Patents

Literature

140results about How to "Removed smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

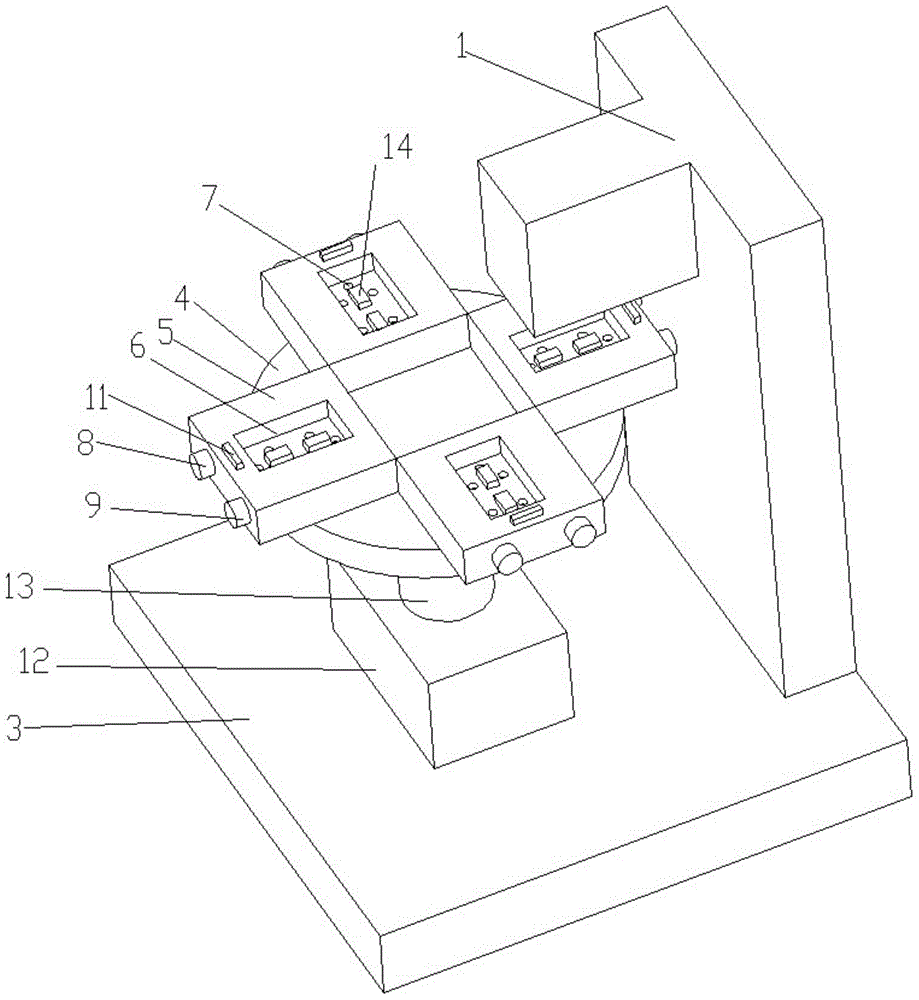

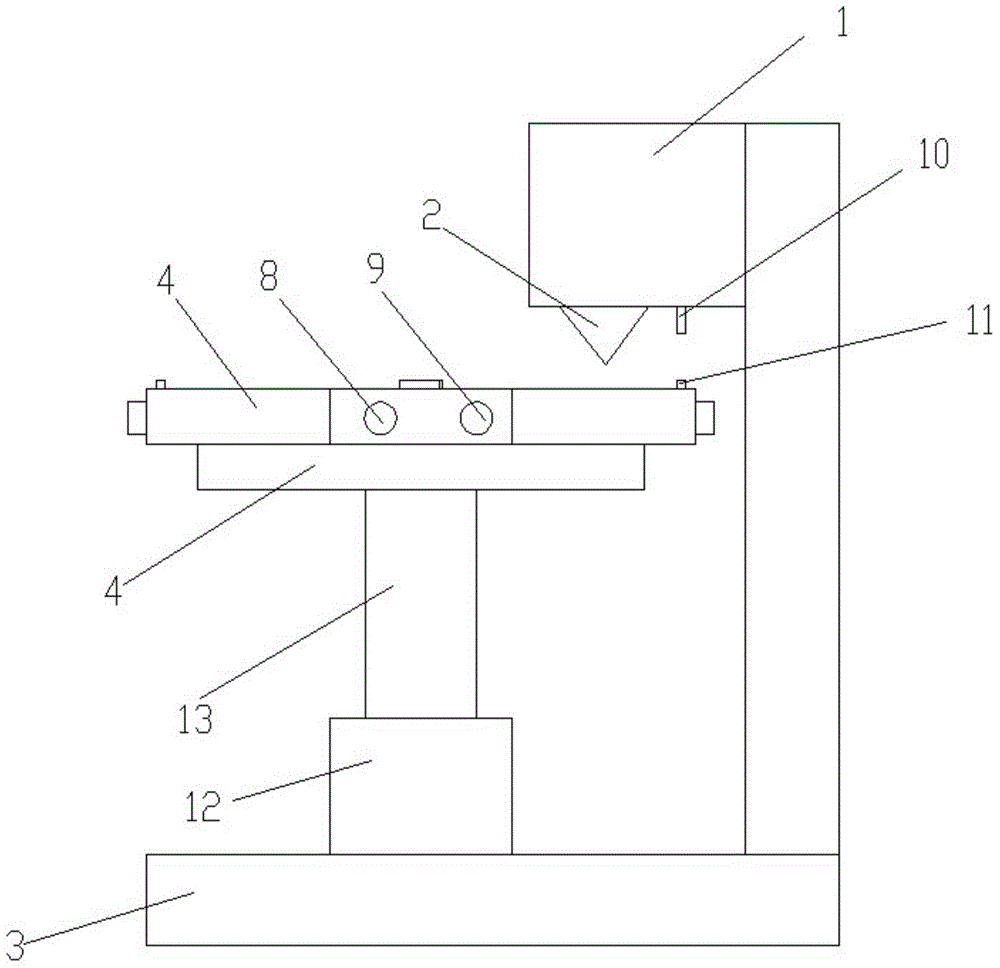

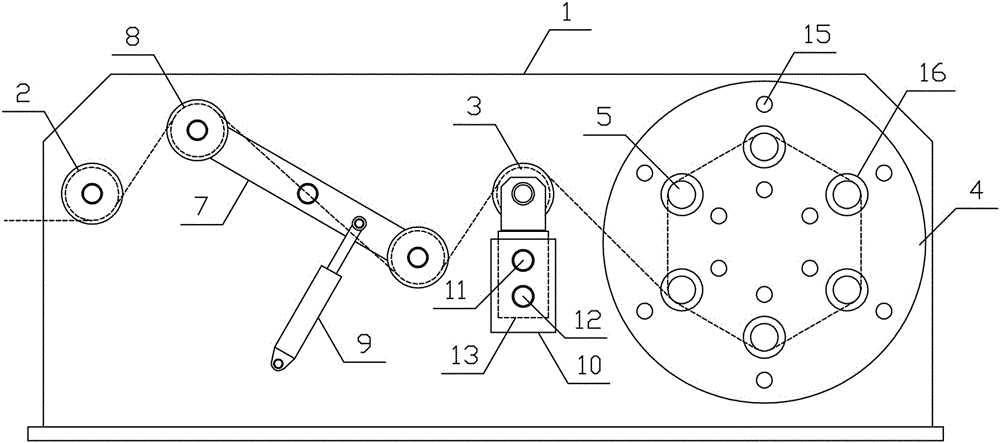

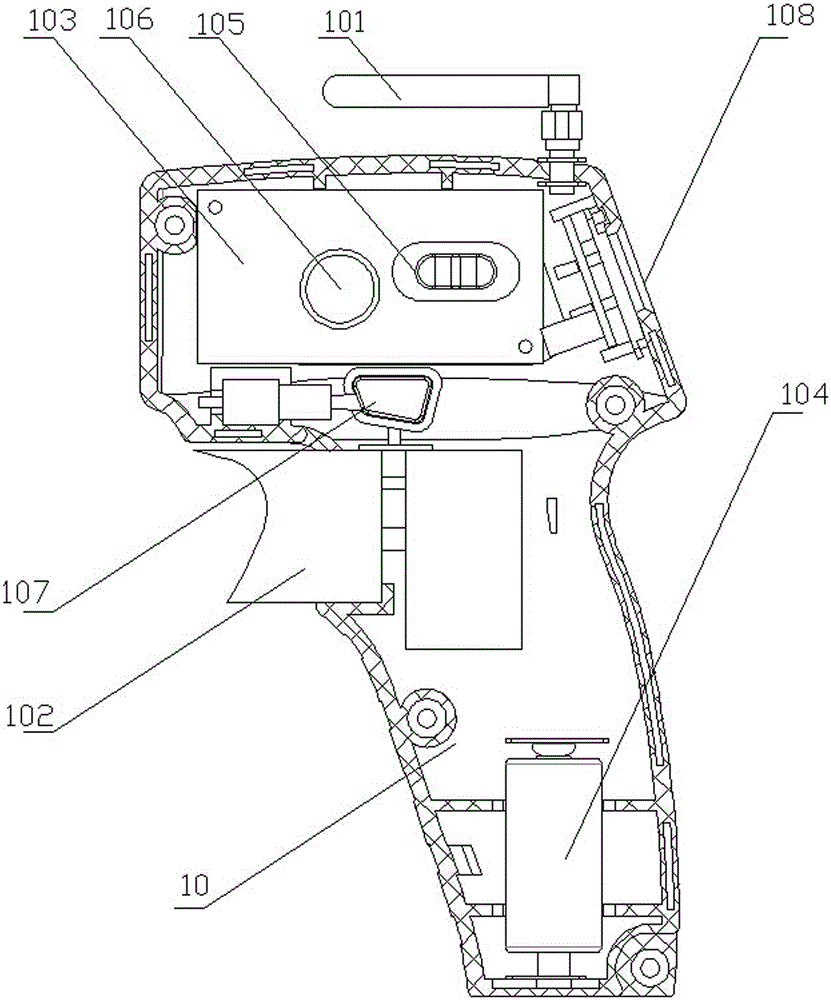

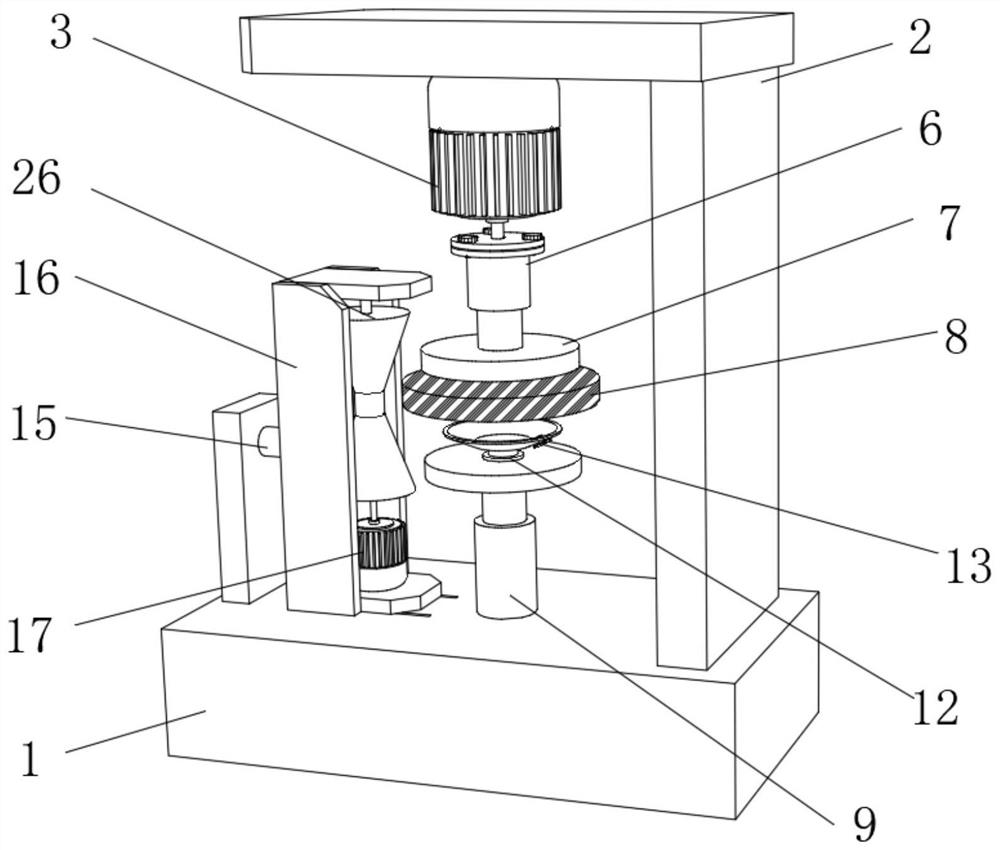

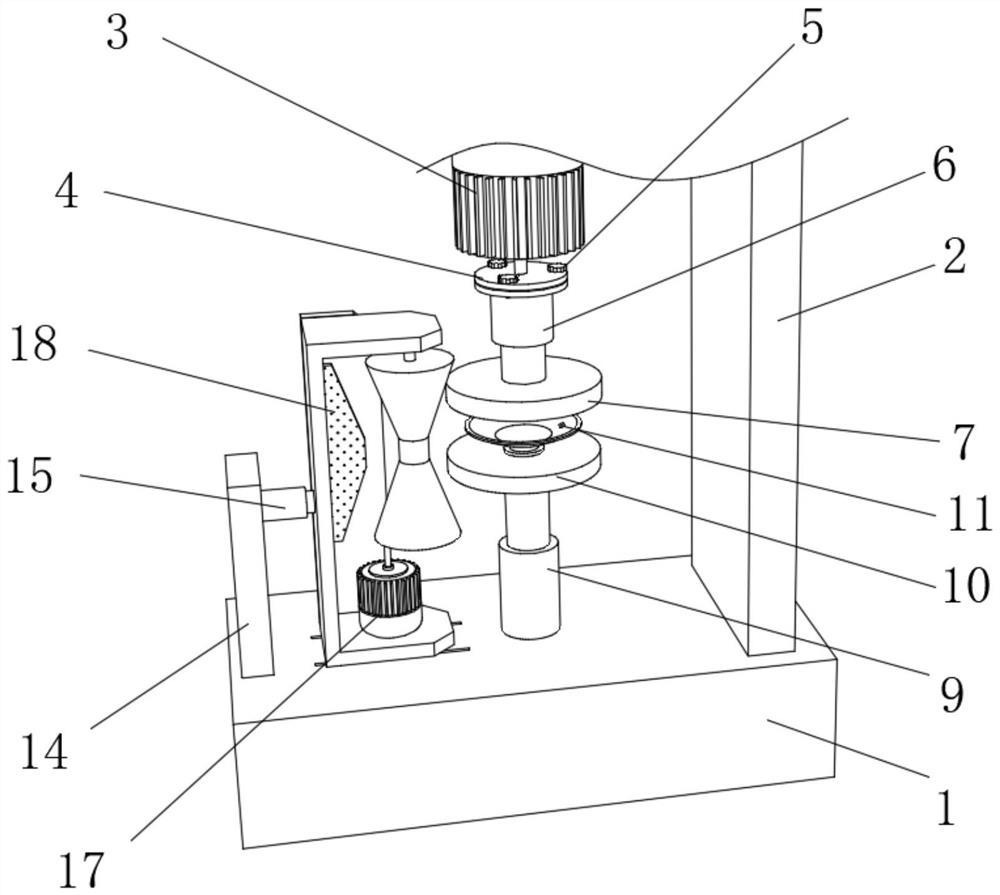

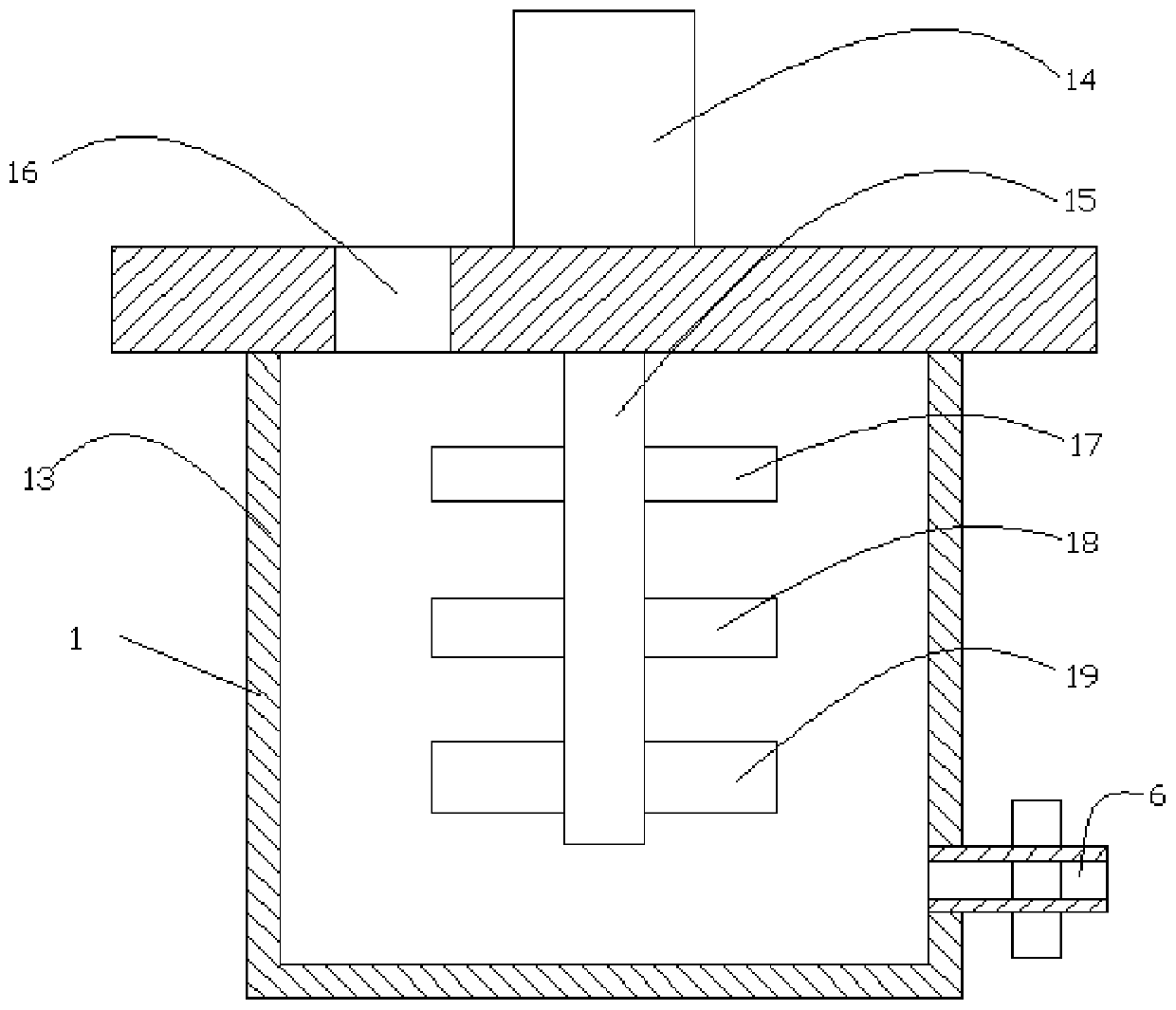

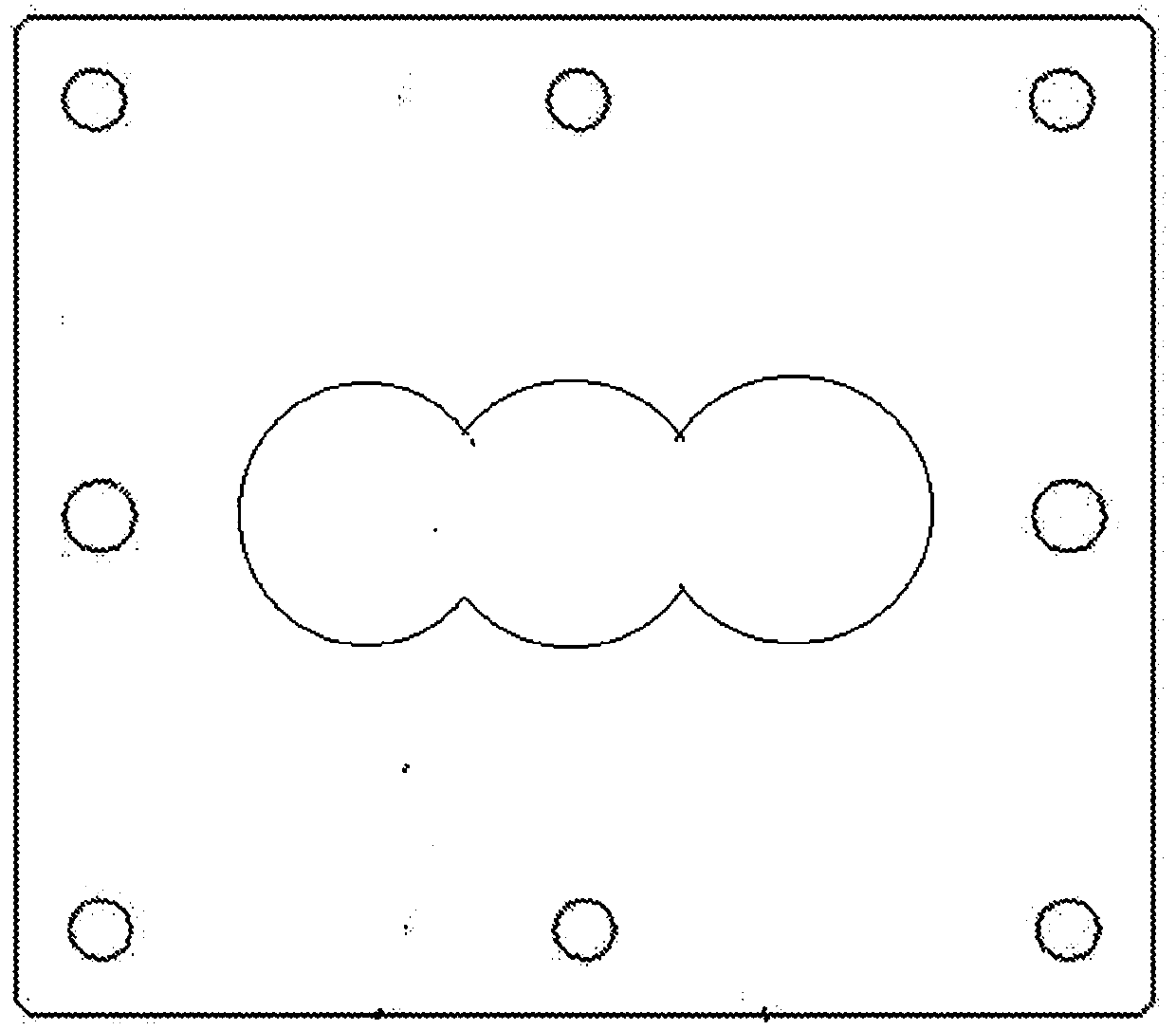

Rotating disc type vacuum perforating apparatus

InactiveCN105108195ARemoved smoothlyThe clamping process is convenientLarge fixed membersPositioning apparatusEngineeringRotating disc

The invention discloses a rotating disc typevacuum perforating apparatus which includes a perforating apparatus main body provided with a perforating drill bit thereon and a workbench thereon. The perforating apparatus main body also includes a rotating discand a plurality of hollow positioning blocks. The rotating disc is rotatably positioned above the workbench. The positioning blocks are secured to the rotating disc. The middle of each positioning block is provided with a positioning groove which is provided with a plurality of apertures. The side wall ofeach positioning groove is provided with an air withdrawing opening and an air charging opening. The perforating apparatus main body is fixedly provided thereon with an infrared emitter closeto the position of the drill bit. Each positioning block is fixedly provided with an infrared sensor thereon.Each infrared sensor is arranged below the infrared emitter. The rotating disc type vacuum perforating apparatus can increase the efficiency of perforating and achieve rotary perforating.

Owner:SUZHOU ENOUXI INTELLIGENT TECH CO LTD

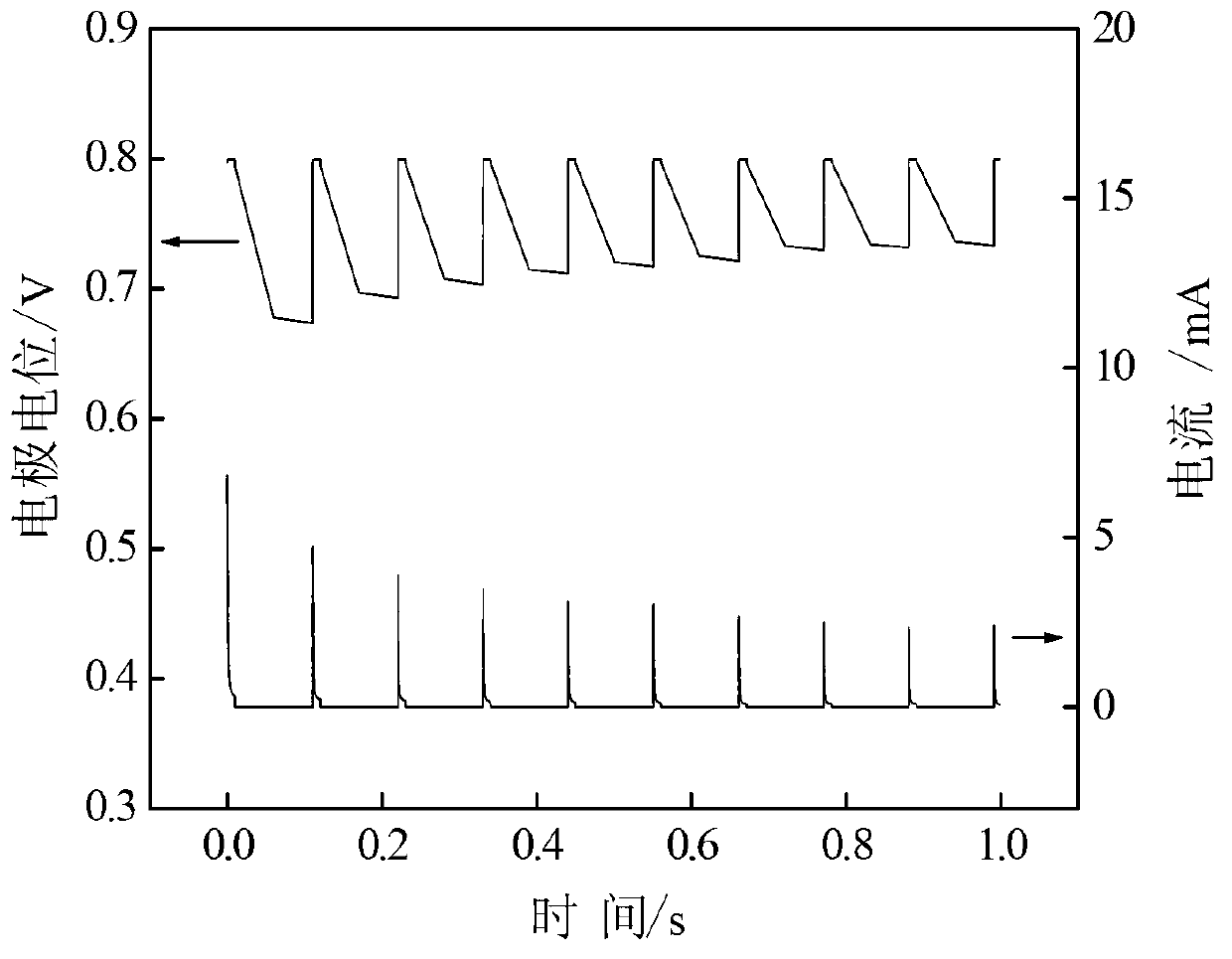

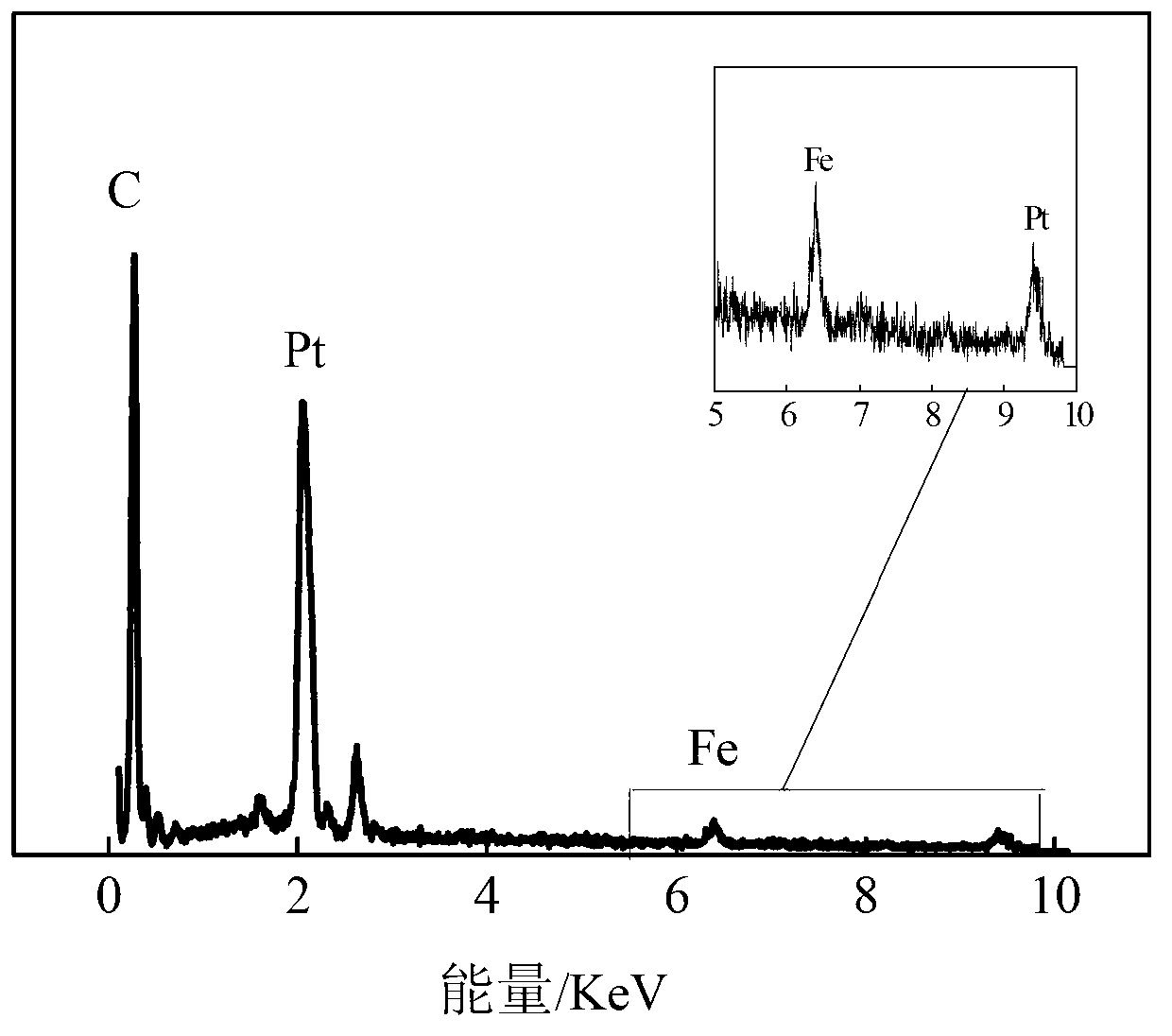

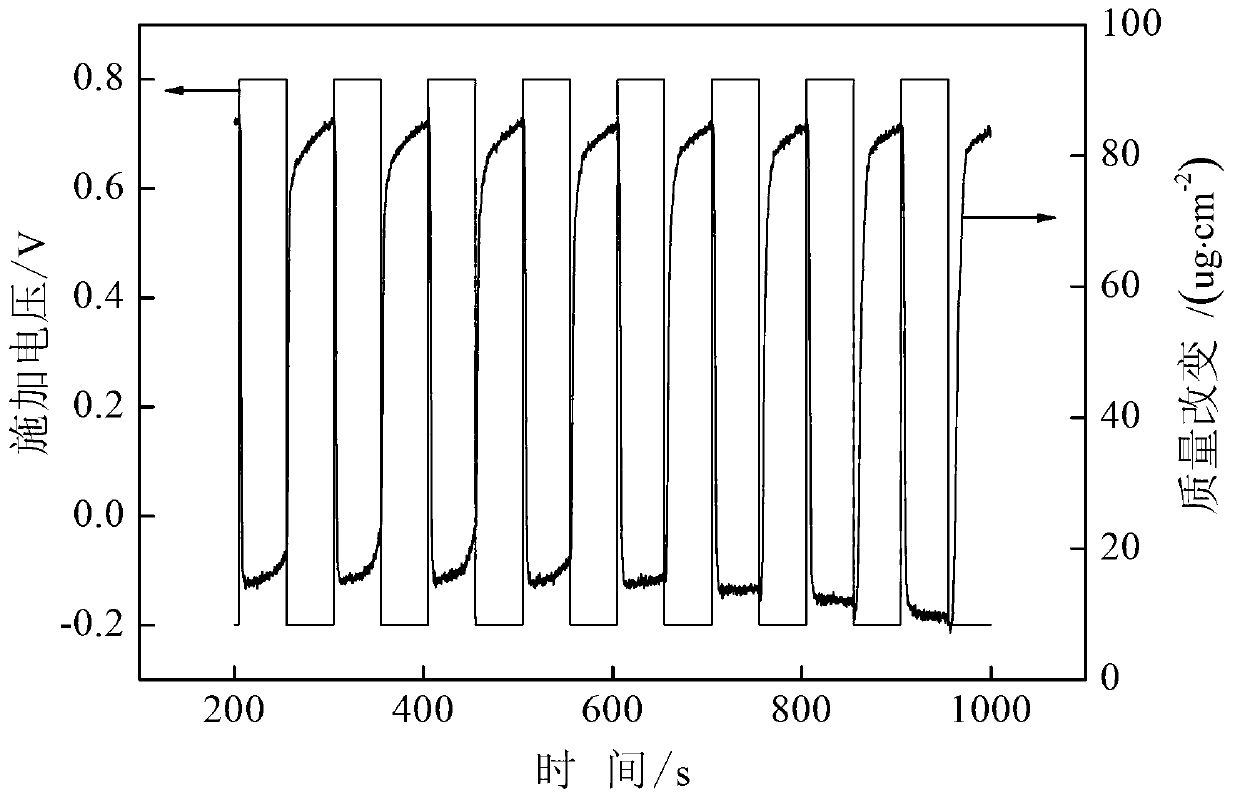

Preparation method of ion imprinted polymer film

ActiveCN103214689AEasy to operateMild preparation conditionsSemi-permeable membranesDispersed particle separationIn situ polymerizationRare earth ions

