Method for controlling molten steel processing of steelmaking workshop

A control method and technology for molten steel, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as cost increase, thermal energy loss, lack of predictability and overall controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

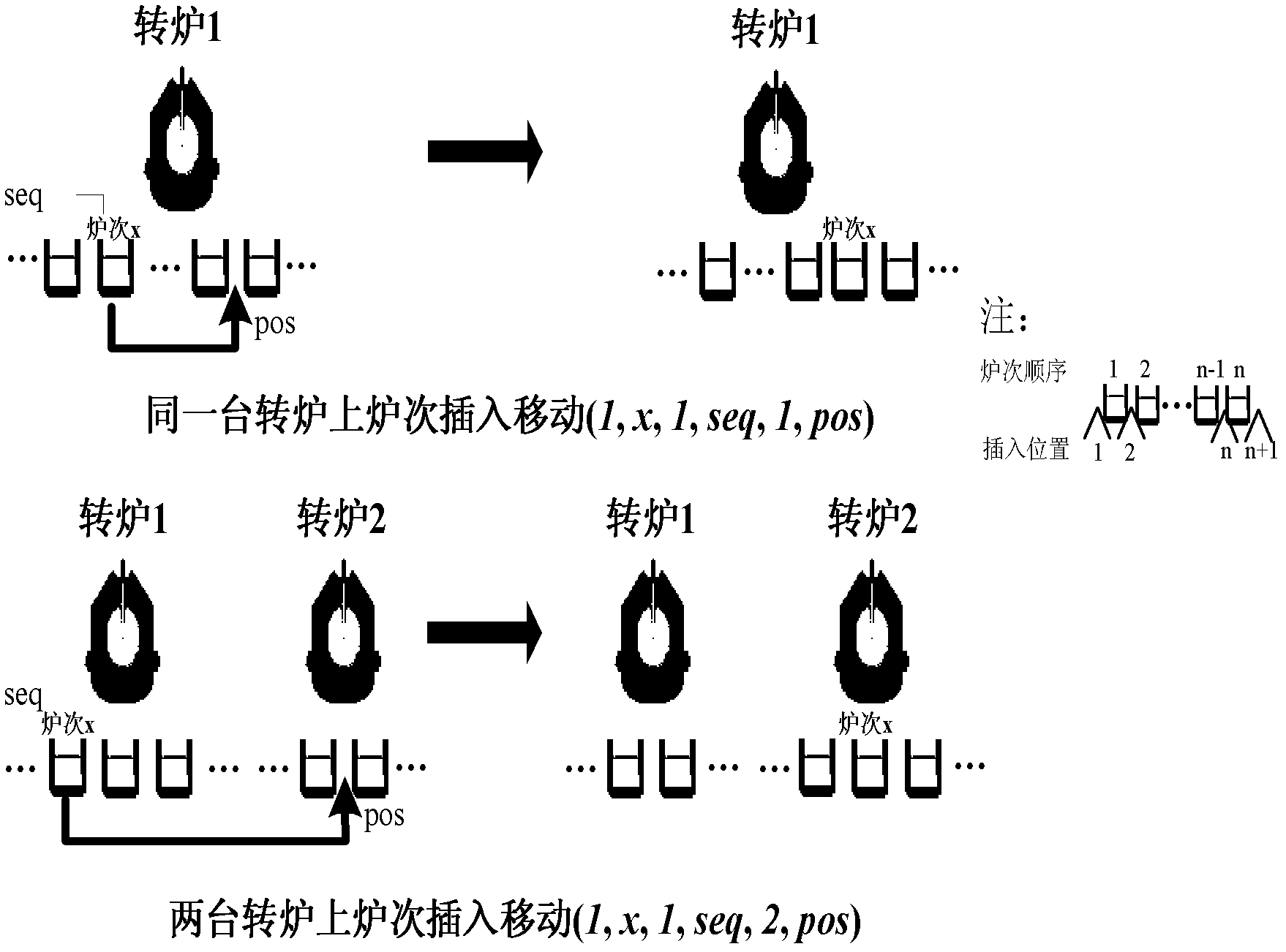

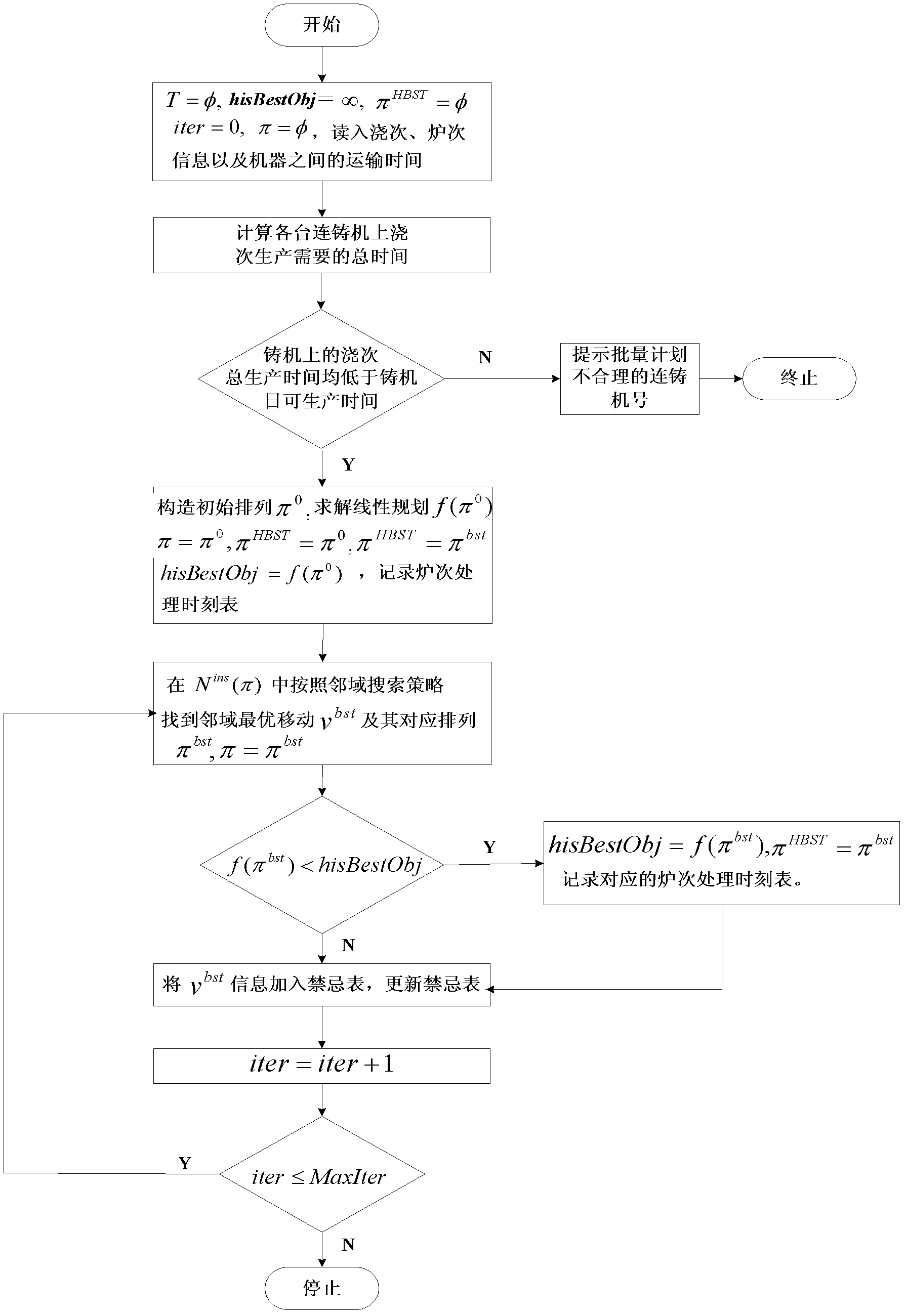

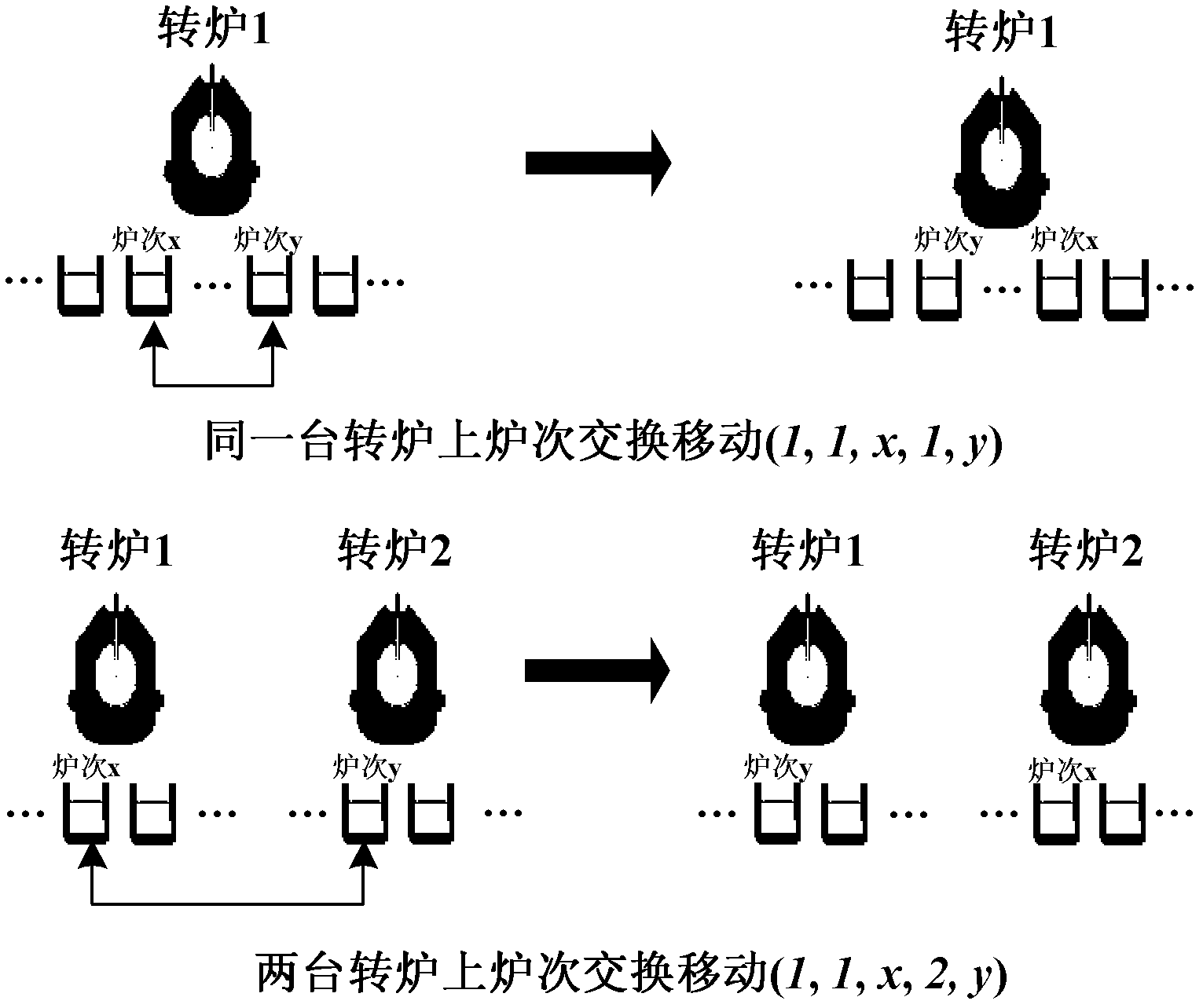

Method used

Image

Examples

Embodiment Construction

[0099] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0100] The implementation of the system of the present invention requires the following devices: at least one PC; at least one cable interface or optical cable interface or telephone dedicated line interface; at least one router. These devices form a small local area network and connect to the enterprise ERP system. The system of the present invention is installed in the PC, and connected to the front end of the production process control system of the steelmaking workshop through a network and a router. The software takes the Windows operating system as the support platform, first installs the Microsoft SQL Server 2000 database system, then installs the system of the present invention, sets the initialization information configuration port, and the installation is completed.

[0101] The data used in this embodiment is based on the production batch pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com