Liquid fuel gasification combustor suitable for mixed alcohol oil and capable of achieving complete combustion

A liquid fuel and burner technology, applied in the field of liquid fuel burners and liquid fuel gasification burners, can solve the problems of reduced ignition reliability, waste of resources, increased heat release area, etc., so as to improve the competitiveness of combustion costs, The effect of reducing the standard of consumables and improving the calorific value of combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below with reference to the drawings and specific embodiments. The following embodiments are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

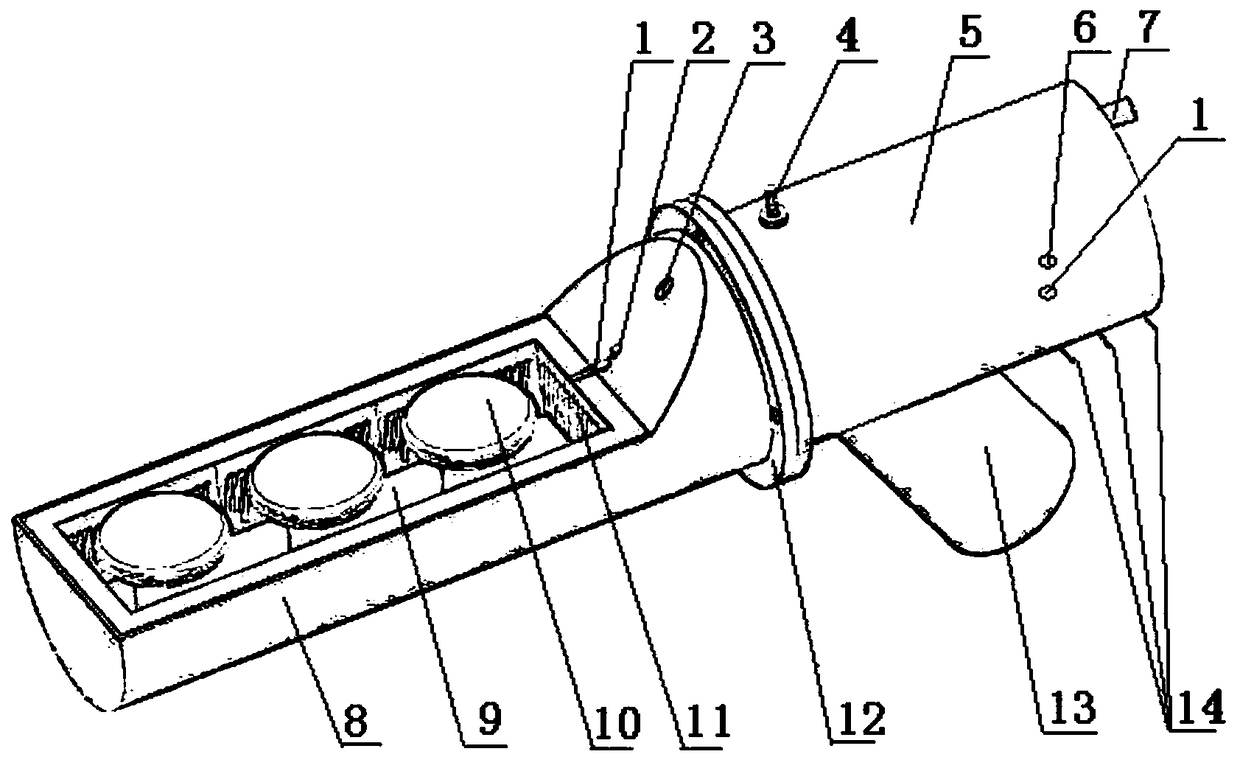

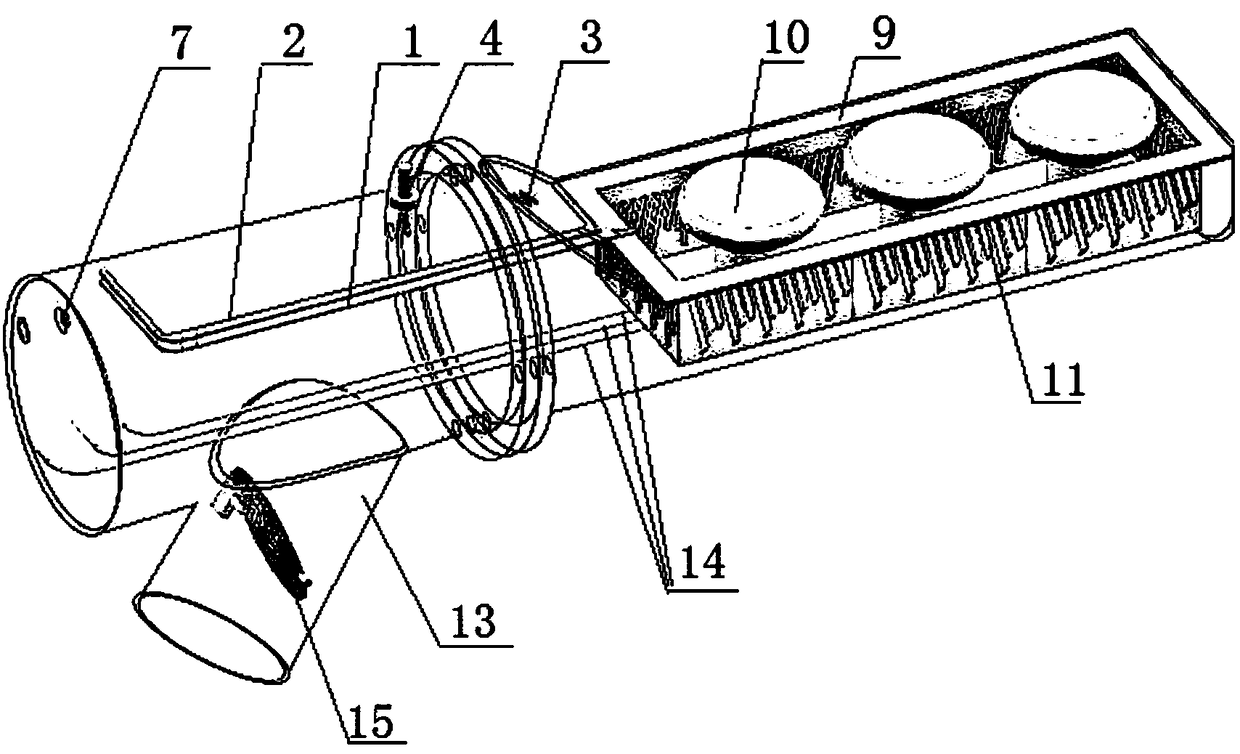