Belonging to the fields of electroactive functional polymer film material preparation and selective separation of ions, the invention relates to a preparation method of an ion imprinted polymer film. The invention is characterized by relating to a preparation method of an ion imprinted polymer film with an electronic control cation exchange function. The method includes: preparing a water solution of the monomer for polymer preparation, an electrolyte solution, a protonic acid solution, an imprinted ion solution and a doping ion solution, then mixing the five solutions, conducting in situ polymerization on a conductive substrate by a monopolar pulse electrodeposition method so as to synthesize imprinted ion removed ferricyanic group doped polymer film by one step. Being simple and fast to operate, the method provided in the invention needs no additional pickling step and can realize imprinted ion removal in situ. Also, the preparation conditions are mild and are easy to control. The ion imprinted polymer film prepared by the method has an electronic control cation exchange function, and can be used for selective removal of heavy metal ions in water or separation recycling of rare earth ions.

Owner:TAIYUAN UNIV OF TECH

Silica gel mold material for casting metal ornament and its application

InactiveCN101066552ARemoved smoothlyReduce weightFoundry mouldsFoundry coresPolymer scienceHeat conducting

The silicone rubber mold material for casting metal ornament consists of polysiloxane with vinyl radical 100 weight portions, reinforcing agent 10-80 weight portions, heat conducting assistant 5-30 weight portions, heat resisting assistant 0.3-5 weight portions and vulcanizing agent 0.5-5 weight portions. The mold of the material has high heat conductivity, high heat resistance, less temperature raise, and long service life. In addition, the mold is light and has easy demolding of the metal ornament.

