convenience for food life of people.

Owner:秦在珍

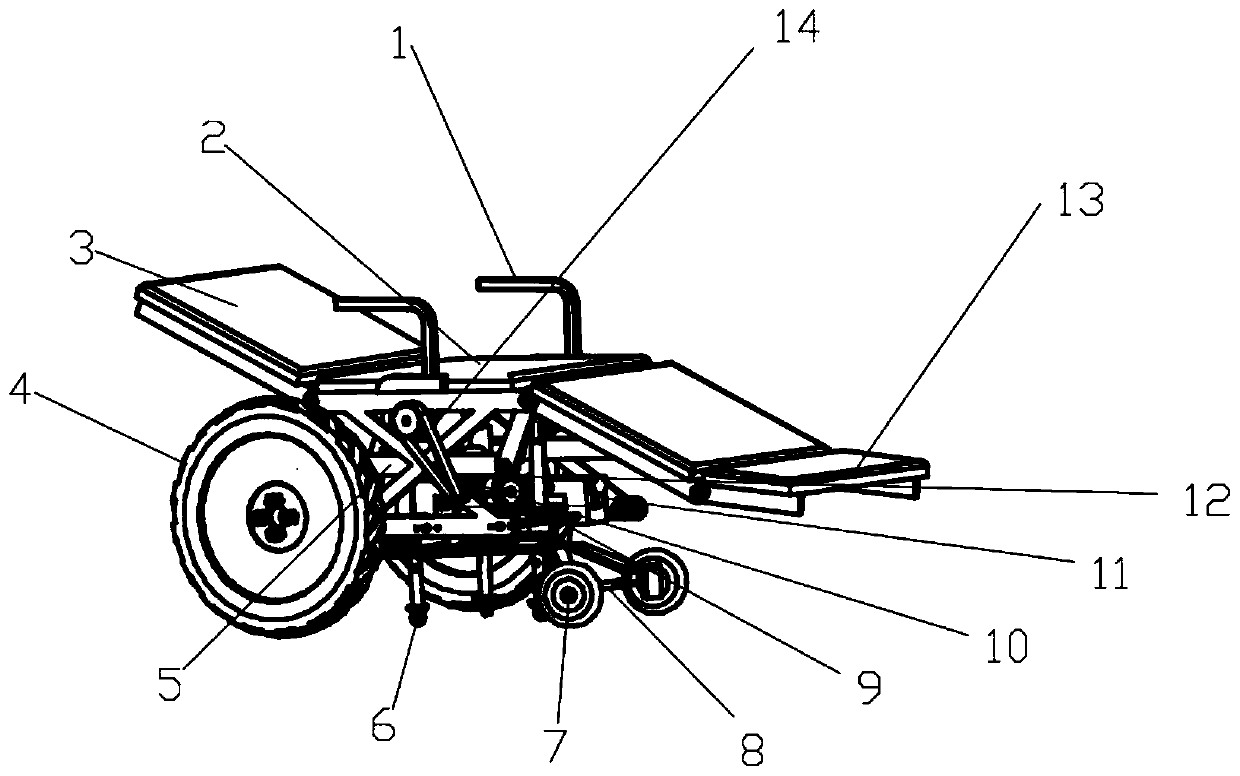

Multifunctional automatic wheelchair

InactiveCN110960362AEasy to useRealize in and outWheelchairs/patient conveyanceNursing bedsWheelchairGear wheel

The invention relates to a multifunctional full-automatic wheelchair, which comprises four parts: an adjusting device, a lifting device, a moving device and a folding structure. The adjusting device realizes the angle adjustment of the wheelchair by controlling a steering gear to drive relevant gears, worm gears, racks and connecting rod parts, and has strong functionality. The lifting device controls the height of the wheelchair through the expansion and contraction of three push rod motors, and has strong adaptability. The moving device uses a single chip microcomputer to drive the motor andthe steering gear to realize forward moving, backward moving and steering of the wheelchair. The folding structure is connected with the push rod motors through a steel wire rope, and the push rod motors drive the steel wire rope and a spring to cooperate to drive the lifting and lowering of supporting wheels, so as to realize the function of the wheelchair from the contracted state under the bedto the state to be used at the bed side. In addition, the structure is novel.

Owner:ANHUI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com