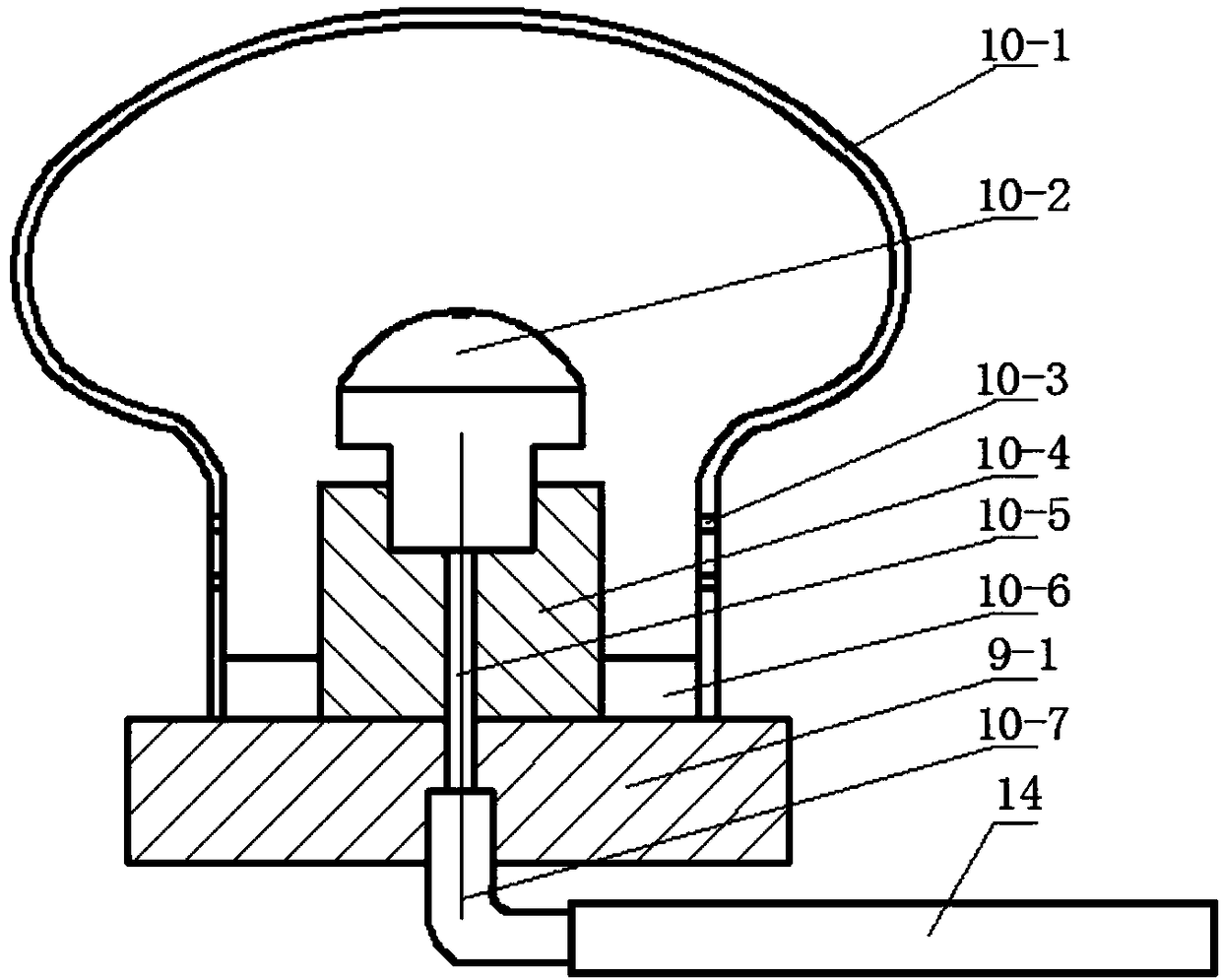

[0040] A liquid fuel gasification burner that can use mixed alcohol oil and 100% combustion includes a wind tube, a plurality of gasification furnace heads 10, an ignition mechanism and a fuel supply system.

[0041] The innovation of the present invention lies in:

[0042] The described air cylinder is composed of two parts, which are divided into furnace air cylinder 8 and furnace external air cylinder 5 according to the positional relationship with the boiler during use. The furnace inner air cylinder and the furnace outer air cylinder are connected through a flange 12, the furnace outer air cylinder is provided with an air inlet 13, and a damper 15 is installed at the air inlet, and the air inlet is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com