Owner:ZHEJIANG NEOGLORY JEWELRY CO LTD +1

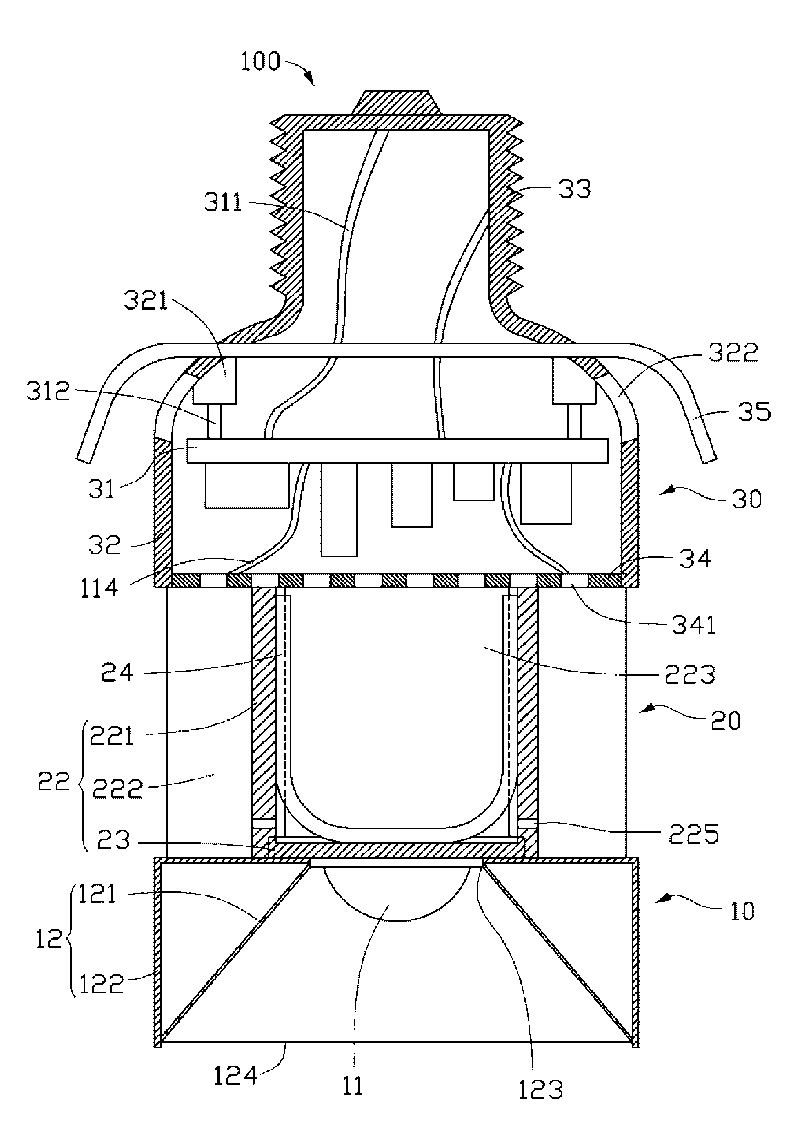

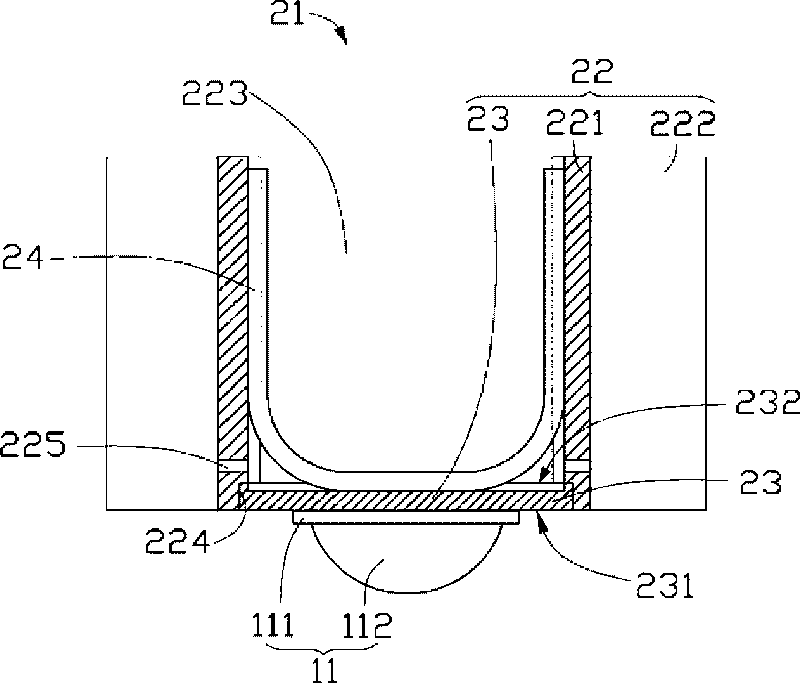

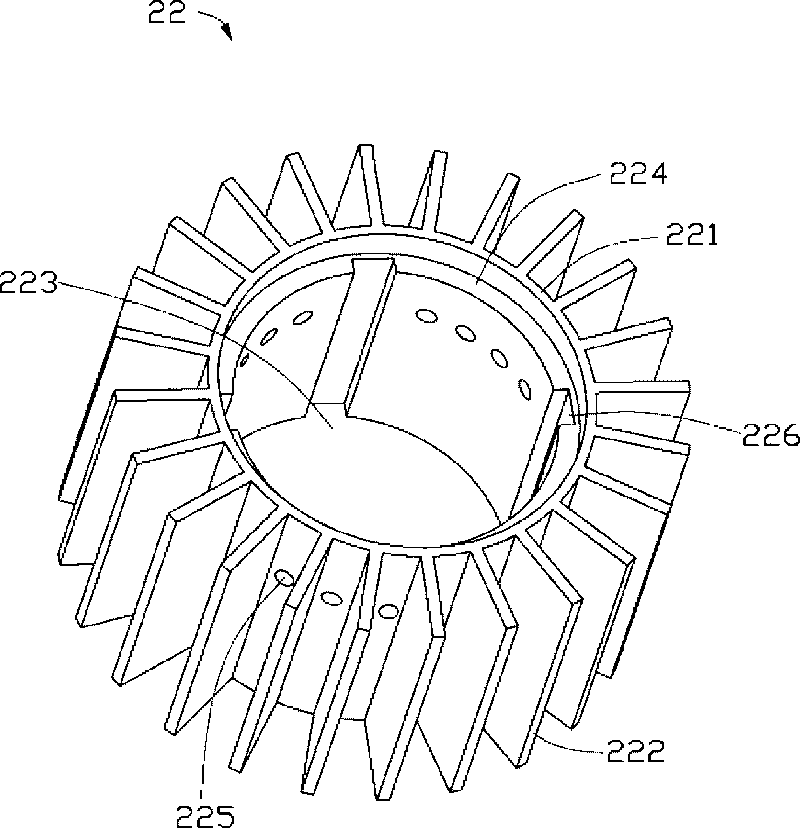

LED light fitting and light engine thereof

InactiveCN101749570AImprove cooling efficiencyImprove uniform cooling efficiencyPoint-like light sourceSemiconductor/solid-state device detailsEvaporationEngineering

The invention relates to an LED light fitting and a light engine thereof; the LED light fitting comprises an optical part, an electrical part and a heat dissipation part, wherein the optical part comprises an LED light source and a light-emitting channel; the electrical part comprises a protecting cover and a circuit board; the heat dissipation part comprises a radiator and at least one heat pipe which are arranged between the protecting cover and the optical part; the radiator comprises a ring-shaped radiating base, a plurality of fins which are distributed on the outer surface of the radiating base in a radial way, and a heat absorbing plate positioned on the radiating base close to one end of the optical part; the radiating base is internally provided with a cavity body provided with an opening towards one end of the protecting cover; the LED light source is in thermal contact with the outer surface of the heat absorbing plate facing the optical part; and the heat pipe is arranged inside the cavity body of the radiating base and comprises an evaporation section and a condensation section, wherein the evaporation section is in thermal contact with the inner surface of the heat absorbing plate facing the electrical part, and the condensation section is in thermal contact with the inner surface of the radiating base.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Semi-aromatic transparent polyamide preparation method and semi-aromatic transparent polyamide

The present invention discloses a semi-aromatic transparent polyamide preparation method and semi-aromatic transparent polyamide. According to the present invention, an acid-alkali neutralization reaction is performed in a polar aprotic solvent, the reaction product semi-aromatic polyamide salt has poor solubility in the polar aprotic solvent, and the product polyamide salt can be precipitated from the reaction mixing liquid after the reaction, such that the semi-aromatic transparent polyamide salt is easily separated from the reaction mixing liquid, and the purity of the semi-aromatic transparent polyamide salt is high; the solid semi-aromatic transparent polyamide salt is subjected to the polymerization reaction, such that the problem that the reaction raw material ratio is difficult to control in the prior art is solved; and the polymerization reaction of the invention is divided into three stages such as the pressurization reaction stage, the normal pressure reaction stage and the pressure reducing reaction stage, wherein the condensation polymerization reaction by-product can be smoothly removed from the reaction system in the pressure reducing reaction stage, such that the reaction balance can easily move to the forward direction so as to obtain the high molecular weight semi-aromatic transparent polyamide.

Owner:CHANGSHU RES INST OF DALIAN UNIV OF TECH CO LTD

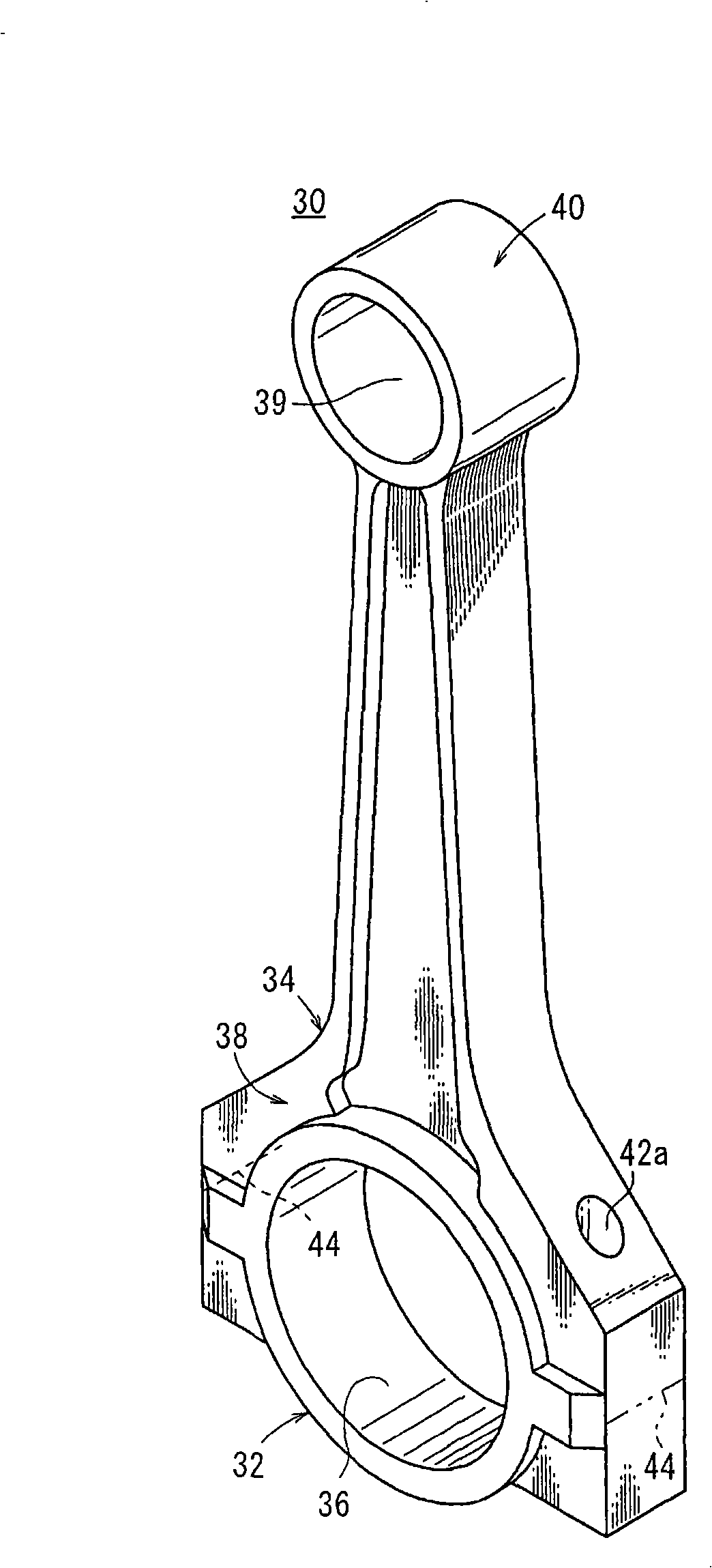

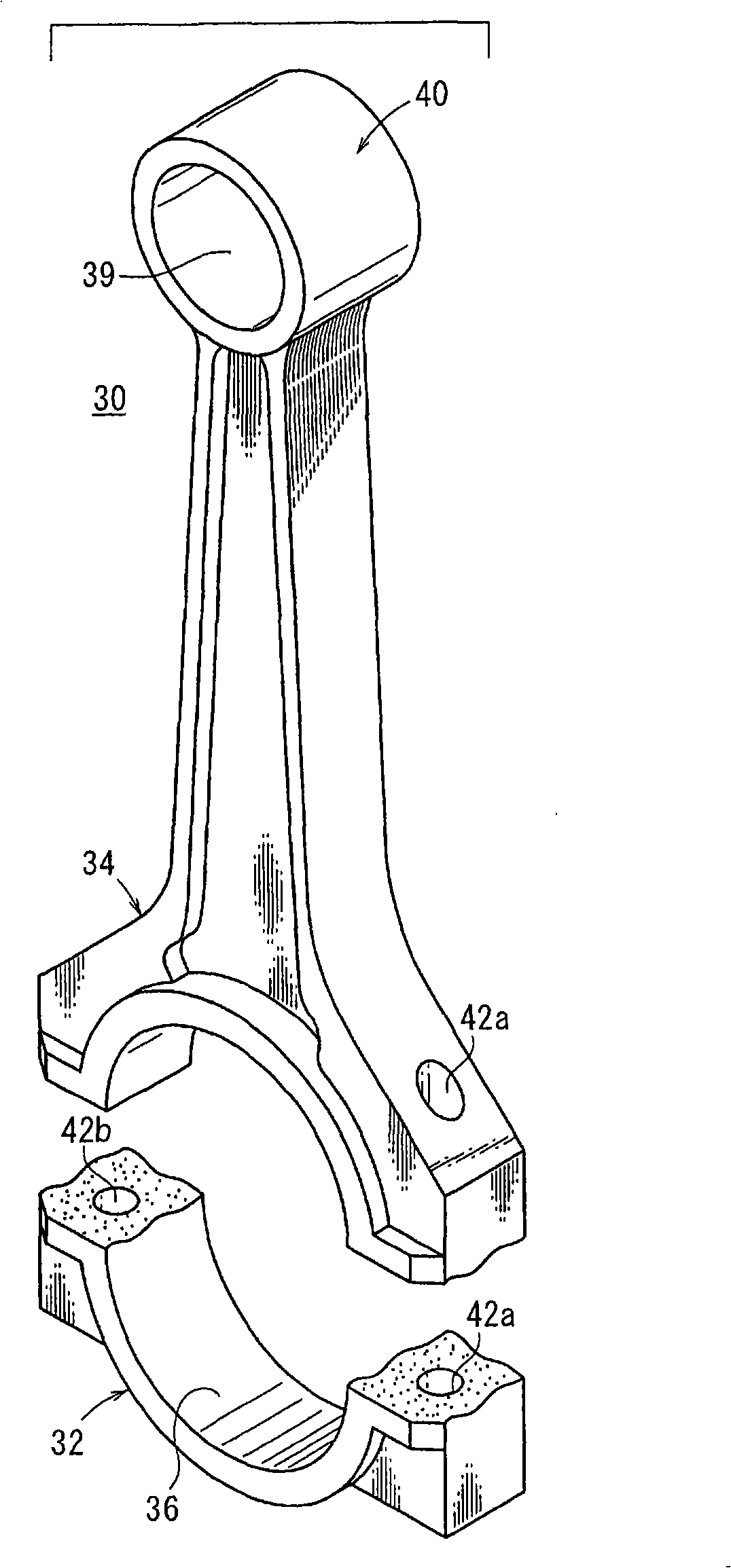

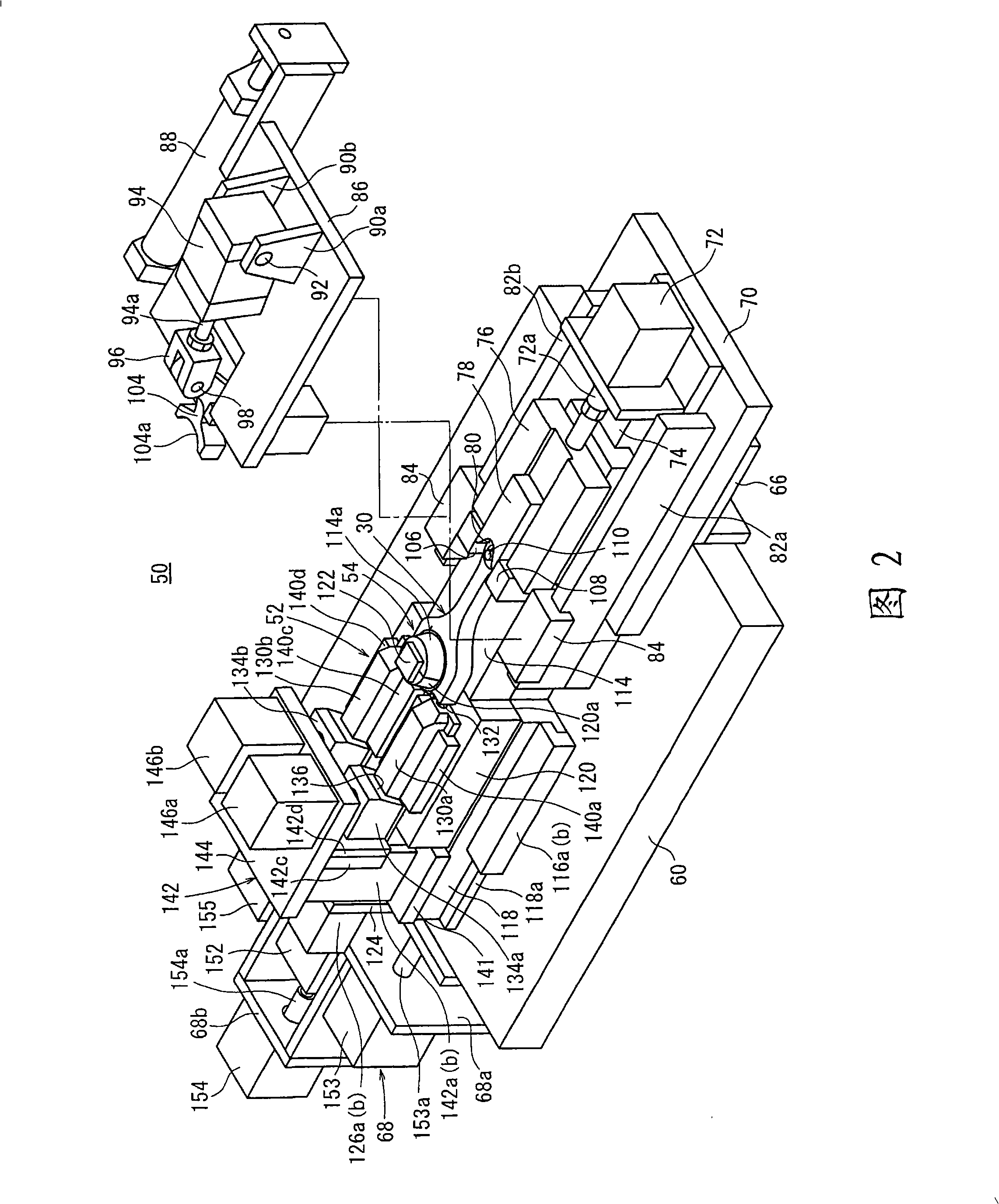

Method and device for manufacture of connecting rod

InactiveCN101304853AAccurate connectionEasy to removeConnecting rodsMetal working apparatusEngineeringMechanical engineering

A device for manufacturing a connecting rod comprises a fixed stage (62) secured onto a base (60), a movable stage (64) so installed as to be move close to and apart from the fixed stage (62), and a set of backup cylinders (153, 155) displacing the overall movable stage (64) along the axial direction of the connecting rod (30). The set of backup cylinders (153, 155) are substantially simultaneously biased to displace a cap part (32) together with the movable stage (64) until the fractured surface of the cap part (32) of the connecting rod abuts on the fractured surface of the rod part (34) of the connecting rod held on the fixed stage (62). Consequently, the removal and release of chips produced on the mating fractured surfaces can be promoted.

Owner:HONDA MOTOR CO LTD

Lithium bis-fluoro-sulfonimide dechlorinating and purifying method

ActiveCN108373143AWill not cause deteriorationRemoved smoothlyNitrosyl chlorideLithiumOrganic solvent

The invention discloses a lithium bis-fluoro-sulfonimide dechlorinating and purifying method. In the method disclosed by the invention, a dewatering temperature is lower, a water reaction type dewatering agent thionyl chloride is utilized to ensure that all generated products are gas and the products are prevented from going bad in a dewatering process; as the dewatering agent directly reacts withwater, crystallization water subjected to molecular complexation can also be successfully removed. According to the method disclosed by the invention, a crude product is dissolved by an organic solvent, water-free alkali is utilized and added to adjust a system pH to be larger than 7, and spin drying of a system is facilitated after acid is removed; furthermore, the used water-free alkali can prevent water from being generated again after reaction; meanwhile, chloride in the system is also effectively removed.

Owner:XIAMEN UNIV

Traditional Chinese medicine preparation for treating chronic nephritis and nephrotic syndrome

InactiveCN101152414APromote blood circulationImprove lesionAnthropod material medical ingredientsUrinary disorderDiseaseMyrrh

The utility model provides a Chinese traditional medicine for curing the chronic nephritis and nephropathy syndrome; the present invention consists of the following raw materials according to corresponding weight proportion of 10 to 50 portion of aweto, 10 to 50 portion of wild glossy ganoderma, 5 to 40 portion of Tibet safflower, 10 to 80 portion of gecko, 10 to 80 portion of cicada slough, 5 to 80 portion of ginseng, 5 to 50 portion of frankincense, 5 to 50 portion of myrrh, 5 to 80 portion of Tianshan snow lotus, 10 to 100 portion of cornel, 10 to 80 portion of prepared rhizome of rehmannia, 10 to 80 portion of root of red salvia, 10 to 80 portion of red peony, 5 to 70 portion of Paris chinensis, 5 to 80 portion of angelica, 10 to 100 portion of honeysuckle, 5 to 50 portion of leech, 5 to 50 portion of ledeboruiella root, 10 to 60 portion of oriental water plantain rhizome and 5 to 80 portion of gynura segetum. The preparation can take effect quickly and the curative effect is stable; with the preparation, the manifestation and the root cause of the disease can be cured; the preparation is convenient for taking and the dosage is less and the price is low.

