Carbon fiber or carbon crystal electric heating floor capable of being cut at random and mounted conveniently, and use method

An electric heating floor, convenient installation technology, applied in electric heating system, application, heating method and other directions, can solve the problems of large cold edge, electric heating floor can not be arbitrarily cut, etc., to achieve the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

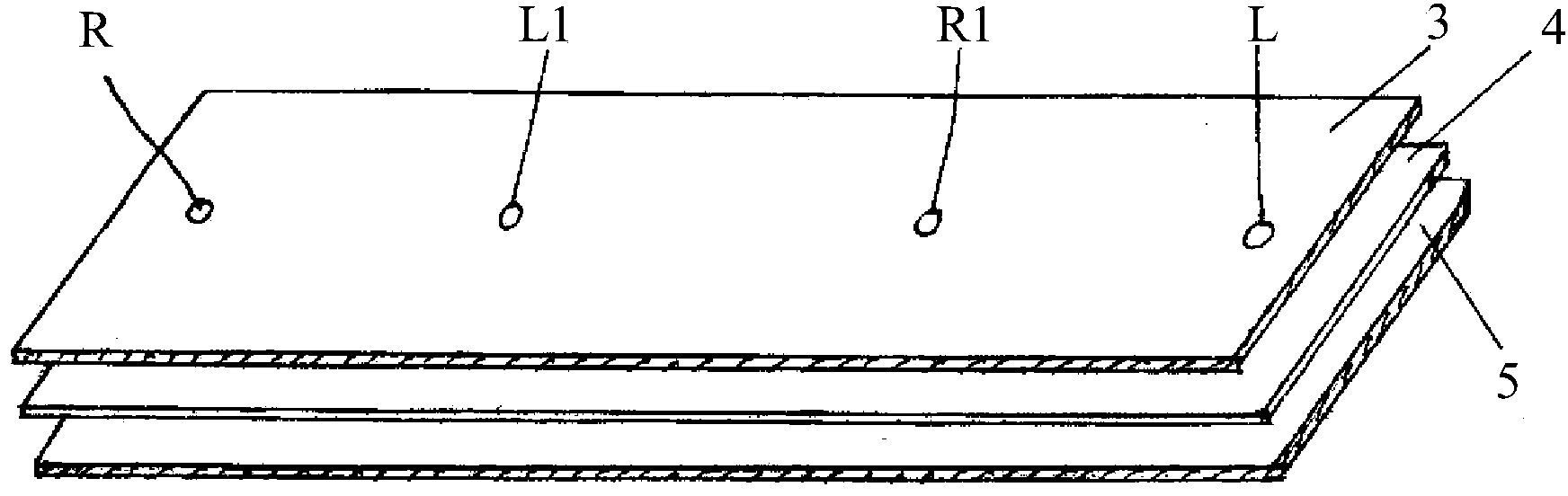

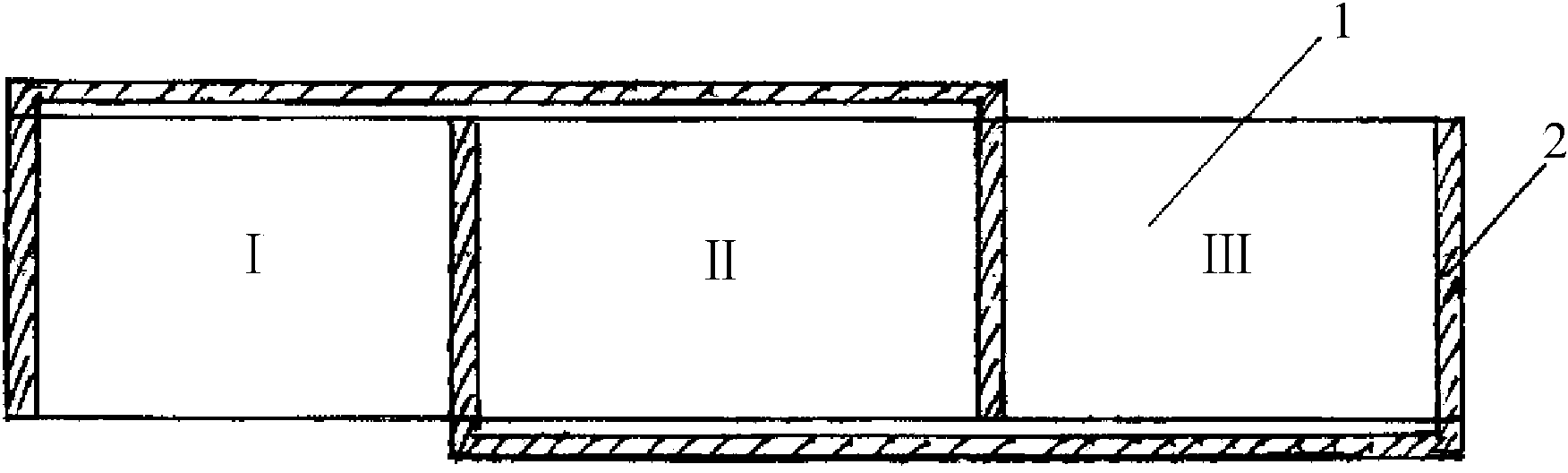

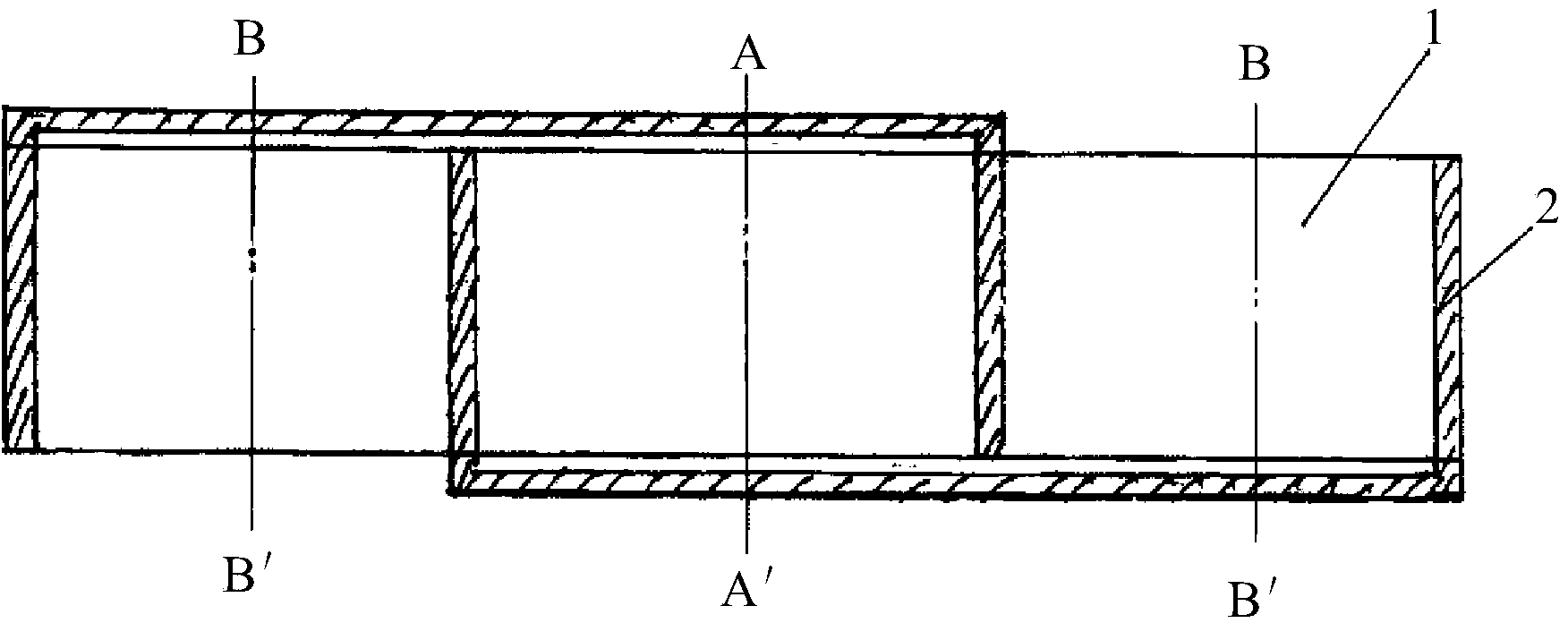

[0040] Such as figure 1 , image 3 As shown, when cut off at A-A' in the middle of the transverse direction, the whole electric heating floor becomes two short electric heating floors of 1 / 2 size. Both wiring methods RL1 or R1L can be used normally. The electric heating floor is heated in an independent heating area, and the non-heating part is only one-third of the remaining short electric heating floor, which is installed on the wall as a cold edge, which can meet national regulations. After cutting in this way, it becomes a cutable electric floor at the beginning or end of floor paving.

[0041] Such as figure 1 , image 3 As shown, when it is cut off at B-B' at 1 / 6 of the lateral side, the entire electric heating floor becomes a short electric heating floor of 5 / 6 size. Both wiring methods R1L1 or R1L can be used normally, respectively. The two independent heating areas of the floor are heated, and the non-heating part is only one-fifth of the remaining electric heating floor...

Embodiment 2

[0045] Such as figure 1 , Figure 4 As shown, when cut off at the vertical middle C-C', the whole electric heating floor becomes two long electric heating floors of 1 / 2 size. The three wiring methods RL1, R1L1, and R1L can all be used normally, respectively. The independent heating area of the electric heating floor is heated in compliance with national regulations. After cutting in this way, it becomes a cutable electric floor at the beginning or end of floor paving.

[0046] Such as figure 1 , Figure 4 As shown, when cut off at 1 / 3 of the vertical side of D-D', the whole electric heating floor becomes two long electric heating floors of 1 / 3 and 2 / 3 size, three wiring methods RL1, R1L1 R1L can be used normally, heating the independent heating areas of two electric heating floors respectively, in line with national regulations. After cutting in this way, it becomes a cutable electric floor at the beginning or end of floor paving.

[0047] In addition, when the electric heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com