Digital 3D printing shoe customization platform

A shoe printing, 3D technology, applied in the direction of footwear, applications, shoe-making machinery, etc., can solve the problems that thousands of people have no way to fit a thousand feet, fit users, and cannot realize the individual needs and satisfaction of shoes, and achieve the realization of Effects of personal needs and satisfaction, improvement of oneness, and reduction of burden on feet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

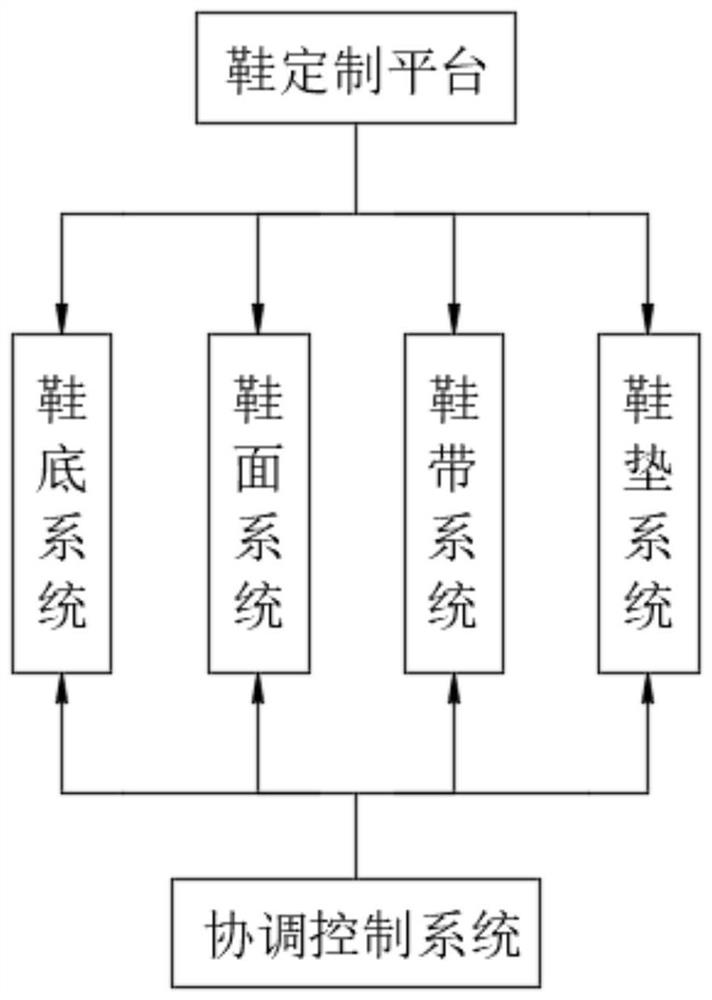

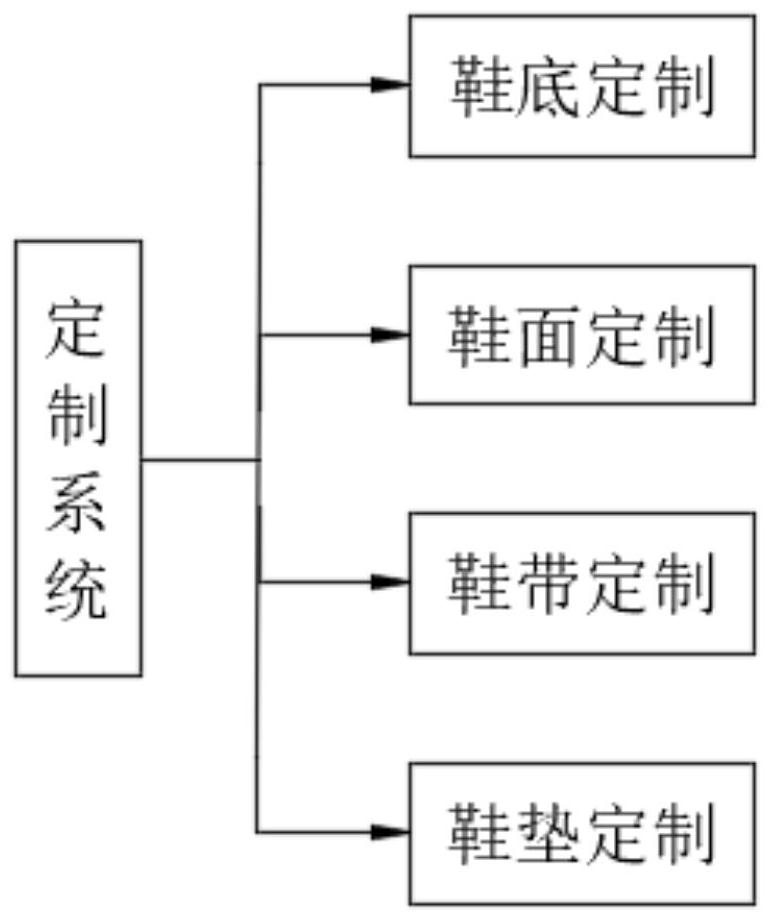

[0024] refer to figure 1 , a digital 3D printing shoe customization platform, including: shoe system, coordinated control system and data acquisition system, shoe system includes sole system, upper system, shoelace system and insole system, according to the data collected by the data acquisition system through Modeling is carried out by computer, in which the coordinated control system controls the size of key equipment for the coordinated control system of soles, uppers, shoelaces and insoles.

[0025] The sole system includes an outsole, an insole and a surrounding structure. The outsole is made of wear-resistant rubber, and the bottom of the outsole is provided with vertical and horizontal anti-skid grooves. Increasing the thickness of the sole can improve wear resistance, and reducing the thickness of the sole can reduce the wear resistance of the shoe. The weight reduces the burden on the feet, and the depth of the anti-slip groove at the bottom and the thickness of the o...

Embodiment 2

[0033] refer to figure 1 and figure 2 As shown, a digital 3D printing shoe customization platform includes: shoe system, coordinated control system and data acquisition system. The shoe system includes sole system, upper system, shoelace system and insole system. According to the data collected by the data acquisition system The data is modeled by computer, and the coordinated control system controls the size of the key equipment for the coordinated control system of the sole, upper, shoelace and insole.

[0034] The sole system includes an outsole, an insole and a surrounding structure. The outsole is made of wear-resistant rubber, and the bottom of the outsole is provided with vertical and horizontal anti-skid grooves. Increasing the thickness of the sole can improve wear resistance, and reducing the thickness of the sole can reduce the wear resistance of the shoe. The weight reduces the burden on the feet, and the depth of the anti-slip groove at the bottom and the thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com