Owner:甘志球

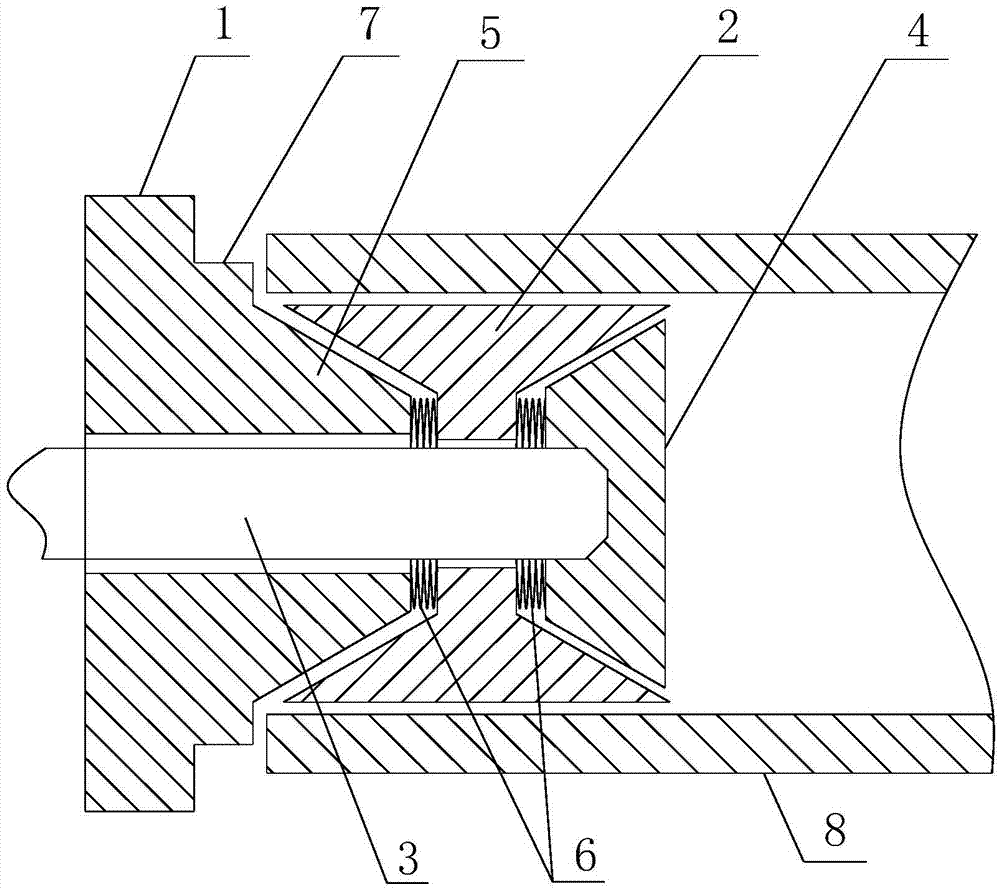

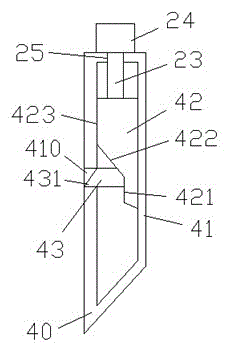

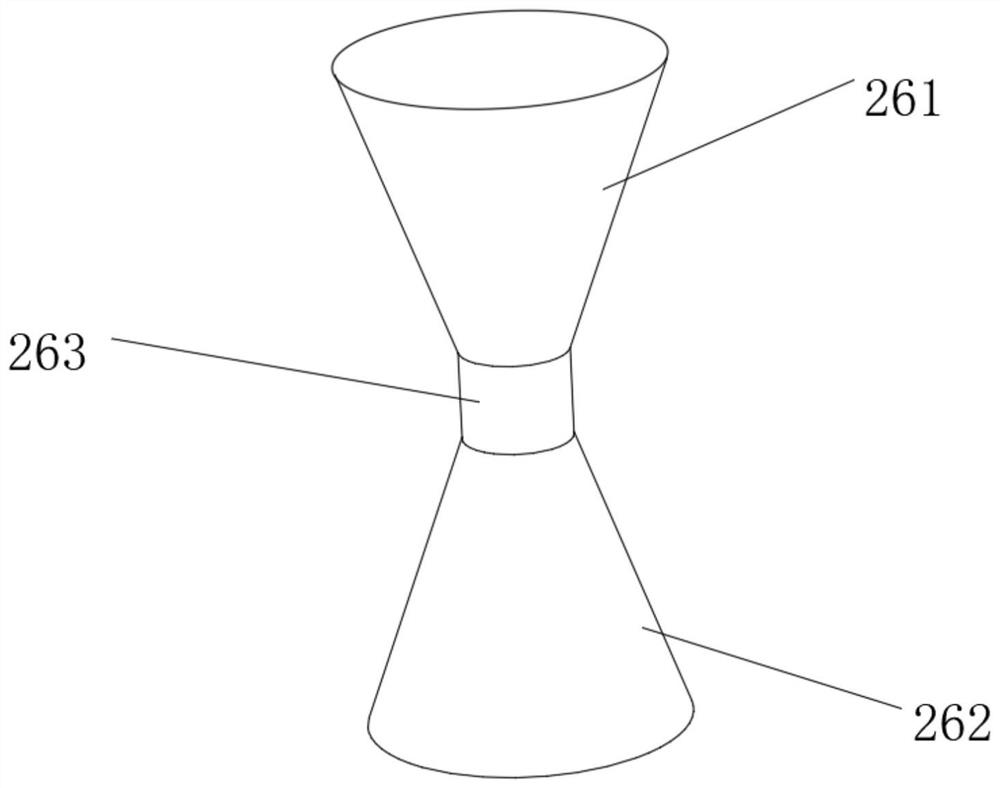

Elastic clamp for thin-walled part

InactiveCN107088765ANo deformationStable clampingWork holdersPositioning apparatusSpring forceBiomedical engineering

The invention relates to the technical field of clamps, in particular to an elastic clamp suitable for thin-walled parts. The elastic clamp for thin-walled parts includes a clamp body, a cylindrical elastic sleeve, a pull rod and a rounded truncated slider. The clamp body is provided with a circular truncated boss, and the boss is provided with a central hole. The described The elastic sleeve is located between the boss and the slider, and the two ends of the elastic sleeve are respectively provided with grooves matching the boss and the slider. The pull rod passes through the boss and the elastic sleeve in turn and is connected with the slider. Pull the slider through the pull rod to make both ends of the elastic sleeve elastically deform evenly, expand the thin-walled parts, and the clamping force acts evenly on the inner wall of the entire part to ensure that the parts are firmly clamped and the parts do not deform. Guarantee the processing quality. When the pull rod is loosened, under the action of the elastic sleeve's own contraction force and spring force, the elastic sleeve can be quickly restored to its original shape, thereby releasing the parts, so that the parts can be smoothly removed from the fixture.

Owner:CHENGDU HONGYU TIMES TECH CO LTD

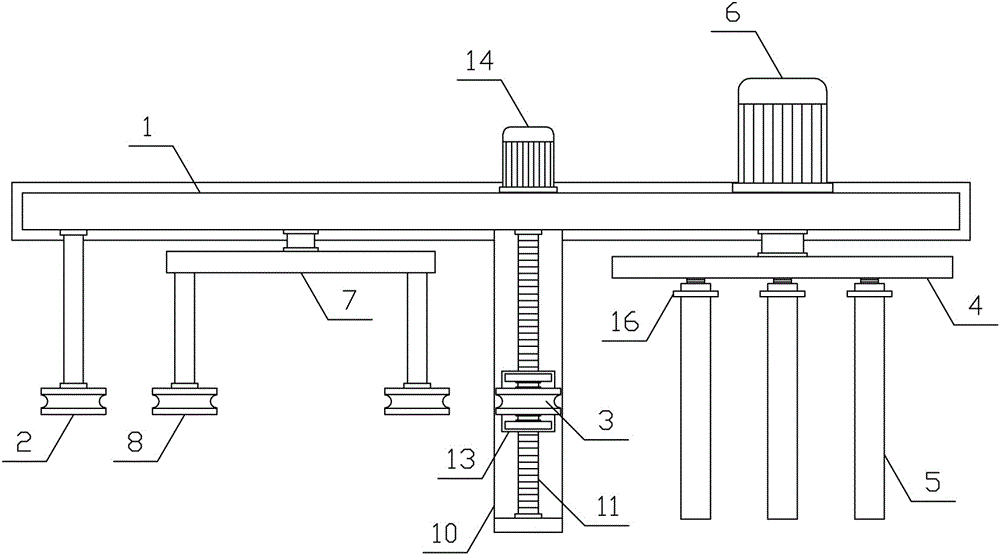

Yarn conveying and winding mechanism

The invention discloses a yarn conveying and winding mechanism and belongs to the field of textile processing machinery and equipment. The yarn conveying and winding mechanism comprises a winding bracket, a yarn feeding wheel, a yarn guide wheel, a yarn adjusting mechanism, a rotary circular plate, winding rods and a winding motor, wherein the yarn feeding wheel is vertically and rotatably connected with the winding bracket; the yarn adjusting mechanism comprises a rotary adjusting plate, adjusting wheels and a rotary hydraulic cylinder; two ends of the rotary adjusting plate are respectively, vertically and rotatably connected with the adjusting wheels; the rotary hydraulic cylinder is arranged between the rotary adjusting plate and the winding bracket; a translation screw rod is in threaded connection with a translation plate; the yarn guide wheel is vertically and rotatably connected with the upper side of the translation plate; and a translation motor drives the translation screw rod, the winding motor drives the rotary circular plate, and one side of the rotary circular plate is horizontally and uniformly provided with multiple winding rods. The yarn conveying and winding mechanism is reasonable in structural design, is capable of quickly, efficiently, uniformly and orderly conveying and winding yarns, and meets the demands of production and use.

Owner:ZHEJIANG ZHONGSHI MACHINERY CO LTD

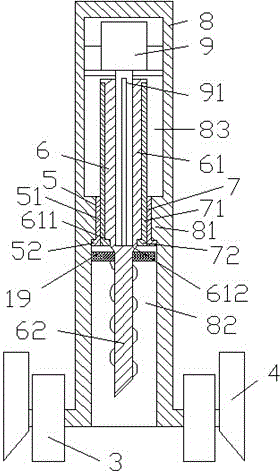

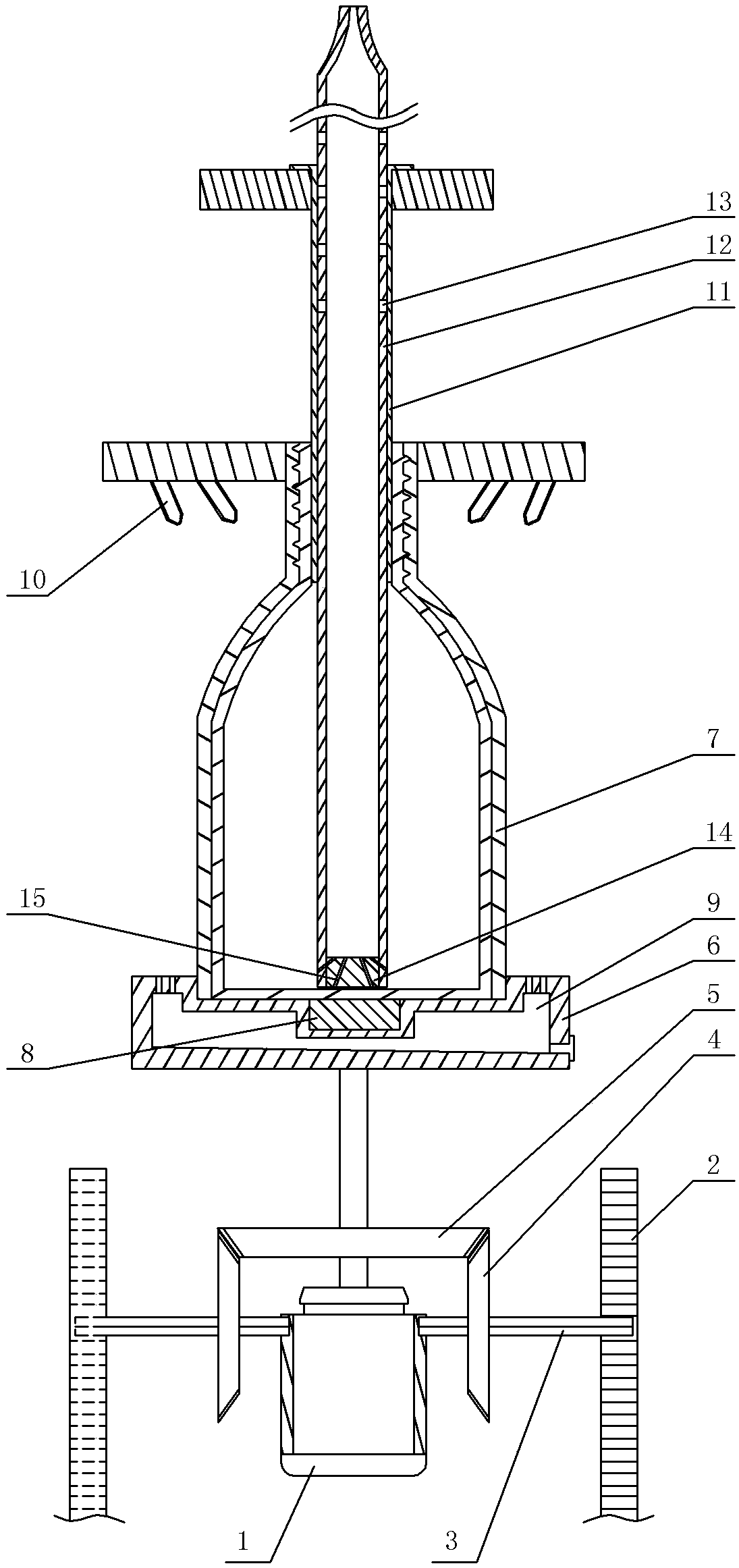

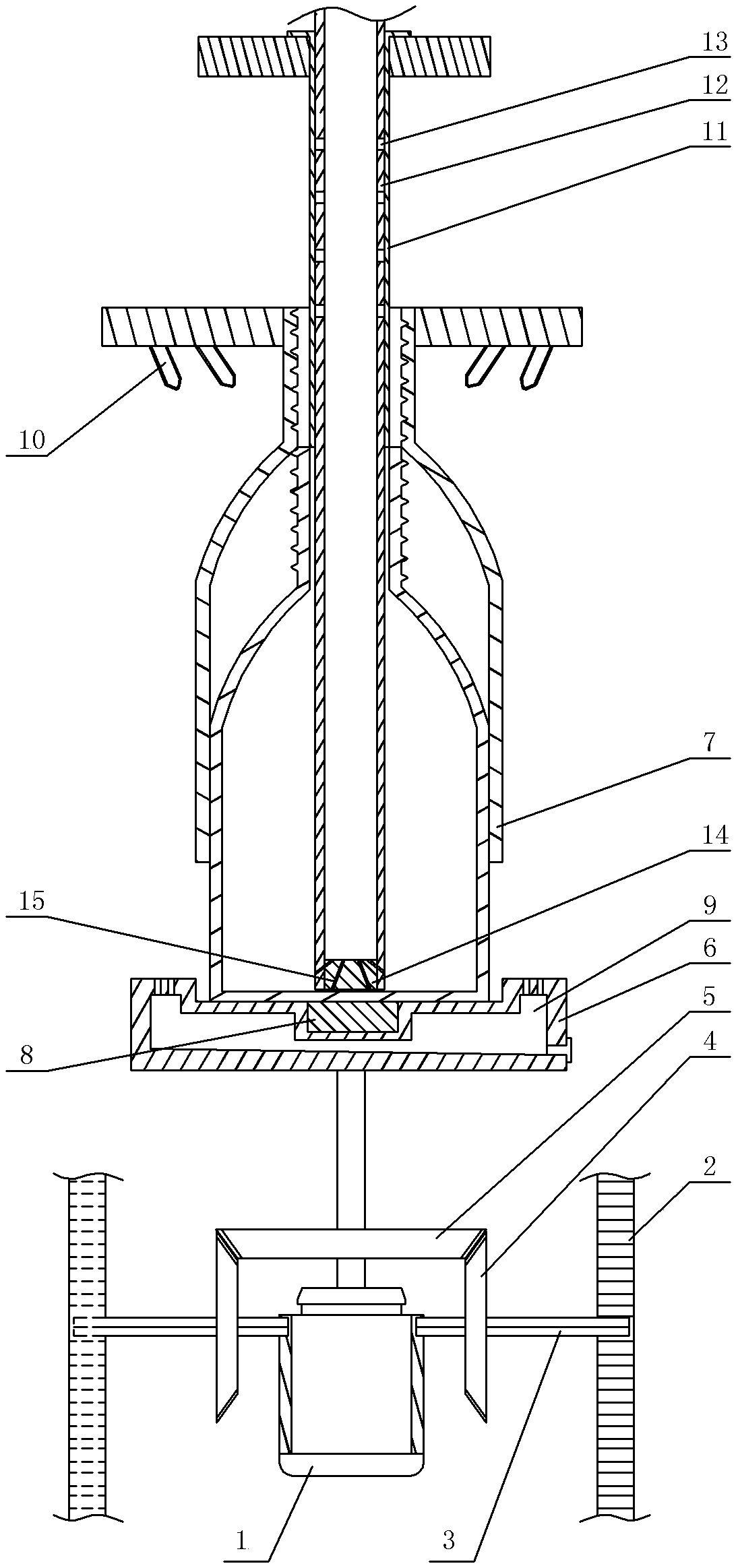

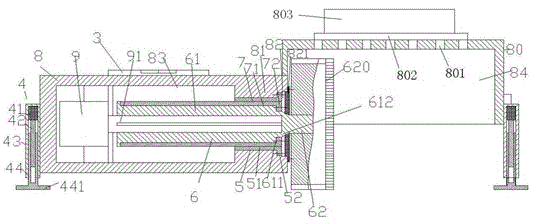

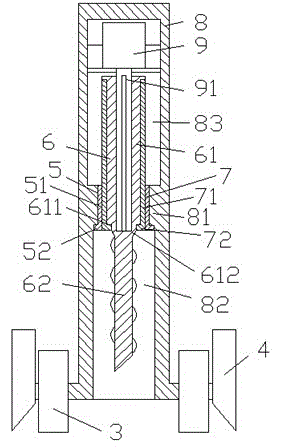

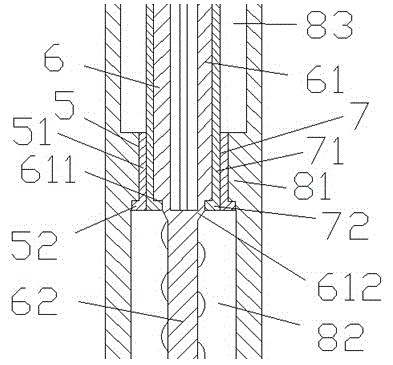

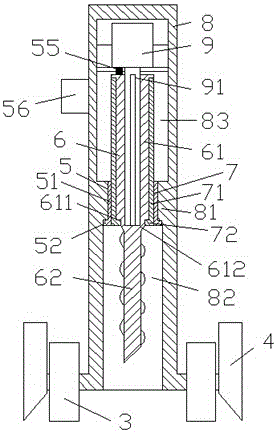

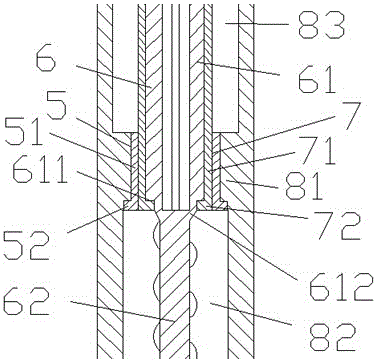

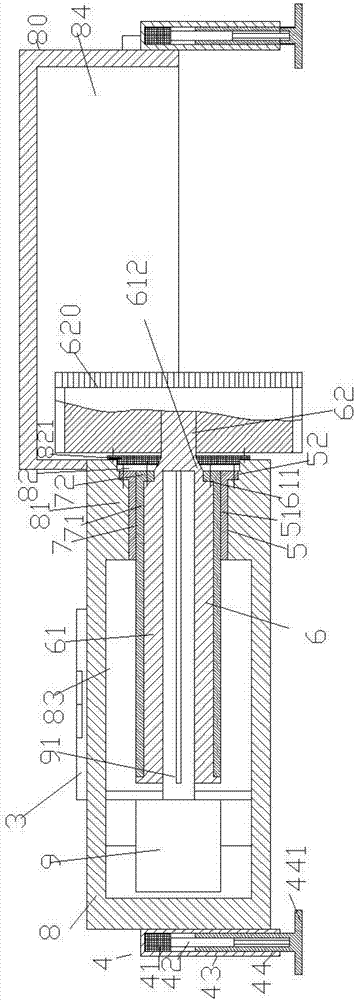

Hole digging machine capable of realizing anchorage through manual control and running safely

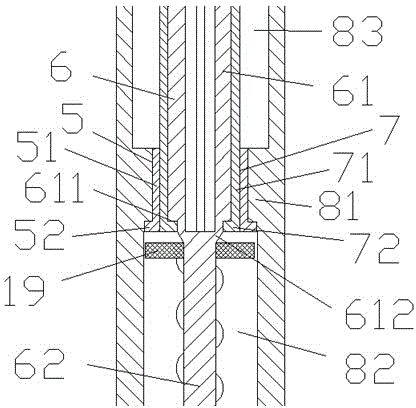

InactiveCN104948110AIncrease the diameterIncrease the reaction force bearing surfacePlantingDrilling rodsDrive motorDrill pipe

A hole digging machine capable of realizing anchorage through manual control and running safely comprises an outer casing (8), a driving motor (9) and a hole digging drill pipe component (6) driven by the driving motor (9), wherein the driving motor (9) is arranged in the outer casing (8) and is in power connection with a spline hole in a driving sleeve part (61) of the hole digging drill pipe component (6) in an axially gliding manner through a fixedly connected spline rod (91), the driving sleeve part (61) of the hole digging drill pipe component (6) is fixedly connected with a drill pipe part (62) of the hole digging drill pipe component (6) through a tapered connecting part (612), and an axial extending key is arranged on the outer circumferential surface of the driving sleeve part (61) and matched with an axial extending key groove in the inner circumferential wall of a cylinder (71) of an outer threaded sleeve component (7).

Owner:孙卫香

Glass bottle manufacturing device and application method thereof

The invention relates to the field of glass processing, in particular to a glass bottle manufacturing device, comprising a rack, a forming and blowing mechanism and a screwing mechanism. The forming and blowing mechanism comprises a forming unit and a blowing unit; the forming unit comprises a support plate and a bottle body mold, the bottle mold is provided with internal thread at the bottleneck,the support plate provided with first magnet can be driven to rotate and move by the screwing mechanism; the blowing unit comprises an outer sleeve and an inner sleeve, second magnet which is in attraction with the first magnet is fixed at the lower end of the inner sleeve, and the second magnet is provided with a plurality of air outlets obliquely. The application method of the glass bottle manufacturing device includes the steps of 1, pushing softened glass into the bottle body mold; 2, forming the glass bottle; 3, hardening the glass bottle; 4, releasing the glass bottle from the bottle body mold; 5, drying the bottle body mold. According to the technical scheme, the glass bottle manufactured by the method has uniform bottom and people do not need to grind the formed thread later.

Owner:CHONGQING HAOSHENG GLASS

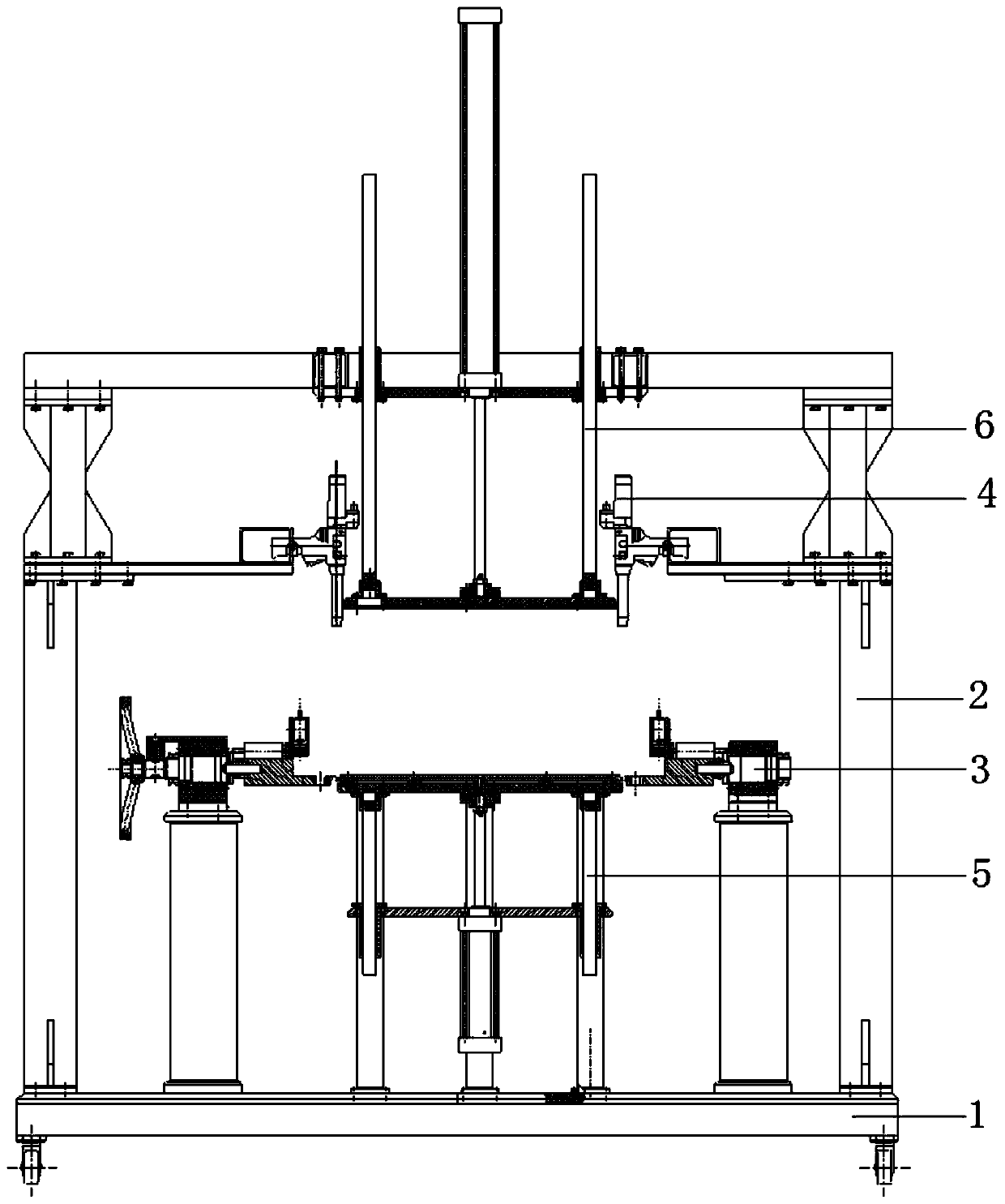

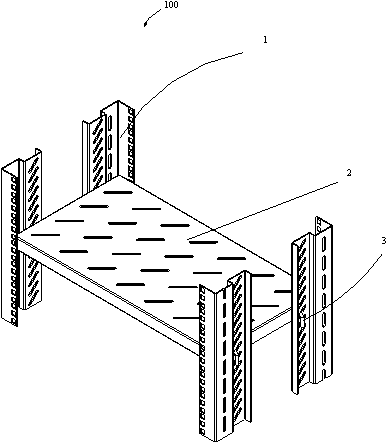

Intercooler double-track welding device

InactiveCN109773304AImprove welding efficiencyPrecise positioningWelding/cutting auxillary devicesElectrode supporting devicesIntercoolerEngineering

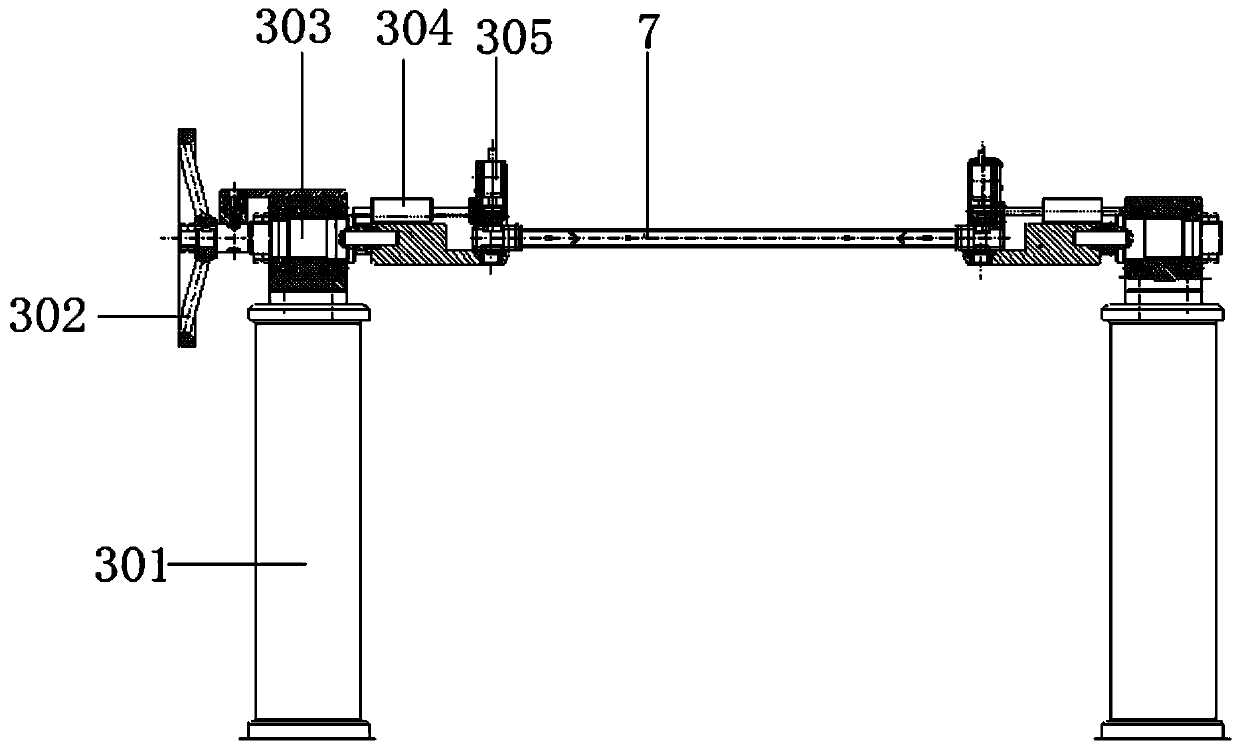

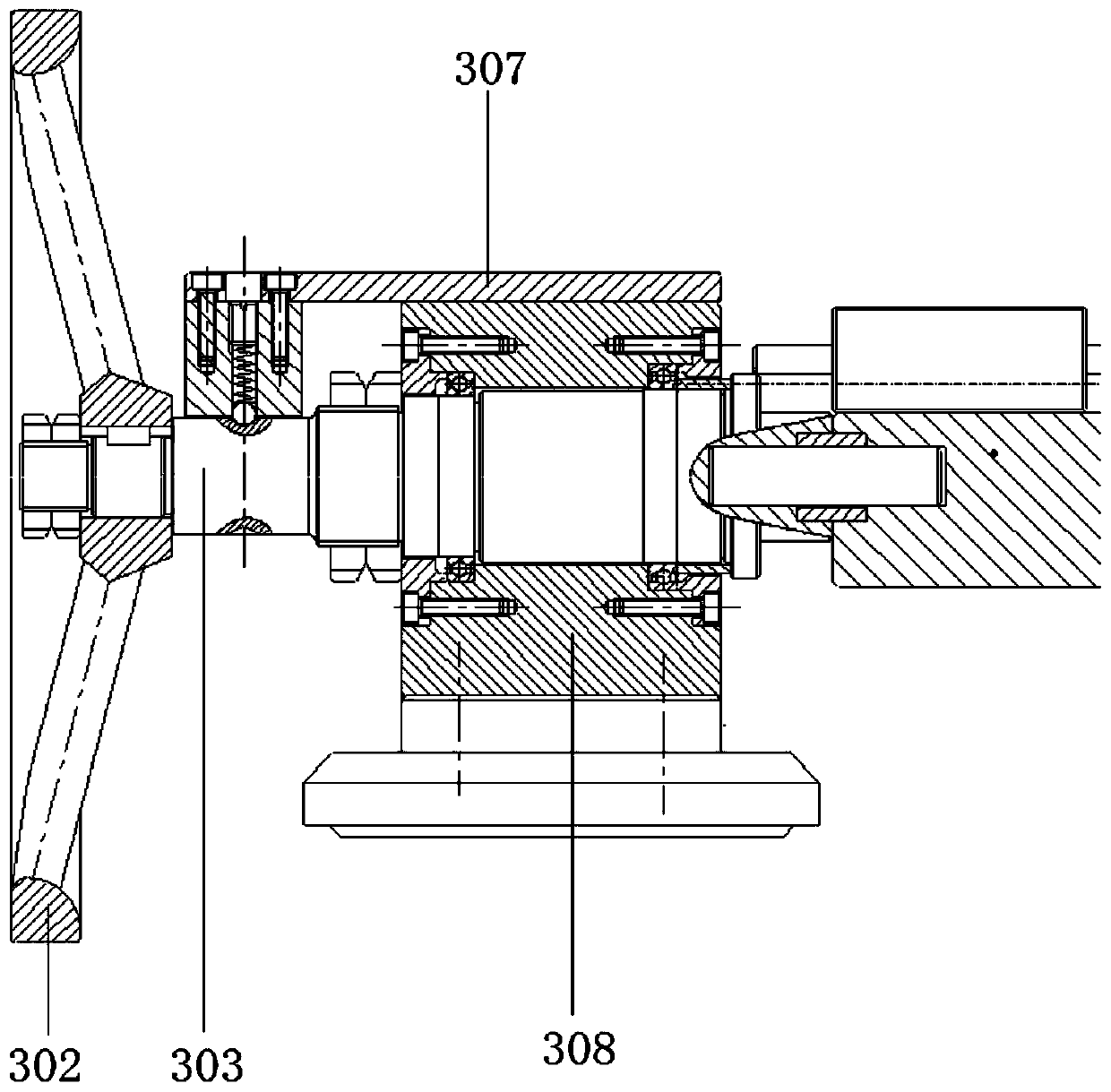

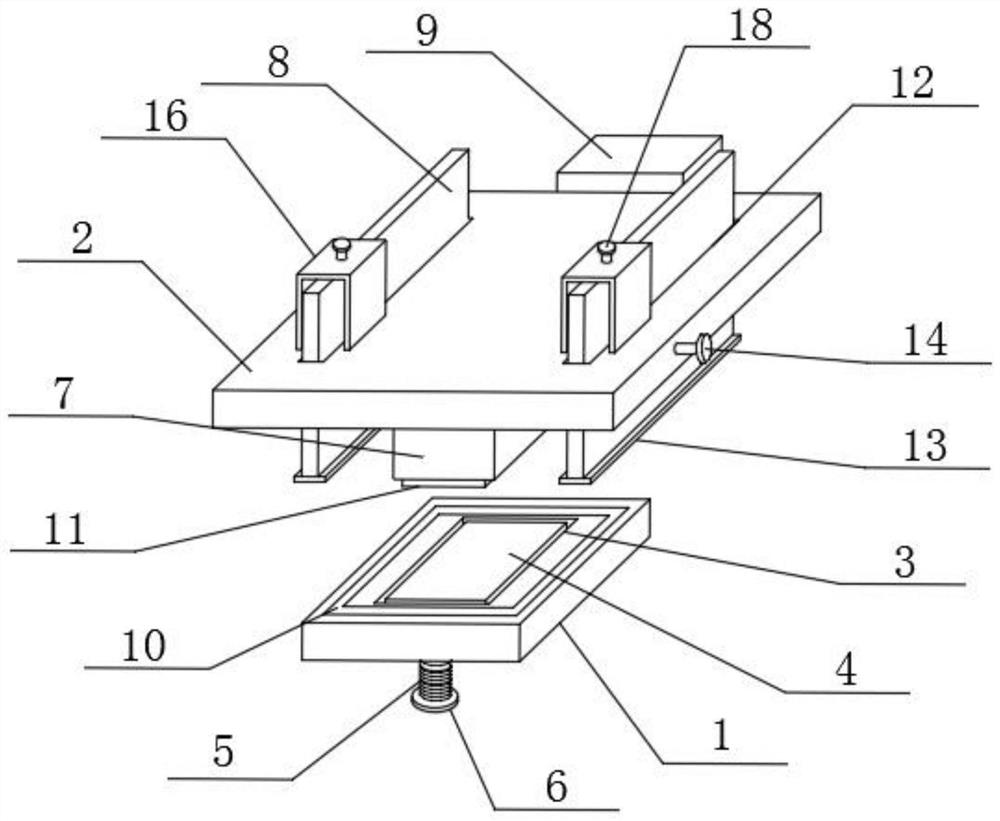

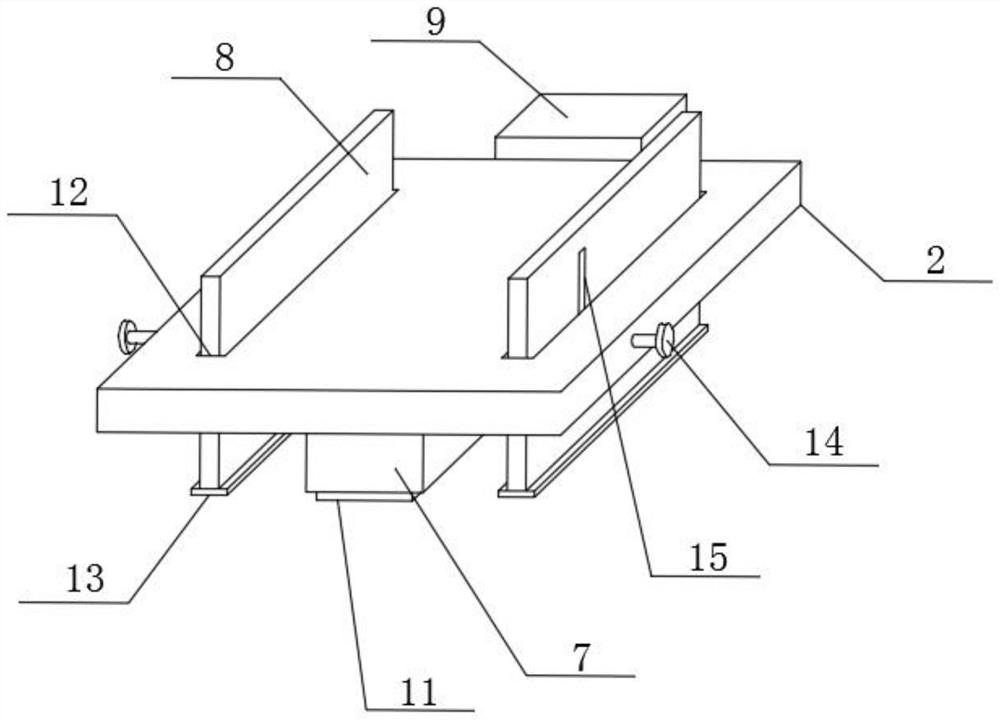

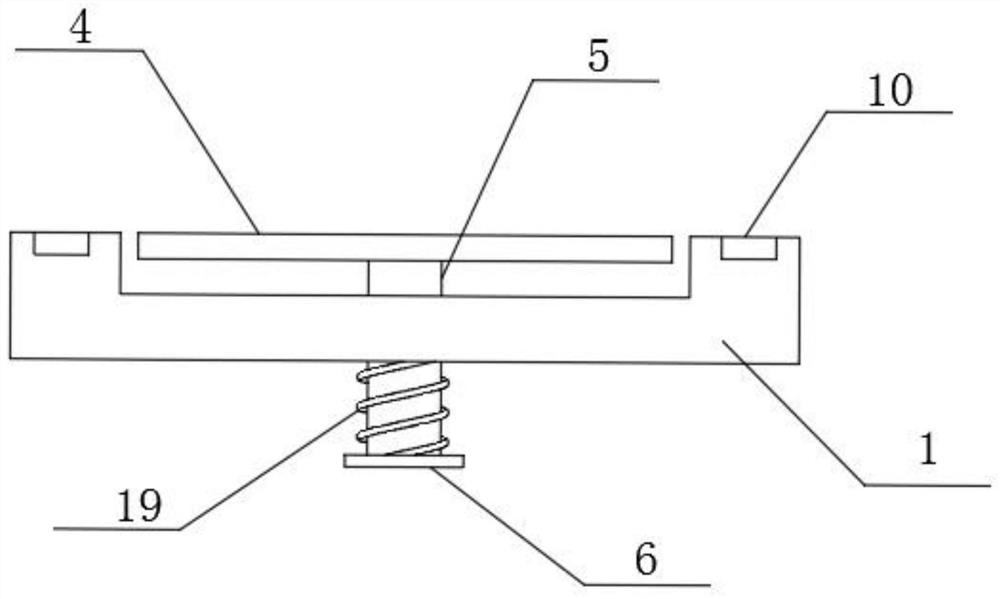

The invention relates to an intercooler double-track welding device. A base plate (1) and a framework (2) are included. A rotation positioning unit (3), welding units (4), a lower supporting unit (5)and an upper pressing unit (6) are further included. A to-be-welded workpiece (7) is fixed to the lower supporting unit (5) through the rotation positioning unit (3) and the upper pressing unit (6). The welding units (4) on the two sides are used for welding, and after one face is welded, the rotation positioning unit (3) is used for overturning the workpiece (7) for welding of the other face. Compared with the prior art, the device is high in welding efficiency, double-track welding is conducted through the double-track and double-gun automatic welding device, left-right erecting frameworks are used for making left and right welding guns run along tracks, the welding guns run to the start position of the workpiece (7) to start welding, and after one side is welded, the workpiece (7) is overturned through a rotation hand wheel.

Owner:SHANGHAI DELANG AUTO PARTS MFG

Road construction device capable of conducting dust fall

The invention provides a road construction device capable of conducting dust fall. The road construction device is used for conducting grinding on the local protrusion on the construction road surface in the road construction process. The road construction device comprises an external shell (8), a motor (9) and a grinding head drive rod component (6) driven by the motor (9). The motor (9) is in power connection with a splined hole in a drive sleeve portion (61) of the grinding head drive rod component (6) in the axial direction in a slidable mode through a spline rod (91) fixedly connected with the motor (9). The drive sleeve portion (61) of the grinding head drive rod component (6) is fixedly connected with a grinding head mounting rod portion (62) of the grinding head drive rod component (6) through gradually contractile connection portions (612).

Owner:BEIJING TIMES HAODING TECH

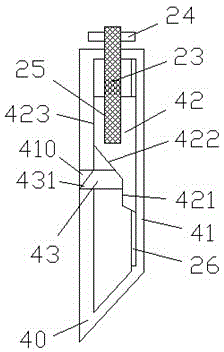

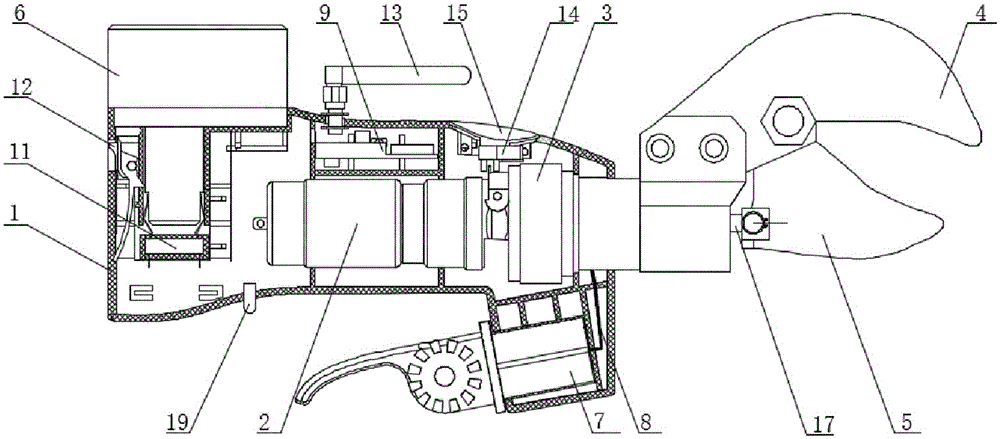

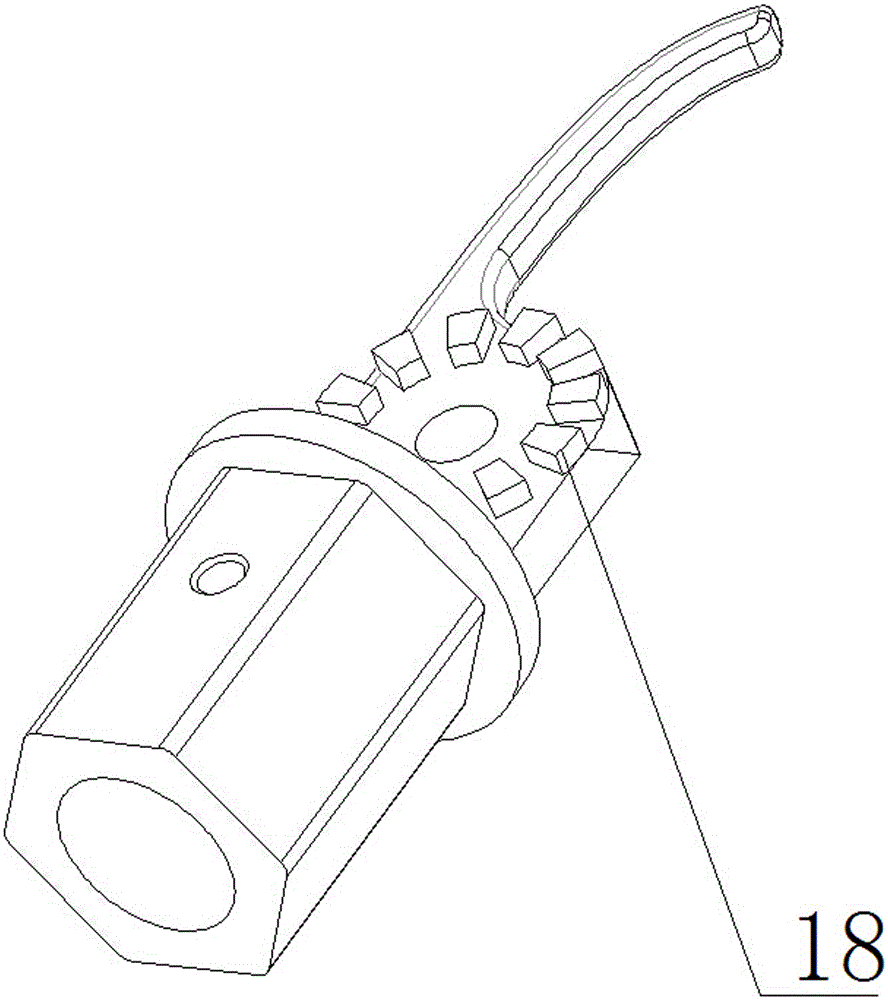

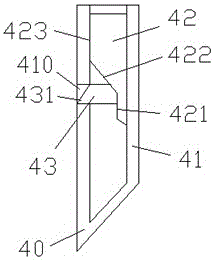

Wireless cutter for power hot-line work

InactiveCN105048347AAchieve normal workRealize wireless remote communicationApparatus for overhead lines/cablesRemote controlDrive motor

The invention relates to a wireless cutter for power hot-line work, in particular to a wireless operated cutter used in an insulating rod operation method used in hot-line work in power industry. The wireless cutter for power hot-line work comprises a cutter shell, a drive motor, a pump body, a fixed cutter, a movable cutter, a cutter battery, a connecting sleeve head, a ground wire, a control circuit and a wireless remote controller, wherein the pump body is controlled to push the movable cutter forwards through the drive motor, so that the movable cutter and the fixed cutter finish the cut-off action. By a wireless communication technology, one-to-one matching control is carried out on the wireless cutter by a special remote controller; a plurality of cutters can simultaneously work; the remote control distance can be up to over 200m; double persons cooperate during operation; and the problem of operation inconvenience due to the fact that double hands of a single person cannot be liberated when an insulating operation rod is used is solved.

Owner:HANGZHOU XIANHENG INT SCI RES CENT CO LTD

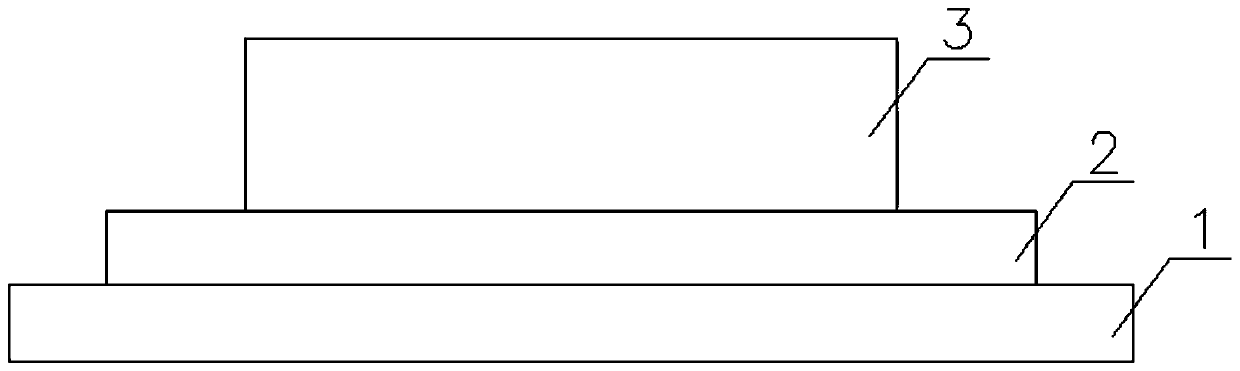

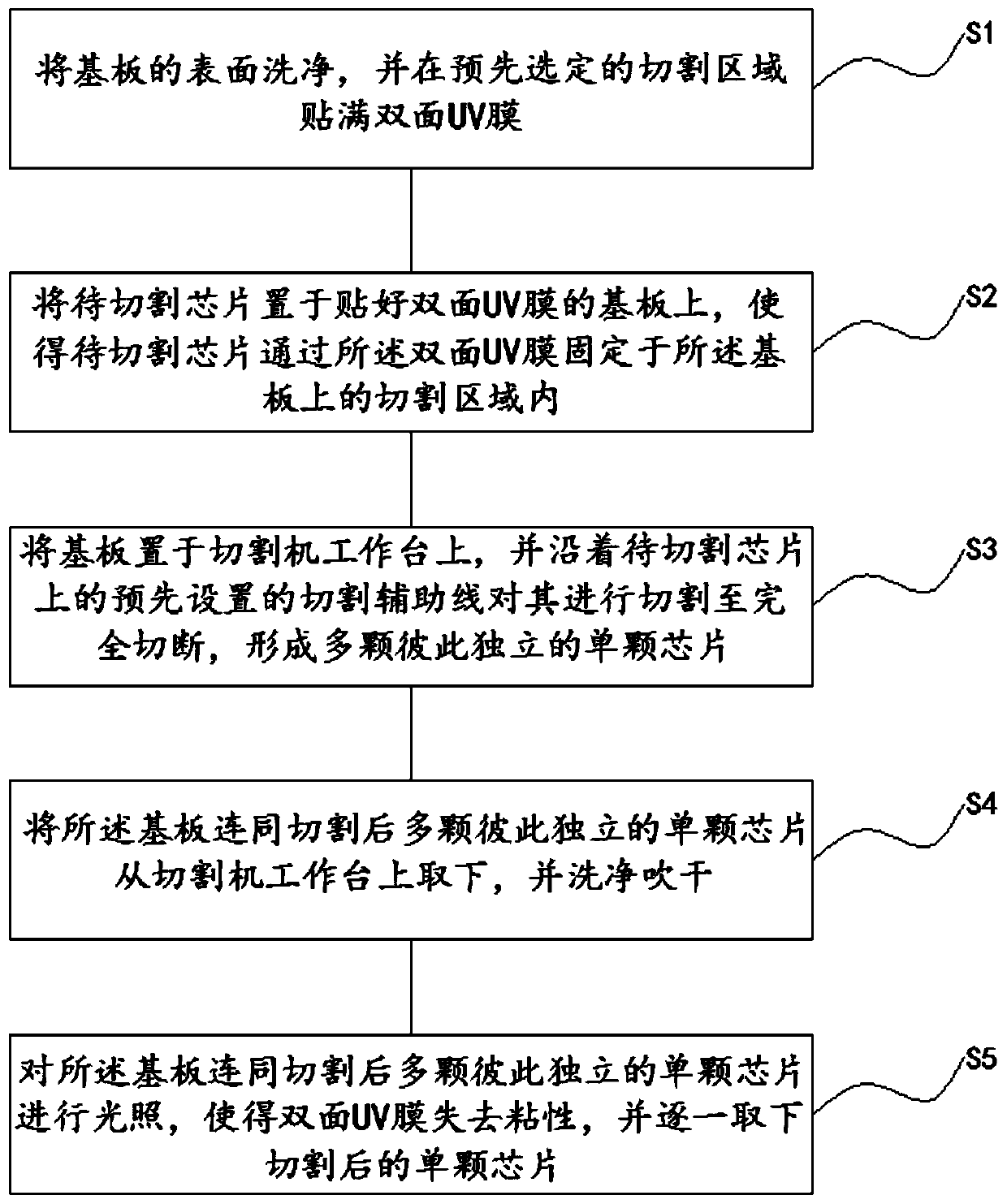

Efficient chip cutting method

ActiveCN110648908AShort cycleGuaranteed cutting accuracySemiconductor/solid-state device manufacturingSingle chipMechanical engineering

The invention relates to an efficient chip cutting method, which comprises the following steps: cleaning the surface of a substrate, and fully pasting a double-sided UV film onto a cutting area; placing a to-be-cut chip on the substrate and fixing the to-be-cut chip in the cutting area through the double-sided UV film; placing the substrate on a workbench of a cutting machine, and cutting the to-be-cut chip along a cutting auxiliary line on the to-be-cut chip until the to-be-cut chip is completely cut off; taking the substrate down from the workbench of the cutting machine, and cleaning and blow-drying the substrate; illuminating the substrate to make the double-sided UV film lose viscosity, and taking down single chips after cutting one by one. Because the double-sided UV film is arrangedon the substrate, the to-be-cut chip can be fixed on the substrate, and it is ensured that the position of the chip is relatively fixed during cutting. After cutting is completed, the double-sided UVfilm loses viscosity through illumination, and single chips are directly taken down and do not need to be cleaned through a chemical solvent. Therefore, the period of the cutting process is shortened, the cutting efficiency is improved, and the cutting precision and the cutting quality can be guaranteed.

Owner:WUHAN YILUT TECH CO LTD

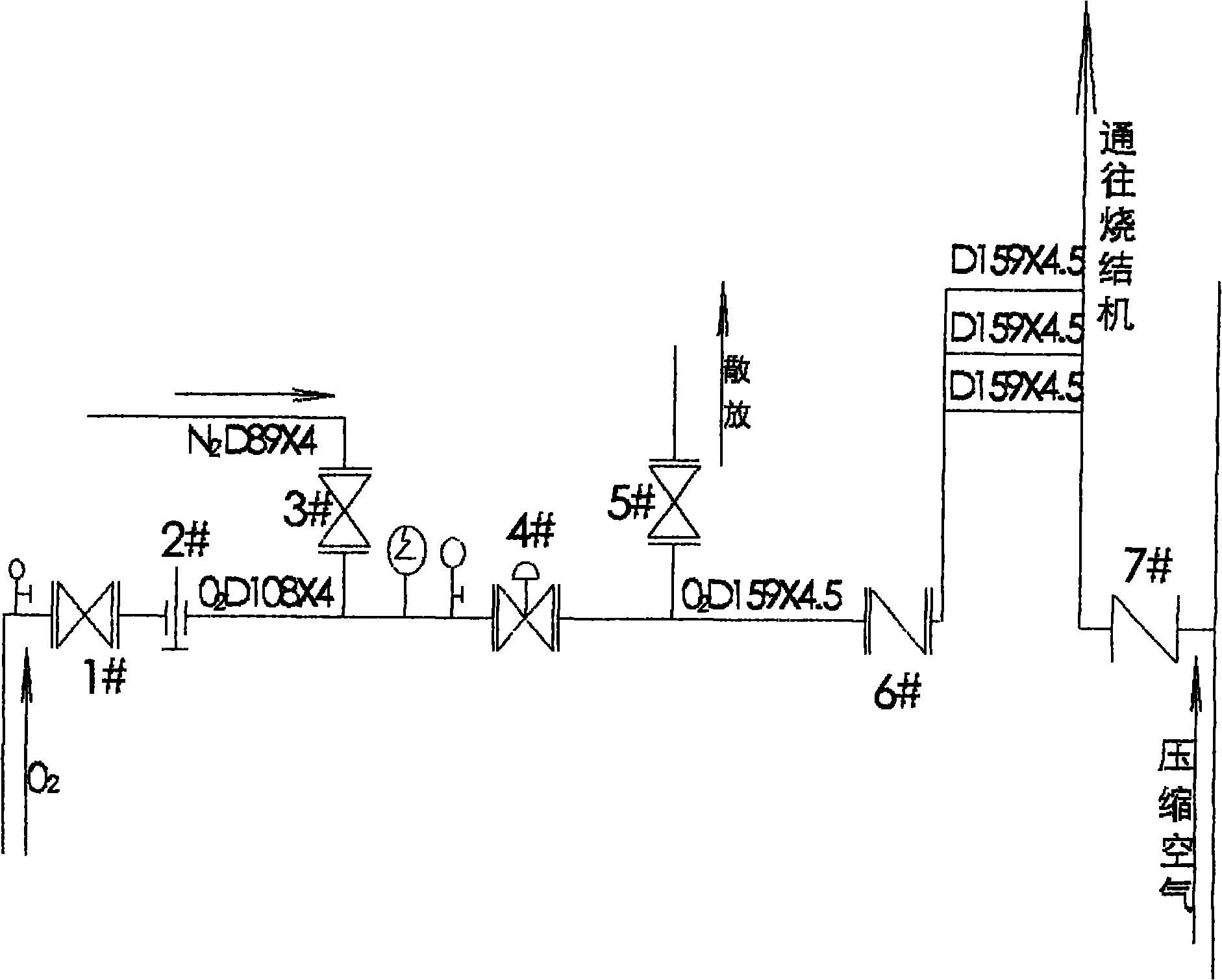

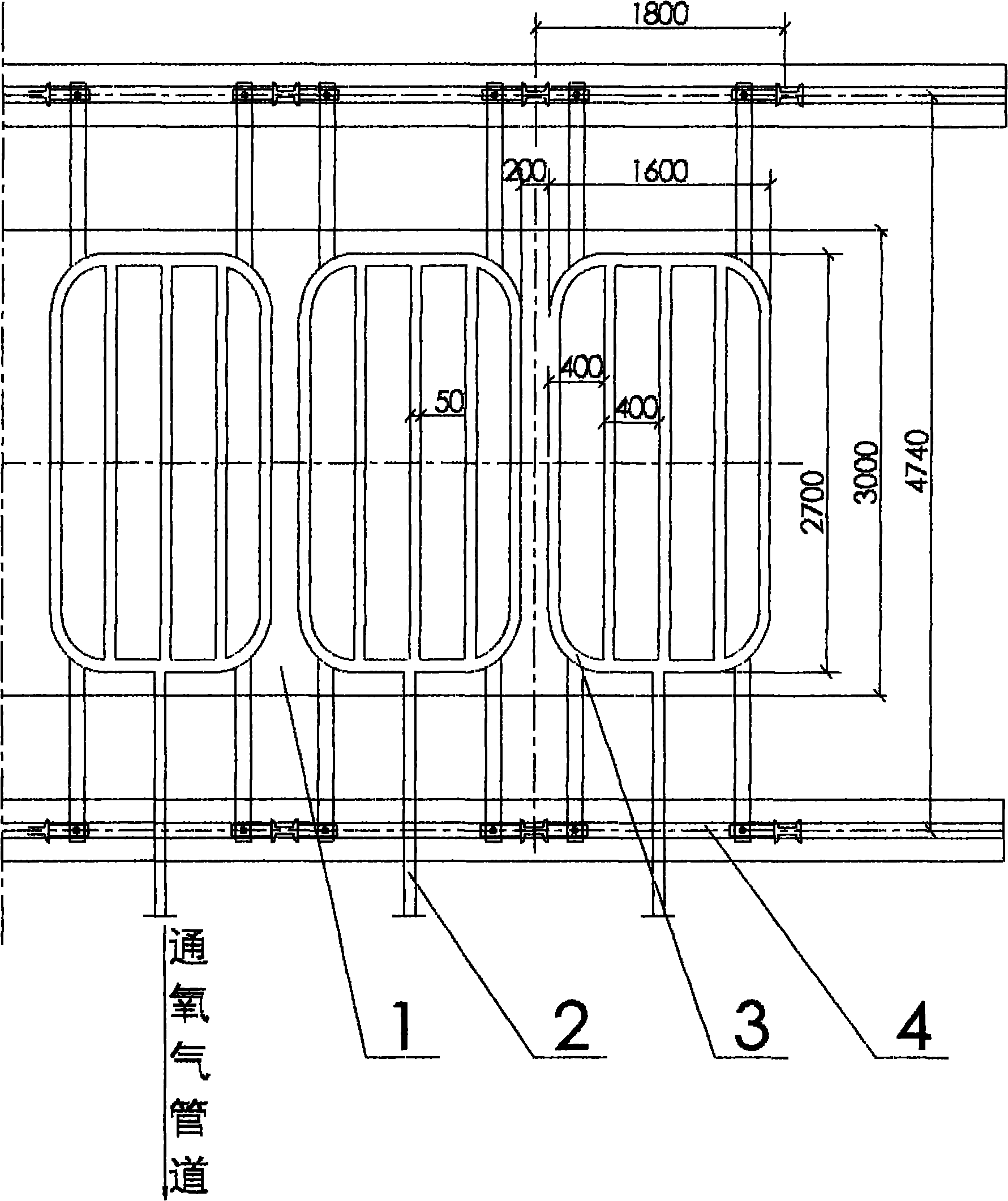

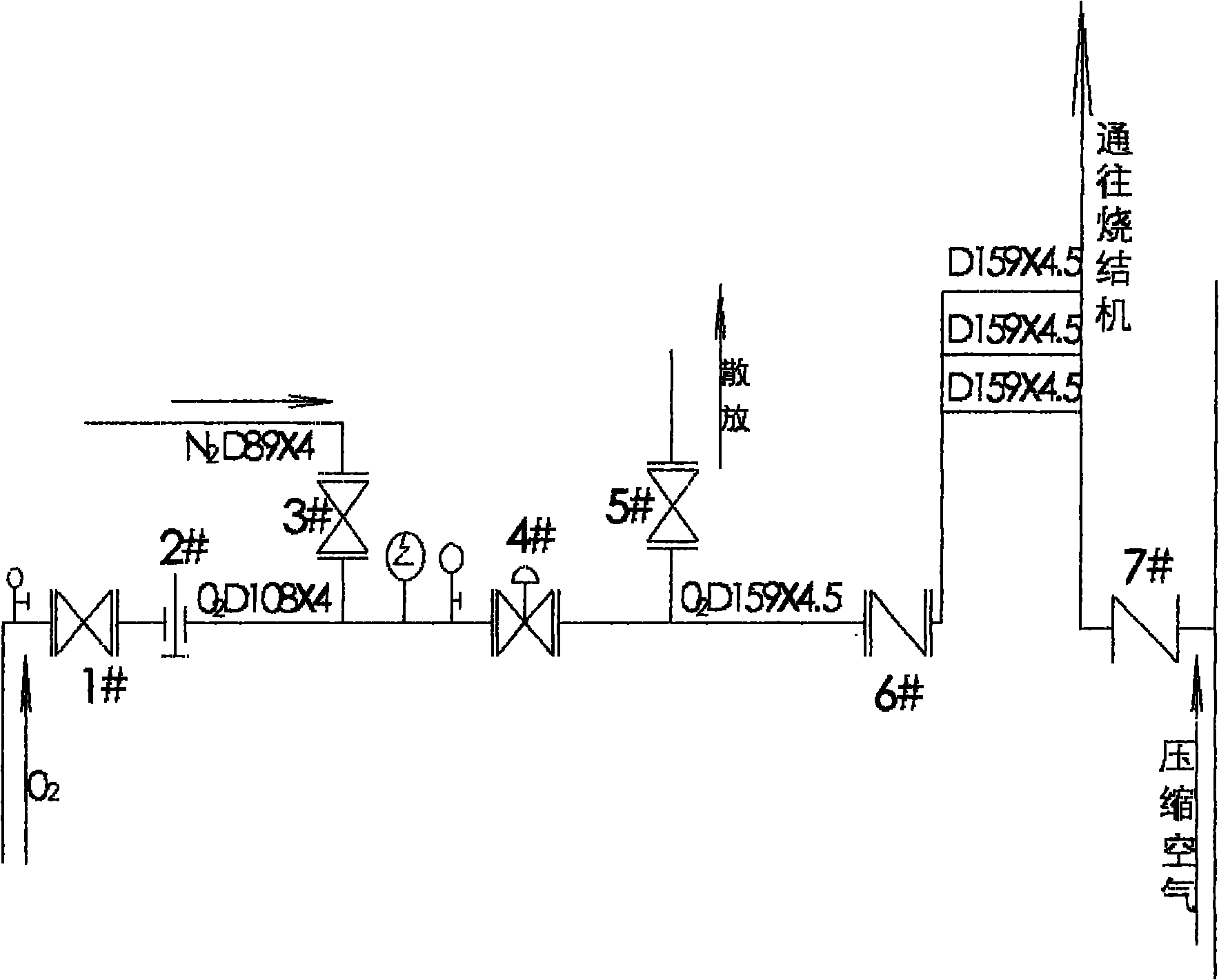

Oxygen-enriched sintering process method

The invention discloses an oxygen-enriched sintering process method. In the sintering production process, air with a certain concentration is blown to the upper part of a sintering machine, and the continuous production of oxygen-enriched sintering is performed by increasing the oxygen content in the air so as to fulfill the aims of improving the quality of sintered minerals and reducing solid fuel consumption. A novel sintering process production method can improve the thickness of material layers, improve the granularity composition of the sintered minerals, reduce the solid fuel consumption and facilitate smooth desulfuration. The oxygen-enriched sintering process is a novel process and novel method for effectively improving the quality of the sintered minerals.

Owner:TIANJIN TIANTIE METALLURGICAL GRP

Formula of gel electrolyte and method for preparing gel electrolyte using the formula

ActiveCN103000941BReduce flammabilityImprove securityFinal product manufactureElectrolyte accumulators manufactureElectrolytic agentPtru catalyst

The invention belongs to the technical field of lithium-ion batteries, and in particular relates to a formulation of a gel electrolyte for lithium-ion batteries, comprising the following components: 100 parts by weight of liquid electrolyte; 1-20 parts by weight of a compound with polyisocyanate; 0.1-10 parts by weight of compound of polyamino group or polyhydroxy group; 0.01-0.1 part by weight of crosslinking agent; 0.001-0.01 part by weight of catalyst; 0.001-0.01 part by weight of end-capping agent. Compared with the prior art, polycondensation reaction occurs between the monomers of the present invention to obtain a polymer gel skeleton, and the free liquid electrolyte is fixed in it, which improves the safety performance of the lithium-ion battery using the gel electrolyte formula . Moreover, there is no free radical initiator in the whole formula, which can effectively improve the electrochemical performance of the lithium ion battery adopting the gel electrolyte formula. In addition, the invention also discloses a method for preparing gel electrolyte by using the formula.

Owner:DONGGUAN AMPEREX TECH

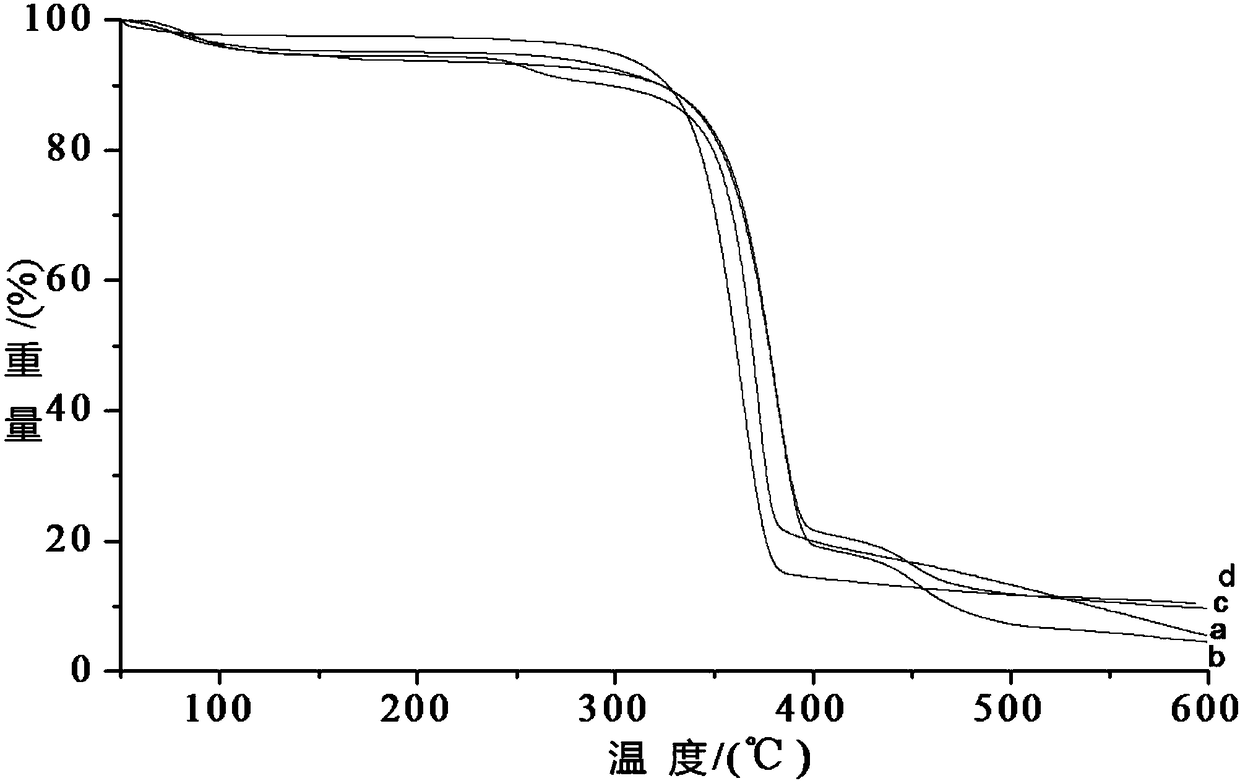

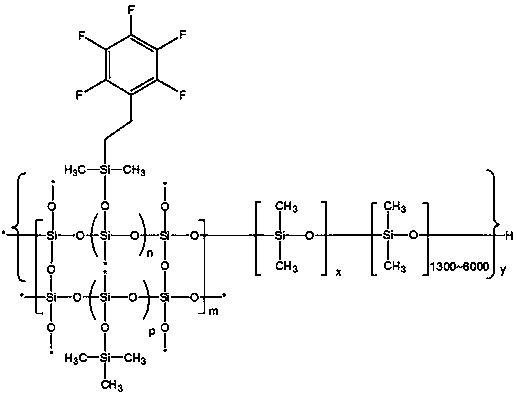

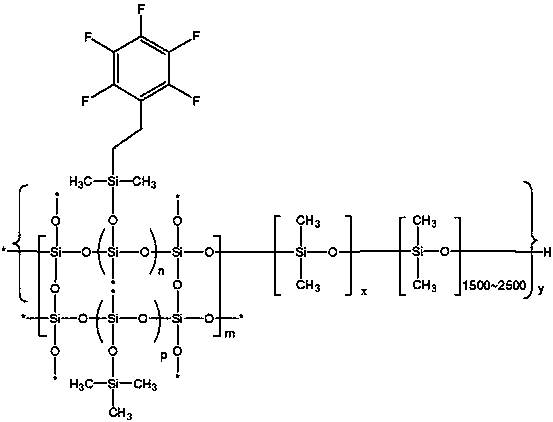

High-temperature-resistant polyester composite material, and preparation method thereof

ActiveCN108314796AImprove heat resistanceOvercoming the problem of poor reactivityFireproof paintsPolymer scienceTemperature resistance

The invention discloses a high-temperature-resistant polyester composite material, and a preparation method thereof. According to the preparation method, a fluorine containing phenyl silicone resin and silicone rubber (107 rubber) are taken as raw materials, and condensation polymerization is adopted to obtain an organosilicon coating agent; a polyester base material is coated with a mixture of the organosilicon coating agent, an oxidizing agent, and a diluents, and drying and curing are carried out so as to obtain the high-temperature-resistant polyester composite material. A certain amount of fluorine containing phenyl groups are introduced into the finished product, so that the high-temperature-resistant polyester composite material is excellent in high temperature resistance and bonding performance. The preparation method is simple; equipment requirement is low; and the preparation method is suitable for industrialized amplification production.

Owner:成都爱极艺新材料科技有限公司

Hole digging machine realizing anchoring through being driven by air pressure cylinder

InactiveCN105064908AIncrease the diameterIncrease the reaction force bearing surfaceConstructionsRotary drillingDrive motorEngineering

The invention provides a hole digging machine realizing anchoring through being driven by an air pressure cylinder. The hole digging machine comprises an outside casing (8), a driving motor (9) and a hole digging drill pipe component (6), wherein the hole digging drill pipe component (6) is driven by the driving motor (9); the driving motor (9) is arranged inside the outside casing (8) and is in axially gliding power connection with a spline hole formed in a driving sleeve part (61) of the hole digging drill pipe component (6) through a fixedly connected spline rod (91); the driving sleeve part (61) of the hole digging drill pipe component (6) is fixedly connected with a drill pipe part (62) of the hole digging drill pipe component (6) through a gradually reduction connecting part (612); and an axial extending key is arranged on the outer peripheral surface of the driving sleeve part (61) and is used for being matched with an axial extending key slot formed in the inner peripheral wall of a tube body (71) of an external threaded sleeve component (7).

Owner:黄爱娟

Grinding device for small-diameter optical lens

InactiveCN111958392AEasy to place and stableRemoved smoothlyEdge grinding machinesOptical surface grinding machinesSurface grindingEngineering

The invention belongs to the technical field of machinery, particularly relates to a grinding device for a small-diameter optical lens. The grinding device aims at solving the problem that in the prior art, a lens and a rubber layer are difficult to take down after being tightly extruded due to the structure of the grinding device for the optical lens for fixing the lens. According to the technical scheme, the grinding device comprises a fixing base with the upper end fixedly connected with an L-shaped fixing seat; a lens fixing mechanism comprises a first motor, a first electric push rod, a first clamping piece, a second clamping piece, a two-way suction cup and a second electric push rod; and the grinding assembly comprises a butterfly surface grinding rod. According to the grinding device for the small-diameter optical lens, the upper and lower edges of the optical lens can be formed through the arranged butterfly surface grinding rod, later reprocessing is avoided, and procedures are saved; through the arrangement of the two-way suction cup, the closed space formed between the rubber layer and the optical lens is freely opened and sealed, so that the suction force between the rubber layer and the optical lens is changed, and the optical lens is conveniently and stably placed and smoothly taken down.

Owner:付小毛

Hole digging machine with alarming device

A hole digging machine with an alarming device comprises an outside shell (8), a driving motor (9) and a hole-drilling drill rod part (6) driven by the driving motor (9). The driving motor (9) is arranged in the outside shell (8) and is in power connection with a spline hole in a driving sleeve portion (61) of the hole-digging drill rod part (6) through a spline rod (91) in fixed connection in an axially slidable manner, the driving sleeve portion (61) of the hole-digging drill rod part 96) is fixedly connected with a drill rod portion (62) of the hole-digging drill rod part (6) through a gradually-contracting connection portion (612), and an axial extending key is arranged on the outer peripheral face of the driving sleeve portion (61) and used for being matched with an axial extending key groove in an inner peripheral wall of a barrel (71) of an outer thread sleeve part (7).

Owner:YONGJIA LULUTONG IMPORT & EXPORT

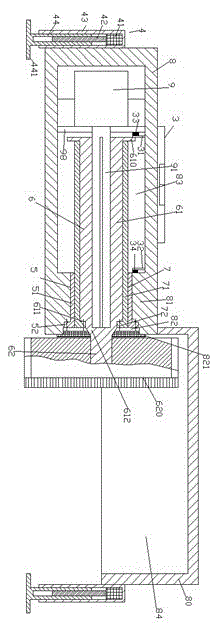

Multifunctional test bench for chip

PendingCN112130059AFit tightlyAids in detectionElectronic circuit testingShort-circuit testingStructural engineeringTest bench

The invention discloses a multifunctional test bench for a chip. The multifunctional test bench comprises a test bench and an extrusion plate, wherein a groove is formed in the middle of the upper surface of the top of the test bench; a detection plate is arranged in the groove; an insertion rod is arranged in the middle of the bottom surface of the test bench; a connection ring is arranged at thebottom end of the insertion rod; a connection block is mounted in the middle of the bottom surface of the extrusion plate; and limiting plates are arranged at positions, close to two sides, in the extrusion plate; and a detector is mounted on the rear surface of the extrusion plate. According to the multifunctional test bench for the chip, the chip can be limited through the limiting plates, so that the chip is prevented from being cracked by the extrusion plate due to a mechanical error; through springs and the insertion rod, the chip can be separated and taken out from the test bench; and the whole test bench is simple in structure, relatively practical and suitable for popularization.

Owner:复汉海志(江苏)科技有限公司

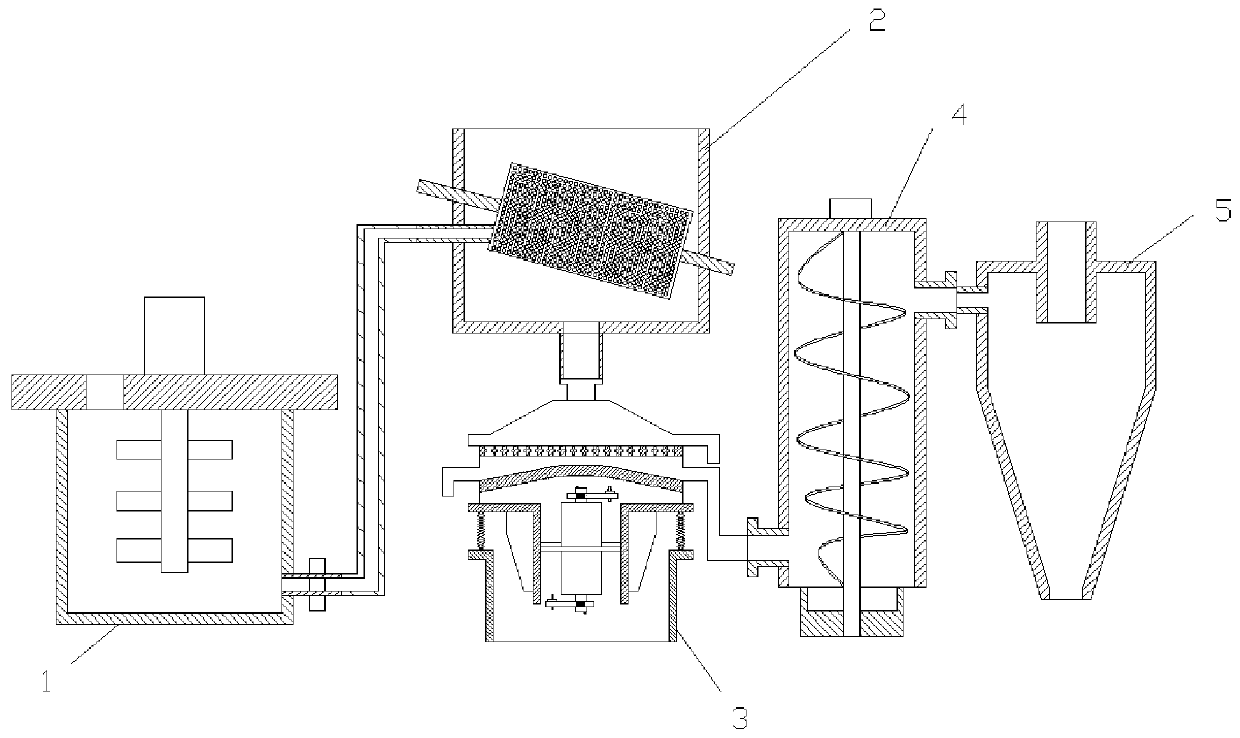

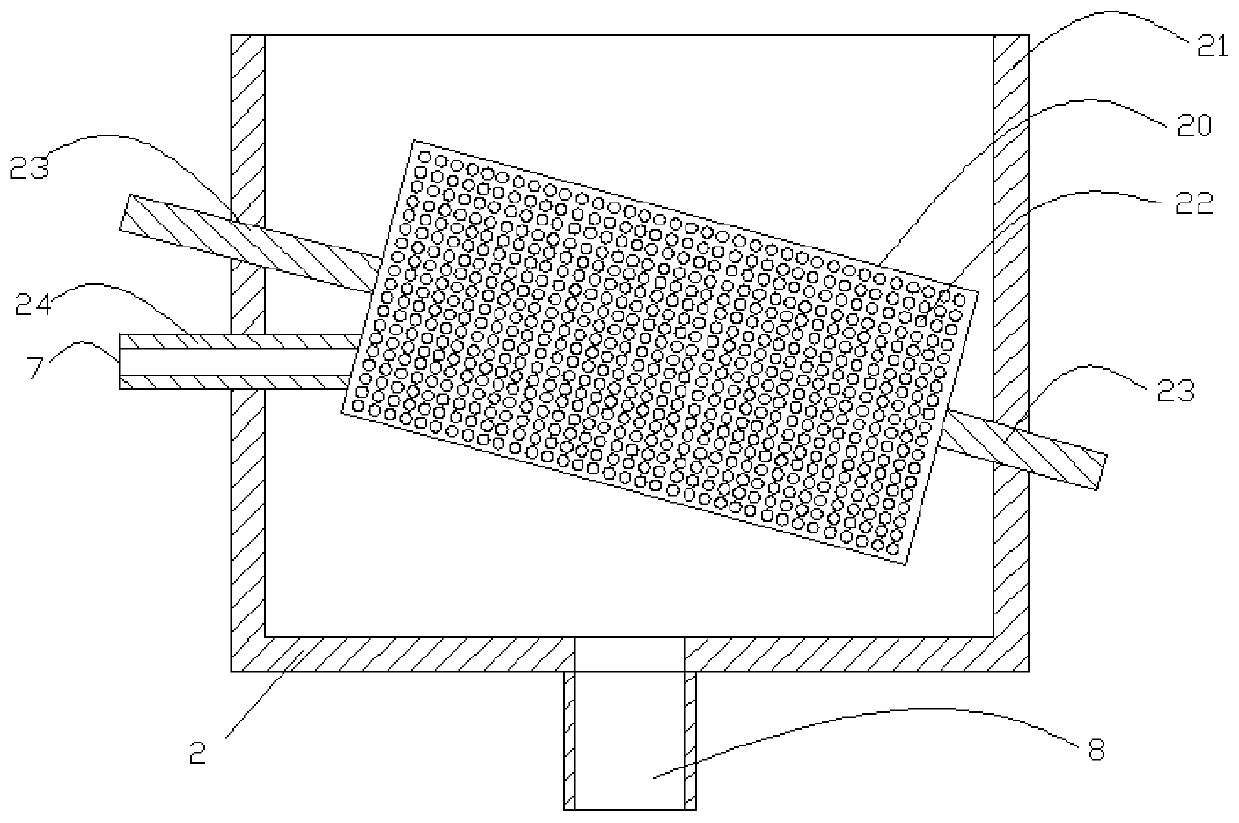

Sediment separating system

PendingCN110882919AEasy to separateImprove efficiencySievingGas current separationWood splinterEnvironmental engineering

The invention discloses a sediment separating system which comprises a device capable of separating wood bits from sediment and a sediment separating device, wherein the device capable of separating wood bits from sediment comprises a stirring tank for dissolving sediment, a pig cage screen for carrying out first-time wood bits removal on sediment, and a vibrating screen for carrying out second-time wood bits removal on sediment; the sediment separating device comprises a screw conveyor for carrying out first-time separation on sediment and a hydrocyclone carrying out second-time separation onsediment; and sediment first enters the device capable of separating wood bits from sediment and then enters the sediment separating device. The invention provides the sediment separating system which has the wood bits removal function and is excellent in separating effect.

Owner:江门市友顺陶瓷原料有限公司

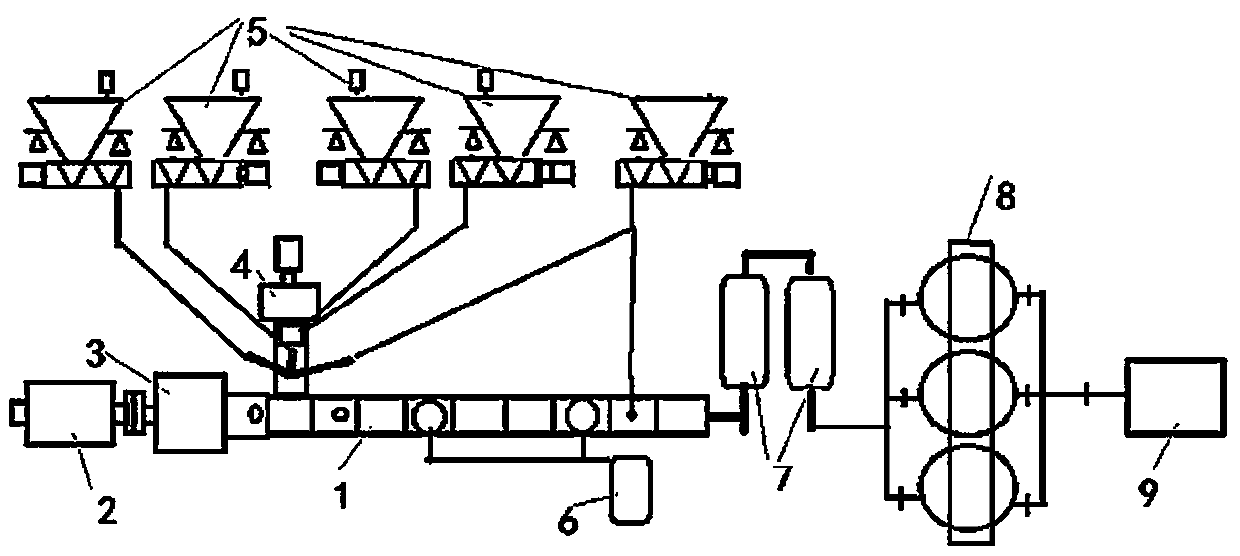

Same-direction linear three-screw full-automatic production line for sealant

The invention discloses a same-direction linear three-screw full-automatic production line for sealant, and relates to the field of chemical machine-sealant automatic production. The full-automatic production line comprises three screws, a speed change gear box, a side feeder, a vacuum buffer tank and a static mixer. The right end of the speed change gear box is provided with the side feeder, theside feeder is connected with a plurality of metering tanks at the upper end, the right end of the lower portion of the three screws is provided with the connected vacuum buffer tank, the right end ofthe three screws is sequentially provided with a condenser, a middle storage tank and the static mixer, and the condenser, the middle storage tank and the static mixer are sequentially connected through pipes, so that the three screws are sequentially divided into a feeding conveying zone, a kneading zone, a vacuuming zone, a vacuum kneading zone, a lowering zone, a splitting feeding zone and a dispersing conveying zone; and the same-direction linear three-screw full-automatic production line has the better diversion effect and more shearing time numbers, and therefore better distribution mixing and dispersion mixing are achieved.

Owner:东莞市锕舒尔智能科技有限公司 +1

Hydraulic-lifting road construction device

The invention relates to a hydraulic-lifting road construction device. The hydraulic-lifting road construction device used for polishing partial protrusions on constructing pavements during road construction comprises an external shell (8), a motor (9) and a polishing head drive rod part (6) driven by the motor (9), wherein the motor (9) is in axial and slidable power connection with a spline hole in the drive sleeve cylinder (61) of the polishing head drive rod part (6) through a fixedly-connected spline rod (91), and the drive sleeve cylinder (61) of the polishing head drive rod part (6) is fixedly connected with the polishing head mounting rod part (62) of the polishing head drive rod part (6) through a gradually-contracted connecting part (612).

Owner:百年建设集团有限公司

Intelligent road construction equipment

InactiveCN105019341AReduce equipment costsIncrease the diameterRoads maintainenceRoad constructionArchitectural engineering

Intelligent road construction equipment is used for grinding local bulges on construction road surface during road construction, and comprises an external housing (8), a motor (9) and a grinding head drive lever member (6) driven by the motor (9), the motor (9) is in axial slidable power connection with a spline hole in a drive sleeve portion (61) of the grinding head drive lever member (6) by a fixedly connected spline rod (91), and the drive sleeve portion (61) of the grinding head drive lever member (6) is fixedly connected with a grinding head mounting rod portion (62) of the grinding head drive lever member (6) by a gradual contractile connecting portion (612).

Owner:曹占波 +5

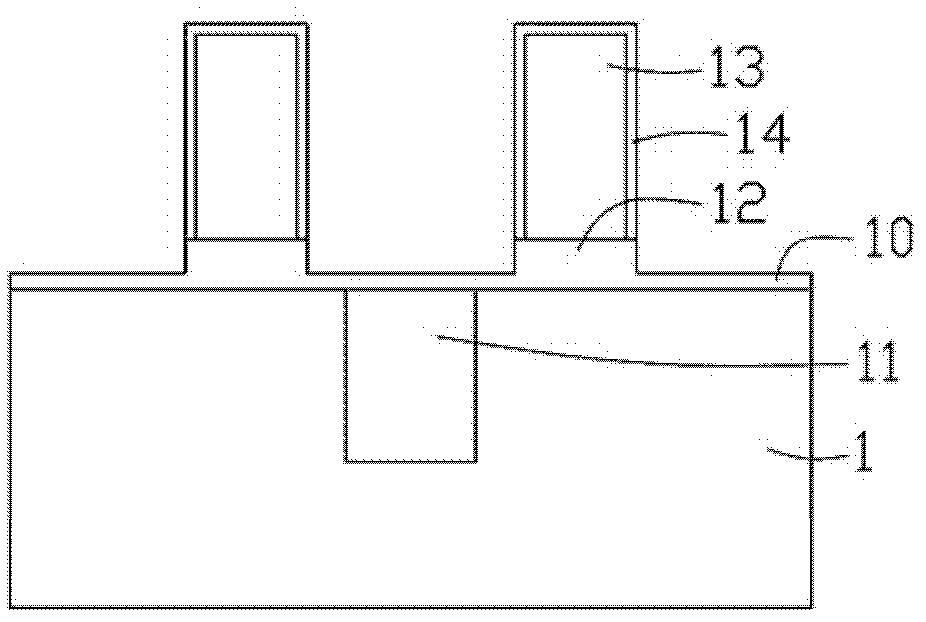

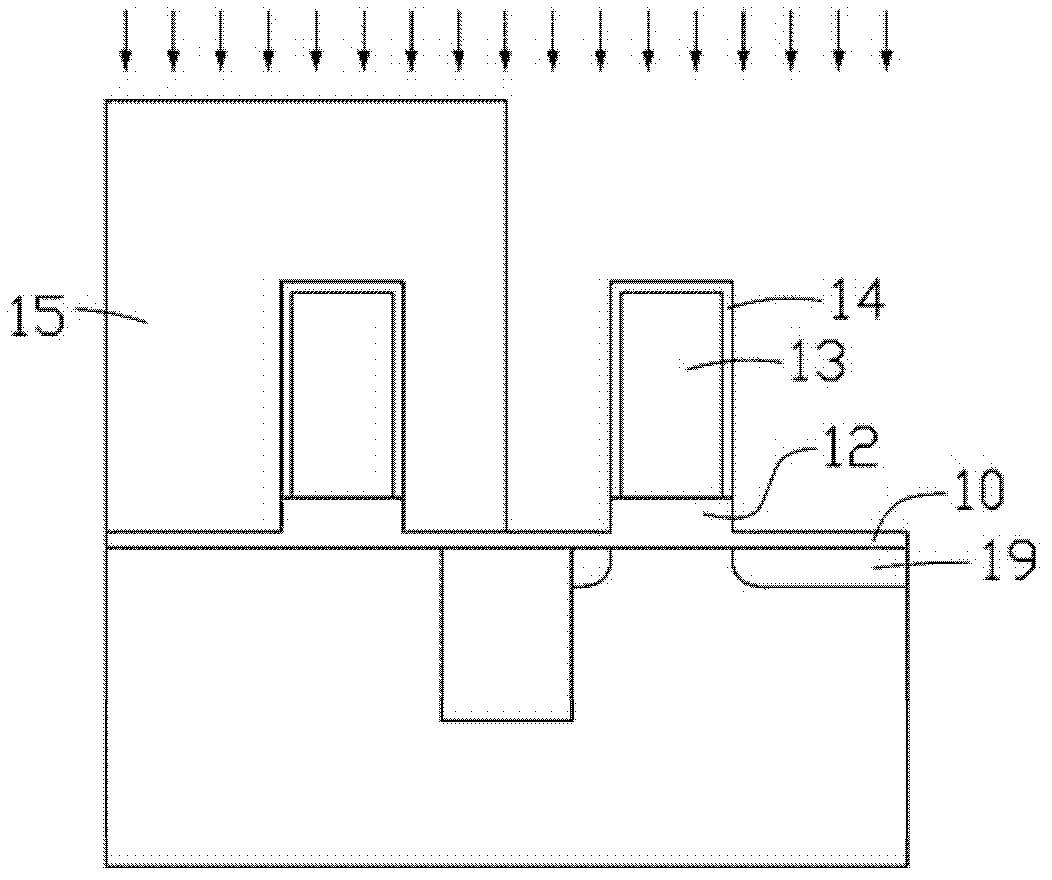

Manufacturing method of semiconductor component

The invention discloses a manufacturing method of a semiconductor component. The manufacturing method comprises the steps of providing a substrate, wherein a silicon gate structure is formed on the substrate; conducting a modification technology on a silicon surface of the silicon gate structure, so that the characteristic of the silicon surface of the silicon gate structure is changed to hydrophily from hydrophobicity; forming a mask structure on the substrate; conducting a dopant injecting technology on the substrate by the silicon gate structure after the modification technology and the mask structure; and removing the mask structure by a mask structure removal technology, wherein the mask structure removal technology comprises a wet clean step. According to the manufacturing method of the semiconductor component, as the surface characteristic of the silicon gate structure is changed into the hydrophily, the residue after an ashing treatment can be removed and cleaned smoothly by the wet clean step.

Owner:UNITED MICROELECTRONICS CORP

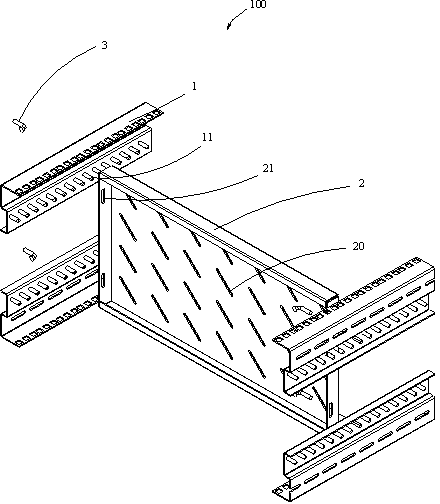

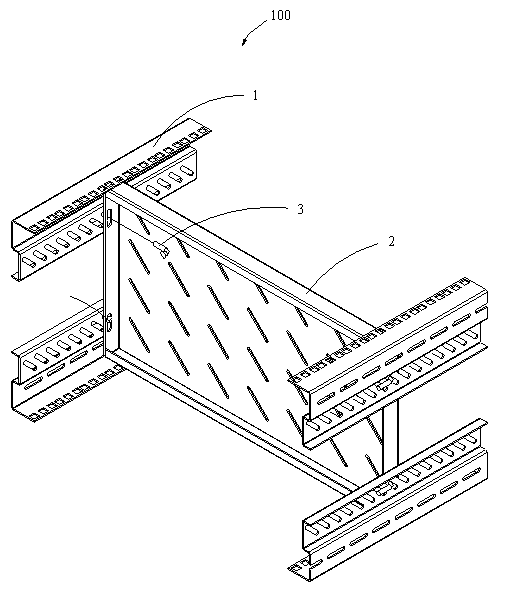

Fixing device

InactiveCN103857243AEasy to operateAchieve installationSupport structure mountingBiomedical engineering

Owner:SUZHOU IND PRAK NEW HONGBO COMM TECH

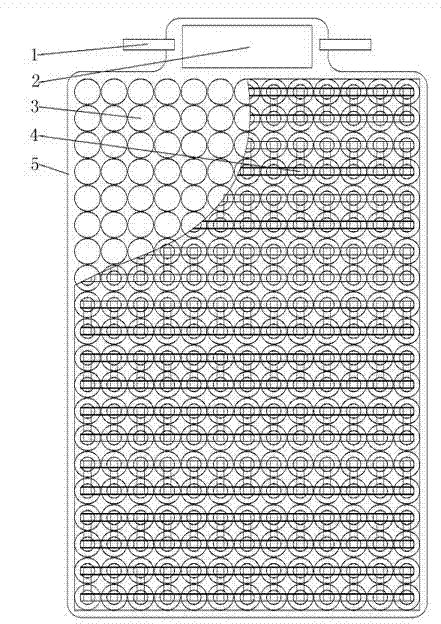

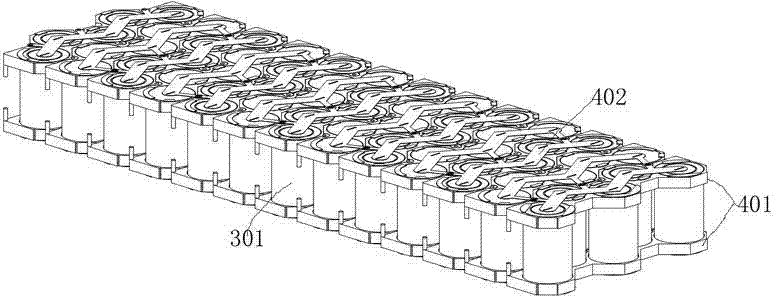

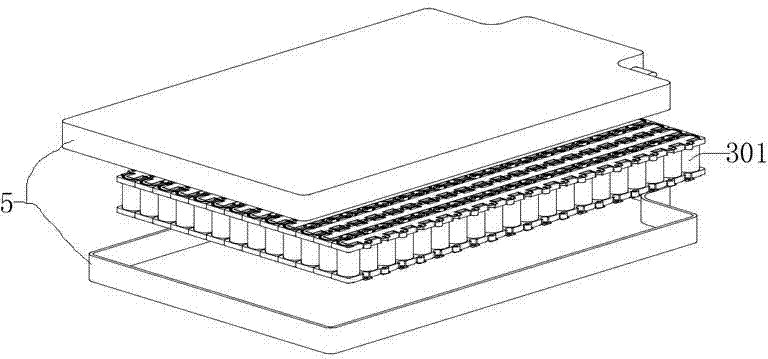

Conveniently-dismounted high-capacity rare-earth lithium battery module used in high-low-temperature range

InactiveCN104766987ARemoved smoothlyNo wasteFinal product manufactureCurrent conducting connectionsProcess engineeringMechanical engineering

The invention discloses a conveniently-dismounted high-capacity rare-earth lithium battery module used in a high-low-temperature range. The conveniently-dismounted high-capacity rare-earth lithium battery module is characterized in that a rare-earth lithium battery cell of the conveniently-dismounted high-capacity rare-earth lithium battery module used in a high-low-temperature range is installed in a support of a detachable spliced structure, and the support is divided into an upper layer and a lower layer; a conducting wire connecting piece is welded to a rare-earth lithium cell part and fixed to the support part by virtue of a bolt. By adopting the conveniently-dismounted high-capacity rare-earth lithium battery module, the single rare-earth lithium battery cell is replaced under the situation that the single rare-earth lithium battery cell is damaged, and the battery can be used normally. The battery does not need to be rejected integrally, and the unnecessary waste can be avoided; the single rare-earth lithium battery cell part with a fault can be successfully dismounted, a good single rare-earth lithium battery can be replaced, finally the rest part can be used continuously, and thus simplicity and economical efficiency in replacement can be realized. The conveniently-dismounted high-capacity rare-earth lithium battery module can be used in an environment of -43 to 65 DEG C and has the advantages of wide high-low-temperature application range, high capacity, small internal resistance, long service life, high efficiency, controllability of current output, and the like.

Owner:QINGHAI GREEN GRASS OF TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com